Recent Advances and Retrospective Review in Bioinspired Structures for Fog Water Collection

Abstract

1. Introduction

2. Theoretical Basis of Fog Water Collection

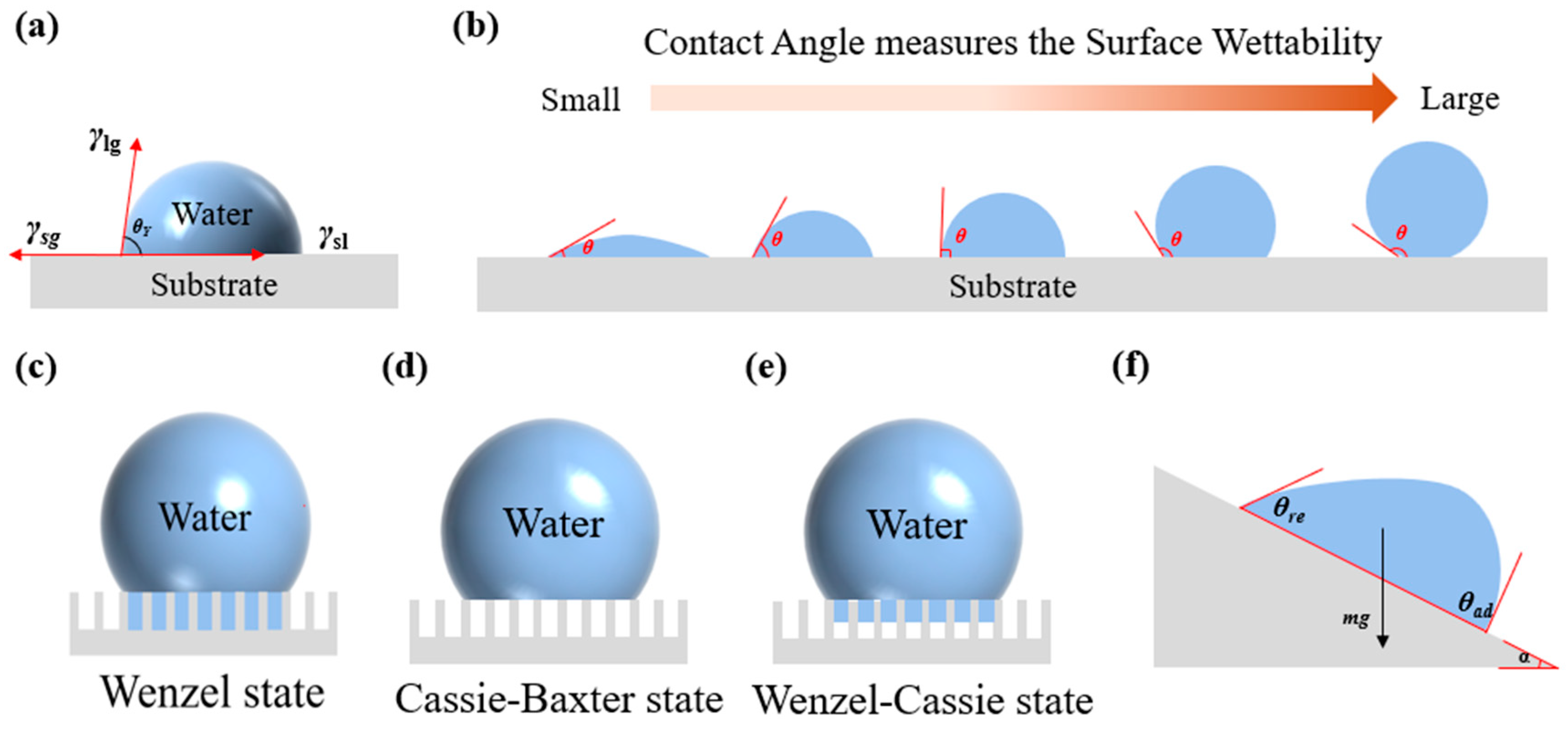

2.1. Surface Wettability and Contact Angle

2.1.1. Young’s Equation

2.1.2. Wenzel State

2.1.3. Cassie–Baxter State

2.1.4. Wenzel–Cassie State

2.1.5. Contact Angle Hysteresis

2.2. Fog Water Capture and Aerodynamic Factors

2.2.1. Collision and Deposition of Small Fog Droplets Without Phase Change

2.2.2. Water Vapor Condensation and Deposition with Phase Change

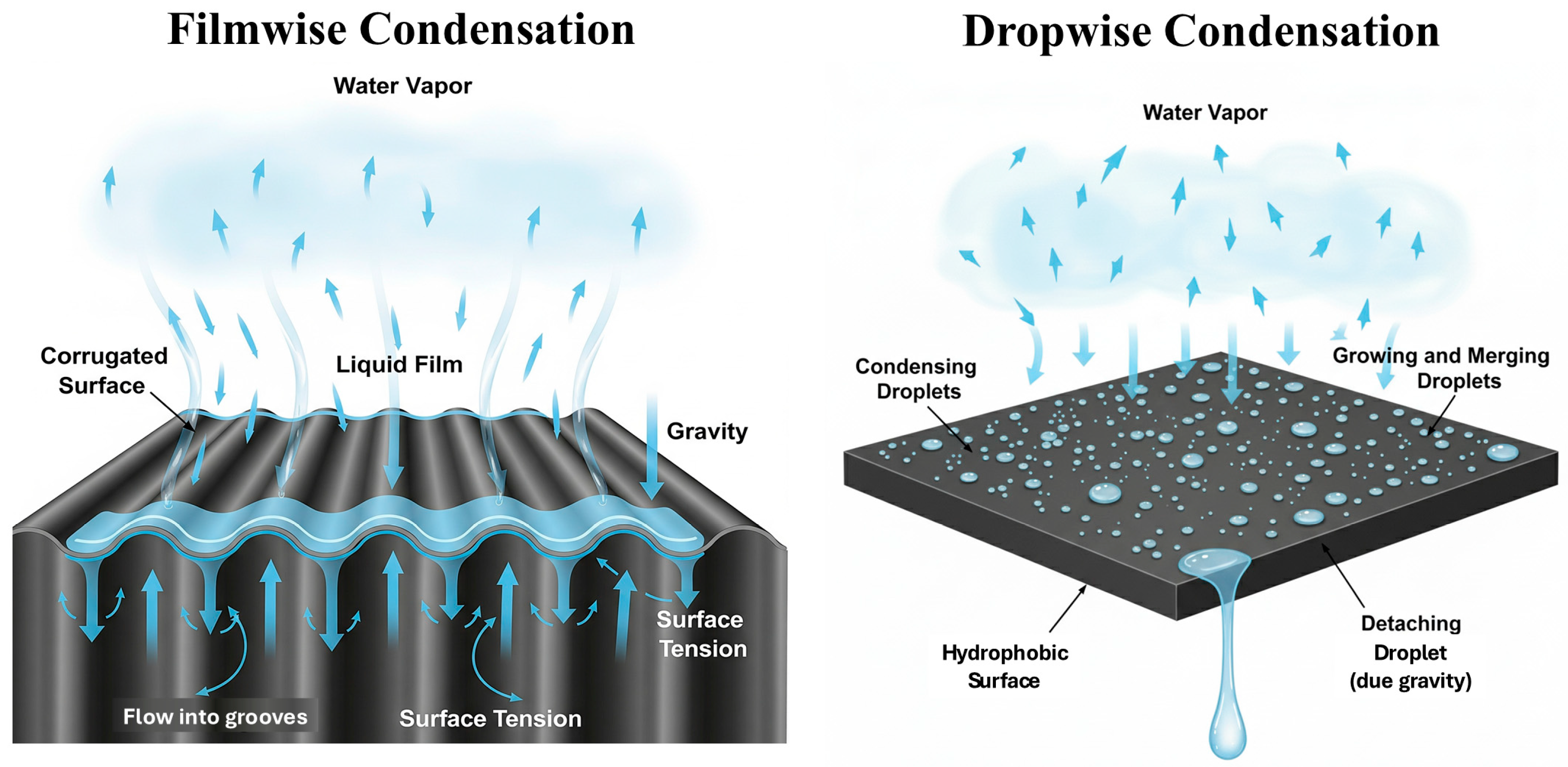

2.2.3. Filmwise and Dropwise Condensation in Fog Water Collection

2.2.4. Overall Efficiency of Fog Water Collection

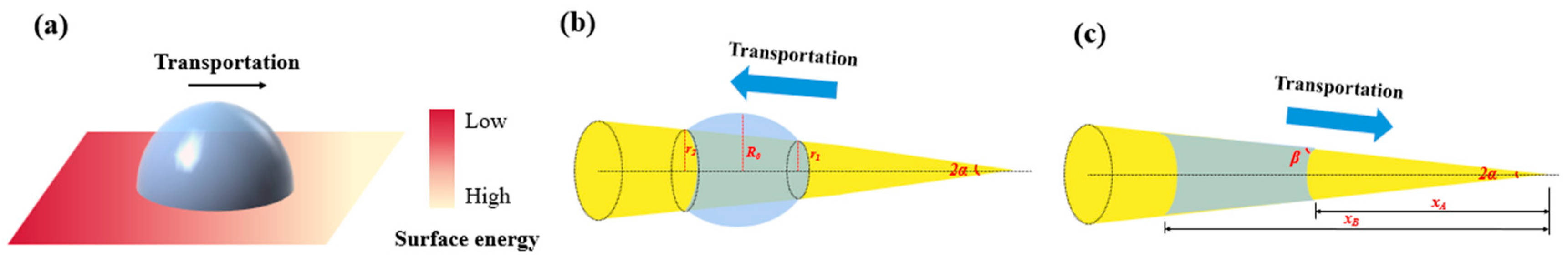

2.3. Surface Energy Gradient and Laplace Pressure Gradient

2.3.1. Surface Energy Gradient

2.3.2. Laplace Pressure Gradient

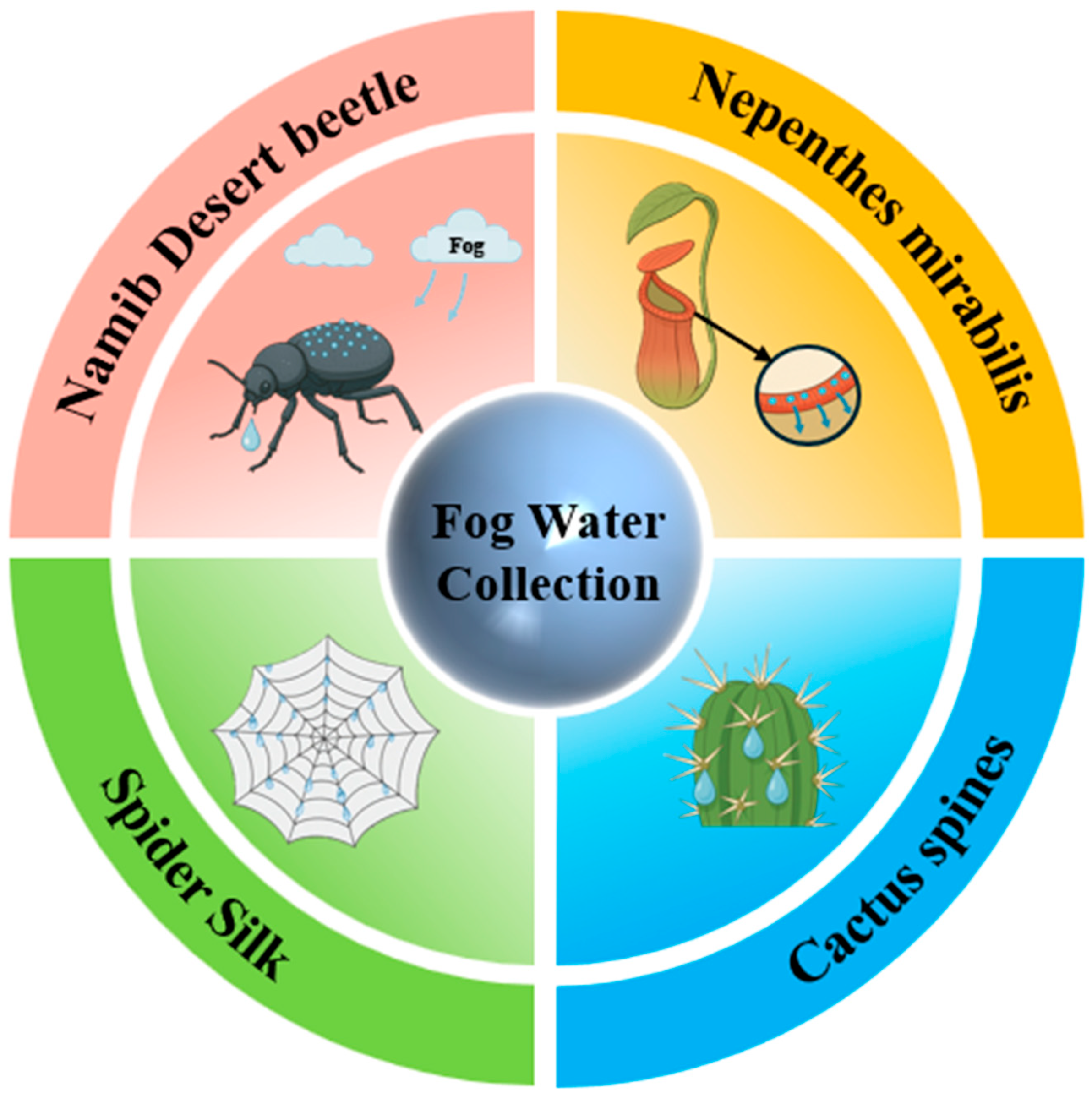

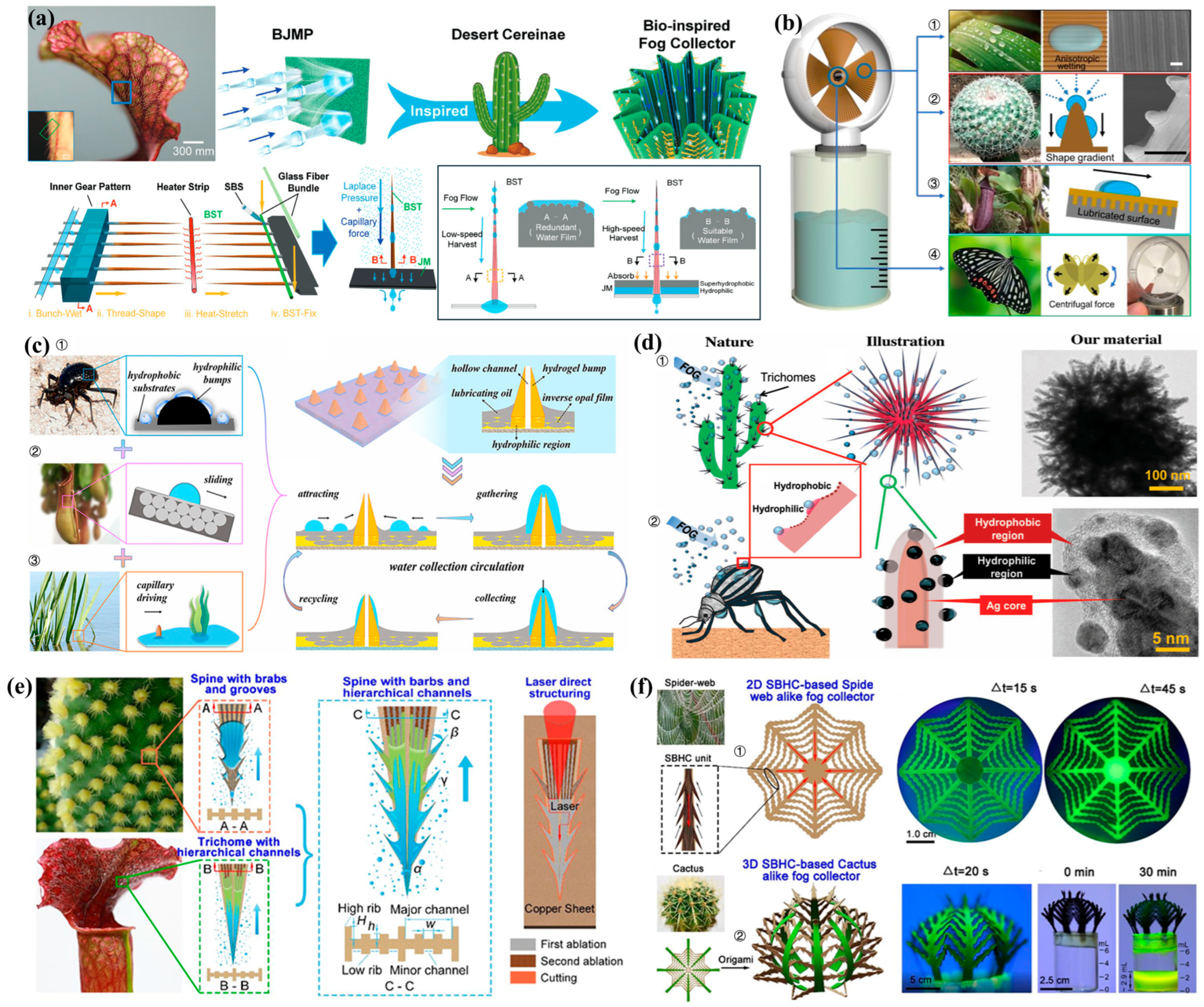

3. Biomimetic Fog Water Collection Structures

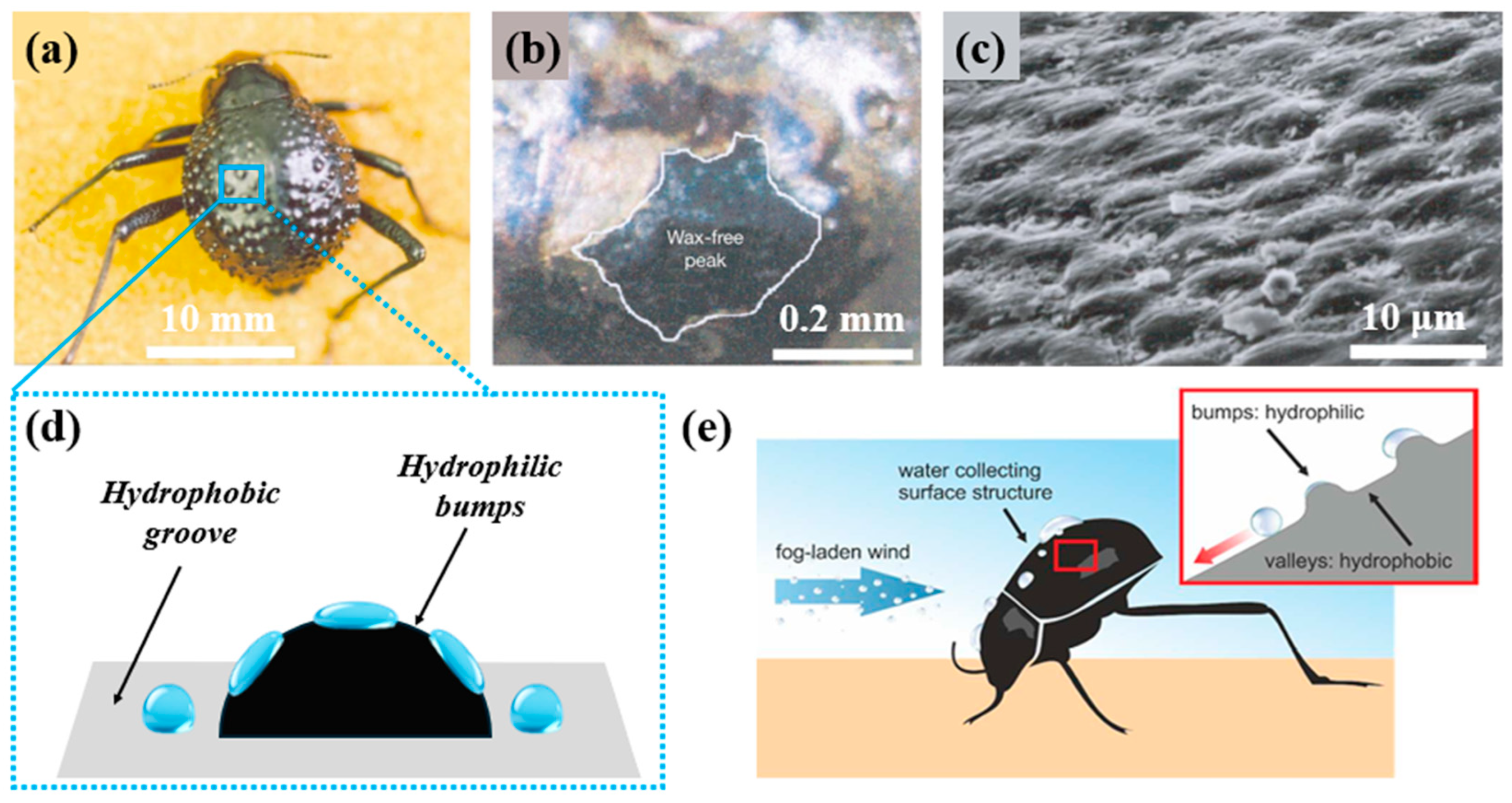

3.1. Namib Desert Beetle

3.1.1. Fog Water Collection Mechanism of the Namib Desert Beetle

3.1.2. Fog Water Collection Structures (FWCSs) and Fabrication Inspired by the Namib Desert Beetle

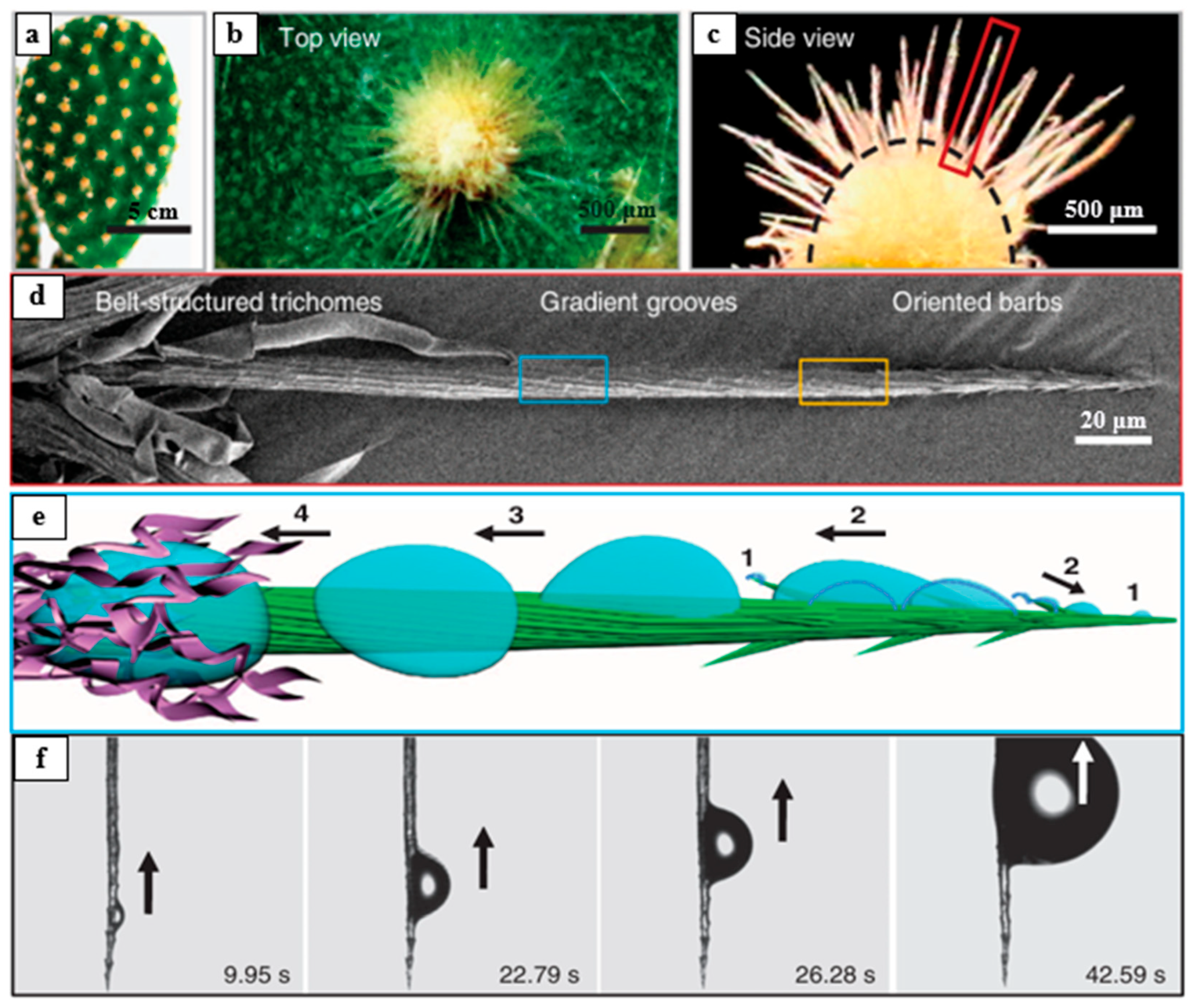

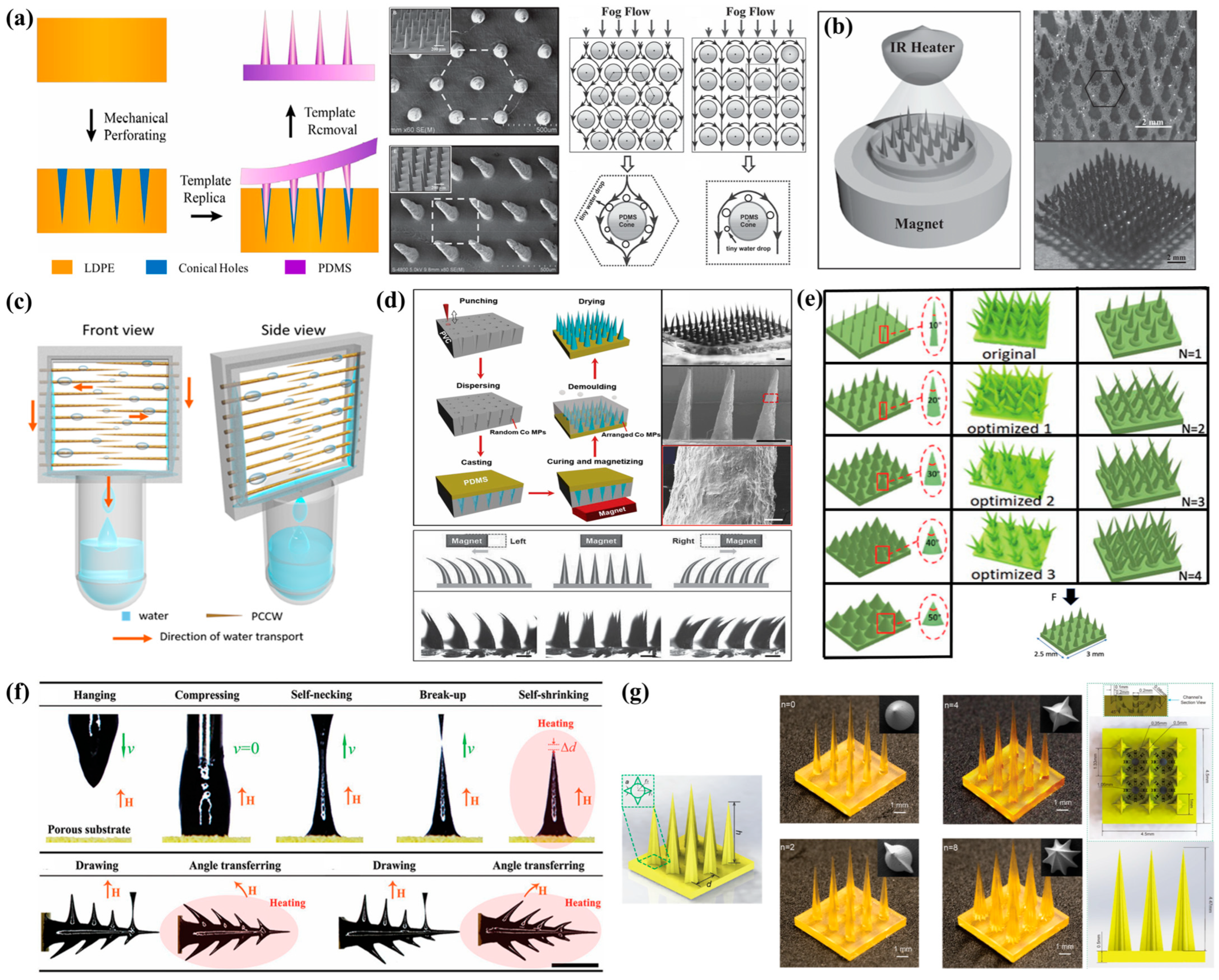

3.2. Cactus Spines

3.2.1. Fog Water Collection Mechanism of Cactus Spines

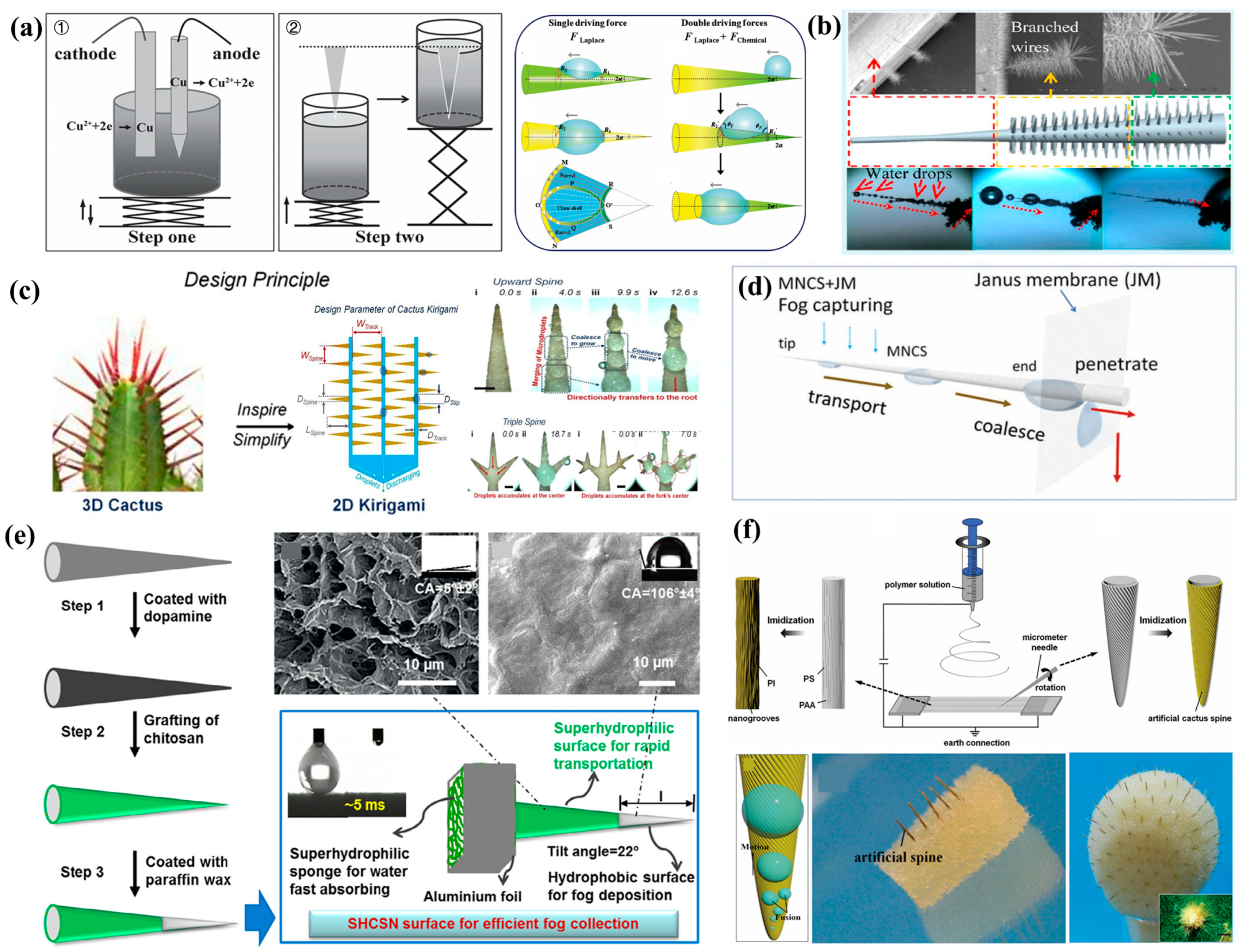

3.2.2. FWCSs and Fabrication Inspired by Cactus Spines

Fabrication of a Single Conical FWCSs Inspired by Cactus Spines

Fabrication of Conical Array FWCSs Inspired by Cactus Spines

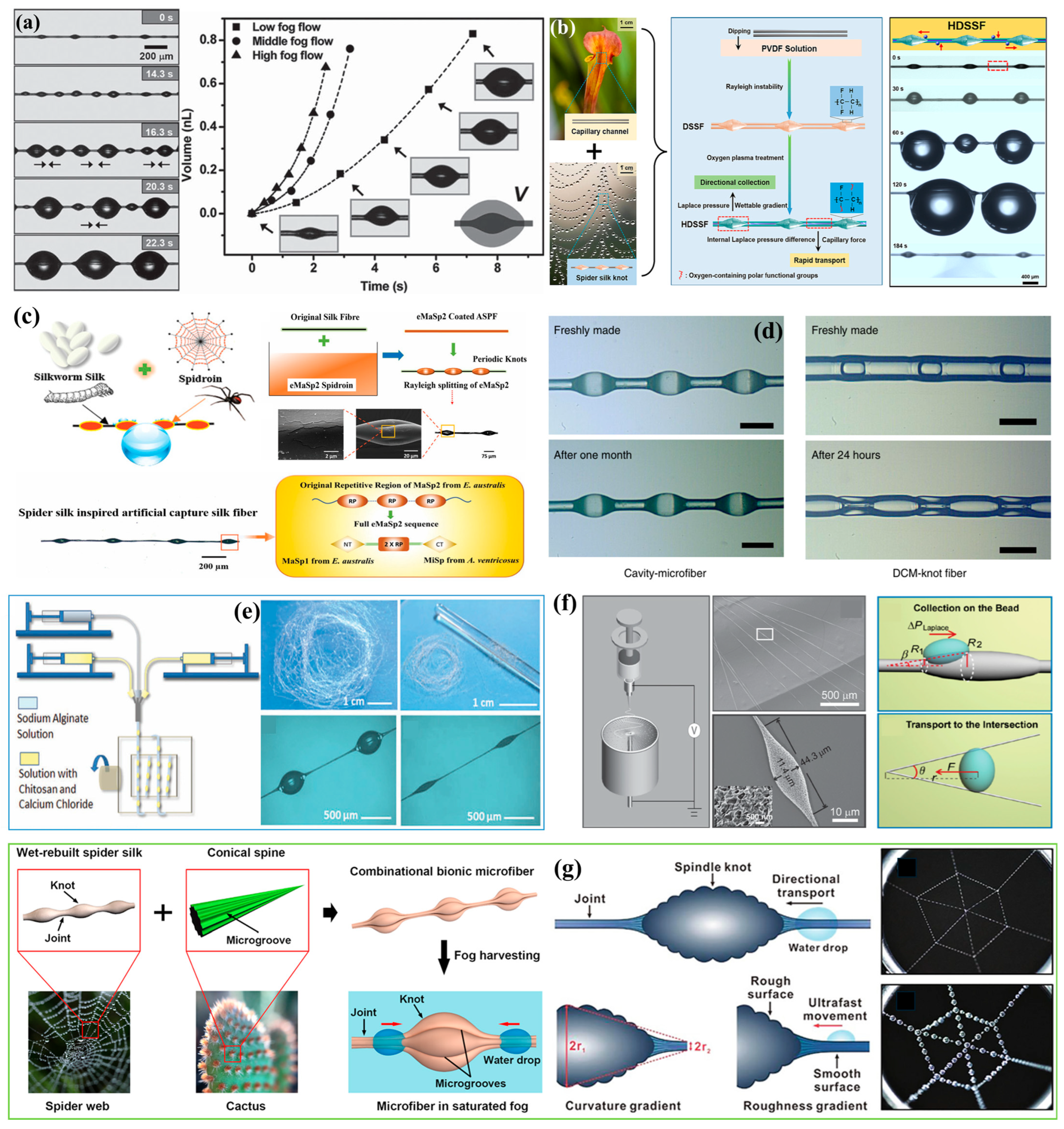

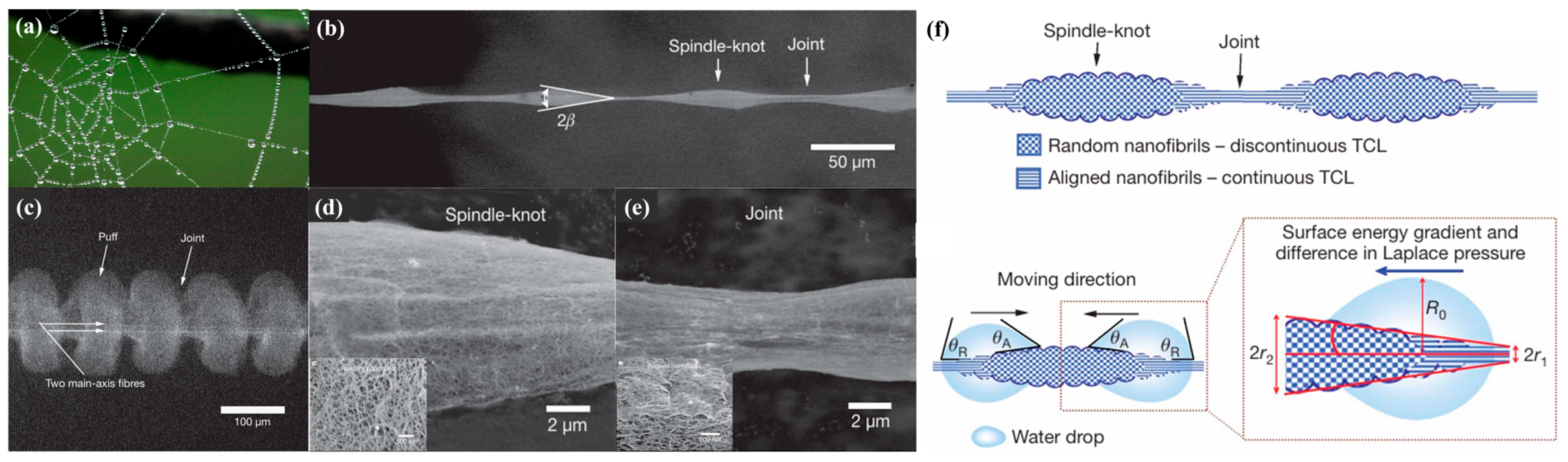

3.3. Spider Silk

3.3.1. Fog Water Collection Mechanism of Spider Silk

3.3.2. Fabrication of FWCSs Inspired by Spider Silk

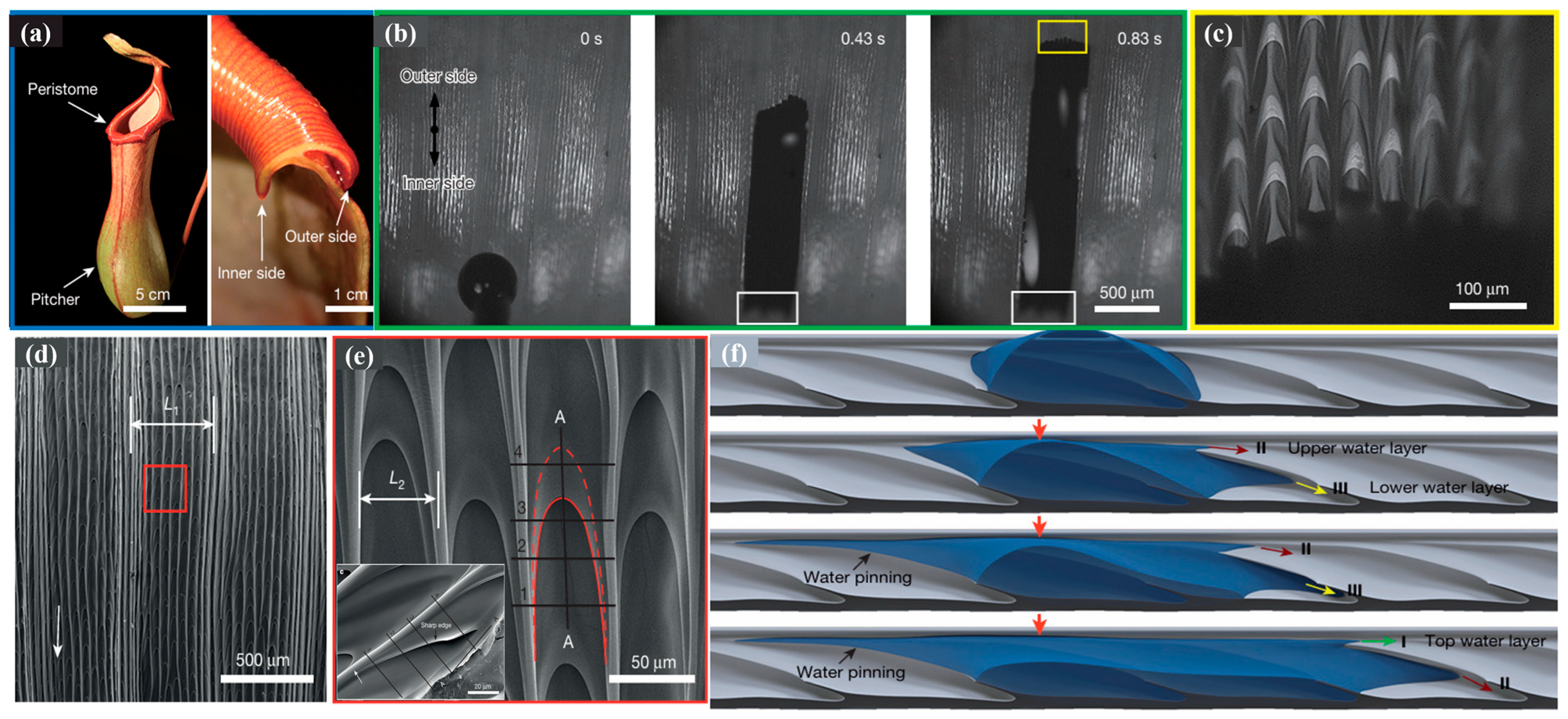

3.4. Nepenthes mirabilis

3.4.1. Droplet Transport Mechanism on the Peristome of Nepenthes mirabilis

3.4.2. Fabrication of Structures for Droplet Transport Inspired by the Peristome of Nepenthes mirabilis

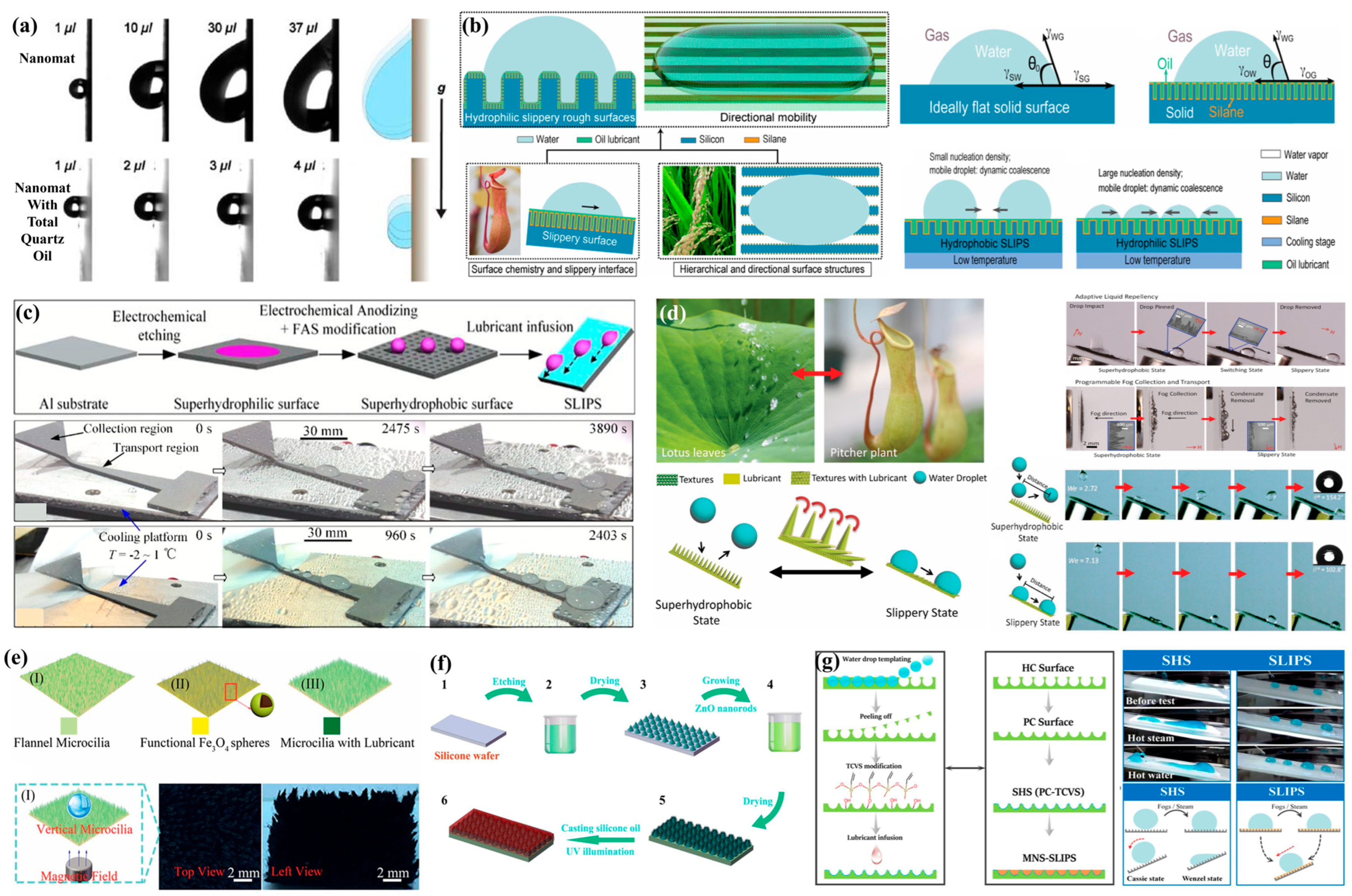

3.5. Multilevel Composite Bioinspired Fog Water Collection Structures

4. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FWCS | Fog water collection structure |

| FWCSs | Fog water collection structures |

| TiO2 | titanium dioxide |

| PS | polystyrene |

| PTFE | polytetrafluoroethylene |

| PDMS | polydimethylsiloxane |

| 3D | three dimensional |

| 2D | two dimensional |

| MNCS | micro/nanostructures |

| JM | Janus membrane |

| MPs | magnetic particles |

| MPAM | magnetic particle-assisted molding |

| PMMA | Polymethylmethacrylate |

| SLIPS | slippery liquid-infused porous surfaces |

References

- Zhang, Z.; Fu, H.; Li, Z.; Huang, J.; Xu, Z.; Lai, Y.; Qian, X.; Zhang, S. Hydrogel Materials for Sustainable Water Resources Harvesting & Treatment: Synthesis, Mechanism and Applications. Chem. Eng. J. 2022, 439, 135756. [Google Scholar] [CrossRef]

- Mishra, A.K.; Singh, V.P. Drought Modeling—A Review. J. Hydrol. 2011, 403, 157–175. [Google Scholar] [CrossRef]

- Gorjian, S.; Ghobadian, B. Solar Desalination: A Sustainable Solution to Water Crisis in Iran. Renew. Sustain. Energy Rev. 2015, 48, 571–584. [Google Scholar] [CrossRef]

- Alenezi, A.; Alabaiadly, Y. Emerging Technologies in Water Desalination: A Review and Future Outlook. Energy Nexus 2025, 17, 100373. [Google Scholar] [CrossRef]

- Campisano, A.; Butler, D.; Ward, S.; Burns, M.J.; Friedler, E.; DeBusk, K.; Fisher-Jeffes, L.N.; Ghisi, E.; Rahman, A.; Furumai, H.; et al. Corrigendum to “Urban Rainwater Harvesting Systems: Research, Implementation and Future Perspectives” [Water Res. 115 (2017) 195–209]. Water Res. 2017, 121, 386. [Google Scholar] [CrossRef]

- Li, X.-Y.; Xie, Z.-K.; Yan, X.-K. Runoff Characteristics of Artificial Catchment Materials for Rainwater Harvesting in the Semiarid Regions of China. Agric. Water Manag. 2004, 65, 211–224. [Google Scholar] [CrossRef]

- Brown, P.S.; Bhushan, B. Bioinspired Materials for Water Supply and Management: Water Collection, Water Purification and Separation of Water from Oil. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2016, 374, 20160135. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Zhao, H.; Zhu, L.; He, T.; Chen, S.; Gao, C.; Zhang, L. Seawater Desalination Technology and Engineering in China: A Review. Desalination 2021, 498, 114728. [Google Scholar] [CrossRef]

- Ali, Z.; Merrium, S.; Habib-ur-Rahman, M.; Hakeem, S.; Saddique, M.A.B.; Sher, M.A. Wetting Mechanism and Morphological Adaptation; Leaf Rolling Enhancing Atmospheric Water Acquisition in Wheat Crop—A Review. Environ. Sci. Pollut. Res. 2022, 29, 30967–30985. [Google Scholar] [CrossRef]

- Weathers, K.C.; Ponette-González, A.G.; Dawson, T.E. Medium, Vector, and Connector: Fog and the Maintenance of Ecosystems. Ecosystems 2020, 23, 217–229. [Google Scholar] [CrossRef]

- Domen, J.K.; Stringfellow, W.T.; Camarillo, M.K.; Gulati, S. Fog Water as an Alternative and Sustainable Water Resource. Clean Technol. Environ. Policy 2014, 16, 235–249. [Google Scholar] [CrossRef]

- Ahmad, Z.; Ahmad, I.; Patel, F. Fog Collection by Mimicking Nature. J. Biomim. Biomater. Tissue Eng. 2010, 8, 35–43. [Google Scholar] [CrossRef]

- Yue, H.; Zeng, Q.; Huang, J.; Guo, Z.; Liu, W. Fog Collection Behavior of Bionic Surface and Large Fog Collector: A Review. Adv. Colloid Interface Sci. 2022, 300, 102583. [Google Scholar] [CrossRef]

- Klemm, O.; Schemenauer, R.S.; Lummerich, A.; Cereceda, P.; Marzol, V.; Corell, D.; Van Heerden, J.; Reinhard, D.; Gherezghiher, T.; Olivier, J.; et al. Fog as a Fresh-Water Resource: Overview and Perspectives. AMBIO 2012, 41, 221–234. [Google Scholar] [CrossRef]

- Jarimi, H.; Powell, R.; Riffat, S. Review of Sustainable Methods for Atmospheric Water Harvesting. Int. J. Low-Carbon Technol. 2020, 15, 253–276. [Google Scholar] [CrossRef]

- Korkmaz, S.; Kariper, İ.A. Fog Harvesting against Water Shortage. Environ. Chem. Lett. 2020, 18, 361–375. [Google Scholar] [CrossRef]

- Zefrehei, A.A.; Sheikhzadeh, M.; Pishevar, A.R. Evaluation of the Geometrical Parameters of Collector Mesh on the Fog Collection Efficiency. J. Ind. Text. 2022, 51, 3466S–3492S. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Zhou, H.; Gao, C.; Li, D.; Hou, Y.; Zheng, Y. Fog Collection on a Bio-Inspired Topological Alloy Net with Micro-/Nanostructures. ACS Appl. Mater. Interfaces 2020, 12, 5065–5072. [Google Scholar] [CrossRef]

- Park, J.; Lee, C.; Lee, S.; Cho, H.; Moon, M.-W.; Kim, S.J. Clogged Water Bridges for Fog Harvesting. Soft Matter 2021, 17, 136–144. [Google Scholar] [CrossRef]

- Damak, M.; Varanasi, K.K. Electrostatically Driven Fog Collection Using Space Charge Injection. Sci. Adv. 2018, 4, eaao5323. [Google Scholar] [CrossRef]

- Liu, K.; Yao, X.; Jiang, L. Recent Developments in Bio-Inspired Special Wettability. Chem. Soc. Rev. 2010, 39, 3240. [Google Scholar] [CrossRef]

- Zhang, M.; Feng, S.; Wang, L.; Zheng, Y. Lotus Effect in Wetting and Self-Cleaning. Biotribology 2016, 5, 31–43. [Google Scholar] [CrossRef]

- Feng, L.; Zhang, Y.; Xi, J.; Zhu, Y.; Wang, N.; Xia, F.; Jiang, L. Petal Effect: A Superhydrophobic State with High Adhesive Force. Langmuir 2008, 24, 4114–4119. [Google Scholar] [CrossRef]

- Roth-Nebelsick, A.; Ebner, M.; Miranda, T.; Gottschalk, V.; Voigt, D.; Gorb, S.; Stegmaier, T.; Sarsour, J.; Linke, M.; Konrad, W. Leaf Surface Structures Enable the Endemic Namib Desert Grass Stipagrostis sabulicola to Irrigate Itself with Fog Water. J. R. Soc. Interface 2012, 9, 1965–1974. [Google Scholar] [CrossRef]

- Comanns, P.; Esser, F.J.; Kappel, P.H.; Baumgartner, W.; Shaw, J.; Withers, P.C. Adsorption and Movement of Water by Skin of the Australian Thorny Devil (Agamidae: Moloch horridus). R. Soc. Open Sci. 2017, 4, 170591. [Google Scholar] [CrossRef] [PubMed]

- Verbrugghe, N.; Khan, A.Z. Water Harvesting through Fog Collectors: A Review of Conceptual, Experimental and Operational Aspects. Int. J. Low-Carbon Technol. 2023, 18, 392–403. [Google Scholar] [CrossRef]

- Fu, Y.; Ai, S.; Guo, Z.; Liu, W. Biomimetic 3D Efficient Fog Harvester by Synergistic Wettability Effect. J. Colloid Interface Sci. 2023, 649, 646–654. [Google Scholar] [CrossRef]

- Comanns, P.; Withers, P.C.; Esser, F.J.; Baumgartner, W. Cutaneous Water Collection by a Moisture-Harvesting Lizard, the Thorny Devil (Moloch Horridus). J. Exp. Biol. 2016, 219, 3473–3479. [Google Scholar] [CrossRef] [PubMed]

- Bhushan, B. Design of Water Harvesting Towers and Projections for Water Collection from Fog and Condensation. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2020, 378, 20190440. [Google Scholar] [CrossRef]

- Azeem, M.; Noman, M.T.; Wiener, J.; Petru, M.; Louda, P. Structural Design of Efficient Fog Collectors: A Review. Environ. Technol. Innov. 2020, 20, 101169. [Google Scholar] [CrossRef]

- Sun, H.; Song, Y.; Zhang, B.; Huan, Y.; Jiang, C.; Liu, H.; Bao, T.; Yu, S.; Wang, H. Bioinspired Micro- and Nanostructures Used for Fog Harvesting. Appl. Phys. A 2021, 127, 461. [Google Scholar] [CrossRef]

- Mei, G.; Guo, Z. Special Wettability Materials Inspired by Multiorganisms for Fog Collection. Adv. Mater. Interfaces 2022, 9, 2102484. [Google Scholar] [CrossRef]

- Lu, H.; Shi, W.; Guo, Y.; Guan, W.; Lei, C.; Yu, G. Materials Engineering for Atmospheric Water Harvesting: Progress and Perspectives. Adv. Mater. 2022, 34, 2110079. [Google Scholar] [CrossRef]

- Qadir, M.; Jiménez, G.; Farnum, R.; Dodson, L.; Smakhtin, V. Fog Water Collection: Challenges beyond Technology. Water 2018, 10, 372. [Google Scholar] [CrossRef]

- Xue, Y.; Wang, T.; Shi, W.; Sun, L.; Zheng, Y. Water Collection Abilities of Green Bristlegrass Bristle. RSC Adv. 2014, 4, 40837–40840. [Google Scholar] [CrossRef]

- Zheng, Y.; Gao, X.; Jiang, L. Directional Adhesion of Superhydrophobic Butterfly Wings. Soft Matter 2007, 3, 178–182. [Google Scholar] [CrossRef]

- Prakash, M.; Quéré, D.; Bush, J.W.M. Surface Tension Transport of Prey by Feeding Shorebirds: The Capillary Ratchet. Science 2008, 320, 931–934. [Google Scholar] [CrossRef] [PubMed]

- Parker, A.R.; Lawrence, C.R. Water Capture by a Desert Beetle. Nature 2001, 414, 33–34. [Google Scholar] [CrossRef]

- Malik, F.T.; Clement, R.M.; Gethin, D.T.; Beysens, D.; Cohen, R.E.; Krawszik, W.; Parker, A.R. Dew Harvesting Efficiency of Four Species of Cacti. Bioinspir. Biomim. 2015, 10, 036005. [Google Scholar] [CrossRef]

- Zheng, Y.; Bai, H.; Huang, Z.; Tian, X.; Nie, F.-Q.; Zhao, Y.; Zhai, J.; Jiang, L. Directional Water Collection on Wetted Spider Silk. Nature 2010, 463, 640–643. [Google Scholar] [CrossRef]

- Li, J.; Ueda, E.; Paulssen, D.; Levkin, P.A. Slippery Lubricant-Infused Surfaces: Properties and Emerging Applications. Adv. Funct. Mater. 2019, 29, 1802317. [Google Scholar] [CrossRef]

- Liu, K.; Vuckovac, M.; Latikka, M.; Huhtamäki, T.; Ras, R.H.A. Improving Surface-Wetting Characterization. Science 2019, 363, 1147–1148. [Google Scholar] [CrossRef]

- Nishida, K.; Taniguchi, R.; Ishizaki, Y.; Tsushima, S.; Hirai, S. Impacts of Channel Wettability and Flow Direction on Liquid Water Transport in the Serpentine Flow Field of a Polymer Electrolyte Fuel Cell. J. Power Sources 2015, 275, 447–457. [Google Scholar] [CrossRef]

- Boyaci San, F.G.; Isik-Gulsac, I. Effect of Surface Wettability of Polymer Composite Bipolar Plates on Polymer Electrolyte Membrane Fuel Cell Performances. Int. J. Hydrogen Energy 2013, 38, 4089–4098. [Google Scholar] [CrossRef]

- Young, T. III. An Essay on the Cohesion of Fluids. Philos. Trans. R. Soc. Lond. 1805, 95, 65–87. [Google Scholar] [CrossRef]

- Widom, B. Capillarity and Wetting Phenomena: Drops, Bubbles, Pearls, Waves; Physics Today: Melville, NY, USA, 2004; Volume 57, pp. 66–67. [Google Scholar] [CrossRef]

- Malinowski, R.; Parkin, I.P.; Volpe, G. Advances towards Programmable Droplet Transport on Solid Surfaces and Its Applications. Chem. Soc. Rev. 2020, 49, 7879–7892. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of Solid Surfaces to Wetting by Water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Wenzel, R.N. Surface Roughness and Contact Angle. J. Phys. Colloid Chem. 1949, 53, 1466–1467. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of Porous Surfaces. Trans. Faraday Soc. 1944, 40, 546. [Google Scholar] [CrossRef]

- Rios, P.F.; Dodiuk, H.; Kenig, S.; McCarthy, S.; Dotan, A. The Effects of Nanostructure and Composition on the Hydrophobic Properties of Solid Surfaces. J. Adhes. Sci. Technol. 2006, 20, 563–587. [Google Scholar] [CrossRef]

- Butt, H.-J.; Liu, J.; Koynov, K.; Straub, B.; Hinduja, C.; Roismann, I.; Berger, R.; Li, X.; Vollmer, D.; Steffen, W.; et al. Contact Angle Hysteresis. Curr. Opin. Colloid Interface Sci. 2022, 59, 101574. [Google Scholar] [CrossRef]

- Xu, W.; Choi, C.-H. From Sticky to Slippery Droplets: Dynamics of Contact Line Depinning on Superhydrophobic Surfaces. Phys. Rev. Lett. 2012, 109, 024504. [Google Scholar] [CrossRef]

- Krumpfer, J.W.; McCarthy, T.J. Contact Angle Hysteresis: A Different View and a Trivial Recipe for Low Hysteresis Hydrophobic Surfaces. Faraday Discuss. 2010, 146, 103. [Google Scholar] [CrossRef] [PubMed]

- Extrand, C.W. A Thermodynamic Model for Contact Angle Hysteresis. J. Colloid Interface Sci. 1998, 207, 11–19. [Google Scholar] [CrossRef]

- Furmidge, C.G.L. Studies at Phase Interfaces. I. The Sliding of Liquid Drops on Solid Surfaces and a Theory for Spray Retention. J. Colloid Sci. 1962, 17, 309–324. [Google Scholar] [CrossRef]

- Rivera, J.D.D. Aerodynamic Collection Efficiency of Fog Water Collectors. Atmos. Res. 2011, 102, 335–342. [Google Scholar] [CrossRef]

- Cox, R.G. The Spreading of a Liquid on a Rough Solid Surface. J. Fluid Mech. 1983, 131, 1–26. [Google Scholar] [CrossRef]

- Tang, X.; Guo, Z. Biomimetic Fog Collection and Its Influencing Factors. New J. Chem. 2020, 44, 20495–20519. [Google Scholar] [CrossRef]

- Zhang, J.; Guang, J.; Chen, C.; Sadik, S. Superwetting Materials for Fog Collection: From Single Function to Smart Responsive: A Review. Chem. Eng. Sci. 2025, 302, 120893. [Google Scholar] [CrossRef]

- Zhan, L.; Chen, J.; Zhang, C.; Wang, T.; Xin, P.; Li, L. Fog Interception Maintains a Major Waterfall Landscape in Southwest China Revealed by Isotopic Signatures. Water Resour. Res. 2020, 56, e2019WR025628. [Google Scholar] [CrossRef]

- Langmuir, I.; Blodgett, K. Mathematical Investigation of Water Droplet Trajectories. In Atmospheric Phenomena; Elsevier: Amsterdam, The Netherlands, 1961; pp. 335–347. ISBN 978-0-08-009362-8. [Google Scholar]

- Finstad, K.J.; Lozowski, E.P.; Gates, E.M. A Computational Investigation of Water Droplet Trajectories. J. Atmos. Ocean. Technol. 1988, 5, 160–170. [Google Scholar] [CrossRef]

- Park, K.-C.; Chhatre, S.S.; Srinivasan, S.; Cohen, R.E.; McKinley, G.H. Optimal Design of Permeable Fiber Network Structures for Fog Harvesting. Langmuir 2013, 29, 13269–13277. [Google Scholar] [CrossRef]

- Sharifvaghefi, S.; Kazerooni, H. Fog Harvesting: Combination and Comparison of Different Methods to Maximize the Collection Efficiency. SN Appl. Sci. 2021, 3, 516. [Google Scholar] [CrossRef]

- Shi, W.; Anderson, M.J.; Tulkoff, J.B.; Kennedy, B.S.; Boreyko, J.B. Fog Harvesting with Harps. ACS Appl. Mater. Interfaces 2018, 10, 11979–11986. [Google Scholar] [CrossRef]

- Gürsoy, M.; Harris, M.T.; Downing, J.O.; Barrientos-Palomo, S.N.; Carletto, A.; Yaprak, A.E.; Karaman, M.; Badyal, J.P.S. Bioinspired Fog Capture and Channel Mechanism Based on the Arid Climate Plant Salsola Crassa. Colloids Surf. Physicochem. Eng. Asp. 2017, 529, 195–202. [Google Scholar] [CrossRef]

- Jiang, Y.; Machado, C.; Park, K.K. From Capture to Transport: A Review of Engineered Surfaces for Fog Collection. Droplet 2023, 2, e55. [Google Scholar] [CrossRef]

- Kim, S.; Kim, D.; Kim, J.; An, S.; Jhe, W. Direct Evidence for Curvature-Dependent Surface Tension in Capillary Condensation: Kelvin Equation at Molecular Scale. Phys. Rev. X 2018, 8, 041046. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Han, P.; Qi, G.; Gao, D.; Zhang, L.; Wang, C.; Che, J.; Wang, Y.; Tao, S. Improved Water Collection from Short-Term Fog on a Patterned Surface with Interconnected Microchannels. Environ. Sci. Technol. 2024, 58, 3812–3822. [Google Scholar] [CrossRef] [PubMed]

- Fisher, L.R.; Gamble, R.A.; Middlehurst, J. The Kelvin Equation and the Capillary Condensation of Water. Nature 1981, 290, 575–576. [Google Scholar] [CrossRef]

- Li, D.; Li, C.; Xiao, M.; Zhang, M.; Li, J.; Yang, Z.; Fu, Q.; Yu, K.; Yang, Y.; Pan, Y.; et al. Sustainable Solutions for Water Scarcity: A Review of Electrostatic Fog Harvesting Technology. Commun. Eng. 2025, 4, 34. [Google Scholar] [CrossRef]

- Yang, J.-L.; Song, Y.-Y.; Zhang, X.; Zhang, Z.-Q.; Cheng, G.-G.; Liu, Y.; Lv, G.-J.; Ding, J.-N. Research Progress of Bionic Fog Collection Surfaces Based on Special Structures from Natural Organisms. RSC Adv. 2023, 13, 27839–27864. [Google Scholar] [CrossRef]

- Tu, Y.; Wang, R.; Zhang, Y.; Wang, J. Progress and Expectation of Atmospheric Water Harvesting. Joule 2018, 2, 1452–1475. [Google Scholar] [CrossRef]

- Medici, M.-G.; Mongruel, A.; Royon, L.; Beysens, D. Edge Effects on Water Droplet Condensation. Phys. Rev. E 2014, 90, 062403. [Google Scholar] [CrossRef]

- Hou, Y.; Shang, Y.; Yu, M.; Feng, C.; Yu, H.; Yao, S. Tunable Water Harvesting Surfaces Consisting of Biphilic Nanoscale Topography. ACS Nano 2018, 12, 11022–11030. [Google Scholar] [CrossRef]

- Jin, Y.; Zhang, L.; Wang, P. Atmospheric Water Harvesting: Role of Surface Wettability and Edge Effect. Glob. Chall. 2017, 1, 1700019. [Google Scholar] [CrossRef] [PubMed]

- Mitrovic, J. The Nusselt Condensation and Nonisothermality. Int. J. Heat Mass Transf. 1998, 41, 4055–4061. [Google Scholar] [CrossRef]

- Gregorig, R. Hautkondensation an feingewellten Oberflächen bei Berücksichtigung der Oberflächenspannungen. Z. Für Angew. Math. Phys. ZAMP 1954, 5, 36–49. [Google Scholar] [CrossRef]

- Glicksman, L.R.; Hunt, A.W. Numerical Simulation of Dropwise Condensation. Int. J. Heat Mass Transf. 1972, 15, 2251–2269. [Google Scholar] [CrossRef]

- Graham, C.; Griffith, P. Drop Size Distributions and Heat Transfer in Dropwise Condensation. Int. J. Heat Mass Transf. 1973, 16, 337–346. [Google Scholar] [CrossRef]

- Bai, H.; Sun, H.; Ye, Z.; Li, Z.; Zhao, T.; Wang, X.; Cheng, M.; Wang, Z.; Huang, S.; Cao, M. Unravelling the Aerodynamic Enhancement of Water Harvesting via Dynamic Liquid Bumps. Mater. Horiz. 2025, 12, 6217–6228. [Google Scholar] [CrossRef]

- Carvajal, D.; Silva-Llanca, L.; Larraguibel, D.; González, B. On the Aerodynamic Fog Collection Efficiency of Fog Water Collectors via Three-Dimensional Numerical Simulations. Atmos. Res. 2020, 245, 105123. [Google Scholar] [CrossRef]

- Ghosh, R.; Ray, T.K.; Ganguly, R. Cooling Tower Fog Harvesting in Power Plants—A Pilot Study. Energy 2015, 89, 1018–1028. [Google Scholar] [CrossRef]

- Findenegg, G.H.; Herminghaus, S. Wetting: Statics and Dynamics. Curr. Opin. Colloid Interface Sci. 1997, 2, 301–307. [Google Scholar] [CrossRef]

- Xu, C.; Jia, Z.; Lian, X. Wetting and Adhesion Energy of Droplets on Wettability Gradient Surfaces. J. Mater. Sci. 2020, 55, 8185–8198. [Google Scholar] [CrossRef]

- Hu, C.; Song, X.; Cai, J.; Lv, C.; Zeng, N.; Liu, A.; Zhou, L.; Liu, Y.; Hu, L.; Song, J.; et al. Self-Propulsion Dynamics of Nanosized Water Droplets on MoS2/Graphene Heterojunction Surface: A Molecular Dynamics Simulation Study. Appl. Surf. Sci. 2022, 596, 153583. [Google Scholar] [CrossRef]

- Zuleta, E.C.; Baena, L.; Rios, L.A.; Calderón, J.A. The Oxidative Stability of Biodiesel and Its Impact on the Deterioration of Metallic and Polymeric Materials: A Review. J. Braz. Chem. Soc. 2012, 23, 2159–2175. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, F.; Dong, Y.; Liu, Z.; Li, W.; Huang, Y. A Multifunctional Polymeric Nanofilm with Robust Chemical Performances for Special Wettability. Nanoscale 2016, 8, 5153–5161. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Pan, Q. Mussel-Inspired Direct Immobilization of Nanoparticles and Application for Oil–Water Separation. ACS Nano 2014, 8, 1402–1409. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.; Guo, F.; Hou, L.; Chen, Y.; Liu, J.; Wang, N.; Zhao, Y.; Jiang, L. Opposite and Complementary: A Superhydrophobic—Superhydrophilic Integrated System for High-Flux, High-Efficiency and Continuous Oil/Water Separation. J. Mater. Chem. A 2016, 4, 4365–4370. [Google Scholar] [CrossRef]

- Hamilton, W.J.; Seely, M.K. Fog Basking by the Namib Desert Beetle, Onymacris unguicularis. Nature 1976, 262, 284–285. [Google Scholar] [CrossRef]

- Nørgaard, T.; Dacke, M. Fog-Basking Behaviour and Water Collection Efficiency in Namib Desert Darkling Beetles. Front. Zool. 2010, 7, 23. [Google Scholar] [CrossRef]

- Hunter, P. Turning Nature’s Inspiration into a Production Line: Exploits of Natural Designs Have Become a Systematic Research Field to Create New Materials and Designs for Architecture, Medicinal Devices and Other Products. EMBO Rep. 2014, 15, 1123–1127. [Google Scholar] [CrossRef]

- Guadarrama-Cetina, J.; Mongruel, A.; Medici, M.-G.; Baquero, E.; Parker, A.R.; Milimouk-Melnytchuk, I.; González-Viñas, W.; Beysens, D. Dew Condensation on Desert Beetle Skin. Eur. Phys. J. E 2014, 37, 109. [Google Scholar] [CrossRef]

- Lee, M.; Yang, K.; Hwang, Y.H.; Byun, Y.; Lee, D.Y.; Cho, S.; Lee, H. Spheroform: Therapeutic Spheroid-Forming Nanotextured Surfaces Inspired by Desert Beetle Physosterna cribripes. Adv. Healthc. Mater. 2015, 4, 511–515. [Google Scholar] [CrossRef]

- Malik, F.T.; Clement, R.M.; Gethin, D.T.; Krawszik, W.; Parker, A.R. Nature’s Moisture Harvesters: A Comparative Review. Bioinspir. Biomim. 2014, 9, 031002. [Google Scholar] [CrossRef] [PubMed]

- Kostal, E.; Stroj, S.; Kasemann, S.; Matylitsky, V.; Domke, M. Fabrication of Biomimetic Fog-Collecting Superhydrophilic–Superhydrophobic Surface Micropatterns Using Femtosecond Lasers. Langmuir 2018, 34, 2933–2941. [Google Scholar] [CrossRef]

- Zhai, L.; Berg, M.C.; Cebeci, F.Ç.; Kim, Y.; Milwid, J.M.; Rubner, M.F.; Cohen, R.E. Patterned Superhydrophobic Surfaces: Toward a Synthetic Mimic of the Namib Desert Beetle. Nano Lett. 2006, 6, 1213–1217. [Google Scholar] [CrossRef]

- Bai, H.; Wang, L.; Ju, J.; Sun, R.; Zheng, Y.; Jiang, L. Efficient Water Collection on Integrative Bioinspired Surfaces with Star-Shaped Wettability Patterns. Adv. Mater. 2014, 26, 5025–5030. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, L.; Wu, J.; Hedhili, M.N.; Wang, P. A Facile Strategy for the Fabrication of a Bioinspired Hydrophilic–Superhydrophobic Patterned Surface for Highly Efficient Fog-Harvesting. J. Mater. Chem. A 2015, 3, 18963–18969. [Google Scholar] [CrossRef]

- Garrod, R.P.; Harris, L.G.; Schofield, W.C.E.; McGettrick, J.; Ward, L.J.; Teare, D.O.H.; Badyal, J.P.S. Mimicking a Stenocara Beetle’s Back for Microcondensation Using Plasmachemical Patterned Superhydrophobic−Superhydrophilic Surfaces. Langmuir 2007, 23, 689–693. [Google Scholar] [CrossRef]

- Yang, H.; Zhu, H.; Hendrix, M.M.R.M.; Lousberg, N.J.H.G.M.; De With, G.; Esteves, A.C.C.; Xin, J.H. Temperature-Triggered Collection and Release of Water from Fogs by a Sponge-Like Cotton Fabric (Adv. Mater. 8/2013). Adv. Mater. 2013, 25, 1149. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, H.; Huang, J.; Li, S.; Zhang, S.; Cheng, Y.; Mao, J.; Dong, X.; Gao, S.; Wang, S.; et al. Namib Desert Beetle Inspired Special Patterned Fabric with Programmable and Gradient Wettability for Efficient Fog Harvesting. J. Mater. Sci. Technol. 2021, 61, 85–92. [Google Scholar] [CrossRef]

- Park, J.; Kim, S. Three-Dimensionally Structured Flexible Fog Harvesting Surfaces Inspired by Namib Desert Beetles. Micromachines 2019, 10, 201. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Guo, Z. Recent Advances in Biomimetic Surfaces Inspired by Creatures for Fog Harvesting. New J. Chem. 2021, 45, 21125–21150. [Google Scholar] [CrossRef]

- Wei, H.; Qin, B.; Luo, H.; Zhou, X.; Wang, X.; Mei, Y. Efficient Fog Harvesting System Inspired by Cactus Spine and Spider Silk with Vertical Crisscross Spindle Structure. Chem. Eng. J. 2025, 507, 160747. [Google Scholar] [CrossRef]

- Ju, J.; Xiao, K.; Yao, X.; Bai, H.; Jiang, L. Bioinspired Conical Copper Wire with Gradient Wettability for Continuous and Efficient Fog Collection. Adv. Mater. 2013, 25, 5937–5942. [Google Scholar] [CrossRef]

- Ju, J.; Bai, H.; Zheng, Y.; Zhao, T.; Fang, R.; Jiang, L. A Multi-Structural and Multi-Functional Integrated Fog Collection System in Cactus. Nat. Commun. 2012, 3, 1247. [Google Scholar] [CrossRef]

- Malik, F.T.; Clement, R.M.; Gethin, D.T.; Kiernan, M.; Goral, T.; Griffiths, P.; Beynon, D.; Parker, A.R. Hierarchical Structures of Cactus Spines That Aid in the Directional Movement of Dew Droplets. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2016, 374, 20160110. [Google Scholar] [CrossRef]

- Heng, X.; Xiang, M.; Lu, Z.; Luo, C. Branched ZnO Wire Structures for Water Collection Inspired by Cacti. ACS Appl. Mater. Interfaces 2014, 6, 8032–8041. [Google Scholar] [CrossRef]

- Bai, H.; Zhao, T.; Wang, X.; Wu, Y.; Li, K.; Yu, C.; Jiang, L.; Cao, M. Cactus Kirigami for Efficient Fog Harvesting: Simplifying a 3D Cactus into 2D Paper Art. J. Mater. Chem. A 2020, 8, 13452–13458. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, M.; Li, C.; Gao, C.; Zheng, Y. Excellent Fog-Droplets Collector via Integrative Janus Membrane and Conical Spine with Micro/Nanostructures. Small 2018, 14, 1801335. [Google Scholar] [CrossRef]

- Chen, D.; Li, J.; Zhao, J.; Guo, J.; Zhang, S.; Sherazi, T.A.; Ambreen; Li, S. Bioinspired Superhydrophilic-Hydrophobic Integrated Surface with Conical Pattern-Shape for Self-Driven Fog Collection. J. Colloid Interface Sci. 2018, 530, 274–281. [Google Scholar] [CrossRef]

- Bai, F.; Wu, J.; Gong, G.; Guo, L. Biomimetic “Cactus Spine” with Hierarchical Groove Structure for Efficient Fog Collection. Adv. Sci. 2015, 2, 1500047. [Google Scholar] [CrossRef] [PubMed]

- Ju, J.; Yao, X.; Yang, S.; Wang, L.; Sun, R.; He, Y.; Jiang, L. Cactus Stem Inspired Cone-Arrayed Surfaces for Efficient Fog Collection. Adv. Funct. Mater. 2014, 24, 6933–6938. [Google Scholar] [CrossRef]

- Cao, M.; Ju, J.; Li, K.; Dou, S.; Liu, K.; Jiang, L. Facile and Large-Scale Fabrication of a Cactus-Inspired Continuous Fog Collector. Adv. Funct. Mater. 2014, 24, 3235–3240. [Google Scholar] [CrossRef]

- Xu, T.; Lin, Y.; Zhang, M.; Shi, W.; Zheng, Y. High-Efficiency Fog Collector: Water Unidirectional Transport on Heterogeneous Rough Conical Wires. ACS Nano 2016, 10, 10681–10688. [Google Scholar] [CrossRef]

- Peng, Y.; He, Y.; Yang, S.; Ben, S.; Cao, M.; Li, K.; Liu, K.; Jiang, L. Magnetically Induced Fog Harvesting via Flexible Conical Arrays. Adv. Funct. Mater. 2015, 25, 5967–5971. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Liu, L.; Chen, Y.; Chu, M.; Sun, H.; Shan, W.; Chen, Y. 3D-Printed Cactus-Inspired Spine Structures for Highly Efficient Water Collection. Adv. Mater. Interfaces 2020, 7, 1901752. [Google Scholar] [CrossRef]

- Yi, S.; Wang, J.; Chen, Z.; Liu, B.; Ren, L.; Liang, L.; Jiang, L. Cactus-Inspired Conical Spines with Oriented Microbarbs for Efficient Fog Harvesting. Adv. Mater. Technol. 2019, 4, 1900727. [Google Scholar] [CrossRef]

- Liu, L.; Liu, S.; Schelp, M.; Chen, X. Rapid 3D Printing of Bioinspired Hybrid Structures for High-Efficiency Fog Collection and Water Transportation. ACS Appl. Mater. Interfaces 2021, 13, 29122–29129. [Google Scholar] [CrossRef]

- Li, J.; Li, M.; Koh, J.J.; Wang, J.; Lyu, Z. 3D-Printed Biomimetic Structures for Energy and Environmental Applications. DeCarbon 2024, 3, 100026. [Google Scholar] [CrossRef]

- Wu, X.; Chen, K.; Chai, Q.; Zhang, X.; Feng, H.; Feng, C.; Wang, D.; Li, X.; Zhang, D. A 3D Printed Multilayer Biomimetic Scaffold with a Gradient-Oriented Structure for Articular Cartilage Repair. J. Mater. Chem. B 2025, 13, 7728–7743. [Google Scholar] [CrossRef] [PubMed]

- Sadeghzade, S.; Fani, N.; Nene, A.; Tavangarian, F. Biomimetic 3D Printed Spicule-like Structure Composite of Organic Material/Rigid Resin Cylinders with Highly Enhanced Strength and Toughness. Compos. Sci. Technol. 2024, 256, 110789. [Google Scholar] [CrossRef]

- Guo, X.; Jin, C.; Li, X.; Zhang, A.; Hong, W.; Yan, Z.; Zhang, X.; Yu, S.; Yu, S.; Zhang, H.; et al. Electromechanical Performance of Flexible Sensor Based on 3D Printed Biomimetic All-PDMS-Coated Multistage Structure: Toward Kinesiology Monitoring and Human-Machine Interaction. Sens. Actuators Phys. 2024, 369, 115193. [Google Scholar] [CrossRef]

- Mahmood, A.; Chen, L.; Chen, S.; Chen, C.; Yu, Y.; Weng, D.; Wang, J. Nature-Inspired Design of Conical Array for Continuous and Efficient Fog Collection Application. Colloid Interface Sci. Commun. 2020, 37, 100283. [Google Scholar] [CrossRef]

- Schacht, K.; Scheibel, T. Controlled Hydrogel Formation of a Recombinant Spider Silk Protein. Biomacromolecules 2011, 12, 2488–2495. [Google Scholar] [CrossRef]

- Elices, M.; Guinea, G.V.; Plaza, G.R.; Karatzas, C.; Riekel, C.; Agulló-Rueda, F.; Daza, R.; Pérez-Rigueiro, J. Bioinspired Fibers Follow the Track of Natural Spider Silk. Macromolecules 2011, 44, 1166–1176. [Google Scholar] [CrossRef]

- Chen, W.; Guo, Z. Hierarchical Fibers for Water Collection Inspired by Spider Silk. Nanoscale 2019, 11, 15448–15463. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, L. Bioinspired Microfibers for Water Collection. J. Mater. Chem. A 2018, 6, 18766–18781. [Google Scholar] [CrossRef]

- Knapczyk-Korczak, J.; Stachewicz, U. Biomimicking Spider Webs for Effective Fog Water Harvesting with Electrospun Polymer Fibers. Nanoscale 2021, 13, 16034–16051. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Song, C.; Zhang, M.; Zheng, Y. Bioinspired Heterostructured Bead-on-String Fibers via Controlling the Wet-Assembly of Nanoparticles. Chem. Commun. 2014, 50, 10651. [Google Scholar] [CrossRef] [PubMed]

- Branković, M.; Zivic, F.; Grujovic, N.; Stojadinovic, I.; Milenkovic, S.; Kotorcevic, N. Review of Spider Silk Applications in Biomedical and Tissue Engineering. Biomimetics 2024, 9, 169. [Google Scholar] [CrossRef] [PubMed]

- Bakhshandeh, B.; Nateghi, S.S.; Gazani, M.M.; Dehghani, Z.; Mohammadzadeh, F. A Review on Advances in the Applications of Spider Silk in Biomedical Issues. Int. J. Biol. Macromol. 2021, 192, 258–271. [Google Scholar] [CrossRef]

- Su, Y.; Shi, S.; Wang, C.; Wang, Z.; Li, P.; Zhang, S.; Fei, B.; Yang, Z.; Hu, J. Spider Silk-Inspired Tough Materials: Multi-Pathway Synthesis, Advanced Processing, and Functional Applications. Nano Today 2024, 55, 102188. [Google Scholar] [CrossRef]

- Bai, H.; Ju, J.; Sun, R.; Chen, Y.; Zheng, Y.; Jiang, L. Controlled Fabrication and Water Collection Ability of Bioinspired Artificial Spider Silks. Adv. Mater. 2011, 23, 3708–3711. [Google Scholar] [CrossRef]

- Chen, W.; Li, S.; Guo, Z. Water Droplet Transport on a Nylon Mesh with Graded Structures by Facile PMMA Spraying and Etching Process Inspired by Spider Silk. Mater. Lett. 2021, 291, 129546. [Google Scholar] [CrossRef]

- Huan, J.; Chen, M.; Hou, Y.; Zheng, Y. Special Fog Harvesting Mode on Bioinspired Hydrophilic Dual-Thread Spider Silk Fiber. Chem. Eng. J. 2023, 473, 145174. [Google Scholar] [CrossRef]

- Hou, Y.; Chen, Y.; Xue, Y.; Zheng, Y.; Jiang, L. Water Collection Behavior and Hanging Ability of Bioinspired Fiber. Langmuir 2012, 28, 4737–4743. [Google Scholar] [CrossRef]

- Wang, S.; Feng, S.; Hou, Y.; Zheng, Y. Controlling of Water Collection Ability by an Elasticity-Regulated Bioinspired Fiber. Macromol. Rapid Commun. 2015, 36, 459–464. [Google Scholar] [CrossRef]

- Venkatesan, H.; Chen, J.; Liu, H.; Liu, W.; Hu, J. A Spider-Capture-Silk-Like Fiber with Extremely High-Volume Directional Water Collection. Adv. Funct. Mater. 2020, 30, 2002437. [Google Scholar] [CrossRef]

- Chen, Y.; Li, D.; Wang, T.; Zheng, Y. Orientation-Induced Effects of Water Harvesting on Humps-on-Strings of Bioinspired Fibers. Sci. Rep. 2016, 6, 19978. [Google Scholar] [CrossRef]

- Tian, Y.; Zhu, P.; Tang, X.; Zhou, C.; Wang, J.; Kong, T.; Xu, M.; Wang, L. Large-Scale Water Collection of Bioinspired Cavity-Microfibers. Nat. Commun. 2017, 8, 1080. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, N.; Li, X.; Li, J.; Pei, W.; Xu, Y.; Hou, Y.; Zheng, Y. Water Harvesting of Bioinspired Microfibers with Rough Spindle-Knots from Microfluidics. Small 2020, 16, 1901819. [Google Scholar] [CrossRef] [PubMed]

- Du, M.; Zhao, Y.; Tian, Y.; Li, K.; Jiang, L. Electrospun Multiscale Structured Membrane for Efficient Water Collection and Directional Transport. Small 2016, 12, 1000–1005. [Google Scholar] [CrossRef]

- Zhang, M.; Zheng, Z.; Zhu, Y.; Zhu, Z.; Si, T.; Xu, R.X. Combinational Biomimetic Microfibers for High-Efficiency Water Collection. Chem. Eng. J. 2022, 433, 134495. [Google Scholar] [CrossRef]

- Bauer, U.; Federle, W. The Insect-Trapping Rim of Nepenthes Pitchers: Surface Structure and Function. Plant Signal. Behav. 2009, 4, 1019–1023. [Google Scholar] [CrossRef]

- Bohn, H.F.; Federle, W. Insect Aquaplaning: Nepenthes Pitcher Plants Capture Prey with the Peristome, a Fully Wettable Water-Lubricated Anisotropic Surface. Proc. Natl. Acad. Sci. USA 2004, 101, 14138–14143. [Google Scholar] [CrossRef]

- He, W.; Liu, P.; Zhang, J.; Yao, X. Emerging Applications of Bioinspired Slippery Surfaces in Biomedical Fields. Chem.–Eur. J. 2018, 24, 14864–14877. [Google Scholar] [CrossRef]

- Deng, R.; Shen, T.; Chen, H.; Lu, J.; Yang, H.-C.; Li, W. Slippery Liquid-Infused Porous Surfaces (SLIPSs): A Perfect Solution to Both Marine Fouling and Corrosion? J. Mater. Chem. A 2020, 8, 7536–7547. [Google Scholar] [CrossRef]

- Lalia, B.S.; Anand, S.; Varanasi, K.K.; Hashaikeh, R. Fog-Harvesting Potential of Lubricant-Impregnated Electrospun Nanomats. Langmuir 2013, 29, 13081–13088. [Google Scholar] [CrossRef] [PubMed]

- Dai, X.; Sun, N.; Nielsen, S.O.; Stogin, B.B.; Wang, J.; Yang, S.; Wong, T.-S. Hydrophilic Directional Slippery Rough Surfaces for Water Harvesting. Sci. Adv. 2018, 4, eaaq0919. [Google Scholar] [CrossRef]

- Luo, H.; Lu, Y.; Yin, S.; Huang, S.; Song, J.; Chen, F.; Chen, F.; Carmalt, C.J.; Parkin, I.P. Robust Platform for Water Harvesting and Directional Transport. J. Mater. Chem. A 2018, 6, 5635–5643. [Google Scholar] [CrossRef]

- Huang, Y.; Stogin, B.B.; Sun, N.; Wang, J.; Yang, S.; Wong, T. A Switchable Cross-Species Liquid Repellent Surface. Adv. Mater. 2017, 29, 1604641. [Google Scholar] [CrossRef]

- Li, D.; Huang, J.; Han, G.; Guo, Z. A Facile Approach to Achieve Bioinspired PDMS@Fe3 O4 Fabric with Switchable Wettability for Liquid Transport and Water Collection. J. Mater. Chem. A 2018, 6, 22741–22748. [Google Scholar] [CrossRef]

- Jing, X.; Guo, Z. Durable Lubricant-Impregnated Surfaces for Water Collection under Extremely Severe Working Conditions. ACS Appl. Mater. Interfaces 2019, 11, 35949–35958. [Google Scholar] [CrossRef]

- Feng, R.; Xu, C.; Song, F.; Wang, F.; Wang, X.-L.; Wang, Y.-Z. A Bioinspired Slippery Surface with Stable Lubricant Impregnation for Efficient Water Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 12373–12381. [Google Scholar] [CrossRef]

- Yu, Z.; Zhu, T.; Zhang, J.; Ge, M.; Fu, S.; Lai, Y. Fog Harvesting Devices Inspired from Single to Multiple Creatures: Current Progress and Future Perspective. Adv. Funct. Mater. 2022, 32, 2200359. [Google Scholar] [CrossRef]

- Chen, H.; Ran, T.; Zhang, K.; Chen, D.; Gan, Y.; Wang, Z.; Jiang, L. Highly Efficient Multiscale Fog Collector Inspired by Sarracenia Trichome Hierarchical Structure. Glob. Chall. 2021, 5, 2100087. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liang, X.; Ma, K.; Zhang, H.; Wang, X.; Xin, J.H.; Zhang, Q.; Zhu, S. Nature-Inspired Windmill for Water Collection in Complex Windy Environments. ACS Appl. Mater. Interfaces 2019, 11, 17952–17959. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, L.; Wang, Y.; Bian, F.; Wang, Y.; Zhao, Y. Multibioinspired Slippery Surfaces with Wettable Bump Arrays for Droplets Pumping. Proc. Natl. Acad. Sci. USA 2019, 116, 20863–20868. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, D.; Mahapatra, A.; Som, A.; Kumar, R.; Nagar, A.; Baidya, A.; Pradeep, T. Patterned Nanobrush Nature Mimics with Unprecedented Water-Harvesting Efficiency. Adv. Mater. Interfaces 2018, 5, 1800667. [Google Scholar] [CrossRef]

- Wang, J.; Yi, S.; Yang, Z.; Chen, Y.; Jiang, L.; Wong, C.-P. Laser Direct Structuring of Bioinspired Spine with Backward Microbarbs and Hierarchical Microchannels for Ultrafast Water Transport and Efficient Fog Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 21080–21087. [Google Scholar] [CrossRef] [PubMed]

- Neumann, S.E.; Neumann, K.; Zheng, Z.; Hanikel, N.; Tsao, J.; Yaghi, O.M. Harvesting Water in the Classroom. J. Chem. Educ. 2023, 100, 4482–4487. [Google Scholar] [CrossRef]

- Parisi, G.; Szewczyk, P.K.; Narayan, S.; Stachewicz, U. Photoresponsive Electrospun Fiber Meshes with Switchable Wettability for Effective Fog Water Harvesting in Variable Humidity Conditions. ACS Appl. Mater. Interfaces 2023, 15, 40001–40010. [Google Scholar] [CrossRef]

- Xu, J.; Lu, P.; Zhao, J.; Zhao, X.; Tian, W.; Ming, W.; Ren, L. Surprisingly Fast Self-Healing Coatings with Anti-Fog and Antimicrobial Activities via Host-Guest Interaction. J. Colloid Interface Sci. 2025, 680, 139–150. [Google Scholar] [CrossRef]

- Saeed, M.H.; Herman, J.A.; Das, A.; Kennedy, D.T.; White, T.J. Inverse Elastocaloric Output in Supramolecular Liquid Crystalline Elastomers. ACS Mater. Lett. 2025, 7, 2688–2694. [Google Scholar] [CrossRef]

| Species Name | Time | Reference |

|---|---|---|

| Lotus Leaf | 1997 | [22] |

| Rose Petal | 2008 | [23] |

| Stipagrostis sabulicola (Namibian needle grass) | 2012 | [24] |

| Thorny devil (Moloch horridus) | 2016 | [25] |

| Foxtail Grass | 2014 | [35] |

| Butterfly | 2007 | [36] |

| Shorebird | 2008 | [37] |

| Namib Desert beetle | 2001 | [38] |

| Cactus Spines | 2012 | [39] |

| Spider Silk | 2010 | [40] |

| Nepenthes mirabilis | 2016 | [41] |

| Species Name | Key Structural Characteristic | The Mechanism of Fog Water Collection | Experiment Condition | FWCSs Efficiency | References | ||

|---|---|---|---|---|---|---|---|

| Wind Speed | Relative Humidity | Size of Fog Droplets | |||||

| Namib Desert Beetle | Hydrophilic protrusions on the back + Hydrophobic grooves | Surface energy gradient | [100] | ||||

| [101] | |||||||

| <0.5 m/s | 92% | [102] | |||||

| 3.5 m/s | 90% | 5–10 μm | 1432.7 mg·h−1·cm−2 | [104] | |||

| 2.8 m/s | 85% | [105] | |||||

| Cactus Spines | Conical tip + Gradient roughness groove + Bottom strip-like protuberances | Surface energy gradient + Laplace pressure gradient | [116] | ||||

| [117] | |||||||

| 3 m/s | 85% | 0.35 μL/min | [118] | ||||

| <0.5 m/s | [119] | ||||||

| 3 m/s | 90% | 6 μm | 2 mg·min−1·mm−3 | [120] | |||

| 2 m/s | 85% | 8–10 μm | [121] | ||||

| 2.5 m/s | 88% | 5–8 μm | [122] | ||||

| Spider Silk | Periodic spindle-knot + Joint structure | Surface energy gradient + Laplace pressure gradient | 10.44 μL·h−1 | [137] | |||

| 2.5 m/s | 88% | 5–8 μm | [139] | ||||

| 0.3 m/s | 95% | 3–8 μm | MAX 6.6 μL | [142] | |||

| 1.5 m/s | 86% | [144] | |||||

| 2 m/s | 85% | 6–9 μm | [145] | ||||

| 2.2 m/s | 87% | [146] | |||||

| 2 m/s | 88% | [147] | |||||

| Nepenthes mirabilis | Surface conical micro-grooves | Surface energy gradient + Laplace pressure gradient | 3 m/s | 82% | 4–9 μm | 118 ± 6 mg·cm−2·h−1 | [152] |

| 2.5 m/s | 90% | 500 mg·cm−2·h−1 | [153] | ||||

| 1.8 m/s | 85% | 61.2 mg·cm−2·h−1 | [154] | ||||

| <0.5 m/s | [155] | ||||||

| 3 m/s | 87% | 5–10 μm | 980 mg·cm−2·h−1 | [156] | |||

| 2 m/s | 86% | [157] | |||||

| 2.5 m/s | 90% | 6–8 μm | 852 mg·cm−2·h−1 | [158] | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, S.; Li, G.; Jin, S.; Hu, H.; Ye, G. Recent Advances and Retrospective Review in Bioinspired Structures for Fog Water Collection. Biomimetics 2025, 10, 791. https://doi.org/10.3390/biomimetics10120791

Dong S, Li G, Jin S, Hu H, Ye G. Recent Advances and Retrospective Review in Bioinspired Structures for Fog Water Collection. Biomimetics. 2025; 10(12):791. https://doi.org/10.3390/biomimetics10120791

Chicago/Turabian StyleDong, Shizhang, Guangze Li, Shaobo Jin, Hong Hu, and Guoyong Ye. 2025. "Recent Advances and Retrospective Review in Bioinspired Structures for Fog Water Collection" Biomimetics 10, no. 12: 791. https://doi.org/10.3390/biomimetics10120791

APA StyleDong, S., Li, G., Jin, S., Hu, H., & Ye, G. (2025). Recent Advances and Retrospective Review in Bioinspired Structures for Fog Water Collection. Biomimetics, 10(12), 791. https://doi.org/10.3390/biomimetics10120791