1. Introduction

Railways play a crucial role in transportation, thanks to their strong load-bearing capacity. However, due to the high speed and heavy weight of trains, accidents can result in a large number of casualties and severe injuries, both in terms of the number of people affected and the severity of injuries. In addition, the sudden nature of such accidents makes it extremely difficult to prevent them completely [

1,

2]. Thin-walled tubes are widely used in energy-absorbing structural designs due to their simple manufacturing process, low cost, excellent load-bearing performance, and high energy absorption efficiency [

3,

4]. Extensive research indicates that under axial impact loading, thin-walled structures primarily convert kinetic energy generated during collision into internal energy through plastic deformation, alongside elastic deformation, friction energy, light energy, and sound energy, thereby achieving energy dissipation [

5]. Different deformation patterns can significantly impact energy absorption performance [

6,

7].

Numerous studies have demonstrated that biomimetic energy-absorbing structures exhibit superior energy absorption and collision resistance compared to traditional structures [

8,

9]. When designing biomimetic energy-absorbing structures, designers often draw inspiration from plants thriving in harsh environments or the tentacles of animals frequently engaged in combat and collisions, using these as biomimetic prototypes for research. New biomimetic energy-absorbing mechanisms are then designed based on analyses of similar structures, loads, and functions. Macro-scale structures such as the dactyl clubs of mantis shrimp [

10], honeycomb [

11], turtle shells [

12], bamboo joints [

13], deep-sea glass sponges [

14,

15], lotus leaf stalks [

16], and rice straw folds [

17] are widely used in structural design because they are easily observable in nature.

In recent years, the integration of 3D printing technology with origami and biomimetic principles has driven breakthroughs in the mechanical properties and functional integration of lightweight structures [

18]. Related research has focused on configuration innovation, performance regulation, and engineering applications, yielding a series of achievements. Wang et al. [

19] incorporated origami design into the multi-cell thin-walled structure of high-speed trains. By optimizing the twist angle, collapse zone height, and wall thickness, they reduced the initial peak impact force by 29.36% without compromising energy absorption, thereby validating the effectiveness of origami configurations in enhancing train collision safety. Dalaq et al. [

20] studied 3D-printed Kresling origami springs, demonstrating that their mechanical behavior can be regulated through pre-deformation height, pre-deformation angle, and aspect ratio, exhibiting diverse characteristics such as linear, quasi-zero stiffness, nonlinear single-stable, and bistable states. Xia et al. [

21] designed a 3D-printed double-layer helical honeycomb (DLHH). By introducing a double-layer helical configuration within the unit cell, the DLHHs reveal a 45% enhancement in the strength and a 200% enhancement in the

SEA. Dalaq et al. [

22] developed a 3D-printed honeycomb pad material based on the Kresling pattern, which demonstrated 70% energy absorption efficiency and 94% energy dissipation efficiency, and exhibited full shape recovery capability, offering a new solution for reusable impact protection materials. Ma et al. [

23] proposed hierarchical re-entry origami honeycomb (HROH), combining biomimetic hierarchical design with Miura origami patterns. Under low-, medium-, and high-speed impacts, the

SEA of HROH increased by 36.37%, 13.36%, and 28.56%, respectively, compared to traditional structures. Shi et al. [

24] designed a trapezoidal origami corrugated tube core acoustic metasurface, combining micro-perforated panels with an origami core. This structure exhibits excellent low-frequency sound absorption performance in the 480–620 Hz and 1120–1340 Hz frequency bands, while also outperforming traditional honeycomb and Miura core structures in energy absorption under low-speed impacts, achieving synergistic optimization of acoustic and mechanical performance.

Among these, biomimetic tree structures have been extensively studied by some scholars and have been proven to have better energy absorption effects. Inspired by the fractal structures of natural tree ladders, Chen et al. [

25] designed a hexagonal hierarchical gradient structure (HHGS). Research indicates that impact resistance comparisons demonstrate that under inclined loading, the gradient structure significantly reduces initial peak forces compared to other structures while maintaining favorable deformation patterns and energy absorption advantages. Wang et al. [

26] were inspired by the branching characteristics of lotus leaf veins to design a circular vein branching nested tube (CVBNT). The introduction of the vein branch thin-walled plates affects the deformation mechanism and leads to more plastic hinges, which will greatly improve the

SEA. Ha et al. [

27] mimicked the hierarchical structure of tree branches and lotus leaf veins to propose a biomimetic hierarchical multi-cell double tube (BHMB). The results demonstrate that the

SEA increases with the hierarchical order and inner diameters. Ha et al. [

28] investigated the impact resistance of a bio-inspired fractal multi-cell circular (BFMC). Its energy absorption rate (SER) was improved by 35.43% compared to conventional multi-unit tubular structures. The complex proportional assessment (COPRAS) method was adopted to optimize the performance of the BFMC. Wu et al. [

29] proposed a tree-like fractal method for developing energy absorption structures. They explored triangular, quadrilateral, and pentagonal structures and found that the third-order tree-like fractal structure exhibited the best load-bearing capacity.

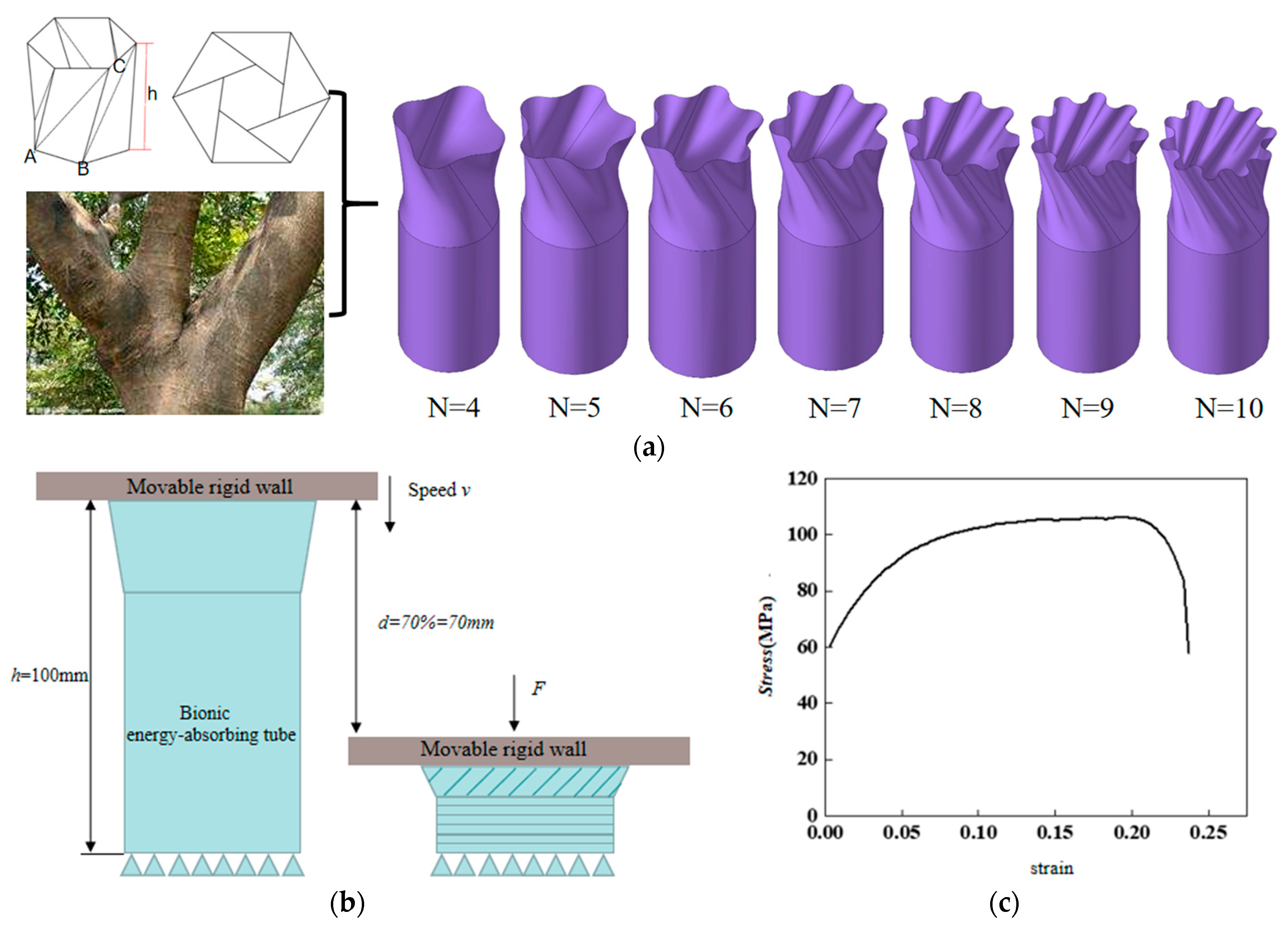

In summary, inspired by origami and tree branches, this study analyzes OTSs for collision energy absorption. Based on finite element models, multi-objective performance analysis and evaluation were conducted on OTSs with varying numbers of wave peaks. The OTS with optimal performance was selected as the target for subsequent optimization. The multi-objective optimization of the OTS was performed using the MOEA/D-DAE algorithm to obtain a set of Pareto optimal solutions. The optimal structure was then determined through the TOPSIS decision-making process. Subsequently, comparative analysis and discussion were performed to validate the effectiveness and practicality of this optimization approach.

Compared with previous studies, this paper summarizes two unique contributions: (1) A biomimetic thin-walled energy-absorbing structure integrating origami and tree-shaped structures was developed, and a subsequent analysis of its mechanical properties was conducted. OTSs offer significant advantages in reducing IPCF without substantially compromising other performance metrics. (2) A multi-criteria decision-making method integrating MOEA/D-DAE and TOPSIS has been developed. This integrated approach is employed to identify the optimal structure. This optimization framework enriches the methods in the field of optimization, providing an alternative optimization decision-making system.

The structure of this paper is as follows:

Section 2 introduces the construction and validation of the OTS finite element (FE) model.

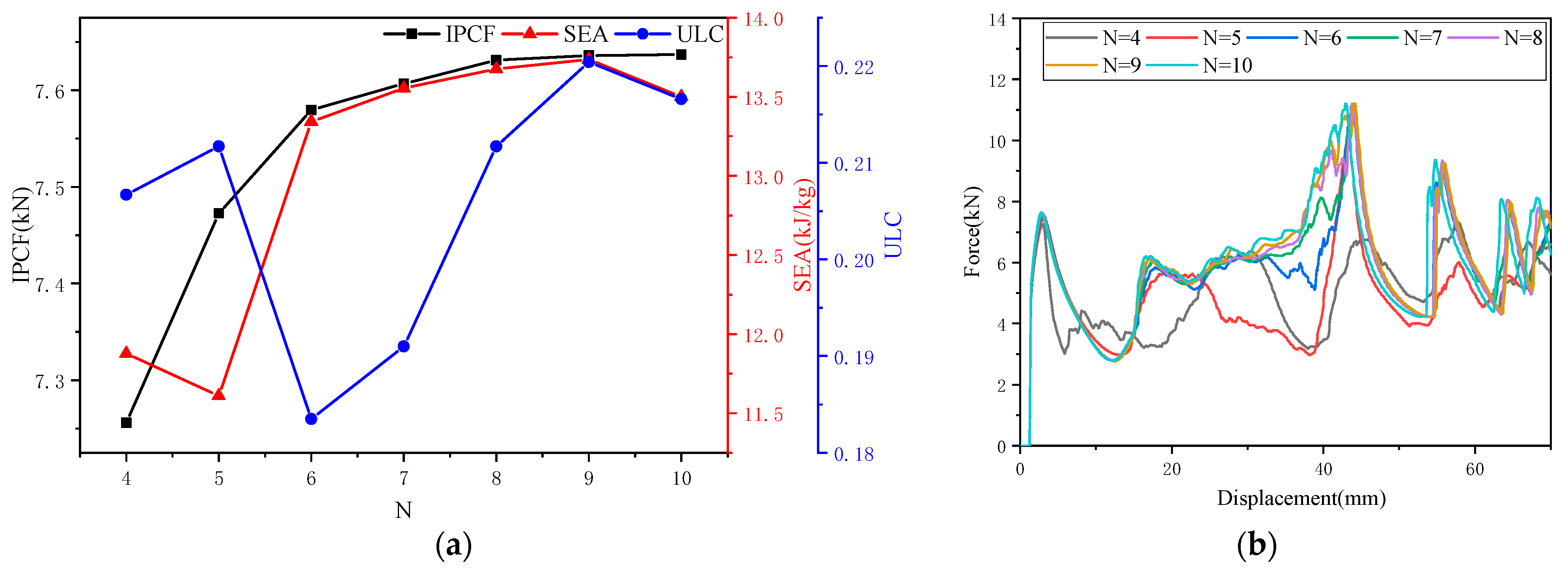

Section 3 analyzes the influence of different OTS parameters on energy absorption performance.

Section 4 employs a multi-criteria decision-making approach to identify the optimal structure. Finally, the conclusions of this paper are drawn in

Section 5.

5. Conclusions

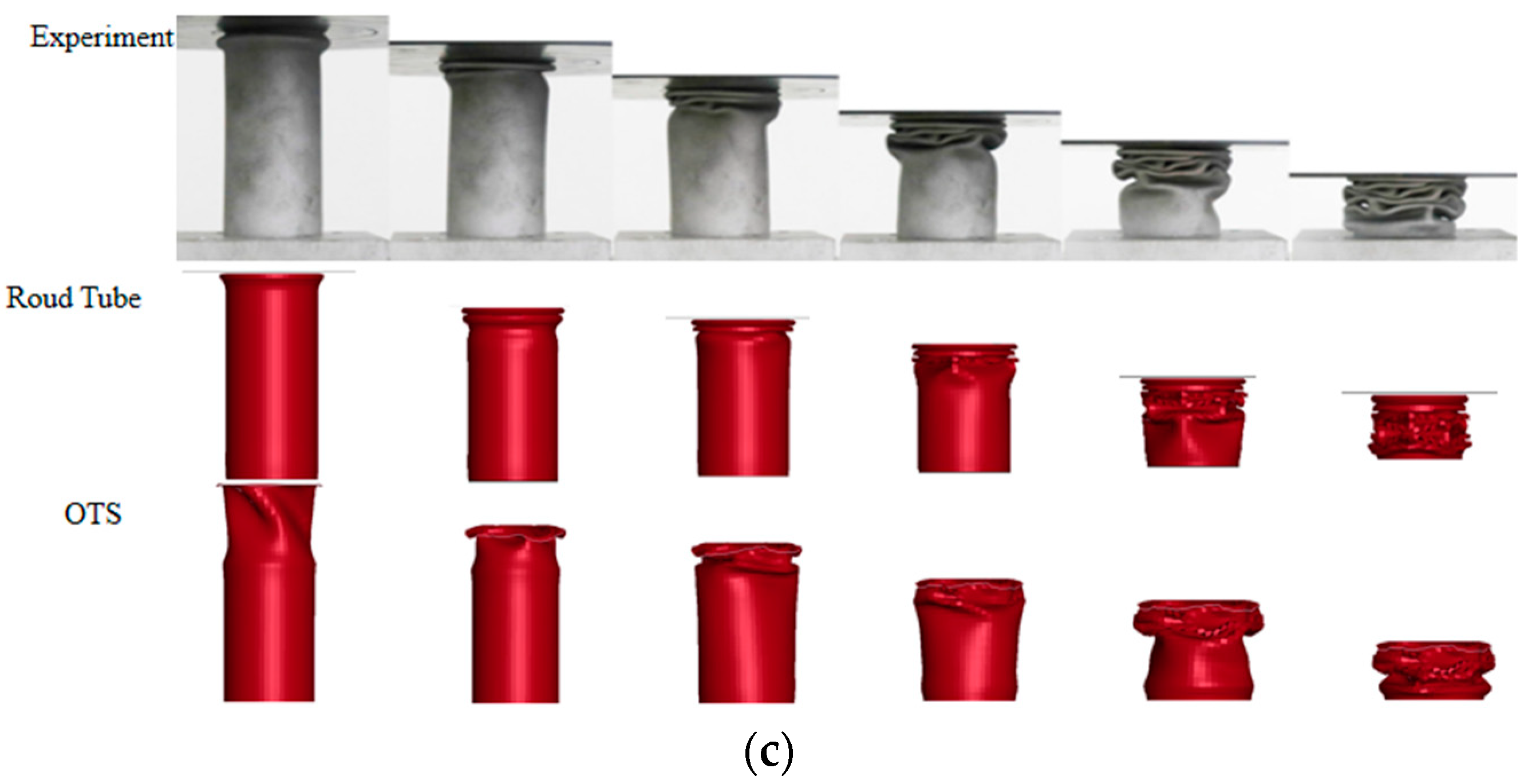

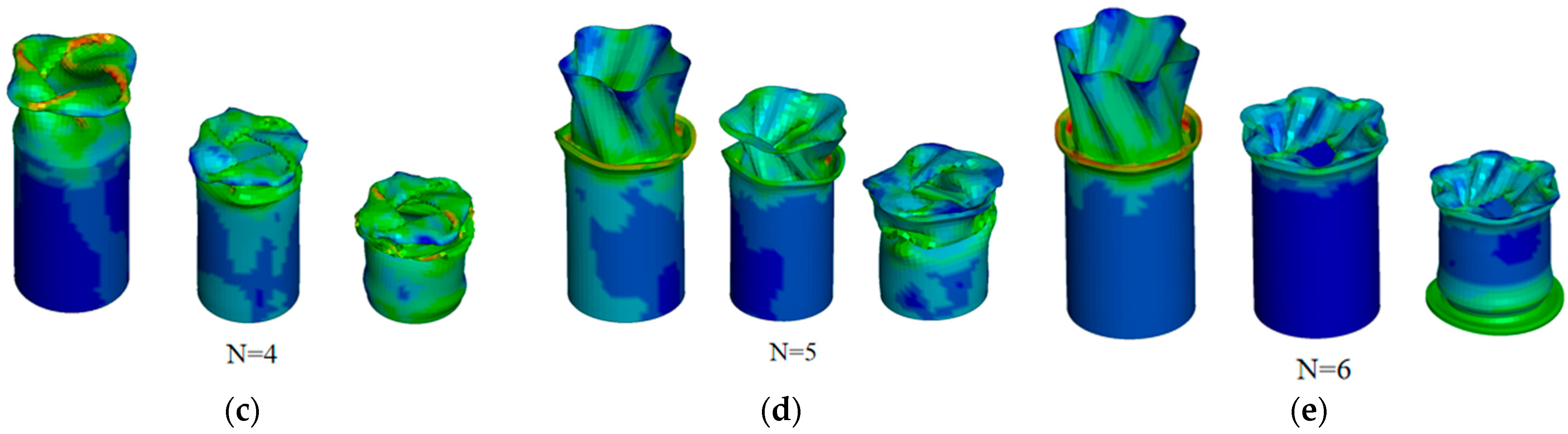

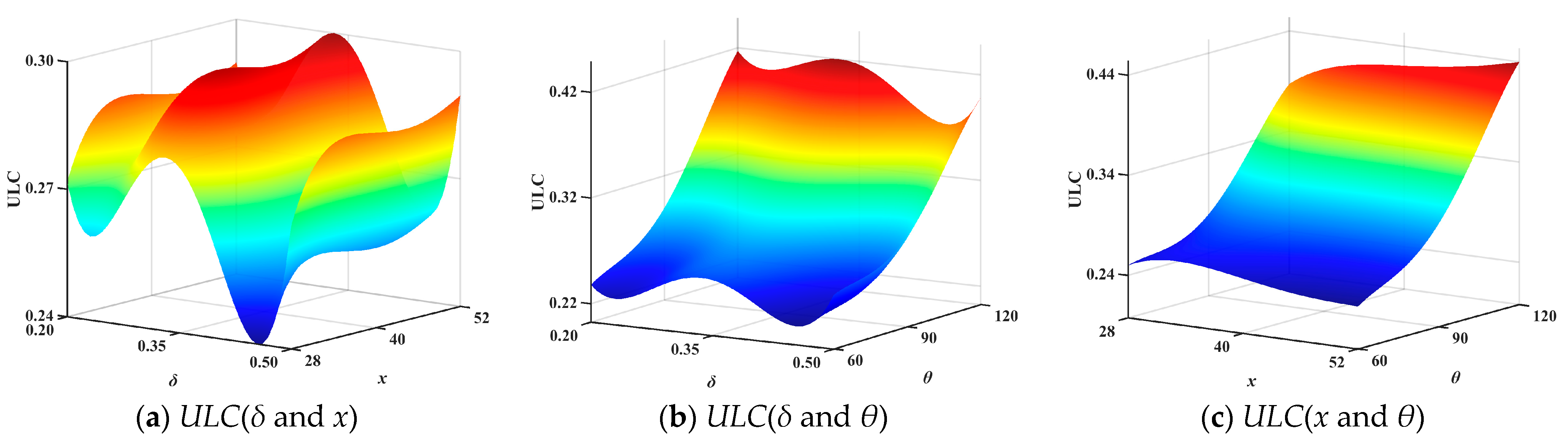

This study proposes the design and analysis of an OTS. First, the geometric concepts and parameters of OTS are outlined. Subsequently, by comparing finite element analysis (FEA) with experimental results, it is found that the force–displacement curves obtained from experiments and FEA are basically consistent, further validating the effectiveness of the finite element model. The entropy-weighted TOPSIS comprehensive evaluation method is employed for multi-attribute decision analysis, identifying OTS (

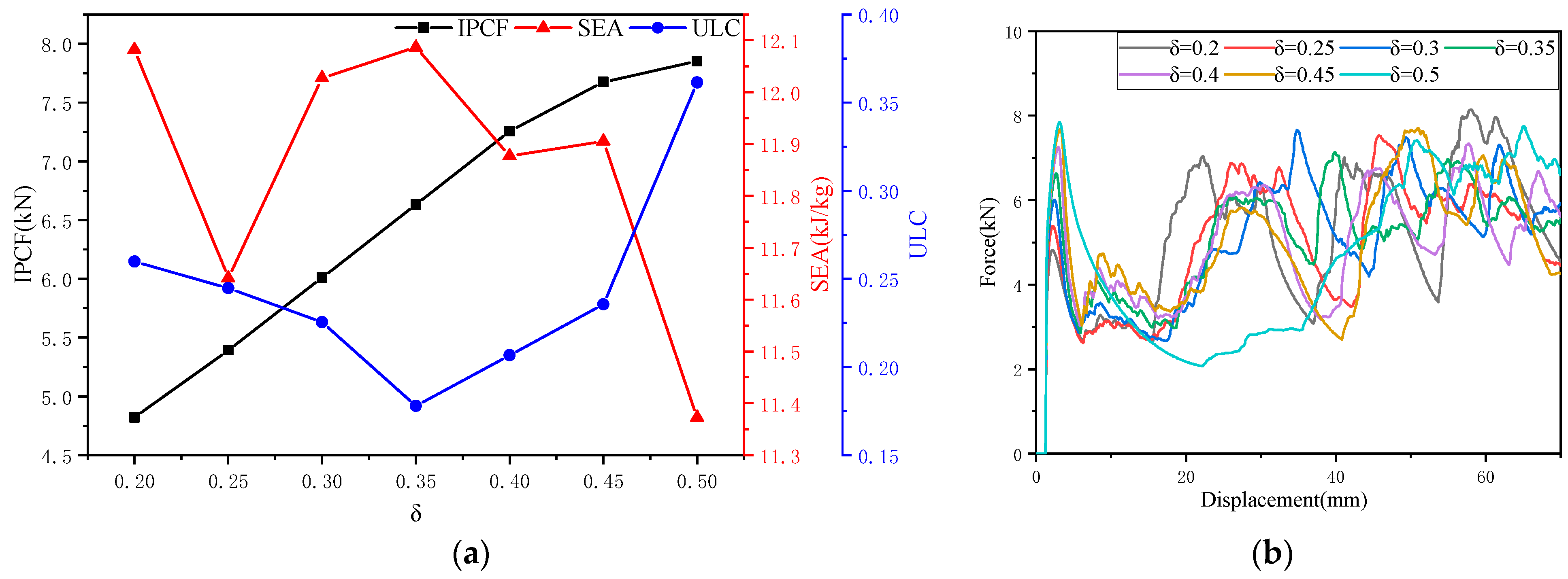

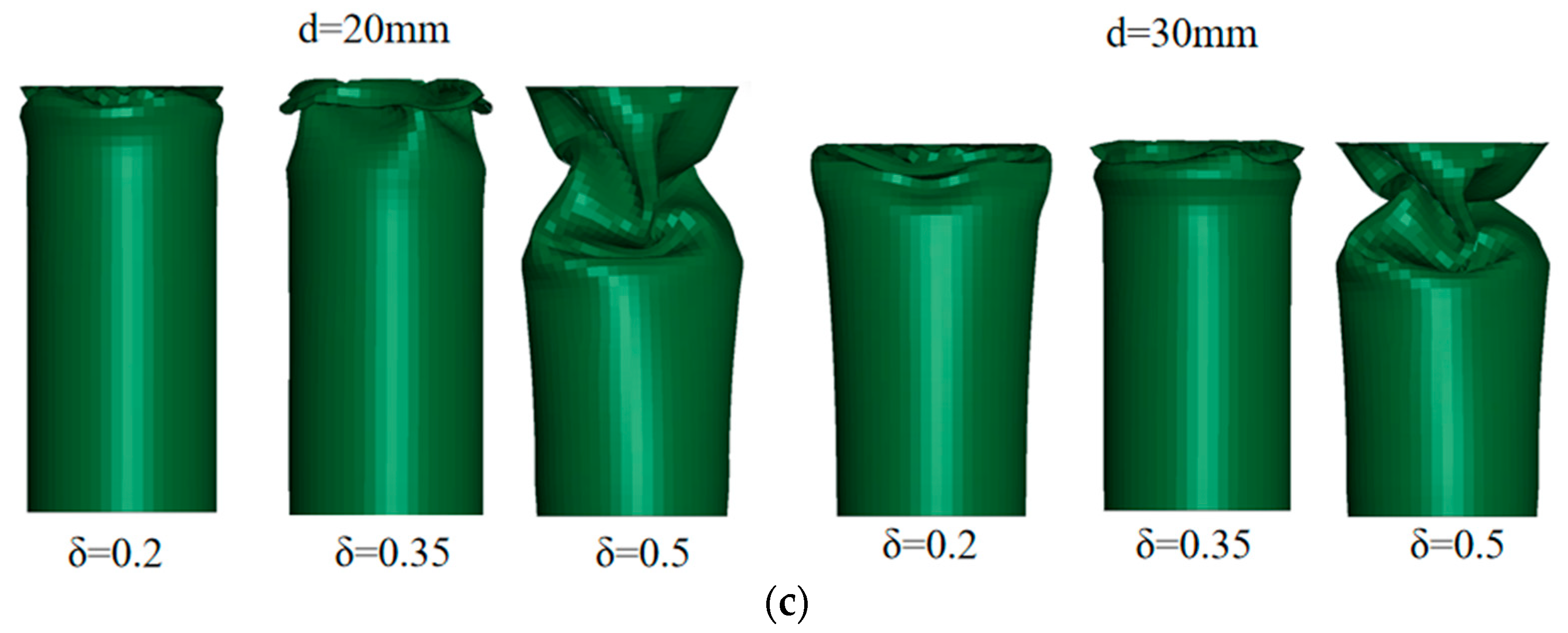

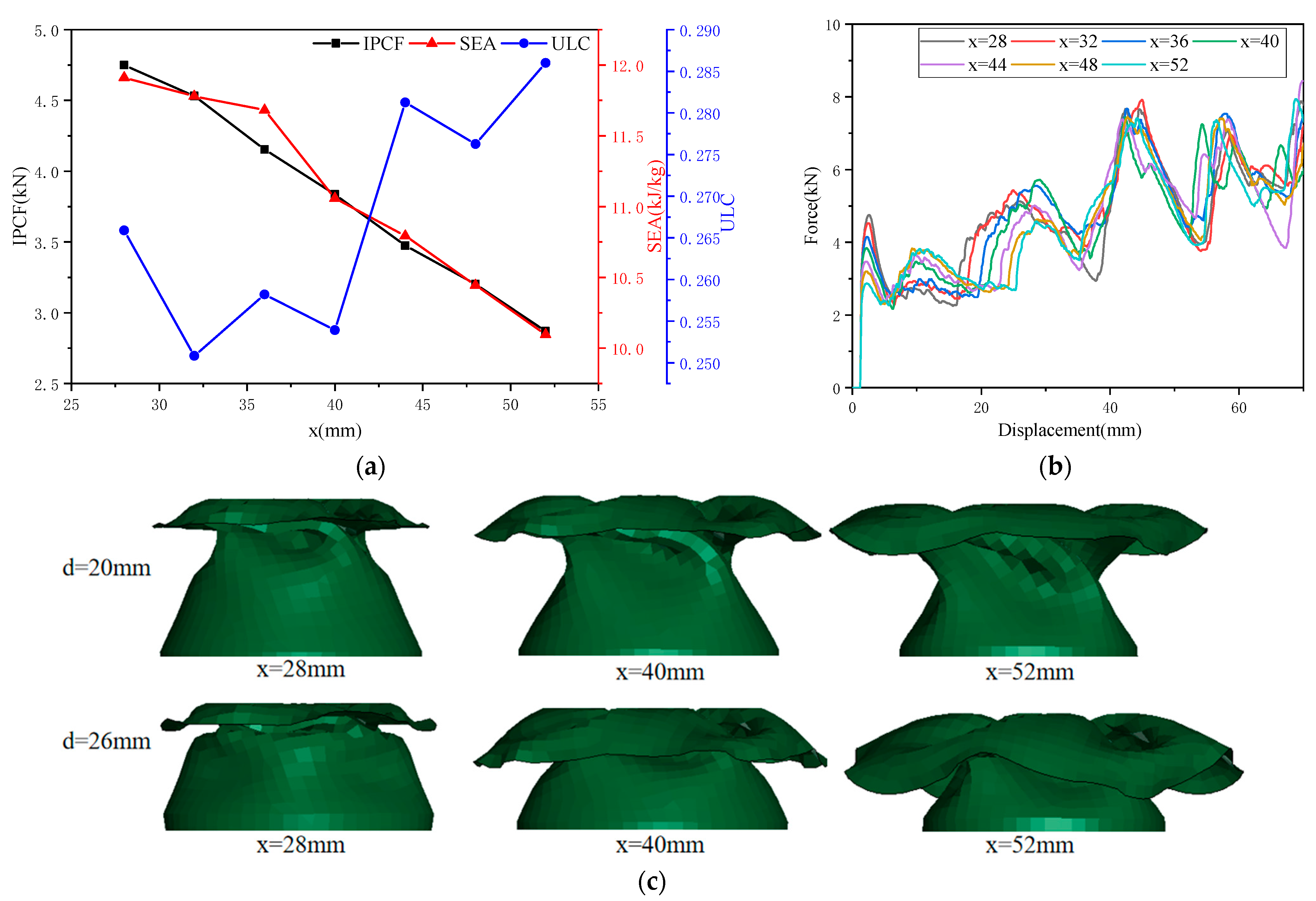

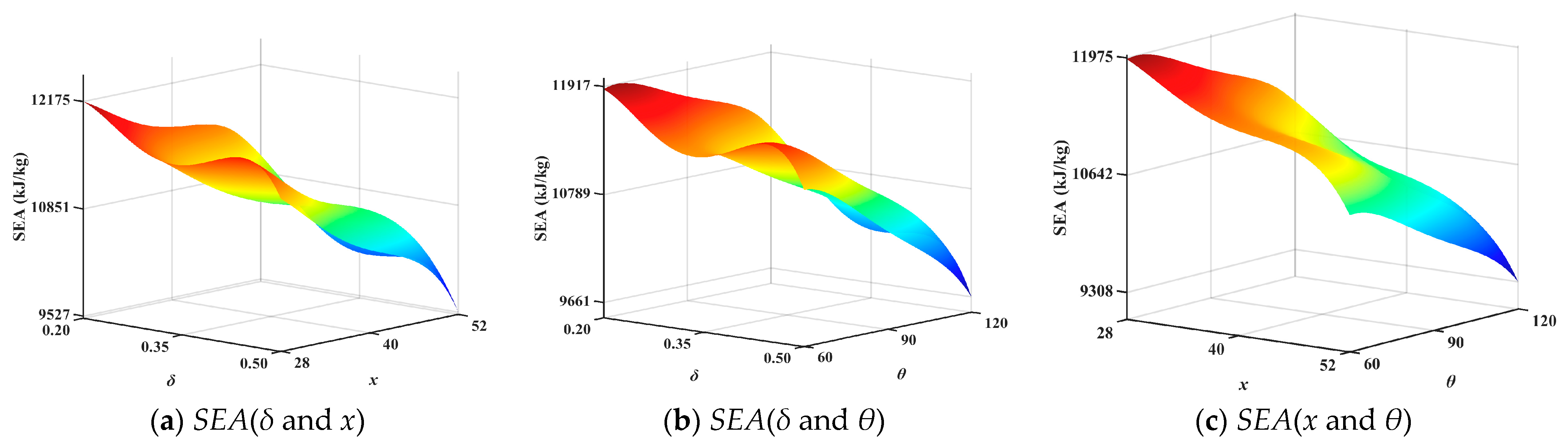

N = 4) as the optimal design scheme. The effects of different

N,

θ,

δ, and

x on the OTS’s

IPCF,

SEA, and

ULC are investigated, as detailed in

Table 7.

Subsequently, five optimization algorithms—MOEA/D-DAE, AGE-MOEA, ANSGAIII, NSGAII, and DCNSGAIII—were compared. Compared to other algorithms, the MOEA/D-DAE algorithm demonstrated the highest hypervolume (

HV) value and the smallest generational distance (

GD) value, indicating its superior suitability for this engineering problem. The effectiveness of the agent model was validated by comparing finite element analysis (FEA) results with the predicted results. Finally, the TOPSIS comprehensive evaluation method was used to adjust the objective weights to obtain the optimal solution. Compared to the OTS before optimization, the results showed that the

IPCF was reduced by 31.2%, the

SEA increased by 3.6%, and the

ULC increased by 10.4%. OTSs can significantly reduce

IPCF without substantially compromising other metrics. It can thus be seen that OTSs offer new insights for the future design of thin-walled energy-absorbing structures. OTSs can be applied to the primary energy-absorbing structures of rail vehicles (as shown in

Figure 11f), as well as to other applications such as crash cushions required for highway maintenance tasks.

In future studies, we will focus on two directions: (1) investigating whether bottom cross-sections of different shapes can enhance OTS performance, and (2) by combining multiple OTSs, we investigate the effects of OTS quantity, surface geometry, head coverage ratio, and OTS group distribution on overall performance to achieve self-cancelation effects through interleaved superposition of ULC at different displacements.