Enhancing Safety Performance in UK Metal Manufacturing: A Revised Framework to Reduce Fatal Accidents

Abstract

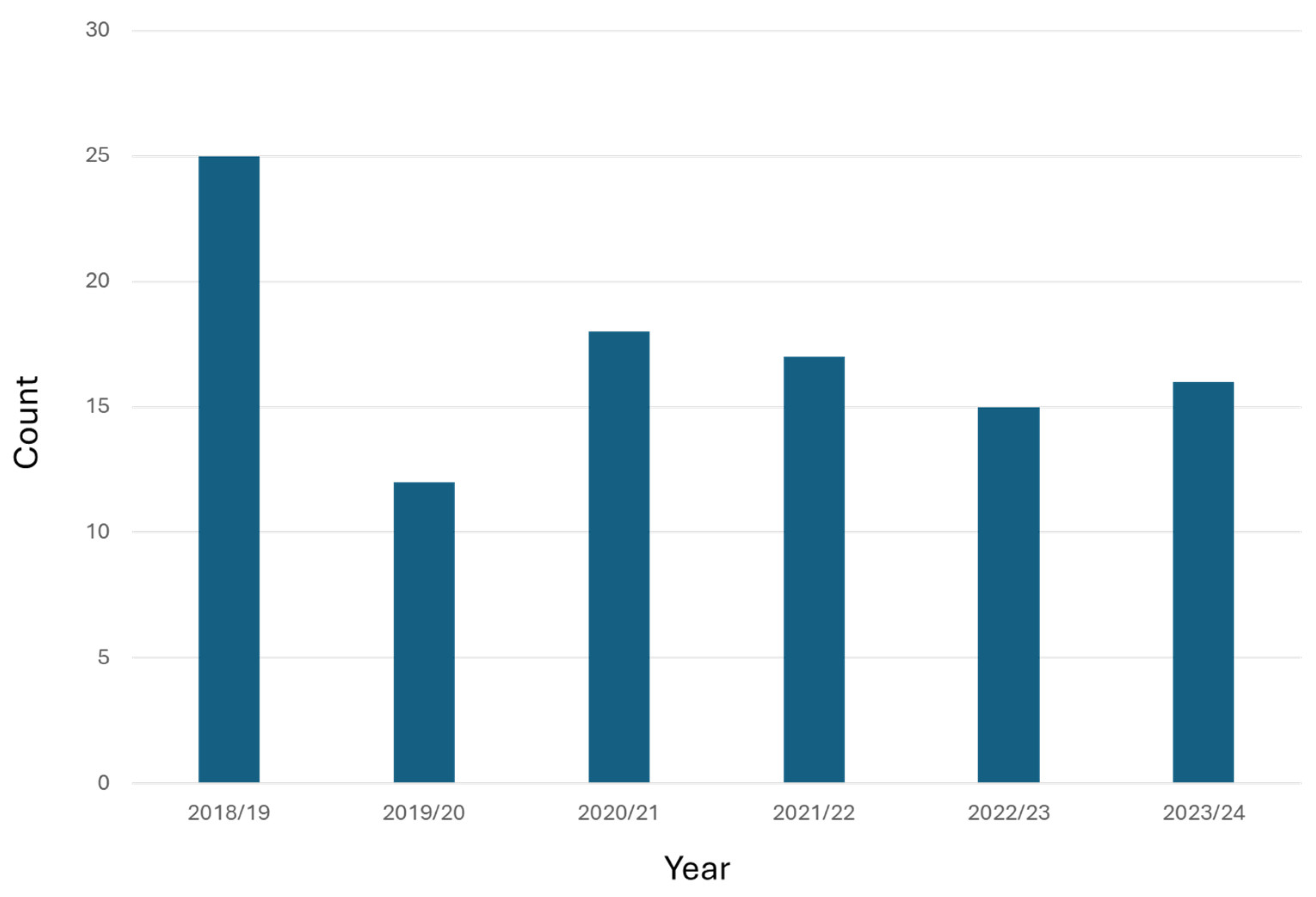

1. Introduction

“Employees who have had an occupational accident endured more physical stress in addition to mental workload (MWL) compared to employees who did not have an accident” [12].

- To establish an in-depth literature review of Safety Frameworks in the Manufacturing sector, as well as other industries, to determine the most significant safety attributes.

- To develop a Safety Framework for the metal manufacturing sector to help prevent further accidents from occurring.

- To validate the developed framework via industry suitably qualified and experienced personnel (SQEP).

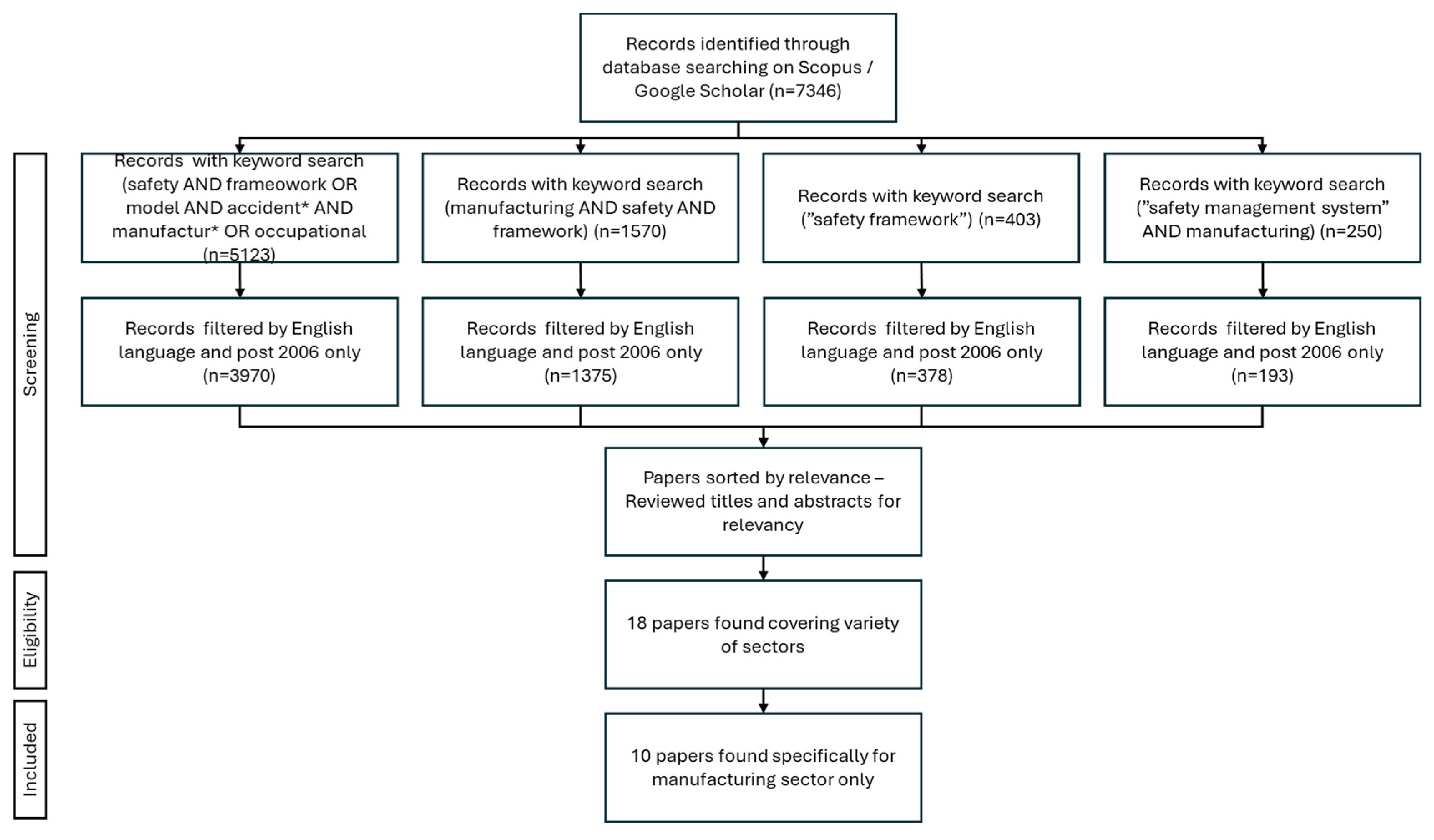

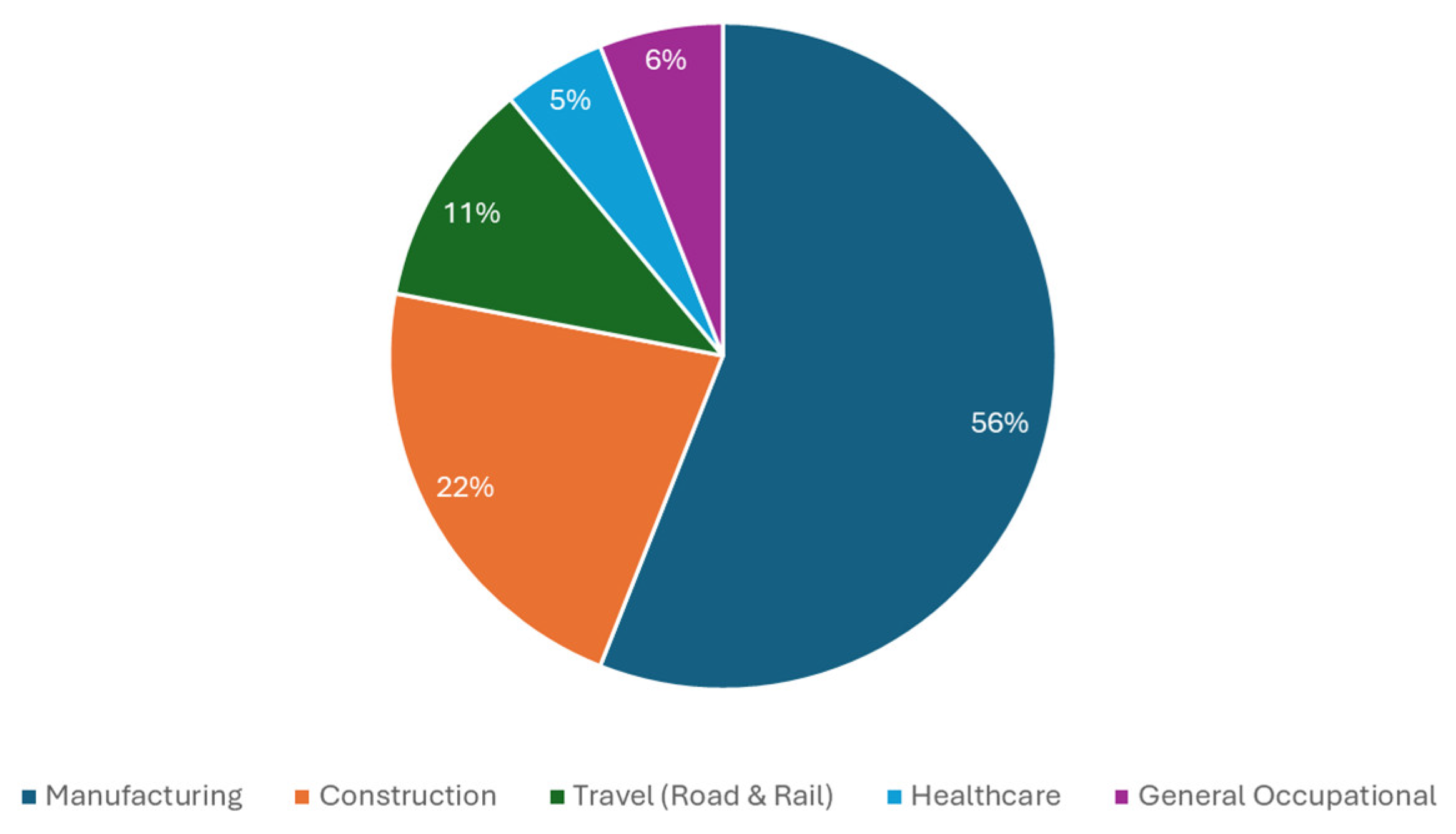

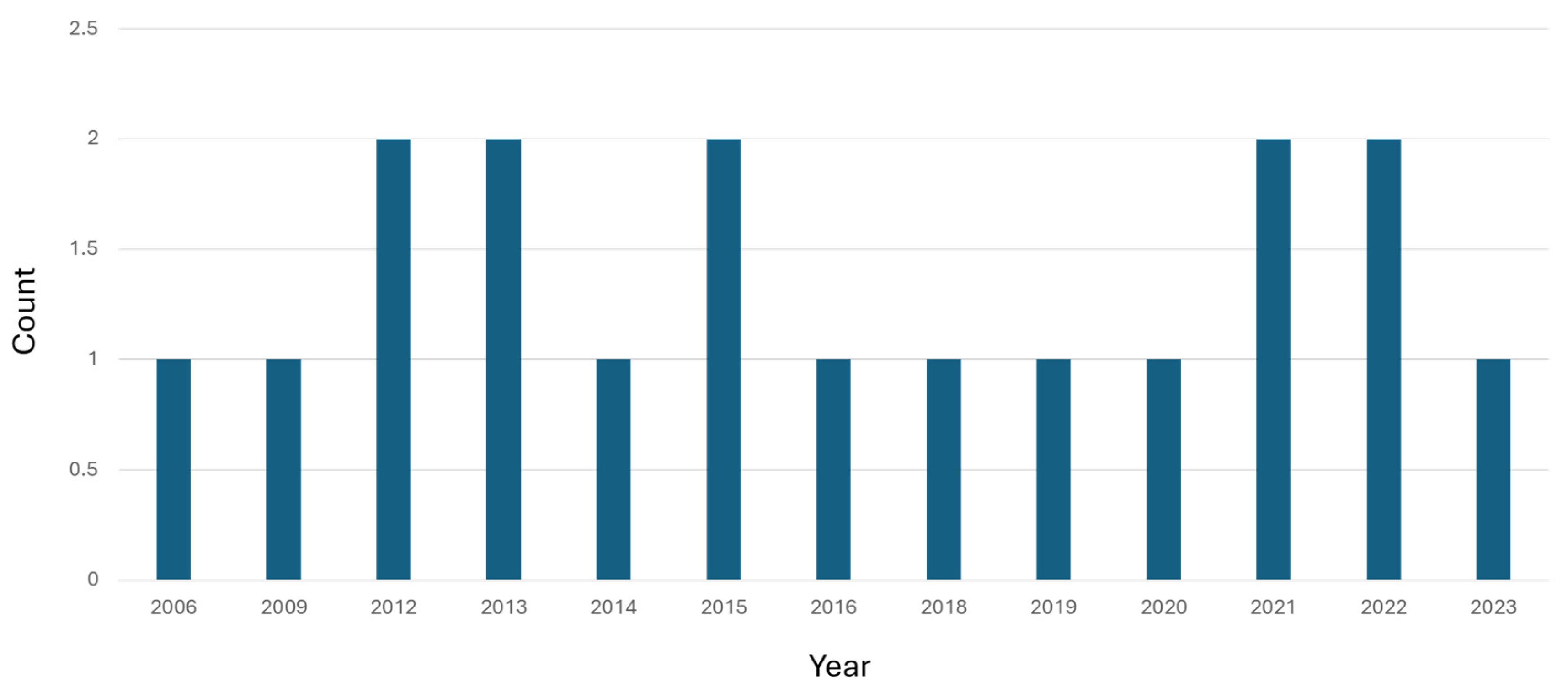

2. Literature Review

2.1. Safety Frameworks

2.2. Literature Divergence

2.3. Literature Convergence

2.4. Analysis of Selected Literature

2.5. Legislation Change

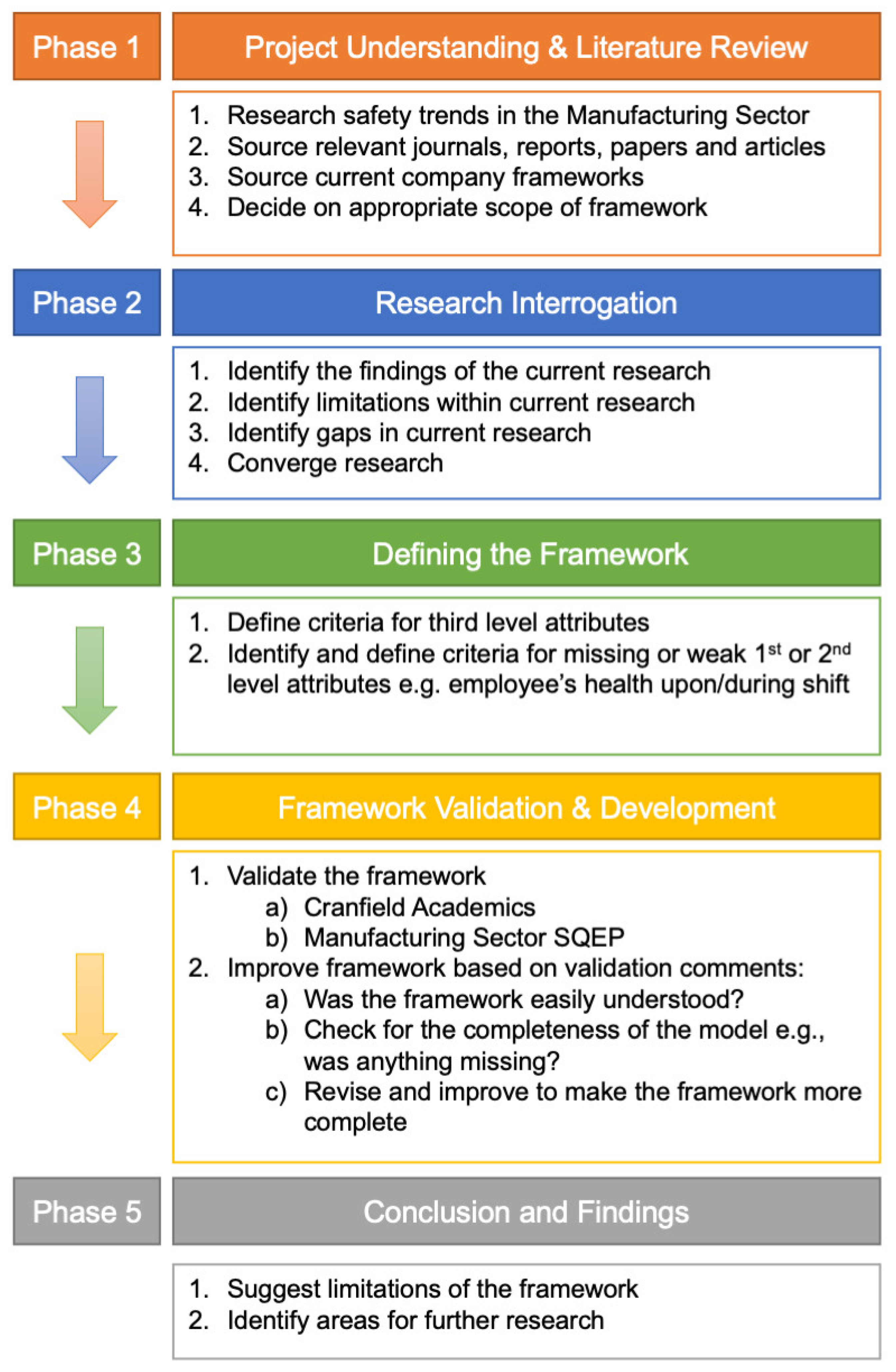

3. Research Methodology

4. Framework Development

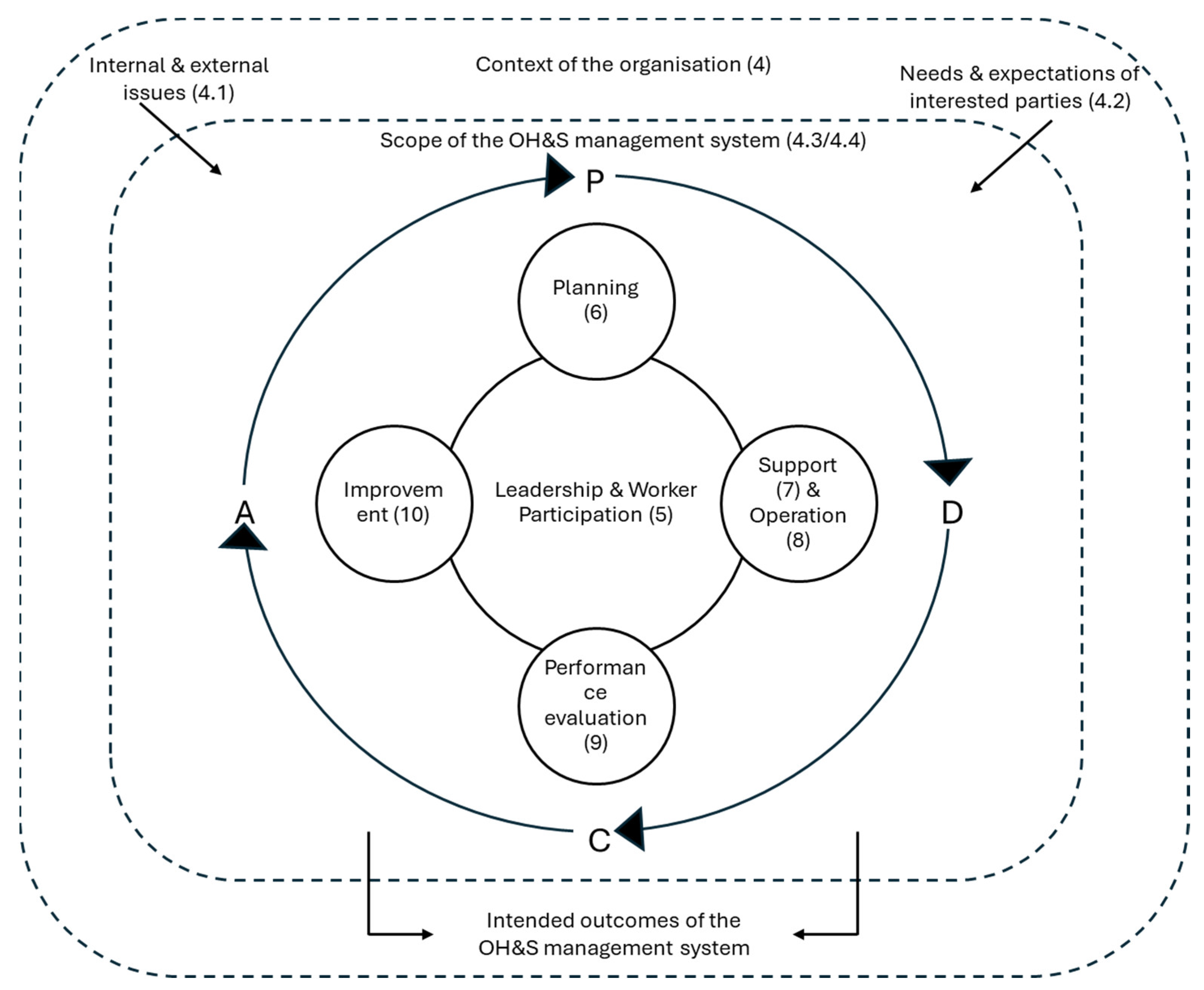

4.1. Foundation

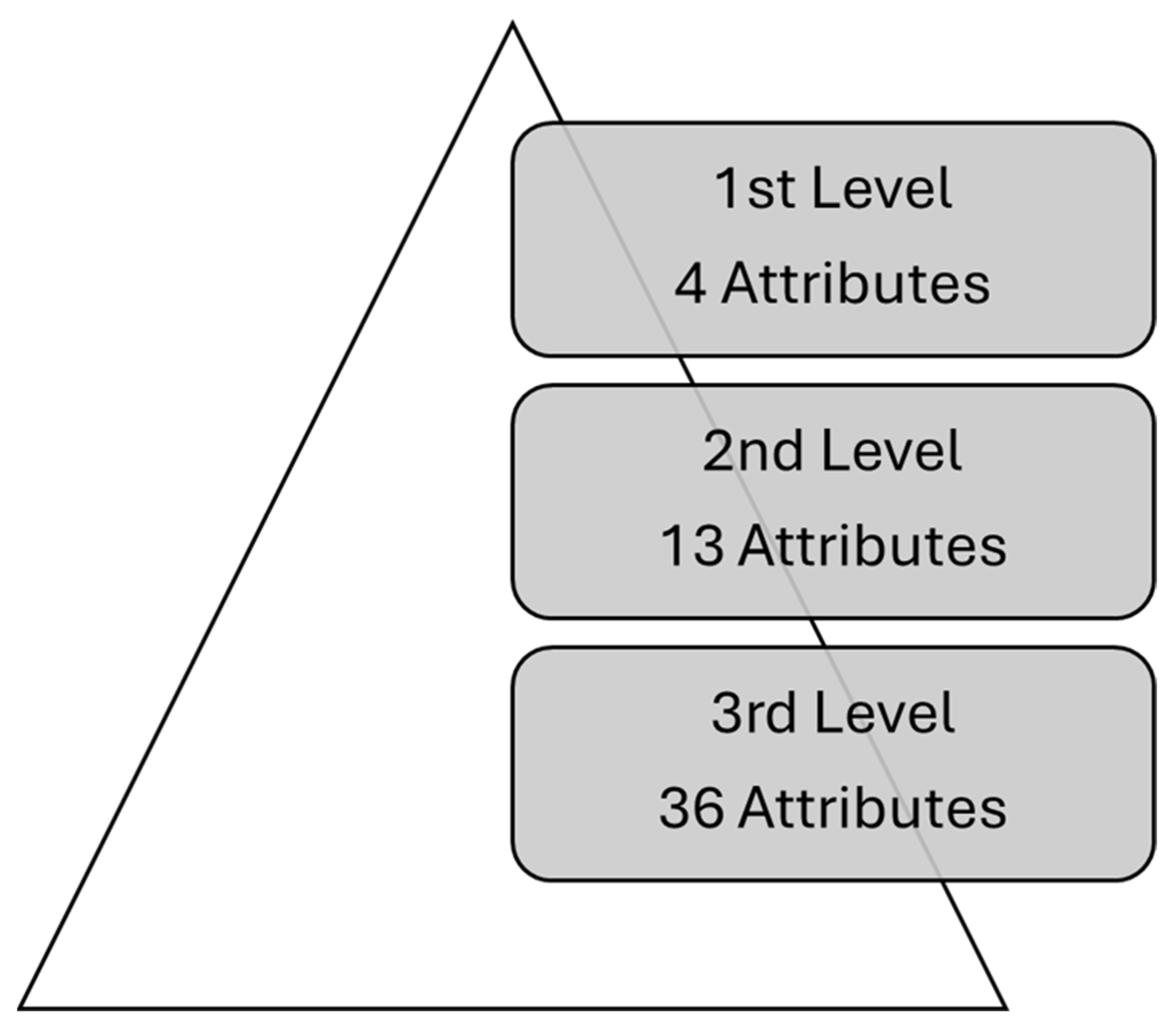

4.2. The First Level

4.3. The Second Level

4.3.1. Coding Original Sources

4.3.2. Removing Attributes

4.3.3. Updating Attributes

4.3.4. Missing Attributes

4.4. The Third Level

4.5. The Resulting Safety Framework

5. Framework Validation

5.1. Validation Type

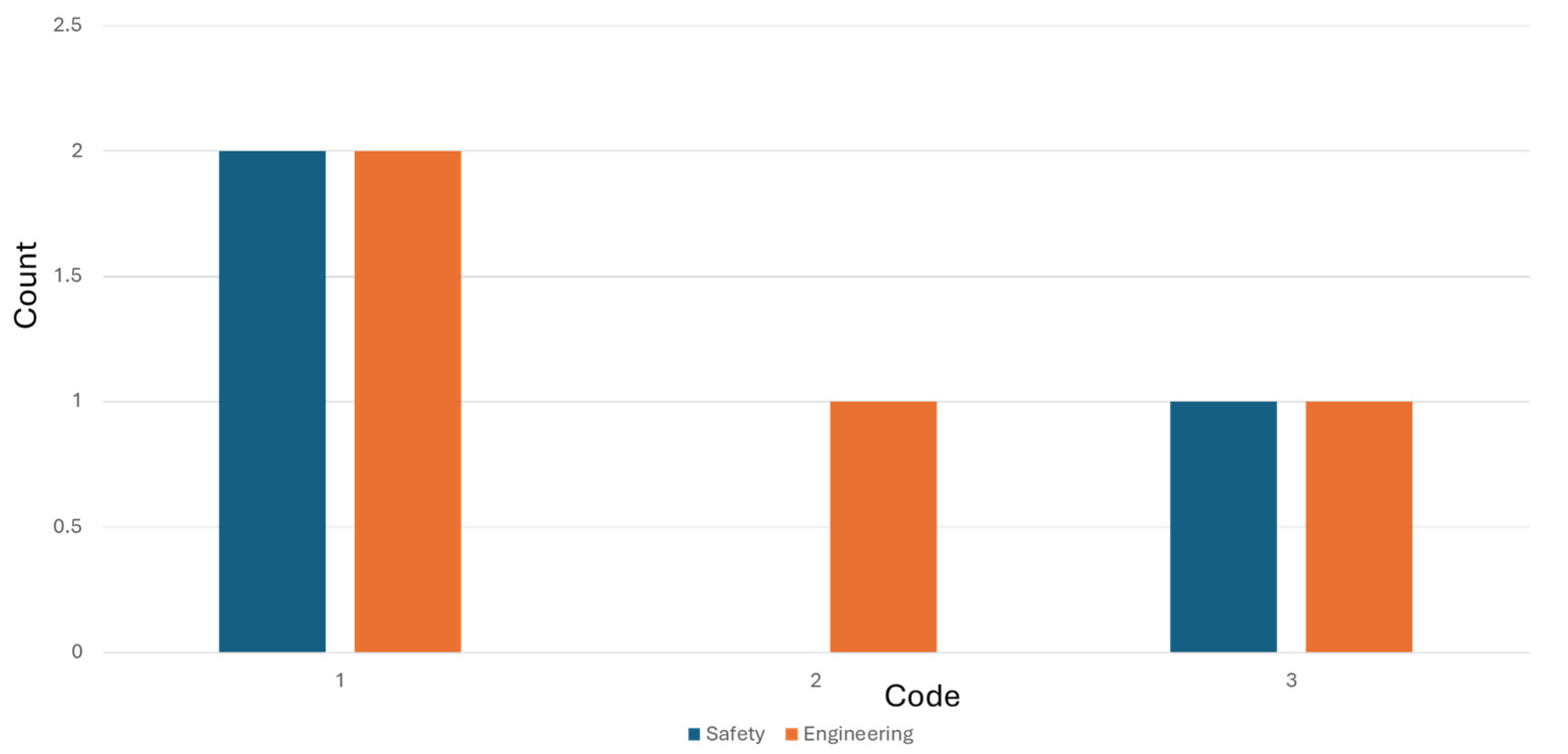

5.2. Validation Demographies

5.3. Validation Results

5.3.1. Similarities

5.3.2. Differences

5.4. Improvements

6. Conclusions, Limitations and Future Scope

- The Safety Framework is up-to-date and aligns to both ILO and BSI standards. First, second and third level attributes were adapted to be relevant for the metal manufacturing industry. The most significant safety attributes can be determined as the attributes that have remained in the framework post legislation update.

- The final Safety Framework has been deemed relevant for the Metal Manufacturing Sector by Industry SQEP personnel. The majority of Interviewees deemed the Safety Framework to have a clear layout and easy to understand.

- The main findings of the Validation suggested the importance of having an emphasis on employee welfare and health, in an effort to reduce accidents in the workplace. This was taken into consideration and an extra attribute (relating the employee welfare) added to the third level of the Safety Framework.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Keyword | Alternatives/Synonyms |

|---|---|

| Accident * | Accidents |

| Case study | |

| Categor * | Category, Categories |

| Classif * | Classification, Classify |

| Conceptual | |

| Construction | |

| Culture | |

| Defence | |

| Defence-in-depth | |

| Defense | |

| Factor * | Factors |

| Framework * | Frameworks, Model |

| Functional | |

| Industr * | Industry, Industries, Industrial |

| Manage * | Management |

| Manufactur * | Manufacture, Manufacturing, Manufactured |

| Nuclear | |

| Occupation * | Occupational, Occupations |

| Organi * | Organisation, Organization |

| ORSAC | Overall Safety Concept |

| Risk | |

| Safe * | Safety |

| Work * | Workplace |

| Original 2nd Level Attributes | Original Source(s) Not Relevant, Updated, Remains Relevant | New 2nd Level Attributes | New Source |

|---|---|---|---|

| High-level commitment | [42]; [43]; [44]; [45]; [46]; [47], [48]; | 6.1 Actions to address risks and opportunities [49] 6.1 OH&S objectives and planning to achieve them [49] 6.1 Hazard identification and assessment of risks and opportunities [49] 6.1 Determination of legal requirements and other requirements [49] 6.1 Planning action [49] 3.5 Occupational safety and health management system in the organisation [50] | [49]; [50]; |

| Organization and responsibility | [45]; [46]; [51]; [52]; [53]; [31]; [48]; | 6.2 OH&S objectives [49] 6.2 Planning how to achieve OH&S objectives [49] 3.3 Responsibility and accountability [50] | [49]; [50]; |

| Laws and regulations | [46]; [53]; [31]; | EN 292: Part 1: 1991—Safety of machinery. Basic concepts, general principles for design [54] EN 292: Part 2: 1991—Safety of machinery. Technical principles and specifications [55] BS EN 1050: 1997—Safety of machinery. Risk assessment [56] | - |

| Risk assessment | [42]; [43]; [46]; [51]; [53]; [31]; [48]; | BS EN 292: Part 1: 1991—Safety of machinery. Basic concepts, general principles for design [54] BS EN 292: Part 2: 1991—Safety of machinery. Technical principles and specifications [55] BS EN 1050: 1997—Safety of machinery. Risk assessment [56] | - |

| Education and training | [43]; [57]; [46]; [48]; [53]; [31]; | 7.1 Resources [49] 3.4 Competence and training [50] | [49]; [50]; |

| Contractor management | [42], [46]; [48]; [43]; [45]; [53]; [31]; | 8.1 Operational planning and control [49] 8.1 Eliminating hazards and reducing OH&S risks [49] 5.1 Management of change [49] 5.1 Procurement (General, Contractors, & Outsourcing) [49] 3.10.5 Contracting [50] | [49]; [50]; |

| Emergency response | [42]; [46]; [48]; [43]; [51]; [58]; | 8.2 Emergency preparedness and response [49] 3.40 Hazard prevention [50] | [49]; [50]; |

| Self-inspection | [52] [53]; | 7.3 Awareness [49] | [49]; |

| Work permit | [42]; [46]; [52]; | 7.2 Competence [49] 3.4 Competence and training [50] | [49]; [50]; |

| Safety equipment management | [42]; [53]; [31]; | 7.5 Documented information [49] 3.5 Occupational safety and health management system documentation [50] | [49]; [50]; |

| Hazardous materials management | [52]; | ||

| Safety protection | [52]; [31]; | ||

| Communication | [42]; [46]; [48]; [43]; [47]; [58]; | 7.4 Internal/External communication [49] 3.6 Communication [50] | [49]; [50]; |

| 1st Level | 2nd Level | 3rd Level |

|---|---|---|

| Plan Planning | Personnel Commitment | Top Management Commitment Consultation and Participation of Workers |

| Organisation and Responsibility | Safety Objectives Responsibility and accountability | |

| Standards Compliance | Legal requirements Other requirements | |

| Risk Assessment | Physical factors (machinery, infrastructure, substances) Social factors (working time directive, culture) External factors (weather, emergencies) | |

| Do Support & Operation | Education and Training | Available Resources Competence and training |

| Contractor Management | Contractor Management | |

| Emergency Response | Preparation Response Recovery & reconstruction | |

| Work Permit | Display Suspension Permit interaction Handover/Hand-back Permit authorisation and supervision | |

| Communication | Internal External | |

| Study Performance Evaluation | Environment Monitoring | Monitoring Measurement Analysis & Evaluation |

| Accident Investigation | Identify Failures (of current SMS) Personnel Investigation Results Communication Corrective Action Reports Produced | |

| Safety Audit | Internal External | |

| Action Improvement | Continuous Improvement | Technology (machines, materials) Processes (improved and standardised practices) People (worker capabilities or competence) Performance |

| Instructions: The Safety Framework foundation was built upon Deming’s sequential PDCA improvement cycle, and therefore must be used in exactly that order i.e., first consult the Plan section (first, second, and then third level attributes), then the Do section, next the Study section, and finally the Action section. The Safety Framework is intended to be used as a basis for an internal facility audit, leaving it for the User to decide whether to qualitatively or quantitatively score each element. | ||

| 1st Level Attributes | 2nd Level Attributes | 3rd Level Attributes |

| Plan Planning | Personnel Commitment | Top Management commitment Consultation and participation of workers |

| Organisation and Responsibility | Safety objectives Responsibility and accountability | |

| Standards Compliance | Legal requirements Other requirements | |

| Risk Assessment | Physical factors (machinery, infrastructure, substances) Social factors (working time directive, culture) External factors (weather, emergencies) | |

| Do Support & Operation | Education and Training | Available Resources Competence and training Employee Support Programme |

| Contractor Management | Contractor Management | |

| Emergency Response | Preparation Response Recovery & reconstruction | |

| Work Permit | Display Suspension Permit interaction Handover/Hand-back Permit authorisation and supervision | |

| Communication | Internal External | |

| Study Performance Evaluation | Environment Monitoring | Monitoring Measurement Analysis & Evaluation |

| Accident Investigation | Identify Failures (of current Safety Management System) Personnel Investigation Results Communication Corrective Action Reports Produced | |

| Safety Audit | Internal External | |

| Action Improvement | Continuous Improvement | Technology (machines, materials) Processes (improved and standardised practices) People (worker capabilities and competence) Performance |

1. Interviewee

|

2. Feasibility of the framework content

|

3. Feasibility of the framework language

|

4. Feasibility of the framework presentation

|

5. Adaptability

|

| Interview 1 | Interview 2 | Interview 3 | Interview 4 | Interview 5 | Interview 6 | Interview 7 | |

|---|---|---|---|---|---|---|---|

| 1. Interviewee | |||||||

| Code | S1 | S1 | E1 | E2 | S3 | E1 | E3 |

| What sector do you work in? | Shipbuilding | Ship Building | Engineering/Manufacturing | Defence | Ship Building | Defence | Public Sector |

| How many years’ experience do you have in your sector? | 0–2 years | 6–10 years | 6–10 years | 3–5 years | 6–10 years | 3–5 years | 21+ years |

| 2. Feasibility of the framework content | |||||||

| Is the content relevant? | Yes | Yes | No | Yes | Yes | Yes | Yes |

| Is the content current? | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Is the content missing any key factors? | Yes, I can’t see anything about PPE, maybe it fits into one of the current categories? | Yes, mental wellbeing of our employees is a key factor in keeping everyone in our workplace safe. I can’t see anything about employee wellbeing in the framework. | No | Yes | No | Yes | Yes |

| How could the framework be improved? | Some more specific risks around metal manufacturing facilities, it still seems quite generic | To include more factors relating to culture and people. | A priority list or ranking of each factor. | References to relevant documents might be useful (although this may clutter the framework) | Some context around each section/level | Some instructions on how to use the framework would be useful. I’d assume it’s like a checklist of things to assess for each facility. I would be interested to know the sources of each factor. | I think the framework is missing some specialised 2nd and 3rd levels for metal manufacturing facilities specifically |

| 3. Feasibility of the framework | |||||||

| Is the content easily understood? | Yes | No | Yes | Yes | Yes | Yes | Yes |

| How could this be improved? | It would be good to remove the acronym SMS, or write it out fully, I don’t know what this is | I don’t understand how to use the safety framework, is it a checklist? Does it need accompanying guidelines? Is there a final score? | No comments made | I think the framework would benefit from a sentence or two of context/how it is to be used/implemented. | Some justification and context as mentioned above. Just to be clear how it relates into the level above. | The language is easily understood. | The language is clear |

| 4. Feasibility of the framework | |||||||

| Is the layout clear? | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| How could this be improved? | It could be presented as a tree diagram working from the top level down, as opposed to left-to-right | I think the framework is clear | Have the layout more clear to the user. Have reference to where you get info i.e. the HSE or who regulates it etc. | The text is a bit out of focus and on the small side | No comments made | It’s a bit blurry when blown up. | I don’t think the framework needs colour, a simple black and white table would suffice. |

| 5. Adaptability | |||||||

| Can you think of another industry this framework could be adapted to? | I think it could be used in the textiles/fashion industry. It would be good to outline attributes that are specific to the metal industry, so that other industries would easily know to adapt/change that specific category but could trust that the rest of the framework is suitable for their industry. | Any of our facilities on site, large steelwork construction, woodwork facilities, it would probably need developing for anything electrical | No | I think this framework could be easily applied to most manufacturing and construction based industries. | Most industries I’ve worked in could benefit. Heavy engineering such as ship building would especially benefit. | I’d imagine any manufacturing industry could adopt this framework. | Any type of construction or manufacturing industry could likely use this safety framework as it is quite generalised. |

References

- Brinia, V.; Efstathiou, M. Evaluation of factors affecting training transfer on safety in the workplace: A case study in a big factory in Greece. Ind. Commer. Train. 2012, 44, 223–231. [Google Scholar] [CrossRef]

- LED Controls. The Future of Factory Automation: Industrial Robotics & Autonomous Systems|LED Controls Blog. Available online: https://www.ledcontrols.co.uk/blog/the-future-of-factory-automation-industrial-robotics-autonomous-systems/ (accessed on 13 August 2024).

- Symon, G.; Clegg, C.W. Technology-led change: A study of the implementation of CADCAM. J. Occup. Psychol. 1991, 64, 273–290. [Google Scholar] [CrossRef]

- Leso, V.; Fontana, L.; Iavicoli, I. The occupational health and safety dimension of Industry 4.0. Med. Lav. 2018, 110, 327–338. [Google Scholar] [CrossRef] [PubMed]

- Alqudhaibi, A.; Aloseel, A.; Jagtap, S.; Salonitis, K. Identifying and Predicting Cybersecurity Threats in Industry 4.0 Based on the Motivations Towards a Critical Infrastructure. In Advances in Manufacturing Technology XXXV; IOS Press: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Alqudhaibi, A.; Albarrak, M.; Aloseel, A.; Jagtap, S.; Salonitis, K. Predicting Cybersecurity Threats in Critical Infrastructure for Industry 4.0: A Proactive Approach Based on Attacker Motivations. Sensors 2023, 23, 4539. [Google Scholar] [CrossRef]

- Alqudhaibi, A.; Deshpande, S.; Jagtap, S.; Salonitis, K. Towards a sustainable future: Developing a cybersecurity framework for manufacturing. Technol. Sustain. 2023, 2, 372–387. [Google Scholar] [CrossRef]

- HSE. Work-Related Fatal Injuries in Great Britain. Available online: https://www.hse.gov.uk/statistics/assets/docs/fatalinjuries.pdf (accessed on 6 May 2024).

- Diamond, L.M.; Alley, J. Rethinking minority stress: A social safety perspective on the health effects of stigma in sexually-diverse and gender-diverse populations. Neurosci. Biobehav. Rev. 2022, 138, 104720. [Google Scholar] [CrossRef]

- Steffey, M.A.; Griffon, D.J.; Risselada, M.; Buote, N.J.; Scharf, V.F.; Zamprogno, H.; Winter, A.L. A narrative review of the physiology and health effects of burnout associated with veterinarian-pertinent occupational stressors. Front. Vet. Sci. 2023, 10, 1184525. [Google Scholar] [CrossRef]

- Karatepe, O.M.; Saydam, M.B.; Okumus, F. COVID-19, mental health problems, and their detrimental effects on hotel employees’ propensity to be late for work, absenteeism, and life satisfaction. Curr. Issues Tour. 2021, 24, 934–951. [Google Scholar] [CrossRef]

- Chenarboo, F.J.; Hekmatshoar, R.; Fallahi, M. The influence of physical and mental workload on the safe behavior of employees in the automobile industry. Heliyon 2022, 8, e11034. [Google Scholar] [CrossRef]

- AC Operational Policy and Assurance. Improving the Operational Safety Management Model. London, August 2020. Available online: https://www.london-fire.gov.uk/media/5387/lfc-0374-safety-management-model.pdf (accessed on 4 August 2024).

- Office for National Statistics. Manufacturing and Production Industry—Office for National Statistics. Available online: https://www.ons.gov.uk/businessindustryandtrade/manufacturingandproductionindustry (accessed on 29 January 2025).

- Innova Search. Health, Safety & Environmental|Innova-Search. Available online: https://www.innova-search.co.uk/health-safety-and-environmental (accessed on 4 August 2024).

- Carthey, J. Measurement and Monitoring of Safety Framework (MMSF): Learning from its implementation in Canada. BMJ Qual. Saf. 2023, 32, 441–443. [Google Scholar] [CrossRef]

- Welsh Government. Quality and Safety Framework: Learning and Improving. 2021. Available online: https://www.gov.wales/sites/default/files/publications/2021-09/quality-and-safety-framework-learning-and-improving_0.pdf (accessed on 4 August 2024).

- Chang, J.I.; Liang, C.-L. Performance evaluation of process safety management systems of paint manufacturing facilities. J. Loss Prev. Process. Ind. 2009, 22, 398–402. [Google Scholar] [CrossRef]

- Manufacturing Operations Management. A Brief History of Smart Manufacturing (Manufacturing Operations Management Talk). Available online: https://www.manufacturing-operations-management.com/manufacturing/2021/06/a-brief-history-of-smart-manufacturing.html (accessed on 5 August 2024).

- Aminbakhsh, S.; Gunduz, M.; Sonmez, R. Safety risk assessment using analytic hierarchy process (AHP) during planning and budgeting of construction projects. J. Saf. Res. 2023, 46, 99–105. [Google Scholar] [CrossRef] [PubMed]

- Quality One. Process FMEA|Process Failure Mode & Effects Analysis|Quality-One. Available online: https://quality-one.com/pfmea/ (accessed on 5 August 2024).

- Tabibzadeh, M.; Khashe, Y.; Somaiya, P. A Proactive Risk Analysis Framework to Enhance Safety and Reliability in Railroad Operations: Assessment of the Positive Safety Culture Traits. In Advances in Human Aspects of Transportation: Proceedings of the AHFE 2018 International Conference on Human Factors in Transportation, Loews Sapphire Falls Resort at Universal Studios, Orlando, FL, USA, 21–25 July 2018; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 625–636. [Google Scholar] [CrossRef]

- Omrany, H.; Al-Obaidi, K.M.; Husain, A.; Ghaffarianhoseini, A. Digital twins in the construction industry: A comprehensive review of current implementations, enabling technologies, and future directions. Sustainability 2023, 15, 10908. [Google Scholar] [CrossRef]

- VMT. Shadow Boards|Effective Workplace Organisation|VMT. Available online: https://v-m-t.co.uk/shadow-boards (accessed on 5 August 2024).

- Di Bona, G.; Silvestri, A.; De Felice, F.; Forcina, A.; Petrillo, A. An Analytical Model to Measure the Effectiveness of Safety Management Systems: Global Safety Improve Risk Assessment (G-SIRA) Method. J. Fail. Anal. Prev. 2016, 16, 1024–1037. [Google Scholar] [CrossRef]

- Cagno, E.; Di Giulio, A.; Trucco, P. Risk and causes-of-risk assessment for an effective industrial safety management. Int. J. Reliab. Qual. Saf. Eng. 2000, 107, 113–128. [Google Scholar] [CrossRef]

- Tong, D.Y.K.; Rasiah, D.; Tong, X.F.; Lai, K.P. Leadership empowerment behaviour on safety officer and safety teamwork in manufacturing industry. Saf. Sci. 2015, 72, 190–198. [Google Scholar] [CrossRef]

- Lean Plan, Do, Check, Act (PDCA)—A Resource Guide. Available online: https://www.lean.org/lexicon-terms/pdca/ (accessed on 4 August 2024).

- BSI. COVID-19—Guidelines|BSI. Available online: https://www.bsigroup.com/en-GB/topics/novel-coronavirus-covid-19/covid-19-guidelines/ (accessed on 13 August 2024).

- Nasa, P.; Jain, R.; Juneja, D. Delphi methodology in healthcare research: How to decide its appropriateness. World J. Methodol. 2021, 11, 116–129. [Google Scholar] [CrossRef]

- Teo, E.A.L.; Ling, F.Y.Y. Developing a model to measure the effectiveness of safety management systems of construction sites. Build. Environ. 2006, 41, 1584–1592. [Google Scholar] [CrossRef]

- Deming. PDSA Cycle—The W. Edwards Deming Institute. Available online: https://deming.org/explore/pdsa/ (accessed on 4 August 2024).

- Nagyova, A.; Balazikova, M.; Markulik, S.; Sinay, J.; Pacaiova, H. Implementation Proposal of OH&S Management System According to the Standard ISO/DIS 45001. Adv. Saf. Manag. Hum. Factors 2017, 604, 472–485. [Google Scholar] [CrossRef]

- HSE. Manufacturing Statistics in Great Britain, 2023. 2023. Available online: https://freshproduce.org.uk/files/manufacturing-stats-23.pdf (accessed on 27 May 2025).

- International Labour Organization. Guidelines on Occupational Safety and Health Management Systems. 2023. Available online: https://www.ilo.org/wcmsp5/groups/public/---ed_protect/---protrav/---safework/documents/normativeinstrument/wcms_107727.pdf (accessed on 4 August 2024).

- Marhavilas, P.K.; Pliaki, F.; Koulouriotis, D. International Management System Standards Related to Occupational Safety and Health: An Updated Literature Survey. Sustainability 2022, 14, 13282. [Google Scholar] [CrossRef]

- British Standards Institution. Occupational Health and Safety Management (ISO 45001); British Standards Institution: London, UK, 2023; Available online: https://www.bsigroup.com/en-SE/search-results/?q=Occupational%20Health%20and%20Safety%20Management%20(ISO%2045001)&Page=1&tab=0&locale=en-SE (accessed on 27 May 2025).

- British Psychological Society. The Delphi Method. Available online: https://www.bps.org.uk/psychologist/delphi-method (accessed on 18 September 2024).

- Kaufman Global. 6Ms of Production (Man, Machine, Material, Method, Mother Nature and Measurement)—Kaufman Global. Available online: https://www.kaufmanglobal.com/glossary/6ms-production-man-machine-material-method-mother-nature-measurement/ (accessed on 4 August 2024).

- Huo, M.-L.; Jiang, Z. Work–life conflict and job performance: The mediating role of employee wellbeing and the moderating role of trait extraversion. Personal. Individ. Differ. 2023, 205, 112109. [Google Scholar] [CrossRef]

- Sawicki, M.; Szóstak, M. Impact of Alcohol on Occupational Health and Safety in the Construction Industry at Workplaces with Scaffoldings. Appl. Sci. 2020, 10, 6690. [Google Scholar] [CrossRef]

- U.S. Department of Labor; Occupational Safety and Health Administration. Process Safety Management of Highly Hazardous Chemicals; Final Rule. Fed. Regist. 1992, 57, 6356–6417. [Google Scholar]

- Lemm, T.C. DuPont Safety Management in a Re-Engineered Corporate Culture. ASME Citrus Eng. Symp. 1996, 99830, 16–26. [Google Scholar]

- Marsh, T.; Davies, R.; Phillips, R.; Duff, R.; Robertson, I.; Weyman, A.; Cooper, D. The Role of Management Commitment in Determining the Success of a Behavioural Safety Intervention. J.-Inst. Occup. Saf. Health 1998, 2, 45–56. [Google Scholar]

- McDonald, N.; Corrigan, S.; Daly, C.; Cromie, S. Safety Management Systems and Safety Culture in Aircraft Maintenance Organisations. Saf. Sci. 2000, 34, 151–176. [Google Scholar] [CrossRef]

- Machida, S.; Bachoo, P. Guidelines on Occupational Safety & Health Management Systems. Afr. News Lett. Occup. Health Saf. 2001, 11, 68–69. [Google Scholar]

- Mearns, K.; Flin, R.; Gordon, R.; Fleming, M. Human and Organizational Factors in Offshore Safety. Work Stress 2001, 15, 144–160. [Google Scholar] [CrossRef]

- BS 8800:2007; Guide to Occupational Health & Safety Management Systems. British Standards Institution (BSI): London, UK, 2007.

- BS ISO 45001:2018; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. British Standards Institution (BSI): London, UK, 2018.

- International Labour Office (ILO). Guidelines on Occupational Safety Uidelines on Occupational Safety and Health Management Systems Nd Health Management Systems ILO-OSH 2001; International Labour Office (ILO): Geneva, Switzerland, 2009. [Google Scholar]

- Basso, B.; Carpegna, C.; Dibitonto, C.; Gaido, G.; Robotto, A.; Zonato, C. Reviewing the Safety Management System by Incident Investigation and Performance Indicators. J. Loss Prev. Process. Ind. 2004, 17, 225–231. [Google Scholar] [CrossRef]

- Hong, Y.; Lin, Y.; Pai, H.; Lai, Y.; Lee, I. Developing a Safety and Health Training Model for Petrochemical Workers. Kaohsiung J. Med. Sci. 2004, 20, 56–61. [Google Scholar] [CrossRef]

- Thomas Ng, S.; Pong Cheng, K.; Martin Skitmore, R. A Framework for Evaluating the Safety Performance of Construction Contractors. Build. Environ. 2005, 40, 1347–1355. [Google Scholar] [CrossRef]

- EN 292-1:1991; Safety of Machinery—Basic Concepts, General Principles for Design—Part 1: Basic Terminology, Methodology. European Committee for Standardization (CEN): Brussels, Belgium, 1991.

- EN 292-2:1991; Safety of Machinery—Basic Concepts, General Principles for Design×Part 2: Technical Principles and Specifications. European Committee for Standardization (CEN): Brussels, Belgium, 1991.

- BS EN 1050:1997; Safety of Machinery—Principles for Risk Assessment. British Standards Institution (BSI): London, UK, 1997.

- AIHA. AIHA Guideline Foundation. Available online: https://www.aiha.org/get-involved/aiha-guideline-foundation (accessed on 13 May 2025).

- Fernández-Muñiz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. Safety Culture: Analysis of the Causal Relationships between Its Key Dimensions. J. Saf. Res. 2007, 38, 627–641. [Google Scholar] [CrossRef] [PubMed]

| Code | Job Role |

|---|---|

| 1 | Employee |

| 2 | Team Leader Level |

| 3 | Higher Management Level |

| S | Safety Department |

| E | Engineer |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eggleston, A.; Sarfraz, S.; Salonitis, K.; Gupta, S.; Trollman, H.; Jagtap, S. Enhancing Safety Performance in UK Metal Manufacturing: A Revised Framework to Reduce Fatal Accidents. Safety 2025, 11, 59. https://doi.org/10.3390/safety11020059

Eggleston A, Sarfraz S, Salonitis K, Gupta S, Trollman H, Jagtap S. Enhancing Safety Performance in UK Metal Manufacturing: A Revised Framework to Reduce Fatal Accidents. Safety. 2025; 11(2):59. https://doi.org/10.3390/safety11020059

Chicago/Turabian StyleEggleston, Alexandra, Shoaib Sarfraz, Konstantinos Salonitis, Sumit Gupta, Hana Trollman, and Sandeep Jagtap. 2025. "Enhancing Safety Performance in UK Metal Manufacturing: A Revised Framework to Reduce Fatal Accidents" Safety 11, no. 2: 59. https://doi.org/10.3390/safety11020059

APA StyleEggleston, A., Sarfraz, S., Salonitis, K., Gupta, S., Trollman, H., & Jagtap, S. (2025). Enhancing Safety Performance in UK Metal Manufacturing: A Revised Framework to Reduce Fatal Accidents. Safety, 11(2), 59. https://doi.org/10.3390/safety11020059