Abstract

Fatal accidents in UK’s manufacturing sector are expected to remain the same or increase in coming years. This paper has tried to combat this issue by adapting and further developing a previously defined Safety Framework for the Paint Sector, to evaluate the safety performance of a metal manufacturing facility. To achieve this, the original Safety Framework was updated to align with the current British safety legislation outlined by the British Standards Institution. The framework was based on a three-level multi-attribute value theory (MAVT). Upon reviewing BSI 45001, the Safety Framework was founded upon the concept of Deming’s Plan, Do, Check, Act (PDCA) which is the foundation for the original framework, therefore, the first-level attributes remained consistent. The 13 attributes of the second level and 36 attributes of the third level were derived from the literature review and updated to relevant legislation. To develop the Safety Framework, the Delphi method was used. This included interviews that were conducted with employees and managers from either a Safety or Engineering background. The second part of the paper involved the improvement of the Safety Framework, based on the interview feedback. The main findings of the study revealed that the final Safety Framework has been deemed relevant for the Metal Manufacturing Sector by Industry Suitably Qualified and Experienced Personnel (SQEP). The majority of Interviewees deemed the Safety Framework to have a clear layout and easy to understand. The interviews and final Safety Framework suggested the importance of a company’s emphasis on employee welfare and health, in order to reduce accidents in the workplace. The originality of this paper lies in its application and validation of a sector-specific safety framework, contributing to the body of knowledge by offering a replicable methodology for adapting safety frameworks to other manufacturing sectors.

1. Introduction

Safety in the workplace is of paramount importance across all sectors. In the manufacturing sector, however, evolving technologies and increasing levels of automation introduce specific and complex safety challenges that require focused attention [1]. The United Kingdom (UK) manufacturing sector continues to develop into an increasingly autonomous and technology-led environment [2,3]. This evolving context brings with it new types of risks compared to those traditionally associated with manufacturing plants [4]. Risks are no longer purely physical; cyber threats have become significant concerns within the manufacturing workplace [5]. For example, hackers could theoretically manipulate machinery to operate in dangerous ways or within hazardous environments [6,7].

Traditionally, a tradesperson would be deemed most susceptible to physical risks such as lacerations, falling objects and working at height [8]. It could be argued that these risks may be amplified depending on the individual’s personal health [9]. Ill physical health and/or mental wellbeing may affect an employees’ concentration, memory and decision making, making them more at-risk in the workplace [10,11]. It has been found that:

“Employees who have had an occupational accident endured more physical stress in addition to mental workload (MWL) compared to employees who did not have an accident” [12].

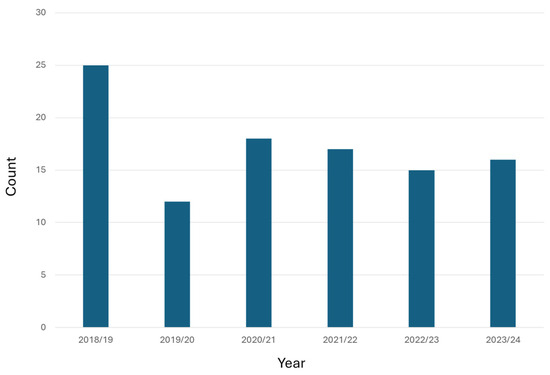

Figure 1 shows the number of employees killed in the Manufacturing sector from work-related accidents, spanning from 2018 through to July 2024 [8]. Unfortunately, being only two-thirds of the way through the year 2023, the fatality count would therefore be expected to remain the same or increase. While the data in Figure 1 do not indicate a consistent increase, the number of fatal accidents has remained unacceptably high over recent years. This level of risk remains a critical concern and requires targeted interventions to improve safety. It’s important to note that these statistics are taken from a sample of 100,000 employees annually, ensuring proportional representation regardless of population fluctuations. Recognising the unsustainable nature of this trend this paper has tried to evaluate the safety performance of a metal manufacturing facility.

Figure 1.

Fatal Accidents in the UK Manufacturing Sector [8].

It is clear that a comprehensive solution needs to be determined to stop this increasing trend in fatal accidents and make the workplace a safer place to be. This solution needs to be equipped with tools that can tackle the various types of risks in the metal manufacturing industry, such as cyber safety, physical safety, and employee wellbeing.

A Safety Framework offers an orthodox methodology for managing safety in the workplace. A Safety Framework is a series of tools or steps that, when followed, can support the accomplishment of a safety goal. The motivation for this study is to reduce risks and therefore accidents in the workplace. Current safety frameworks are often categorised as either strategic or tactical [13]. The gap between strategic safety goals and specific legislation for operational tasks in the workplace is abundant. There is a requirement for a Safety Framework that can bridge the gap between the strategic higher-management goals, and operational workers’ tangible actions.

The Manufacturing sector is made up of a variety of industries including mining and quarrying, energy supply, water supply and waste management [14]. As shown in Figure 1, fatal accidents in the UK manufacturing sector have remained relatively steady. According to Innova [15], the manufacturing sector employs approximately 2.5 million workers and has reported an average of 22 worker fatalities per year over the past five years. In addition, there are typically over 3100 major injuries and around 4100 injuries that result in absences of seven days or more. These persistent safety issues highlight the need for more effective frameworks tailored to high-risk environments like metal.

The main aim of this research is to improve workplace safety and reduce accident and fatality rates in UK metal manufacturing facilities by developing a Safety Framework that will serve as a guideline for companies to consider, with the intention of accident prevention and reduction. The following objectives were identified to achieve the aforementioned aim.

- To establish an in-depth literature review of Safety Frameworks in the Manufacturing sector, as well as other industries, to determine the most significant safety attributes.

- To develop a Safety Framework for the metal manufacturing sector to help prevent further accidents from occurring.

- To validate the developed framework via industry suitably qualified and experienced personnel (SQEP).

Since, safety is a broad category; the scope of the research has been bound based upon the British Standards Institution (BSI) categories. The BSI has four main categories, namely, ISO 9001 Quality Management Systems, ISO 14001 Environmental Management, ISO/IEC 27001 Information Security Management, and ISO 45001 Occupational Health and Safety Management. This paper will focus on the latter category only.

2. Literature Review

2.1. Safety Frameworks

Before delving into the current literature, it was important to clearly define what a Safety Framework is. Carthey [16] described a Safety Management Framework as “a broader framework for safety, in contrast to individual interventions (e.g., bundles, checklists)”. Whereas Welsh Government [17] describe a Safety Framework as “the interlinked key elements that must always be working together to ensure continuous improvement in quality: planning; improvement; and control; and to provide overall assurance that the system is working effectively to deliver the outcomes”. Either way, it is clear that a Safety Framework is a proactive step up in terms of governance (when compared with a list of legislation) for safety in the workplace and employees.

2.2. Literature Divergence

The literature review aimed to investigate current and pertinent research related to Safety Frameworks and, consequently, initiatives aimed at mitigating workplace accidents. The literature review drew insights from papers source from both the Scopus database and Google Scholar. Google Scholar was particularly useful as it often provided access to papers that Scopus did not. Initially, 23 key words were pinpointed, encompassing 45 key words that included alternatives and synonyms for common terms associated with the topics: manufacturing, accidents, and safety. See Table A1 for the list of key words utilised in various combinations with Boolean Operators, ensuring a comprehensive and thorough literature review.

In spite of developments in safety management frameworks and the incorporation of cyberinfrastructure considerations, there remains a prominent research gap in the development of sector-specific safety frameworks personalised to the unique needs of the UK metal manufacturing industry. Existing frameworks, such as the one developed by Chang and Liang [18] for the paint sector, have shown the potential for cross-sector adaptation. However, these frameworks often fail to address the growing risks linked with modern manufacturing environments, specifically those involving cyber threats, digital transformation, and the mental wellbeing of employees. Additionally, the literature reveals limited exploration of incorporating emotional accident prevention and education factors, such as trust and employee wellbeing, into safety frameworks. Furthermore, while some studies propose comprehensive attributes for safety frameworks, there is a lack of empirical validation of these frameworks across varied facilities within the metal manufacturing sector. This highlights the need for an updated, validated, and sector-specific framework that connects the gap between strategic safety objectives and practical on-ground safety implementations, while incorporating emerging risks and legislative changes.

2.3. Literature Convergence

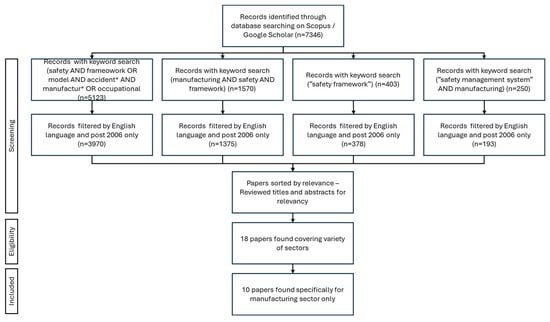

The initial searches returned a minimum of 7346 papers, see the breakdown of papers sourced in Figure 2. These papers were then filtered by English language only. The subsequent step involved narrowing down the results to encompass papers published from 2006 onwards. This refined filter led to a reduced count of 5916 papers. The year 2006 was chosen because according to [19]

Figure 2.

Flow diagram showing literature filtration process. Note: The asterisk * symbol in the figure acts as a wildcard, representing any number of characters after the root word. For example, if you search for “accident” it would likely return results for “accident”, “accidents”, and “accidental”.

The next step was to sort a selection of the papers in order of relevance by skim-reading the paper titles, abstracts, key words, and dates published. At this point in time, the papers had not been filtered by sector. This was a lengthy process and resulted in 18 relevant papers.

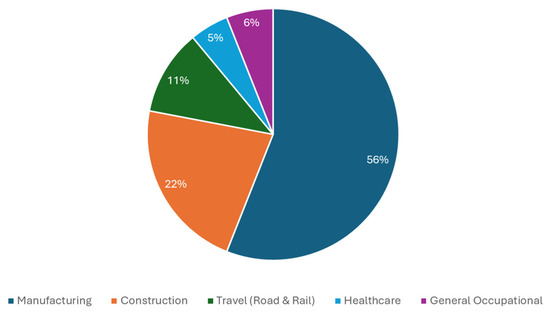

The final step was to thoroughly review all 18 papers in further depth. To make the revision consistent, and clear to refer back to, a table was created which included columns for Paper Author(s), Paper Title, Manufacturing Sector Type, Publication Year, Type (of Framework), Limitations of the Research, Research Findings, and Research Gaps. The papers covered a wide range of sectors, namely Manufacturing, Travel (Road), Travel (Rail), Construction, Healthcare, and General Occupational. Ten of these papers were associated with the manufacturing sector specifically, see Figure 3 for the proportion of papers from each sector.

Figure 3.

Proportion of Research Papers Across Various Manufacturing Sectors.

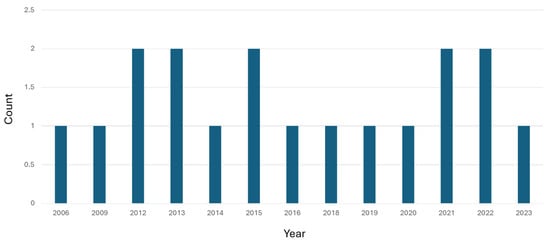

The spread of publication year can be seen in Figure 4, paper publication ranged from 2006 through to 2023.

Figure 4.

Years of Publication of the chosen Literature Review Papers.

The papers adopted diverse strategies for accident reduction. Various terms were employed to characterize the models proposed in these papers, including framework, business process model, risk assessment framework, accident classification framework, safety management system, and conceptual model.

Interestingly, Chang and Liang’s [18] paper regarding an Accident Classification Framework for the construction sector, determined categories based upon negatives as opposed to positives. For example, some of the categories were labelled: unsafe management, unsafe machine/tool, unsafe environment, and so on. The framework was derived based upon the frequency of accidents relating to each category. Two different perspectives to approach reduction of accidents are reactive and proactive. Chan and Liang [18] took a reactive approach through the collation of past events data, which resulted in an output of recurring factors and accident patterns. Aminbakhsh et al. [20] took a similar reactive approach but alternatively calculated the magnitude of each risk through the product of probability and severity, more similar to Process Failure Mode and Effects Analyses [21]. The metal manufacturing industry is subject to many safety risks, including occupational injuries, workshop risks such as slips, trips, poor housekeeping, manual handling, and close proximity to machinery, and substance hazards. Studies by the Health and Safety Executive (HSE) have revealed that the most injuries sustained in metal fabrication are related to handling and carrying or being struck by moving machinery or falling objects (18%). In contrast, the results of Aminbakhsh, et al. [20] indicated that the category Trips and Falls required the most significant investment.

Alternatively, Tabibzadeh et al. [22] took a proactive approach through the development of a risk assessment framework by “integrating the 10 traits of the positive safety culture, initially introduced by the U.S. Nuclear Regulatory Commission”. The framework comprised of six levels (top-to-bottom order) namely: Government, Regulators and associations, Company, Management, Staff, and Work. An identified gap with this paper was that the “Not Applicable” column (“comprised of framework factors that were not directly associated with violating one of the traits of a positive safety culture”), was not further explored.

A completely different proactive approach adopted by Omrany et al. [23] was to create a digital map of a physical workshop, which “can establish the twins of the physical workshop from different dimensions such as geometry, behaviour, and environment”. The digital mock-up could detect risks such as workers close proximity to a dangerous area, or equipment being moved from a safe area to unsafe area. This approach would heavily rely on 5S Six Sigma [24] physical implementations such as shadow boards. A significant limitation of this approach was that the workshop behaviours ever-changing and complex, making it difficult to use the virtual dataset to train the network which ultimately resulted in a low detection accuracy.

In the industrial context, the relationships between safety management systems and risk assessment activities is critical for realising high consistency and operational safety. Safety management systems provide the tactical and practical framework, whereas risk assessment extends the analytical footing for recognising and reducing hazards. Di Bona et al. [25] proposed the Global Safety Improve Risk Assessment (G-SIRA) model which uses analytical hierarchy process (AHP) to effectively and efficiently recognise and mitigate risks compared to traditional methods.

Similarly, Cagno et al. [26] introduced an AHP-based risk assessment method that holistically assesses and prioritises workplace hazards and their causes—machine, operator, procedures, and environment—offering more flexible and systematic safety management than traditional approaches.

The different models mentioned above may not apply directly to the metal manufacturing industry, but the methodologies used could be applied to develop an all-inclusive Safety Framework suitable to the UK metal manufacturing industry.

A clear gap in the current research was the inclusion of a suppressor variable, as proposed by Tong et al. [27]. This paper concluded that the attribute “trust” increases the predictive validity of other attributes (when used in a regression equation). This paper addressed the importance of emotional accident prevention and reduction factors, as opposed to simply physical factors.

One particular paper; Chang and Liang [18] derived a Safety Framework for auditing paint facilities. It seemed appropriate to assume a similar Safety Framework could be updated and adapted for a different manufacturing industry, such as the metal manufacturing industry. Chang and Liang [18] suggested “testing the validity of this model on more facilities in the paint industry as well as in other industrial sectors.”

2.4. Analysis of Selected Literature

To appropriately develop the previously determined Safety Framework (originally for the paint sector), for the metal manufacturing sector, it was critical to explore all citations of the Chang and Liang [18] paper since publication in 2009. There were 69 citations in total, of which 11 papers were inaccessible using Cranfield University portals via both Google Scholar and Scopus. This was a minor limitation of the research as it was assumed that the Safety Framework developed by Chang and Liang [18] had not since been developed or adapted for an alternative sector. All remaining 57 papers did not cite the original paper in terms of either developing or adapting the framework. The citations were predominantly used to explain Demings Plan Do Check Act (PDCA) process [28].

2.5. Legislation Change

The critical element that needed to be addressed was that the original paper was published in 2009. Since then, there have been significant changes in terms of safety legislation on a global scale due to the COVID-19 pandemic. For example, BSI have published a complete new set of guidelines, namely PD ISO/PAS 45005:2020, Occupational health and safety management–General guidelines for safe working during the COVID-19 pandemic [29]. It was therefore of upmost importance to not only adapt the framework to a different sector (metal manufacturing sector), but also to update the framework based on developments in European legislation since 2009.

3. Research Methodology

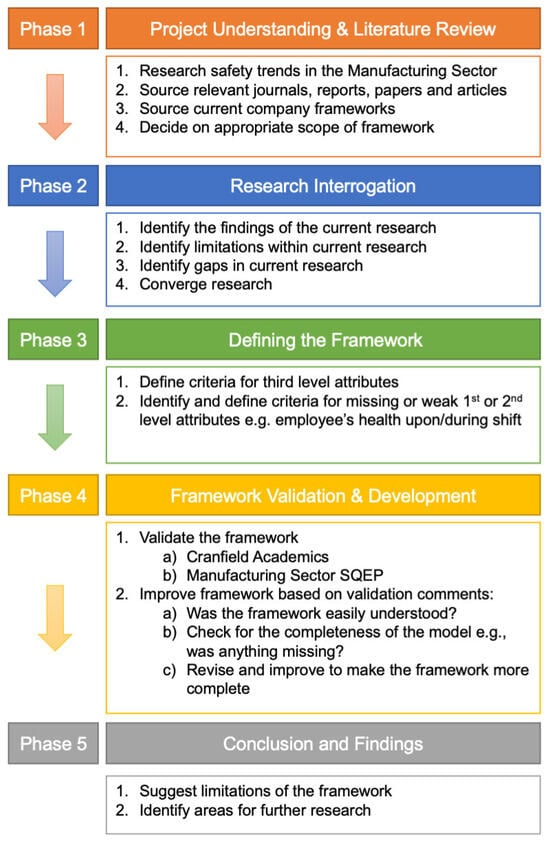

The methodology was split into 5 phases, see Figure 5. Phase 1 aimed to ensure the research was relevant and covered a variety of framework designs for different sectors.

Figure 5.

Research Methodology.

The research then converged to the metal manufacturing sector specifically in Phase 2, looking at papers post-2006 to ensure they were current. The year 2006 was chosen because according to [19] “The concept of cyberinfrastructure entered the vocabulary around that time.” It was therefore important to recognise that accident prevention and reduction would also need to consider risks associated with cyberinfrastructure, as opposed to traditional occupational risks.

Phase 3 defined the framework itself. Phase 4 validated the framework through industry professional’s opinions otherwise known as the Delphi method [30]. Finally, Phase 5 discussed the research conclusions, limitations to the framework, and any areas for future research.

4. Framework Development

4.1. Foundation

Teo and Ling [31] developed a model to measure the effectiveness of a Safety Management System framework based upon the following attributes: policy, process, personnel, and incentive, as well as using a 3-level MAVT approach. Using the model determined by Teo and Ling [31], Chang and Liang [18] used the multi-attribute value theory (MAVT) to derive a Safety Index (SI) for each paint facility. The SI of metal manufacturing facilities could also be determined based upon the assessment of Safety Representatives; however, this is not part of the scope of this research.

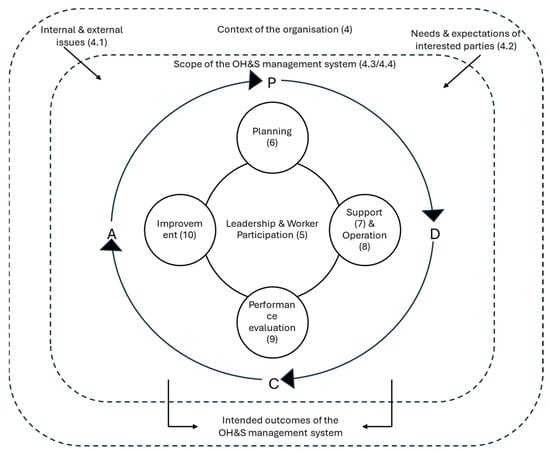

4.2. The First Level

The original Safety Framework was developed and updated using a systematic process. To begin with, the first levels were reviewed to see if the foundation, namely PDCA (see Figure 6), remained unchanged and relevant to UK industry. The infographic shows numbers four to nine (from ISO 45001 OH&S Management System), but neglects to include numbers 1, 2, and 3. This is because the infographic is numbered in such a way that each number corresponds to the chapter within the Occupational Health and Safety Management Systems publication, therefore chapters 1, 2, and 3 are Scope, Normative References, and Terms and Definitions, respectively. These sections were not relevant to the PDCA cycle. It transpired that Deming had since developed the PDCA process to PDSA (Plan, Do, Study, Act) [32]. Deming [32] had found that the term Check focussed solely on implementing a change, with a binary outcome of either success or failure. Whereas the term Study encouraged the user to study the results but then use said results to revise or update any previous theories.

Figure 6.

ISO 45001 OH&S Management System Scope [33].

4.3. The Second Level

4.3.1. Coding Original Sources

The next step was to look at the second level attributes and their corresponding original sources. It was assumed that the attribute weightings determined from the original Chang and Liang [18] paper (via MAVT and The Analytical Hierarchy Process and factor analysis) were still relevant. One, by one, every original source for all remaining second attributes were reviewed. Sources were colour coded as red, amber, and green, meaning the source was either not relevant, updated, or remained relevant (to either the UK or metal manufacturing facilities) respectively. See Table A2 for an example of the colour coding used. The red sources were removed, amber sources were updated with current UK legislation, and green sources remained.

4.3.2. Removing Attributes

The only second-level attribute that was completely removed was “Hazardous Materials Management”. While paints and other chemicals are rightly considered hazardous, this category is a primary risk area in the paint industry, which justified its inclusion as a standalone attribute in the original framework. In contrast, the metal manufacturing sector presents a broader range of risks where hazardous materials are relevant, but not central enough to require a dedicated second-level attribute. These risks are addressed under broader categories. The most significant safety issues in metal manufacturing remain “Slips, trips or falls on same level” [34] for non-fatal injuries, and “Contact with moving machinery” [34] for fatal injuries.

4.3.3. Updating Attributes

Current UK legislation and guidelines were sourced from reputable companies and constitutions, namely International Labour Organization (ILO) [35], International Organization for Standardization (ISO) [36], and British Standards Institution (BSI) [37]. BSI 45001 is one of four categories defined by BSI as Occupational Health and Safety Management, all BSI sources were taken from this category only. Rather than simply source either BSI or ILO for each attribute, the specific standard was documented, this should make future updates of the Safety Framework an easier task to complete.

4.3.4. Missing Attributes

The final step was to determine if there were any missing second level attributes, keeping metal manufacturing facilities in mind. It was determined that there were no missing attributes.

4.4. The Third Level

A similar approach (as for second level attributes) was taken for third level attributes; however, both the attributes and corresponding sources from the original Safety Framework were not made available to the public. Therefore, the third level attributes for this new Safety Framework were derived completely based upon a deeper level of categories relating to their predecessor; the corresponding second level attributes.

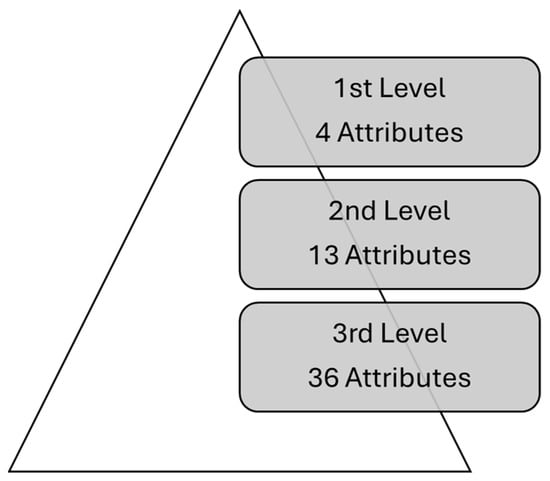

4.5. The Resulting Safety Framework

The resulting Safety Framework (see Table A3) consisted of four consecutive stages and three levels, see Table A3. The framework had 4 first level attributes, 13 s level attributes, and 36 third level attributes, see Figure 7. While most attributes reflect commonly accepted safety management elements, the inclusion of “Environmental Monitoring” under the Study category is intended to support early detection of potentially unsafe conditions—such as toxic emissions or overheating machinery—which can act as precursors to accidents. This proactive surveillance role aligns with the prevention focus of the framework. To help user to understand, the Safety Framework is proposed to be used as a structured tool for internal audits and continuous improvement. It follows the Plan-Do-Study-Act cycle and is not a checklist. Users may designate qualitative or quantitative scores based on facility-specific relevance and performance.

Figure 7.

Safety Framework Levels and their Corresponding Number of Attributes.

The framework is portrayed in a similar format to that of Chang and Liang [18]. However, there was a significant reduction in the number of third level attributes. The original framework read left-to-right and was coloured in black and white. The new framework also read left-to-right but was coloured coded to clearly define the order of the first level attributes.

5. Framework Validation

5.1. Validation Type

The validation process of the developed Safety Framework was a critical step because it demonstrated that the framework was accurate in its guidance towards accident reduction.

The Delphi method [30] was chosen to validate the Safety Framework. The British Psychological Society [38] described it as “a method for structuring a group communication process so that the process is effective in allowing a group of individuals, as a whole, to deal with a complex problem”. This seemed relevant for justification of the Safety Framework. Using the Delphi method also made the validation consistent with that of the original Safety Framework derived by Chang and Liang [18].

5.2. Validation Demographies

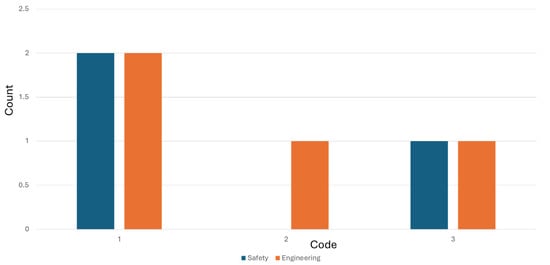

The Safety Framework was validated by seven industry professionals; three Engineers, three Safety, Health, and Environment (SHE) Representatives and a Digital Architect who each individually analysed the Safety Framework and completed the interview survey (see Table A5 for the list of questions). All of the industry professionals provided responses (see Table A6 for the responses).

The combined industry experience across the participants was at least 45 years, with a median of 8 years and an estimated mean of 10.9 years. The specific job titles have been coded for anonymity, see Table 1 below for further details, and Figure 8 for the respondents’ data.

Table 1.

Coding of Job Roles for the Validation Interviewees.

Figure 8.

Bar Chart of Job Role coding of Validation Interviewees.

It was important to include responses from different levels of the business, such as ground-level employees, middle management, all the way up to higher level management. Each of these different levels of employee would be exposed to different risks and behaviours. For example, a ground-floor employee would be more likely to comment from the perspective of their peers, and as someone who operates machinery on the shop floor. Whereas a higher-level manager may perceive risks from a more strategic perspective.

In hindsight, a rating from 1–10 (with 1 being the lowest and 10 being the highest) alongside the free-text field questions would have allowed quantitative test statistics to be used, such as the Chi-square test and the Wilcoxon signed rank test. This data was not collected so the tests cannot be performed.

By taking the midpoint of each category for the question, “How many years’ experience do you have in your sector?”, it can be deduced that the median experience of respondents is 8 years and the mean is 10.93 years. Note that for the 21+ year’s category, the upper bound was deemed to be the current UK retirement age of 66 years old.

The interview survey started with three demographic style questions. The main body of the interview comprised of nine sub-questions contained within four main question themes: feasibility of the framework content, feasibility of the framework language, feasibility of the framework presentation, and adaptability of the framework. All questions were mandatory and in a multiple-choice format with an accompanying free text field if the interviewee felt further comments were necessary. The mandatory multiple-choice questions were put in place to avoid any blank free-text fields and therefore incomplete surveys.

5.3. Validation Results

The results of the interview survey demonstrated that the industry professionals (with varying levels of experience) generally agreed with the use of the Safety Framework for the metal manufacturing industry, pending some minor improvements.

5.3.1. Similarities

The question that returned a concurrent answer was with regards to the Safety Framework’s layout. All respondents selected “Yes”. Associated respondent comments were regarding the clarity of the text in the framework, commenting that it was “blurry”. A change of format would quickly resolve this issue. Some further comments offered suggestions such as a black and white colour scheme, and a top-to-bottom tree-diagram layout.

Another question that returned mainly “Yes” results (bar one response from a SHE representative) was with regards to how easy the content of the Safety Framework was to understand. The “No” respondent exclaimed “I don’t understand how to use the Safety Framework, is it a checklist? Does it need accompanying guidelines? Is there a final score?”, raising cause for concern that the Safety Framework itself needed further introduction or explicit instructions provided prior to distribution. Most “Yes” respondents gave supplementary comments, all echoing the former comment. One respondent commented on the use of the unexplained acronym “SMS”.

5.3.2. Differences

Some differences were seen in response to the “Feasibility of the Framework” questions. Of the respondents, 86% found the content relevant. Similarly, the same 86% believed the content was current. The “no” respondent commented that the Safety Framework could have “a priority list or ranking of each attribute”. The framework has not been derived with a priority list of attributes in mind as this could mislead internal Auditors to focus on attributes that are in fact less important for said facility. However, the respondent raises a good point in offering internal Auditors the option of ranking the attributes (using their subject matter expert knowledge) prior to audit to determine the most important attributes for specific or specialised facilities.

Another respondent commented on the visibility of the sources used to derive the attributes. The sources were not included in the survey version of the Safety Framework as to not clutter the table. However, the intention would be to provide this information to the internal Auditors within the digital version of the framework, with the option of hiding the information for clarity. Two respondents agreed that the framework could include some more specific attributes relating to risks in the metal manufacturing industry specifically.

Finally, one respondent made a comment regarding the lack of attributes covering “culture and people”. It could be suggested that each attribute may be approached with Ishikawa’s 6M [39] mnemonic in mind, Manpower, Method, Machine, Material, Milieu and Measurement. This addition would add a further dimension to the framework and thus leaves room for complication and audit duration concerns (46 third level attributes being approached using 6M results in a staggering 276 attributes to consider). However, the addition of a 6M layer could resolve the issue of the lack of “culture and people” attributes, as it would encourage each attribute to be approached from a “man” perspective.

The most divisive question was concerning whether the content was “missing any key attributes?”. Three out of seven respondents answered ‘Yes’ and four answered ‘No’. Interestingly, the majority of “No” respondents were those of less experience. This is to be expected and could indicate a lack of confidence in forming own opinions at such an early stage in the respondents’ careers. One of the “Yes” respondents mentioned the lack of a mental wellbeing attribute. Another mentioned the lack of a personal protective equipment specific attribute.

The final question queried whether the respondent knew of “another industry this framework could be adapted to?”. This question yielded varying answers as it was a free-text field. Comments ranged from “most industries I’ve worked in”, and “any type of construction or manufacturing industry”, to “the textiles/fashion industry”. The answers to this question were particularly enlightening as they painted a picture that the respondents viewed the Safety Framework as very generalised, especially when combined with previous comments regarding the lack of metal manufacturing specific attributes. Improvements were required to tailor the framework even further towards the metal manufacturing industry.

5.4. Improvements

Upon receiving the interview survey responses, numerous changes were made to the Safety Framework. Firstly, a title and short instruction was added which explained how the Safety Framework was intended to be used. The instruction stated “The Safety Framework foundation was built upon Deming’s sequential PDCA improvement cycle, and therefore must be used in exactly that order i.e., first consult the Plan section (first, second, and then third level attributes), then the Do section, next the Study section, and finally the Action section. The Safety Framework is intended to be used as a basis for an internal facility audit, leaving it for the User to decide whether to qualitatively or quantitively score each element”.

The next improvement made to the Safety Framework was to recolour the table in black and white. This new colour scheme made visibility easier for colour-blind people, and also looked more professional. Another minor improvement was made by expanding the acronym SMS to Safety Management System. A final minor improvement was to improve the quality of the Safety Framework image for the User.

Bearing in mind the interview comment “Mental wellbeing of our employees is a key factor in keeping everyone in our workplace safe. I can’t see anything about employee wellbeing in the framework”. It was decided to add an additional third level attribute to the Safety Framework, namely Employee Support Programme. This new attribute is located within the 1st Level Do, 2nd Level Education and Training. The addition of the Employee Support Programme attribute puts more focus on the emotional wellbeing of the employees. As discovered by Jame Chenarboo et al. [12], an employee with ill physical or mental state is more at risk to accidents when compared with that of a sound-minded person. Obviously, the scale of a person’s state of mind is very subjective and complex. It could be suggested to begin with a simple measuring tool such as a regular employee questionnaire, with answers in the format of a Likert scale, similar to Huo and Jiang’s approach [40].

The final Safety Framework can be seen in Table A4. The final framework had four first level attributes, 13 s level attributes, and 37 third level attributes.

6. Conclusions, Limitations and Future Scope

A Safety Framework designed to measure the safety performance (and therefore reduce accidents in the workplace) of metal manufacturing facilities has been developed based upon the original framework proposed for the paint industry by Chang and Liang [18] and the MAVT approach. The framework is more user-friendly for the auditor because it is bespoke to the metal manufacturing industry and has only 37 third-level attributes as opposed to 276.

Referring back to the three objectives defined in Section 2, the following conclusions can be made:

- The Safety Framework is up-to-date and aligns to both ILO and BSI standards. First, second and third level attributes were adapted to be relevant for the metal manufacturing industry. The most significant safety attributes can be determined as the attributes that have remained in the framework post legislation update.

- The final Safety Framework has been deemed relevant for the Metal Manufacturing Sector by Industry SQEP personnel. The majority of Interviewees deemed the Safety Framework to have a clear layout and easy to understand.

- The main findings of the Validation suggested the importance of having an emphasis on employee welfare and health, in an effort to reduce accidents in the workplace. This was taken into consideration and an extra attribute (relating the employee welfare) added to the third level of the Safety Framework.

A benefit of this research is that it has proved useful through adapting and updating a pre-determined Safety Framework (for the paint industry) and making it relevant for a different industry (the metal manufacturing industry). This provides confidence in the opportunity to further adapt the new Safety Framework for other industry sectors. It also encourages continuous improvement of pre-determined research, as opposed to starting from scratch every time, and therefore wasting valuable time and resources.

One sustained disadvantage (from the original framework) is that no incentive factor has been explored within the attributes, as well as the effectiveness of either safety incentive or disincentives. With the recent COVID-19 pandemic, and a company’s safety largely in the hands of their employees and subsequent willingness to test, there should be a surplus of data within industry to explore incentive factors.

The framework is complimentary to companies that have already adopted a safety management system in line with BSI’s three essential elements (Product, Process, and People) such as ISO 45001. This is an advantage to said companies as they are already aligned to the foundation of the Safety Framework, however this is a disadvantage to companies whose safety management system is derived from other principles.

A final limitation of the framework is the number of third level attributes that require on-site evaluation. Alternatively, the digital push that COVID-19 encouraged (to mitigate germ spread) could combat this timely issue. Shop floor tablets, pooled laptops and personal devices mean digital auditing is a far more accessible option than ever before.

Future work could focus on retrieving more industry-SQEP opinions, further defining the criteria for scoring the different elements, and testing the validity of the framework on more facilities in the metal manufacturing industry.

Future work should also explore interactions between attributes, as understanding how different elements influence each other could offer deeper insights into systemic safety risks and intervention points.

It would be particularly interesting to approach elements of the Safety Framework audits from a factorial design method as opposed to experimental design. Looking at interactions between some of the attributes may yield useful trends, indicating facility future focus areas to de-risk. However, careful consideration would need to be made in terms of timeframes as factorial design can be costly and impractical.

Another topic of future research could delve further into the employee wellbeing attribute. Many businesses enforce thresholds on e.g., alcohol and drugs to safeguard against the effects these have on human physical and cognitive performance. Research has proven the significant effect that fatigue and alcohol have on human performance [41]. Artisan manufacturing plants with limited onsite robotics (due to perhaps long lead items or complex product manufacture) may have a lack of automation. This can result in a heavy reliance on human performance, making employee wellbeing (including workplace fatigue) a critical factor in the safety of the company employees. An individual’s sleep duration and quality cannot be controlled as easily as their decision to ingest/not ingest a substance. It would be interesting to explore whether there are particular groups at-risk.

Additionally, while the current validation was conducted through industry expert interviews to ensure the framework’s relevance, future work should incorporate case studies with descriptive and inferential statistical analysis. This would provide deeper insights into the framework’s effectiveness and strengthen the validation process. Expanding the validation through empirical data across multiple organisations and industry settings would enhance the framework’s applicability and generalisability.

Ultimately, the aim is to further update and develop Safety Frameworks across numerous different industry sectors to further reduce accidents and minimise risks in the workplace. Additionally, the structure of the proposed Safety Framework shows considerable alignment with elements of CSA Z-767:2024 (Process Safety Management). This similarity provides external validation of the framework’s comprehensiveness and relevance, particularly for high-risk industrial settings.

Author Contributions

Conceptualization, A.E. and S.S.; methodology, A.E., S.S. and H.T.; software, A.E., S.S. and S.G.; validation, K.S., S.S. and S.J.; formal analysis, A.E., S.S., H.T. and S.G.; investigation, A.E. and S.S.; resources, K.S.; data curation, A.E.; writing—original draft preparation, A.E. and S.S.; writing—review and editing, S.J.; visualization, A.E.; supervision, K.S. and S.J.; project administration, S.S.; funding acquisition, S.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was reviewed and approved by the Cranfield University Research Ethics Committee (CURES) on 4 November 2023 (approval date), for research conducted by Alexandra Eggleston (Approval number: CURES/18173/2023).

Informed Consent Statement

Informed consent was obtained from all participants involved in this study.

Data Availability Statement

The data presented in this study is available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

List of key Words.

Table A1.

List of key Words.

| Keyword | Alternatives/Synonyms |

|---|---|

| Accident * | Accidents |

| Case study | |

| Categor * | Category, Categories |

| Classif * | Classification, Classify |

| Conceptual | |

| Construction | |

| Culture | |

| Defence | |

| Defence-in-depth | |

| Defense | |

| Factor * | Factors |

| Framework * | Frameworks, Model |

| Functional | |

| Industr * | Industry, Industries, Industrial |

| Manage * | Management |

| Manufactur * | Manufacture, Manufacturing, Manufactured |

| Nuclear | |

| Occupation * | Occupational, Occupations |

| Organi * | Organisation, Organization |

| ORSAC | Overall Safety Concept |

| Risk | |

| Safe * | Safety |

| Work * | Workplace |

Note: The asterisk * symbol acts as a wildcard, representing any number of characters after the root word. For example, if you search for “accident” it would likely return results for “accident”, “accidents”, and “accidental”.

Table A2.

Colour Coding Example of Original Sources.

Table A2.

Colour Coding Example of Original Sources.

| Original 2nd Level Attributes | Original Source(s) Not Relevant, Updated, Remains Relevant | New 2nd Level Attributes | New Source |

|---|---|---|---|

| High-level commitment | [42]; [43]; [44]; [45]; [46]; [47], [48]; | 6.1 Actions to address risks and opportunities [49] 6.1 OH&S objectives and planning to achieve them [49] 6.1 Hazard identification and assessment of risks and opportunities [49] 6.1 Determination of legal requirements and other requirements [49] 6.1 Planning action [49] 3.5 Occupational safety and health management system in the organisation [50] | [49]; [50]; |

| Organization and responsibility | [45]; [46]; [51]; [52]; [53]; [31]; [48]; | 6.2 OH&S objectives [49] 6.2 Planning how to achieve OH&S objectives [49] 3.3 Responsibility and accountability [50] | [49]; [50]; |

| Laws and regulations | [46]; [53]; [31]; | EN 292: Part 1: 1991—Safety of machinery. Basic concepts, general principles for design [54] EN 292: Part 2: 1991—Safety of machinery. Technical principles and specifications [55] BS EN 1050: 1997—Safety of machinery. Risk assessment [56] | - |

| Risk assessment | [42]; [43]; [46]; [51]; [53]; [31]; [48]; | BS EN 292: Part 1: 1991—Safety of machinery. Basic concepts, general principles for design [54] BS EN 292: Part 2: 1991—Safety of machinery. Technical principles and specifications [55] BS EN 1050: 1997—Safety of machinery. Risk assessment [56] | - |

| Education and training | [43]; [57]; [46]; [48]; [53]; [31]; | 7.1 Resources [49] 3.4 Competence and training [50] | [49]; [50]; |

| Contractor management | [42], [46]; [48]; [43]; [45]; [53]; [31]; | 8.1 Operational planning and control [49] 8.1 Eliminating hazards and reducing OH&S risks [49] 5.1 Management of change [49] 5.1 Procurement (General, Contractors, & Outsourcing) [49] 3.10.5 Contracting [50] | [49]; [50]; |

| Emergency response | [42]; [46]; [48]; [43]; [51]; [58]; | 8.2 Emergency preparedness and response [49] 3.40 Hazard prevention [50] | [49]; [50]; |

| Self-inspection | [52] [53]; | 7.3 Awareness [49] | [49]; |

| Work permit | [42]; [46]; [52]; | 7.2 Competence [49] 3.4 Competence and training [50] | [49]; [50]; |

| Safety equipment management | [42]; [53]; [31]; | 7.5 Documented information [49] 3.5 Occupational safety and health management system documentation [50] | [49]; [50]; |

| Hazardous materials management | [52]; | ||

| Safety protection | [52]; [31]; | ||

| Communication | [42]; [46]; [48]; [43]; [47]; [58]; | 7.4 Internal/External communication [49] 3.6 Communication [50] | [49]; [50]; |

Table A3.

Original Safety Framework.

Table A3.

Original Safety Framework.

| 1st Level | 2nd Level | 3rd Level |

|---|---|---|

| Plan Planning | Personnel Commitment | Top Management Commitment Consultation and Participation of Workers |

| Organisation and Responsibility | Safety Objectives Responsibility and accountability | |

| Standards Compliance | Legal requirements Other requirements | |

| Risk Assessment | Physical factors (machinery, infrastructure, substances) Social factors (working time directive, culture) External factors (weather, emergencies) | |

| Do Support & Operation | Education and Training | Available Resources Competence and training |

| Contractor Management | Contractor Management | |

| Emergency Response | Preparation Response Recovery & reconstruction | |

| Work Permit | Display Suspension Permit interaction Handover/Hand-back Permit authorisation and supervision | |

| Communication | Internal External | |

| Study Performance Evaluation | Environment Monitoring | Monitoring Measurement Analysis & Evaluation |

| Accident Investigation | Identify Failures (of current SMS) Personnel Investigation Results Communication Corrective Action Reports Produced | |

| Safety Audit | Internal External | |

| Action Improvement | Continuous Improvement | Technology (machines, materials) Processes (improved and standardised practices) People (worker capabilities or competence) Performance |

Table A4.

Post-Validation Safety Framework.

Table A4.

Post-Validation Safety Framework.

| Instructions: The Safety Framework foundation was built upon Deming’s sequential PDCA improvement cycle, and therefore must be used in exactly that order i.e., first consult the Plan section (first, second, and then third level attributes), then the Do section, next the Study section, and finally the Action section. The Safety Framework is intended to be used as a basis for an internal facility audit, leaving it for the User to decide whether to qualitatively or quantitatively score each element. | ||

| 1st Level Attributes | 2nd Level Attributes | 3rd Level Attributes |

| Plan Planning | Personnel Commitment | Top Management commitment Consultation and participation of workers |

| Organisation and Responsibility | Safety objectives Responsibility and accountability | |

| Standards Compliance | Legal requirements Other requirements | |

| Risk Assessment | Physical factors (machinery, infrastructure, substances) Social factors (working time directive, culture) External factors (weather, emergencies) | |

| Do Support & Operation | Education and Training | Available Resources Competence and training Employee Support Programme |

| Contractor Management | Contractor Management | |

| Emergency Response | Preparation Response Recovery & reconstruction | |

| Work Permit | Display Suspension Permit interaction Handover/Hand-back Permit authorisation and supervision | |

| Communication | Internal External | |

| Study Performance Evaluation | Environment Monitoring | Monitoring Measurement Analysis & Evaluation |

| Accident Investigation | Identify Failures (of current Safety Management System) Personnel Investigation Results Communication Corrective Action Reports Produced | |

| Safety Audit | Internal External | |

| Action Improvement | Continuous Improvement | Technology (machines, materials) Processes (improved and standardised practices) People (worker capabilities and competence) Performance |

Table A5.

Interview Survey.

Table A5.

Interview Survey.

1. Interviewee

|

2. Feasibility of the framework content

|

3. Feasibility of the framework language

|

4. Feasibility of the framework presentation

|

5. Adaptability

|

Table A6.

Interview Survey Response.

Table A6.

Interview Survey Response.

| Interview 1 | Interview 2 | Interview 3 | Interview 4 | Interview 5 | Interview 6 | Interview 7 | |

|---|---|---|---|---|---|---|---|

| 1. Interviewee | |||||||

| Code | S1 | S1 | E1 | E2 | S3 | E1 | E3 |

| What sector do you work in? | Shipbuilding | Ship Building | Engineering/Manufacturing | Defence | Ship Building | Defence | Public Sector |

| How many years’ experience do you have in your sector? | 0–2 years | 6–10 years | 6–10 years | 3–5 years | 6–10 years | 3–5 years | 21+ years |

| 2. Feasibility of the framework content | |||||||

| Is the content relevant? | Yes | Yes | No | Yes | Yes | Yes | Yes |

| Is the content current? | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Is the content missing any key factors? | Yes, I can’t see anything about PPE, maybe it fits into one of the current categories? | Yes, mental wellbeing of our employees is a key factor in keeping everyone in our workplace safe. I can’t see anything about employee wellbeing in the framework. | No | Yes | No | Yes | Yes |

| How could the framework be improved? | Some more specific risks around metal manufacturing facilities, it still seems quite generic | To include more factors relating to culture and people. | A priority list or ranking of each factor. | References to relevant documents might be useful (although this may clutter the framework) | Some context around each section/level | Some instructions on how to use the framework would be useful. I’d assume it’s like a checklist of things to assess for each facility. I would be interested to know the sources of each factor. | I think the framework is missing some specialised 2nd and 3rd levels for metal manufacturing facilities specifically |

| 3. Feasibility of the framework | |||||||

| Is the content easily understood? | Yes | No | Yes | Yes | Yes | Yes | Yes |

| How could this be improved? | It would be good to remove the acronym SMS, or write it out fully, I don’t know what this is | I don’t understand how to use the safety framework, is it a checklist? Does it need accompanying guidelines? Is there a final score? | No comments made | I think the framework would benefit from a sentence or two of context/how it is to be used/implemented. | Some justification and context as mentioned above. Just to be clear how it relates into the level above. | The language is easily understood. | The language is clear |

| 4. Feasibility of the framework | |||||||

| Is the layout clear? | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| How could this be improved? | It could be presented as a tree diagram working from the top level down, as opposed to left-to-right | I think the framework is clear | Have the layout more clear to the user. Have reference to where you get info i.e. the HSE or who regulates it etc. | The text is a bit out of focus and on the small side | No comments made | It’s a bit blurry when blown up. | I don’t think the framework needs colour, a simple black and white table would suffice. |

| 5. Adaptability | |||||||

| Can you think of another industry this framework could be adapted to? | I think it could be used in the textiles/fashion industry. It would be good to outline attributes that are specific to the metal industry, so that other industries would easily know to adapt/change that specific category but could trust that the rest of the framework is suitable for their industry. | Any of our facilities on site, large steelwork construction, woodwork facilities, it would probably need developing for anything electrical | No | I think this framework could be easily applied to most manufacturing and construction based industries. | Most industries I’ve worked in could benefit. Heavy engineering such as ship building would especially benefit. | I’d imagine any manufacturing industry could adopt this framework. | Any type of construction or manufacturing industry could likely use this safety framework as it is quite generalised. |

References

- Brinia, V.; Efstathiou, M. Evaluation of factors affecting training transfer on safety in the workplace: A case study in a big factory in Greece. Ind. Commer. Train. 2012, 44, 223–231. [Google Scholar] [CrossRef]

- LED Controls. The Future of Factory Automation: Industrial Robotics & Autonomous Systems|LED Controls Blog. Available online: https://www.ledcontrols.co.uk/blog/the-future-of-factory-automation-industrial-robotics-autonomous-systems/ (accessed on 13 August 2024).

- Symon, G.; Clegg, C.W. Technology-led change: A study of the implementation of CADCAM. J. Occup. Psychol. 1991, 64, 273–290. [Google Scholar] [CrossRef]

- Leso, V.; Fontana, L.; Iavicoli, I. The occupational health and safety dimension of Industry 4.0. Med. Lav. 2018, 110, 327–338. [Google Scholar] [CrossRef] [PubMed]

- Alqudhaibi, A.; Aloseel, A.; Jagtap, S.; Salonitis, K. Identifying and Predicting Cybersecurity Threats in Industry 4.0 Based on the Motivations Towards a Critical Infrastructure. In Advances in Manufacturing Technology XXXV; IOS Press: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Alqudhaibi, A.; Albarrak, M.; Aloseel, A.; Jagtap, S.; Salonitis, K. Predicting Cybersecurity Threats in Critical Infrastructure for Industry 4.0: A Proactive Approach Based on Attacker Motivations. Sensors 2023, 23, 4539. [Google Scholar] [CrossRef]

- Alqudhaibi, A.; Deshpande, S.; Jagtap, S.; Salonitis, K. Towards a sustainable future: Developing a cybersecurity framework for manufacturing. Technol. Sustain. 2023, 2, 372–387. [Google Scholar] [CrossRef]

- HSE. Work-Related Fatal Injuries in Great Britain. Available online: https://www.hse.gov.uk/statistics/assets/docs/fatalinjuries.pdf (accessed on 6 May 2024).

- Diamond, L.M.; Alley, J. Rethinking minority stress: A social safety perspective on the health effects of stigma in sexually-diverse and gender-diverse populations. Neurosci. Biobehav. Rev. 2022, 138, 104720. [Google Scholar] [CrossRef]

- Steffey, M.A.; Griffon, D.J.; Risselada, M.; Buote, N.J.; Scharf, V.F.; Zamprogno, H.; Winter, A.L. A narrative review of the physiology and health effects of burnout associated with veterinarian-pertinent occupational stressors. Front. Vet. Sci. 2023, 10, 1184525. [Google Scholar] [CrossRef]

- Karatepe, O.M.; Saydam, M.B.; Okumus, F. COVID-19, mental health problems, and their detrimental effects on hotel employees’ propensity to be late for work, absenteeism, and life satisfaction. Curr. Issues Tour. 2021, 24, 934–951. [Google Scholar] [CrossRef]

- Chenarboo, F.J.; Hekmatshoar, R.; Fallahi, M. The influence of physical and mental workload on the safe behavior of employees in the automobile industry. Heliyon 2022, 8, e11034. [Google Scholar] [CrossRef]

- AC Operational Policy and Assurance. Improving the Operational Safety Management Model. London, August 2020. Available online: https://www.london-fire.gov.uk/media/5387/lfc-0374-safety-management-model.pdf (accessed on 4 August 2024).

- Office for National Statistics. Manufacturing and Production Industry—Office for National Statistics. Available online: https://www.ons.gov.uk/businessindustryandtrade/manufacturingandproductionindustry (accessed on 29 January 2025).

- Innova Search. Health, Safety & Environmental|Innova-Search. Available online: https://www.innova-search.co.uk/health-safety-and-environmental (accessed on 4 August 2024).

- Carthey, J. Measurement and Monitoring of Safety Framework (MMSF): Learning from its implementation in Canada. BMJ Qual. Saf. 2023, 32, 441–443. [Google Scholar] [CrossRef]

- Welsh Government. Quality and Safety Framework: Learning and Improving. 2021. Available online: https://www.gov.wales/sites/default/files/publications/2021-09/quality-and-safety-framework-learning-and-improving_0.pdf (accessed on 4 August 2024).

- Chang, J.I.; Liang, C.-L. Performance evaluation of process safety management systems of paint manufacturing facilities. J. Loss Prev. Process. Ind. 2009, 22, 398–402. [Google Scholar] [CrossRef]

- Manufacturing Operations Management. A Brief History of Smart Manufacturing (Manufacturing Operations Management Talk). Available online: https://www.manufacturing-operations-management.com/manufacturing/2021/06/a-brief-history-of-smart-manufacturing.html (accessed on 5 August 2024).

- Aminbakhsh, S.; Gunduz, M.; Sonmez, R. Safety risk assessment using analytic hierarchy process (AHP) during planning and budgeting of construction projects. J. Saf. Res. 2023, 46, 99–105. [Google Scholar] [CrossRef] [PubMed]

- Quality One. Process FMEA|Process Failure Mode & Effects Analysis|Quality-One. Available online: https://quality-one.com/pfmea/ (accessed on 5 August 2024).

- Tabibzadeh, M.; Khashe, Y.; Somaiya, P. A Proactive Risk Analysis Framework to Enhance Safety and Reliability in Railroad Operations: Assessment of the Positive Safety Culture Traits. In Advances in Human Aspects of Transportation: Proceedings of the AHFE 2018 International Conference on Human Factors in Transportation, Loews Sapphire Falls Resort at Universal Studios, Orlando, FL, USA, 21–25 July 2018; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 625–636. [Google Scholar] [CrossRef]

- Omrany, H.; Al-Obaidi, K.M.; Husain, A.; Ghaffarianhoseini, A. Digital twins in the construction industry: A comprehensive review of current implementations, enabling technologies, and future directions. Sustainability 2023, 15, 10908. [Google Scholar] [CrossRef]

- VMT. Shadow Boards|Effective Workplace Organisation|VMT. Available online: https://v-m-t.co.uk/shadow-boards (accessed on 5 August 2024).

- Di Bona, G.; Silvestri, A.; De Felice, F.; Forcina, A.; Petrillo, A. An Analytical Model to Measure the Effectiveness of Safety Management Systems: Global Safety Improve Risk Assessment (G-SIRA) Method. J. Fail. Anal. Prev. 2016, 16, 1024–1037. [Google Scholar] [CrossRef]

- Cagno, E.; Di Giulio, A.; Trucco, P. Risk and causes-of-risk assessment for an effective industrial safety management. Int. J. Reliab. Qual. Saf. Eng. 2000, 107, 113–128. [Google Scholar] [CrossRef]

- Tong, D.Y.K.; Rasiah, D.; Tong, X.F.; Lai, K.P. Leadership empowerment behaviour on safety officer and safety teamwork in manufacturing industry. Saf. Sci. 2015, 72, 190–198. [Google Scholar] [CrossRef]

- Lean Plan, Do, Check, Act (PDCA)—A Resource Guide. Available online: https://www.lean.org/lexicon-terms/pdca/ (accessed on 4 August 2024).

- BSI. COVID-19—Guidelines|BSI. Available online: https://www.bsigroup.com/en-GB/topics/novel-coronavirus-covid-19/covid-19-guidelines/ (accessed on 13 August 2024).

- Nasa, P.; Jain, R.; Juneja, D. Delphi methodology in healthcare research: How to decide its appropriateness. World J. Methodol. 2021, 11, 116–129. [Google Scholar] [CrossRef]

- Teo, E.A.L.; Ling, F.Y.Y. Developing a model to measure the effectiveness of safety management systems of construction sites. Build. Environ. 2006, 41, 1584–1592. [Google Scholar] [CrossRef]

- Deming. PDSA Cycle—The W. Edwards Deming Institute. Available online: https://deming.org/explore/pdsa/ (accessed on 4 August 2024).

- Nagyova, A.; Balazikova, M.; Markulik, S.; Sinay, J.; Pacaiova, H. Implementation Proposal of OH&S Management System According to the Standard ISO/DIS 45001. Adv. Saf. Manag. Hum. Factors 2017, 604, 472–485. [Google Scholar] [CrossRef]

- HSE. Manufacturing Statistics in Great Britain, 2023. 2023. Available online: https://freshproduce.org.uk/files/manufacturing-stats-23.pdf (accessed on 27 May 2025).

- International Labour Organization. Guidelines on Occupational Safety and Health Management Systems. 2023. Available online: https://www.ilo.org/wcmsp5/groups/public/---ed_protect/---protrav/---safework/documents/normativeinstrument/wcms_107727.pdf (accessed on 4 August 2024).

- Marhavilas, P.K.; Pliaki, F.; Koulouriotis, D. International Management System Standards Related to Occupational Safety and Health: An Updated Literature Survey. Sustainability 2022, 14, 13282. [Google Scholar] [CrossRef]

- British Standards Institution. Occupational Health and Safety Management (ISO 45001); British Standards Institution: London, UK, 2023; Available online: https://www.bsigroup.com/en-SE/search-results/?q=Occupational%20Health%20and%20Safety%20Management%20(ISO%2045001)&Page=1&tab=0&locale=en-SE (accessed on 27 May 2025).

- British Psychological Society. The Delphi Method. Available online: https://www.bps.org.uk/psychologist/delphi-method (accessed on 18 September 2024).

- Kaufman Global. 6Ms of Production (Man, Machine, Material, Method, Mother Nature and Measurement)—Kaufman Global. Available online: https://www.kaufmanglobal.com/glossary/6ms-production-man-machine-material-method-mother-nature-measurement/ (accessed on 4 August 2024).

- Huo, M.-L.; Jiang, Z. Work–life conflict and job performance: The mediating role of employee wellbeing and the moderating role of trait extraversion. Personal. Individ. Differ. 2023, 205, 112109. [Google Scholar] [CrossRef]

- Sawicki, M.; Szóstak, M. Impact of Alcohol on Occupational Health and Safety in the Construction Industry at Workplaces with Scaffoldings. Appl. Sci. 2020, 10, 6690. [Google Scholar] [CrossRef]

- U.S. Department of Labor; Occupational Safety and Health Administration. Process Safety Management of Highly Hazardous Chemicals; Final Rule. Fed. Regist. 1992, 57, 6356–6417. [Google Scholar]

- Lemm, T.C. DuPont Safety Management in a Re-Engineered Corporate Culture. ASME Citrus Eng. Symp. 1996, 99830, 16–26. [Google Scholar]

- Marsh, T.; Davies, R.; Phillips, R.; Duff, R.; Robertson, I.; Weyman, A.; Cooper, D. The Role of Management Commitment in Determining the Success of a Behavioural Safety Intervention. J.-Inst. Occup. Saf. Health 1998, 2, 45–56. [Google Scholar]

- McDonald, N.; Corrigan, S.; Daly, C.; Cromie, S. Safety Management Systems and Safety Culture in Aircraft Maintenance Organisations. Saf. Sci. 2000, 34, 151–176. [Google Scholar] [CrossRef]

- Machida, S.; Bachoo, P. Guidelines on Occupational Safety & Health Management Systems. Afr. News Lett. Occup. Health Saf. 2001, 11, 68–69. [Google Scholar]

- Mearns, K.; Flin, R.; Gordon, R.; Fleming, M. Human and Organizational Factors in Offshore Safety. Work Stress 2001, 15, 144–160. [Google Scholar] [CrossRef]

- BS 8800:2007; Guide to Occupational Health & Safety Management Systems. British Standards Institution (BSI): London, UK, 2007.

- BS ISO 45001:2018; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. British Standards Institution (BSI): London, UK, 2018.

- International Labour Office (ILO). Guidelines on Occupational Safety Uidelines on Occupational Safety and Health Management Systems Nd Health Management Systems ILO-OSH 2001; International Labour Office (ILO): Geneva, Switzerland, 2009. [Google Scholar]

- Basso, B.; Carpegna, C.; Dibitonto, C.; Gaido, G.; Robotto, A.; Zonato, C. Reviewing the Safety Management System by Incident Investigation and Performance Indicators. J. Loss Prev. Process. Ind. 2004, 17, 225–231. [Google Scholar] [CrossRef]

- Hong, Y.; Lin, Y.; Pai, H.; Lai, Y.; Lee, I. Developing a Safety and Health Training Model for Petrochemical Workers. Kaohsiung J. Med. Sci. 2004, 20, 56–61. [Google Scholar] [CrossRef]

- Thomas Ng, S.; Pong Cheng, K.; Martin Skitmore, R. A Framework for Evaluating the Safety Performance of Construction Contractors. Build. Environ. 2005, 40, 1347–1355. [Google Scholar] [CrossRef]

- EN 292-1:1991; Safety of Machinery—Basic Concepts, General Principles for Design—Part 1: Basic Terminology, Methodology. European Committee for Standardization (CEN): Brussels, Belgium, 1991.

- EN 292-2:1991; Safety of Machinery—Basic Concepts, General Principles for Design×Part 2: Technical Principles and Specifications. European Committee for Standardization (CEN): Brussels, Belgium, 1991.

- BS EN 1050:1997; Safety of Machinery—Principles for Risk Assessment. British Standards Institution (BSI): London, UK, 1997.

- AIHA. AIHA Guideline Foundation. Available online: https://www.aiha.org/get-involved/aiha-guideline-foundation (accessed on 13 May 2025).

- Fernández-Muñiz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. Safety Culture: Analysis of the Causal Relationships between Its Key Dimensions. J. Saf. Res. 2007, 38, 627–641. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).