Circularity: Understanding the Environmental Tradeoffs of Additive Manufacturing with Waste Plastics

Abstract

1. Introduction

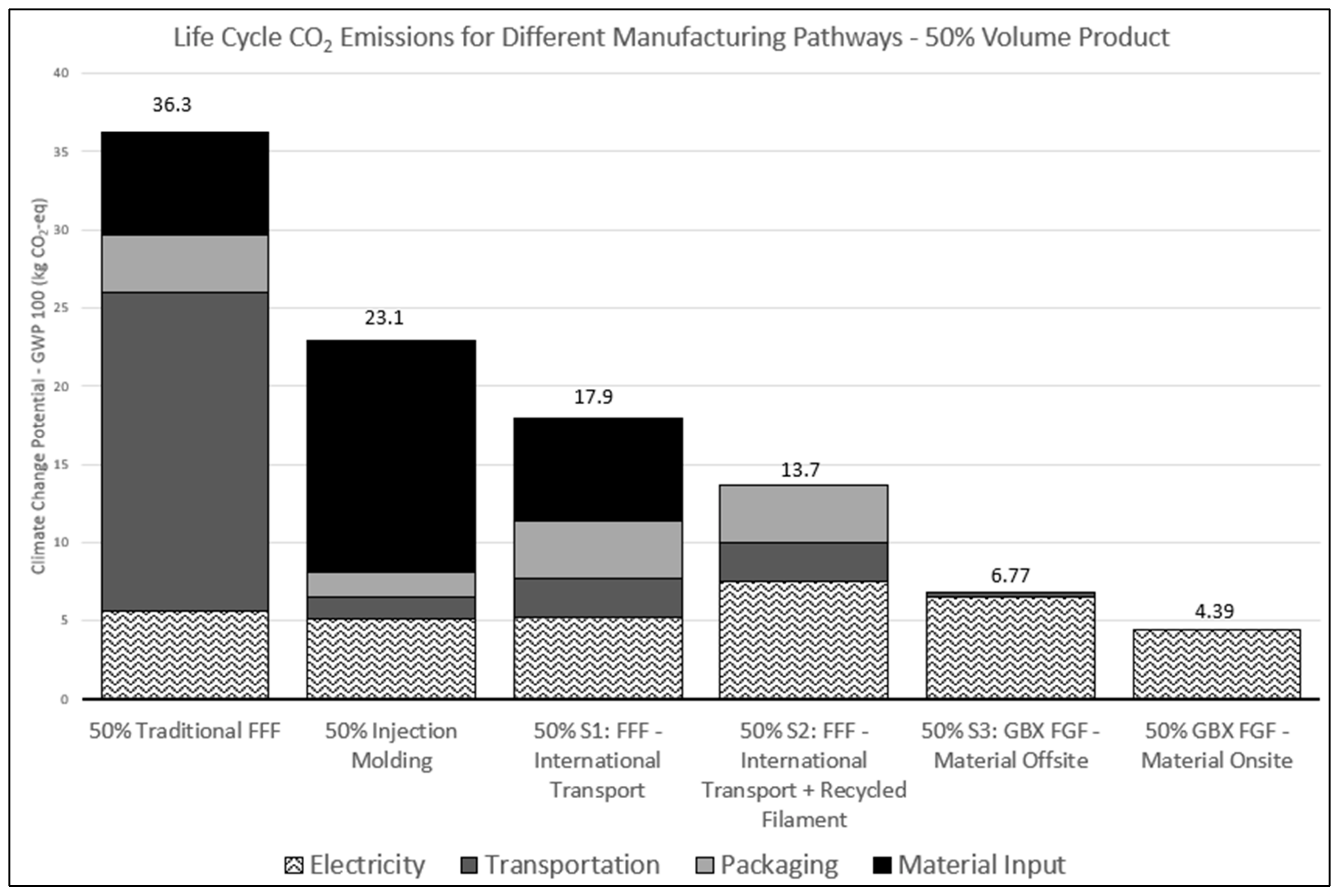

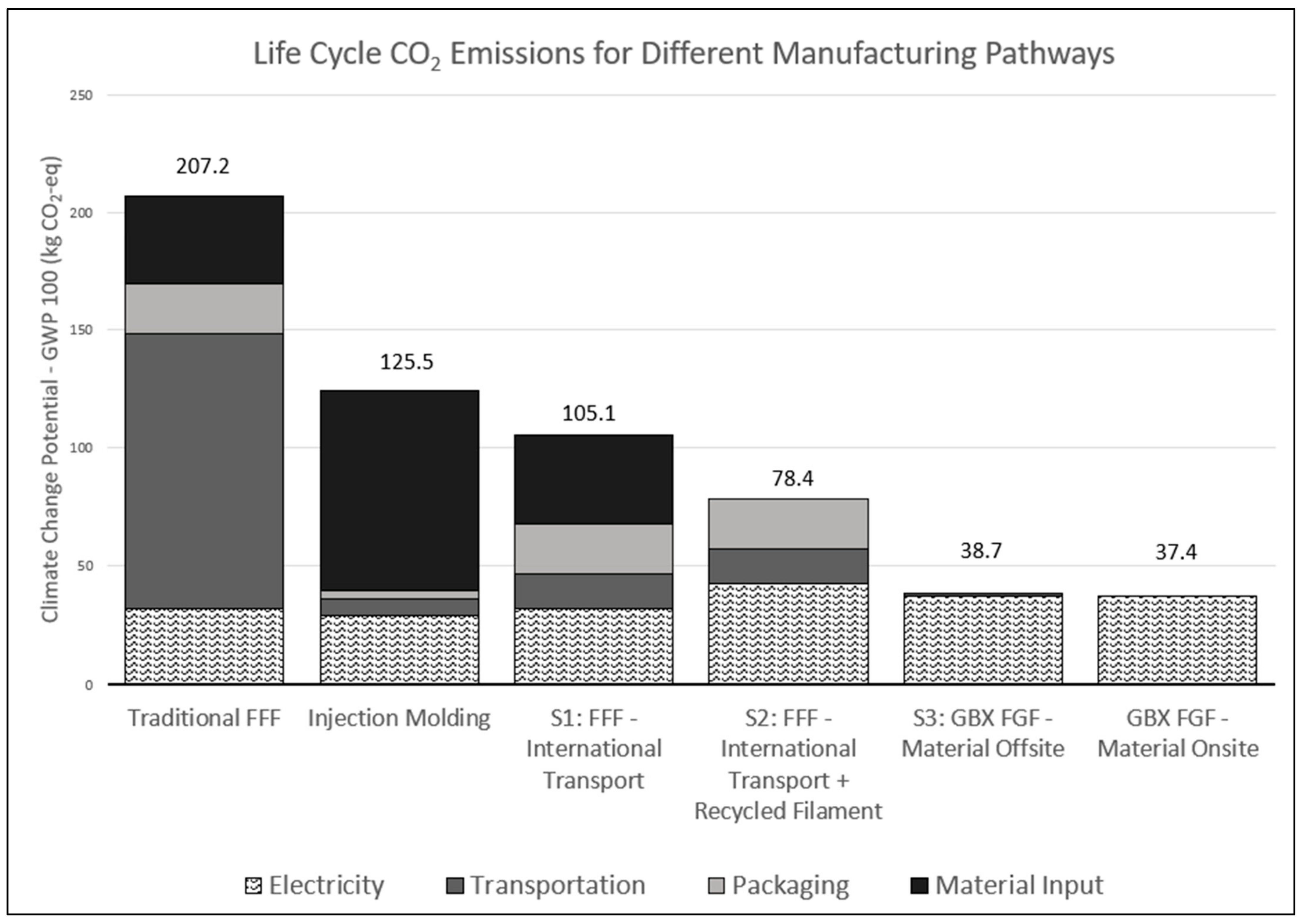

2. Results

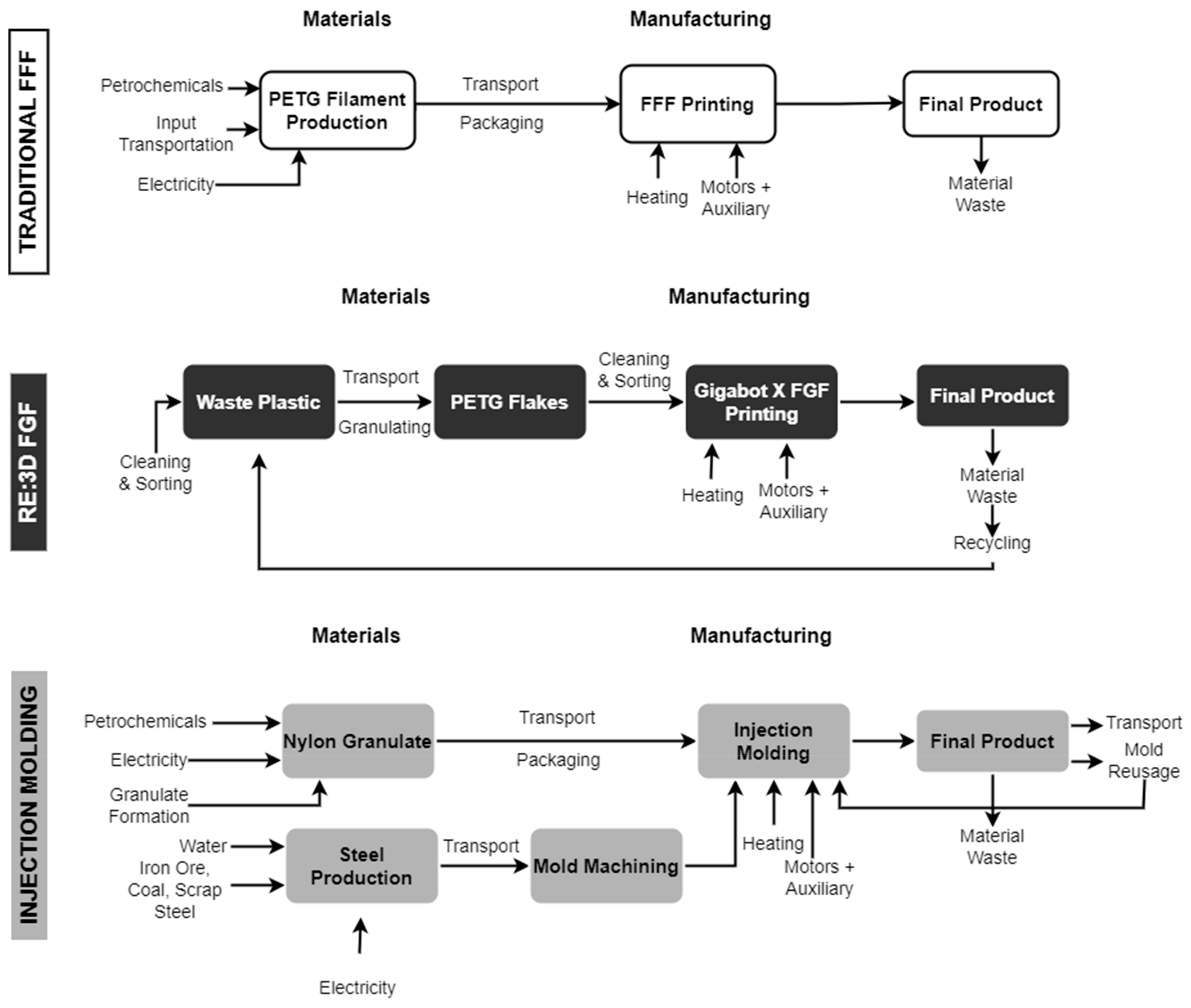

2.1. Goal and Scope of LCA

2.2. LCA Results

2.2.1. Transportation

2.2.2. Material Input

2.2.3. Packaging

2.2.4. Electricity

3. Materials and Methodology

3.1. LCA Methodology

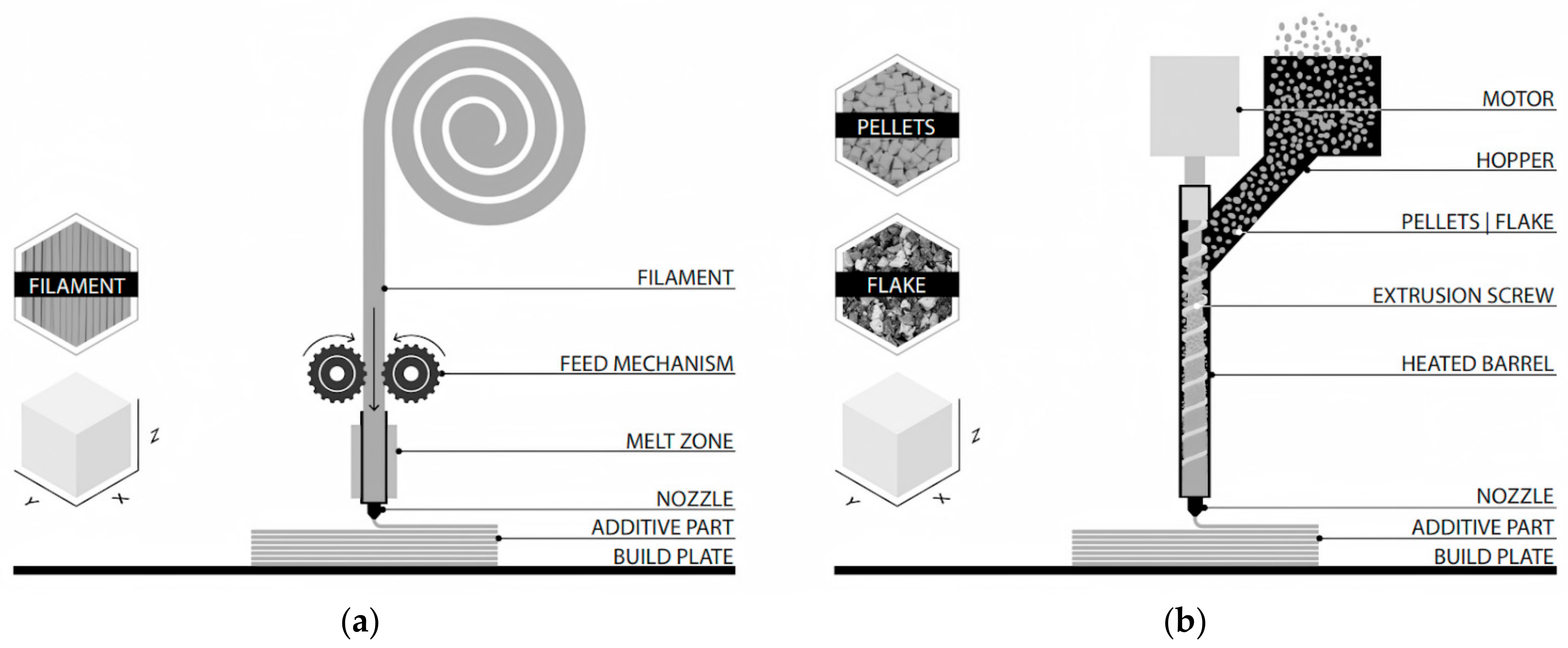

3.2. Traditional FFF

3.3. Gigabot X FGF

3.4. Scenario 1 (S1): Traditional FFF International

3.5. Scenario 2 (S2): Traditional FFF Recycled

3.6. Scenario 3 (S3): GBX FGF with Transport

3.7. Injection Molding

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Climate Change Potential—GWP 100 (kg CO2) | |||||||

|---|---|---|---|---|---|---|---|

| Electricity | Transportation | Packaging | Material Input | Steel Production | Waste Treatment | Total | |

| Traditional FFF | 31.82 | 116.55 | 21.03 | 37.47 | 0 | 0.37 | 207.24 |

| Fifty percent Traditional FFF | 5.61 | 20.37 | 3.68 | 6.55 | 0 | 0.07 | 36.27 |

| Injection Molding | 29.32 | 7.011 | 3.32 | 84.75 | 0.56 | 0.01 | 125.51 |

| Fifty percent Injection Molding | 5.12 | 1.34 | 1.66 | 14.81 | 0.10 | 0 | 23.14 |

| S1: FFF—International Transport | 32.08 | 14.57 | 21.03 | 37.47 | 0 | 0.37 | 105.14 |

| Fifty percent S1: FFF—International Transport | 5.18 | 2.53 | 3.68 | 6.55 | 0 | 0.07 | 17.93 |

| S2: FFF—International Transport + Recycled Filament | 42.82 | 14.57 | 21.03 | 0 | 0 | 0 | 78.42 |

| Fifty percent S2: FFF—International Transport + Recycled Filament | 7.48 | 2.53 | 3.68 | 0 | 0 | 0 | 13.69 |

| S3: FGF—Material Offsite | 37.43 | 1.32 | 0 | 0 | 0 | 0 | 38.74 |

| Fifty percent S3: FGF—Material Offsite | 6.54 | 0.23 | 0 | 0 | 0 | 0 | 6.77 |

| GBX FGF—Material Onsite | 37.43 | 0 | 0 | 0 | 0 | 0 | 37.43 |

| Fifty percent GBX FGF—Material Onsite | 4.39 | 0 | 0 | 0 | 0 | 0 | 4.39 |

Appendix C

| Traditional FFF | ||

|---|---|---|

| Step | Ecoinvent Inputs/Outputs | Value |

| PETG Filament Production | polyethylene terephthalate production, granulate, bottle grade|polyethylene terephthalate, granulate, bottle grade|Cutoff, U—US | 1.00 kg |

| electricity, low voltage—|Cutoff, U—US-MRO | 0.36 kWh | |

| acrylonitrile-butadiene-styrene copolymer production|acrylonitrile-butadiene-styrene copolymer|Cutoff, U—RoW | 0.32 kg | |

| extrusion, plastic film|extrusion, plastic film|Cutoff, U—RoW | 0.07 kg | |

| white lined chipboard carton production|white lined chipboard carton|Cutoff, U—RoW | 0.08 kg | |

| transport, freight, light commercial vehicle|transport, freight, light commercial vehicle|Cutoff, U—RoW | 2.20 t·km | |

| Printing | market for electricity, low voltage|electricity, low voltage|Cutoff, U—US-TRE | 4641.96 Wh |

| transport, freight, light commercial vehicle|transport, freight, light commercial vehicle|Cutoff, U—RoW | 2.11 t·km | |

| treatment of waste polyethylene terephthalate, sanitary landfill|waste polyethylene terephthalate|Cutoff, U—RoW | 0.33 kg | |

| T: Packaging Waste (original flow) | 0.47 kg | |

| Traditional FFF | |||

|---|---|---|---|

| Step | Ecoinvent Inputs/Outputs | S1 | S2 |

| PETG Filament Production | polyethylene terephthalate production, granulate, bottle grade|polyethylene terephthalate, granulate, bottle grade|Cutoff, U—US | 1.00 kg | 0 kg |

| market for electricity, low voltage|electricity, low voltage|Cutoff, U—CN-CCG | 0.36 kWh | 1.09 kWh | |

| acrylonitrile-butadiene-styrene copolymer production|acrylonitrile-butadiene-styrene copolymer|Cutoff, U—RoW | 0.32 kg | 0.32 kg | |

| extrusion, plastic film|extrusion, plastic film|Cutoff, U—RoW | 0.07 kg | 0.07 kg | |

| white lined chipboard carton production|white lined chipboard carton|Cutoff, U—RoW | 0.08 kg | 0.08 kg | |

| transport, freight, light commercial vehicle|transport, freight, light commercial vehicle|Cutoff, U—RoW | 0.10 t·km | 0.10 t·km | |

| Printing | market for electricity, low voltage|electricity, low voltage|Cutoff, U—US-TRE | 4641.96 Wh | 4641.96 Wh |

| transport, freight, light commercial vehicle|transport, freight, light commercial vehicle|Cutoff, U—RoW | 0.37 t·km | 0.37 t·km | |

| transport, freight, sea, container ship|transport, freight, sea, container ship|Cutoff, U—GLO | 13.47 t·km | 13.47 t·km | |

| treatment of waste polyethylene terephthalate, sanitary landfill|waste polyethylene terephthalate|Cutoff, U—RoW | 0.33 kg | 0.33 kg | |

| T: Packaging Waste (original flow) | 0.47 kg | 0.47 kg | |

| GBX FGF | |||

|---|---|---|---|

| Step | Ecoinvent Inputs/Outputs | FGF | S3: Local Transport |

| PETG Flake Production | U: PETG Flake Source (original flow) | 1.00 kg | 1.00 kg |

| market for electricity, low voltage|electricity, low voltage|Cutoff, U—US-TRE | 731.78 Wh | 731.78 Wh | |

| transport, freight, light commercial vehicle|transport, freight, light commercial vehicle|Cutoff, U—RoW | 0 t·km | 0.05 t·km | |

| Printing | market for electricity, low voltage|electricity, low voltage|Cutoff, U—US-TRE | 5144.84 Wh | 5144.84 Wh |

| Recycling | treatment of waste polyethylene terephthalate, sanitary landfill|waste polyethylene terephthalate|Cutoff, U—RoW * | −0.33 kg | −0.33 kg |

| IM | ||

|---|---|---|

| Step | Ecoinvent Inputs/Outputs | Value |

| Steel Production | market for electricity, low voltage|electricity, low voltage|Cutoff, U—CN-CCG | 31,128.78 MJ |

| market for steel, low-alloyed|steel, low-alloyed|Cutoff, U—GLO | 1004.15 kg | |

| Mold Machining (50,000 items) | market for electricity, low voltage|electricity, low voltage|Cutoff, U—CN-CCG | 1,287,377.30 kJ |

| transport, freight, light commercial vehicle|transport, freight, light commercial vehicle|Cutoff, U—RoW | 23.69 t·km | |

| Nylon Granulate Formation | market for electricity, low voltage|electricity, low voltage|Cutoff, U—CN-CCG | 6401.58 Wh |

| nylon 6 production|nylon 6|Cutoff, U—RoW | 8.75 kg | |

| Injection Molding | market for electricity, low voltage|electricity, low voltage|Cutoff, U—CN-CCG | 96.23 MJ |

| transport, freight, light commercial vehicle|transport, freight, light commercial vehicle|Cutoff, U—RoW | 0.27 t·km | |

| plastic granulate, unspecified, recycled | 0.39 kg | |

| treatment of waste plastic, mixture, sanitary landfill|waste plastic, mixture|Cutoff, U—RoW | 0.14 kg | |

| End Usage | transport, freight, light commercial vehicle|transport, freight, light commercial vehicle|Cutoff, U—RoW | 3.28 t·km |

| transport, freight, sea, bulk carrier for dry goods|transport, freight, sea, bulk carrier for dry goods|Cutoff, U—GLO | 117.65 t·km | |

| white lined chipboard carton production|white lined chipboard carton|Cutoff, U—RoW | 2.27 kg | |

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- OECD. Plastic Waste Projections to 2060. Available online: https://www.oecd.org/en/publications/2022/06/global-plastics-outlook_f065ef59/full-report/component-10.html (accessed on 21 June 2022).

- United States Environmental Protection Agency. National Overview: Facts and Figures on Materials, Wastes and Recycling [Overviews and Factsheets]. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials (accessed on 2 October 2017).

- Brooks, A.L.; Wang, S.; Jambeck, J.R. The Chinese import ban and its impact on global plastic waste trade. Sci. Adv. 2018, 4, eaat0131. [Google Scholar] [CrossRef]

- Cotteleer, M.; Joyce, J. 3D Opportunity: Additive manufacturing paths to performance, innovation, and growth. Deloitte Rev. 2014, 14, 3–19. [Google Scholar]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Kreiger, M.; Pearce, J.M. Environmental Life Cycle Analysis of Distributed Three-Dimensional Printing and Conventional Manufacturing of Polymer Products. ACS Sustain. Chem. Eng. 2013, 1, 1511–1519. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef]

- Telenko, C.; Conner Seepersad, C. A comparison of the energy efficiency of selective laser sintering and injection molding of nylon parts. Rapid Prototyp. J. 2012, 18, 472–481. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Kluppel, H.-J. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Y. Energy, time and material consumption modelling for fused deposition modelling process. Procedia CIRP 2020, 90, 510–515. [Google Scholar] [CrossRef]

- Ulkir, O. Energy-Consumption-Based Life Cycle Assessment of Additive-Manufactured Product with Different Types of Materials. Polymers 2023, 15, 1466. [Google Scholar] [CrossRef]

- Faludi, J.; Bayley, C.; Bhogal, S.; Iribarne, M. Comparing Environmental Impacts of Additive Manufacturing vs. Traditional Machining via Life-Cycle Assessment. Rapid Prototyp. J. 2015, 21, 14–33. [Google Scholar] [CrossRef]

- Faludi, J.; Hu, Z.; Alrashed, S.; Braunholz, C.; Kaul, S.; Kassaye, L. Does Material Choice Drive Sustainability of 3D Printing? Int. J. Mech. Aerosp. Ind. Mech. Eng. 2015, 9, 216–223. [Google Scholar]

- Shi, Y.; Faludi, J. Using life cycle assessment to determine if high utilization is the dominant force for sustainable polymer additive manufacturing. Addit. Manuf. 2020, 35, 101307. [Google Scholar] [CrossRef]

- Faludi, J.; Van Sice, C.M.; Shi, Y.; Bower, J.; Brooks, O.M.K. Novel materials can radically improve whole-system environmental impacts of additive manufacturing. J. Clean. Prod. 2019, 212, 1580–1590. [Google Scholar] [CrossRef]

- Faludi, J.; Cline-Thomas, N.; Agrawala, S. The Next Production Revolution, Implications for Government and Business—3D Printing and Its Environmental Implications; OECD Publishing: Paris, France, 2017; pp. 171–213. [Google Scholar] [CrossRef]

- Caceres-Mendoza, C.; Santander-Tapia, P.; Sanchez, F.A.; Troussier, N.; Camargo, M.; Boudaoud, H. Life Cycle Assessment of Filament Production in Distributed Plastic Recycling via Additive Manufacturing. Clean. Waste Syst. 2023, 5, 100100. [Google Scholar] [CrossRef]

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the Loop on the Circular Economy: Coupled Distributed Recycling and Manufacturing with Recyclebot and RepRap 3-D Printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life Cycle Analysis of Distributed Recycling of Post-Consumer High Density Polyethylene for 3-D Printing Filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Garcia, F.L.; Nunes, A.O.; Martins, M.G.; Belli, M.C.; Saavedra, Y.M.; Silva, D.A.; Moris, V.A. Comparative LCA of convention manufacturing vs additive manufacturing: The case of injection moulding for recycled polymers. Int. J. Sustain. Eng. 2021, 14, 1604–1622. [Google Scholar] [CrossRef]

- Alexandre, A.; Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Mechanical Properties of Direct Waste Printing of Polylactic Acid with Universal Pellets Extruder: Comparison to Fused Filament Fabrication on Open-Source Desktop Three-Dimensional Printers. 3D Print. Addit. Manuf. 2020, 7, 237–247. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef] [PubMed]

- Oladapo, B.I.; Bowoto, O.K.; Adebiyi, V.A.; Ikumapayi, O.M. Net Zero on 3D Printing Filament Recycling: A Sustainable Analysis. Sci. Total Environ. 2023, 894, 165046. [Google Scholar] [CrossRef] [PubMed]

- Byard, D.J.; Woern, A.L.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Green Fab Lab Applications of Large-Area Waste Polymer-Based Additive Manufacturing. Addit. Manuf. 2019, 27, 515–525. [Google Scholar] [CrossRef]

- Yassine, E. (Director). Attributional vs. Consequential LCA. Available online: https://www.youtube.com/watch?v=3Rj7IlustcQ (accessed on 31 May 2022).

- Enemuoh, E.U.; Menta, V.G.; Abutunis, A.; O’Brien, S.; Kaya, L.I.; Rapinac, J. Energy and Eco-Impact Evaluation of Fused Deposition Modeling and Injection Molding of Polylactic Acid. Sustainability 2021, 13, 1875. [Google Scholar] [CrossRef]

- Toor, R. How Much Plastic Waste Does 3D Printing Really Generate? Available online: https://www.filamentive.com/how-much-plastic-waste-does-3d-printing-really-generate/ (accessed on 1 December 2023).

- Aluminum Molds vs. Steel Molds | Plastic Injection Molding—Xcentric Mold. Available online: https://xcentricmold.com/aluminum-molds-vs-steel-molds/ (accessed on 13 October 2023).

- Thiriez, A.; Gutowski, T. An Environmental Analysis of Injection Molding. In Proceedings of the 2006 IEEE International Symposium on Electronics and the Environment 2006, Scottsdale, AZ, USA, 8–11 May 2006; pp. 195–200. [Google Scholar] [CrossRef]

- Injection Molding, Rigid Polypropylene Part, at Plant | GLAD. Available online: https://www.globallcadataaccess.org/injection-molding-rigid-polypropylene-part-plant (accessed on 13 October 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bilal, E.; Glazer, Y.R.; Sassaman, D.M.; Seepersad, C.C.; Webber, M.E. Circularity: Understanding the Environmental Tradeoffs of Additive Manufacturing with Waste Plastics. Recycling 2024, 9, 72. https://doi.org/10.3390/recycling9050072

Bilal E, Glazer YR, Sassaman DM, Seepersad CC, Webber ME. Circularity: Understanding the Environmental Tradeoffs of Additive Manufacturing with Waste Plastics. Recycling. 2024; 9(5):72. https://doi.org/10.3390/recycling9050072

Chicago/Turabian StyleBilal, Eesha, Yael R. Glazer, Doug M. Sassaman, Carolyn C. Seepersad, and Michael E. Webber. 2024. "Circularity: Understanding the Environmental Tradeoffs of Additive Manufacturing with Waste Plastics" Recycling 9, no. 5: 72. https://doi.org/10.3390/recycling9050072

APA StyleBilal, E., Glazer, Y. R., Sassaman, D. M., Seepersad, C. C., & Webber, M. E. (2024). Circularity: Understanding the Environmental Tradeoffs of Additive Manufacturing with Waste Plastics. Recycling, 9(5), 72. https://doi.org/10.3390/recycling9050072