Sustainable WPC Production: A Novel Method Using Recycled High-Density Polyethylene and Wood Veneer

Abstract

:1. Introduction

2. Results and Discussion

2.1. Development of WPC Panels

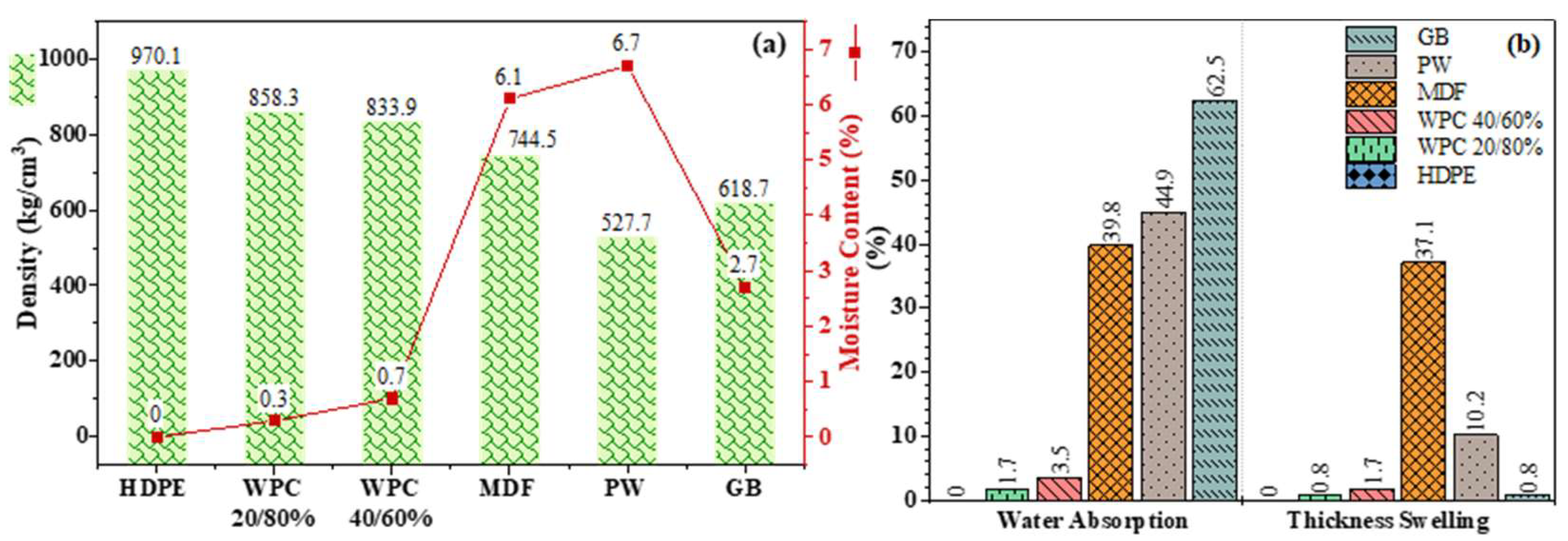

2.2. Density, Moisture Content, Water Absorption, and Thickness Swelling

2.3. Flexural Strength

3. Materials and Methods

3.1. Design and Elaboration of Panels

3.1.1. Materials

3.1.2. Sample Sizing and Steel Mold Manufacture

3.1.3. Manufacture of WPC Panels and Machining of Test Pieces

3.2. Physical-Mechanical Tests

Density and Moisture Content, Water Absorption, and Thickness Swelling

3.3. Flexural Strength

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hernádez Castillo, L.A.; Ángel Ortiz Lozano, J. La construcción de viviendas con el sistema Steel Framing en zonas de subsidencia: Pertinencia y Sustentabilidad. Labor Eng. 2014, 8, 52–61. [Google Scholar] [CrossRef]

- Zhan, Q.; Pungercar, V.; Musso, F.; Ni, H.; Xiao, Y. Hygrothermal investigation of lightweight steel-framed wall assemblies in hot-humid climates: Measurement and simulation validation. J. Build. Eng. 2021, 42, 103044. [Google Scholar] [CrossRef]

- Rahim, M.; Djedjig, R.; Wu, D.; Bennacer, R.; Ganaoui, M. Experimental investigation of hygrothermal behavior of wooden-frame house under real climate conditions. Energy Built Environ. 2023, 4, 122–129. [Google Scholar] [CrossRef]

- Makenji, K. Mechanical methods for recycling waste composites. In Management, Recycling and Reuse of Waste Composites; Woodhead Publishing: Warwick, UK, 2010; pp. 217–252. [Google Scholar] [CrossRef]

- Friedrich, D. Post-process hot-pressing of wood-polymer composites: Effects on physical properties. J. Build. Eng. 2022, 46, 103818. [Google Scholar] [CrossRef]

- Hill, C.; Norton, A.; Kutnar, A. Environmental impacts of wood composites and legislative obligations. In Wood Composites; Woodhead Publishing: Cambridge, UK, 2015; pp. 311–333. [Google Scholar] [CrossRef]

- Rivero-Be, O.E.; Peraza-Góngora, J.M.; Cupul-Manzano, C.V.; Carrillo-Baeza, J.G.; Guillén-Mallette, J.; Rivero-Ayala, M.A.; Valadez-González, A.; Cruz-Estrada, R.H. Preparation of Pinewood Residues/Recycled HDPE Composites with Potential to Substitute Medium-density Fiberboards. BioResources 2018, 13, 1303–1328. [Google Scholar] [CrossRef]

- Khui, P.L.N.; Rahman, M.R.; Jayamani, E.; Bakri, M.K.B. Recycling of sustainable polymers and composites. In Advances in Sustainable Polymer Composites; Woodhead Publishing: Amsterdam, The Netherlands, 2021; pp. 267–282. [Google Scholar] [CrossRef]

- Sain, M.; Pervaiz, M. Mechanical properties of wood–polymer composites. In Wood–Polymer Composites; Woodhead Publishing: Toronto, ON, Canada, 2008; pp. 101–117. [Google Scholar] [CrossRef]

- Toghyani, A.M. Forming Challenges of Extruded Wood Plastic Composite Products in a Post-Production Process. Procedia CIRP 2020, 93, 502–507. [Google Scholar] [CrossRef]

- Friedrich, D.; Luible, A. Investigations on ageing of wood-plastic composites for outdoor applications: A meta-analysis using empiric data derived from diverse weathering trials. Constr. Build. Mater. 2016, 124, 1142–1152. [Google Scholar] [CrossRef]

- Faure, F.; Perrot, A.; Pimbert, S.; Lecompte, T. Water absorption measurements on WPCs: Assessment of size and direction dependencies in order to design fast and accurate tests. Polym. Test. 2019, 77, 105899. [Google Scholar] [CrossRef]

- Schirp, A.; Ibach, R.E.; Pendleton, D.E.; Wolcott, M.P. Biological Degradation of Wood-Plastic Composites (WPC) and Strategies for Improving the Resistance of WPC against Biological Decay. In Development of Commercial Wood Preservatives; American Chemical Society: Washington, DC, USA, 2008; pp. 480–507. [Google Scholar] [CrossRef]

- Spear, M.J. Preservation, Protection and Modification of Wood Composites. In Wood Composites; Ansell, M.P., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 253–310. [Google Scholar] [CrossRef]

- Azman Mohammad Taib, M.N.; Julkapli, N.M. 4—Dimensional stability of natural fiber-based and hybrid composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 61–79. [Google Scholar] [CrossRef]

- McDaniel, M.P.; DesLauriers, P.J. Ethylene Polymers, HDPE. In Kirk-Othmer Encyclopedia of Chemical Technology; Wiley: New York, NY, USA, 2015; pp. 1–40. [Google Scholar] [CrossRef]

- Crawford, R.J.; Martin, P.J. General properties of plastics. In Plastics Engineering; Crawford, R.J., Martin, P.J., Eds.; Butterworth-Heinemann: Oxford, UK, 2020; pp. 1–57. [Google Scholar] [CrossRef]

- Arman, N.S.N.; Chen, R.S.; Ahmad, S. Review of state-of-the-art studies on the water absorption capacity of agricultural fiber-reinforced polymer composites for sustainable construction. Constr. Build. Mater. 2021, 302, 124174. [Google Scholar] [CrossRef]

- Ratanawilai, T.; Taneerat, K. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr. Build. Mater. 2018, 172, 349–357. [Google Scholar] [CrossRef]

- Benthien, J.T.; Thoemen, H. Effects of raw materials and process parameters on the physical and mechanical properties of flat pressed WPC panels. Compos. Part A Appl. Sci. Manuf. 2012, 43, 570–576. [Google Scholar] [CrossRef]

- Lisperguer, J.; Bustos, X.; Sarabia, Y.; Escobar, C.; Venegas, H. Efecto de las características de harina de madera en las propiedades físico-mecánicas y térmicas de polipropileno reciclado. Maderas Cienc. Tecnol. 2013, 15, 321–336. [Google Scholar] [CrossRef]

- Birnin-Yauri, A.U.; Ibrahim, N.A.; Zainuddin, N.; Abdan, K.; Then, Y.Y.; Chieng, B.W. Influence of Kenaf Core Fiber Incorporation on the Mechanical Performance and Dimensional Stability of Oil Palm Fiber Reinforced Poly(lactic acid) Hybrid Biocomposites. BioResources 2016, 11, 3332–3355. [Google Scholar] [CrossRef]

- Bujjibabu, G.; Das, V.C.; Ramakrishna, M.; Nagarjuna, K. Mechanical and Water Absorption Behavior of Natural Fibers Reinforced Polypropylene Hybrid Composites. Mater. Today Proc. 2018, 5, 12249–12256. [Google Scholar] [CrossRef]

- Lopez, Y.M.; Paes, J.B.; Gustave, D.; Gonçalves, F.G.; Méndez, F.C.; Nantet, A.C.T. Production of wood-plastic composites using cedrela odorata sawdust waste and recycled thermoplastics mixture from post-consumer products—A sustainable approach for cleaner production in Cuba. J. Clean. Prod. 2020, 244, 118723. [Google Scholar] [CrossRef]

- Jubinville, D.; Esmizadeh, E.; Tzoganakis, C.; Mekonnen, T. Thermo-mechanical recycling of polypropylene for the facile and scalable fabrication of highly loaded wood plastic composites. Compos. Part B Eng. 2021, 219, 108873. [Google Scholar] [CrossRef]

- Brauns, J.; Rocens, K.; Lawal, S.A. Modification of Wood: Mechanical Properties and Application. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–9. [Google Scholar] [CrossRef]

- ASTM D 790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D 2395; Standard Test Methods for Density and Specific Gravity (Relative Density) of Wood and Wood-Based Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D 4442; Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Base Materials. ASTM International: West Conshohocken, PA, USA, 2003.

- ASTM D 570; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 1999.

- ASTM E 72; Standard Test Methods of Conducting Strength Test of Panels for Building Construction. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C 271; Standard Test Method for Density of Sandwich Core Materials. ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM C 272; Standard Test Method for Water Absorption of Core Materials for Structural Sandwich Constructions. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM D 1037; Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. ASTM International: West Conshohocken, PA, USA, 2012.

- Friedrich, D. Thermoplastic moulding of Wood-Polymer Composites (WPC): A review on physical and mechanical behaviour under hot-pressing technique. Compos. Struct. 2021, 262, 113649. [Google Scholar] [CrossRef]

- Selke, S.E. Wood fiber/polyolefin composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 321–326. [Google Scholar] [CrossRef]

- Stanaszek-Tomal, E. Recycling of Wood-Polymer Composites in Relation to Substrates and Finished Products. IOP Conf. Ser. Mater. Sci. Eng. 2020, 960, 022053. [Google Scholar] [CrossRef]

- Teuber, L.O.-S. Wood polymer composites and their contribution to cascading utilisation. J. Clean. Prod. 2016, 110, 9–15. [Google Scholar] [CrossRef]

| Test | PW | WPC 40/60% (Estimated) | WPC 40/60% | Difference WPC Estimated vs. PW (%) | Difference WPC vs. PW (%) |

|---|---|---|---|---|---|

| Water absorption | 44.9 | 18.0 | 3.5 | 27.0 | 41.4 |

| Thickness swelling (%) | 10.2 | 4.1 | 1.7 | 6.1 | 8.6 |

| Name | Density (kg/m3) | Moisture Content (%) | Water Absorption (%) | Thickness Swelling (%) | Flexural Strength (MPa) | Modulus of Elasticity (MPa) | Reference |

|---|---|---|---|---|---|---|---|

| WF1/Po1 50/50% | - | - | ~18 | ~3 | ~26 | ~2400 | [20] |

| rPP/WF (60 mesh) 50/50% | 1100 | - | 1.6 | 8.2 | ~40 | ~4600 | [21] |

| PLA/MF 40/60% | ~1062 | - | ~8 | ~2.3 | ~27 | 4400 | [22] |

| Banana/coir fiber/PP 5/15/80% | - | - | 1 | - | 28.1 | 598.3 | [23] |

| S6_WF/TP 40/60% | ~1080 | ~2.5 | ~2 | ~2.3 | ~12 | 3980 | [24] |

| PP/WF 60/40% (1 xp) | 1060 | - | ~4.5 | <1 | - | - | [25] |

| HDPE/rWF 60/35.8% | - | - | - | - | 18.8 | 827.1 | [19] |

| WPC 20/80% | 858.3 | 0.3 | 1.7 | 0.8 | 37.1 | 1170.9 | This study |

| WPC 40/60% | 833.9 | 0.7 | 3.5 | 1.7 | 44.5 | 1384.5 | This study |

| Panel Type | ASTM Standards | |||

|---|---|---|---|---|

| Flexural Strength | Density | Moisture Content | Water Absorption and Thickness Swelling | |

| WPC (plastic–wood composite) | D 790 [27] | D 2395 [28] | D 4442 [29] | D 570 [30] |

| GB (gypsum board) | E 72 [31] | C 271 [32] | C 272 [33] | C 272 |

| PW (plywood Caobilla, 3 layers interspersed) | D 1037 [34] | D 2395 | D 1037 | D 1037 |

| MDF (medium-density fiberboard) | D 1037 | D 2395 | D 1037 | D 1037 |

| ASTM Standards | Sample Dimensions | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| E 72 | D790 | D1037 | C271 | D2395 | C272 | D4442 | D570 | ||

| Flexural strength | Total samples | 4 | 4 | 4 | |||||

| L (mm) | 370 | 150 | 190 | ||||||

| W (mm) | 75 | 30 | 50 | ||||||

| T (mm) | 12.7 | 6 | 4.1/5.8 | ||||||

| Density | Total samples | 4 | 4 | 4 | |||||

| L (mm) | 75 | 300 | 75 | ||||||

| W (mm) | 150 | 300 | 25 | ||||||

| T (mm) | 4.1/5.8 | 12.7 | 6 | ||||||

| Moisture content | Total samples | 4 | 5 | 4 | |||||

| L (mm) | 75 | 75 | 75 | ||||||

| W (mm) | 150 | 75 | 25 | ||||||

| T (mm) | 4.1/5.8 | 12.7 | 6 | ||||||

| Water absorption and thickness swelling | Total samples | 4 | 5 | 4 | |||||

| L (mm) | 150 | 75 | 75 | ||||||

| W (mm) | 150 | 75 | 25 | ||||||

| T (mm) | 4.1/5.8 | 12.7 | 6 | ||||||

| Sample | Per Panel | Per Layer | Total Material to Be Used | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Mat | % | L * (cm) | W * (cm) | T (cm) | A * (cm2) | Vol (cm3) | Vol. Mat per % (cm3) | ρ *** (g/cm3) | Wt (g) | T (cm) | Vol (cm3) | No. Layers | Wt (g) | Panels ** | HDPE (g) | WV Sheet **** |

| Control | HDPE | 100 | 24.1 | 16.5 | 0.6 | 397.7 | 238.6 | 238.6 | 0.96 | 229.1 | 0.60 | 238.6 | 1.00 | 229.1 | 4.00 | 916.2 | N/A |

| WPC 20/80% | HDPE | 80 | 24.1 | 16.5 | 0.6 | 397.7 | 238.6 | 190.9 | 0.96 | 183.2 | 0.16 | 63.6 | 3.00 | 61.1 | 4.00 | 733.0 | N/A |

| WV | 20 | 47.7 | N/A | N/A | 0.06 | 23.9 | 2.00 | N/A | N/A | 0.2 | |||||||

| WPC 40/60% | HDPE | 60 | 24.1 | 16.0 | 0.6 | 397.7 | 238.6 | 143.2 | 0.96 | 137.4 | 0.07 | 28.6 | 5.00 | 27.5 | 4.00 | 549.7 | N/A |

| WV | 40 | 95.4 | N/A | N/A | 0.06 | 23.9 | 4.00 | N/A | N/A | 0.4 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canto-Borges, L.C.; Cruz, J.C.; Nahuat-Sansores, J.R.; Domínguez-Lepe, J.A.; Gurrola, M.P. Sustainable WPC Production: A Novel Method Using Recycled High-Density Polyethylene and Wood Veneer. Recycling 2024, 9, 1. https://doi.org/10.3390/recycling9010001

Canto-Borges LC, Cruz JC, Nahuat-Sansores JR, Domínguez-Lepe JA, Gurrola MP. Sustainable WPC Production: A Novel Method Using Recycled High-Density Polyethylene and Wood Veneer. Recycling. 2024; 9(1):1. https://doi.org/10.3390/recycling9010001

Chicago/Turabian StyleCanto-Borges, Leslie Cristell, Julio César Cruz, Javier Rodrigo Nahuat-Sansores, José Antonio Domínguez-Lepe, and Mayra Polett Gurrola. 2024. "Sustainable WPC Production: A Novel Method Using Recycled High-Density Polyethylene and Wood Veneer" Recycling 9, no. 1: 1. https://doi.org/10.3390/recycling9010001

APA StyleCanto-Borges, L. C., Cruz, J. C., Nahuat-Sansores, J. R., Domínguez-Lepe, J. A., & Gurrola, M. P. (2024). Sustainable WPC Production: A Novel Method Using Recycled High-Density Polyethylene and Wood Veneer. Recycling, 9(1), 1. https://doi.org/10.3390/recycling9010001