Abstract

The global air transport industry is predicted to continue its rapid growth. A by-product of air transport operations, however, is the substantial volumes of waste generated at airports. To mitigate the environmental impact of waste and to comply with regulatory requirements, airports are increasingly implementing sustainable waste management policies and systems. Using an in-depth case study research design, this study has examined waste management at Kansai International Airport from 2002 to 2015. Throughout its history the airport has implemented world best practices to achieve its goal of being an eco-friendly airport. The qualitative data gathered for the study were analysed using document analysis. The quantitative data were analysed using t-tests. Statistically significant results were found in the reduction in waste per passenger and aircraft movement (for total waste, incinerated waste, and landfill waste). In addition, a statistically significant increase in the proportion of waste recycled, and a decrease in the proportion of waste sent to landfill was observed. As such, quantitatively speaking, Kansai International Airport has shown significant waste management improvements. The study concludes that Kansai Airport’s waste management approaches and policies can be transferred to other airport facilities. This would greatly improve sustainability across airports, globally.

1. Introduction

Airports play a vital role in the global air transport value chain acting as the critical interface point between the surface-based and air transport modes. The management of waste is now viewed as one of the critical environmental issues confronting airports. This is because the various activities that are performed at airports produce considerable volumes of waste [1,2,3]. Thus, the issue of waste management within airports is becoming especially important due to the significant increases in passenger numbers and the consequent volumes of waste that is generated. Airports generate both solid and hazardous waste, which is typically processed in three ways: recycling, incineration or by disposal to landfill. Like other industries, airports need to comply with government waste legislation and regulations. Many countries and businesses now follow the 3Rs waste management hierarchy, that is, reduce, re-use, and recycle. Under such a policy, waste is reduced, re-used and recycled to mitigate the volume of waste that is disposed by landfill. Furthermore, waste should be viewed as a potential resource, and, as such, it is necessary to optimize the best use of this material(s). As a result, of waste minimization, recovery, and recycling, society not only saves valuable scare resources but also protects the environment and alleviates the burden on the government or public agencies who are responsible for managing the waste [4].

Many airports around the world have implemented sustainable waste management policies, strategies and systems. Sustainable waste management has been defined “as the achievement of a reasonably reliable waste service (for example, collection and waste disposal) that is of a reasonably reasonable high standard that is acceptable to the community and is reasonably affordable primarily utilizing local finance and resources, constitutes a reasonable sustainable waste management system” [5] (p. 50). Sustainable management of materials, products, and wastes all contribute to resource efficiency and quality recyclates. It also involves the implementation of measures for waste prevention, on-site segregation of the unavoidable waste and separate waste collection and disposal [6]. Seadon [7] (p. 1639) notes that “waste management is viewed as part of a generation, collection and disposal system”, and further suggests that “a sustainable waste management system incorporates feedback loops, is focused on processes, embodies adaptability and diverts wastes from disposal”. Despite the importance of waste management for airports, there have only been a few reported studies [3,8,9,10] that have examined this prominent issue.

The aim of this study is to build on the previous airport waste management studies by examining the sustainable aspects of a modern, large hub airport’s waste management and how they fit within the regulatory framework and government waste management hierarchy policies. Osaka’s Kansai International Airport was selected as the case study airport as, throughout its history, the airport has embraced sustainable waste management practices and has implemented world best practice waste management systems and infrastructure. These initiatives form part of the airport’s policy of being a leader in sustainable airport operations. An additional objective of the study was to examine the sources, types and volumes of waste generated at Kansai International Airport, and the methods used to mitigate the environmental impact of the waste produced at the airport. It was agreed at the Group of Eight (G8) Sea Island Summit in June 2004 that member countries would introduce the 3Rs Waste Management Hierarchy [11]. On 1 June 2007, the Japanese Government Cabinet launched Japan’s strategy and policy for the country to become a sustainable society. A crucial element of the policy and strategy was the creation of sustainable material-cycles through the 3Rs [12]. Considering this policy, an additional objective of the study is to examine the regulatory framework that applies to Kansai International Airport’s waste management. To address the study objectives, the following research questions were posed:

- What are the primary sources of waste generated at Kansai International Airport?

- What types of waste are generated at Kansai International Airport?

- What are the annual volumes of incinerated, recycled waste and waste disposed by landfill at Kansai International Airport?

- How does Kansai International Airport process waste to minimize and mitigate its environmental impact?

2. Background

2.1. Sources of Airport Waste

Waste is generated at airports from a variety of sources. The primary sources include:

- waste that is generated from aircraft;

- waste produced in airport offices;

- retail outlets and restaurants;

- restrooms;

- flight catering centres;

- air cargo terminals;

- aircraft and ground service equipment (GSE) maintenance facilities and areas;

- landscaping undertaken at the airport; and

- from construction, and demolition projects undertaken at the airport.

Each of these areas creates discrete waste streams [13]. Importantly, each of these areas have the potential to generate significant volumes of waste [14].

The waste generated at airports can be broadly divided into the waste generated by the landside activities undertaken at the airport as well as the waste produced by the key stakeholders involved in airport’s airside area operations. Landside means those parts of an airport as well as the adjacent terrain and buildings or portions thereof that are not in the airside precinct. The airside means the movement area at an airport, adjacent terrain and buildings/infrastructure, or portions, the access to which is restricted [15]. Table 1 shows the key airport landside stakeholders and the distinct types of wastes that are generated from their activities and operations at an airport. The typical types of waste generated by the stakeholders operating on an airport’s airside are presented in Table 2. Like the landside wastes, the wastes generated on the airside are also heterogeneous in nature.

Table 1.

Key airport landside stakeholders and typical types of waste generated.

Table 2.

Key airport airside stakeholders and typical types of waste generated.

2.2. Solids and Hazardous Wastes Produced at Airports

Waste management at airports comprises both solid and hazardous waste [16,17]. There are seven discrete types of solid waste generated at airports: (1) municipal solid waste (MSW); (2) construction and demolition waste (C&D); (3) green waste; (4) food waste; (5) deplaned waste; (6) lavatory waste; and (7) spill clean-up and remediation waste [10,16]. These are each defined as:

- Municipal solid waste (MSW) compromises everyday items that are used and then subsequently discarded (e.g., product packaging, furniture, clothing, bottles, food scraps, and newspapers) [16].

- Construction and demolition waste (C&D) is any non-hazardous solid waste produced from land clearing, excavation, and the construction, demolition, renovation or repair of structures, roads, and utilities at an airport (for example, concrete, wood, metals, drywall, carpet, plastic, pipes, land clearing debris, cardboard, and salvaged building components).

- Green waste is categorized as MSW and may also referred to as “yard waste”. The green waste generated at airports comprises tree, shrub and grass clippings, leaves, weeds, small branches, seeds, pods and similar debris generated from the airport’s landscape maintenance activities.

- Food waste is food that has not been consumed or is the waste generated and discarded during food preparation activities [16] (p. 2).

- Deplaned aircraft waste is waste originating from aircraft flights. This waste includes bottles, cans, papers, plastic cups, service ware, food waste, as well as paper towels [16]. The type of meals served varies according to the duration of a flight, and thus, the quantity and content of the generated waste stream also varies [18,19]. A low-cost carrier (LCC), for example, may not offer meals, so most of their waste comes from passenger’s beverage containers and small snack wrappers. A similar trend is occurring with larger full-service network carrier (FSNC), where waste levels can be like those of an LCC. However, long-haul international flights have more extensive in-flight services, and hence greater volumes of waste [9].

- Lavatory waste is a form of special waste and is generated when the lavatory tanks of the aircraft are emptied via a hose and pumped into a lavatory service vehicle. These vehicles can be either a self-powered truck or a lavatory cart that is pulled by a tractor or tug. The lavatory waste that has been removed from the aircraft is transported to a triturator facility, which is usually located airside, for pre-treatment prior to discharge to the sanitary sewage system and publicly owned treatment works (POTW). Importantly, lavatory waste, which contains chemicals and potential enteric pathogens, can present significant risks to the environment and human health if they are not handled appropriately [16] (p. 2).

- Spill clean-up and remediation wastes are another form of special waste. These materials are generated during the clean-up of spills and/or the remediation of contamination from diverse types of sites on an airport. These storage tanks, oil and gas production, vehicular leaks, spills from maintenance activities, and so forth) [16] (p. 2).

The primary environmental concerns related to solid waste is the quantity of waste produced at the airport; specifically, the amount of waste sent to landfill. A further environmental concern is the location of the landfills in relation to airport runways and flight paths [17]. Hence, to minimize the negative impact on the environment from the disposal of waste, it is necessary for airports to identify ways and means to decrease the volume of waste generated. This can be achieved through recycling, composting, reuse of waste as well as the introduction of wasteless technologies [20]. The objective of waste management is therefore to reduce the volume of waste generated, thereby reducing disposal costs and, thus, the environmental impact of the airport [21]. In addition, social costs will be decreased in terms of residential communities that are located near waste landfill sites and incinerators [3]. Many airports, for example, Copenhagen Airport, Kansai International Airport, Munich Airport, Oslo Airport Gardermoen, and San Francisco International Airport, now have recycling initiatives in place [22].

Aircraft refuelling, aircraft maintenance activities (minor activities at all airports, and major activities if they are conducted at the airport), rental car maintenance (waste oil), and emergency power generators may produce hazardous waste. Hazardous waste could also be present at airports because of past activities that may have contaminated the soil or water. In addition, hazardous waste being transported by aircraft or vehicle onto airport property may have entered the airport’s environment [20]. Some of this hazardous waste can pose a threat to human health and the environment if it is not handled in specific and safe ways [23].

2.3. Airport Waste Management Systems

Waste mitigation measures form part of the airport waste management system, which are in place at many airports around the world [24]. Airports need to develop a waste management system that incorporates a range of measures. These include source separation and recycling of waste on the airport site; waste minimization; a charging regime for airport waste; and the re-use of equipment and material whenever this is possible. In addition, airports should promote the usage of products that are renewable and have the least environmental impact [1].

The airport waste management system will normally be designed and operated in accordance with the applicable waste management regulatory framework. This especially applies to the storage and disposal of waste in dedicated areas which cannot be used for other, more profitable activities. The airport waste management system typically includes the identification of the various waste sources, facilities, equipment and infrastructure required to deal with the diverse types and volumes of waste. The waste management system will also focus on the efficiency and effectiveness of the waste collection, storage, recycling, and waste disposal at the airport [24].

An efficient and effective airport waste management system normally implies waste avoidance, waste minimization, as well as waste disposal. This will involve the following:

- separation (sorting) of the waste at airport’s waste collection points, that is, at the source, into solid and liquid, hazardous and non-hazardous waste;

- a reduction in the generated waste volumes;

- continuous increase in reuse, recycling and reprocessing of wastes; and

- a permanent improvement in airport waste management practices.

Recycling may involve the conversion of waste into energy through thermal treatment (processing) [25,26]. Energy recovery reduces the amount of waste that is disposed by landfill and produces useable energy, in terms of heat, electricity or fuel, through a variety of processes. These processes include combustion, gasification, pyrolysis, and anaerobic digestion [27].

There are three key waste disposal options available to airports [28]:

- Recycling: With this option, the waste fraction is utilized again to produce raw materials that can be used for making new products or new forms of energy [29]. The types of waste that can be recycled include paper, card board, glass, plastics and metal [30,31].

- Incineration: With this option, the waste fraction is incinerated. Incineration is defined as “a controlled combustion process for reducing solid, liquid, or gaseous combustible wastes primarily to carbon dioxide, water vapour, other gases, and a relatively small, non-combustible residue, that can be further processed or land-filled in an environmentally acceptable manner” [32] (p. 3). An option is for the waste to be incinerated in a combined heat power plant (CHP) that produces heat and/or electricity [33,34].

- Landfill: Waste that is neither suitable for recycling nor incineration will be deposited to landfill. In many cases, it may be necessary to pre-treat the rubbish to remove hazardous substances [30] or to reduce the volume of waste to be sent to the landfill.

2.4. Centralized or De-Centralized Airport Waste Management Systems

Airports can operate either centralized, de-centralized waste management systems or a combination of both procedures [18,20]. Centralized waste management systems will have a single waste management point for all airport terminal and aircraft waste except for flight catering centres, which often manage their own waste [10,18]. A critical part of the system is the selective collection system. According to Ponte-Cueto and González-Manteca [35], a selective collection system is the point of contact between the waste generators and waste disposal operations.

In the case of airports that utilize centralized waste management systems, the airport authorities provide waste and recycling receptacles for use by the airport tenants and airlines [9]. The waste generators are charged a fee based on the amount of waste generated or included in tenant/concessionaire leases or airline landing charges [18]. Centralized waste management system (centralized collection and sorting) requires high investment and staff costs but is considered tidier and provides better separation of individual fractions and therefore provides better opportunities for negotiations with consumers of classified waste [20]. Furthermore, although a centralized system requires higher levels of coordination between the airport authority, tenants/concessionaire, and airlines, the volume of waste handled under a single centralized contract is larger. Hence, due to the volume of waste that is generated from a single contract, an airport authority is in a more advantageous position to realize favourable economies of scale and thereby can negotiate lower per-tonne (ton) disposal and recycling costs with waste handling providers. The other advantages of a centralized waste management system for airports are:

- Centralized coordination of waste haulage and container maintenance results in less truck traffic on the airfield, less fuel usage, and a reduced risk of airfield collisions.

- Greater control by the airport authority over the type, placement, and maintenance of compactors and dumpsters saves space whilst also eliminating the requirement for each airline to have its own containers.

- Airlines that only produce small volumes of waste can recycle it with fewer overhead costs; and by directly billing tenants and airlines for waste management services, the airport authority can develop incentives to promote waste recycling [9] (p. 3).

Decentralized waste collection permits certain kinds of waste, for example paper and cardboard cartons, to be separated at each location [20]. In a decentralized waste management system, the airport authority, terminal tenants (concessionaires), airlines, and flight catering firms, for example, will each have independent waste management contracts. From an airport management perspective, a decentralized waste management system enables an airport authority to minimize its obligations to coordinate the firms or agencies operating at the airport. In addition, it also enables each firm and agency operating at the airport to control their own waste management contract. Notwithstanding, decentralization does have some disadvantages:

- The system may be less efficient because more dumpsters than necessary may be used to handle the quantity of waste that is being disposed.

- It introduces the possibility of improper dumping in another airline’s dumpster.

- Quantifying and tracking the amount of waste generated and recycled at an airport becomes more complicated.

- Achieving the scale necessary to make recycling more economical for any single tenant is more difficult [9] (p. 5).

In addition, over the past 15 years, many cities have constructed Mechanical Biological Treatment Facilities (MBT). The objective of these facilities is to reduce the waste to be finally dumped or burnt. The results of such facilities are dependent upon every case. Importantly, MBT can play a role in transitional strategies to reduce residual waste without being dependent on more expensive undesirable options such as incineration. MBT covers a broad range of activities and technologies to deal with residual waste, that is, waste that has not been separated for recycling or for composting. MBT systems are composed of a mechanical part in which waste is mechanically separated to recover recyclables. The biological part is used to either compost or digest the organic fraction [36].

3. Research Method

This study used a mixed methods research design [37,38,39] that was exploratory in nature. The initial qualitative phase was a case study utilizing document analysis to develop a general sense of airport waste management. This qualitative stage was followed by a longitudinal study, incorporating correlation [40,41]. This methodology was chosen to build a theory [42], specifically of airport waste management. To triangulate the data, a site visit to Kansai International Airports was undertaken, where observations of the waste management process were undertaken, and interviews with airport staff facilitated the collection of additional data.

To alleviate potential biases and to support measurement validity, careful attention has been paid to the selection of sources used in the study [43]. The qualitative and quantitative data for this study were obtained from a range of documents, including Kansai International Airport 2007 Eco-Island Report 2007; New Kansai International Company Environmental 2014 and 2015 Reports, New Kansai International Company 2014 and 2015 Kansai International Airport Smart Island Reports and the Kansai International Airports Smart Island Report 2016. Qualitative data were also gathered from websites, air transport and airport industry-related magazines, and press articles. The study therefore used secondary data analysis to investigate the research problem. The three principles of data collection suggested by Yin [44] were followed in this study: the use of multiple sources of case evidence, creation of a database on the subject, and the establishment of a chain of evidence.

The empirical data collected for the case studies were examined using document analysis. Document analysis is often used in case studies and focuses on the information and data from formal documents and company records [44,45]. The documents collected for the study were examined according to four criteria: authenticity, credibility, representativeness and meaning [46,47]. Prior to conducting the formal analysis of the documents gathered in the study, the context in which the documents were created was determined and the authenticity of the documents was assessed [48]. Authenticity involves an assessment of the collected documents for their soundness and authorship. Scott and Marshall [49] (p. 188) note that “soundness refers to whether the document is complete and whether it is an original and sound copy”. Authorship relates to such issues as collective or institutional authorship. In this study, the source of the case study documents was Kansai International Airport. The documents were available in the public domain. The credibility criterion concerns the accuracy and sincerity of a document. The representativeness criterion involved an assessment of the availability and survival of the documents gathered. The fourth criterion, meaning, is a most important matter and occurs at two levels. The first is the literal understanding of a document, by which is meant its physical readability, the language used and whether it can be read, as well as the date of the document [49]. In this study the original meaning of the gathered documents was retained.

Following the recommendations of O’Leary [50], the qualitative document analysis process in the present study was undertaken in six distinct phases as follows:

- Phase 1: This phase involved planning the types and required documentation and their availability.

- Phase 2: The data collection involved gathering the documents and developing and implementing a scheme for the document management.

- Phase 3: Documents were reviewed to assess their authenticity, credibility and to identify any potential bias.

- Phase 4: The content of the collected documents was interrogated, and the key themes and issues were identified.

- Phase 5: This phase involved the reflection and refinement to identify and difficulties associated with the documents, reviewing sources, as well as exploring the documents content.

- Phase 6: The analysis of the data was completed in this final phase of the study [50] (p. 179).

The quantitative data analysis assessed the statistical significance of the various year-on-year changes was quantitatively examined. Specifically, Student t-tests were utilized to determine if the various correlation coefficients, r, were zero, positive, or negative. As such, only one-sided tests were utilized. The student t-test followed the standard as outlined by Andrews et al. [51], Heavey [52] and Heiman [53]. In this study, a statistical significance of 99% was utilized.

4. Results

4.1. Japan’s Waste Management Regulatory Framework

Prior to examining the background to Kansai International Airport, it is important to note the Japan’s waste management regulatory framework, as this has a major impact on the airport’s waste management. Japan has adopted a sound material-cycle policy, under which the various entities, including national and local governments (prefectures and municipalities), businesses and consumers recognize their respective roles specified in the Basic Recycling Act in promoting the 3Rs. It is also critical that each stakeholder performs their own responsibilities for waste management and functionally collaborate with each other to create and sustain systems for proper waste management. Accordingly, the Waste Management Act, clearly specifies the responsibilities of national and local governments, and businesses that are generating waste. This act also applies to other waste generators [54].

In Japan, the National Government helps other entities to properly perform their waste management responsibilities. The national government also formulates and implements fundamental and comprehensive waste management strategies, enacting laws and regulations, promoting technological development, as well as providing technological and financial support for municipalities and prefectures. The prefectures also provide technological support for municipalities to help them perform their responsibilities. The prefectures also collect information on how industrial waste is managed in areas under their jurisdiction, promote waste management plans, and also provide guidance and supervision to ensure the appropriate management of industrial waste. In addition, the prefectures authorize and supervise the waste processing operations of waste management business operators. The municipalities are responsible for the management of municipal waste within their jurisdiction, and to formulate and implement waste management plans [54] (p. 20).

Business operators in Japan are responsible for the proper management of waste (industrial waste) that is generated from their activities and operations. Business operators need to reduce waste through recycling and implement measures, for example, outsourcing waste management operations, to ensure proper waste management [54].

The Basic Environment Act (1993) forms the backbone of Japan’s environmental policies. Japan’s legal system for the establishment of a sound material-cycle society comprises the Basic Act for Establishing a Sound Material-Cycle Society (2000) (Basic Recycling Act). This act provides the fundamental principles and guidelines for the development of a sound material-cycle society. Japan’s Government has also formulated a Fundamental Plan for Establishing a Sound Material-Cycle Society (Fundamental Recycling Plan) which is based on the country’s Recycling Act [44]. This plan was first established in March 2003 and was revised in 2013 [54].

A number of other laws have been introduced to establish a sound material-cycle society. The Waste Management and Public Cleansing Act (1970) (Waste Management Act) aims to protect the living environment and also to improve public health through waste generation control as well as ensuring the appropriate waste management treatment. The Act on the Promotion of the Effective Utilization of Resources (1981) (Effective Resource Promotion Act) aims to ensure the effective use of resources, to reduce waste generation as well as preserving the environment. In addition, there are six Recycling Acts (Containers and Packing Recycling Act 1995; Home Appliance Recycling Act 1998; Construction Recycling Act 2000; Automobile Recycling Act 2002 and the Small Home Appliance Recycling Act 2012) that have been implemented in accordance with the properties of individual products. The Act on the Promotion of Procurement of Eco-Friendly Goods and Services by the State and Other Entities (2000) (Green Purchasing Act 2000), aims to create a society which is capable of sustainable development and promotes the purchase of recycled products by the government [54] (p. 17).

4.2. Waste Classification System in Japan

In Japan, at the macro-level, waste is classified into “industrial waste” and “municipal waste”, in accordance with Japanese legislation and regulations. Waste classification principles are principally based on the waste generation source [55]. There are two key noticeable features of waste classification at the macro-level. First, in accordance with the Waste Management and Public Cleaning Law, municipal solid waste refers to waste other than industrial waste. As noted by Wen et al. [55] (p. 327), “there is a ‘0–1’ (complementary) relationship between ‘industrial waste’ and ‘municipal solid waste’”. Secondly, the legal requirements for waste management are very clearly specified. For industrial waste, it is the waste generator’s responsibility to manage their waste management. As previously noted, the prefectural governments enforce the waste management related law and regulations [54]. Under the Waste Management and Public Cleansing Law, “specially controlled industrial waste” (and specially controlled municipal waste) are classified in accordance with their hazardous properties. In Japan, industrial waste comprises 20 distinct types of waste, of which 12 types are substance-oriented wastes. Specially controlled industrial waste is split into two distinct types according to their hazardous properties, for example, toxicity and corrosiveness [55] (p. 329).

4.3. Kansai International Airport Case Study

Kansai International Airport was constructed as a man-made island five kilometres off-shore in Osaka Bay. The concept for Kansai International Airport appeared in 1968, following a survey of potential airport sites in the Osaka area. Due to the high population density in the Osaka region and the scarcity of available land, a man-made island was determined to be the only feasible option for the new airport. Noise pollution and other environmental concerns assisted the Ministry of Transport in granting approval to construct the airport in 1986 [56]. The airport, which had an overall cost of around $USD 13 billion [57], commenced operations in 1994 as Japan’s first 24-h airport and now plays a key role as an important international hub in the world air transport network [58]. Table 3 summarizes some key interesting statistics about the airport.

Table 3.

Kansai International Airport information, adapted from [59].

On 1 April 2012, the New Kansai International Airport Company (NKIAC) was established. The management of Kansai International Airport (IATA Airport Code: KIX) and Osaka International Airport (IATA Airport Code: ITM) was integrated into a single company on 1 July 2012. The establishment of NKIAC was a new business model for Japan as it was the first time that the management of multiple airports were managed and operated by a single company [60].

From its inception of operations in 1994, Kansai International Airport has sought to bring to reality the concept of a pollution-free airport, whilst concurrently exists and prospers together with the community. Kansai International Airport has historically focused on sustainable environmental management and places an emphasis on sustainable waste management. A key objective of Kansai International Airport is to be an “environmentally advanced airport” that is both people and earth-friendly. Importantly, the airport is driven by its objective of becoming a pollution-free airport that also co-exists and prospers with the local Kansai region. Consequently, environmental management forms an integral part of Kansai International Airport governance, strategy, and management system. The airport has implemented and adopted a wide-ranging sustainable environment policy that is underpinned by three fundamental principles—Green Innovation, Eco Operations, and Eco Relations—as well as five basic sustainable environmental principles—an airport that co-exists with the local region, airports that protect a sound local environment, airports with a minimal impact on the global environment, airports that recycle resources, and airports that keep biodiversity in mind [61,62]. It is important to note that the sustainable waste management at Kansai Airport is governed by legislation and the Japanese Government’s 3Rs waste hierarchy policy.

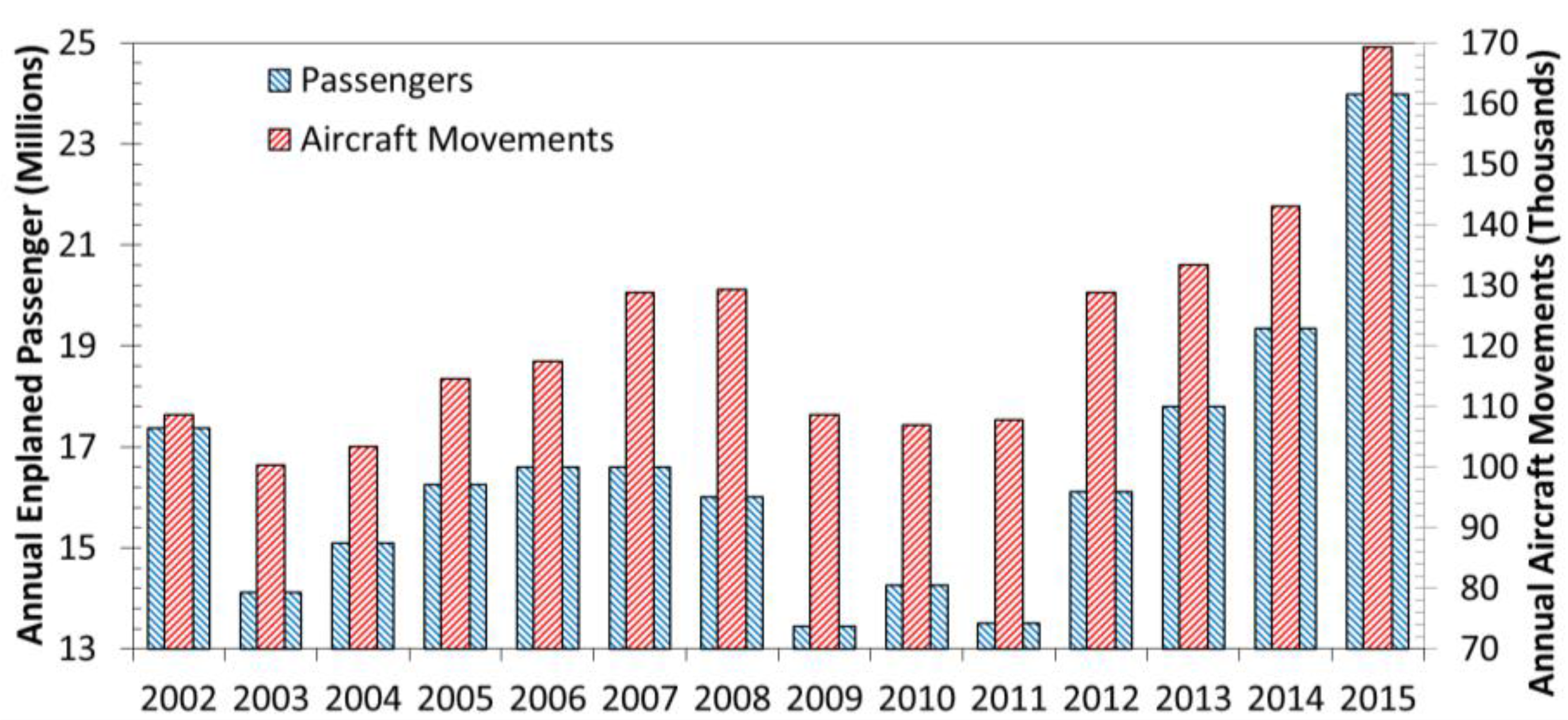

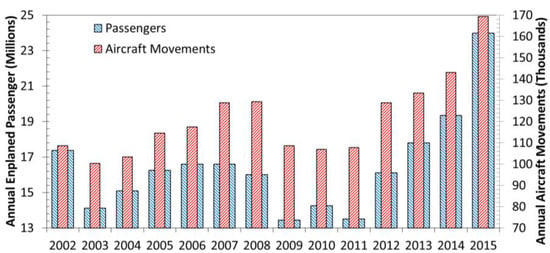

Figure 1 shows the total annual passengers (domestic and international) at Kansai International Airport since its inception of operations in 2002 to 2015. The impacts of 9/11 and the 2008 global financial crisis (GFC) can clearly be seen in the decline in the annual enplaned domestic and international passengers because of these major global events. It can also be seen that the international passenger numbers are more significant relative to the domestic passenger numbers. This is due to Osaka International Airport primarily acting as the major local domestic terminal for the city of Osaka. In addition, since 2012, the LCCs have emerged in the Japanese market and appear to be particularly important for Kansai International Airport. Peach Aviation, a joint venture including ANA (All Nippon Airlines), is now one the airport’s leading airlines in terms of weekly departures. In July 2012, JetStar Japan, also a LCC, commenced business at Kansai International Airport, and has subsequently grown their operations at the airport. The LCCs have helped to drive passenger traffic growth at the airport [63]. Figure 1 also shows the total annual aircraft movements (domestic and international) at Kansai International Airport from 2002 to 2015.

Figure 1.

Annual enplaned passengers and aircraft movements (both domestic and international) at Kansai International Airport: 2002 to 2015. Source: Data derived from [64,65].

4.4. Waste Handling at Kansai International Airport

At Kansai International Airport, combustible waste is incinerated at the airport’s incineration plant. The airport’s incineration plant is designed with a fluidized bed furnace and is well-equipped with pollution-prevention equipment. The flu-gas treatment equipment includes a filter-type precipitator that uses catalysts to remove nitrogen oxides (NOX), as well as humidity-regulated fly ash stabilizing equipment. In addition, consideration has been given to ensure the incineration plant fits in with the local surroundings. The incineration emissions, which are at temperatures of between 800 °C and 950 °C in the furnace, are directed into a cooling chamber via air heaters which are designed to prevent white smoke, and then through a reactor. All dust and hazardous gases are subsequently removed by a filter-type precipitator. Following this exhaust gases are released into the atmosphere via an induced draft fan and an exhaust stack. Importantly, the airport has voluntarily adopted strict standards at the stack outlets for dust, sulphur oxides, hydrogen chlorides, and nitrogen oxides, with the maximums being 0.02 g/Nm3, 20 ppm, 30 ppm and 70 ppm, respectively [60] (p. 10).

In addition, the installation of a garbage shredder has significantly enhanced the furnace’s incineration efficiency and has also ensured that the concentration of air pollutants such as nitrogen oxides (NOX) that are present in emissions are below the regulated standards legislated in Japan’s Air Pollution Control Act. The dioxin emissions produced from the plant are also well below established standards. In addition, the heat from incineration is used as a heat source for the air heaters which are used to prevent white smoke. Hot water generators also provide heat for room heating as well as tap water at the incineration plant [60] (p. 10).

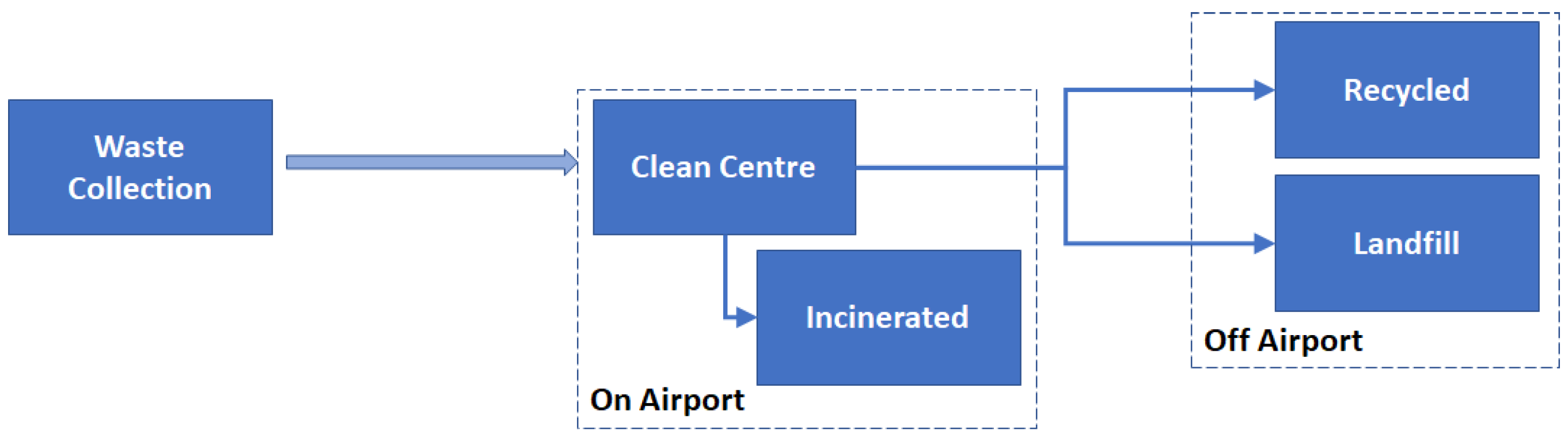

Figure 2 shows the waste disposal chain at Kansai International Airport and highlights the key role played by the airport’s Clean Centre Incineration Plant. In processing the various types of combustible wastes generated at the airport, the Clean Centre Incineration Plant acts as the critical interface point between the various stakeholders generating waste and the ways that waste is processed and disposed at the airport.

Figure 2.

The waste disposal chain at Kansai International Airport.

There are different types of combustible waste generated at Kansai International Airport and which are sent for incineration. These include kitchen waste, wood waste, non-recyclable paper, and rags. Similar to many other airports there is a variety of recyclable waste produced at Kansai International Airport; these include steel and aluminium cans, unbroken glass and plastic bottles, newspaper (non-advertising), magazines, high quality paper, copier paper, paper generated in offices, non-confidential documents as well as cardboard. The various types of bulky combustible waste comprise wood waste, clothing, briefcases, vegetation clippings, and wood products. These bulky or large combustible wastes are also disposed by incineration. The principal types of non-combustible waste that are disposed by landfill are also diverse in nature [60,61].

Furthermore, at Kansai International Airport, “Zero Waste” outdoor clean-up activities are held on 30 May each year. This is the same day when clean-up campaigns are conducted in neighbourhoods around Japan [59]. The airport became involved in this initiative by holding a Zero Waste campaign that is held from 27 May to 9 June, in conjunction with members of the airport’s Smart Island Council [60].

4.5. Reported Airport Wastes

The activities and operations undertaken at Kansai International Airport generate more than 10,000 tons of general waste each year. The primary sources of this waste are from aircraft, flight catering centers, and the airport’s terminal buildings. To achieve greater recycling and a reduction in the volumes of waste generated, the airport has defined written rules for waste separation at the airport—Regulations Governing the Use of Waste Processing Facilities. Kansai Airports works closely with the various airlines and airport firms and urges them to sort their waste [60,66]. It has been estimated that approximately 20% of the total amount of waste generated at Kansai International Airport comes from aircraft. In recognition of the requirement to reduce waste through sortation and reducing the volumes generated, Japan’s two major airlines—ANA and Japan Airlines (JAL)—are sorting the waste generated from their aircraft passenger cabins. In addition, both airlines are also separating out the newspapers received from aircraft passengers. Another large source of waste is the packing material (plastic) used in air cargo operations to prevent leakage and possible water damage to the contents of a cargo pallets or aircraft unit load devices [60,61]. Aircraft unit load devices, or ULDs, are pallets and containers which are used to carry air cargo, mail and passenger baggage on wide-body passenger and freighter aircraft [67]. Consequently, considerable efforts are being made at the airport to recycle the plastic that has been used for this purpose rather than disposing of it as waste. In relation to industrial waste, the airport operator is encouraging the various firms operating at the airport to make efforts to manage their waste properly, avoid waste generation, and, where possible, recycle the wastes that are generated [60,61,68]. As previously noted, Kansai International Airport complies with the Japanese Government’s 3Rs waste management hierarchy policy. As such, the airport aims to reduce waste and re-use and/or recycle waste wherever possible.

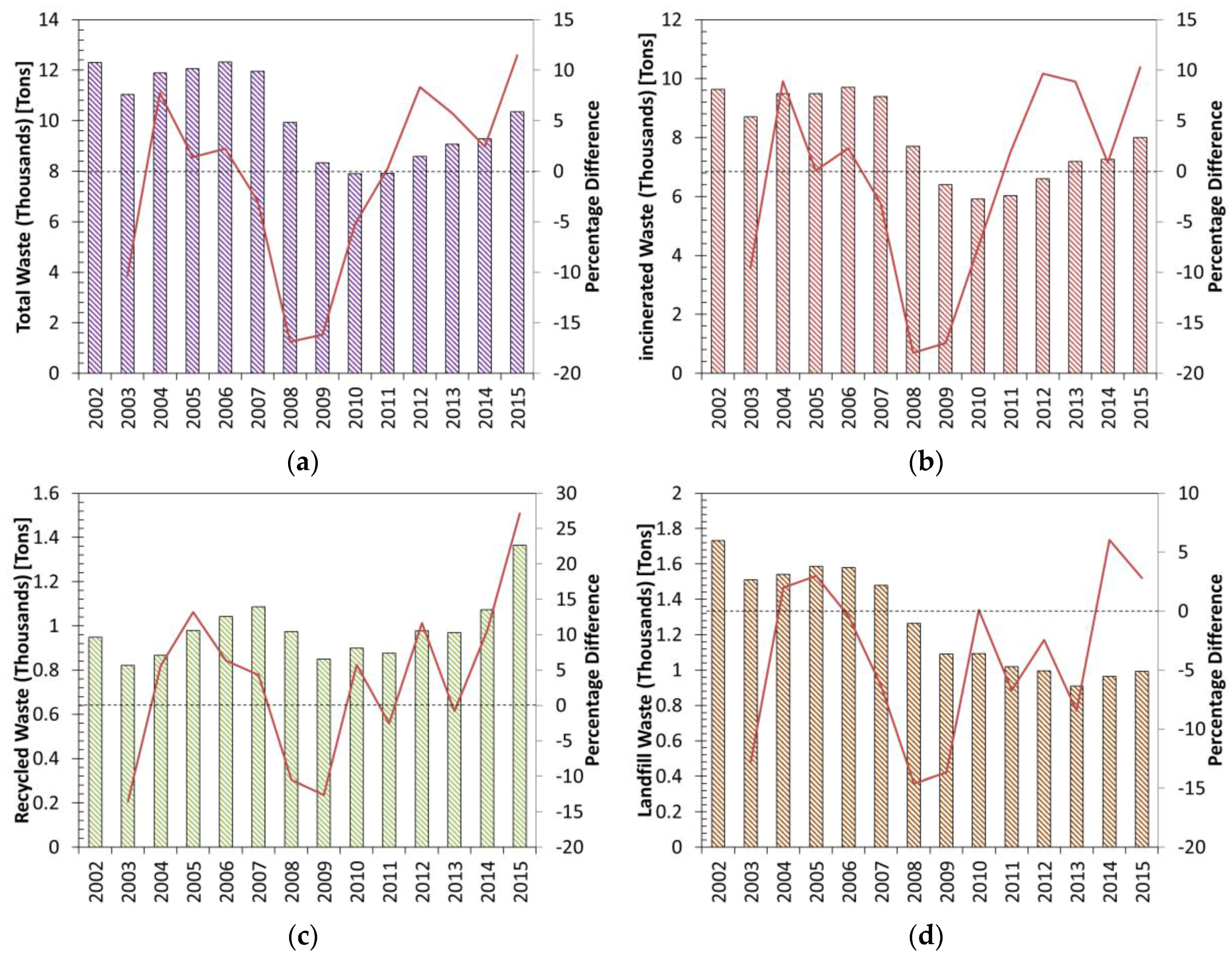

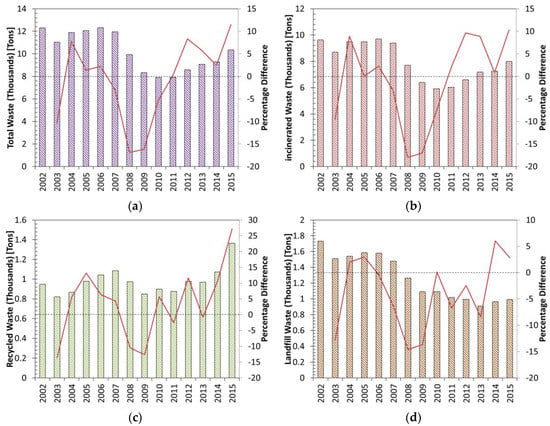

Figure 3 presents the annual quantities of waste produced at Kansai International Airport from 2002 to 2015. This is broken down in to the: (a) total waste; (b) incinerated waste; (c) recycled waste; and (d) landfill waste. The construction of Kansai Airport second island commenced in 1999 and the construction of the runway started in 2003 (the runway become operational in 2007) [69]. The solid waste produced during construction projects would have contributed to the waste at the airport. For example, during the second phase island reclamation project, the airport dirt originating from Phase 1 of the project. Following the completion of Phase 1 of the reclamation project on 7 June 2006, around 750,000 m3 required waste disposal. From financial year 2002 to March 2006, the dirt generated by projects external to the airport island amounted to some 80,000 m3 [70].

Figure 3.

Annual waste quantities at Kansai International Airport during 2002–2015: (a) total; (b) incinerated; (c) recycled; and (d) landfill. The solid line shows the year-on-year percentage change relative to the dashed line (0%). Data derived from [60,66].

In Figure 3a, the year-on-year values suggest that there is additional waste present in the period of 2002 to 2007, as there is a decline which is maintained from 2008 onwards. As discussed previously, the construction projects are the probable cause of the additional waste prior to 2008. This trend can also be seen in the incinerated waste data (Figure 3b). In the case of industrial waste, Kansai Airport encourages business operating at the airport to manage their waste properly, avoid waste generation, and to recycle wastes where ever they can [60,67]. As part of its environmental policy and strategy, Kansai Airport places significant importance on the recycling of waste. Figure 3c shows that there is a clear relationship between the amount of waste generated and amount per passenger or aircraft movements at Kansai International Airport (when compared to Figure 1). As noted earlier, the disposal of waste in landfill sites is the viewed as the least desirable waste management option [3]. Notwithstanding, airports do generate distinct types of waste that is neither suitable for recycling or incineration and is, therefore, required to be disposed at landfill. Hence, the waste generated at Kansai International Airport that is neither suited for recycling nor for incineration is required to be deposited to a landfill. Figure 3d, shows a similar polarity to Figure 3a,b.

5. Quantitative Analysis

5.1. Summary Tables

In Section 4.4, the notable difference between the waste quantities during 2002–2007 and 2008–2015 was highlighted. These are the noticeable features in Figure 3. Table 4 shows the results of utilizing two-sampled t-tests assuming equal variance, to assess if the mean for 2008–2015 was significantly less than the mean for 2002–2007. As such, a one-tailed test was utilized. With 12 degrees of freedom, at the 99% confidence level, the critical value for the test was 2.68. The total waste, incinerated waste, and landfill waste all produced statistically significant results, and it can be concluded that there is less waste in the period of 2008–2015 relative to 2002–2007 (excluding recycling). The null result for recycling is not negative, as this suggests that a greater proportion of waste is being recycled.

Table 4.

Two sampled t-test results for quantities of waste 2002–2007 compared to 2008–2015.

Table 5 presents the results for the statistical testing from the regression analysis. Here, the waste parameters (total, incinerated, recycled, and landfill wastes) are statistically tested for various efficiency measures (per passenger, PAX, per aircraft movement, ATM, and as a percentage of total waste). As with the two-sample t-tests, a confidence level of 99% was utilized, and with 12 degrees of freedom for the one-tailed test, the critical t-value was 2.68. The table includes the correlation coefficients (r), the corresponding t-value, the conclusion to the statistical test, and the direction of the observed trend (increasing, decreasing, or constant. Each of these values is referred to specifically in the following sections.

Table 5.

Correlation assessment of waste parameters for various efficiency measures, all testing at the 99% confidence level, with 12 degrees of freedom, using a one-tailed test, with tcrit = 2.68.

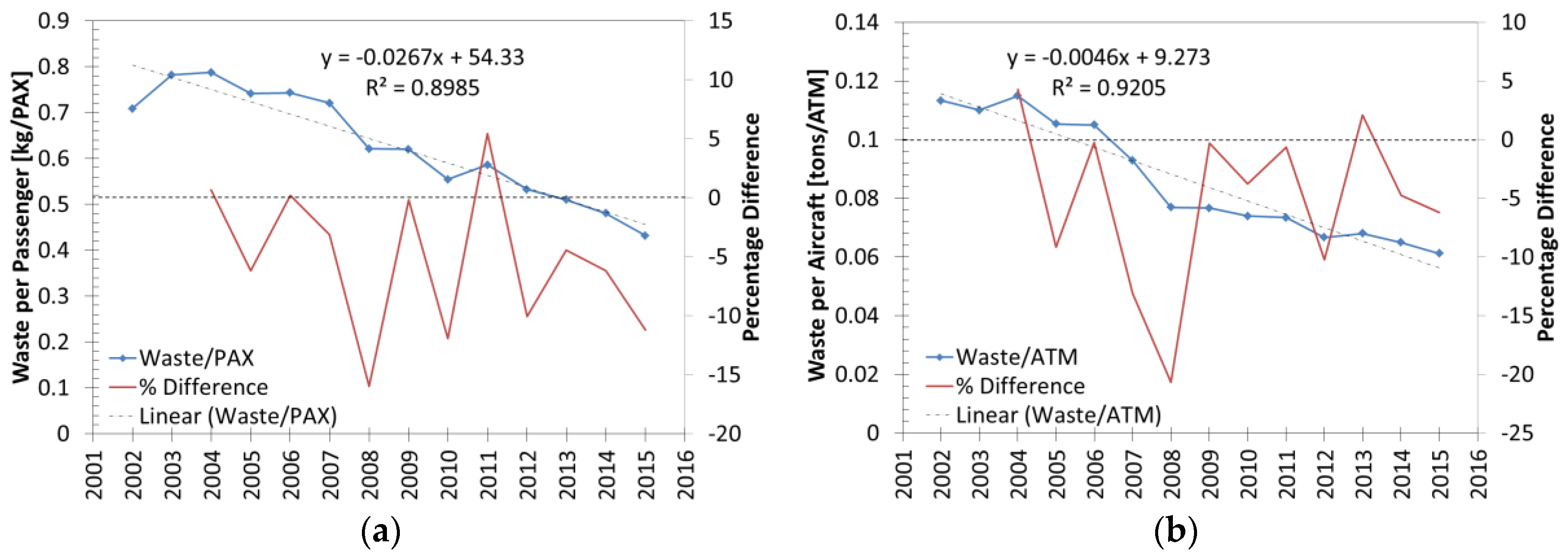

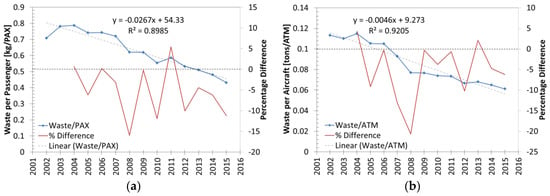

5.2. Total Waste Measures

One of the primary indicators of waste management efficiency at airports is the waste generated per passenger [3,14]. Figure 4a shows the total waste relative to the number of passengers through the airport. Based on the result of Table 5, the quantity of total waste per passenger (total per PAX) has decreased with time. Similarly, Figure 4b shows the trends in the total waste per aircraft movement at Kansai International Airport from 2002 to 2015. Again, Table 5 shows that the quantity of total waste per aircraft movement (total per ATM) has decreased with time. These metrics are major efficiency measures, and per year Kansai has managed to reduce the total waste per passenger by 26 g. Similarly, the airport has reduced the waste per aircraft movement per year by 4.6 kg.

Figure 4.

Total waste and year on year percentage difference at Kansai International Airport during 2002–2015: (a) per passenger; and (b) per aircraft movement. Source: Data derived from [60,66].

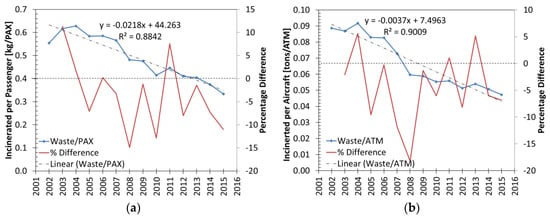

5.3. Incinerated Waste Measures

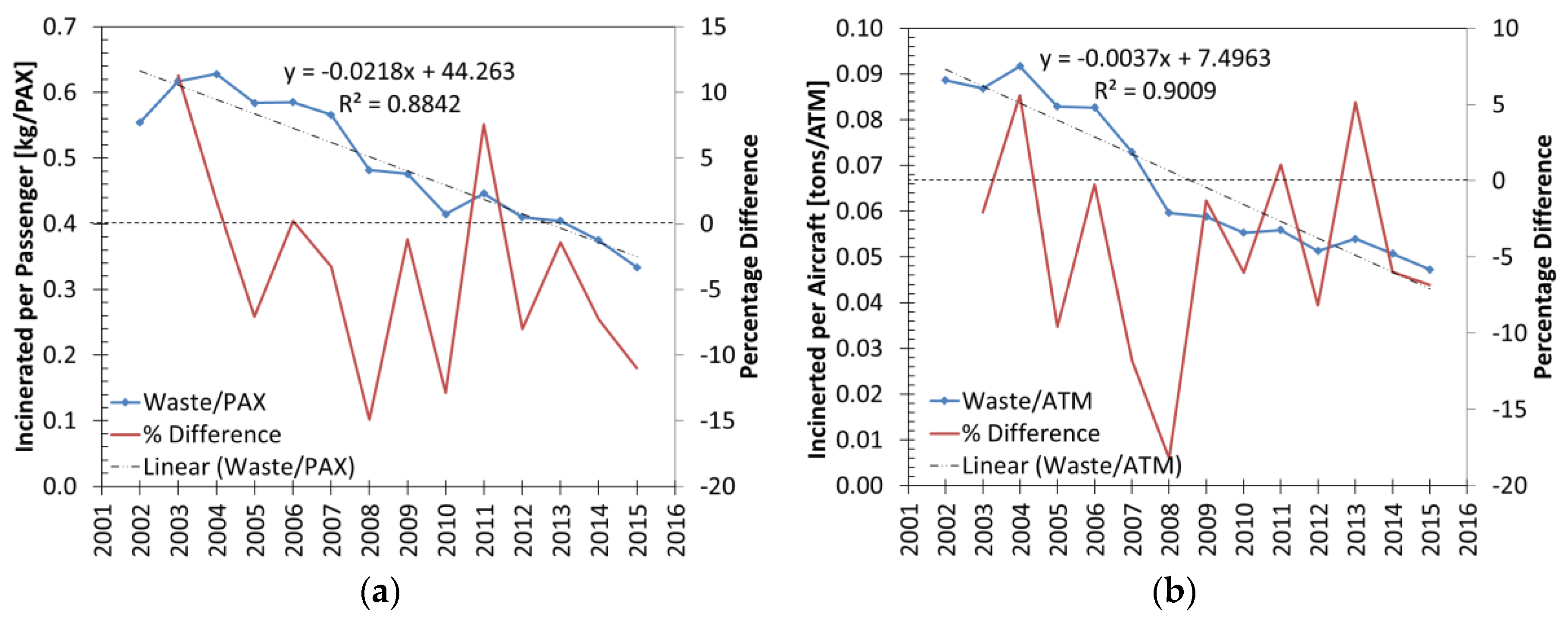

The amount of waste incinerated per passenger and per aircraft movement are illustrated in Figure 5a,b, respectively. In Table 5, both measures (incinerated per PAX and incinerated per ATM) show statistically significant reductions. That is, incinerated waste per passenger and per aircraft have both decreased overtime. Specifically, the reduction per year in incinerated waste per passenger has been 22 g, while the reduction per year in incinerated waste per aircraft movement has been 3.7 kg.

Figure 5.

Incinerated waste and year on year percentage difference at Kansai International Airport during 2002–2015: (a) per passenger; and (b) per aircraft movement. Source: Data derived from [60,66].

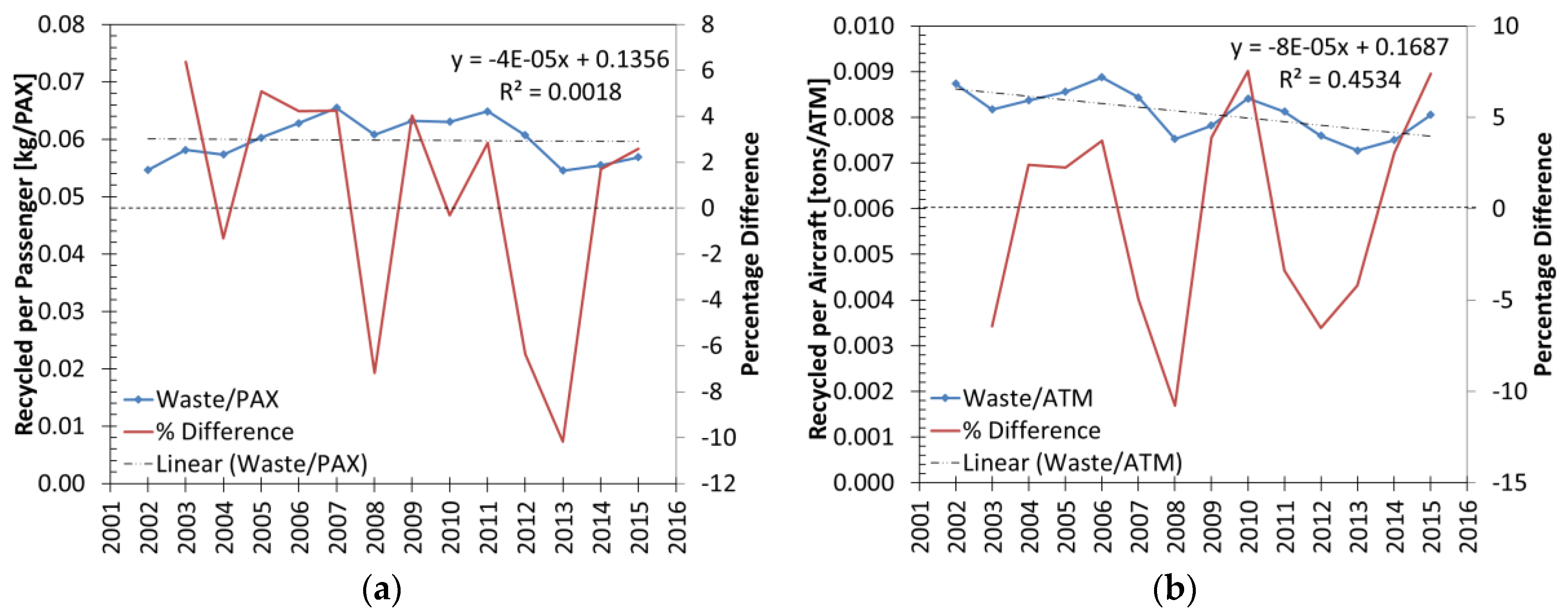

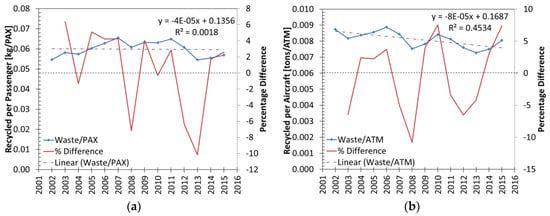

5.4. Recycled Waste Measures

The amount of waste recycled per passenger (PAX) and per aircraft movement (ATM) are illustrated in Figure 6a ,b, respectively. In Table 5, the recycled waste per PAX is statistically insignificant, indicating that the amount of waste per passenger has remained constant. In contrast, the recycled per ATM has a statistically significant decrease. That is, per year the amount of waste recycled per aircraft movement has reduced by 80 g. It is worth noting that no logical correlation between passengers or aircraft movements and amount of waste recycled is apparent. The marginally significant result for recycled per ATM is due more to the fact that ATMs have grown at a slower rate than the PAX. As such, the key parameter is the waste per PAX.

Figure 6.

Recycled waste and year on year percentage difference at Kansai International Airport during 2002–2015: (a) per passenger; and (b) per aircraft movement. Source: Data derived from [60,66].

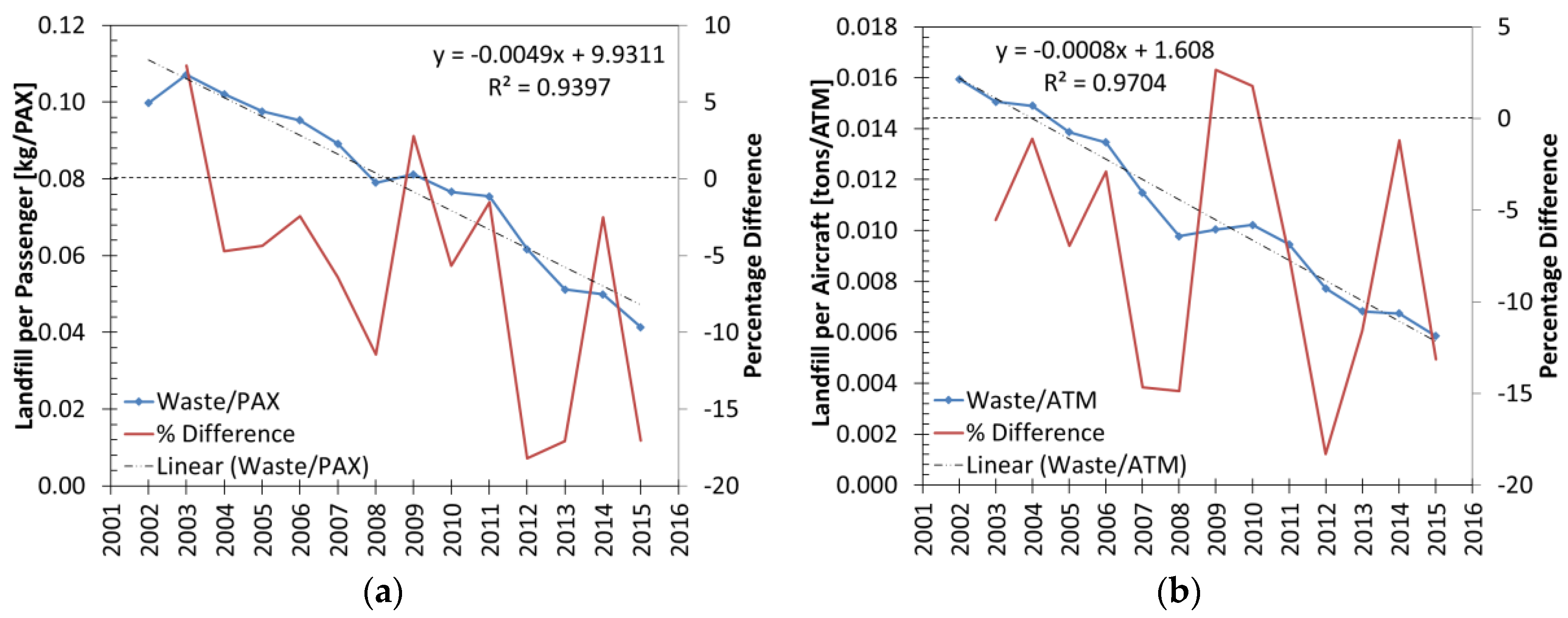

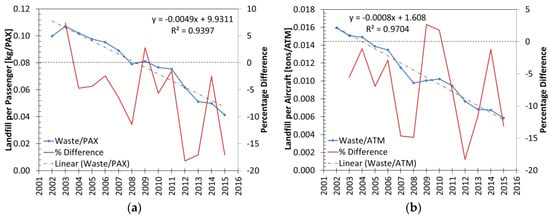

5.5. Landfill Waste Measures

Next, the amount of landfill per passenger (PAX) (Figure 7a) and per aircraft movement (ATM) (Figure 7b), are considered. Both datasets show a clear decrease in the amount of waste per passenger or aircraft movement. The results in Table 5 indicate that the landfill per PAX and landfill per ATM are the most statistically significant results. That is, both show a significant improvement over time, with the landfill per PAX per year reducing by 5 g, and the landfill per ATM per year reducing by 800 g.

Figure 7.

Landfill waste and year on year percentage difference at Kansai International Airport during 2002–2015: (a) per passenger; and (b) per aircraft movement. Source: Data derived from [60,66].

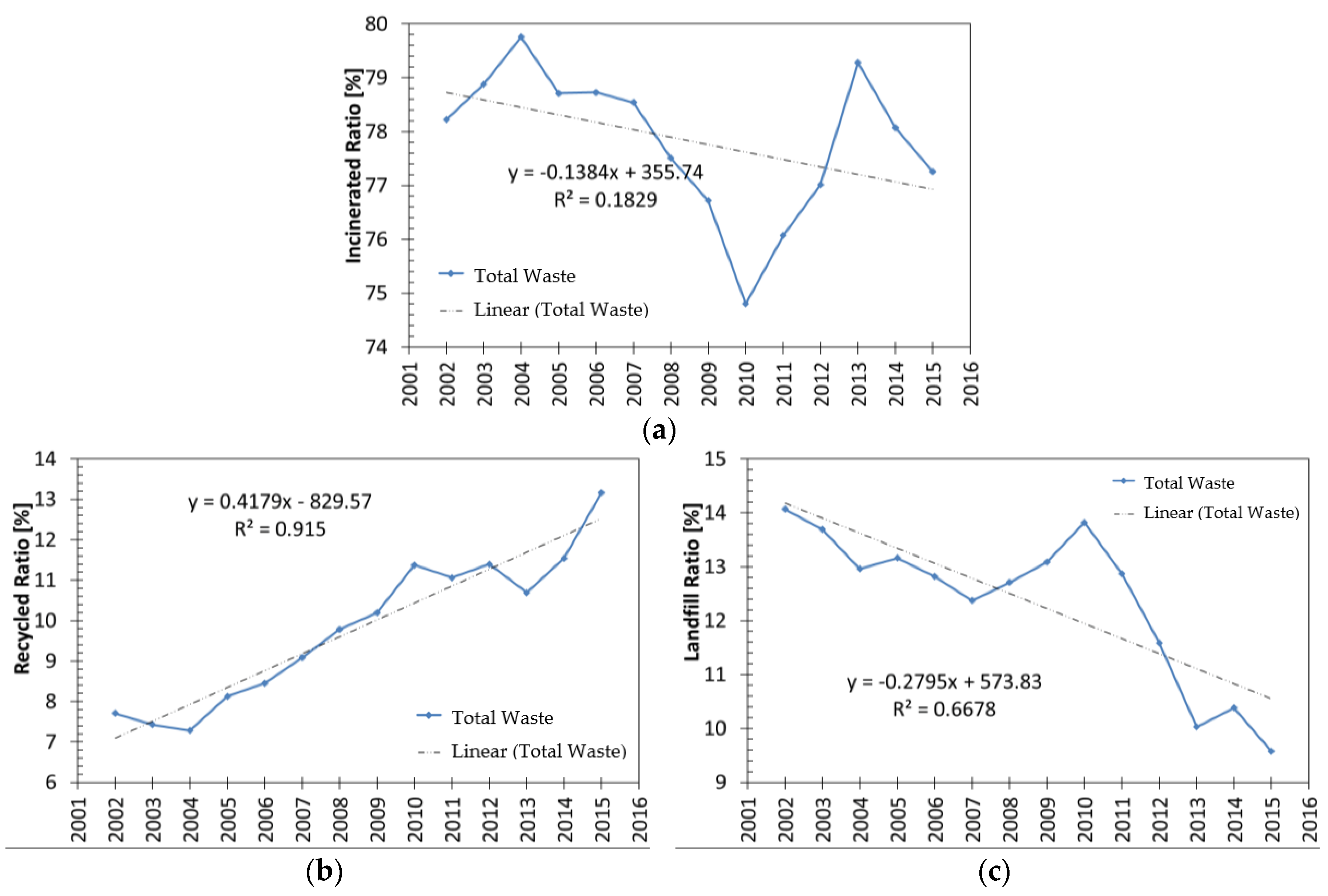

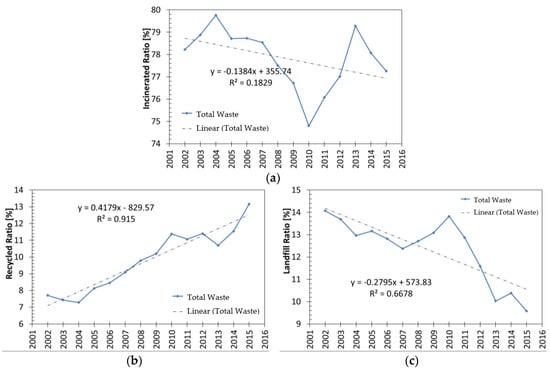

5.6. Waste Percentages

To quantitatively assess the environmental sustainability of the airport’s waste strategy, the proportions of waste incinerated, recycled, and sent to landfill are key metrics. Figure 8 shows the proportions of the total waste that are incinerated (Figure 8a), recycled (Figure 8b), and sent to landfill (Figure 8c). Figure 8a shows a slight decreasing trend in the percentage of waste incinerated; however, the result in Table 5 indicates the result is not statistically significant, and the general trend in the incinerated waste proportion has been constant from 2002 to 2015. In contrast, Figure 8b,c shows a positive and negative trend, respectively. The results in Table 5 indicates that the increase in the proportion of recycled waste is statistically significant, and the decrease in landfill waste is also statistically significant. Therefore, over the 14-year period of the study, total waste has decreased, and of that waste, less waste is being sent to landfill, and more is being recycled. This is a positive result for the waste management at Kansai International Airport, due to its waste management and handling systems and by working closely with the airport’s key stakeholders.

Figure 8.

Waste categories as a percentage of total waste at Kansai International Airport during 2002–2015: (a) incinerated; (b) recycled; and (c) landfill wastes. Note: solid blue line represents the annual trends in the incinerated, recycled and landfill wastes, the dash lines show the linear trend in these wastes. Source: Data derived from [60,66].

6. Discussion

6.1. Findings

Passenger and air cargo traffic are predicted to grow, and this will result in greater of volumes of waste at airports. To mitigate the environmental impact of aviation, all major airports should consider introducing sustainable waste management policies and systems. They will also need to comply with the relevant waste management regulatory framework.

This study has analysed waste management at Kansai International Airport, Japan’s third busiest airport. A key aim of Kansai International Airport is for the airport to be an “environmentally advanced airport” that is both people and earth-friendly. Accordingly, the airport has defined and implemented environmental policies and systems to mitigate the environmental impact of the waste generated at the airport. In addition to its environmental policies, Kansai International Airport needs to comply with the government’s 3Rs waste management hierarchy policy and a range of environment-related legislation. Whilst it is impossible to avoid waste at the airport, measures and systems are in place to reclaim and recycle as much waste as possible.

The case study has shown that the primary sources of the waste generated at Kansai International Airport are incinerable wastes such as those from the aircraft serving the airport, flight catering centres, and the airport’s terminal buildings. Airline generated waste accounts for approximately twenty per cent of the total waste generated at the airport. In general, the types of waste generated at Kansai International Airport is heterogeneous in nature. These wastes comprise kitchen waste, wood waste, non-recyclable paper, rags, steel and aluminium cans, unbroken glass and plastic bottles, newspaper (non-advertising), magazines, high quality paper, copier paper, paper generated in offices, and non-confidential documents as well as cardboard. In addition, wood waste, clothing, briefcases, vegetation clippings, wood products, glass containers, ceramic containers, broken glass bottles, and waste metal are also generated at the airport.

The case study showed that recycled waste is currently at 1364 tons per year, which represents 13% of the airport’s total annual waste, whilst the waste disposed by landfill is currently at 992 tons per year, and accounts for 9.6% of the airport’s total annual waste. The remaining 8000 tons (77%) are incinerated. To minimize and mitigate the environmental impact of waste generated, Kansai International Airport aims wherever possible to recycle as much waste as possible. The combustible waste is incinerated at the airport’s Clean Centre Incineration Plant. The wastes that are not suitable for incineration, that is, non-combustible wastes are sent to landfill for disposal. The recycling of resources is a key element in the airport’s environment policy, and thus, the airport works closely and collaboratively with the business operating at the airport to ensure that they sort their waste, so a greater amount of waste can be recycled.

6.2. Future Work

The airport’s Clean Centre Incineration plant plays a critical role in the waste disposal chain acting as the interface point with the stakeholders producing waste. The Clean Centre Incineration plant utilizes a range of technologies to mitigate the environmental impact of the exhaust gases released into the atmosphere. At the time of the current study, the incineration plant was not using combustible waste as a source of energy. Other airports around the world, for example, Copenhagen Airport, incinerate waste for district heating. A potential future study could examine the benefits of such an approach for Kansai International Airport.

As noted throughout this paper, the various activities that are performed at airports produce considerable volumes of waste. Considering the importance of waste management for airports and the relatively few studies reported in the literature, suggestions for future research would be to map the airport waste disposal chain and to identify possible areas for greater efficiency. In the case of Kansai International Airport, a further study could examine and map the waste handling practices inside the airport’s Clean Centre Incineration plant.

At the time of the present study, the annual volume of wastes by the waste classification number was not available. Thus, should these data become available, a future study could empirically examine the annual trends in waste by their classification number.

6.3. Recommendations

Procedures and technologies should be implemented by Kansai International Airport in terms of the Clean Centre Incineration plant, a centralized waste management centre onsite at the airport responsible for waste handling and distributing waste for offsite recycling and landfill. In addition to the practical waste management, the technology utilized in the plant is well suited to reduce the environmental impact of an airport. However, there is the potential to utilize the waste for energy generation, as seen at Copenhagen Airport [14].

The fundamental strategy to be taken from Kansai International Airport is the migration of non-combustible waste from landfill to recycling. Clearly, there is an operation cost in the collection and sorting of waste to increase the proportions of recyclable waste. However, as demonstrated by Kansai International Airport, working with other stakeholders, especially airlines, can result in improved recycling rates, without an associated operation cost for the airport. In fact, an airport can negation with stakeholders, who are almost always tenants, to have them implement strategies to recycle. The associated financial incentive an airport can offer to an airline could be a value less than the cost for the airport alone to implement.

The final recommendation goes towards the social sustainability. The “zero waste day” initiative is an ideal way for an airport to achieve environmental sustainability goals while simultaneously achieving social sustainability goals. It is typical for various nations to have such days; for example, Australia has Clean Up Australia Day. Initiatives such as this are ideal for airports to be involved, as such initiatives can help airports to reduce their waste volumes, whilst also raising waste awareness.

Acknowledgments

The authors would like to express their sincere gratitude to Mr. H. Shintani, Manager of the Environmental Division, Kansai International Airport for the permission to the use the airport’s annual environmental performance data.

Author Contributions

Glenn Baxter conceived the paper and wrote the first draft paper. All authors contributed equally to the data analysis and editing of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dimitriou, D.J.; Voskaki, A.J. Regional airports’ environmental management: key messages from the evaluation of ten European airports. In Regional Airports; Postorino, M.N., Ed.; WIT Press: Southampton, UK, 2011; pp. 73–86. [Google Scholar]

- Edwards, B. The Modern Airport Terminal: New Approaches to Airport Architecture, 2nd ed.; Spon Press: Abingdon, UK, 2005. [Google Scholar]

- Pitt, M.; Smith, A. An assessment of waste management efficiency at BAA airports. Constr. Manag. Econ. 2003, 21, 421–431. [Google Scholar] [CrossRef]

- Zhu, D.; Asnani, P.U.; Zurbrugg, C.; Anapolsky, S.; Mani, S. Improving Municipal Solid Waste Management in India: A Sourcebook for Policy Makers; The World Bank: Washington, DC, USA, 2008. [Google Scholar]

- Rushbrook, P. The challenge to achieve better landfills where only dumps are achieved now: An anthology. In Health Impacts of Waste Management Policies, Proceedings of the Seminar ‘Health Impacts of Waste Management Policies’, Hippocrates Foundation, Kos, Greece, 12–14 November 1998; Nicolopoulou-Stamati, P., Hens, L., Howard, V.C., Eds.; Springer Science+Business Media: Dordrecht, The Netherlands, 2000; pp. 41–56. [Google Scholar]

- Jiménez-Rivero, A.; de Guzmán-Báez, A.; García-Navarro, J. Enhanced on-site waste management of plasterboard in construction works: A case study in Spain. Sustainability 2017, 9, 450. [Google Scholar] [CrossRef]

- Seadon, J.K. Sustainable waste management systems. J. Clean. Prod. 2010, 18, 1639–1651. [Google Scholar] [CrossRef]

- Pitt, M.; Smith, A. Waste management efficiency at UK airports. J. Air Transp. Manag. 2003, 9, 103–111. [Google Scholar] [CrossRef]

- Atkin, P.; Hershkowitz, A.; Hoover, D. Trash Landings: How Airlines and Airports Can Clean Up their Recycling Programs. Available online: https://www.nrdc.org/cities/recycling/airline/airline.pdf (accessed on 24 November 2017).

- Mehta, P. Aviation waste management: An insight. Int. J. Environ. Sci. 2015, 5, 179–186. [Google Scholar]

- Ministry of the Environment. The 3R Initiative. Available online: https://www.env.go.jp/recycle/3r/en/outline.html (accessed on 21 January 2018).

- Yoshida, H. Japans’ Experience in Waste Management and Recycling. Available online: https://www.env.go.jp/en/earth/ecoasia/congress/2007sept/03–1.pdf (accessed on 21 January 2018).

- Thomas, C.; Hooper, P. Sustainable development and environmental capacity of airports. In Airport Operations, 3rd ed.; Ashford, N.J., Stanton, H.P.M., Moore, C.A., Coutu, P., Beasley, J.R., Eds.; McGraw-Hill: New York, NY, USA, 2013; pp. 553–578. [Google Scholar]

- Baxter, G.; Wild, G.; Sabatini, R. A sustainable approach to airport design and operations: A case study of Munich Airport. In Proceedings of the 2014 Conference on Practical Response to Climate Change (PRCC), Melbourne, Australia, 25–27 November 2014; Arora, M., Sutherland, G., Moore, G., Eds.; Engineers Australia: Melbourne, Australia, 2014; pp. 227–237. [Google Scholar]

- Rossi Dal Pozzo, F. EU Legal Framework for Safeguarding Air Passenger Rights; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- United States Federal Aviation Administration. Recycling, Reuse and Waste Reduction at Airports: A Synthesis Document. Available online: https://www.faa.gov/airports/resources/publications/reports/environmental/media/RecyclingSynthesis2013.pdf (accessed on 12 September 2017).

- Culberson, S.D. Environmental impact of airports. In Airport Engineering: Planning, Design, and Development of 21st Century Airports, 4th ed.; Ashford, N.J., Mumayiz, S.A., Wright, P.H., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 704–738. [Google Scholar]

- Chandrappa, R.; Das, D.B. Solid Waste Management: Principles and Practice; Springer: Heidelberg, Germany, 2012. [Google Scholar]

- El-Mobaidh, A.M.; Taha, M.A.R.; Lassheen, N.K. Classification of in-flight catering wastes in Egypt air flights and its potential as energy source (chemical approach). Waste Manag. 2006, 26, 587–591. [Google Scholar] [CrossRef] [PubMed]

- Kazda, T.; Caves, B.; Kamenický, M. Environmental control. In Airport Design and Operation, 3rd ed.; Kazda, A., Caves, R.E., Eds.; Emerald Group Publishing: Bingley, UK, 2015; pp. 457–500. [Google Scholar]

- Pitt, M.; Brown, A.; Smith, A. Waste management at airports. Facilities 2002, 20, 198–207. [Google Scholar] [CrossRef]

- Graham, A. Managing Airports: An International Perspective, 4th ed.; Routledge: Abingdon, UK, 2014. [Google Scholar]

- Hooper, P.; Heath, B.; Maughan, J. Environmental management and the aviation industry. In Towards Sustainable Aviation; Upham, P., Maughan, J., Raper, D., Thomas, C., Eds.; Earthscan Publications: London, UK, 2003; pp. 115–130. [Google Scholar]

- Janić, M. Greening Airports: Advanced Technology and Operations; Springer: London, UK, 2011. [Google Scholar]

- Fulekar, M.H. Environmental Biotechnology; AK Peters/CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Skrifvars, M.; Åkesson, D. Recycling of thermoset composites. In Resource Recovery to Approach Zero Municipal Waste; Taherzadeh, M.J., Richards, T., Eds.; CRC Press: Boca Raton, FL, USA, 2016; pp. 249–260. [Google Scholar]

- Rahman, M.; Pudasainee, P.; Gupta, R. Urban waste (municipal solid waste-MSW) to energy. In Sustainability in the Mineral and Energy Sectors; Devasahayam, S., Dowling, K., Mahapatra, M.K., Eds.; CRC Press: Boca Raton, FL, USA, 2017; pp. 499–530. [Google Scholar]

- Fleuti, E. Waste Management. Presented at the 2nd ACI Airport Environment Seminar, Quito, Ecuador, 24–25 November 2010; Available online: http://www.aci.aero/Media/aci/file/2008%20Events/Envirnonmental%20Colloquium/presentations%20pdf/42%20fleuti%20WasteMgmt.pdf (accessed on 27 September 2017).

- Spilsbury, L. Waste and Recycling Challenges; The Rosen Publishing Group: New York, NY, USA, 2010. [Google Scholar]

- Carysforth, C.; Neild, M. GCSE Applied Business for Edexcel: Double Award; Heinemann Publishers: Oxford, UK, 2002. [Google Scholar]

- Copenhagen Airports A/S. Environmental Report 2008. Available online: https://www.cph.dk/contentassets/fe47a2fb90bd4688a72aa2987119d645/miljo2008_uk.pdf (accessed on 20 September 2017).

- Guyer, J.P. Engineering Soundbite: Solid Waste Incineration; Amazon Digital Services, Inc.: Seattle, WA, USA, 2011. [Google Scholar]

- McDougall, F.R.; White, P.R.; Franke, M.; Hindle, P. Integrated Solid Waste Management: A Life Cycle Inventory; Blackwell Science: Oxford, UK, 2007. [Google Scholar]

- Scragg, A.H. Biofuels: Production, Application and Development; CABI: Wallingford, UK, 2009. [Google Scholar]

- Ponte-Cueto, E.; González-Manteca, J.A. Impact of emerging environmental regulations on the reverse logistics system for portable batteries in Spain. In Environmental Issues in Supply Chain Management: New Trends and Applications; Golinska, P., Andres Romano, C., Eds.; Springer: Berlin, Germany, 2012; pp. 155–172. [Google Scholar]

- Marc Simon, J. Mechanical Biological Treatment (MBT) & Zero Waste. Available online: https://zerowasteeurope.eu/2011/09/mechanical-biological-treatment-mbt-zero-waste/ (accessed on 21 January 2018).

- Creswell, J.W.; Plano Clark, V.L. Designing and Conducting Mixed Methods Research, 3rd ed.; SAGE Publications: Singapore, 2017. [Google Scholar]

- Andrew, S.; Halcomb, E.J. Mixed Methods Research for Nursing and the Health Sciences; Blackwell Publishing: Chichester, UK, 2009. [Google Scholar]

- Creswell, J.W. A Concise Introduction to Mixed Methods Research; SAGE Publications: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- McNabb, D.E. Research Methods in Public Administration and Nonprofit Management: Quantitative and Qualitative Approaches, 3rd ed.; Routledge: Abingdon, UK, 2015. [Google Scholar]

- Morgan, D. Integrating Qualitative and Quantitative Methods: A Pragmatic Approach; SAGE Publications: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Beach, D.; Pedersen, R.B. Causal Case Study Methods: Foundations and Guidelines for Comparing, Matching, and Tracing; The University of Michigan Press: Ann Arbor, MI, USA, 2018. [Google Scholar]

- Fasone, V.; Maggiore, P. “Non-Aviation” activities and the introduction of new thinking and ideas in the airport business: Empirical evidence from an Italian case study. J. Airl. Airpt. Manag. 2012, 2, 34–50. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods, 6th ed.; SAGE Publications: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Ramon Gil-Garcia, J. Enacting Electronic Government Success: An Integrative Study of Government-Wide Websites, Organizational Capabilities, and Institutions; Springer Science-Business Media: New York, NY, USA, 2012. [Google Scholar]

- Chester, L. A rėgulationist analysis of an industry sector using mixed research methods. In Handbook of Research Methods and Applications in Heterodox Economics; Lee, F.S., Cronin, B., Eds.; Edward Elgar Publishing: Cheltenham, UK, 2016; pp. 569–590. [Google Scholar]

- Fitzgerald, T. Documents and documentary analysis. In Research Methods in Educational Leadership and Management, 3rd ed.; Briggs, A.N.R.J., Coleman, M., Morrison, M., Eds.; SAGE Publications: London, UK, 2012; pp. 296–308. [Google Scholar]

- Love, P. Document analysis. In Research in the College Context: Approaches and Methods; Stage, F.K., Manning, K., Eds.; Brunner-Routledge: New York, NY, USA, 2003; pp. 83–96. [Google Scholar]

- Scott, J.; Marshall, G. A Dictionary of Sociology, 3rd ed.; Oxford University Press: Oxford, UK, 2009. [Google Scholar]

- O’Leary, Z. The Essential Guide to doing Research; SAGE Publications: London, UK, 2004. [Google Scholar]

- Andrews, D.P.S.; Pedersen, P.M.; McEvoy, C.D. Research Methods and Design in Sport Management; Human Kinetics: Champaign, IL, USA, 2011. [Google Scholar]

- Heiman, G.W. Basic Statistics for the Behavioral Sciences, 6th ed.; Wadsworth Cengage Learning: Belmont, CA, USA, 2011. [Google Scholar]

- Heavey, E. Statistics for Nursing: A Practical Approach; Jones & Bartlett Learning: Sudbury, MA, USA, 2011. [Google Scholar]

- Ministry of the Environment. History and Current State of Waste Management in Japan. Available online: https://www.env.go.jp/en/recycle/smcs/attach/hcswm.pdf (accessed on 17 January 2018).

- Wen, X.; Luo, Q.; Hu, H.; Wang, N.; Chen, Y.; Jin, J.; Hao, Y.; Xu, G.; Li, F.; Fang, W. Comparison research on waste classification between China and the EU, Japan, and the USA. J. Mater. Cycles Waste Manag. 2014, 16, 321–334. [Google Scholar] [CrossRef]

- Moorman, R.W. Osaka to me. Air Transp. World 1994, 31, 62–65. [Google Scholar]

- Ishikura, T.; Sugimura, Y.; Ishii, M. Fiscal characteristics of Incheon International Airport and Kansai International Airport. Proc. East. Asia Soc. Transport. Stud. 2005, 5, 520–532. [Google Scholar]

- Morikawa, Y.; Tabata, T.; Emura, T. Ground improvement for the second phase construction of Kansai International Airport. In Advances in Deep Foundations: International Workshop on Recent Advances of Deep Foundations; Kikuchi, Y., Kimura, M., Otani, J., Morikawa, Y., Eds.; Taylor & Francis Balkema: Leiden, The Netherlands, 2007; pp. 389–394. [Google Scholar]

- Kansai Airports. Premises and Facilities at Kansai International Airport. Available online: http://www.kansai-airports.co.jp/en/company-profile/about-airports/kix.html (accessed 24 November 2017).

- New Kansai International Airport Company, Ltd. Environmental Report 2014. Available online: http://www.kansai-airports.co.jp/en/efforts/environment/file/envreport2014.pdf (accessed on 23 November 2017).

- Kansai Airports. Smart Island Report 2016. Available online: http://www.kansai-airports.co.jp/en/efforts/environment/kix/smart-island/file/smart_rprt16.pdf (accessed on 23 November 2017).

- Kansai International Airport Company, Ltd. Kansai International Airport Environmental Management Project. Available online: http://www.kiac.co.jp/pdf/report_emp_en.pdf (accessed on 24 November 2017).

- Anna Aero. Kansai International Airport Benefits from LCC Expansion from Peach Aviation and Jetstar Japan. Available online: http://www.anna.aero/2014/11/19/kansai-international-airport-benefits-from-lcc-expansion/ (accessed on 24 November 2017).

- Kansai Airports. Kansai International Airport Statistics. Available online: http://www.kansai-airports.co.jp/en/company-profile/about-airports/kix.html (accessed on 24 November 2017).

- Kansai Airports. KIX—International Flights Per Week (Departure & Arrival). Available online: http://www.kansai-airports.co.jp/en/company-profile/about-airports/file/flight.pdf (accessed on 24 November 2017).

- Kansai International Airport. KIX Eco-Island Environmental Report 2013. Available online: http://www.kansai-airports.co.jp/en/efforts/environment/kix/smart-island/file/kixeco_rprt13.pdf (accessed on 23 November 2017).

- Baxter, G.; Kourousis, K. Temperature controlled aircraft unit load devices: The technological response to growing global air cargo cool chain requirements. J. Technol. Manag. Innov. 2015, 10, 157–172. [Google Scholar] [CrossRef]

- Kansai International Airport. KIX Smart Island Environmental Report 2015. Available online: http://www.kansai-airports.co.jp/en/efforts/environment/kix/smart-island/file/smart_rprt15.pdf (accessed on 23 November 2017).

- Airport Technology. Kansai International Airport (KIX/RJBB). Available online: http://www.airport-technology.com/projects/kansai/ (accessed on 25 November 2017).

- Kansai International Airport. Kansai International Airport Eco-Island Report 2007. Available online: http://www.kansai-airports.co.jp/en/efforts/environment/kix/smart-island/file/kixeco_rprt07.pdf (accessed on 26 November 2017).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).