Abstract

The printed electronics sector is experiencing significant growth driven by societal expectations. The use of cellulosic substrates is an excellent strategy that offers interesting research prospects, but also sets challenges in terms of management and recycling of these new wastes to avoid their accumulation. This work investigates the recycling ability of paper-based printed electronics (a simple RFID antenna printed on paper), containing silver particles in the functional ink, using processes already applied in conventional paper and board recycling lines. These operations, commonly used in the papermaking industry, are pulping, screening, centrifugal cleaning, and flotation. The efficiency of each unit operation was evaluated. Mass balances between the inlet and the outlet of each studied operation have been established in order to evaluate the separation efficiency of Ag and cellulosic fibers, the objective being to reuse the fibers to manufacture a recycled paper, and to recover Ag in another fraction for further valorization. The results are encouraging, with more than 70% of silver and over 80% of cellulose fibers recovered, demonstrating a higher recovery efficiency compared to typical recycling methods reported in the literature. Thus, it has been shown that existing processes used in conventional recycling lines can be adapted to efficiently separate functional materials from cellulosic fibers, offering an improvement in both metal and fibers’ recovery.

1. Introduction

Today, there is a high demand for electrical and electronic equipment (EEE), which generates a significant amount of waste at the end of its life cycle. This waste is known as electronic waste (e-waste). E-waste includes all components, subassemblies, and consumables that become part of the equipment when it is discarded, reused, recycled, recovered, disposed of, or manufactured. According to the European Union [1,2], e-waste is a category of waste that includes equipment that operates under the influence of electric current or electromagnetic fields. However, their classification into precisely defined different categories has to be considered carefully [3,4,5]. Considering the large amount of e-waste, which may be due to the rapid growth of technology, consumer demand, and the rapid growth of Internet of Things (IoT) technology [6,7,8,9], several actions have been taken to minimize and overcome the huge amount of electronic waste.

This strategy focuses on recent research into new technologies that can solve the emerging problem of electronic waste accumulation more effectively and efficiently [10,11,12,13]. In this context, printed electronics (PEs) is a promising and environmentally friendly technology that consists of printing electrical circuits on substrates of various types. This technique makes it possible to add new features such as device flexibility, low cost, and technologically innovative products [14,15,16,17]. Although the introduction of electronic products printed on paper represents an interesting solution to reduce the production of conventional electrical and electronic equipment waste, their end of life remains a key issue that requires deeper research. Electronic devices printed on cellulosic substrates are developing rapidly. These printed products are found on packaging, magazines, or labels, and, after their use, they may be eliminated as part of traditional selective sorting. These electronic devices on cellulosic supports are composed of more than 90% cellulose, a natural and renewable bioresource that is also inexpensive and recyclable. However, PEs contain many precious materials containing conductive noble metals (such as gold, silver, copper, and palladium), conductive or insulating polymers, and silicon components.

These paper-based electronic components can be recycled, and the functional materials and fibers could be recovered and reused for other applications. Several recent works [18,19,20,21] clearly show that recycling paper printed with electronic circuits is an effective method of fiber recovery [18,21]. The main challenge in recycling electronic paper products is to sufficiently remove contaminants while obtaining clean fibers suitable for new paper production cycles. Thus, efficient fiber–metal separation performance is necessary because metals are considered impurities in the paper recycling process [22,23]. The choices of conductive materials are strongly linked to the nature of the functional materials to be prepared and their intrinsic characteristics (nano- and/or micro-sized metal particles, polymers, carbon nanostructures, etc.), which can be used in ink formulations [24]. In printed electronics, the choice of formulation is highly dependent on the nature of the materials, which can be categorized according to their function: (i) conductor; (ii) semiconductor; (iii) dielectric/insulator. For example, in the case of conductive inks, metal-based inks have the highest conductivity compared to other types of conductive inks. In particular, silver is the most widely used metal for printed electronics due to its high conductivity and stability even after oxidation [18]. To ensure an efficient recycling cycle, the separation of silver from cellulosic fibers and their recovery and reuse is of equal importance [21,25,26]. This approach is part of a framework of eco-design development and the circular economy. To achieve this, the recycling process must be optimized to achieve the highest possible separation efficiency while remaining economically viable. The aim of this work is to identify and optimize the most promising unit operations for the recycling of electronic devices printed on cellulose substrates, the principal objective being to separate efficiently the cellulose fibers and the silver originating from the functional ink. The operations studied are those used for printed graphical paper recycling. This includes pulping, screening, centrifugal cleaning, and flotation deinking, since they are classical technologies to separate ink from cellulosic fibers. A description of these technologies is provided in Section 3.

Recent studies have highlighted the growing importance of recycling printed electronics, particularly in recovering valuable metals such as silver. Mishra et al. [27] reviewed hydrometallurgical methods for recovering silver from waste printed circuit boards (WPCBs), emphasizing the significance of silver recovery in electronic waste management. Sudheshwar [28] compared paper-based printed electronics with conventional printed circuit boards, underscoring the need for design-for-recycling approaches. Xia [29] reviewed sustainable technologies for recycling metals from e-waste, providing insights into the challenges and advancements in the field. Erkmen [30] discussed novel technologies for recycling critical metals from end-of-life materials, addressing the challenges and opportunities in e-waste recycling. Mohamed [31] analyzed the role of electronic waste as a secondary source of critical and precious minerals, discussing the environmental, economic, and technological aspects of e-waste recovery. These studies align with the United Nations Sustainable Development Goals, particularly SDG 12 (Responsible Consumption and Production) and SDG 9 (Industry, Innovation, and Infrastructure), by promoting sustainable recycling practices and the recovery of valuable resources from electronic waste.

To assess the possibility for a paper-based electronic device to be recycled in a classical paper and board recycling line, the recycling of a simple PE has been investigated at lab scale, testing one by one the separation processes in a batch mode. A material balance and a characterization of the fractions separated by each unit operation have been conducted to evaluate the efficiency, and in the first part, the PE, supplied by an industrial papermaker, has been characterized.

2. Results and Discussion

2.1. Paper-Based Printed Electronic (PE) Characterization

First, the industrial PE has been characterized in terms of composition and properties.

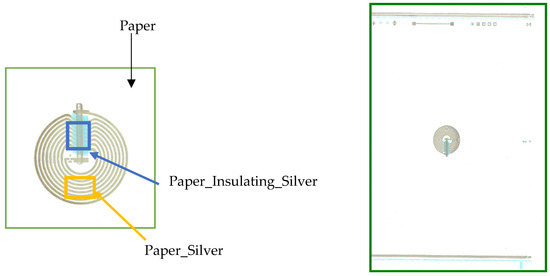

The basis weight of the paper substrate is close to 80 g·m−2. The surface of the printed paper was analyzed, in particular at the level of the antenna, which contains silver (5 mg ± 0.1/antenna) ink (gray) and an insulator (blue). The antenna is circular and is printed on an area of 4 cm2. The electrical resistance is measured with an ohmmeter (50 Ω). The chemical composition of the printed electronic has been determined. The analysis consists of calcination of a given mass of material in an oven at 525 ± 25 °C for 4 h. At this temperature, all organic matter, including fibers, is burned, and the residue called “ash” corresponds to the inorganic matter content (mineral fillers and other possible inorganics, in particular silver). The studied printed electronic is made of 73.8% organic and 26.2% inorganic matter. Then, the inorganic fraction was further calcined at 900 °C to decompose any remaining organic matter and stabilize the mineral matrix, and the resulting residue was acid leached to determine the Ag content using atomic absorption spectroscopy (AAS).

The morphological analysis of the fibers contained in the paper substrate of the PE was also carried out using the Morfi to evaluate the quality of the fibers. The average arithmetic length of the fibers, the average diameter, and the percentage of fine elements are 736 µm, 22.5 µm, and 29.5%, respectively. The ratio of length to diameter (form factor) is of the order of 33. The average arithmetic lengths of softwood and hardwood fibers are typically 2–3 mm and 1–2 mm, respectively, and the corresponding length-to-diameter ratios are close to 100 and 60, respectively. Thus, the cellulose fibers present in the studied PE are mainly hardwood fibers.

The mechanical properties as well as brightness of the unprinted paper substrate (XD80 paper) were measured on laboratory sheet (handsheet) of similar basis weight (i.e., 77 g·m−2 versus 80 g·m−2 for the paper roll), after paper disintegration in water, in order to be compared with sheets also made at lab scale using fibers recovered after the recycling operations. The paper was easily disintegrated, using classical pulping conditions, and the handsheets were produced in good conditions without any problems. The results are provided in Table 1. These values are the reference ones and will be compared to the paper sheets issued from the recycling process.

Table 1.

Mechanical and optical properties of the unprinted XD80 industrial paper.

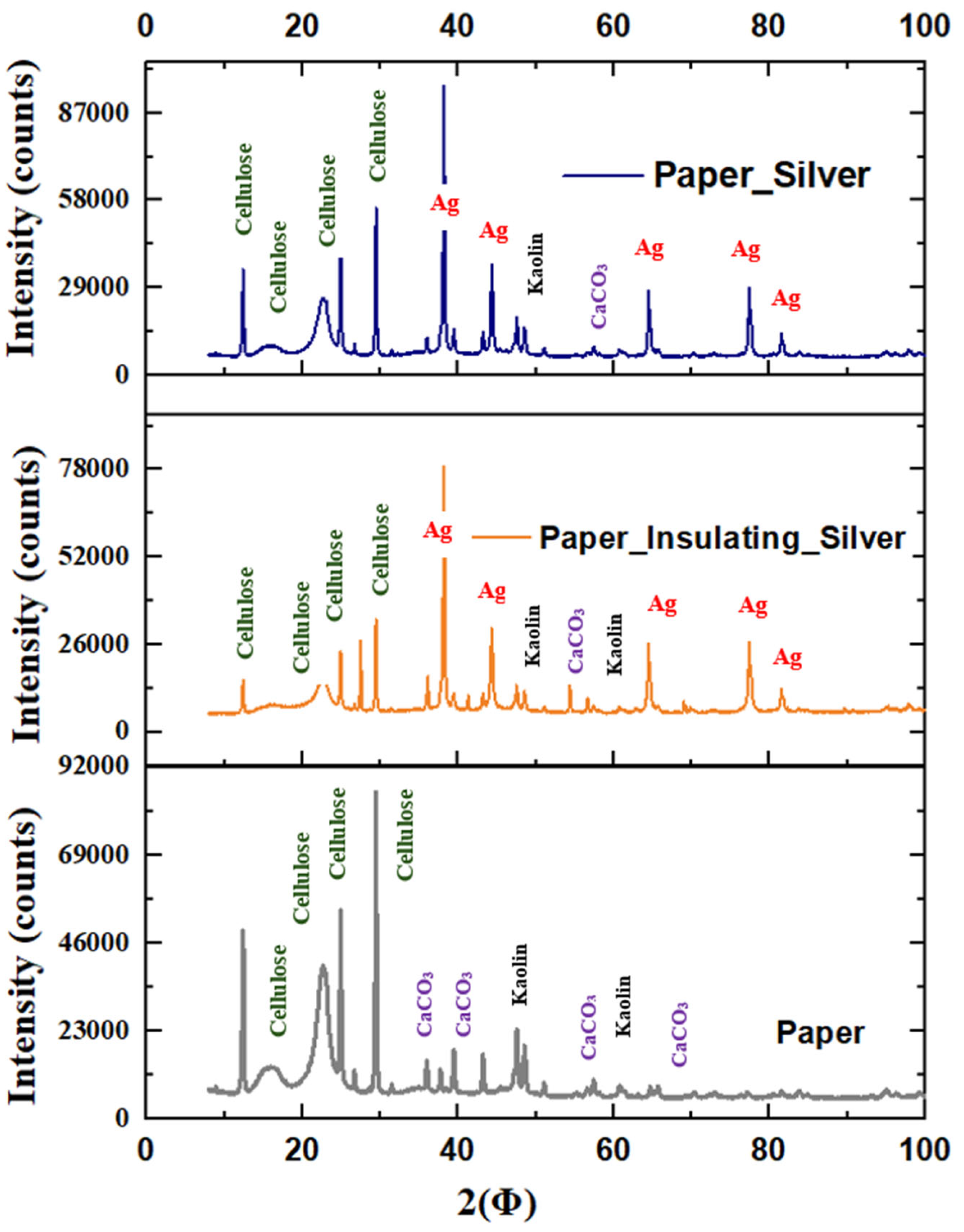

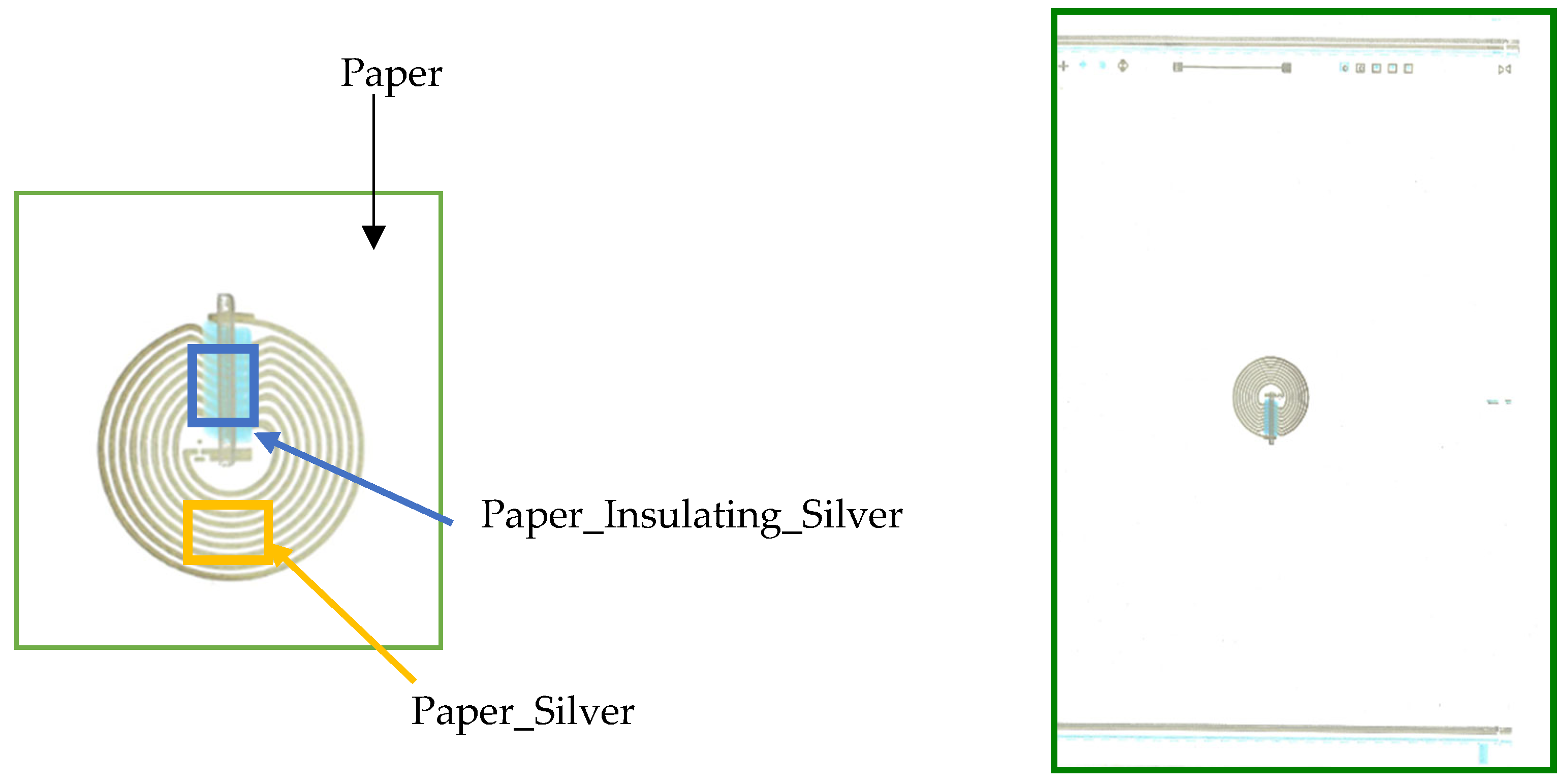

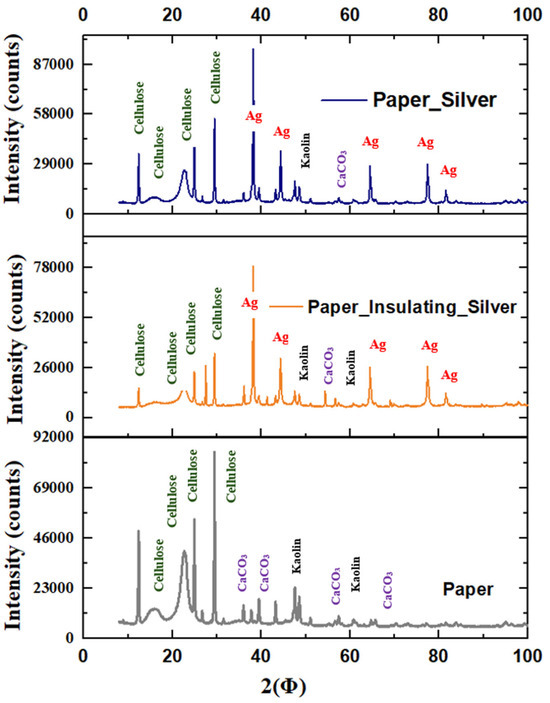

To investigate in more detail the composition of the industrial paper and of the antenna, an XRD analysis of the paper surface was carried out using the conventional Bragg–Brentano method. Figure 1 shows the XRD results obtained after analyzing three different areas on the PE device (paper alone, paper with silver, and paper with silver and insulation material, see Section 3, part 1).

Figure 1.

XRD spectra of PE device, analysis made on 3 different zones (paper, paper with silver, and paper with silver and insulation material).

From these spectra, several crystalline phases have been detected and identified: Cellulose I beta, CaCO3 (calcite form), TiO2 (rutile form), AgCl (minority), and Ag (majority). These phases are polycrystalline, since all the expected planes are found in the spectra, regardless of their intensities. The analysis of each plane can lead to the following conclusions:

- The paper itself is composed of cellulose I beta and CaCO3 (calcite form), which are mainly observed. The peaks of the typical structure of cellulose I in the diffraction pattern are detected at 16° and 22°. They correspond to the (110) and (002) planes of the crystalline zone. The peaks associated with the amorphous part of cellulose are observed at 34.8°, corresponding to the (004) plane. Other compounds such as minerals, in particular CaCO3 (calcite form) were observed at 29.3°, 36°, 39.5°, 47–49°, 57–58°, and 61–62°. The analysis also highlights some very low-intensity peaks, which may be related to the presence of kaolinite-1A, traces of talc-2M, and another phase very close to talc (Mg3Si4O10(OH)2,H2O). These elements are fillers commonly used in the paper industry in the bulk and/or on the surface of the paper. The layer deposited on the surface of the paper consists essentially of a mixture of calcium carbonate and kaolin.

- Analysis of the “Paper_Silver zone” surface: the result is very similar to that of the “Paper” surface. The same peaks as described above can be observed within the diffraction pattern. In addition, silver particles can be detected clearly at 38°, 44°, 64.5°, 78°, 83°, and 98°.

- Analysis of the “Paper_Insulating_Silver” reveals an additional presence of TiO2 rutile form (27°, 41°, 54°, 57°, 63°, 69.70°, 90°, 95°). On the other hand, the traces that we had previously observed for talc and “talc hydrate” are now almost imperceptible.

From this analysis, it can be concluded that fillers mainly come from the paper substrate itself, and they were identified as mainly calcium carbonate with a minor contribution of kaolin. The functional ink contains silver, and the insulating material also provides some minerals under TiO2 form, but in a rather low quantity (traces).

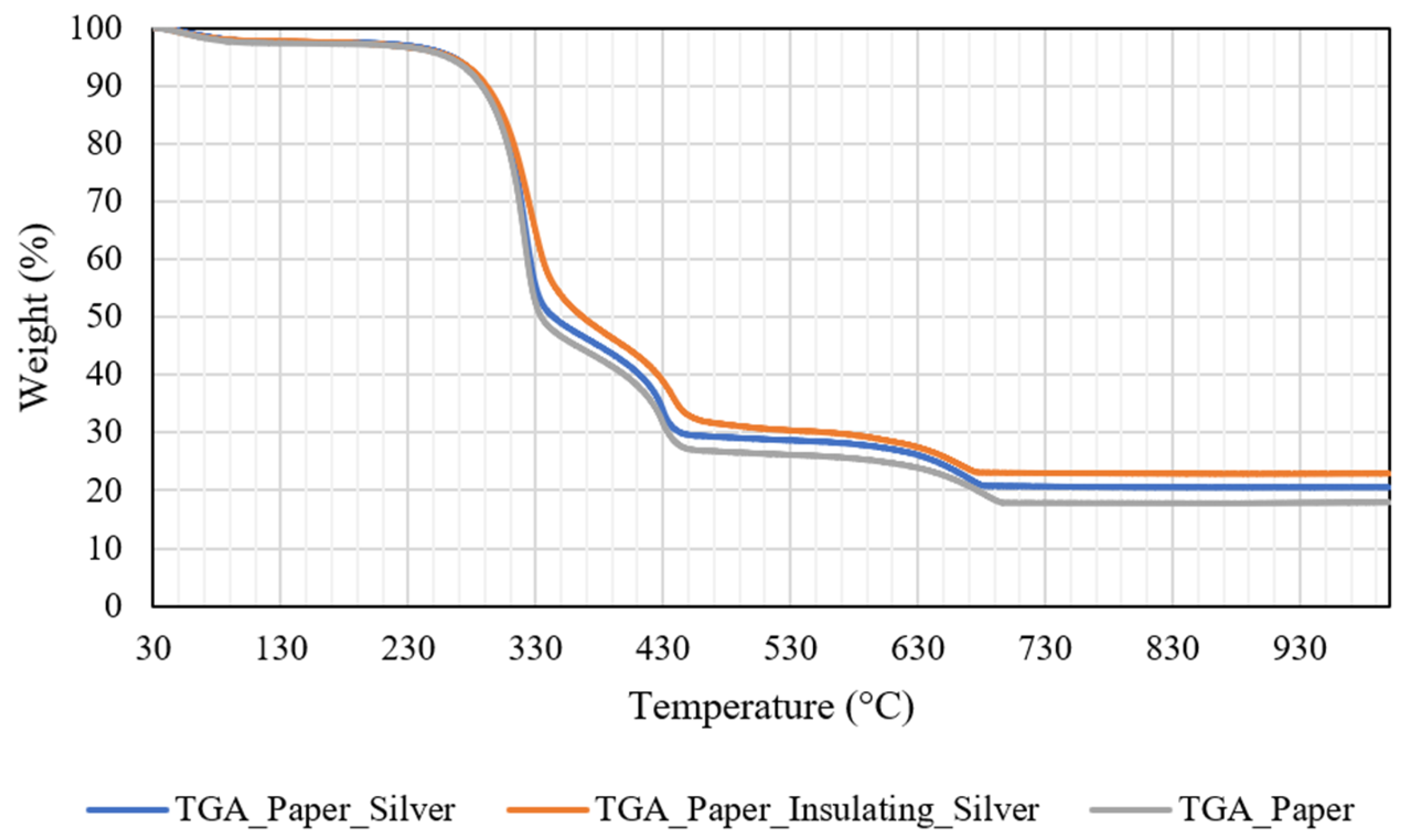

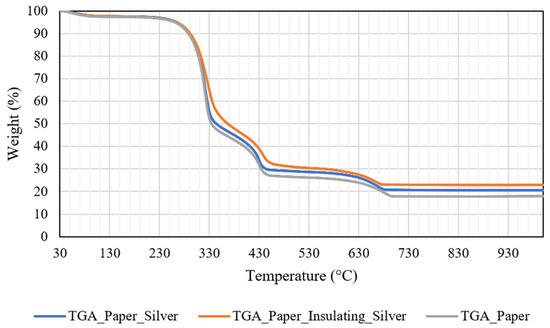

Finally, the thermal stability of the PE has been analyzed, also focusing on the three aforementioned zones. The corresponding TGA/TDA thermograms are presented in Figure 2.

Figure 2.

TGA spectra of PE device, analysis made on 3 different zones (paper alone, paper with silver, and paper with silver and insulation material).

The three surface analyzed zones show a similar thermal degradation with three distinct stages of weight loss: (i) between 25 °C and 150 °C, a loss of mass of about 3% is observed, corresponding to the removal of moisture since the paper substrate is not fully dry; (ii) then, between 200 °C and 525 °C, a second loss of mass of about 70% is proceeding, attributed to the thermal degradation of various organic components present in the paper formulation, i.e., mainly hemicelluloses and cellulose; (iii) finally, a third loss of mass, not exceeding 10% appears between 525 °C and 900 °C, which coincides with the thermal decomposition of CaCO3 into calcium oxide, CaO, and carbon dioxide, CO2.

The water and ash (and/or organic matter) contents were respectively determined from TGA curves presented in Figure 2, at the temperatures of 150 °C and 525 °C. The percentage of organic matter was evaluated by subtracting the percentage of water and the percentage of inorganic matter. Table 2 shows the water and ash contents of the different surfaces tested. The ash content logically increases when the surface analyzed contains silver and the insulator.

Table 2.

Water, ash, and organic matter content of the PE device determined by TGA.

The ash content of the air-dried PE measured by TGA (30.4%) is in agreement with the value determined by calcination at 525 °C on a dry matter (26.2%).

To conclude, the PE is mainly composed of organic matter (more than 70% of the dry matter content) corresponding to cellulose and hemicelluloses coming from the paper substrate, and to a lesser extent of mineral materials, but it also contains traces of water (less than 3%). The mineral part is mainly composed of calcium carbonate originating from the paper substrate, whereas the silver content in the antenna represents only a very minor part.

2.2. Recycling Line Study

The very first step typically carried out in a paper recycling line consists of the pulping operation, whose objective is to disintegrate the paper into individualized fibers, also provoking the detachment of inks and fillers. The pulping should be seen as a homogenization operation that is then followed by proper separations.

After the disintegration of the PE by the action of both water and mechanical mixing in the pulper, the pulp containing both the individualized fibers and the detached contaminants is sent to the screening, to the centrifugal cleaning, or to the flotation cell to separate the fibers and the silver. After the separation step, two fractions are obtained:

- The accepts: an aqueous suspension, rich in fibrous material with minor contamination by Ag and other minerals and substances coming from the paper substrate.

- The rejects: an aqueous suspension poor in fibrous material, where silver concentrates. This fraction also contains part of the minerals.

The accepted fraction corresponds to the separated fibers, which will be recovered to manufacture a recycled paper, while the rejected fraction corresponds to the fraction that is classically removed from the recycling circuit after the separation process and is not valorized. In our case, this fraction will be treated to recover silver.

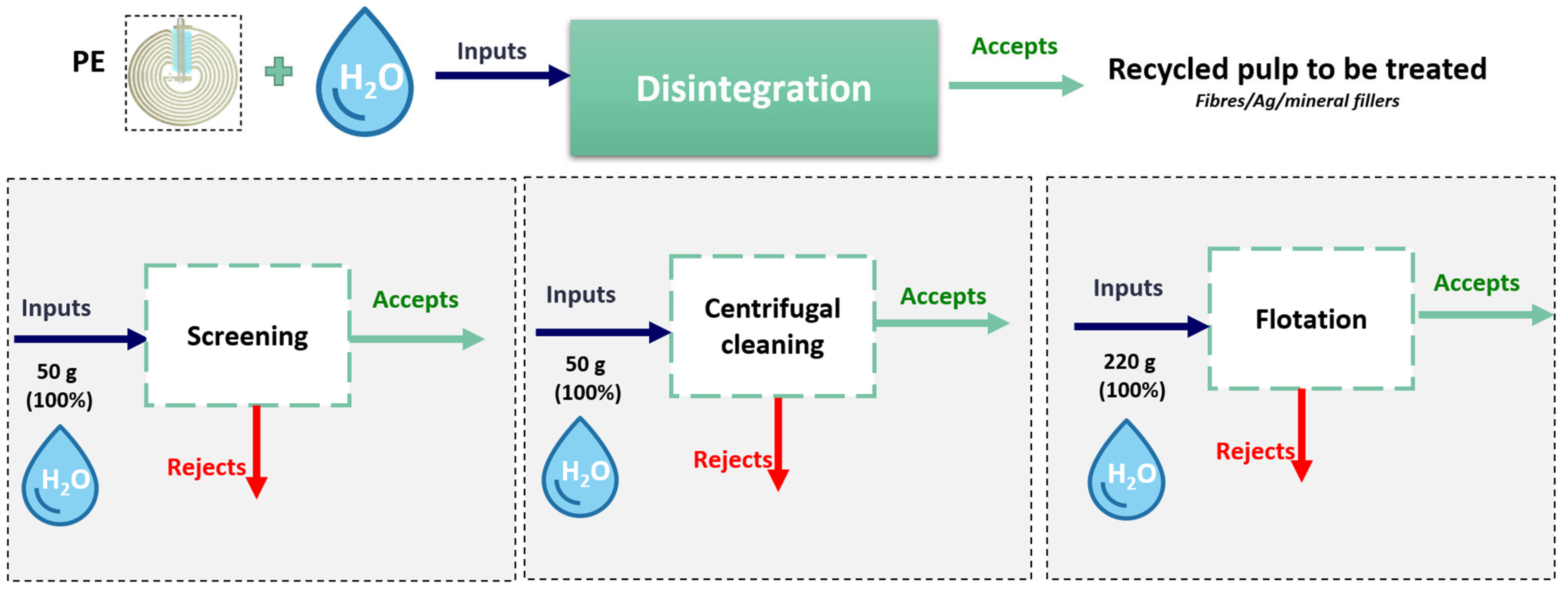

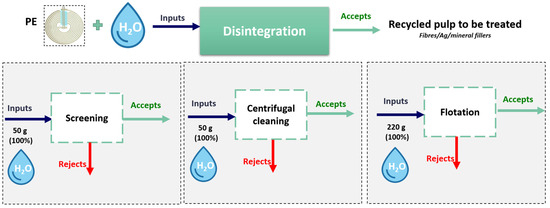

To assess the separation efficiency of the investigated unit operations (Figure 3), cellulose fibers and silver have been tracked throughout the recycling process [39] by the analysis of the chemical composition of the reject and accept fractions.

Figure 3.

Representation of the recycling process: pulping (disintegration) and the three separation operations, i.e., screening, centrifugal cleaning, and flotation.

The PE pulping conditions were carried out as described in Section 3, using 1 kg of PE, corresponding to 200 antennas.

The studied sample does not contain any hydrophobic elements, such as resin coatings or encapsulations, which can interfere with the pulping process [40]. This results in good individualization of the fibers, with few fiber aggregates. After pulping, the fiber suspension was sent to the three different separation operations, which might or might not be combined.

For screening, the chosen operating conditions were adapted both from the existing literature and from the ATICELCA standard used for the recycling of cellulosic materials [41]. A 150 µm slotted sieve was used. The accepts correspond to the fraction that passes through the screen, and the rejects are aggregates that are retained on the screen due to their high size. The PE pulp quantity introduced at the entrance of the screen was 50 g (counted in dry matter).

The centrifugal cleaning conditions have also been chosen according to the literature and previous results of our research team [42]. The main process parameter, the solid concentration, has been fixed at 0.5% (expressed again in dry matter content) to favor the sedimentation of dense particles such as silver. Beyond this value, the efficiency of density separation is minimal. The centrifugal cleaning separation rate is quite fast, and generally, a few minutes are sufficient to separate the dense elements from the fibers. The PE pulp quantity introduced at the entrance of the cleaner was again 50 g (counted in dry matter content).

Finally, flotation conditions were chosen based on industrial practice, where it was observed that the optimal flotation efficiency is usually achieved when the solid dry matter concentration is approximately 1% [43]. Indeed, if the concentration of the solid material in the suspension is beyond this threshold, the fibers can be brought to the surface of the flotation equipment by air bubbles, resulting in a loss of material. The PE pulp quantity introduced at the entrance of the flotation cell was 220 g (counted in dry matter)

The chemical composition of the recycled pulp at the entrance of the three different separation operations is summarized in Table 3.

Table 3.

Chemical composition of the recycled pulp to be treated at the entrance of the 3 separation processes (the Ag quantity is part of the inorganic quantity).

The screening efficiency has been analyzed first since this operation is usually implemented just after pulping in a classical recycling line to remove non-individualized fibers and high-size contaminants. As the studied PE was easily disintegrated, no matter was retained on the screen. All the PE components are in the accepted fraction, meaning that silver is not separated and goes with the fibers in the same fraction. Screening is thus not a suitable operation to separate silver from the cellulosic fibers.

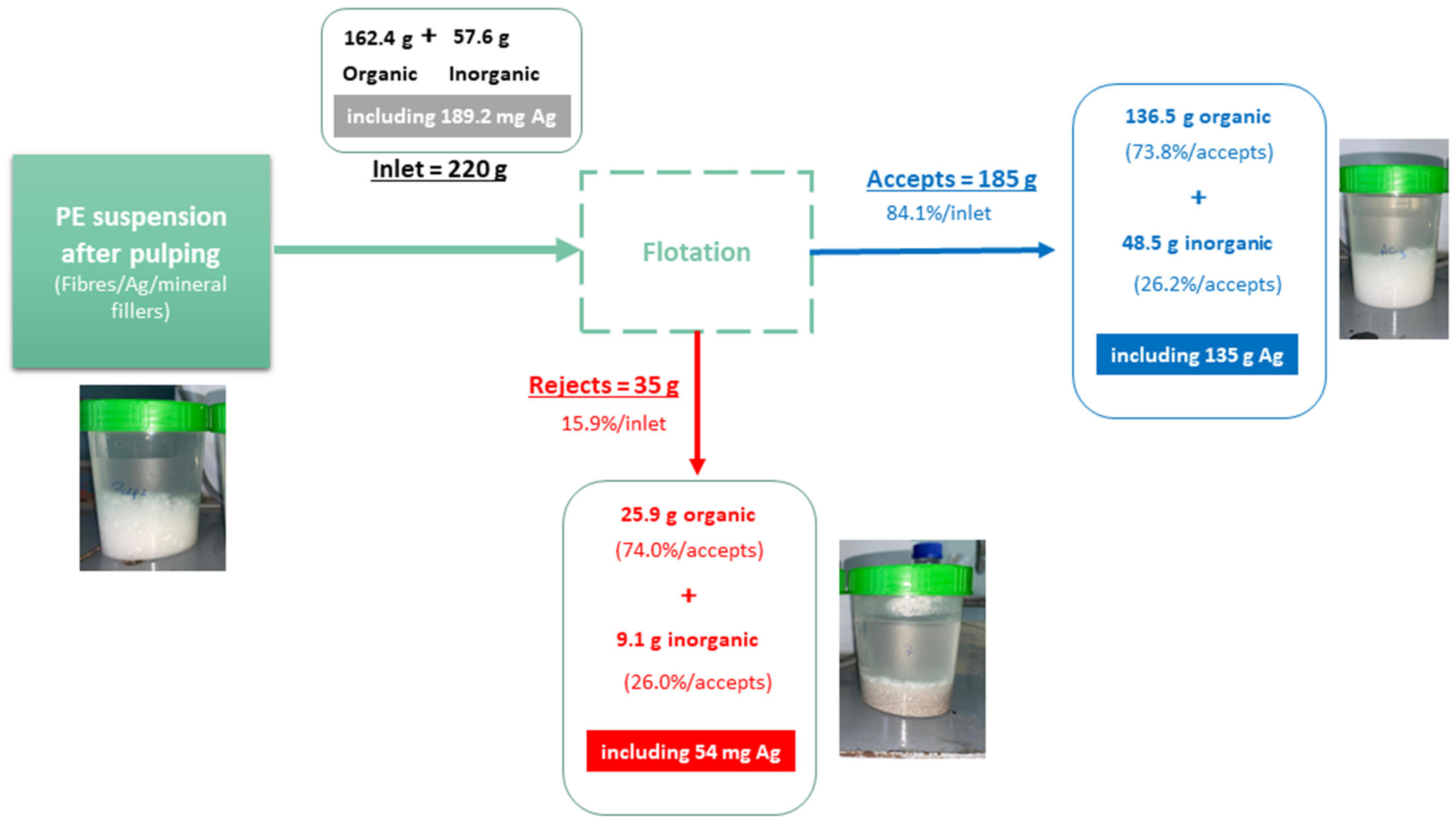

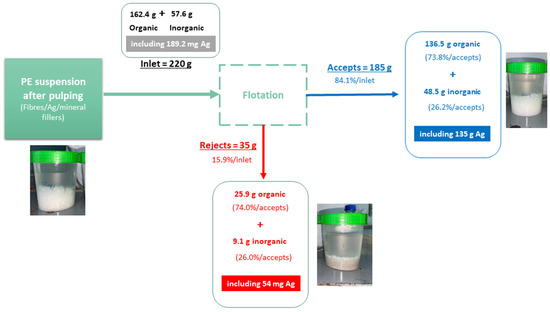

The second investigated operation is flotation. Contrary to screening, two fractions were obtained at the exit of the flotation cell. The mass balance made on this operation is presented in Figure 4.

Figure 4.

Mass balance of the flotation operation.

Interestingly, flotation shows a poor ability to separate silver from the fibers, with only 28.5% of Ag (54.0 mg/189.2 mg) recovered in the rejected fraction, which is unsatisfactory. A total of 71.5% of the silver remains in the accepted fraction mixed with the fibers. This can be explained by the fact that this operation is efficient only if the ink particles to be separated are hydrophobic, such as graphic inks [44,45]. The separation of hydrophilic particles from the fibers by flotation is known to be difficult [40]. Hydrophilic particles do not allow a stable bubble/particle contact, and they quickly detach from the bubble. However, these hydrophilic particles can be transferred to the flotation cell surface by a secondary mechanism: air bubbles smaller than one millimeter create symmetrical vortices in their wake; these vortices create streamlines that can carry the hydrophilic particles to the collecting foam. In particular, CaCO3 mineral filler particles (within a 20–25 µm range) have been shown to be entrained by this mechanism. However, this entrainment effect of the particles depends on their size and density. A high density or size increases the sedimentation phenomenon and the compressive forces acting on their surface, which affects the entrainment effect [46]. In this study, a low recovery rate of silver indicates that the separation conditions are not ideal. It can then be assumed that the metallic ink particles are not suitable for flotation separation from the fibers. However, the recovery rate of the fibers, i.e., organic matter used to make recycled paper, is important in the accepted fraction with 84.0% (136.5 g organic/162.4 g organic).

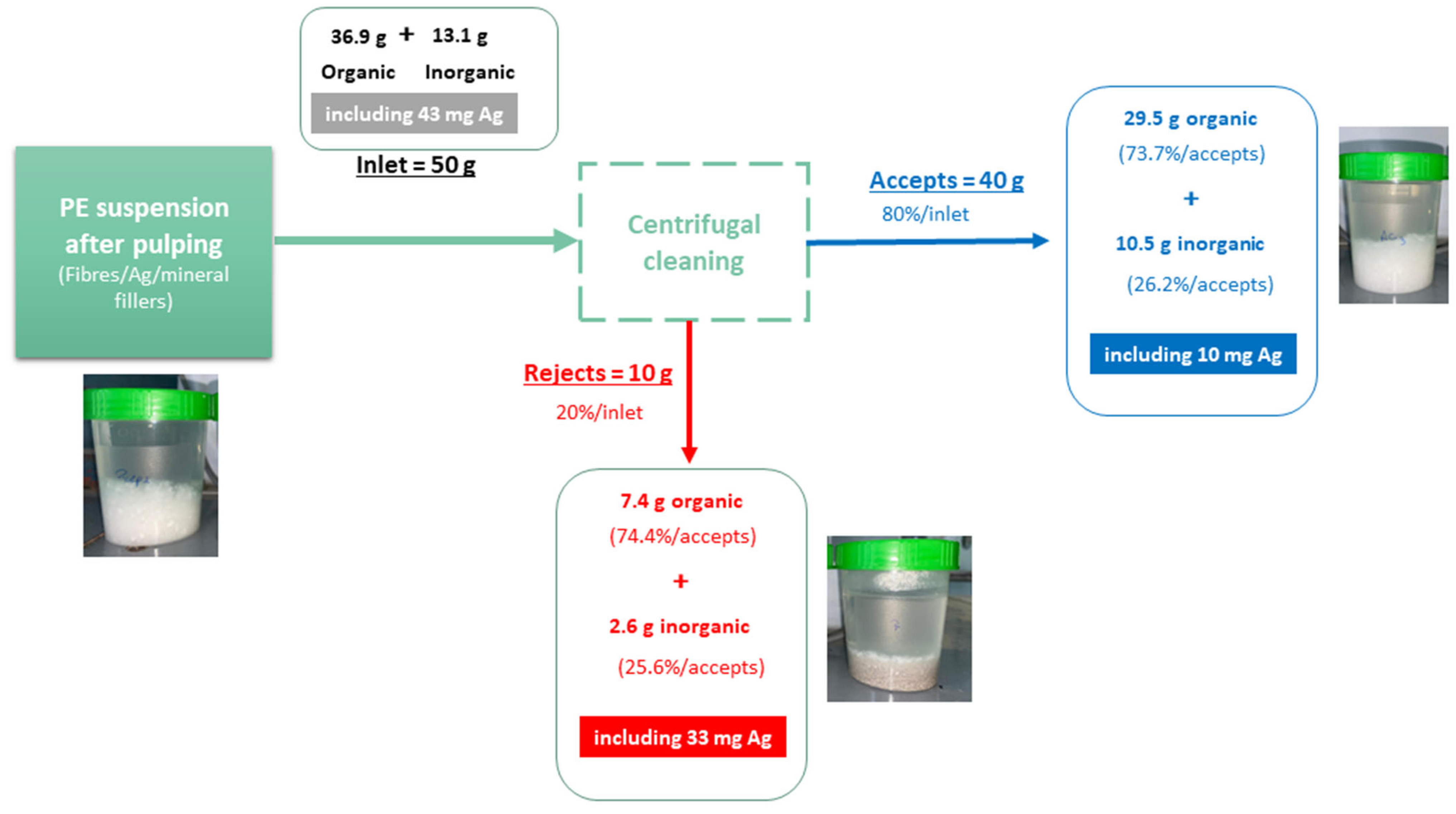

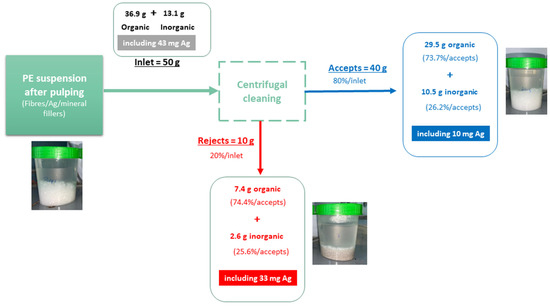

Finally, the most promising separation operation appears to be the centrifugal cleaning. The achieved mass balance is presented in Figure 5.

Figure 5.

Mass balance of the centrifugal cleaning operation.

Centrifugal cleaning is able to concentrate 33 mg Ag (of 43 mg present in the inlet flow) in the rejected stream, resulting in more than 76% of the silver efficiently separated from the fibers, while only 23% remains in the accepted fraction. In the paper industry, centrifugal cleaning is able to separate sand particles from the pulp and, more broadly, elements ranging from 10 µm to 70 µm if they exhibit a different density from that of the fiber suspension (either lower or higher than the cellulosic fibers) [40]. As metallic silver has a high density (10.49 g/cm3) compared to that of the fiber suspension (close to 1 g/cm3), Ag is easily separated.

Regarding the fibers, 80% (29.5 g/36.9 g) of the organic matter has been recovered in the accepted fraction. The fiber separation yield of the recycling process is within the range of that which is classically obtained for conventional graphic paper recycling.

Among all the investigated separation techniques, the centrifugal cleaning appears to be the most efficient operation for the separation of metallic particles from the fibers. In our work, the accepted fractions will be tested for their ability to produce recycled paper, and the rejected fraction will be used for silver recovery.

In conclusion, the two key operations for recycling simple electronic devices printed on cellulosic substrates are pulping and centrifugal cleaning. The excellent recovery rate after recycling the PE device also confirms that the centrifugal cleaning operation is very promising and allows a good separation of silver particles from the fibrous fraction, with a separation rate of 76.7% silver in the tested conditions.

2.3. Characterization of the Recycled Fibers for Reuse

The accepted fraction obtained after PE disintegration and centrifugal cleaning has been recovered to make handsheets (laboratory sheet) for mechanical properties testing in order to assess the recyclability of the recycled fibers. Handsheets were prepared as the control handsheet made of the unprinted paper roll, using the same basis weight. Thickness, tear strength, burst strength, and brightness were determined. The results are provided in Table 4 and compared to those of the control (non-recycled paper).

Table 4.

Mechanical and optical properties of the recycled fibers.

A comparison of the results obtained with the original substrate (see Table 1) shows that the fibers maintained their mechanical properties throughout the recycling process. This suggests, as expected, that the fibers were not damaged by the unit operations. For this particular paper, the fibers are not used to produce a paper with high mechanical properties. Consequently, these characteristics do not drop drastically for the recycled paper. Indeed, with these initially short fibers, the effect of successive recycling is less measurable than with virgin high-quality fibers. As a result, key properties such as burst index and tear strength remain largely unchanged despite repeated processing.

Mineral fillers such as calcium carbonate or kaolin can be partially or completely lost during the recycling steps because they exhibit a very low size, generally close to the micrometers [47]. Even during the sheet formation, fillers may be lost in the white waters originating from the fiber suspension filtration on the paper machine. This is the case in this study, and this slightly affects the surface properties and opacity of the recycled paper, but most importantly, it does not directly affect the fibers’ properties mentioned above. This study demonstrates that cellulose fibers undergo very limited mechanical modification during the first recycling cycles under industrial conditions. These results are in perfect agreement with the work of Hubbe et al. [47], who, in their review of cellulosic fibers such as bleached kraft pulps and mechanical pulps, observed that more than 90% of the structural properties of fibers remain unchanged after several processing cycles, particularly when fibers have not been subjected to excessive drying or severe pre-treatment.

In conclusion, the proposed recycling cycle does not affect the strength properties of the fibers themselves, which remain almost the same in well-established paper recycling processes.

3. Materials and Methods

3.1. Printed Electronic Device (PE)

An industrial roll of XD80 paper free of charge, industrially printed with an RFID antenna, has been provided by Fedrigoni (https://specialpapers.fedrigoni.com, accessed on 14 September 2024). The antennas were printed using the flexographic printing technology with a silver-based functional ink. The pattern of the antenna is shown in Figure 6. The amount of ink (silver particles) deposited per antenna was estimated to be approximately 5 mg ± 0.1, as determined from the analysis of the silver content in the printed electronic device according to the method developed by Conceição et al. [21]. The composition of this printed electronic device has been further characterized (Section 2.1).

Figure 6.

Industrial PE device printed with a roll-to-roll flexographic press.

3.2. Chemical Reagent

Various chemical reagents were used in the recycling process, including nitric acid (CAS N°: 7697-37-2, Sigma Aldrich, Singapore), sodium silicate (338443, Sigma Aldrich), sodium hydroxide (CAS N°: 1310-73-2, Sigma Aldrich), and surfactant (Brij® S100, CASN°: 466387, Sigma Aldrich). The reagents were used without any purification step.

3.3. Process Recycling of the Printed Electronic Device

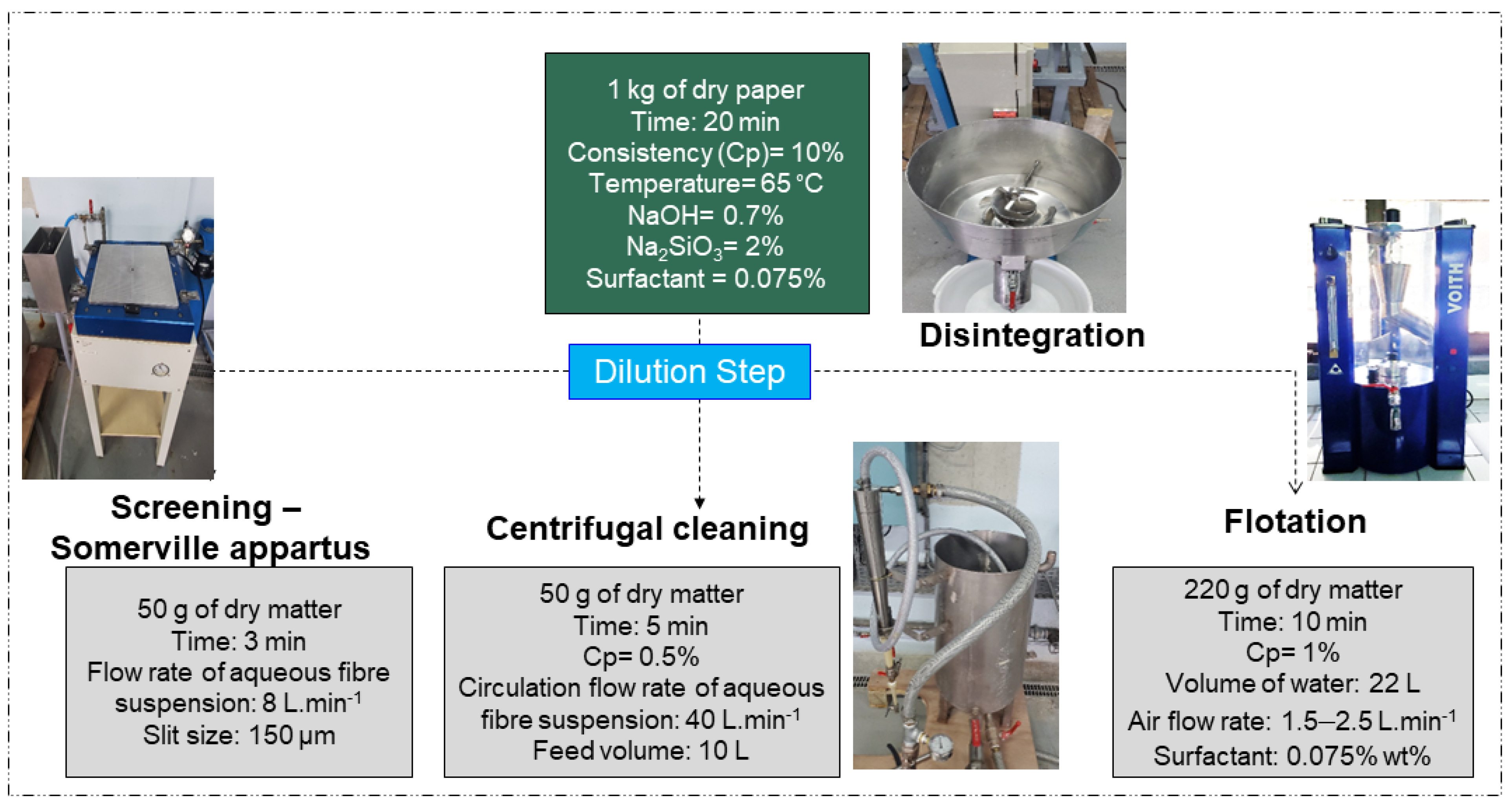

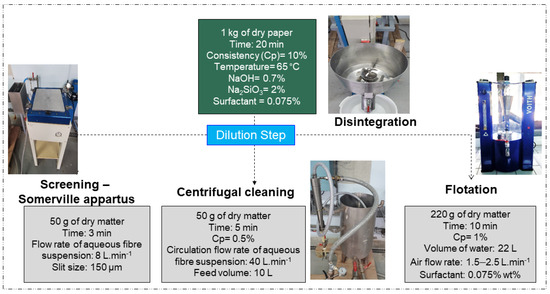

Figure 7 illustrates the recycling line that was investigated in this study. This line starts with the disintegration of the PE in water. This operation takes place in a laboratory pulper of 36 L capacity, running in batch mode, using the following operating conditions: 1 kg of PE (counted as dry matter), 20 min of pulping, helical rotor with 1300 rpm speed and 10% of dry mass concentration (1 kg of dry matter PE and 9 kg of water containing the chemicals) at a water temperature of 65 °C. Chemicals were added, namely NaOH = 0.7%, Na2SiO3 = 1% and surfactant (Brij® S100) = 0.075%. For chemicals, all the % are expressed as the weight of the chemical/weight of PE counted as dry matter. At the end of the disintegration operation, a fibrous suspension, i.e., the recycled pulp, containing separated fibers and detached contaminants, was obtained. After pulping, three unit operations, conventionally used to separate contaminants from fibers during paper recycling, are investigated separately: screening, centrifugal cleaning, and flotation. The screening principle is based on the recycled pulp filtration on a screen with slots or holes of a calibrated size. In this study, fiber screening was carried out using a laboratory Somerville screen equipped with 150 µm slots, in accordance with standard screening procedures. A suspension containing 50 g of dry matter was diluted with water and screened at a flow rate of 8 L.min−1 for 3 min. The coarse fraction retained on the screen, commonly referred to in the paper industry as the “rejects,” contained few fibers and a high proportion of non-fibrous elements. In contrast, the material that passed through the screen (the “accepts”) was enriched in fibers along with small contaminants.

Figure 7.

Experimental conditions of unit operations studied for the recycling of paper-based electronic devices.

The second operation is centrifugal cleaning, which usually completes the screening in conventional recycling lines by eliminating very small contaminant particles (<10 µm) by separating the suspension flow into two flows of different densities. Laboratory equipment has also been used. The density separation conditions are the following. Input: 50 g of PE (counted as dry matter) in suspension, recovered at the exit of the pulper (10% material concentration), diluted with a water flow rate of 40 L.min−1 for 5 min. Two fractions are recovered at the exit of the operation, one containing dense material and the other light material, both in diluted aqueous suspension.

Finally, the last operation tested is flotation by air flow. This is a physico-chemical operation that allows the removal of particles between 50 and 250 µm from the fiber suspension, provided that these particles have a hydrophobic character. Since conventional printing inks are hydrophobic particles, this operation is commonly used for deinking. A Voith laboratory flotation cell running in batch mode has been used in our study. Air bubbles injected on the bottom of the cell collect hydrophobic ink particles and rise to the top of the cell, forming foam. The foam, removed from the equipment, is the reject fraction since it concentrates ink particles. The suspension that stays in the cell is the accept fraction with fibers free of ink.

3.4. Characterization

Many tools were used to measure morphological, thermal, and mechanical properties in order to characterize the PE (e-waste substrate) and the fractions obtained after each unit operation. A brief description is provided below.

3.4.1. Morphological Properties

The morphological properties of the recycled fibers were evaluated using a Morfi analyzer (LB-01) developed by Techpap (Toulouse, France). Fiber length, width, and fine element content were measured using an image processing technique. In this method, a diluted pulp suspension (0.3 g of pulp in 8 L of water) flowing in a transparent flat channel was observed by a measuring cell that ensures image capture, recording, and data processing. The Morfi software (version 2015) distinguishes these three elements according to size criteria (length, width). The morphology of the PE was observed using a scanning electron microscope (SEM) using an ESEM Quanta 200 microscope (FEI) (FEI Company, Hillsboro, OR, USA) with an acceleration voltage of 10 kV. Dry, non-conducting samples were pre-coated with a thin layer (6 nm) of a gold/palladium mixture prior to analysis.

3.4.2. Structure Properties: XRD

X-ray diffraction was used to determine the crystallinity of the samples. The XRD analyses were carried out at the CMTC (Consortium des Moyens Technique Commun) platform using X-ray diffractometry. The tests were carried out under vacuum using a Philips X’Pert X-ray generator (Malvern Panalytical, Palaiseau, France) with a voltage of 40 kV and an intensity of 40 mA. The diffracted intensity of CuKα radiation (wavelength 0.1542 nm) was recorded between 2θ = 5° and 50°.

3.4.3. Thermal Properties

Thermal properties were determined by TGA analysis using a Mettler Toledo TGA/DSC 3+ (Mettler Toledo, Greifensee, Switzerland) equipped with a single differential thermal analysis (SDTA) sensor under air and nitrogen conditions. The test was carried out between 25 °C and 900 °C at a heating rate of 5 °C per minute. Two measurements were taken per sample.

3.4.4. The Schopper–Riegler Degree, WRV, and Physical Properties of Paper Sheets

The Schopper–Riegler degree is a method used to evaluate the drainage capacity of a fiber suspension under specified experimental conditions. It is based on measuring the volume of water (V) overflowing as a result of filtering 1 L of a fiber suspension at 2 g·L−1 through a wire mesh. The Water Retention Value (WRV) was determined on fiber suspension samples collected before or after disintegration. Laboratory handsheets were prepared using a British sheet mold from 1 L of fiber suspension at a concentration of 1 g·L−1. Each handsheet was divided into several sectors, and one sector (1/6 of the sheet area) was sampled and centrifuged at 3000× g for 15 min in specialized tubes [27]. The wet centrifuged sample was weighed and then dried in an oven at 105 °C until a constant mass was reached. The Sheet Formation Index (Epair) measures the uniformity of fiber distribution in a paper sheet, with higher values indicating more homogeneous formation. Brightness (457 nm) is the reflectance of the sheet at 457 nm, representing its whiteness and optical quality. Both parameters are commonly used to assess the physical and optical properties of paper.

During recycling, laboratory sheets were prepared using recycled fiber fractions on a “Rapid Khoten” apparatus according to standard methods (ISO 5269-2) [48]. The recycled fiber suspension was diluted in water to 2 g·L−1. One liter of this fiber suspension was placed in the vessel of the “Rapid Khoten” apparatus, and this volume was then diluted with 5 to 7 L of water. After a stirring and calming phase, the suspension was filtered through a metallic wire where fibers were deposited. After pressing, the wet sheet was collected on blotting paper, protected between two sheets, and dried under vacuum at 80 °C for 10 min. Ten standard laboratory handsheets were prepared. The obtained sheets were conditioned at 23 °C and 50% relative humidity for 48 h prior to testing, as recommended by the ISO 187 standard method [49]. Grammage (ISO 536), thickness (ISO 534), tensile strength (NF Q 03-002) [50], tear strength (NF Q 03-011), burst strength (NF Q 03-053) [51], and brightness (TAPPI method, T 452) [52] were measured.

3.4.5. Ash Content

Ash content was determined according to the TAPPI T211 om-07 standard method [53]. Calcination has been carried out at 525 ± 25 °C for at least 4 h, to determine the organic fraction (disappearing material), since the residue is the mineral material containing carbonates. To remove carbonates and concentrate silver in the ash, a further calcination is made at 900 °C ± 25 °C.

3.4.6. Silver Content

The silver amount in the different produced separated fractions was evaluated using the procedure described and developed previously by our team [21]. The procedure consists of an initial calcination step followed by a leaching phase. In more detail, the investigated fractions were first dehydrated on a sand bath and then calcinated at 900 °C for 2 h. Subsequently, the calcined samples were leached with 40 mL of HNO3 at a concentration of approximately 3.1 mol·L−1, at 25 °C for 24 h. The obtained leachate was analyzed by atomic absorption spectroscopy (AAS) at a wavelength of 328.07 nm. The test was performed in triplicate. Two indicators were used to assess the efficiency of the recycling operations.

- The organic matter recovery rate is defined as the amount of organic matter in the accepted fraction relative to the initial amount of organic matter introduced at the inlet of the studied operation:

%TRorg = 100 × (Organic mass in the accepted fraction/Initial organic mass at the inlet)

- 2.

- The silver (Ag) separation rate measures the amount of silver that concentrates in the rejects, relative to the total amount of silver measured at the outlet (accept + rejects) of the studied operation:

%SEAg, rejects = 100 × (Mass of Ag in the rejects/Mass of Ag at the outlet)

4. Conclusions

Preliminary recycling trials involving pulping, screening, flotation, and centrifugal cleaning were conducted on an industrial paper-based printed electronic device (PE) to develop an efficient, water-based process for separating silver from cellulosic fibers. The aim was to recover usable fibers for recycled paper production and to reuse the extracted silver.

Under standard graphic paper recycling conditions, pulping effectively disintegrated the PE, producing a fibrous suspension containing individualized fibers and efficiently detached fillers and contaminants, including silver. Among the tested separation operations, screening and flotation proved to be of limited efficiency, while centrifugal cleaning was the most efficient method, efficiently separating the silver (concentrated in the reject fraction) from the fibers (collected in the accept fraction) due to the significant difference in density between the silver particles and cellulosic fibers.

Although the tested PE contained a low silver concentration (approximately 1 g of silver per kg of PE), the study demonstrated the technical feasibility of fiber–silver separation. Future work will focus on optimizing the pulping process and centrifugal cleaning using PEs with a higher silver content to enhance recovery efficiency and process scalability.

Author Contributions

R.K.: investigation, conceptualization, validation, visualization, writing—original draft; D.C. and L.S.: supervision and validation; N.M. and N.R.-B.: supervision, validation, conceptualization, writing—reviewing and editing, funding acquisition; M.A.: reviewing. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully express their sincere gratitude to the ANR-FRANCE (Agence Nationale de la Recherche) for their financial support for the REVeBIO project n°ANR-22-CE43-0003-01.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author(s).

Acknowledgments

The authors would like to thank the company FEDRIGONI for generously providing the e-waste free of charge, particularly Gael DEPRES for his help, advice, and consideration. LGP2 is part of the LabEx Tec 21 (Investissements d’Avenir—grant agreement n°ANR-11-LABX-0030) and of PolyNat Carnot Institute (Investissements d’Avenir—grant agreement n° ANR-16-CARN-0025-01).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Radley-Gardner, O.; Beale, H.; Zimmermann, R. (Eds.) Directive 2011/7/EU of the European Parliament and of the Council. In Fundamental Texts on European Private Law; Hart Publishing: Oxford, UK, 2016. [Google Scholar] [CrossRef]

- Kavčič, U.; Kolar, M.; Žigon, M. Deinking of screen-printed electrodes printed on invasive plant-based paper. Sustainability 2020, 12, 1350. [Google Scholar] [CrossRef]

- Tabelin, C.B.; Park, I.; Phengsaart, T.; Jeon, S.; Villacorte-Tabelin, M.; Alonzo, D.; Ramos, R.; Yu, J. Copper and critical metals production from porphyry ores and E-wastes: A review of resource availability, processing/recycling challenges, socio-environmental aspects, and sustainability issues. Resour. Conserv. Recycl. 2021, 170, 105610. [Google Scholar] [CrossRef]

- Nassajfar, M.N.; Zakeri, B.; Sahebkar, A.; Ashrafi, M.; Mousavi, S.M.; Housaindokht, M.R. Alternative materials for printed circuit board production: An environmental perspective. Sustainability 2021, 13, 12126. [Google Scholar] [CrossRef]

- Kamyshny, A.; Magdassi, S. Conductive nanomaterials for printed electronics. Small 2014, 10, 3515–3535. [Google Scholar] [CrossRef]

- Barras, R.; Heitz, J.; Saiter, A.; Boukherroub, R. Printable cellulose-based electroconductive composites for sensing elements in paper electronics. Flex. Print. Electron. 2017, 2, 014006. [Google Scholar] [CrossRef]

- Hakola, L.; Hermansson, U.; Bäckström, M. Sustainable roll-to-roll manufactured multi-layer smart label. Int. J. Adv. Manuf. Technol. 2021, 117, 2921–2934. [Google Scholar] [CrossRef]

- Roselli, L.; Sardini, E.; Serpelloni, M.; Ceriotti, M. Review of the present technologies concurrently contributing to the implementation of the Internet of Things (IoT) paradigm: RFID, green electronics, WPT and energy harvesting. In Proceedings of the 2015 IEEE Topical Conference on Wireless Sensors and Sensor Networks (WiSNet), San Diego, CA, USA, 25–28 January 2015; pp. 1–3. [Google Scholar]

- Hui, Z.; Ma, J.; Xu, B. Green flexible electronics: Natural materials, fabrication, and applications. Adv. Mater. 2023, 35, 2211202. [Google Scholar] [CrossRef]

- Mir, S.; Dhawan, N. A comprehensive review on the recycling of discarded printed circuit boards for resource recovery. Resour. Conserv. Recycl. 2022, 178, 106027. [Google Scholar] [CrossRef]

- Murthy, V.; Ramakrishna, S. A review on global e-waste management: Urban mining towards a sustainable future and circular economy. Sustainability 2022, 14, 647. [Google Scholar] [CrossRef]

- Schmidt, C.W. e-Junk explosion. Environ. Health Perspect. 2002, 110, 188–194. [Google Scholar] [CrossRef]

- Yang, W.; Lu, Y.; Zhao, J.; Li, H.; Zhang, Y. Design, fabrication and applications of flexible RFID antennas based on printed electronic materials and technologies. J. Mater. Chem. C 2023, 11, 406–425. [Google Scholar] [CrossRef]

- Déprès, G.; Chevremont, A.; Schaubroeck, T.; Ragaert, K. Recycling of paper electronics in standard paper and board recycling lines. IEEE J. Flex. Electron. 2023, 2, 18–24. [Google Scholar] [CrossRef]

- Nandy, S.; Mohanty, A.K.; Nayak, S.K. Cellulose: A contribution for the zero e-waste challenge. Adv. Mater. Technol. 2021, 6, 2000994. [Google Scholar] [CrossRef]

- Sudheshwar, A.; Malinverno, N.; Hischier, R.; Nowack, B.; Som, C. The need for design-for-recycling of paper-based printed electronics—A prospective comparison with printed circuit boards. Resour. Conserv. Recycl. 2023, 189, 106757. [Google Scholar] [CrossRef]

- Zareeipolgardani, B.; Piednoir, A.; Joyard-Pitiot, B.; Depres, G.; Charlet, L.; Colombani, J. Multiscale investigation of the fate of silver during printed paper electronics recycling. Composite 2022, 1, 671–684. [Google Scholar] [CrossRef]

- Hoeng, F.; Denneulin, A.; Bras, J. Use of nanocellulose in printed electronics: A review. Nanoscale 2016, 8, 13131–13154. [Google Scholar] [CrossRef] [PubMed]

- Jansson, E.; Isotalo, T.; Tuukkanen, S. Suitability of paper-based substrates for printed electronics. Materials 2022, 15, 957. [Google Scholar] [CrossRef] [PubMed]

- Tobjörk, D.; Österbacka, R. Paper electronics. Adv. Mater. 2011, 23, 1935–1961. [Google Scholar] [CrossRef]

- Conceição, J.H.F.; Party, M.; Curtil, D.; Svecova, L.; Marlin, N.; Reverdy-Bruas, N. Investigation of methods to quantify silver screen-printed onto cellulosic substrate: Towards recycling of printed electronics. Flex. Print. Electron. 2023, 8, 035014. [Google Scholar] [CrossRef]

- Subramanian, V.; Kim, B.; Volkman, S.K.; Huang, Y.-Y.; Lee, J.; Poon, S.; Murukeshan, V.M.; Chu, W.-S.; Yu, X.; Sarma, S.; et al. Progress toward development of all-printed RFID tags: Materials, processes, and devices. Proc. IEEE 2005, 93, 1330–1338. [Google Scholar] [CrossRef]

- Aliaga, C.; Scharfe, M.; Langlois, F.; Brouzes, E. The influence of printed electronics on the recyclability of paper: A case study for smart envelopes in courier and postal services. Waste Manag. 2015, 38, 41–48. [Google Scholar] [CrossRef]

- Wu, W. Inorganic nanomaterials for printed electronics: A review. Nanoscale 2017, 9, 7342–7372. [Google Scholar] [CrossRef] [PubMed]

- Wiklund, J.; Österbacka, R.; Virkki, J.; Wågberg, L. A review on printed electronics: Fabrication methods, inks, substrates, applications and environmental impacts. J. Manuf. Mater. Process. 2021, 5, 89. [Google Scholar] [CrossRef]

- Xu, J.; Peng, C.; Jiang, Z.; Chen, Y.; Yang, J. Printable and recyclable conductive ink based on a liquid metal with excellent surface wettability for flexible electronics. ACS Appl. Mater. Interfaces 2021, 13, 7443–7452. [Google Scholar] [CrossRef] [PubMed]

- Mishra, G.; Jha, R.; Dhanunjaya Rao, M.; Meshram, A.; Singh, K.K. Recovery of silver from waste printed circuit boards (WPCBs) through hydrometallurgical route: A review. Environ. Chall. 2021, 4, 100073. [Google Scholar] [CrossRef]

- Khrustalev, D.; Tirzhanov, A.; Khrustaleva, A.; Mustafin, M.; Fedorov, F.; Anisimov, A.; Melnikov, G. A new approach to designing easily recyclable printed circuit boards. Sci. Rep. 2022, 12, 22199. [Google Scholar] [CrossRef]

- Xia, J.; Ghahreman, A. Sustainable technologies for the recycling and upcycling of precious metals from e-waste. Sci. Total Environ. 2024, 916, 170154. [Google Scholar] [CrossRef]

- Erkmen, A.N.; Ulber, R.; Jüstel, T.; Altendorfner, M. Towards sustainable recycling of critical metals from e-waste: Bioleaching and phytomining. Resour. Conserv. Recycl. 2025, 215, 108057. [Google Scholar] [CrossRef]

- Mohamed, D.; Fayad, R. The role of e-waste in sustainable mineral resource management. J. Waste Manag. 2025, 3, 27. [Google Scholar] [CrossRef]

- ISO 534:2011; Paper and Board—Determination of Thickness, Density and Specific Volume. International Organization for Standardization: Geneva, Switzerland, 2011.

- ISO 536:2019; Paper and Board—Determination of Grammage. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 2758:2014; Paper—Determination of Bursting Strength. International Organization for Standardization: Geneva, Switzerland, 2014.

- NF Q03-011:1992; Paper—Determination of Tearing Resistance (Elmendorf Method). Association Française de Normalisation (AFNOR): Paris, France, 1992.

- NF T12-030:1994; Paper, Board and Pulps—Measurement of Diffuse Blue Reflectance Factor (ISO Brightness). Association Française de Normalisation (AFNOR): Paris, France, 1994.

- ISO 5267-1:1999; Pulps—Determination of Drainability—Part 1: Schopper-Riegler Method. International Organization for Standardization: Geneva, Switzerland, 1999.

- Silvy, J.; Romatier, G.; Chiodi, R. Méthodes pratiques de contrôle du raffinage. Revue ATIP 1968, 22, 31–53. [Google Scholar]

- Upola, H. Disintegration of Packaging Material: An Experimental Study of Approaches to Lower Energy Consumption. Available online: https://urn.fi/URN:ISBN:9789526214788 (accessed on 14 September 2024).

- Marlin, N.; Carre, B. Chapter 4: Recycled fibres. In Lignocellulosic Fibres and Wood Handbook: Renewable Materials for Today’s Environment; Belgacem, N., Pizzi, A., Eds.; Wiley-Scrivener: Hoboken, NJ, USA, 2016. [Google Scholar]

- Vilaseca, F.; Méndez, J.A.; Espinach, F.X.; Pelach, M.A.; Mutjé, P. Study and modeling of the disintegration kinetics of coated paper. BioResources 2011, 6, 1659–1669. [Google Scholar] [CrossRef]

- Statie, E.; Tanguy, P.A.; Begin, B.; Paris, J. A computational study of particle separation in hydrocyclones. J. Pulp Pap. Sci. 2002, 3, 28. [Google Scholar]

- Chaiarrekij, S.; Jiraratananon, R.; Intaravanne, Y. Deinking of recycled pulps using column flotation: Energy and environmental benefits. Resour. Conserv. Recycl. 2000, 28, 219–226. [Google Scholar] [CrossRef]

- Husovska, V. Investigation of Recycled Paper Deinking Mechanisms. Master’s Thesis, Western Michigan University, Kalamazoo, MI, USA, 2013. [Google Scholar]

- Kemper, M. State-of-the-art and new technologies in flotation deinking. Int. J. Miner. Process. 1999, 56, 317–333. [Google Scholar] [CrossRef]

- Zheng, Y.; He, Z.Z.; Gao, Y.; Liu, J. Direct desktop printed-circuits-on-paper flexible electronics. Sci. Rep. 2013, 3, 1786. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Venditti, R.A.; Rojas, O.J. What happens to cellulosic fibers during papermaking and recycling? BioResources 2007, 2, 739–788. [Google Scholar] [CrossRef]

- ISO 5269-2:2004; Pulps—Preparation of Laboratory Sheets for Physical Testing—Part 2: Rapid-Köthen Method. International Organization for Standardization: Geneva, Switzerland, 2004.

- ISO 187:2022; Paper, Board and Pulps—Standard Atmosphere for Conditioning and Testing and Procedure for Monitoring the Atmosphere and Conditioning of Samples. International Organization for Standardization: Geneva, Switzerland, 2022.

- NF Q 03-002; Paper and Board—Determination of Tensile Properties—Part 2: Constant Rate of Elongation Method (20 mm/min). Association Francaise de Normalisation: Paris, France, 2009.

- NF Q 03-053; Paper and Board Testing—Determination of Burst Strength (Strength Between 70 kPa and 1300 kPa). Association Francaise de Normalisation: Paris, France, 1983.

- TAPPI T 452 OM-23; Brightness of Pulp, Paper, and Paperboard (Directional Reflectance at 457 nm). Technical Association of the Pulp and Paper Industry (TAPPI): Peachtree Corners, GA, USA, 2023.

- TAPPI T 211 OM-07; Sampling and Preparing Handsheets for Physical Tests. Technical Association of the Pulp and Paper Industry (TAPPI): Peachtree Corners, GA, USA, 2007.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).