Abstract

Worldwide volume production and consumption of engineered composite materials, namely fiber reinforced polymers (FRP), have increased in the last decades, mostly in the construction, automobile, aeronautic and wind energy sectors. This rising production and consumption have also led to an increasing amount of FRP waste, either end-of-life (EoL) products or manufacturing rejects. Taking into account the actual and impending EU framework on waste management, in which clear targets are set with concrete measures to ensure effective implementation, landfill and incineration will be progressively unavailable as traditional end-routes for this kind of waste. Recycling techniques and end-use applications for the recyclates have been investigated over the past twenty years, but even so, more cost-effective and feasible market outlets for the recyclates should be identified that meet both the economic and the environmental points of view. This paper is aimed at enclosing and summarizing an update overview regarding all these issues: current legislation, recycling techniques and end-use applications for the recyclates. Additionally, as a case study, the assessment of the potential improvements that could be made on the eco-efficiency performance (sustainability) of a typical FRP composite materials’ industry by recycling and re-engineering process approaches is also reported.

1. Introduction

Worldwide volume production and consumption of fiber reinforced polymers (FRP) have increased in the last decades in several fields, mostly in the construction, automobile, aeronautic and wind energy sectors [1,2,3,4]. FRP composite materials are generally made of glass (GFRP), carbon (CFRP) or aramid (AFRP) reinforcing fibers dispersed in an organic matrix, usually polyester, epoxy or vinyl-ester thermoset resins. GFRP are by far the largest group of materials in the composites industry, representing over 95% of all FRP composites [5]. According to the Lucintel market report, a leading global management consulting and market research firm, the global glass fiber market is expected to grow at a compound annual growth rate of 5.4% over the five year-period 2015–2020 [6]. Although some contraction in specific market sectors (e.g., sheet and bulk molding compounds), and in some European countries (e.g., Scandinavian countries and France), the last “Federation of Reinforced Plastics” market report of the European Composites Industry Association (EuCIA) also confirms the steady global growth of GFRP composites industry over the last four years and estimated that the overall European-GFRP production by volume increased in 2015 by 2.5% to 1069 megatons [5].

Despite all the advantages of GFRP based products over more traditional materials, the growing production and consumption also lead to an increasing amount of GFRP waste, either end-of-life (EoL) products or manufacturing rejects. Since GFRP based products present, in general, a long life-span (20–25 years), end-of life disposal was not a major concern until a few years ago. However, the waste amount resulting from EoL GFRP products will increase strongly within the next few years, and this issue has become particularly worrying. The wind energy sector only is expected to cover 15.7% of the total EU electricity demand by 2020 and 50% by 2050, and the resulting EoL wind turbine blade material, mainly constituted of GFRP based components, is estimated to reach 100,000 tons per year in Europe [4,7]. Additionally, the total amount of production waste per year of the GFRP composite industry (e.g., non-conform products and manufacturing rejects) is also following the raising production. It is estimated that the total combined volume of EoL and production waste generated by the GFRP composite market in Europe has reached 304,000 tons in 2015 [8].

Taking into account the above figures, FRP waste management has become more and more an important concern. Whereas thermoplastic based FRP materials can be easily recycled by remelting and remolding, recyclability of thermoset based FRP products, with fiber recovering, is a more difficult task due to the inherent cross-linked nature of resin matrix [9,10].

Until now, landfilling and incineration have been the most common end-routes for EoL thermoset FRP products and scrap material. However, considering the actual and impending EU framework legislation on waste management, as well as the increasing price of landfill taxes, these end-routes will be progressively unavailable. Waste management legislation focuses on dealing waste through “waste hierarchy” and will therefore put more pressure on solving FRP waste management through recycling and reuse [11]. In particular, Waste Framework Directive 2008/98/EC stipulates that “Member States shall take the necessary measures designed to achieve that by 2020 a minimum of 70% (by weight) of non-hazardous construction and demolition waste…shall be prepared for re-use, recycled or undergo other material recovery” [12]. The Directive 2000/53/EC on end-of-life vehicles, which is already in force, also follows the same principle and settled minimum limits for the amount of parts and components of EoL vehicles that should be reused, recovered or recycled: “…the reuse and recovery should be equal or higher than 95% and the re-use and recycling should be equal or higher than 85% (average weight per vehicle and year)…” [13]. Therefore, in the near future, due to these more restrictive and coercive EU directives, FRP producers and suppliers could lose their market share to metals and other industries if they cannot ensure that their FRP components can be reused or recycled at the end of their service life cycle [11]. Thus, at the present time, the perceived lack of economical recyclability of thermoset FRP composites is more and more important and seen as a crucial barrier to the development or even continued use of these materials in some markets.

This increases awareness of environmental matters, and the search for further sustainable materials has driven several recycling techniques to be analyzed and proposed for FRP composites, mainly for GFRP and CFRP waste materials. Although research on recycling methods is underway, related research on end-use applications for the recyclates is still at a very elementary stage; however, in order to be cost-effective, recycling approaches should always embrace both interdependent issues.

The aim of this work is to enclose and summarize an updated review regarding all these features with special emphasis on GFRP waste: available recycling techniques, end-use applications for the recyclates and market outlook. Additionally, as a case study, the assessment of the potential improvements that could be made on the eco-efficiency performance (sustainability) of a typical FRP composite materials’ industry by recycling and re-engineering process approaches is also reported.

2. Waste Recycling Solutions for Thermoset FRP Wastes

2.1. Recycling Techniques for Thermoset FRP Wastes

There are three main recycling processes that can be used to get an added value from FRP thermoset waste materials: (a) incineration, with partial energy recovery from heat generated during combustion of the organic part, and co-incineration with both energy and raw material recovering; (b) thermal and/or chemical recycling, such as solvolysis, pyrolysis and similar decomposition processes, with partial recovering of energy and reinforcing fibers; and (c) mechanical recycling, involving the composite break-down by shredding, milling, comminution or other similar mechanical processes, resulting in size reduction to fibrous and/or powdered products. A detailed description of these methods can be found on Pickering [9,14] and Asmatulu et al. [15]. The main key points are summarized in the following sections.

2.1.1. Incineration and Co-Incineration

Incineration of FRP scrap with energy recovery is listed as a recycling method in some literature, but this feature is still up for debate. Incineration does recover part of the energy of the scrap materials whereas landfilling does not; however, air pollution resulting from incineration is a drawback of this method. On the other hand, the fiber and filler content of the materials still wind up as landfilled waste, potentially becoming hazardous waste depending on chemical analysis of the ashes [16]. According to the current legislation, limits are settled concerning levels of emissions to air, water and soil, and the residues from the incineration process should be minimized in their amount and harmfulness [17]. The benefit of energy recovering is also discussable: calorific value will depend on the organic fraction and for typical GFRP/CFRP composites that only account for 30%–40% in weight. On the other hand, incinerator operators actually charge more for accepting FRP waste in order not to overload the system. Burning plastic waste limits the amount of household waste that can be processed, which means that large volumes of domestic waste (of which there is an unlimited supply) must be sent to the landfill [11]. At present, incineration, with partial energy recovering, as the first alternative to landfilling, is less and less considered as a cost-effective end-route for composite waste.

Co-incineration in cement kilns constitutes a recent alternative end-route for GFRP waste and is thought as a slightly better and cost-effective option, as this offers combined material and energy recovering. GFRP typically contains E-glass, which is alumina-borosilicate, along with the organic resin and often calcium carbonate filler. When fed into a cement kiln, the organic resin burns providing energy and the mineral constituents provide feedstock for the cement clinker, namely Si, Ca and Al. This means that no residue is left at the end. However, there is still a significant gate fee for this process. In addition, the total amount of fuel replacement in cement kilns by GFRP waste is limited due to the presence of boron commonly found in the E-glass fiber reinforcement. More than 0.2% of boron oxide in the cement increases the setting time and reduces the early strength. In practical terms, this means that no more than about 10% of the fuel input to a cement kiln could be replaced by GFRP waste material if no significant effect on the performance of the cement is required [14]. Other drawbacks of co-incineration in cement kilns rely on the requirements that GFRP waste must comply with: fragments of composite waste should be smaller than a designated size (20 mm × 20 mm), contain low concentrations of toxic materials and heavy metals, contain no foreign material (such as metal inserts or fasteners), have a specific calorific value (higher than 5000 kcal/kg), and must not generate dust such as pulverized glass fibers [18]. At present, co-incineration in cement kilns is commercially active in Germany through CompoCycle (Zajons Zerkleinerungs GmbH, Melbeck, Germany/Holcim AG, Hamburg, Germany) and is supported by EuCIA [19].

2.1.2. Thermal/Chemical Recycling

Thermo-chemical decomposition processes have been applied for fiber and partial energy recovering, mostly for CFRP composite waste due to the inherent economic value of carbon fibers. Although it recovers both energy and material, these recycling processes are only cost-effective in the areas where paybacks are the highest (high economic value of the fibers), and where the volume of material to be processed is large enough to justify the capital cost of the technical plant.

The most common thermal process is pyrolysis, which consists of heating the scrap material in an inert atmosphere in order to recover the polymer material as oil. This kind of atmosphere prevents combustion, and, as result, the air pollution effects are less harmful in this process than in incineration. Another advantage is that the recovered oil can be used either as fuel or be refined to regenerate resin feedstock chemicals. As a limitation of this technique, the surface fragilities induced by the thermal stress on the recovered fibers, thus reducing its original strength, have been reported [10]. Oxidation in fluidized beds is another thermal process for FRP recycling, and it consists of combusting the polymer matrix in a hot and oxygen-rich flow. Recovered fibers by this process are clean and show very little surface contamination by char deposition; however, strength and fiber length degradation also occur [9,14]. Some recent research has shown that specific etching processes can significantly recover the original strength of reinforcing fibers that have been previously damaged by a thermal treatment [20,21], but this approach is still far away from an industrial realization.

The chemical recycling methods involve dissolution of the resin by means of chemical products and are based on a reactive medium (e.g., catalytic solutions and supercritical fluids) under low temperature [22]. Being thermal stress-free and quite gentle processes, chemical methods allow the fibers to retain most of their original strength. However, some limitations of these methods have also been pointed out: they usually involve the use of hazardous solvents, they require the previous granulation of scrap material in order to improve the specific surface, which causes length reduction of recovered fibers, and, additionally, they generally lead to weak adhesion to polymer matrix in posterior applications of recycled fibers [10]. As in the case of thermal recycling plants, chemical plants for composite recycling are not yet economically viable, at least for GFRP or relatively low volumes of CFRP waste to be processed [19].

2.1.3. Mechanical Recycling

Among the recycling technologies available for thermoset FRP composite materials, the most mature technique is mechanical recycling with size reduction by shredding, crushing or milling processes. The resultant recyclates, a mix of powdered and fibrous material, can be incorporated as filler or reinforcement replacement into new composite materials or as a closed-loop recycling process. This technique usually involves three steps: (a) initial size reduction of scrap material in some primary crushing process to pieces in the order of 50–100 mm in size; (b) final size reduction in jaw crushers, hammer or knife mills where the waste material is ground into a finer product ranging to 10 mm in size down to particles less than 50 µm; and (c) sorting and classifying operations to grade the resultant recyclates into fractions of different size (through cyclones or air zig-zag separators combined with sieving techniques) [23]. Typically, the finer grade fractions are mostly of a powdered nature with a high proportion of filler and resin particles, whereas the coarser fractions tend to be of a fibrous nature where the particles have a high aspect ratio and fiber content [9]. Although mechanical recycling has been considered mostly for GFRP composites, in which reinforcing fibers have a relatively low economic value, it can also be applied to process CFRP waste with environmental benefits as demonstrated by Howarth et al. [24].

Mechanical recycling shows significant environmental and economic advantages when compared to the previous recycling routes. In fact, mechanical size reduction: (a) does not produce atmospheric pollution by gas emission or water pollution by chemical solvents effluents; (b) does not require sophisticated, and expectably expensive, equipment like the ones that are required in the other processes; and (c) allows the processing of larger amounts of waste at higher throughputs. As drawbacks, two less attractive features have been pointed out: (a) safety issues due to risk of ignition during the shredding process; and (b) the lower value of the final product hardly competitive with homologous virgin raw materials such as calcium carbonate or shopped glass fibers. Nevertheless, ensuring that economically viable end-use applications for the recyclates exist, mechanical recycling at industrial scale processing is so far considered the most suitable recovery technique, at least for relatively low cost and promoter-free FRP materials.

2.2. End-Use Applications for GFRP Recyclates

Over the last 25 years, several end-use applications were investigated for mechanically recycled thermoset GFRP waste or recovered glass fibers, either as raw material for new composites or into a closed-loop recycling process for the same source-material. In the envisioned applications, GFRP recyclates were applied as filler, reinforcement or core material replacement as follows [25,26]: (a) filler material for artificial wood, high density polyethylene plastic lumber, rubber pavement blocks, dense bitumen macadam and bulk or sheet (BMC/SMC) molding compounds; (b) reinforcement for wood particleboard and soils; and (c) core material for textile sandwich structures. Most of the foreseen applications have not succeeded for one or both of the following reasons: (a) tendency of the recyclate addition to negatively affect the mechanical properties of final composite; and (b) negative cost balance, where mechanical recycling and sorting operational costs outweighed the market value of the virgin product.

Among the several potential applications of mechanically recycled FRP waste in new composite materials, a significant amount of research work has been carried out on Portland cement concrete in which the effect of GFRP recyclates, and more rarely CFRP recyclates, has been analyzed and assessed either as reinforcement, aggregate or filler replacement [27,28,29,30,31,32,33,34,35,36,37,38,39,40,41]. In the analyzed studies, a wide-range of replacement amounts was assessed: between 1% up to 20% in weight of total aggregates (after conversion of volume content to weight content). The applied FRP waste size fraction also differs widely, to relatively large pieces of GFRP or CFRP waste (5–30 mm square by 0.02–10 mm depth) [27,28] down to very fine grade fractions with particle average diameter less than a few microns [29,30,31,32,33,41]. However, in the biggest part of research studies, GFRP waste addition consisted of fluffy mixtures of powdered and fibrous particulate material with different lengths of glass fibers [34,35,36,37,38,39,40]. In addition, recovered glass fibers through pyrolysis recycling process were investigated for short reinforcement in cement mortars [42].

Besides the environmental benefits, and as a function of specific mix design formulation, reported added values due to FRP recyclate incorporation in cement based materials include slight to strong decreases of permeability with subsequent improved durability [29,31,32,33,35], less drying shrinkage [29,35], better workability [27,30,31,32], reduced risk of cracking induced by restrained shrinkage [31,35], improved fracture and tensile behavior [28,31,40], higher thermal insulation [32,41], and a global cost reduction of raw materials. In some particular cases, for lower sand replacement ratios, slender increases on compressive [34,35,36,37,38,39], splitting tensile [27,35], and/or flexural strengths [28,32,34,37,38,39] were observed. However, most of the time, undesirable features were noticed such as significant losses in the mechanical properties (in most of the cases due to high water–cement ratio required to achieve the desirable workability) [27,28,29,30,31,33,34,36,37,38,39,41,42], higher wear loss [33], higher setting times [30,31], potential incompatibility problems derived from alkalis–silica reaction (depending upon glass fiber nature and content) [29,30,31,32,33,34,35,36,37,38,39], higher susceptibility to chloride ion penetration [42], and weak adhesion at recyclate-binder interface [27]. This last issue, commonly found in the design process of composite materials modified with recycled plastics, was also addressed in some research works through the combined incorporation of GFRP recyclates and chemical coupling agents [32].

The global outputs of part of the above research works were addressed by Yazdanbakhsh and Bank (as 2013) in their revision study [43]. The resultant main highlights, benefits and drawbacks of FRP waste incorporation into Portland cement concrete materials are still valid today, even considering the most recent advances in that field. As they state in their conclusions, in general, the partial replacement of aggregates in Portland cement concretes and mortars by mechanically recycled FRP “do not notably affect the durability of the final cementitious materials, but significantly reduce their mechanical properties” [43]. In addition, the partial replacement of mineral aggregates by GFRP recyclates generally leads to minor decays in mechanical properties of final composite if fibrous GFRP waste fractions are applied instead of finely powdered GFRP recyclates.

Recently, some experiments were also carried out undertaking the incorporation of GFRP recyclates into polymer concretes (PC) and polymer mortars (PM) [25,26,44,45,46,47]. The effect of different replacement ratios of sand aggregates by both fine and coarse GFRP waste fractions on final mechanical properties of polyester based PM was assessed, as well as the effect of the incorporation of silane coupling agents. The obtained results showed that the partial replacement of sand aggregates by either of both GFRP waste fractions (up to 15% in weight of total aggregates) improves the compressive and flexural behavior of resultant PC/PM materials. Lately, the Global Fiberglass Solutions Inc. group (GFSI) also started to investigate this recycling route [48]. Compared to the end-use applications in cementitious based concrete materials already reported, the proposed solution overcomes some of the problems found, namely: (a) the possible incompatibilities problems due to alkalis–silica reaction; (b) the decrease in the mechanical properties; and (c) the poor bond between GFRP recyclates and matrix binder. Taking into account the obtained results, this last approach seems to be a very promising alternative end-route for mechanically recycled GFRP waste in concrete materials.

3. Sustainability Improvement of FRP Composite Materials’ Industry: A Case Study

The sustainability of a business, company or industry is closely related to its eco-efficiency performance. Eco-efficiency is a management philosophy that encourages the companies to search for environmental improvements that also yield parallel economic benefits. The term was aimed at summing up, in a single expression, the business end of sustainable development: “doing more with less”, which means delivering more value while using fewer resources. Its focus is on business opportunities allowing companies to be more environmentally responsible and more cost-effective. Hence, implementing eco-efficiency is first and foremost about navigating for opportunities, and such opportunities can be found through four main approaches: (a) the re-engineering process approach, in order to reduce the consumption of resources and reduce pollution while at the same time saving costs; (b) the recycling approach, re-valorizing by-products and production waste through cooperation with other companies, promoting recycling and the reuse of recyclates into new added value products; (c) the re-designing approach according to ecological design rules that lead to less environmental impact, higher rate of recyclability and dissemble facility; and (d) the re-thinking market approach in order to find new ways of meeting customer needs [49].

In the present case study, the sustainability improvements that can be made in a composite materials industry were assessed by measuring the eco-efficiency performance of the company before and after the implementation of certain measures related to both the re-engineering process and recycling approaches. A pultrusion manufacturing company with headquarters in Maia (Portugal),—ALTO, Perfis Pultrudidos Lda.—,was the subject of this case study, and the analysis was restricted to the main business branch of this small/medium enterprise: the production and selling of standard GFRP pultrusion profiles.

3.1. Methods

3.1.1. Measurement of Eco-Efficiency Performance

The quantification of eco-efficiency performance of a company or business is a complex process that involves the measurement and control of several relevant parameters or indicators, globally applied to all companies (Generally Applicable Indicators), or specific according to the nature and specificities of the business itself (Business Specific Indicators). The indicators fall into two main groups based on the eco-efficiency formula represented by the ratio of the two “eco” dimensions of economy and ecology relating products or service values to environmental influence.

The Generally Applicable Indicators for product/service value are: quantity of goods produced or quantity of services provided to costumers (i) and net sales (ii). Those relating to the environmental influence in product/service creation are linked to the consumption of energy (i); raw materials (ii) and water (iii); emission of greenhouse gases (iv); and ozone depleting substances (v). The Business Specific Indicators are also discriminated according to their economic or ecological nature, but they are not global and must be individually defined from one business to another. A complete company’s eco-efficient profile will include both types of indicators, value profile and environmental profile, and additionally, the eco-efficient ratios given by the previous two elements as “numerator” and “denominator” data.

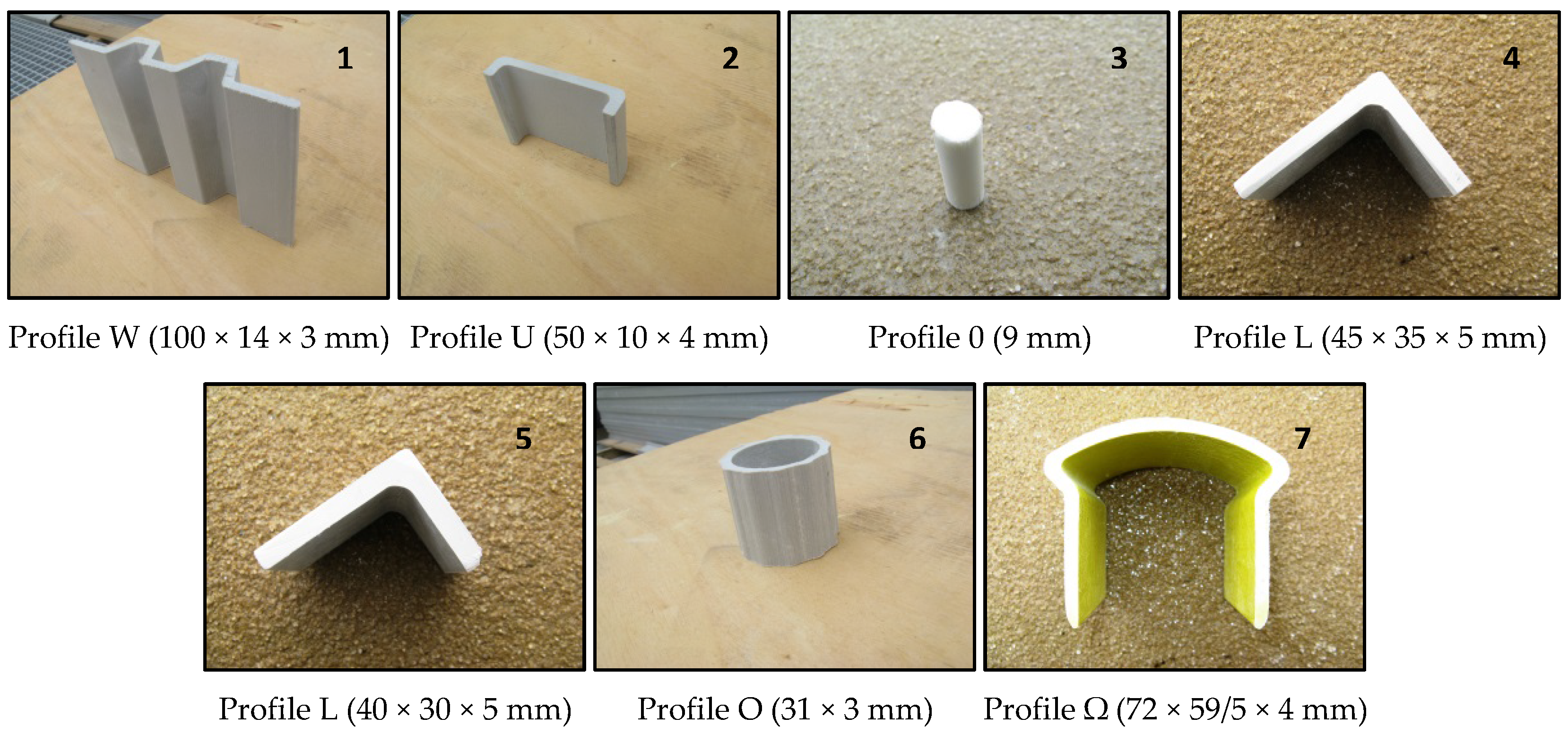

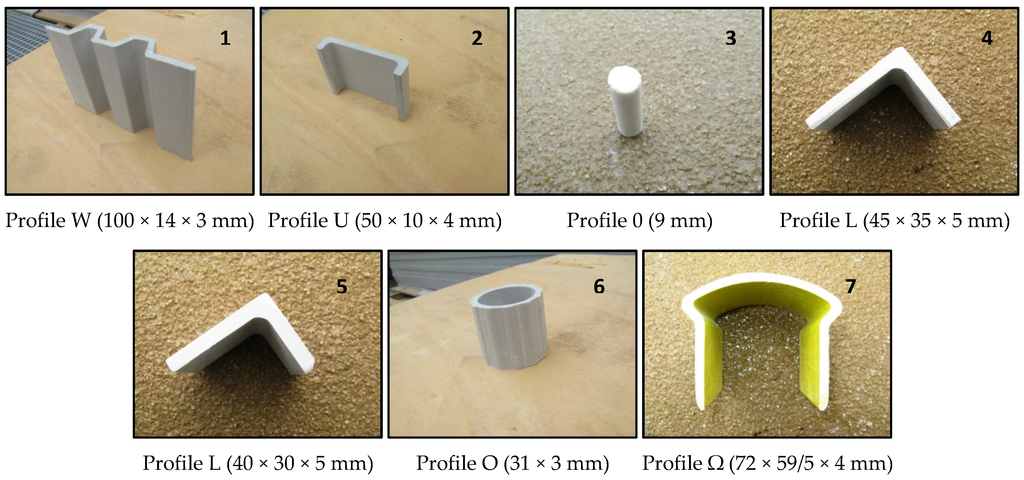

In this particular study, the framework recommended by “The World Business Council for Sustainable Development” (WBCSD) was adopted [50] and the guidelines of the ISO 14301:1999 standard [51] were followed and applied. The main pertinent Generally Applicable Indicators for this case study, as well as the Business Specific Indicators, were defined and determined according to the above standard recommendations. With basis on indicators’ figures, the value profile, the environmental profile and the pertinent eco-efficiency ratios were established and analyzed. The analysis was restricted to the main business branch of the company (ALTO): the production and selling of GFRP pultrusion profiles. The time-scale of the analysis was 75 working days and enclosed the production of seven different standard GFRP profiles illustrated in Figure 1. The main inputs and outputs of the pultrusion production process of ALTO are specified in Table 1.

Figure 1.

Cross-sections of the GFRP pultrusion profiles analyzed in this case study.

Table 1.

Main inputs and outputs of pultrusion manufacturing process of ALTO.

Three Generally Applicable Indicators (two for product value and one for environmental influence), and one Business Specific Indicator of environmental influence were selected for eco-efficiency assessment. The specifications of each indicator are detailed in Table 2.

Table 2.

Selected Generally Applicable and Business Specific Indicators for eco-efficiency performance assessment.

For each pair of “product value” and “environmental influence” indicators, the respective six eco-efficiency ratios were computed for the analyzed framework period (75 days). The same indicators and eco-efficient ratios were then predicted for an equivalent time period taking into account the implementation of improvement strategies.

3.1.2. Improvement Strategies: Re-Engineering Process and Recycling Approaches

After analyzing all the procedures involved in the production process of GFRP profiles, it was concluded that it would be possible to improve the sustainability and eco-efficiency ratios of the company by reducing the environmental influence indicators: energy consumption, materials consumption and total waste to landfill. This can be possible by taking action on two key fronts, as described in the following two items.

- Re-engineering Process Approach: Optimization of die heating system

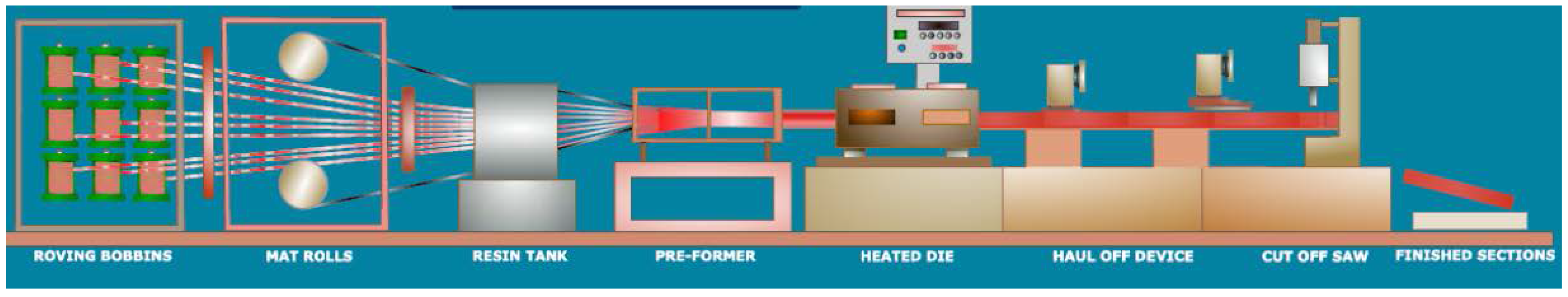

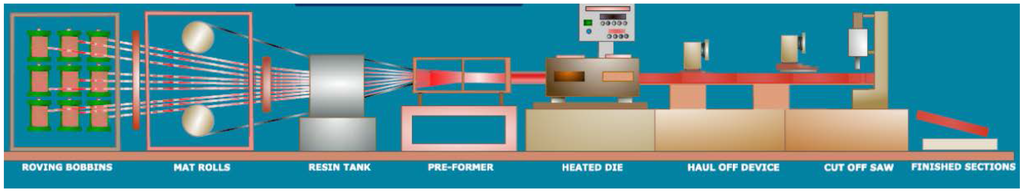

In the pultrusion process implemented in the company (ALTO), dry glass reinforcing fibers are pulled through a thermoset polyester resin bath for impregnation, and after the wetting process, the reinforcement is allowed to enter into a heated forming die where it attains the cross-section shape of the die and cures. Finally, outside the die, the composite profile already consolidated is pulled by a continuous pulling system and then a cut-off saw cuts the profile at a desired length. A schematic representation of the pultrusion process is presented in Figure 2.

Figure 2.

Schematic diagram of pultrusion manufacturing process.

Typically in the pultrusion process, and also in this case, the die is heated by external planar heaters as the most common heating system. However, this type of external heating system leads to a significant loss of heat in the surroundings of the die.

Earlier studies conducted by the authors showed that significant savings on energy consumption of the pultrusion process could be achieved using embedded cylindrical heaters into the die instead of external planar resistances [52]. Experiments were conducted in a 900 mm length die during the manufacturing process of a standard pultrusion profile (Profile U: 50 × 10 × 4), keeping all the other process parameters constant—pulling speed, pulling force, total resistance power and temperature profile (TP)—along the die. These process parameters were already fine-tuned by the large experience of the manufacturer, and conducted to a high standard of quality of pultruded part. Temperature profile was first experimentally obtained by thermography techniques for the external heating system, and then numerically simulated by finite element analysis (FEA). After validation of FEA simulation, energy consumption with an internal heating system was estimated using the same technique. The obtained results showed that internal resistances significantly enhance the energetic performance of pultrusion process, leading to a 57% decrease of energy dispended in the die heating process, which represents a reduction of 17% of total energy consumed in the pultrusion process. The warm-up time is also reduced up to 50%, which reduces significantly the lead-time of each order and increases the production time. Moreover, in posterior studies, it was also found that the optimized position of the internal heaters throughout the die could even additionally reduce the energy consumption linked to the heating process 8% more [53]. More details of conducted research studies can be found in Silva et al. [52,53].

- Recycling Approach: Mechanical recycling of production waste and reuse of recyclates in new composite materials

In the actual framework of the pultrusion sector and, in general, in that of the composite materials’ industry, production waste, non-conform and end-of-life products are usually landfilled due to their limited recycling ability, even when thermoplastic-based products are considered [54]. Currently, by-products, non-conform profiles and production waste of ALTO are also landfilled (Figure 3), with subsequent negative environmental impacts and supplementary added costs to this company. Waste to landfills constitute around 7% of total annual production of 40 tons and leads to an estimated cost for the company of 4 M€ per year. However, mechanical recycling of GFRP waste materials, with reduction to powdered and fibrous particulates (Figure 3), constitutes a recycling process that can be easily attained in heavy-duty cutting mills. The posterior reuse of obtained recyclates, either into a closed-loop process as calcium carbonate replacement for resin matrix of GFRP profiles (which represents an average of 20% in weight of total raw materials applied in the manufacturing process), or as reinforcement into new composite materials, will lead to both cost reduction in raw materials and landfill process and minimization of total amount of waste to landfill.

Figure 3.

(a) typical waste of GFRP pultrusion process; (b) samples of obtained recyclates after mechanical recycling in a heavy-duty cutting mill using different sized-meshes inside the grinding chamber.

As referred in Section 2.2, mechanically recycled GFRP waste remains, however, mired by the scarceness of cost-effective end-use applications and clearly developed recycling routes (logistics, infrastructures and recycling facilities) between waste producers and potential consumers for the recyclates. Presently, new outlets and end-markets with added value for the GFRP recyclates are required. Regarding this subject, the use of the recyclates as raw materials in the production of polymer based concrete materials (precast industry) seems to be a very promising end-use application.

Polymer concrete (PC) materials are high performance resin based concretes, in which a polymer acts as binder matrix for the mineral aggregates. High mechanical strength, improved resistance to chemical and frost attack, high damping characteristics, very fast curing time and excellent bond to several substrates are the main advantages of these materials over cement based concretes [55,56,57,58]. Nevertheless, at present, the main asset of PC materials over conventional concretes is their great ability for incorporating recycled waste products, mainly due to the hermetic nature of resin matrix. Recycling and waste encapsulation constitute nowadays a new and emerging branch market for PCs. Most of the successful applications involve either industrial by-products or end-of-life products [59,60,61,62,63].

The previous and impending experimental works carried out by the present research team have already demonstrated that GFRP recyclates can be successfully incorporated into PC materials as reinforcement and partial replacement of aggregate components, leading to both flexural and compressive strength increase of modified concrete materials [25,26,44,45,46,47]. The main outcomes of these studies show that the upcycling of GFRP waste is possible resulting in added value PC products. It was demonstrated that aggregate replacement amounts up to 15% in weight by mechanically recycled GFRP waste are viable and cost-effective. Larger replacement amounts are also technically possible but lead to progressive drops in mechanical strength of the final products. Compared with related end-use applications in conventional Portland cement concrete materials, the proposed solution overcomes some of the limitations found (see sub-chapter 2.2). These limitations, by and large resultant from the use of a cementitious binder as matrix, are avoided using a cementless concrete as host material for the recyclates.

The above recycling approach highlights a viable technological option for improving the quality of GFRP filled PC materials, thus opening a door to selective recycling of GFRP waste. It is expected that around 80% of actual production waste of ALTO can be mechanically recycled and reduced to fibrous/filler material, and posteriorly reused either as reinforcement for polymer based concrete materials (pre-casting industry) or as partial calcium carbonate replacement of resin matrix in the pultrusion process, into a closed-loop recycling process.

3.2. Results and Discussion

3.2.1. Current and Predicted Value and Environmental Indicators

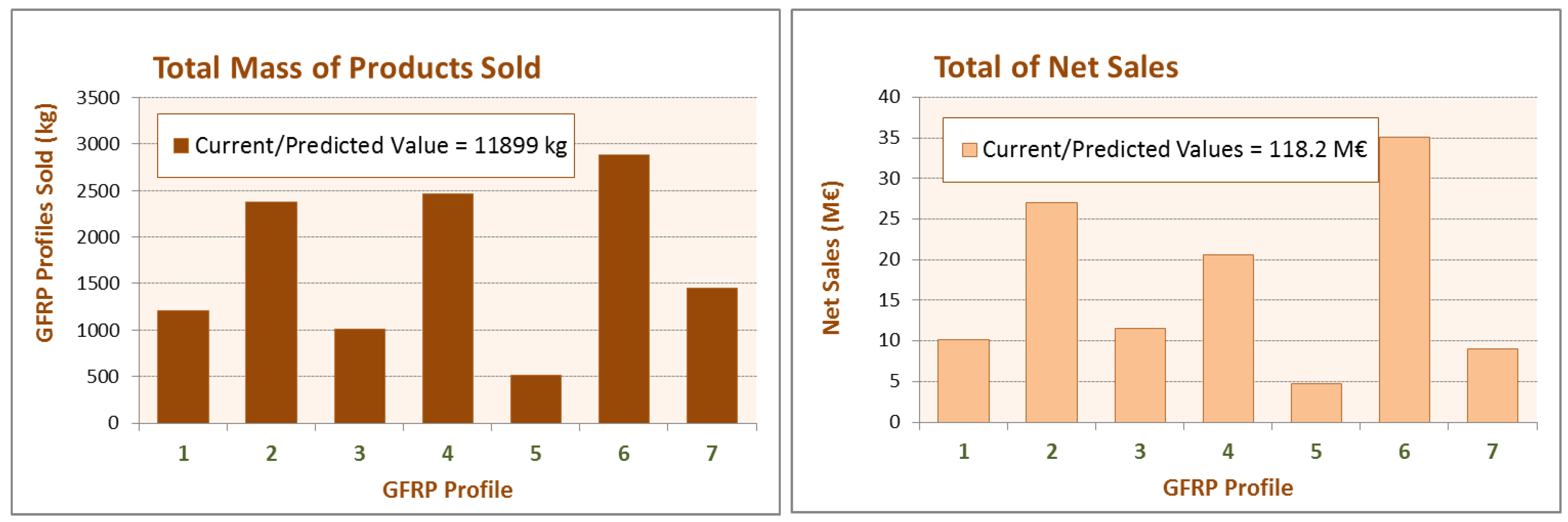

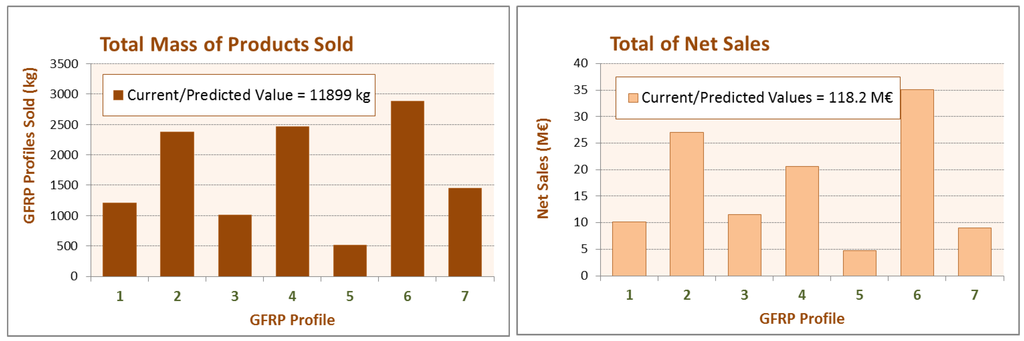

In the present analysis, it was assumed that the value indicators, namely the total amount of products sold and net sales, would not be affected by the implementation of the new improvement strategy approaches. This means that the current and the predicted value indicators will be the same, whereas the current and the predicted environmental influence indicators will be differentiated, taking into account the turnovers of those measures.

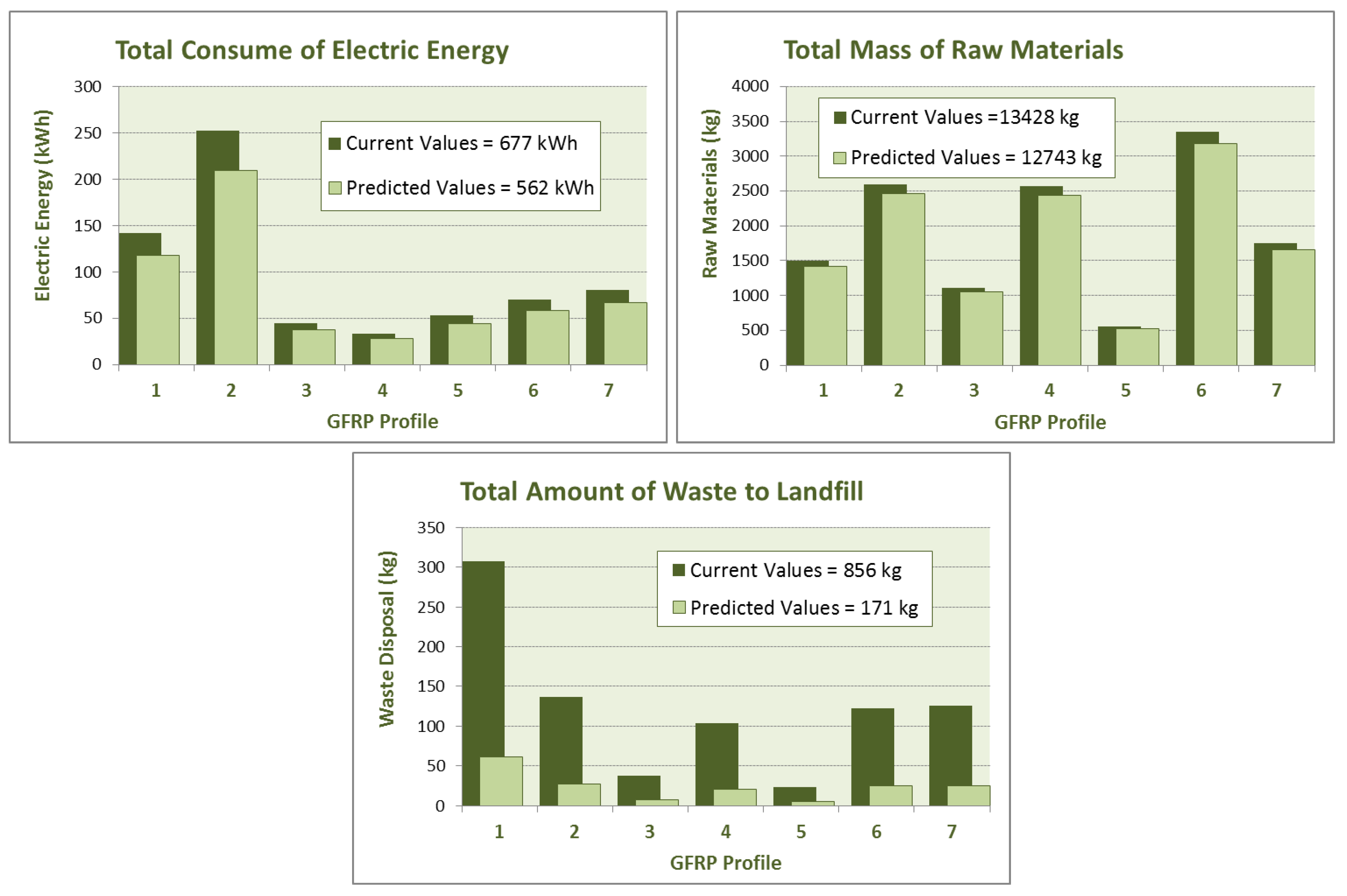

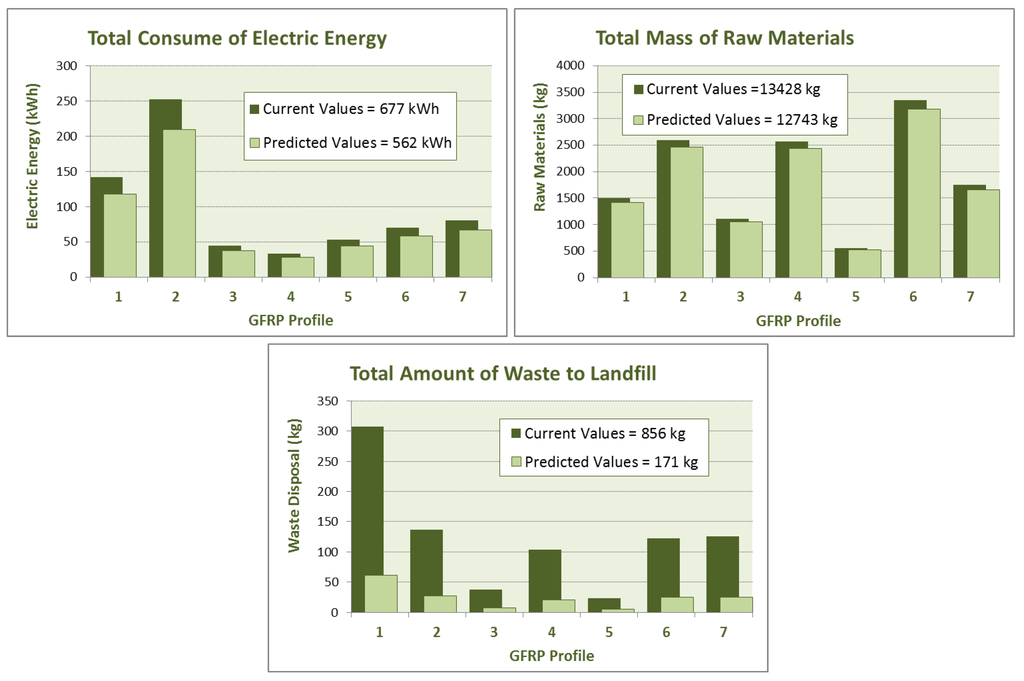

In what concerns the prediction of the new environmental influence indicators, the following assumptions were assumed:

- The replacement of the die heating system (external planar resistances by internal cylindrical heaters) leads to 17% savings on the total consume of electric energy due to the pultrusion process, irrespective of the type of die/GFRP profile production;

- The savings on electric energy due to the optimization of heater position along the die are not taken into account;

- The reduction on warm-up periods of the die at the beginning of each run/order is disregarded and is not reflected in an eventual increase of production rate (the value indicators were kept equal);

- Eighty-percent of the current amount of production waste to landfill is able to be mechanically recycled. This percentage corresponds to the average production waste fraction constituted of relatively unaltered and clean GFRP material—non-conform products and left-overs resulting from cutting and assembly processes of GFRP profiles on site. The remained 20% of production waste is mainly constituted of roving, veil and mat scrap, not properly consolidated in a resin matrix, and other manufacturing rejects not able for mechanical recycling;

- Twenty-five percent of the total amount of calcium carbonate applied in the production process of GFRP profiles is the maximum amount that could be replaced by fine-ground GFRP recyclates into a closed-loop recycling process. Higher amounts of replacement, as experimentally tested by the producer, lead to slight decays in final mechanical properties and fire reaction performance of standard profiles.

The obtained value indicators are presented in Figure 4, whereas the measured and predicted environmental indicators are depicted in Figure 5. Presented values are discriminated according to the seven types of pultrusion profiles produced during the framework time. They include four Generally Applicable Indicators of product value and environmental influence indicated in Table 2 and one Business Specific Indicator of environmental influence (total of production waste to landfill).

Figure 4.

Value indicators according to the type of GFRP profile produced by the company ALTO.

Figure 5.

Current and predicted environmental influence indicators according to the type of GFRP profile produced by the company ALTO.

3.2.2. Current and Predicted Eco-Efficient Ratios

With basis on the above indicators, current eco-efficient ratios were determined and compared with those that could be obtained implementing the improvement strategy approaches. The obtained results are presented in Table 3.

Table 3.

Current and predicted eco-efficiency ratios (before and after implementation of improvement strategies).

As shown in Table 3, the turnovers resultant from the re-engineering manufacturing process and the recycling approach lead to significant potential increases in the eco-efficient ratios of the company. The energy savings with the new die heating system leads to an increase of 20% in the “value indicators” to “energy consumption” eco-efficient ratios, and the recycling approach conducts increases of around 5% and 400% on the two other main groups of eco-efficient ratios (“value indicators” to “raw materials consumption” and “value indicators” to “total waste disposal”, respectively).

3.2.3. Case Study: Main Conclusions and Revenues

The implementation of a new die heating system and, especially, mechanical recycling approach, with partial waste reuse of scrap material derived from manufacturing, cutting and assembly processes of GFRP profiles, lead to both minimization of waste disposal and cost reduction on raw materials, electric energy and landfill process. These features lead to significant improvements in the subsequent assessed eco-efficiency ratios of the present composite materials’ industry, yielding to a more sustainable product and manufacturing process of pultruded GFRP profiles.

At present, as a result of this case study, the company implemented the new die heating systems in four of their production lines. In addition, part of production waste is diverted to mechanical recycling and reused into a closed-loop process as a partial substitute of calcium carbonate in the production of GFRP profiles. Regrettably, and in spite of the several attempts that have been made, the remaining production waste able to be mechanically recycled and intended to be diverted to the PC precast industry is still sent to landfill, jointly with the other manufacturing rejects. Eighty-percent of the total production waste of ALTO (which corresponds to around 2.2 tons per year) is not enough to challenge or attract the PC precast industry: the relatively small quantity does not justify the necessary adjustments that would be required in the production lines. Clusters and cooperative initiatives should be first created and implemented in order to create efficient “bridges” between the industries that generate GFRP waste in a certain region, the recycling plants and the potential PC precast industries.

4. Market Outlook and Future Perspectives for GFRP Recyclates

The intended perspectives for final applications of concrete and/or composite materials modified with GFRP recyclates include, among others, molding compounds, precast slabs, paving blocks, railroad sleepers, wall panels, manhole covers, valve chambers, cement floor screeds, valley gutters, roofing sheets and flat sheets for signage; however, few of these products came out of the investigation field and had an industrialized expression. One of the few successful applications (manhole covers, utility boxes and urban furniture made of thermoset and glass fiber flakes waste aggregated in a resin under high pressure cold molding) was developed by Reprocover, in Belgium, and it has been commercialized since 2011 [64]. Nevertheless, apart from some in-house recycling (such as the above example), until now, attempts to commercialize these products as a recycling route for GFRP waste have failed.

Recently, some progress made by Extreme EcoSolutions (Nijkerk, The Netherlands) and Hambleside Danelaw (Daventry, UK) in this field, reported by Job in 2014 [48], seemed to indicate that they were close to commercializing some end-use applications for mechanically recycled GFRP waste, namely, as filler for polyethylene film products and as reinforcement for construction elements, respectively. However, as far as it has been publicized, these products have not yet arrived to the market [65,66].

Regarding the application of GFRP recyclates to PC materials, the investigation line that was started by Ribeiro and co-workers in 2010 [25,26,44,45,46,47] also gained the attention of Global Fiberglass Solutions Inc. group. Over the last two years, this company has invested significant efforts on research and product development and expects to commercialize final precast products for rail and roadways infrastructures under the trademark of “Ecopolycrete” [67].

Even so, and despite all of the efforts that have been done on developing cost-effective recycling routes, the industrial applications of GFRP recyclates still remain hindered by the lack of clearly developed recycling paths (logistics, infrastructures and recycling facilities) between GFRP waste producers and potential consumers for the recyclates, and this seems to be the main barrier to a more generalized use of these recyclates in commercial applications. However, it is foreseen that this scenario will change in the next few years as strong investments are being made in this field. This will meet the EU circular economy policy on waste management with objectives and targets to improve waste management, stimulating innovation in recycling, limiting the use of landfilling, and creating incentives to change consumer behavior.

Acknowledgments

The financial support of “Fundação para a Ciência e a Tecnologia” (FCT), under the “Programa Operacional Potencial Humano” (POPH/ESF), Operational Program funded by the European Social Fund (SFRH/BPD/98869/2013 grant), as well as the technical support of ALTO, Perfis Pultrudidos, Lda., are gratefully acknowledged.

Author Contributions

Maria Cristina Santos Ribeiro, António Fiúza and Maria de Lurdes Dinis conceived and designed the experiments; Mário Rui Alvim performed the experiments; Maria Cristina Santos Ribeiro, Ana Cristina Meira Castro and João Paulo Meixedo analyzed the data; Mário Rui Alvim and António Ferreira contributed with analysis tools and resources; Maria Cristina Santos Ribeiro, Maria de Lurdes Dinis and António Fiúza wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hollaway, L.C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Zaman, A.; Gutub, S.A.; Wafa, M.A. A review on FRP composites applications and durability concerns in the construction sector. J. Reinf. Plast. Compos. 2013, 32, 1966–1988. [Google Scholar] [CrossRef]

- GWEC, Global Wind Turbines Council. Market forecast for 2015–2019. Available online: http://www.gwec.net/global-figures/market-forecast-2012-2016/ (accessed on 9 May 2016).

- Beauson, J.; Tilholt, H.; Brøndsted, P. Recycling solid residues recovered from glass fiber-reinforced composites—A review applied to wind turbine blade materials. J. Reinf. Plast. Compos. 2014, 33, 1542–1556. [Google Scholar] [CrossRef]

- EuCIA—European Composites Industry Association. Composites Market Report 2015: Market developments, trends, challenges and opportunities (The European GRP Market/The Global CRP Market). Available online: http://www.eucia.eu/news/composites-market-report-2015 (accessed on 9 May 2016).

- Global Glass Fiber Market 2015–2020: Trends, Forecast, and Opportunity Analysis. Available online: http://www.lucintel.com/glass_fiber_market_2020.aspx (accessed on 9 May 2016).

- Recycling of Wind Turbine Rotor Blades—Fact or Fiction? Available online: http://www.dewi.de/dewi_res/fileadmin/pdf/publications/Magazin_34/05.pdf (accessed on 9 May 2016).

- Jacob, A. Composites can be recycled? Reinf. Plast. 2011, 55, 45–46. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling thermoset composite materials. In Wiley Encyclopedia of Composites, 2nd ed.; Nicolais, L., Borzacchiello, A., Lee, S.M., Eds.; John Wiley & Sons: New York, NY, USA, 2012; Volume 4, pp. 2599–2614. [Google Scholar]

- Pimenta, S.; Pinho, S. Recycling carbon fiber reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2010, 31, 378–392. [Google Scholar] [CrossRef] [PubMed]

- Conroy, A.; Halliwell, S.; Reynolds, T. Composite recycling in the construction industry. Compos. Part A 2006, 37, 1216–1222. [Google Scholar] [CrossRef]

- 2008/98/EC. Directive 2008/98/EC of the European Parliament and of the Council of 18 November of 2008 on Waste and repealing some Directives. Available online: http://eur-lex.europa.eu/oj/direct-access.html (accessed on 9 May 2016).

- 2000/53/EC. Directive 2000/53/EC of the European Parliament and of the Council of 18 September of 2000 on end-of-life vehicles—Commission Statemets. Available online: http://eur-lex.europa.eu/oj/direct-access.html (accessed on 9 May 2016).

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Asmatulu, E.; Twomey, J.; Overcash, M. Recycling of fiber-reinforced composites and direct structural composite recycling concept. J. Compos. Mater. 2014, 48, 539–608. [Google Scholar] [CrossRef]

- Bartholomew, K. Fiberglass reinforced plastics recycling, technical report – Minnesota technical assistance program, December 2004. Available online: http://mntap.umn.edu/fiber/resources/report12-04.pdf (accessed on 9 May 2016).

- 2000/76/EC. Directive 2000/76/EC of the European Parliament and of the Council of 4 December of 2000 on the incineration of waste. Available online: http://eur-lex.europa.eu/oj/direct-access.html (accessed on 9 May 2016).

- Nomaguchi, K.; Hayashi, S.; Abe, Y. A Solution for Composites Recycling Cement Process. In Proceedings of the COMPOSITES 2001: Convention and Trade Show Composites Fabricators Association, Tampa, FL, USA, 3–6 October 2001.

- Job, S. Recycling glass fiber reinforced composites—History and progress. Reinf. Plast. 2013, 57, 19–23. [Google Scholar] [CrossRef]

- Yildirir, E.; Miskolczi, N.; Onwudili, J.A.; Németh, K.E.; Williams, P.T.; Sója, J.S. Evaluating the mechanical properties of reinforced LDPE composites made with carbon fibers recovered via solvothermal processing. Compos. Part B 2015, 78, 393–400. [Google Scholar] [CrossRef]

- Yang, L.; Sáez, E.R.; Nagel, U.; Thomason, J.L. Can thermally degraded glass fiber be regenerated for close-loop recycling of thermosetting composites? Compos. Part A 2015, 72, 167–174. [Google Scholar] [CrossRef]

- Morin, C.; Loppinet-Serani, A.; Cansell, F. Near and supercritical solvolysis of carbon fiber reinforced polymers (CFRPs) for recycling carbon fibers as a valuable resource: State of the art. J. Supercrit. Fluids 2012, 66, 232–240. [Google Scholar] [CrossRef]

- Palmer, J.; Ghita, O.R.; Savage, L.; Evans, K.E. Successful closed-loop recycling of thermoset composites. Compos. Part A 2009, 40, 490–498. [Google Scholar] [CrossRef]

- Howarth, J.; Mareddy, S.R.; Mativenga, P.T. Energy intensity and environmental analysis of mechanical recycling of carbon fiber composite. J. Clean. Prod. 2014, 81, 46–50. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Meira-Castro, A.C.; Silva, F.G.; Santos, J.; Meixedo, J.P.; Fiúza, A.; Dinis, M.L.; Alvim, M.R. Re-use assessment of thermoset composite waste as aggregate and filler replacement for concrete-polymer composite materials: A case study regarding GFRP pultrusion waste. Resour. Conserv. Recycl. 2015, 104, 417–426. [Google Scholar] [CrossRef]

- Meira Castro, A.C.; Carvalho, J.P.; Ribeiro, M.C.S.; Meixedo, J.P.; Silva, F.J.G.; Fiúza, A.; Dinis, M.L. An integrated recycling approach for GFRP pultrusion waste: recycling and reuse assessment into new composite materials using Fuzzy Boolean Nets. J. Clean. Prod. 2014, 66, 420–430. [Google Scholar] [CrossRef]

- Alam, M.S.; Slater, E.; Billah, A.H.M. Green concrete made with RCA and FRP scrap aggregate: Fresh and hardened properties. J. Mater. Civil Eng. 2013, 25, 1783–1794. [Google Scholar] [CrossRef]

- Ogi, K.; Shinoda, T.; Mizui, M. Strength in concrete reinforced with recycled CFRP pieces. Compos. Part A 2005, 36, 893–902. [Google Scholar] [CrossRef]

- Tittarelli, F.; Moriconi, G. Use of GFRP industrial by-products in cement based composites. Cem. Concr. Compos. 2010, 32, 219–225. [Google Scholar] [CrossRef]

- Tittarelli, F.; Kawashima, S.; Tregger, N.; Moriconi, G.; Shah, S.P. Effect of GRP by product addition on plastic and hardened properties of cement mortars. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010.

- Tittarelli, F.; Shah, S.P. Effect of low dosage of waste GRP dust on fresh and hardened properties of mortars: Part 1. Constr. Build. Mater. 2013, 47, 1532–1538. [Google Scholar] [CrossRef]

- Tittarelli, F. Effect of low dosage of waste GRP dust on fresh and hardened properties of mortars: Part 2. Constr. Build. Mater. 2013, 47, 1539–1543. [Google Scholar] [CrossRef]

- Correia, J.R.; Almeida, N.M.; Figueira, J.R. Recycling of FRP composites: Reusing fine GFRP in concrete mixtures. J. Clean. Prod. 2011, 19, 1745–1753. [Google Scholar] [CrossRef]

- Asokan, P.; Osmani, M.; Price, A.D.F. Assessing the recycling potential of glass fiber reinforced plastic waste in concrete and cement composites. J. Clean. Prod. 2009, 17, 821–829. [Google Scholar] [CrossRef]

- Asokan, P.; Osmani, M.; Price, A.D.F. Improvement of the mechanical properties of glass fiber reinforced plastic waste powder filled concrete. Constr. Build. Mater. 2010, 24, 448–460. [Google Scholar] [CrossRef]

- Osmani, M.; Pappu, A. An assessment of the compressive strength of glass reinforced plastic waste filled concrete for potential applications in construction. Concr. Res. Lett. 2010, 1, 1–5. [Google Scholar]

- Osmani, M.; Pappu, A. Utilization of glass reinforced plastic waste in concrete and cement composites. In Proceedings of the 2nd International Conference on sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010.

- Osmani, M. Innovation in cleaner production through concrete and cement composite recycling. In Proceedings of the 3rd International Workshop Advances in Cleaner Production, S. Paulo, Brazil, 18–20 May 2011.

- Garcia, D.; Vegas, I.; Cacho, I. Mechanical recycling of GFRP waste as short-fiber reinforcements in microconcrete. Constr. Build. Mater. 2014, 64, 293–300. [Google Scholar] [CrossRef]

- Sebaibi, N.; Benzerzour, M.; Abriak, N.E. Influence of the distribution and orientation of fibers in reinforced concrete with waste fibers and powders. Constr. Build. Mater. 2014, 65, 254–263. [Google Scholar] [CrossRef]

- Corinaldesi, V. Lightweight plasters containing plastic waste for sustainable and energy-efficient buildings. Constr. Build. Mater. 2015, 94, 337–345. [Google Scholar] [CrossRef]

- Criado, M.; Garcia-Dáz, I.; Bastidas, J.M.; Alguacil, F.J.; López, F.A.; Monticelli, C. Effect of recycled glass fiber on the corrosion behavior of reinforced mortar. Constr. Build. Mater. 2014, 64, 261–269. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C. A critical review of research on reuse of mechanically recycled FRP production and end-of-life waste for construction. Polymers 2014, 6, 1810–1826. [Google Scholar] [CrossRef]

- Castro, A.C.M.; Ribeiro, M.C.S.; Santos, J.; Meixedo, J.P.; Silva, F.J.G.; Fiúza, A.; Dinis, M.L.; Alvim, M.R. Sustainable waste recycling solution for the glass fiber reinforced polymer composite materials industry. Constr. Build. Mater. 2013, 45, 87–94. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Fiúza, A.; Castro, A.C.M.; Silva, F.G.; Dinis, M.L.; Meixedo, J.P.; Alvim, M.R. Mix design process of polyester polymer mortars modified with recycled GFRP waste materials. Compos. Struct. 2013, 105, 300–310. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Fiúza, A.; Castro, A.C.M.; Meixedo, J.P.; Dinis, M.L.; Costa, C.; Ferreira, F.; Alvim, M.R. Recycling of Pultrusion Production Waste into Innovative Concrete-Polymer Composite Solutions. Adv. Mater. Res. 2011, 295–297, 561–565. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Meixedo, J.P.; Fiúza, A.; Dinis, M.L.; Castro, A.C.M.; Silva, F.J.G.; Costa, C.; Ferreira, F.; Alvim, M.R. Mechanical Behavior Analysis of Polyester Polymer Mortars Modified with Recycled GFRP Waste Material. World Acad. Sci. Eng. Technol. 2011, 75, 365–371. [Google Scholar]

- Job, S. Recycling composites commercially. Reinf. Plast. 2014, 58, 32–38. [Google Scholar] [CrossRef]

- Lehni, M. Eco-efficiency: Creating more value with less impact. In WBCSD Report; World Business Council for Sustainable Development: Geneva, Switzerland, 2000. [Google Scholar]

- Verfaillie, H.A.; Bidwell, R. Measuring Eco-Efficiency—A Guide to Reporting Company Performance; World business Council for Sustainable Development: Geneva, Switzerland, 2000. [Google Scholar]

- International Organization for Standardization. ISO 14301:1999. Environmental Management—Environmental performance evaluation—Guidelines. ISO Standard, International Organization for Standardization: Geneva, Switzerland, 1999. [Google Scholar]

- Silva, F.J.G.; Ferreira, F.; Costa, C.; Ribeiro, M.C.S.; Castro, A.C.M. Comparative study about heating systems for pultrusion process. Compos. Part B 2012, 43, 1823–1829. [Google Scholar] [CrossRef]

- Silva, F.J.G.; Ferreira, F.; Ribeiro, M.C.S.; Castro, A.C.M.; Castro, M.R.A.; Dinis, M.L.; Fiúza, A. Optimising the energy consumption on pultrusion process. Compos. Part B 2014, 57, 13–20. [Google Scholar] [CrossRef]

- Halliwell, S. End of Life Options for Composite Waste: Recycle, Reuse or Disposal? National Composites Network Best Practice Guide; National Composites Network: Chesterfield, UK, 2006. [Google Scholar]

- Bhutta, M.A.R.; Ohama, Y. Recent status of research and development of concrete-polymer composites in Japan. Concr. Res. Lett. 2010, 1, 125–130. [Google Scholar]

- Fowler, D.W. State of the art in concrete polymer materials in the US. In Proceedings of the 12th International Congress on Polymer Concrete, Chuncheon, Korea, 27–28 September 2007.

- Ribeiro, M.C.S.; Nóvoa, P.R.; Ferreira, A.J.M.; Marques, A.T. Flexural performance of polyester and epoxy polymer mortars under severe thermal conditions. Cem. Concr. Compos. 2004, 26, 803–809. [Google Scholar] [CrossRef]

- Suh, J.D.; Lee, D.G. Design and manufacture of hybrid polymer concrete bed for high-speed CNC milling machine. Int. J. Mech. Mater. Des. 2008, 4, 113–121. [Google Scholar] [CrossRef]

- Barrera, M.G.; Campos, M.C.; Gencel, O. Polyester polymer concrete: Effect of the marble particle sizes and high gamma radiation. Constr. Build. Mater. 2013, 41, 204–208. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Saccani, A.; Sandrolini, F. New polymer mortars containing polymeric waste. Part 1: microstructure and mechanical properties. Compos. Part A 2000, 31, 97–106. [Google Scholar] [CrossRef]

- Garbacz, A.; Sokolowska, J.J. Concrete-like polymer composites with fly ashes–comparative study. Constr. Build. Mater. 2013, 38, 689–699. [Google Scholar] [CrossRef]

- Nóvoa, P.J.R.O.; Ribeiro, M.C.S.; Ferreira, A.J.M.; Marques, A.T. Mechanical characterization of lightweight polymer mortars modified with cork granules. Compos. Sci. Technol. 2004, 64, 2197–2205. [Google Scholar] [CrossRef]

- Reis, J.M.L.; Jurumenha, M.A.G. Experimental investigation on the effects of recycled aggregate on fracture behavior of polymer concrete. Mater. Res. 2011, 14, 326–330. [Google Scholar] [CrossRef]

- Reprocover. Available online: http://reprocover.com (accessed on 9 May 2016).

- Extreme EcoSolutions. Available online: http://extreme-ecosolutions.com (accessed on 9 May 2016).

- Hambleside Danelaw, Building Products. Available online: http://www.hambleside-danelaw.co.uk/ (accessed on 9 May 2016).

- Ecopolycrete. Available online: http://www.ecopolycrete.com (accessed on 9 May 2016).

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).