End-of-Life Strategies for Used Mobile Phones Using Material Flow Modeling

Abstract

:1. Introduction

2. Material Flow Modeling of Used Mobile Phone

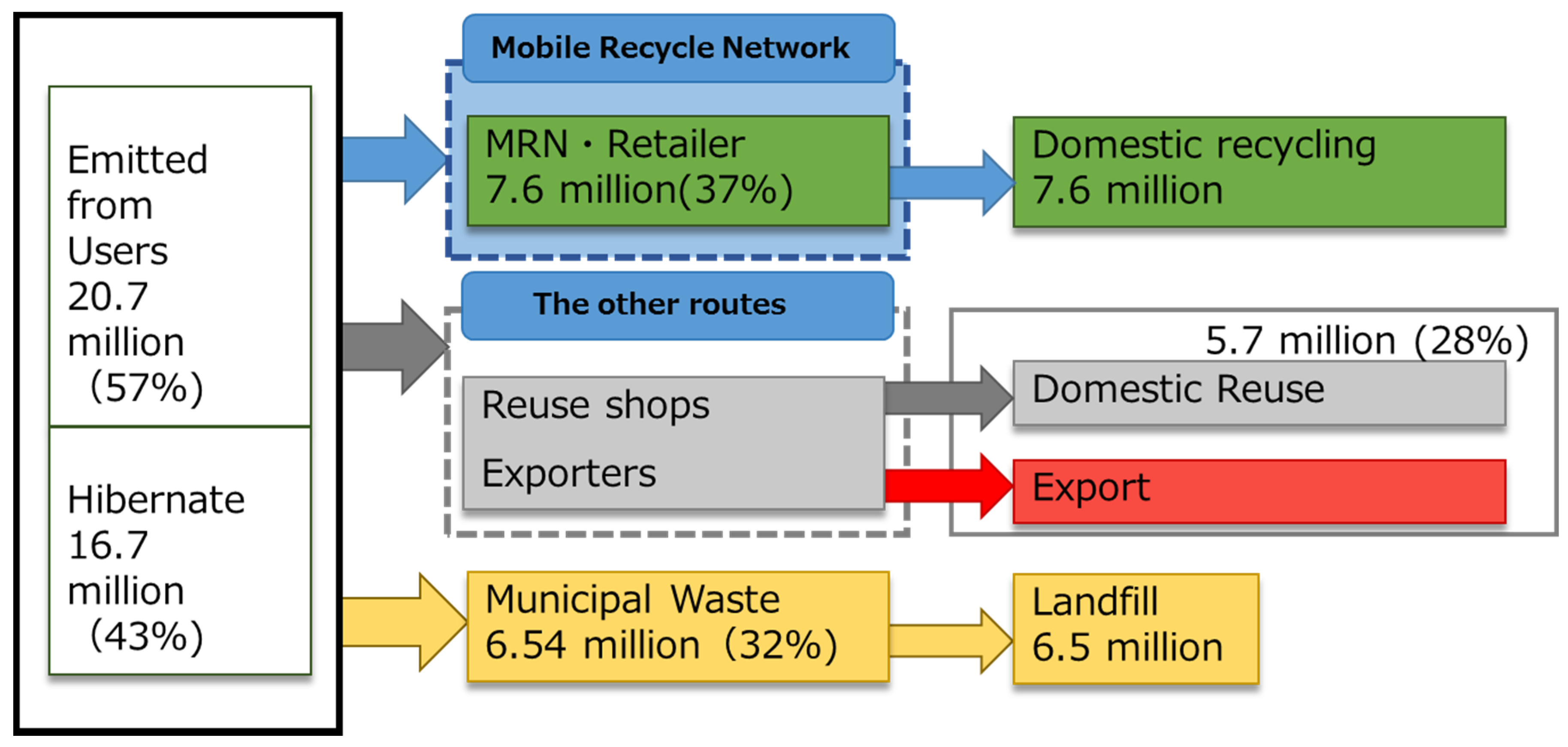

2.1. Collection of Used Mobile Phone

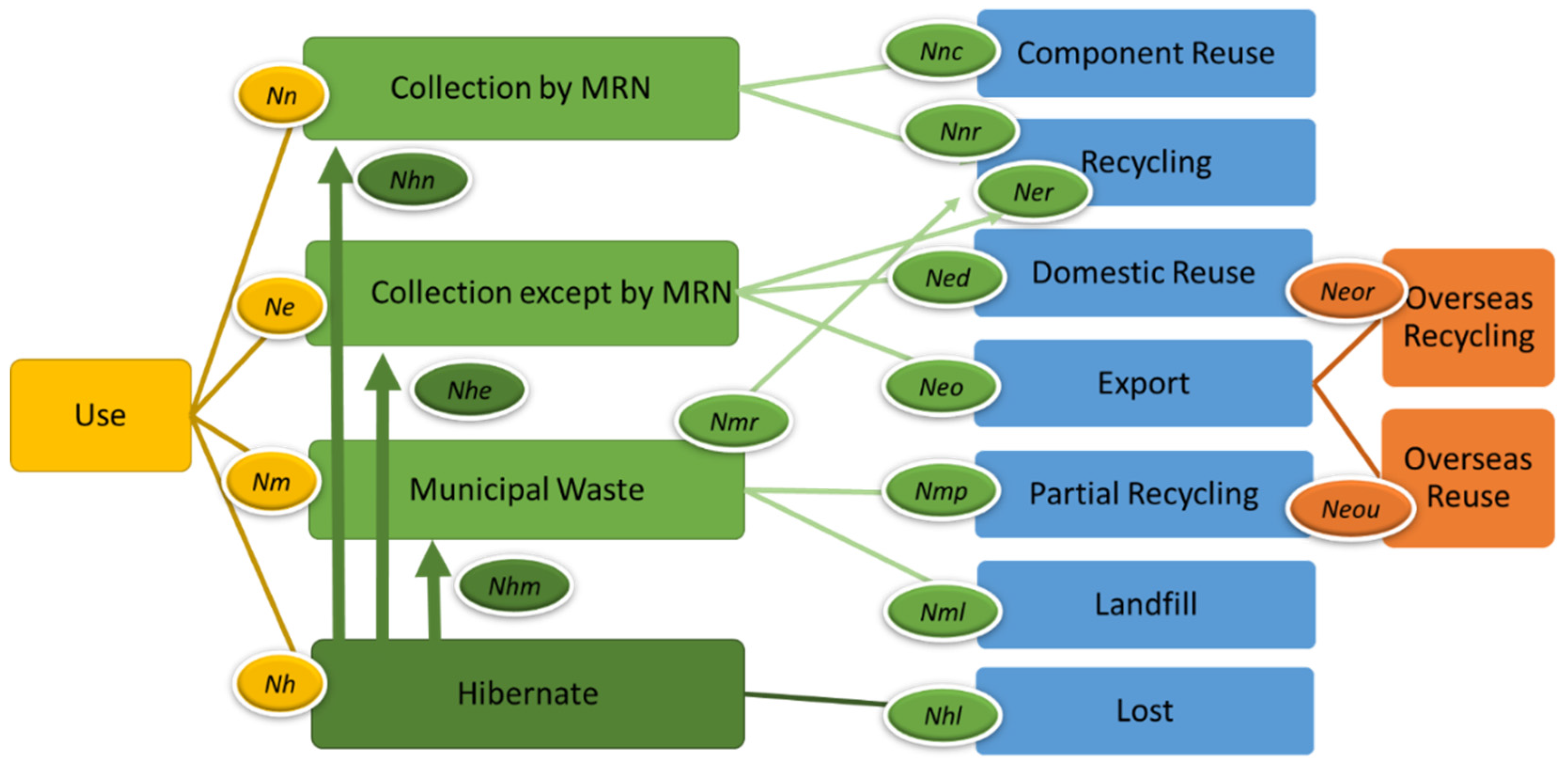

2.2. Detailed Material Flow Model

2.3. Quantification of the Flow

- The consumer will return their used mobile phones to MRN, when they purchase new phones. Thus, Nhn is negligible.

- Once the used mobile phones have been hibernated, independent collectors do not collect (purchase) these products. Thus, Nhe is negligible.

- The amount of flow from non-MRN agencies to recyclers is considered negligible, since non-reusable products will not be undertaken or purchased. Thus, Ner is negligible.

- Some products will be sent to recyclers from municipal waste. The total of the three major options is 20.2 million units. The difference between this number and the total number of used mobiles is the number of independently recycled mobiles.

- “Lost” can be assumed that the used products are dumped unconsciously. Thus, Nhl should be added to the numbers of municipal waste.

- The difference between the number collected by MRN and the number sent to recyclers is equivalent to the number sent from municipal waste to recyclers (Nmr).

- Used mobile phones collected except by MRN will be domestically reused or exported.

| Variables | Meaning of the Variables | Amount (Million Units) |

|---|---|---|

| Nn | number of mobile phones collected by MRN | 6.97 [17] |

| Ne | number of mobile phones collected except by MRN (including undertake) | 5.72 [18] |

| Nm | number of mobile phones collected as municipal waste | 7.21 (calculated) |

| Nl | Number of mobile phone landfilled | 6.54 [18] |

| Nhn | number of mobile phones collected by MRN after hibernation | 0 (assumed) |

| Nhe | number of mobile phones collected except by MRN after hibernation | 0 (assumed) |

| Nhm | number of mobile phones collected as municipal waste after hibernation | 0.13 [19] |

| Nnc | number of mobile phones sent to remanufacturers from MRN | 0.02 (calculated) |

| Nnr | number of mobile phones sent to recyclers(smelters) | 7.60 [18] |

| Ner | number of mobile phones collected except by MRN and domestically recycled | 0 (assumed) |

| Ned | number of mobile phones collected except by MRN and domestically reused | 0.14 [18] |

| Neo | number of mobile phones exported | 5.58 (calculated) |

| Nmr | number of mobile phones collected as municipal waste and sent to recyclers | 0.65 (calculated) |

| Nmp | number of mobile phones collected as municipal waste and partially recycled | 0.15 (calculated) |

| Nml | number of mobile phones collected as municipal waste and landfilled | 6.54 [18] |

| Neor | number of mobile phones exported and recycled | 5.58 in total (calculated) |

| Neou | number of mobile phones exported and reused |

3. Quantitative Analysis of the Material Flow Model

3.1. Method of the Analysis

3.2. Quantification of Matetrial Usage

- PI: production increase rate [22]

- Wy: weight of material used for mobile phone production in year y

- Ny: number of annual production of year y

- M: average weight of a mobile phone

- Rr: material recycling rate

- Rc: component reusable rate

- Rpr: partial recycling rate in municipal waste

- Rn: collection rate by MRN

- Re: collection rate except by MRN

- Rm: municipal waste rate

- Rnr: sent rate for material recycling from MRN

- Rnc: sent rate for component reuse from MRN

- Rhn: collection rate by MRN after hibernation

- Rhe: collection rate except by MRN after hibernation

- Rhm: collection rate as municipal waste after hibernation

- Rmr: rate of used products recovered from municipal waste and sent to recycler

- Rmp: rate of used products put into a low-tech recycling process

3.3. Calculation of Matetrial Usage Using Sensitivity Analysis

3.4. Calculation of CO2 Emission

| Variable | Corresponding Activity |

|---|---|

| Etotal | Total |

| Ep | Production |

| Eu | Use |

| Etd | Domestic transportation |

| Eto | Overseas transportation |

| Erd | Domestic recycling |

| Ero | Overseas recycling |

| El | Landfill |

4. Results and Discussion

4.1. Calculation of Material Reduction

4.2. Discussion on Material Reduction

- Collection of used mobile phones for secondhand use in domestic market.

- Collection of used mobile phones by the MRN.

- Collection of hibernated phones by MRN.

- Collection of used mobile phones for component reuse.

- Technological development to increase material recycling rate.

- Collection of used mobile phones for municipal waste landfill.

- Collection of used mobile phones by non-MRN agencies for any purpose.

4.3. Calculation of CO2 Reduction

| Variable | Environmental Impact (kg-CO2/unit) |

|---|---|

| Ep | 43 |

| Eu | 1 |

| Etd | negligible |

| Eto | 0.5 |

| Erd | 1.8 |

| Ero | 3.0 |

| El | 2.7 |

4.4. Discussion on CO2 Reduction

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Nanjyo, M. Urban Mine, New Resource for the Year 2000 and Beyond. Bull. Res. Inst. Miner. Dress. Metall. 1998, 43, 239–251. [Google Scholar]

- Shiratori, T.; Nakamura, T. Concept of “Artificial Deposit” 2—Transition of the metal potential of spent electric and electronic appliances. J. MMIJ 2007, 4, 171–178. [Google Scholar] [CrossRef]

- Halada, K.; Ijima, K.; Shimada, M.; Katagiri, N. A possibility of urban mining in Japan. J. Jpn. Inst. Metals 2009, 73, 151–160. [Google Scholar] [CrossRef]

- Yamane, E.; Minamoto, R.; Numata, T.; Nakajima, K.; Murakami, S.; Daigo, I.; Hashimoto, S.; Okumura, H.; Ishihara, K. Novel Evaluation Method of Elemental Recyclability from Urban Mine—Concept of Urban Ore TMR. Mater. Trans. 2009, 50, 1536–1540. [Google Scholar]

- Report of Social Experiment on Promoting Collection of Used Mobile Phones as of Fiscal Year 2009. Available online: http://www.meti.go.jp/meti_lib/report/2010fy01/0020863.pdf (accessed on 20 January 2016). (In Japanese)

- Murakami, S.; Ohsugi, H.; Murakami-Suzuki, R.; Mukaida, A.; Tsujimura, H. Average lifespan of mobile phones and in-use and hibernating stocks in Japan. J. Life Cycle Assess. Jpn. 2009, 5, 139–145. (In Japanese) [Google Scholar] [CrossRef]

- Mishima, K.; Nishimura, H. Requirement Analysis to Promote Small-sized e-waste Collection from Consumers. Waste Manag. Res. 2015. in printing. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, A.; Tasaki, T.; Terazono, A. Material flow analysis of used personal computers in Japan. Waste Manag. 2009, 29, 1602–1614. [Google Scholar] [CrossRef] [PubMed]

- Murakami, S. Flow Scenarios and Resource Potentials for End-of-life Electric Appliances. Mater. Cycles Waste Manag. Res. 2009, 20, 237–244. [Google Scholar] [CrossRef]

- Ministry of Environment, Ministry of Economy, Trade and Industry. Report of Committee for Recycling Systems and Re-Utilization of Valuable Metals in Small-Sized e-Waste. Available online: http://www.env.go.jp/council/former2013/03haiki/yoshi03–24.html (accessed on 20 January 2016). (In Japanese)

- Case Study on Critical Metals in Mobile Phones Final Report, OECD. 2011. Available online: http://www.oecd.org/env/waste/Case%20Study%20on%20Critical%20Metals%20in%20Mobile%20Phones.pdf (accessed on 20 January 2016).

- Soo, V.K.; Doolan, M. Recycling Mobile Phone Impact on Life Cycle Assessment. Procedia CIRP 2014, 15, 263–271. [Google Scholar] [CrossRef]

- Duygan, M.; Meylan, G. Strategic management of WEEE in Switzerland—Combining material flow analysis with structural analysis. Resour. Conserv. Recycl. 2015, 103, 98–109. [Google Scholar] [CrossRef]

- Neira, J.; Favret, L.; Fuji, M.; Miller, R.; Mahdavi, S.; Blass, V.D. End-of-Life Management of Cell Phones in the United States, Master’s of Environmental Science and Management for the Donald Bren School of Environmental Science and Management. Available online: http://www.bren.ucsb.edu/research/documents/cellphonethesis.pdf (accessed on 20 January 2016).

- Takahashi, K.; Nakamura, J.; Otabe, K.; Tsuruoka, M.; Matsuno, Y.; Adachi, Y. Resource Recovery from Mobile Phone and the Economic and Environmental Impact. J. Jpn. Inst. Metals 2009, 73, 747–751. [Google Scholar] [CrossRef]

- G7 Summit Declaration. Available online: http://www.bundesregierung.de/Content/DE/_Anlagen/G8_G20/2015–06–08-g7-abschluss-eng.pdf?__blob=publicationFile&v=5 (accessed on 26 December 2015).

- Web page of Mobile Recycle Network. Available online: http://www.mobile-recycle.net/ (accessed on 20 January 2016).

- Web page of Ministry of Economy, Trade and Industry, Material Flow of Used Products. Available online: http://www.meti.go.jp/committee/summary/0003198/pdf/report01_02_02.pdf (accessed on 29 January 2016). (In Japanese)

- Web page of Polis Department of Tokyo. Available online: http://www.keishicho.metro.tokyo.jp/toukei/bunsyo/toukei23/pdf/kt23d132.pdf (accessed on 20 January 2016).

- Telecommunications Carriers Association, Recycling Statistics of Mobile Phones. Available online: http://www.tca.or.jp/press_release/pdf/150623.pdf (accessed 29 January 2016). (In Japanese)

- Ministry of Economy, Trade and Industry, Case Studies of Small-Sized e-Waste Recycling in Local Governments. Available online: http://www.meti.go.jp/policy/recycle/main/admin_info/committee/o/27/hairi27_01–02.pdf (accessed on 29 January 2016). (In Japanese)

- Internal Affairs and Communications. Available online: http://www.soumu.go.jp/main_content/000299758.pdf (accessed 26 December 2015). (In Japanese)

- Repro Electric Co. Available online: http://www.reproele.jp/e/ (accessed 5 January 2016).

- Yamaguchi, H.; Itsubo, N.; Tahara, K.; Inaba, A. Evaluation of CO2 Emissions of Cellurar Phone Manufacturing. 2005. Available online: https://www.jstage.jst.go.jp/article/ilcaj/2005/0/2005_0_9/_pdf (accessed on 20 January 2016).

- Sugiyama, K.; Honma, O.; Mishima, N. Quantitative Analysis of Material Flow of Used Mobile Phones in Japan. In Proceedings of the 13th GCSM, Binh-Duong, Vietnam, 16–18 September 2015.

- Takeshima, A.; Fujinami, T.; Yamada, K.; Nakamura, R.; Yamaguchi, H.; Itsubo, T. LCA including the disposal and recycling stages of a mobile telephone. In Proceedings of the 2nd Conferene of the Institute of Life Cycle Assessment Japan, Tsukuba, Japan, 14–15 November 2006.

- LCA Inventory Database by Ministry of Environment. Available online: http://www.env.go.jp/earth/ondanka/supply_chain/com04/ref02.pdf (accessed on 5 January 2016).

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mishima, K.; Rosano, M.; Mishima, N.; Nishimura, H. End-of-Life Strategies for Used Mobile Phones Using Material Flow Modeling. Recycling 2016, 1, 122-135. https://doi.org/10.3390/recycling1010122

Mishima K, Rosano M, Mishima N, Nishimura H. End-of-Life Strategies for Used Mobile Phones Using Material Flow Modeling. Recycling. 2016; 1(1):122-135. https://doi.org/10.3390/recycling1010122

Chicago/Turabian StyleMishima, Kuniko, Michele Rosano, Nozomu Mishima, and Hidekazu Nishimura. 2016. "End-of-Life Strategies for Used Mobile Phones Using Material Flow Modeling" Recycling 1, no. 1: 122-135. https://doi.org/10.3390/recycling1010122

APA StyleMishima, K., Rosano, M., Mishima, N., & Nishimura, H. (2016). End-of-Life Strategies for Used Mobile Phones Using Material Flow Modeling. Recycling, 1(1), 122-135. https://doi.org/10.3390/recycling1010122