A Deep Learning Approach for State-of-Health Estimation of Lithium-Ion Batteries Based on a Multi-Feature and Attention Mechanism Collaboration

Abstract

1. Introduction

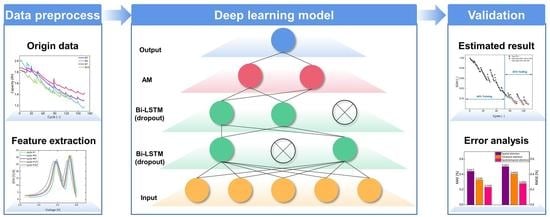

2. Degradation Data and Multi-Feature Extraction

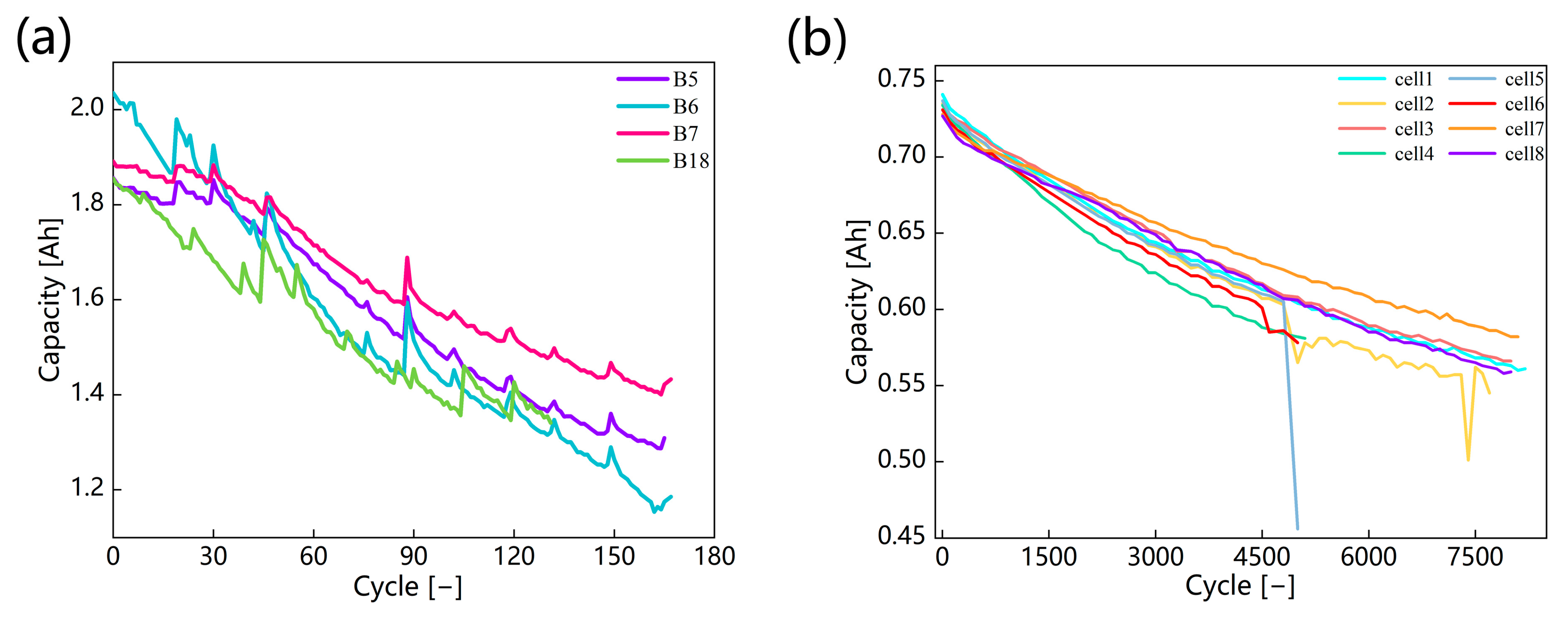

2.1. Dataset Description

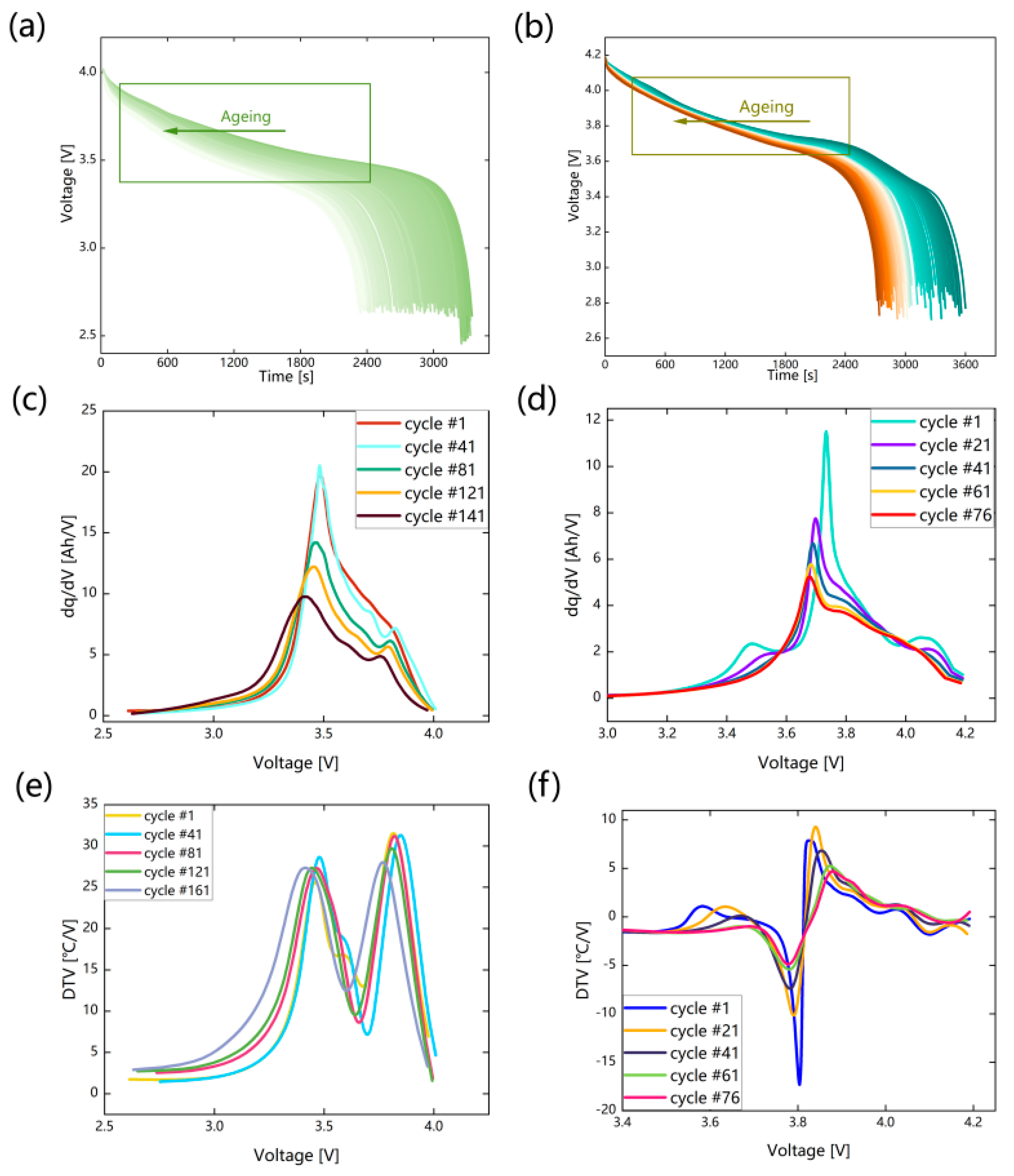

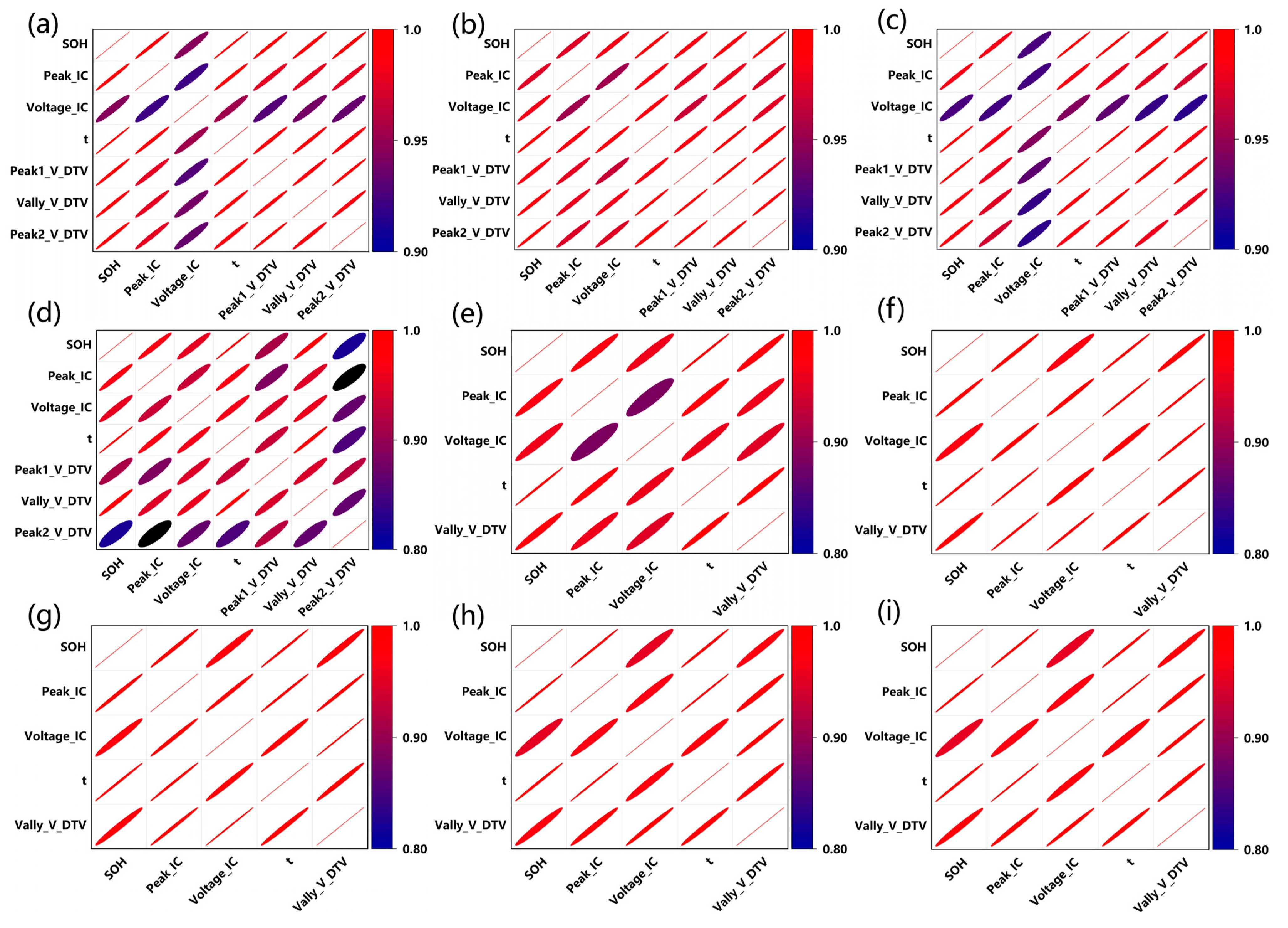

2.2. Feature Extraction and Correlation Analysis

2.2.1. Duration of the Same Discharging Voltage Range

2.2.2. Incremental Capacity Analysis

2.2.3. Differential Thermal Voltammetry

3. Methodology

3.1. Bi-LSTM Network

3.2. Attention Mechanism

3.3. Framework of the Proposed SOH Estimation Model

4. Results and Discussion

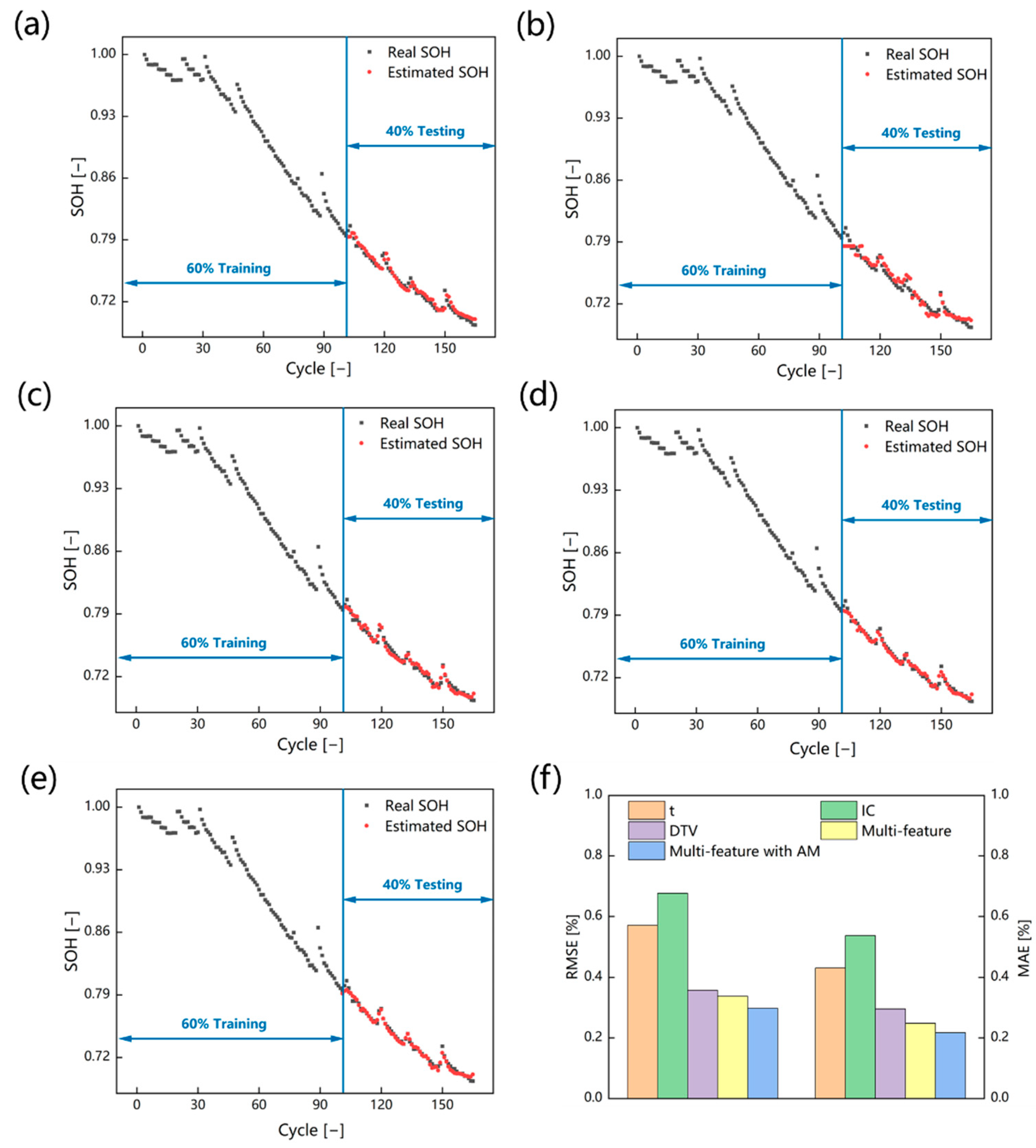

4.1. Estimation Results Based on a Single Feature and Multiple Features

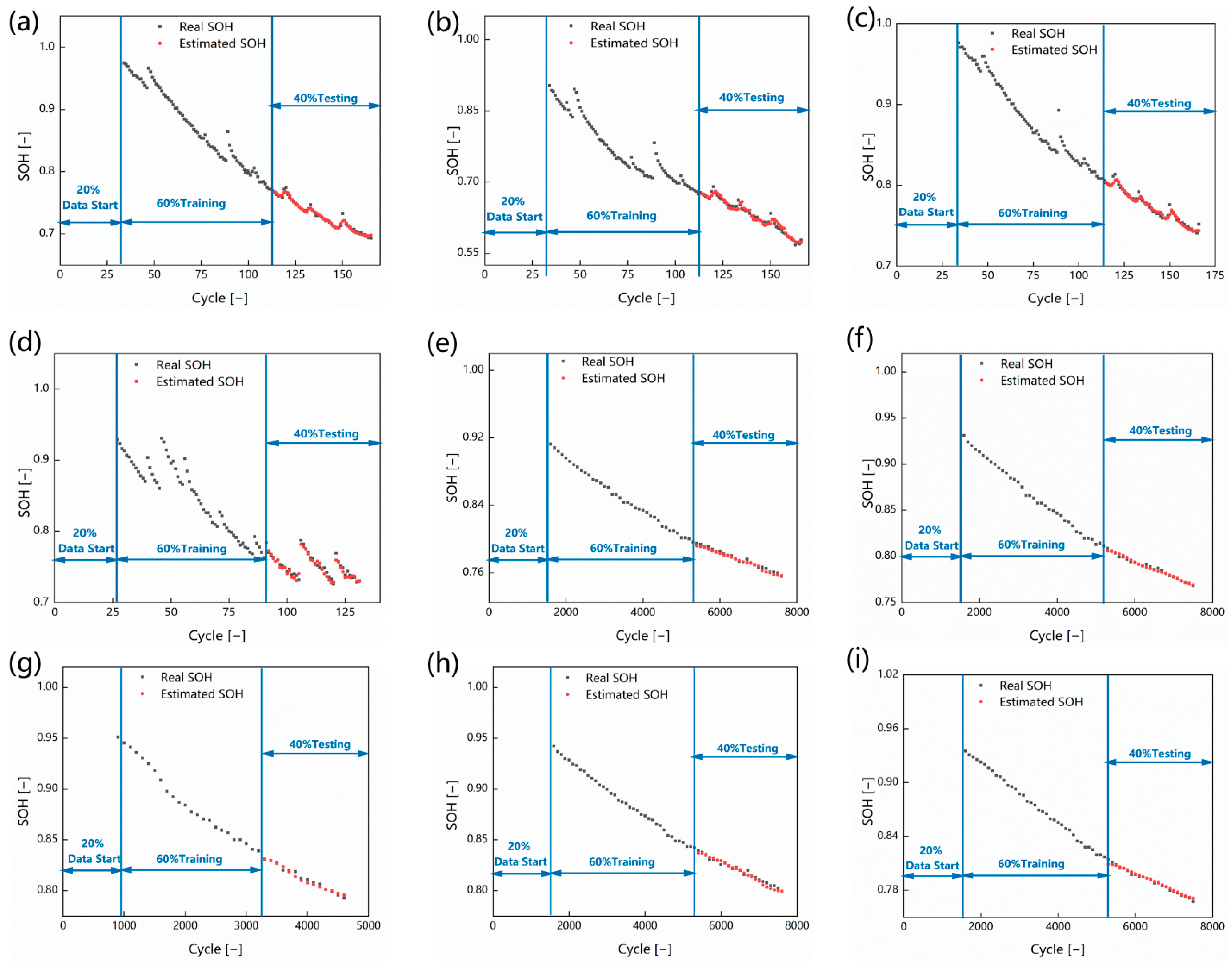

4.2. Validation and Robustness Verification on Different Batteries

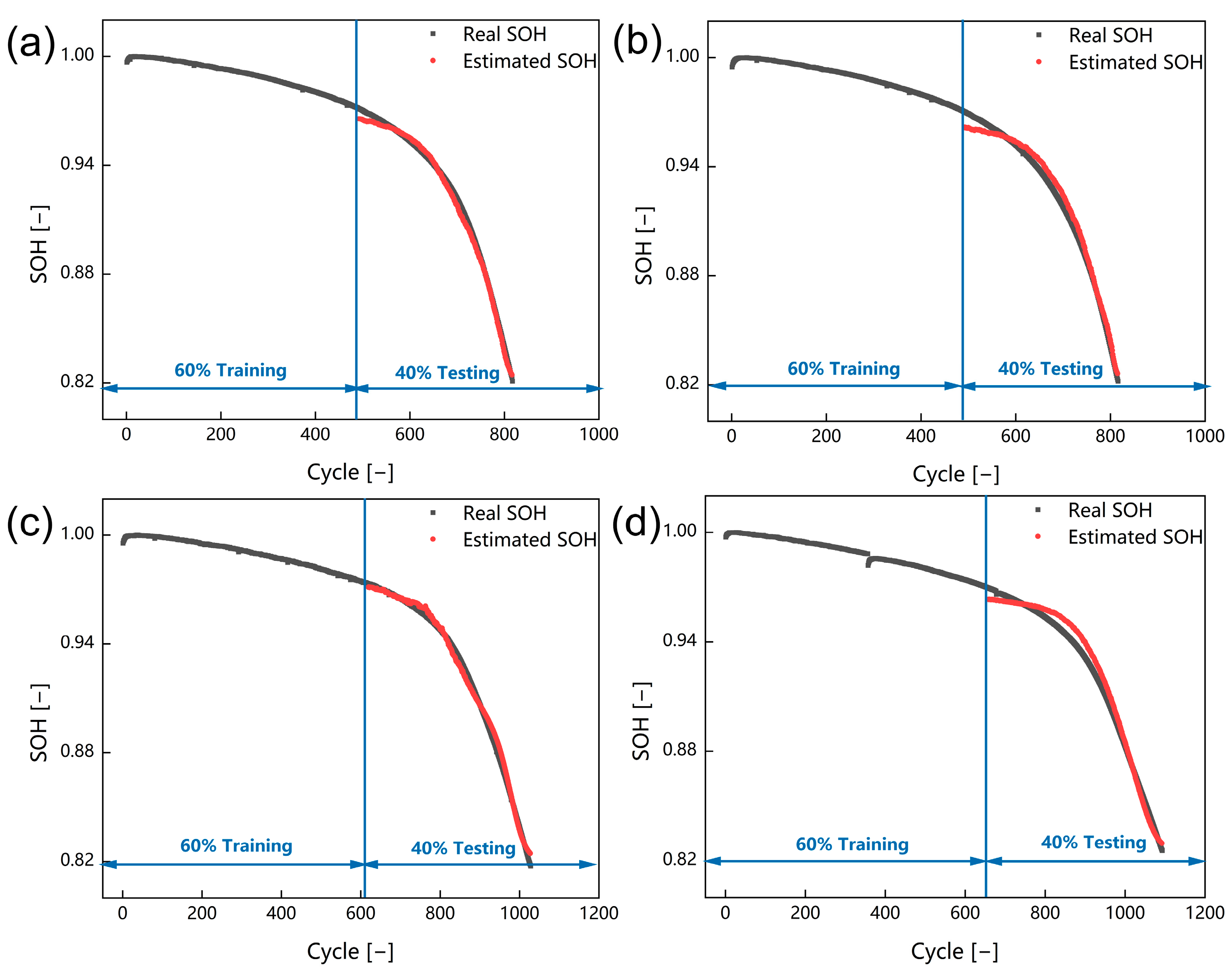

4.3. Validation on Batteries with Different Material Systems and Comparison with Other Works

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chaoui, H.; Ibe-Ekeocha, C.C. State of Charge and State of Health Estimation for Lithium Batteries Using Recurrent Neural Networks. IEEE Trans. Veh. Technol. 2017, 66, 8773–8783. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Li, H.B.; Qu, Z.G.; Zhang, J.F. Recent Progress in Lithium-Ion Battery Thermal Management for a Wide Range of Temperature and Abuse Conditions. Int. J. Hydrogen Energy 2022, 47, 9428–9459. [Google Scholar] [CrossRef]

- Jiang, Z.; Qu, Z. Lattice Boltzmann Simulation of Ion and Electron Transport in Lithium Ion Battery Porous Electrode during Discharge Process. In Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; Volume 88, pp. 642–646. [Google Scholar]

- Jiang, Z.Y.; Qu, Z.G.; Zhou, L.; Tao, W.Q. A Microscopic Investigation of Ion and Electron Transport in Lithium-Ion Battery Porous Electrodes Using the Lattice Boltzmann Method. Appl. Energy 2017, 194, 530–539. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, X.; Zhou, S.; Huang, Y.; Ling, H.; Yang, S. Toward Sustainable Reuse of Retired Lithium-Ion Batteries from Electric Vehicles. Resour. Conserv. Recycl. 2021, 168, 105249. [Google Scholar] [CrossRef]

- Lin, J.; Liu, X.; Li, S.; Zhang, C.; Yang, S. A Review on Recent Progress, Challenges and Perspective of Battery Thermal Management System. Int. J. Heat. Mass. Transf. 2021, 167, 120834. [Google Scholar] [CrossRef]

- Mou, J.; Duan, P.; Gao, L.; Liu, X.; Li, J. An Effective Hybrid Collaborative Algorithm for Energy-Efficient Distributed Permutation Flow-Shop Inverse Scheduling. Future Gener. Comput. Syst. 2022, 128, 521–537. [Google Scholar] [CrossRef]

- Pang, M.C.; Yang, K.; Brugge, R.; Zhang, T.; Liu, X.; Pan, F.; Yang, S.; Aguadero, A.; Wu, B.; Marinescu, M.; et al. Interactions Are Important: Linking Multi-Physics Mechanisms to the Performance and Degradation of Solid-State Batteries. Mater. Today 2021, 49, 145–183. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, L.; Yu, H.; Wang, J.; Li, J.; Yang, K.; Zhao, Y.; Wang, H.; Wu, B.; Brandon, N.P.; et al. Bridging Multiscale Characterization Technologies and Digital Modeling to Evaluate Lithium Battery Full Lifecycle. Adv. Energy Mater. 2022, 12, 2200889. [Google Scholar] [CrossRef]

- You, H.; Zhu, J.; Wang, X.; Jiang, B.; Sun, H.; Liu, X.; Wei, X.; Han, G.; Ding, S.; Yu, H.; et al. Nonlinear Health Evaluation for Lithium-Ion Battery within Full-Lifespan. J. Energy Chem. 2022, 72, 333–341. [Google Scholar] [CrossRef]

- Xiong, R.; Tian, J.; Shen, W.; Lu, J.; Sun, F. Semi-Supervised Estimation of Capacity Degradation for Lithium Ion Batteries with Electrochemical Impedance Spectroscopy. J. Energy Chem. 2023, 76, 404–413. [Google Scholar] [CrossRef]

- Shen, S.; Sadoughi, M.; Li, M.; Wang, Z.; Hu, C. Deep Convolutional Neural Networks with Ensemble Learning and Transfer Learning for Capacity Estimation of Lithium-Ion Batteries. Appl. Energy 2020, 260, 114296. [Google Scholar] [CrossRef]

- Meng, J.; Azib, T.; Yue, M. Early-Stage End-of-Life Prediction of Lithium-Ion Battery Using Empirical Mode Decomposition and Particle Filter. Proc. Inst. Mech. Eng. Part A J. Power Energy 2023, 0. [Google Scholar] [CrossRef]

- Singh, P.; Chen, C.; Tan, C.M.; Huang, S.C. Semi-Empirical Capacity Fading Model for SoH Estimation of Li-Ion Batteries. Appl. Sci. 2019, 9, 3012. [Google Scholar] [CrossRef]

- Rahimifard, S.; Habibi, S.; Goward, G.; Tjong, J. Adaptive Smooth Variable Structure Filter Strategy for State Estimation of Electric Vehicle Batteries. Energies 2021, 14, 8560. [Google Scholar] [CrossRef]

- Yang, B.; Wang, D.; Zhang, B.; Chen, S.; Sun, X.; Wang, T. Aging Diagnosis-Oriented Three-Scale Impedance Model of Lithium-Ion Battery Inspired by and Reflecting Morphological Evolution. J. Energy Storage 2023, 59, 106357. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, J. An Online Estimation Method of State of Health for Lithium-Ion Batteries Based on Constant Current Charging Curve. J. Electrochem. Soc. 2022, 169, 050514. [Google Scholar] [CrossRef]

- Li, G.; Li, B.; Li, C.; Wang, S. State-of-Health Rapid Estimation for Lithium-Ion Battery Based on an Interpretable Stacking Ensemble Model with Short-Term Voltage Profiles. Energy 2023, 263, 126064. [Google Scholar] [CrossRef]

- Fan, Z.; Zi-xuan, X.; Ming-hu, W. State of Health Estimation for Li-Ion Battery Using Characteristic Voltage Intervals and Genetic Algorithm Optimized Back Propagation Neural Network. J. Energy Storage 2023, 57, 106277. [Google Scholar] [CrossRef]

- Lin, M.; Wu, D.; Meng, J.; Wang, W.; Wu, J. Health Prognosis for Lithium-Ion Battery with Multi-Feature Optimization. Energy 2023, 264, 126307. [Google Scholar] [CrossRef]

- Xu, J.; Liu, B.; Zhang, G.; Zhu, J. State-of-Health Estimation for Lithium-Ion Batteries Based on Partial Charging Segment and Stacking Model Fusion. Energy Sci. Eng. 2023, 11, 383–397. [Google Scholar] [CrossRef]

- Merla, Y.; Wu, B.; Yufit, V.; Brandon, N.P.; Martinez-Botas, R.F.; Offer, G.J. Extending Battery Life: A Low-Cost Practical Diagnostic Technique for Lithium-Ion Batteries. J. Power Sources 2016, 331, 224–231. [Google Scholar] [CrossRef]

- Merla, Y.; Wu, B.; Yufit, V.; Brandon, N.P.; Martinez-Botas, R.F.; Offer, G.J. Novel Application of Differential Thermal Voltammetry as an In-Depth State-of-Health Diagnosis Method for Lithium-Ion Batteries. J. Power Sources 2016, 307, 308–319. [Google Scholar] [CrossRef]

- Wu, B.; Yufit, V.; Merla, Y.; Martinez-Botas, R.F.; Brandon, N.P.; Offer, G.J. Differential Thermal Voltammetry for Tracking of Degradation in Lithium-Ion Batteries. J. Power Sources 2015, 273, 495–501. [Google Scholar] [CrossRef]

- Zhang, Z.; Min, H.; Guo, H.; Yu, Y.; Sun, W.; Jiang, J.; Zhao, H. State of Health Estimation Method for Lithium-Ion Batteries Using Incremental Capacity and Long Short-Term Memory Network. J. Energy Storage 2023, 64, 106934. [Google Scholar] [CrossRef]

- Meng, H.; Geng, M.; Han, T. Long Short-Term Memory Network with Bayesian Optimization for Health Prognostics of Lithium-Ion Batteries Based on Partial Incremental Capacity Analysis. Reliab. Eng. Syst. Saf. 2023, 236, 107427. [Google Scholar] [CrossRef]

- Lin, M.; Yan, C.; Wang, W.; Dong, G.; Meng, J.; Wu, J. A Data-Driven Approach for Estimating State-of-Health of Lithium-Ion Batteries Considering Internal Resistance. Energy 2023, 277, 127675. [Google Scholar] [CrossRef]

- Yang, S.; He, R.; Zhang, Z.; Cao, Y.; Gao, X.; Liu, X. CHAIN: Cyber Hierarchy and Interactional Network Enabling Digital Solution for Battery Full-Lifespan Management. Matter 2020, 3, 27–41. [Google Scholar] [CrossRef]

- Birkl, C. Oxford Battery Degradation Dataset 1 VO-RT-Aggregated Database. OP. Available online: https://ora.ox.ac.uk/objects/uuid:03ba4b01-cfed-46d3-9b1a-7d4a7bdf6fac (accessed on 11 April 2022).

- Birkl, C. Diagnosis and Prognosis of Degradation in Lithium-Ion Batteries; University of Oxford: Oxford, UK, 2017. [Google Scholar]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-Driven Prediction of Battery Cycle Life before Capacity Degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Gong, Q.; Wang, P.; Cheng, Z. A Data-Driven Model Framework Based on Deep Learning for Estimating the States of Lithium-Ion Batteries. J. Electrochem. Soc. 2022, 169, 030532. [Google Scholar] [CrossRef]

- Gu, X.; See, K.W.; Li, P.; Shan, K.; Wang, Y.; Zhao, L.; Lim, K.C.; Zhang, N. A Novel State-of-Health Estimation for the Lithium-Ion Battery Using a Convolutional Neural Network and Transformer Model. Energy 2023, 262, 321–330. [Google Scholar] [CrossRef]

| Test Condition | Technical Specifications | |||

|---|---|---|---|---|

| Nominal capacity | 2 Ah | Cathode materials | LiCoO2 | |

| Charging current | 1.5 A | |||

| Upper cutoff voltage | 4.2 V | Charge test | CC-CV | |

| Cut-Off Voltage | B5 | 2.7 V | Discharge test | CC |

| B6 | 2.5 V | |||

| B7 | 2.2 V | Environmental temperature | 24 ℃ | |

| B18 | 2.5 V | |||

| Technical Specifications | Test Environment | ||

|---|---|---|---|

| Test subjects | 8 × Kokam CO LTD | Battery tester | Bio-Logic MPG-205, 8 channel |

| Nominal voltage | 3.7 V | Environmental chamber | Binder thermal chamber |

| Nominal capacity | 740 mAh | Cathode material | LCO/NCO |

| Limit charge voltage | 4.2 V ± 0.03 V | Charge test | 2C-rate charge |

| Discharge test | Attemis drives cycle discharge | ||

| Cut-Off voltage | 2.7 V | ||

| Environmental temperature | 40 °C | ||

| Battery | B5 | B6 | B7 | B18 | #1 | #3 | #4 | #7 | #8 |

|---|---|---|---|---|---|---|---|---|---|

| RMSE (%) | 0.292 | 0.696 | 0.341 | 0.434 | 0.216 | 0.162 | 0.231 | 0.229 | 0.191 |

| MAE (%) | 0.198 | 0.531 | 0.248 | 0.357 | 0.184 | 0.124 | 0.188 | 0.182 | 0.148 |

| Method | Data Split Portion | Feature | RMSE (%) | ||||

|---|---|---|---|---|---|---|---|

| #1 | #3 | #4 | #7 | #8 | |||

| Proposed | 6:4 | DTV IC Duration of the same discharging voltage range | 0.216 | 0.162 | 0.231 | 0.229 | 0.191 |

| EBM-ACO [27] | Leave-one-out cross validation | IC DTV DTC Internar resistance | 0.77 | 1.49 | 0.59 | 0.79 | 0.77 |

| Stacking-based ensemble learning model [21] | Leave-one-out cross validation | Voltage Temperature IC | 0.72 | 0.62 | 0.42 | 0.53 | 0.45 |

| LSTM-BP [32] | Leave-one-out cross validation | Voltage | 0.22 | 0.27 | 0.3 | 0.29 | 0.25 |

| Method | Data Split Portion | Feature | RMSE (%) | |||

|---|---|---|---|---|---|---|

| B5 | B6 | B7 | B18 | |||

| Proposed | 6:4 | DTV IC Duration of the same discharging voltage range | 0.292 | 0.696 | 0.341 | 0.434 |

| LSTM [25] | K-fold cross validation | Improved IC analysis | 0.7 | - | 1.3 | 1.7 |

| LSTM with Bayesian optimization [26] | 4:6 | Partial IC curve | 1.27 | 1.53 | 1.62 | 1.72 |

| CNN-Transformer [33] | 6:4 | Capacity Current Voltage Temperature Sampling time | 0.34 | 0.32 | 0.37 | 0.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, B.; Xiong, M.; Wang, H.; Ding, W.; Jiang, P.; Hua, W.; Zhang, Y.; Zhang, L.; Wang, W.; Tan, R. A Deep Learning Approach for State-of-Health Estimation of Lithium-Ion Batteries Based on a Multi-Feature and Attention Mechanism Collaboration. Batteries 2023, 9, 329. https://doi.org/10.3390/batteries9060329

Zou B, Xiong M, Wang H, Ding W, Jiang P, Hua W, Zhang Y, Zhang L, Wang W, Tan R. A Deep Learning Approach for State-of-Health Estimation of Lithium-Ion Batteries Based on a Multi-Feature and Attention Mechanism Collaboration. Batteries. 2023; 9(6):329. https://doi.org/10.3390/batteries9060329

Chicago/Turabian StyleZou, Bosong, Mengyu Xiong, Huijie Wang, Wenlong Ding, Pengchang Jiang, Wei Hua, Yong Zhang, Lisheng Zhang, Wentao Wang, and Rui Tan. 2023. "A Deep Learning Approach for State-of-Health Estimation of Lithium-Ion Batteries Based on a Multi-Feature and Attention Mechanism Collaboration" Batteries 9, no. 6: 329. https://doi.org/10.3390/batteries9060329

APA StyleZou, B., Xiong, M., Wang, H., Ding, W., Jiang, P., Hua, W., Zhang, Y., Zhang, L., Wang, W., & Tan, R. (2023). A Deep Learning Approach for State-of-Health Estimation of Lithium-Ion Batteries Based on a Multi-Feature and Attention Mechanism Collaboration. Batteries, 9(6), 329. https://doi.org/10.3390/batteries9060329