Abstract

Recycling plays a crucial role in achieving a sustainable production chain for lithium-ion batteries (LIBs), as it reduces the demand for primary mineral resources and mitigates environmental pollution caused by improper disposal. Disassembly of the LIBs is typically the preliminary step preceding chemical recovery operations, facilitating early separation of components consisting of different materials. Despite that extensive research has been conducted on the chemical processes involved in the recycling of LIBs, systematic studies on disassembly processes in the recycling process are relatively scarce. In this research, a systematic review was conducted on the publications from major databases, such as Scopus, SpringerLink, and others, to explore the current state of disassembly processes in LIBs’ recycling. The results emphasize disassembly as a crucial process for achieving a high material separation rate and ensuring a high degree of purity of the recycled active material. Moreover, automated disassembly can significantly raise productivity and reduce disassembly costs. Thus, it improves disassembly efficiency and increases economic as well as environmental benefits. Most researchers have focused on disassembly at the pack or module level. Investigation into extending the disassembly depth from cell to individual components is limited, particularly in automated approaches. Therefore, further research is highly recommended to explore the feasibility and potential of novel automated disassembly procedures at the cell level. This can contribute to improving the efficiency and sustainability of the recycling process for LIBs.

1. Introduction

The development of electric mobility presents a key role in the transition of the transportation sector from fossil fuel combustion to renewable energy sources. This transition is necessary to achieve the worldwide decarbonization targets in the automotive industry. In particular, the lithium-ion batteries (LIBs) have been recognized as the most appropriate energy storage solution for electric vehicles (EVs) and other large-scale stationary equipment over the past few decades. In 2021, LIBs accounted for 90.9% of the global electrochemical energy storage sector [1]. This is primarily due to the fact that LIBs are characterized by a higher energy density, longer lifetime, and improved electrical and chemical properties compared to other battery types, such as lead-acid batteries [2,3]. However, the growing utilization of LIBs has raised concerns about the sustainability and independence of the raw mineral material supply, particularly for critical materials such as lithium (Li) and cobalt (Co). Furthermore, the improper disposal of spent LIBs can result in hazardous environmental and health effects. The increasing number of obsolete LIBs generated each year underscores the urgent need for effective recycling.

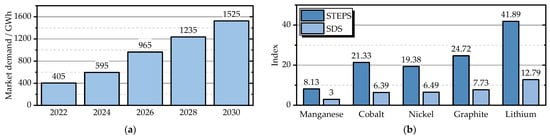

With the staggering development of the market for electric mobility, the demand for batteries will rapidly increase, as illustrated in Figure 1a. This leads to a correspondingly growing requirement of the major primary raw minerals (recognized as lithium, graphite, nickel, manganese, and cobalt) for production, as outlined in Figure 1b. However, despite the widespread utilization of LIBs, the raw minerals are mined and processed in very few countries globally, as mining resources are known to be limited. In 2022, according to the data from the U.S. Geological Survey [4], Australia produced nearly 47% of the world’s mineral production of Li, followed by Chile with 30%. Along with Argentina and China, these four countries collectively contribute 96.31% of Li production, while holding a total of 77.69% of the world’s Li reserves. DR Congo produced 68.42% of Co and owns 48.19% of the world’s Co reserves. South Africa supplied 36% of the manganese (Mn) and accounts for the largest share of the total world reserves as well, with over 37%. Indonesia mined over 48% of the nickel (Ni) in 2022, and combined with Brazil and Australia, they share 58% of the world’s Ni reserves. To sum up, critical raw material reserves are primarily concentrated in a limited number of countries. Other countries and regions, especially in the European Union (EU), possess a restricted quantity of mineral resources. Therefore, the independence of the raw material supply must be secured, especially in extreme situations such as trade wars or even during military conflict.

Figure 1.

Development of the LIBs market and raw material demand: (a) Estimated market demand for LIBs used in EVs [5]. (b) Demand growth index of selected minerals worldwide in 2040 relative to 2020, by scenario: STEPS = Sustainable Development Scenario, SDS = Stated Policies Scenario [6].

Valuable materials contained in discarded LIBs can be recycled and recirculated back into the production cycle, which ensures a more sustainable development of the LIBs industry. Based on the average battery composition in 2020 [7], a total material loss of up to 92% for Li, Co, and Ni can be avoided if the retired LIBs are recycled under the targets of the European Commission (EC). By 2035, recycling could provide 22% of Li and Ni as well as 65% of Co needed for LIBs production in the EU [7]. However, the collection and recycling rates of used LIBs are unexpectedly low. In Australia, for example, only 10% of the obsolete LIBs were recycled in 2021 [8]. In Germany, the collection rate of spent LIBs is 32% or lower [9]. The majority of used LIBs end up in landfills, leading to potential threats to human health and the environment [10]. For instance, 25% of all landfill fires in the UK in 2017–2018 were caused by LIBs deposited in landfills [11], producing a mixture of toxic gas emissions. Moreover, leaching and slag deposition as well as dissolution can release pollutants into the soil and groundwater. Therefore, End-of-Life (EoL) LIBs must be thoroughly recycled to avoid various hazards and problems. New regulations have come into effect in some regions to manage the recycling of LIBs. For example, the EC proposed a mandatory regulation which specifies the recycled content in new batteries. By 2035, LIBs production for EVs must contain at least 20%, 12%, and 10% recycled Co, Ni, and Li, respectively [12].

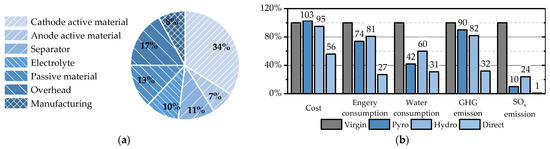

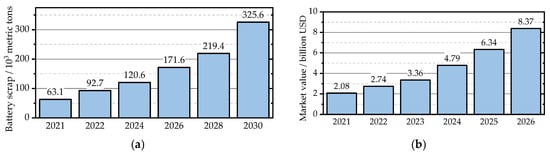

To ensure long-term development of LIBs production, the material cost of LIBs must be reduced. For a single battery cell, the cathode materials account for the largest share of the cell cost at 34%, as shown in Figure 2a, while the overall material input makes up 75% of the total cost [13]. Compared to virgin materials, the use of recycled secondary materials in LIBs production enables cost savings of 5–44% and 38–43%, respectively, when the active material lithium-nickel-manganese-cobalt-oxide (NMC) [14] or lithium-cobalt-oxide (LCO) [15] is recovered, depending on the method. In addition to the economic benefits, recycling and processing of spent LIBs can also provide significant ecological advantages, including reductions of energy and water consumption as well as greenhouse gas (GHG) and sulfur oxides (SOx) emissions, as shown in Figure 2b. Typically, the average lifetime of LIBs is about 8–10 years [16], indicating that a large number of used LIBs will be accumulated in the near future, thereby flooding the LIBs recycling market (Figure 3). Thus, the recycling of spent LIBs occupies a substantial role in preserving natural resources, minimizing pollution, and mitigating supply chain risks. It ensures a sustainable, circular, and economic product chain of LIBs.

Figure 2.

(a) Estimated electric vehicle battery cell price breakdown as of 2020 [13]. (b) Cost and environmental impacts to produce 1 kg of NMC111. Virgin = virgin raw material; Pyro = pyrometallurgical recycling process; Hydro = hydrometallurgical recycling process; Direct = direct recycling process. Data from [14] under CC BY 4.0 license, without any change.

Figure 3.

Forecasting of the LIBs recycling situation: (a) available spent LIBs for recycling in Europe [17], and (b) market value of recycling of LIBs worldwide [18].

Recycling of spent LIBs is gaining more and more attention nowadays. A complete recycling route includes pretreatments and chemical recovery processes. However, majority of studies are concerned with chemical processes, such as the development of novel methods for recovering valuable materials from spent LIBs [19,20]. In a comprehensive review conducted by Regatieri et al. [20], a total of 591 publications were examined, and the most frequently mentioned keywords are summarized. The top five were “Cobalt”, “Lithium-ion battery”, “Recovery”, “Valuable Metals”, and “Lithium”, which make up more than 66% of all keyword occurrences, taking into account all relevant publications about LIBs’ recycling. Pretreatment processes, such as disassembly, receive very little attention. However, without appropriate and efficient disassembly processes, the complex battery packs cannot be further treated in the recycling process in an economic and ecological way. Several review articles have discussed the disassembly process, but they have predominantly chosen not to focus on the disassembly technologies for recycling itself. For instance, Xiao et al. [21] provided an overview of the dismantling of LIBs from EVs, while focusing on the discussion of different possible applications for echelon utilization.

Therefore, this review presents a systematic summary of the disassembly process of LIBs being utilized in EVs. The emphasis is on the disassembly operation as one of the important pretreatment steps in the recycling process. Additionally, the state-of-the-art in disassembly technologies is accordingly thoroughly outlined. Though LIBs are also widely applied in other fields, for example, portable LIBs for consumer devices such as laptops, the disassembly of these battery types is outside the scope of this review. In the following sections, the background of the current recycling methods is explained, achieving a general overview of the recycling technologies. Then, the methods used for the systematic review are introduced. Based on this, the search results as well as analyses and conclusions are discussed. The studied publications are classified into various categories, including disassembly conceptions and experiments. In particular, research gaps are identified in the area of automated disassembly of battery cells, which requires further investigation.

2. Research Background

At present, the obsolete battery packs are removed from EVs and mostly discharged, followed by disassembly of the entire pack into modules or cells. However, some batteries could be directly reused for utilization in a second life, such as stationary energy storages in households, as their state of health (SOH) is often still 70–80% of the original capacity [22]. If the entire module presents a lower SOH value, it can be discharged and recycled, or dismantled and remanufactured at the cell level [23]. In this case, cells with minimal SOH values would be replaced to ensure that the module can have a second life. As a result, recycling of the second-use LIBs requires less energy and reduces the overall carbon footprint [24].

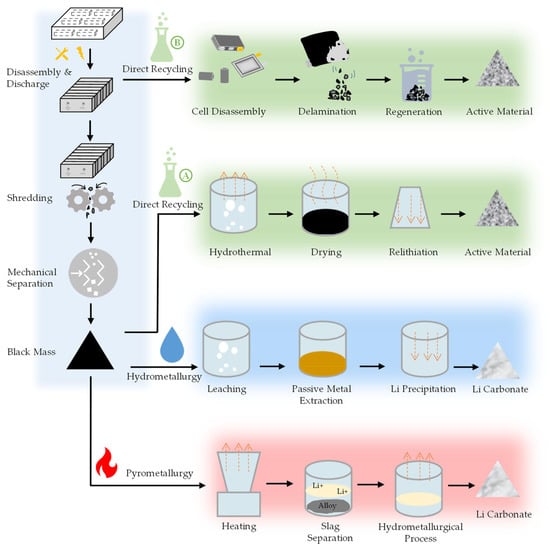

Nevertheless, the spent LIBs eventually need to be recycled, regardless of whether they come from EVs or secondary utilization, meaning that recycling is the final route for a closed-loop economy of LIBs. The typical recycling process for spent LIBs is shown in Figure 4. Following discharge operation, spent battery modules tend to be subsequently crushed into fragments, which undergo further processing involving physical and chemical treatments. Briefly, these traditional recycling paths of LIBs can be respectively classified into three catalogs: pyrometallurgy, hydrometallurgy, and direct recycling.

Figure 4.

Recycling routes for spent LIBs.

Pyrometallurgy has the shortest process chain among the three methods. After crushing, the shredded materials are subjected to a separation process to remove passive fragments and large-sized particles. The resulting powder, also referred to as “black mass”, is composed of the cathodic active materials and graphite from anodes. The black mass is then exposed to thermal treatment in order to eliminate the binders, carbon, solvents, etc. The remaining materials are further burned at high temperatures of up to 1700 °C, leading to the formation of lithium-rich slag and alloy containing Co, Ni, etc. [25,26,27,28], followed by leaching and filtering to separate the Li carbonate from other metal materials. After evaporation, Li carbonate is ultimately obtained. In some pyrometallurgical process, the unpretreated battery modules and cells are melted in a furnace under extremely high temperatures without discharge and disassembly [16,29,30]. However, this process poses challenges in high energy consumption and GHG emissions, as well as material loss.

Hydrometallurgy essentially consists of a leaching process with a wide variety of acids or alkalis and a subsequent separation and refinement process. The black mass separated by crushing and screening is dissolved in a reagent solution. By adding other chemical precipitants and extractants, metals such as Co, Mn, and Ni can be separated via precipitation, extraction, or adsorption [27]. The Li dissolves in the remaining solution for further purification in order to obtain Li carbonate. The hydrometallurgical route involves pretreatments, such as discharge and dismantling, resulting in a longer recycling process chain. However, it allows for a higher recovery purity of active materials with lower energy consumption and emission of toxic gases, compared to pyrometallurgy [31].

Both pyrometallurgy and hydrometallurgy usually require no further disassembly of modules down to the cell or electrode level. The modules can be crushed mechanically, which is considered as a dangerous process due to the remaining electrical energy and flammable solvent within the cells. Shredding LIBs that are not fully discharged can cause a temperature rise in the fragments, leading to fire hazards [32,33]. For direct recycling, in case of the modules or cells being exposed to shredding operations, the black mass can be subsequently followed by hydrothermal, froth, and sinter operation to regenerate the active material [34]. This not only extends the process chain, but also reduces the purity of the recovered cathode materials [35].Thus, battery cells should be disassembled down to the individual electrodes to achieve a pure separation as well as efficient collection of the active materials [36], as shown in Figure 4 (direct recycling with route B). The separated electrodes can be subjected to the delamination process, such as soaking in organic solvent, leading to the separation of the cathode materials from the aluminum foil [35,37]. The cathode material can be treated further with regeneration processes after the removal of the binders. It should be noted that Figure 4 illustrates only the general recycling processes, which should not be considered as standard methods.

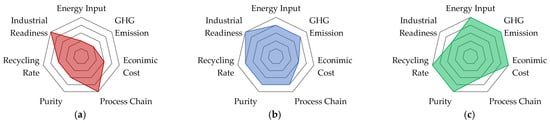

Direct recycling, as seen in Figure 5, provides numerous advantages, such as distinct separation of the different materials, minimal cross-contamination, and lower energy consumption. Additionally, it involves a more efficient regeneration process that requires fewer chemical auxiliaries. Direct recycling has proven to be a more effective and optimal method compared to other approaches for recycling of LIBs.

Figure 5.

Comparison of different recycling methods [36,38,39]: (a) pyrometallurgy, (b) hydrometallurgy, and (c) direct recycling.

Regardless of whether recycling operations or procedures are involved, disassembly of the battery packs and mechanical treatment are generally mandatory in all cases. These preliminary stages precede further chemical recovery operations. The remaining question is how and to what depth should the packs be dismantled. For the pyrometallurgy and hydrometallurgy procedures, the disassembly operations normally end at the cell level or even at the module level. However, to ensure better quality of recycling, the battery modules should be dismantled to individual cells so that even some components such as electronic parts could be reused. In order to facilitate efficient reclamation of valuable active materials, the cells necessitate further disassembly to allow separation of the electrodes. Thus, the pretreatment process chain of an optimal direct recycling is comparatively longer than that of the other two routes. Nevertheless, disassembly and mechanical processing are indispensable steps within the LIBs recycling process. They are gaining increasing attention as the number of phased out LIBs will only increase in the coming years.

3. Methods

This systematic review considered publications regarding the topic “disassembly of LIBs for recycling”, using the Preferred Reporting Items for Systematic Reviews an Meta-Analyses (PRISMA) guidelines [40]. The databases used for the search were Scopus, SpringerLink, Web of Science, ScienceDirect, and IEEE Xplore. In each database, the publications were searched up to the year 2023 (search carried out in February 2023) and performed without language restrictions.

Keywords such as “disassembly”, “lithium-ion battery”, and “recycling” were used in the separate searches across the various databases. To avoid an incomplete search, the wildcard * was added to match all possibilities, e.g., “disassembl*”, which included all possible words such as “disassembly”, “disassemble”, “disassembling”, or “disassembled”. The keywords and Boolean Operators employed for each database are summarized in Table 1.

Table 1.

Search database and keywords.

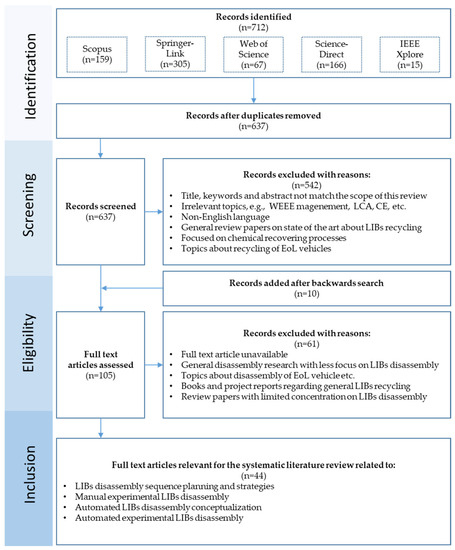

All search results were subsequently imported into a literature management software and analyzed. Some duplicates were automatically detected during the import and were therefore excluded. An overall total of 712 records were retrieved, as seen in Figure 6, showing that the records were evaluated using the PRISMA method. After duplicates were removed during the import process, 637 records remained. During the screening of keywords and abstracts, 542 items were excluded due to reasons such as irrelevant topics, non-English language, and general overview articles on recycling technologies.

Figure 6.

The systematic review results overview shown in the PRISMA flow diagram. WEEE = Waste of Electrical and Electronic Equipment; LCA = Life Cycle Assessment; CE = Circular Economy.

A further 95 articles remained for subsequent evaluation. Throughout the records’ examination, quick assessments were additionally performed regarding the abstracts and conclusions as well as the main contents of the articles. During the full-text assessment, ten more articles were added through backward reference searching. A total of 61 articles were eliminated due to their limited relevance to the disassembly process of LIBs, or their focus on the disassembly of EoL vehicles and other general disassembly technologies. Similarly, studies concentrating on general overviews of the state-of-the-art in recycling and technologies for LIBs with reduced contributions toward dismantling processes were not included. For some publications, it was not possible to retrieve the full text, which also led to an exclusion from the data. A number of publications were mainly centered on chemical recovery processes, which were also outside the scope of this review.

The final 44 full-text publications were divided according to the main research topics into the following 4 categories:

- Disassembly Sequence and Strategies

- Manual Experimental Disassembly

- Automated Disassembly Conceptualization

- Automated Disassembly Implementation

Publications with multiple categories were classified by the topic with majority of coverage inside the publication. For example, Wegener et al. [41] mainly discussed a planning approach for battery pack disassembly using a priority matrix and disassembly graph. They featured the disassembly of the Audi Q5 Hybrid pack to develop the sequence and strategy while proposing a basic workstation layout for the disassembly process. The manual disassembly is considered as a method and the layout is the by-product. Since majority of the publication is dedicated to the analysis and design of the disassembly sequence, the disassembly activities are considered as a case study to support the planning approach. Thus, this research was categorized as “Disassembly Sequence and Strategies”.

4. Results

This section first highlights an overview of the total studied records by the year of the publication. Detailed results for each of the four categories are then further analyzed. The ultimate goal of disassembling LIBs for recycling is to achieve a high degree of automation across the entire process, as LIBs contain hazardous substances that could potentially involve human workers in dangerous circumstances. To achieve automated disassembly, it is essential to begin with a well-considered planning of the disassembly sequence. This is then followed by manual experimental disassembly to validate the sequence and strategies. After acquiring practical knowledge, a concrete layout for automated disassembly can be conceptualized. In the end, appropriate automation solutions can be selected to implement the disassembly process. Thus, the analysis in this review paper follows this sequence to summarize the results.

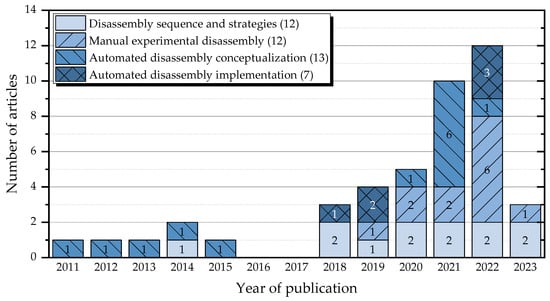

4.1. Publications Per Year and Category

Despite an unspecified start year being set for the literature search, the first publication addressing the disassembly of used LIBs did not appear until 2011. At that time, the total production of LIBs was less than 30 GWh, with a market share of less than 5% for EVs [42]. This was a time when the total EVs stock worldwide consisted of merely around 61.33 thousand vehicles [43] (which is negligible compared to over 16 million in 2021 [44]). Since then, the EVs market has rapidly expanded. Correspondingly, research on LIBs recycling as well as disassembly has continued to attract more and more attention. In particular, the publications from 2020 to 2022 account for a percentage of 63.64%, in which the EU contributed 42.86% and Asia 35.71%, indicating that the EU and Asia are the largest hotspots for the development as well as recycling of LIBs.

As shown in Figure 7, attempts to explore the possibility of automated disassembly commenced very early in 2011, when one publication proposed a concept. These efforts peaked in 2021, with six publications all centered on the development of automated disassembly conceptions. In total, the Automated Disassembly Conceptualization category accounts for 13 publications, nearly 30% of the studied publications on LIBs disassembly for recycling. Following this is Manual Experimental Disassembly as well as Disassembly Sequence and Strategies with 27.27%, which received more interest from researchers lately, with a peak in 2022 with up to six publications. Research in the field of Disassembly Sequence and Strategies presents a medium number of publications over the examined timespan, while the studies on the topic of Automated Disassembly Implementation started to appear in 2018. However, both topics are gaining more and more attention in recent times.

Figure 7.

Studied publications sorted by year and category.

Summarizing the previous paragraphs, the interest in LIBs recycling has considerably increased, concentrating on mechanical pretreatment, including LIBs disassembly. In the following sections, each category will be thoroughly elucidated to highlight the current state-of-the-art, including the key findings pertaining to investigated parameters such as disassembly time, cost, etc., in the relevant works.

4.2. Disassembly Sequence and Strategies

Batteries at their EoL stage are usually collected after being dismantled from EVs and transported to recycling facilities, where valuable active materials and other components can be recycled. Disassembly is an essential step in this recycling process chain. The spent batteries should be handled according to an optimal disassembly strategy to ensure a safe, economical, and environmentally friendly dismantling process. Therefore, the planning of the dismantling sequence and strategy is of major importance.

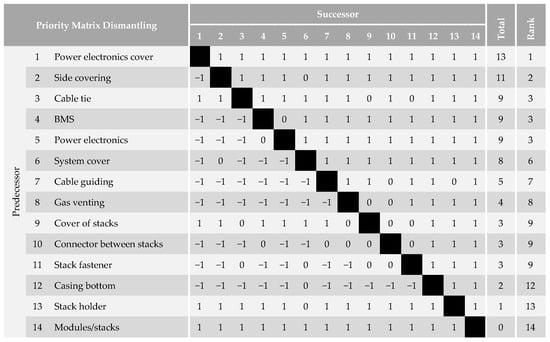

Disassembly of the entire battery pack is a significantly complex process. There are several methods for planning an optimal disassembly sequence for obsolete LIBs. Most approaches implement a case study with manual disassembly of a battery pack to analyze and determine an efficient disassembly process. For example, Ke et al. [45] proposed a disassembly planning method based on a frame–subgroup structure. They conducted a validation experiment for manual disassembly of a pack. In the defined frame–subgroup structure, the pack is treated as a frame and other components are subgroups. They studied the relationship between each component during disassembly and solved the disassembly planning problem by applying a genetic algorithm. Using this method, the disassembly time and revenue were improved by 12.04% and 2.54% compared to conventional methods, respectively. Gentilini et al. [46] presented a mathematical model for disassembly planning determination, aiming at lowering the human workers’ exposure to hazardous voltages. As a case study, they used a battery pack from Toyota. Choux et al. [47] studied the disassembly task planner, employing an image-processing system with an Audi A3 Sportback e-tron hybrid pack as a case study. They investigated the accuracy of screw detection and demonstrated that the proposed system has an accuracy of less than 5 mm. Wegener et al. [41] manually disassembled the Audi Q5 Hybrid battery pack and created a disassembly priority matrix (Figure 8) as well as the priority graph, yielding an unambiguous disassembly order.

Figure 8.

Disassembly priority matrix of Audi Q5 battery pack, using one-to-one comparison between the different parts to determinate the disassembly priority. Figure reprinted without any change from [41] with permission from Elsevier.

An overall summary of the study results on this topic is shown in Appendix A1. It is not possible to conclude which of the methods is the most appropriate. Considering the variation in the design and structure of battery packs from different manufacturers, the uncertainty of the sequence and strategies cannot be avoided. For the case study in the corresponding research, the selected packs vary in their design and characteristics. Therefore, the result is not universal, but mostly valid only for the selected pack types or similar packs with a comparable design. Hence, for a higher dismantling efficiency and profit in the future, a more standard design of the battery pack will be of great significance [48,49]. Another essential summary is that when planning the disassembly operations, the batteries were mostly manually disassembled, meaning a slight degree of automation was taken into account.

Table 2 provides an overview of the investigated parameters in Disassembly Sequence and Strategies for spent LIBs. Disassembly time, safety, and economic profit are the most frequently mentioned parameters. Researchers have often focused on reducing the disassembly time while improving the efficiency, safety, as well as economic revenue. Some publications have also analyzed the parameter of “Automated Disassembly”. As partially automated disassembly is applied, the safety of human workers must be considered. LIBs contain harmful substances and carry high voltages with electric hazard potential if improperly discharged. Thus, appropriate safety measures should be implemented to ensure the health and well-being of workers involved in the disassembly process.

Table 2.

Parameter investigation in the studies regarding Disassembly Sequence and Strategies.

4.3. Manual Experimental Disassembly

Manual disassembly of spent LIBs offers the advantages of quick sorting and identification of different components of the complex battery pack, as robots cannot deal with the varying designs and layouts of LIBs at a highly successful rate [58,59]. Therefore, considerable investigations have already been carried out concerning manual disassembly.

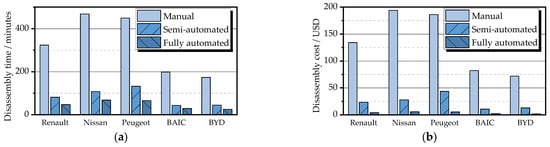

The manual disassembly process is currently predominantly applied in the pretreatment process for recycling of LIBs. It is a crucial step that needs to be approached with a focus on safety, disassembly time, and cost-effectiveness. Achieving higher disassembly revenue requires reducing the disassembly time and improving the cost savings. Hence, establishing an efficient disassembly process that can handle various types of packs from different manufacturers is of paramount importance for the recycling. In an effort to provide a comprehensive economic analysis of packs, Lander et al. [60] performed an analysis of the disassembly process of six commercial packs to cells from Renault, Nissan, Tesla, BAIC, Peugeot, and BYD. A detailed techno-economic analysis was completed in terms of the disassembly time, cost, and design contributions to the total disassembly cost. An evaluation and comparison of the disassembly time and cost for manual, semi-automatic, and fully automatic processes was conducted. Using the BAIC battery pack as an example, it was demonstrated that a 50% decrease in the number of modules and connecting screws can result in a reduction in disassembly costs of more than 24% and 29%, respectively. A time improvement of up to 88% and a cost saving of up to 97% can be obtained when replacing the manual disassembly by fully automated operation (Figure 9). The BYD pack, with its Cell-to-Pack design, requires the least disassembly time as well as the lowest disassembly cost. It is highly advantageous for the disassembly of packs in the recycling phase, which consist of modules with multiple cells in each individual module. Thus, a higher disassembly efficiency can be achieved by using Cell-to-Pack technology.

Figure 9.

(a) Comparison of disassembly times. (b) Comparison of disassembly costs per pack. Figure redrawn with original data from [60] under the CC BY 4.0 license, without any change.

Rosenberg et al. [61] and Rallo et al. [62] examined the disassembly time and cost as well as the required human power. The disassembly time needed for disassembly from the pack to the module was usually 20–40 min, depending on the packs [52,53,63]. The results from Rosenberg et al. indicate that one worker needs 22 min to disassemble a Mercedes PHEV pack into modules, while two workers require about 16 min. The total cost per pack disassembly into modules ranges from EUR 80 to 110, depending on the size of the disassembly plants, in Germany. Rallo et al. considered the laboratory scale and determined a total cost of EUR 1325 to disassemble the Smart ForFour battery pack into cells. Here, the cost of disassembling the modules into cells accounted for 62.26% of the total disassembly costs for the entire dismantling processes (excluding removal of the pack from cars). In both cases, the battery packs used are relatively small in terms of size, weight, and capacity.

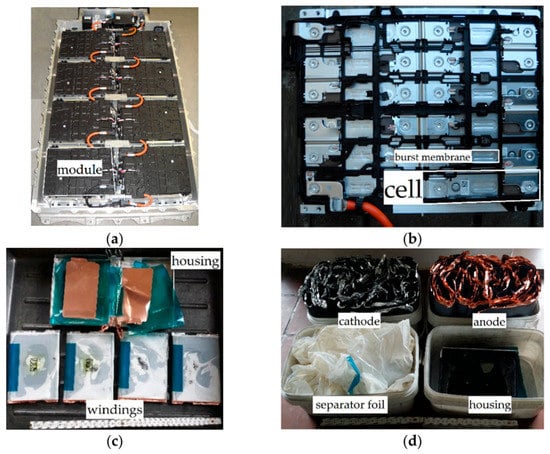

In addition to considering the disassembly time and cost, many studies have also explored the possibility of separating materials at the electrodes level. In this approach, cells are manually opened, and the active materials are separated from electrodes, resulting in a purer separation process. This procedure provides the potential to improve the recovery rate of the active materials. The individual cell components, such as the casing as well as electrolytes, can be separately recycled. Werner et al. [64,65] studied the impact of cell disassembly and crushing operations on the removal of the electrolytes, considering that the recycling of electrolytes by cell disassembly was not addressed yet. The research revealed that a higher disassembly depth leads to an increased removal of organic solvents. The battery pack was manually disassembled down to the electrode level (Figure 10) and parameters such as the disassembly time and disassembly depth were also studied.

Figure 10.

Manual disassembly of a battery pack: (a) Pack with eight modules, (b) module with 12 cells, (c) cell disassembly after separation of electrode-separator composites (ESC) and housing, and (d) ESC disassembly after separation of different cell components. Figure captured from [64] under the CC BY 4.0 license, without any change.

Kim et al. [66] extended the disassembly depth and they dismantled not only the pack and module, but also cells. The pouch cell was dismantled into individual components. This resulted in a Li recovery efficiency of over 96%. In addition, a recovery efficiency of other metals such as Co, Mn, Ni, etc., of approximately 90% was also achieved. Santos et al. [67] presented a technology for recycling of cells consisting of conditioning, disassembly, and separation. The efficiency of disassembly was analyzed using the mass variation monitoring method. The experimental results indicated that more than 90% of active materials were recovered for LCO and 80% for NMC cells. Marshall et al. [68] have disassembled the cells in a fume cupboard without using an inert gas environment for the extraction and separation of cell components. The cathodes and anodes were delaminated using ultrasonic bath with oxalic acid solution, with nearly 100% effective separation rate. Wu et al. [69] proposed a physical separation strategy for the recovery of cathodic active materials. The cell was dismantled, and the cathode foils were separated, followed by other processes such as thermal treatment, mechanical vibration, shredding, etc. The separation rate of cathode materials reached 85%. Bi et al. [70] established a procedure for disassembly and crushing of LIBs, in which the separated electrodes were thermally treated, crushed, and separated by an eddy current. The recovery rate exceeded 92% with the manual disassembly of cells.

The disassembly of an individual cell enables efficient separation of its components. However, for safety reasons, the spent cell should be discharged before disassembly to eliminate any remaining electrical potential, which can pose a hazardous situation. Discharging requires additional time and investment in special equipment. Therefore, it would be beneficial to find a way to disassemble spent cells and separate their components without discharging. Zhao et al. [71] separated ESC of non-discharged spent LiFePO4 cells in water, reducing environmental pollution. By eliminating the discharge process, the entire pretreatment process chain can be shortened. Compared with the pyrometallurgical process, this methodology can achieve energy conservation of almost 72% and reduce waste gas by up to 86%. With this approach, the economic profit is 32.22% higher than that of other direct separations and even higher in comparison with traditional pyrometallurgy and hydrometallurgy. Nevertheless, the proposed approach presents a highly innovative direct recycling process, as the separated electrode materials have been directly regenerated.

To summarize, the disassembly of the battery pack targets an improved recycling route and simplified processes. The disassembly of cells addresses a higher recovery rate of the active materials with potentially increased purity and thus a better economic gain. The aforementioned researchers concentrated on a number of parameters, which are grouped together in Table 3. Concerning manual disassembly, most researchers have anticipated significant potential to the studies at the cell level, seeking to minimize the disassembly time and to more successfully separate the materials.

Table 3.

Parameter investigation in the studies regarding Manual Experimental Disassembly.

Overall, 12 full-text articles were reviewed in this category. Majority of authors disassembled the battery at the cell level. In addition to the disassembly time and material separation, disassembly costs and energy consumption are also of primary concern. Specifically, efficient disassembly and recycling routes are of particular interest.

4.4. Automated Disassembly Conceptualization

The desirability of an automation of the disassembly processes for LIBs has been repeatedly expressed, as the manual disassembly process is hazardous as well as time- and cost-intensive. To achieve a safe and efficient automated disassembly process, the investigation and application of appropriate tools, such as a gripper system, has been highlighted in previous studies.

Schmitt et al. [73] developed an automated disassembly concept in 2011 with the design of a gripper system, aiming to extract cells from modules. The gripper system can diagnose the cell condition to ensure safe disassembly. This gripper system was further discussed to assess the automation potential for the disassembly operation in [74] by Herrmann et al. They proposed the two key indicators for a methodological approach to evaluate the automation potential, which are “technical ability of a disassembly process to be automated” (TAA) and “necessity to automate the corresponding disassembly operation” (NA). They continued the development of this gripper system and built a prototype, which was applied in the disassembly of cells from modules and measurement of the cell voltage as well as the inner resistance at the same time [75]. With the TAA and NA indicators, Hellmuth et al. [76] assessed the automation potential based on a disassembly graph of the Audi Q5 Hybrid battery. They also compared the calculated automation potentials of the 2017 Chevrolet Bolt BEV and Audi Q5 HEV batteries.

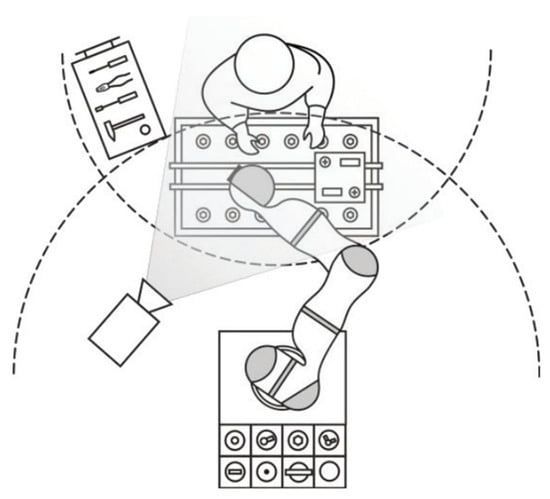

In addition to gripper systems, the deployment of robot arms has emerged as a promising avenue for achieving efficient and safe LIBs’ disassembly. With screw fastening being a prevalent feature of packs and modules, unscrewing has been identified as a key step in the automated disassembly process. This further highlights the value of robot arms in the pursuit of sustainable and effective LIBs’ recycling. Wegner et al. [77] dismantled the Audi Q5 Hybrid battery into cells and investigated the screw detection, combined with a camera system. They proposed an unscrewing tool assembled on a robot arm, which was used in a workstation concept (Figure 11). Humans are responsible for complex tasks such as disassembling of components joined with adhesive, while the robot takes care of repetitive simple tasks such as the loosening of screws and bolts.

Figure 11.

Schematic presentation of disassembly workstation. Figure reprinted without any change from [77] with permission from Elsevier.

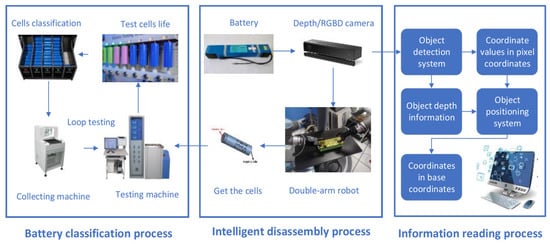

Research conducted by Garg et al. [78] and Zhou et al. [79] has demonstrated the potential of robotic unscrewing to significantly reduce the disassembly time. They presented a qualitative framework based on robots for a safer and more efficient disassembly of battery modules with cylindrical cells. The framework integrates a battery information acquisition system, a robot-based disassembly system, and a battery classification system (Figure 12). A disassembly time comparison was carried out between manual and robotic disassembly. Robotic unscrewing operation achieved a time saving of 55%. Collectively, an implementation of robotic disassembly reduced 80–90% of the disassembly time [79].

Figure 12.

Proposed recycling framework based on intelligent robotics [78]. Figure captured from [78] under the CC BY 3.0 license, without any change.

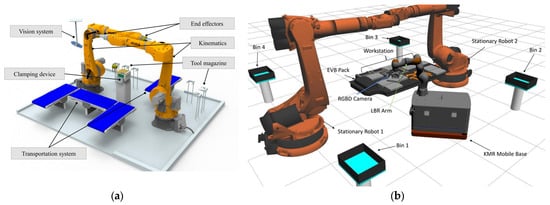

During the conceptualization phase, the design of specialized tools and prototypes is not always necessary in the development of a concept. As the design of the concept is at the theoretical level, an automated disassembly concept, such as a layout with robotics, can be represented through a 3D-design model. Furthermore, performance simulation can be conducted without any physical invention necessary in the establishment of the workstation. For example, Fleischer et al. [80] introduced a robot-based flexible concept for a disassembly station comprising kinematics, end effectors, etc., as shown in Figure 13a. Rastegarpanah et al. [81] examined a system for semi-automatic disassembly using a mobile manipulator. The goal was to automate the process of sorting components in an unstructured setting. The framework was subjected to simulations with different settings and demonstrated a minimum overall success rate of 82%.

Figure 13.

Semi-automated disassembly concepts: (a) Concrete layout with robots, and (b) disassembly pack with 3 robots, robots 1 and 2 disassemble the pack, while the LBR Arm collects and places the components into bins. Figure captured from [80,81] under the CC BY 4.0 license, without any change.

In some studies, conceptualizations of automated disassembly focus on evaluating critical factors or parameters for successful implementation, rather than developing specific functional elements. These abstract concepts provide a framework for assessing the feasibility and potential benefits of automated operations. The parameters include important considerations such as safety, time, cost, design, uncertainties, and other relevant factors. For example, Yin et al. [82] proposed a collaborative human–robot system to overcome the difficulties of the uncertain disassembly process. These uncertain factors involve structural features, joining methods, as well as others. Blankemeyer et al. [83] explored the automated disassembly process and developed a feasible layout for a disassembly station. Several possible provisions (design, uncertainties, safety, etc.) for automated disassembly were discussed, showing that the variation in the design of LIBs renders the automation of disassembly uneconomical. Tan et al. [84] outlined a disassembly scheme consisting of a hybrid disassembly station, which used both modified automated robotic arms and custom tooling to shorten the disassembly time. A conceptual disassembly procedure was proposed to achieve a reduction of the LIBs disassembly steps by a total of five steps, with a similar pack design compared to other concepts [50,77]. Weyrich et al. [85] described a general concept for semi-automated disassembly of LIBs. An estimation of several sensors and actuators based on criteria such as accuracy, takt time, reliability, cost, complexity, etc., was performed.

An overall summary of the full-text evaluation of the Automated Disassembly Conceptualization can be found in Table 4. The analysis revealed that half of the categorized research contributions only presented abstract layouts of automated disassembly concepts. These findings indicate that even in the conceptualization phase, significant challenges exist, which can complicate the implementation of these concepts and the validation of their effectiveness through novel experiments.

Table 4.

Summary of the full-text evaluation of the Automated Disassembly Conceptualization.

4.5. Automated Disassembly Implementation

Results for research regarding automatic disassembly of retired LIBs make up the smallest topic for publications found in the scope of this review. As aforementioned, the various configurations of LIBs from different manufacturers pose challenges in designing automated disassembly concepts. This requires innovative tool selection, workstation layout, and other considerations. Moreover, the practical implementation of these concepts through concrete experiments and investigations is a more significant challenge. Despite the early emergence of the concept of automated disassembly, its implementation has been restricted.

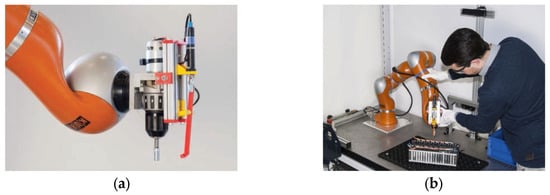

The first attempt for automated disassembly of LIBs was conducted in 2018 by Gerbers et al. [86], who implemented the previous concept from [77] through the development of a human–robot collaboration station. The concept was elaborated in detail with respect to ergonomic and safety aspects. A cost-optimized robotic arm was equipped with a screwdriver used to loosen the connections in the pack and module (Figure 14). Disassembly tests were executed with the demonstrator. Findings proved that semi-automated disassembly of battery systems is feasible. They have developed a concept, i.e., a workstation for more flexibility, productivity, and safety in the disassembly of LIBs, at the module level.

Figure 14.

Semi-automated disassembly: (a) Prototype of screwdriving tool without housing, and (b) implementation of the hybrid disassembly workstation. Copyrights: (a) Figure captured from [87] without any change, reprinted with permission from Elsevier; (b) Figure captured from [88] without any change, reprinted with permission from Reinhart, Handbuch Industrie 4.0, © 2017 Carl Hanser Verlag GmbH & Co. KG., Munich, Germany.

In certain experiments on automated disassembly, dummy samples have been utilized instead of actual modules or cells to prevent hazardous situations. Kay et al. [58] presented the process of battery disassembly using industrial robots under the supervision of human workers. Experiments were performed on the disassembly of dummy modules and dummy cells, which demonstrated that the process time required for automated opening of the modules and cells could be reduced by 50%. A robot provides both safety and time advantages over the current manual disassembly process for LIBs. It has been proven that an optimal option for pack disassembling is a human–robot collaboration. The robot conducts efficient cutting on the battery module and allows the operator to quickly sort the battery components and remove connectors or closures.

In addition to disassembling modules, attempts have also been made to automate the disassembly of packs. Zorn et al. [59] proposed a computational vision workflow to realize automated disassembly focused on sorting of various components. For the purpose of improving the sorting operation and achieving high-quality recycling after disassembly, an identification system including relevant information (e.g., cathode chemistry) about the battery pack was suggested. In addition, the use of sensor-based sorting technologies for peripheral components of the battery pack was evaluated.

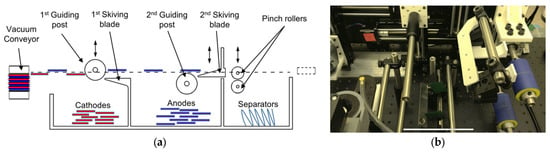

The aforementioned researchers mostly focused on the pack or the module level, although Kay et al. demonstrated a method and tools for automated opening of dummy cells without further investigation on electrodes’ separation. The only systematic research work in this field was performed by Li et al. [89,90], focused on studying the automated mechanical separation method for EoL pouch cells with z-folded ESC (Figure 15). The main components of pouch LIBs can be automatically separated and extracted in the verification experiments with dummy cells. Specifically, in [90], the integration of online sensors into the electrode separation process step was explored. The applied method for electrode separation makes the subsequent material extraction and processing easier for the direct recycling of LIBs.

Figure 15.

(a) Schematic and (b) prototype of the electrode sorting module. Figure captured from [89] without any change. Copyrights: Li et al., JOM, Vol. 71, No. 12, 2019, Springer Nature.

Further explorations on automated disassembly of cells can also be found in two other publications. Bi et al. [91,92] developed a complete material recovery process for spent batteries, which was described as environmentally friendly and highly efficient, while generating minimal waste. However, the cell disassembly process was not the main subject in this research. The hard-casing battery cells were cut, and the ESC was removed in an automated process [91]. In another case, an automated cutting of the casing was carried out by a custom device, and ESC was manually removed [92]. The laboratory experience showed that the complete disassembly of a battery cell took 20 min [91].

A summary regarding this category of publications can be found in Table 5. The analysis of the above-mentioned publications thereby highlights the fundamental challenges that exist in automated disassembly of LIBs. Considering that various battery designs and complexities exist, it is impractical to develop a universal workstation, which is suitable for large variations in battery packs or modules. A semi-automated workstation appears to be a promising solution to automate the disassembly of spent LIBs.

Table 5.

Summary of the full-text evaluation of the Automated Disassembly Implementation.

5. Conclusions

Since the battery packs are an integrated system containing different components and are usually geometrically unwieldy, it is necessary to disassemble the packs into modules or cells before initiating further recycling steps. In addition, disassembling, separating, and sorting the different parts made of varying materials enables a more efficient and profitable recycling. Extending the disassembly depth from the module and cell level to the individual components facilitates advanced material separation at the electrode level. Specifically, the anode and cathode are separated at this stage. The cathode material can thus be directly delaminated, resulting in a higher purity of the active material and more economical direct regeneration.

This review summarized a total of 44 studies with regard to the topic disassembly of LIBs for recycling, including manual and automated approaches. Among those studies, 13 have performed the disassembly process at the cell level with varying emphases. However, systematic studies of the cell disassembly processes are limited to a few studies. For instance, the work of Zhao et al. [71], which addressed on manual separation of ESC in water, and the work of Li et al. [89,90], which specifically concentrated on cell automated disassembly and electrode separation. In particular, in [71], as summarized above, the author demonstrated a successful separation process of electrodes, providing numerous advantages. While in [89,90], the automated disassembly process was performed with dummy cells containing z-folded ESC. However, the experiments were conducted without actual spent cells to account for possible damages or difficulties in separating cell components after years of service in EVs, thereby limiting the prototype disassembly station.

As the demand for LIBs in the electrical markets continues to grow, the pressure on the economic and environmental recycling of the obsolete LIBs is increasing in order to ensure a closed loop of valuable and scarce materials. Appropriate pretreatment methods are essential to develop a better recycling process which includes disassembly as a fundamental operation. In this review paper, the state-of-the-art regarding the disassembly process in LIBs recycling was investigated, and the results of previous research were summarized into four categories. The following topics should be discussed further:

- Recycling of LIBs has gained considerable attention, and numerous publications can be found in various databases. However, research focusing on the narrower aspect, i.e., disassembly, is less extensive than expected, although the number of relevant publications is continuously increasing.

- Planning disassembly sequences and determining the strategy occupies a significant position in the overall disassembly process, as a reasonable disassembly sequence can potentially reduce process times and costs, improving the overall efficiency. However, due to a wide variety of designs and layouts of LIBs from different manufacturers, it is impossible to find a universally applicable method for establishing a standard disassembly sequence or determining a universal strategy for all discarded LIBs. Therefore, a standardized or relatively uniform design and layout, as well as a similar choice of connection technologies for the LIBs, would greatly benefit the disassembly and recycling of the retired LIBs.

- Numerous parameters of interest in the disassembly of LIBs are repeatedly investigated in different categories. The major objective is to reduce the disassembly time and cost in a safe disassembly process. Optimal disassembly depth and novel material separation processes are equally desired. The identification of these interested parameters should be helpful to highlight the future research directions in the field of LIBs disassembly for recycling.

- Currently, most LIBs are manually disassembled, which can be challenging due to safety and efficiency concerns. Moreover, the capacity of manual disassembly cannot match the rapid growth of the number of LIBs consumed. The findings of the systematic literature review emphasize the importance of disassembling LIBs for recycling purposes. While significant research has been conducted on this topic from diverse perspectives, it is evident that further research is necessary, especially in automated disassembly and expanding the disassembly depth. Several gaps in the literature have been identified in this study, indicating potential areas for future research.

- Although many publications have already discussed concepts of automated disassembly, the implementation of such concepts is rather difficult and has not been widely explored. To ensure high efficiency and safe operation of automated disassembly process chains, it is imperative to develop novel concepts and conduct comprehensive investigations.

- Majority of the reviewed publications concentrate on disassembling LIBs at the pack and module levels, but they exhibit limited automated operations. Complete automated disassembly appears to be unfeasible. A partially automated disassembly workstation that incorporates robot–human collaboration has been demonstrated to be the most optimal option. Nevertheless, further research is required to investigate the degree of automation of the LIBs disassembly process.

- To date, no research has been found which explores the optimal depth of a disassembly process in correlation to parameters such as disassembly efficiency and the recycling rate. In the category Manual Experimental Disassembly, more than half of the researchers disassembled the cell, yet the disassembly process was not the main focus of their work, rather only a narrow scope of it. Only two publications specifically focused on systematic studies of the cell disassembly process. Thus, the research to extend the disassembly depth to individual components of the cells is insufficient and should be explored further.

In summary, promoting sustainable growth in the EVs market and enabling efficient recycling of valuable battery materials are crucial goals. To achieve these objectives, it is imperative to prioritize research efforts that focus on achieving more optimal and effective recycling outcomes. Specifically, advancing research on the development of automated disassembly technologies, and expanding the depth of disassembly, are both critical areas that require more attention. By enhancing these research areas, spent LIBs can significantly be treated in a more novel recycling process, reducing the waste generation. The recovery process of valuable materials could thus be more efficient. Therefore, further research in this area is essential for the development of innovative and sustainable solutions that can meet the rapidly expanding demand for LIBs in the burgeoning electric markets.

Author Contributions

Conceptualization, S.W.; methodology, S.W. and N.K.; software, S.W. and N.K.; validation, S.W.; formal analysis, S.W.; investigation, S.W.; resources, S.W. and K.D.; data curation, S.W.; writing—original draft preparation, S.W.; writing—review and editing, N.K. and K.D.; visualization, S.W. and N.K.; supervision, K.D.; project administration, K.D.; funding acquisition, K.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was conducted within the Research Training Group CircularLIB, supported by the Ministry of Science and Culture of Lower Saxony, with funds from the program zukunft.niedersachsen of the Volkswagen Foundation.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A1. Summary of Full-Text Assessments within the Category Disassembly Sequence and Strategies

| Reference | Research Highlights | |

| Approach | Case Study and Main Conclusions | |

| Wegener et. al. [41] | Planning approach based on priority matrix with disassembly graph. |

|

| Ke et. al. [45] | Sequence planning method based on frame–subgroup structure. |

|

| Gentilini et. al. [46] | Mathematical model to determine the disassembly sequence with the minimal hazardous voltages. |

|

| Choux et. al. [47] | Autonomous task planner through computer vision system with YOLO algorithm |

|

| Cerdas et al. [50] | Methodology for the estimation of disassembly sequences and automation potentials assessment |

|

| Zhan et. al. [51] | Dual-objective disassembly sequence planning (DSP) optimization model |

|

| Schwarz et al. [52] | Virtual disassembly tool based on the MTM-UAS method |

|

| Baazouzi et. al. [53] | An adaptive disassembly planner with an integrated disassembly strategy optimizer |

|

| Kong et. al. [54] | Parallel disassembly sequence planning using heuristic algorithms: NSGA-II, SPEA2, FPA, ABC, SAA. |

|

| Gumanová et al. [55] | Disassembly sequences with disassembly graph derived from priority matrix. |

|

| Cong et. al. [56] | Multi-objective mathematical model and hybrid genetic-firework algorithm based on the precedence graph. |

|

| Alfaro-Algaba et. al. [57] | Model for disassembly process design of battery pack, based on the disassembly sequence planning (DSP). |

|

References

- China Energy Storage Alliance. Energy Storage Industry White Paper 2022 (Summary Version). Available online: https://en.cnesa.org/our-work (accessed on 26 March 2023).

- Mondal, A.; Das, H.T. Energy storage batteries: Basic feature and applications. Ceramic Science and Engineering; Elsevier: Amsterdam, The Netherlands, 2022; pp. 323–351. ISBN 9780323899567. [Google Scholar]

- Gao, Y.; Pan, Z.; Sun, J.; Liu, Z.; Wang, J. High-Energy Batteries: Beyond Lithium-Ion and Their Long Road to Commercialisation. Nano-Micro Lett. 2022, 14, 94. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Mineral Commodity Summaries 2023; Mineral Commodity Summaries No. 2023; U.S. Geological Survey: Reston, VA, USA, 2023. Available online: http://pubs.er.usgs.gov/publication/mcs2023 (accessed on 20 March 2023).

- Statista. Estimated Market Demand for Lithium-Ion Batteries Used in Electric Vehicles in 2019 with a Forecast for 2020 through 2030 (in Gigawatt Hours) [Graph]. 2021. Available online: https://www.statista.com/statistics/309570/lithium-ion-battery-market-in-electric-vehicles/ (accessed on 13 March 2023).

- Statista. Demand Growth Index of Selected Battery-Related Minerals Worldwide for Clean Energy Technologies in 2040 Relative to 2020, by Scenario. 2023. Available online: https://www.statista.com/statistics/1270191/demand-growth-index-of-battery-minerals-for-clean-energy-worldwide/?locale=en (accessed on 20 March 2023).

- Transport & Environment. From Dirty Oil to Clean Batteries—Batteries vs Oil: A Comparison of Raw Material Requirements. 2021. Available online: https://www.transportenvironment.org/discover/batteries-vs-oil-comparison-raw-material-needs/ (accessed on 21 March 2023).

- CSIRO. The Challenge—A Serious Waste Problem. 2023. Available online: https://www.csiro.au/en/research/technology-space/energy/energy-in-the-circular-economy/battery-recycling (accessed on 20 March 2023).

- Deutsche Umwelthilfe e.V. Neues Batteriegesetz floppt: Nicht mal die niedrige Sammelmenge von 50 Prozent wird erreicht. 2022. Available online: https://www.duh.de/presse/pressemitteilungen/pressemitteilung/neues-batteriegesetz-floppt-nicht-mal-die-niedrige-sammelmenge-von-50-prozent-wird-erreicht/ (accessed on 26 March 2023).

- Zhao, Y.; Ruether, T.; Bhatt, A.; Staines, J. Australian Landscape for Lithium Ion Battery Recycling and Reuse in 2020—Current Status, Gap Analysis and Industry Perspectives; CSIRO: Canberra, Australia; FBI CRC: Bentley, Australia, 2021. [Google Scholar] [CrossRef]

- Mrozik, W.; Rajaeifar, M.A.; Heidrich, O.; Christensen, P. Environmental impacts, pollution sources and pathways of spent lithium-ion batteries. Energy Environ. Sci. 2021, 14, 6099–6121. [Google Scholar] [CrossRef]

- Environment, Public Health and Food Safety. New EU Regulatory Framework for Batteries—Setting Sustainability Requirements. 2022. Available online: https://www.europarl.europa.eu/thinktank/en/document/EPRS_BRI(2021)689337 (accessed on 20 March 2023).

- Statista. Estimated Electric Vehicle Battery Cell Price Breakdown as of 2020, by Category. 2020. Available online: https://www.statista.com/statistics/1176656/electric-vehicle-battery-price-by-category/?locale=en (accessed on 20 March 2023).

- Gaines, L.; Dai, Q.; Vaughey, J.T.; Gillard, S. Direct Recycling R&D at the ReCell Center. Recycling 2021, 6, 31. [Google Scholar] [CrossRef]

- Steward, D.; Mayyas, A.; Mann, M. Economics and Challenges of Li-Ion Battery Recycling from End-of-Life Vehicles. Procedia Manuf. 2019, 33, 272–279. [Google Scholar] [CrossRef]

- Chen, M.; Ma, X.; Chen, B.; Arsenault, R.; Karlson, P.; Simon, N.; Wang, Y. Recycling End-of-Life Electric Vehicle Lithium-Ion Batteries. Joule 2019, 3, 2622–2646. [Google Scholar] [CrossRef]

- Bloomberg. Battery Scrap Available for Recycling in Europe in 2021, with a Forecast until 2030 (in 1000 Metric Tons). 2022. Available online: https://www.statista.com/statistics/1333918/europe-battery-scrap-available-recycling/ (accessed on 21 March 2023).

- Statista. Size of The Global Market for Lithium-Ion Battery Recycling in 2019 with Forecasts for 2020 to 2027 (in Billion U.S. Dollars). 2021. Available online: https://www.statista.com/statistics/1103263/li-ion-battery-recycling-market-size/ (accessed on 21 March 2023).

- Islam, M.T.; Iyer-Raniga, U. Lithium-Ion Battery Recycling in the Circular Economy: A Review. Recycling 2022, 7, 33. [Google Scholar] [CrossRef]

- Regatieri, H.R.; Ando Junior, O.H.; Salgado, J.R.C. Systematic Review of Lithium-Ion Battery Recycling Literature Using ProKnow-C and Methodi Ordinatio. Energies 2022, 15, 1485. [Google Scholar] [CrossRef]

- Xiao, J.; Jiang, C.; Wang, B. A Review on Dynamic Recycling of Electric Vehicle Battery: Disassembly and Echelon Utilization. Batteries 2023, 9, 57. [Google Scholar] [CrossRef]

- Lai, X.; Huang, Y.; Gu, H.; Deng, C.; Han, X.; Feng, X.; Zheng, Y. Turning waste into wealth: A systematic review on echelon utilization and material recycling of retired lithium-ion batteries. Energy Storage Mater. 2021, 40, 96–123. [Google Scholar] [CrossRef]

- Kampker, A.; Wessel, S.; Fiedler, F.; Maltoni, F. Battery pack remanufacturing process up to cell level with sorting and repurposing of battery cells. J. Remanufacturing 2021, 11, 1–23. [Google Scholar] [CrossRef]

- Tao, Y.; Rahn, C.D.; Archer, L.A.; You, F. Second life and recycling: Energy and environmental sustainability perspectives for high-performance lithium-ion batteries. Sci. Adv. 2021, 7, eabi7633. [Google Scholar] [CrossRef]

- Makuza, B.; Tian, Q.; Guo, X.; Chattopadhyay, K.; Yu, D. Pyrometallurgical options for recycling spent lithium-ion batteries: A comprehensive review. J. Power Sources 2021, 491, 229622. [Google Scholar] [CrossRef]

- Jena, K.K.; AlFantazi, A.; Mayyas, A.T. Comprehensive Review on Concept and Recycling Evolution of Lithium-Ion Batteries (LIBs). Energy Fuels 2021, 35, 18257–18284. [Google Scholar] [CrossRef]

- Bae, H.; Kim, Y. Technologies of lithium recycling from waste lithium ion batteries: A review. Mater. Adv. 2021, 2, 3234–3250. [Google Scholar] [CrossRef]

- Lv, W.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z. A Critical Review and Analysis on the Recycling of Spent Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2018, 6, 1504–1521. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef]

- Georgi-Maschler, T.; Friedrich, B.; Weyhe, R.; Heegn, H.; Rutz, M. Development of a recycling process for Li-ion batteries. J. Power Sources 2012, 207, 173–182. [Google Scholar] [CrossRef]

- Latini, D.; Vaccari, M.; Lagnoni, M.; Orefice, M.; Mathieux, F.; Huisman, J.; Tognotti, L.; Bertei, A. A comprehensive review and classification of unit operations with assessment of outputs quality in lithium-ion battery recycling. J. Power Sources 2022, 546, 231979. [Google Scholar] [CrossRef]

- Perea, A.; Paolella, A.; Dubé, J.; Champagne, D.; Mauger, A.; Zaghib, K. State of charge influence on thermal reactions and abuse tests in commercial lithium-ion cells. J. Power Sources 2018, 399, 392–397. [Google Scholar] [CrossRef]

- Wuschke, L.; Jäckel, H.-G.; Leißner, T.; Peuker, U.A. Crushing of large Li-ion battery cells. Waste Manag. 2019, 85, 317–326. [Google Scholar] [CrossRef]

- Sloop, S.; Crandon, L.; Allen, M.; Koetje, K.; Reed, L.; Gaines, L.; Sirisaksoontorn, W.; Lerner, M. A direct recycling case study from a lithium-ion battery recall. Sustain. Mater. Technol. 2020, 25, e00152. [Google Scholar] [CrossRef]

- Ji, Y.; Kpodzro, E.E.; Jafvert, C.T.; Zhao, F. Direct recycling technologies of cathode in spent lithium-ion batteries. CTR 2021, 1, 124–151. [Google Scholar] [CrossRef]

- Lu, Y.; Peng, K.; Zhang, L. Sustainable Recycling of Electrode Materials in Spent Li-Ion Batteries through Direct Regeneration Processes. ACS EST Eng. 2022, 2, 586–605. [Google Scholar] [CrossRef]

- Bai, Y.; Muralidharan, N.; Li, J.; Essehli, R.; Belharouak, I. Sustainable Direct Recycling of Lithium-Ion Batteries via Solvent Recovery of Electrode Materials. ChemSusChem 2020, 13, 5664–5670. [Google Scholar] [CrossRef]

- Yu, X.; Li, W.; Gupta, V.; Gao, H.; Tran, D.; Sarwar, S.; Chen, Z. Current Challenges in Efficient Lithium-Ion Batteries’ Recycling: A Perspective. Glob. Chall. 2022, 6, 2200099. [Google Scholar] [CrossRef]

- Duan, X.; Zhu, W.; Ruan, Z.; Xie, M.; Chen, J.; Ren, X. Recycling of Lithium Batteries—A Review. Energies 2022, 15, 1611. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Wegener, K.; Andrew, S.; Raatz, A.; Dröder, K.; Herrmann, C. Disassembly of Electric Vehicle Batteries Using the Example of the Audi Q5 Hybrid System. Procedia CIRP 2014, 23, 155–160. [Google Scholar] [CrossRef]

- European Commission; Joint Research Centre; Tarvydas, D.; Tsiropoulos, I.; Lebedeva, N. Li-Ion Batteries for Mobility and Stationary Storage Applications: Scenarios for Costs and Market Growth; Publications Office of the European Unionn: Luxembourg, 2018; ISBN 978-92-79-97254-6. [Google Scholar] [CrossRef]

- IEA. Global EV Outlook 2018—Towards Cross-Modal Electrification. 2018. Available online: https://www.iea.org/reports/global-ev-outlook-2018 (accessed on 21 March 2023).

- IEA. Global EV Outlook 2022—Securing Supplies for an Electric Future. 2022. Available online: https://www.iea.org/reports/global-ev-outlook-2022 (accessed on 21 March 2023).

- Ke, Q.; Zhang, P.; Zhang, L.; Song, S. Electric Vehicle Battery Disassembly Sequence Planning Based on Frame-Subgroup Structure Combined with Genetic Algorithm. Front. Mech. Eng. 2022, 6, 576642. [Google Scholar] [CrossRef]

- Gentilini, L.; Mossali, E.; Angius, A.; Colledani, M. A safety oriented decision support tool for the remanufacturing and recycling of post-use H&EVs Lithium-Ion batteries. Procedia CIRP 2020, 90, 73–78. [Google Scholar] [CrossRef]

- Choux, M.; Marti Bigorra, E.; Tyapin, I. Task Planner for Robotic Disassembly of Electric Vehicle Battery Pack. Metals 2021, 11, 387. [Google Scholar] [CrossRef]

- Gaines, L. The future of automotive lithium-ion battery recycling: Charting a sustainable course. Sustain. Mater. Technol. 2014, 1–2, 2–7. [Google Scholar] [CrossRef]

- Norgren, A.; Carpenter, A.; Heath, G. Design for Recycling Principles Applicable to Selected Clean Energy Technologies: Crystalline-Silicon Photovoltaic Modules, Electric Vehicle Batteries, and Wind Turbine Blades. J. Sustain. Metall. 2020, 6, 761–774. [Google Scholar] [CrossRef]

- Cerdas, F.; Gerbers, R.; Andrew, S.; Schmitt, J.; Dietrich, F.; Thiede, S.; Dröder, K.; Herrmann, C. Disassembly Planning and Assessment of Automation Potentials for Lithium-Ion Batteries. In Recycling of Lithium-Ion Batteries. Sustainable Production, Life Cycle Engineering and Management; Kwade, A., Diekmann, J., Eds.; Springer International Publishing: Cham, Germany, 2018; pp. 83–97. ISBN 978-3-319-70572-9. [Google Scholar] [CrossRef]

- Zhan, C.; Zhang, X.; Tian, G.; Pham, D.T.; Ivanov, M.; Aleksandrov, A.; Fu, C.; Zhang, J.; Wu, Z. Environment-oriented disassembly planning for end-of-life vehicle batteries based on an improved northern goshawk optimisation algorithm. Environ. Sci. Pollut. Res. 2023, 30, 47956–47971. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, T.; Rübenbauer, W.; Rutrecht, B.; Pomberger, R. Forecasting Real Disassembly Time of Industrial Batteries Based on Virtual MTM-UAS Data. Procedia CIRP 2018, 69, 927–931. [Google Scholar] [CrossRef]

- Baazouzi, S.; Rist, F.P.; Weeber, M.; Birke, K.P. Optimization of Disassembly Strategies for Electric Vehicle Batteries. Batteries 2021, 7, 74. [Google Scholar] [CrossRef]

- Kong, S.; Zhang, Y.; Liu, W. Parallel Disassembly Sequence Planning of Retired Lithium-ion-battery Pack based on Heuristic Algorithm. J. Phys. Conf. Ser. 2022, 2254, 012010. [Google Scholar] [CrossRef]

- Gumanová, V.; Sobotová, L. Proposal for disassembly of electric vehicle batteries used in the volkswagen jetta hybrid system. In Proceedings of the ICTEP 2019 —International Council of Environmental Engineering Education—”Technologies of Environmental Protection”—Proceedings, Starý Smokovec, Slovakia, 23–25 October 2019. [Google Scholar] [CrossRef]

- Cong, L.; Zhou, K.; Liu, W.; Li, R. Retired Lithium-Ion Battery Pack Disassembly Line Balancing Based on Precedence Graph Using a Hybrid Genetic-Firework Algorithm for Remanufacturing. J. Manuf. Sci. Eng. Trans. Asme 2023, 145, 051007. [Google Scholar] [CrossRef]

- Alfaro-Algaba, M.; Ramirez, F.J. Techno-economic and environmental disassembly planning of lithium-ion electric vehicle battery packs for remanufacturing. Resour. Conserv. Recycl. 2020, 154, 104461. [Google Scholar] [CrossRef]

- Kay, I.; Farhad, S.; Mahajan, A.; Esmaeeli, R.; Hashemi, S.R. Robotic Disassembly of Electric Vehicles’ Battery Modules for Recycling. Energies 2022, 15, 4856. [Google Scholar] [CrossRef]

- Zorn, M.; Ionescu, C.; Klohs, D.; Zähl, K.; Kisseler, N.; Daldrup, A.; Hams, S.; Zheng, Y.; Offermanns, C.; Flamme, S.; et al. An Approach for Automated Disassembly of Lithium-Ion Battery Packs and High-Quality Recycling Using Computer Vision, Labeling, and Material Characterization. Recycling 2022, 7, 48. [Google Scholar] [CrossRef]

- Lander, L.; Tagnon, C.; Nguyen-Tien, V.; Kendrick, E.; Elliott, R.; Abbott, A.P.; Edge, J.S.; Offer, G.J. Breaking it down: A techno-economic assessment of the impact of battery pack design on disassembly costs. Appl. Energy 2023, 331, 120437. [Google Scholar] [CrossRef]

- Rosenberg, S.; Huster, S.; Baazouzi, S.; Glöser-Chahoud, S.; Al Assadi, A.; Schultmann, F. Field Study and Multimethod Analysis of an EV Battery System Disassembly. Energies 2022, 15, 5324. [Google Scholar] [CrossRef]

- Rallo, H.; Benveniste, G.; Gestoso, I.; Amante, B. Economic analysis of the disassembling activities to the reuse of electric vehicles Li-ion batteries. Resour. Conserv. Recycl. 2020, 159, 104785. [Google Scholar] [CrossRef]

- Rohr, S.; Wagner, S.; Baumann, M.; Muller, S.; Lienkamp, M. A techno-economic analysis of end of life value chains for lithium-ion batteries from electric vehicles. In Proceedings of the 2017 Twelfth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 11–13 April 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–14, ISBN 978-1-5386-1692-5. [Google Scholar]

- Werner, D.M.; Mütze, T.; Peuker, U.A. Influence of Cell Opening Methods on Electrolyte Removal during Processing in Lithium-Ion Battery Recycling. Metals 2022, 12, 663. [Google Scholar] [CrossRef]

- Werner, D.M.; Mütze, T.; Peuker, U.A. Influence of cell opening methods on organic solvent removal during pretreatment in lithium-ion battery recycling. Waste Manag. Res. 2022, 40, 1015–1026. [Google Scholar] [CrossRef]

- Kim, H.-I.; Sohn, J.-S.; Kim, S.-K.; Yang, D.-H.; Byun, S.-H. Development of Technology for Recycling Large-Capacity Lithium-Ion Batteries for EV, ESS. In REWAS 2022: Developing Tomorrow’s Technical Cycles (Volume I); The Minerals, Metals & Materials Series; Lazou, A., Daehn, K., Fleuriault, C., Gökelma, M., Olivetti, E., Meskers, C., Eds.; Springer: Cham, Germany, 2022; pp. 173–180. ISBN 978-3-030-92563-5. [Google Scholar] [CrossRef]

- Santos, M.d.; Garde, I.A.A.; Ronchini, C.M.B.; Filho, L.C.; de Souza, G.B.M.; Abbade, M.L.F.; Regone, N.N.; Jegatheesan, V.; de Oliveira, J.A. A technology for recycling lithium-ion batteries promoting the circular economy: The RecycLib. Resour. Conserv. Recycl. 2021, 175, 105863. [Google Scholar] [CrossRef]

- Marshall, J.; Gastol, D.; Sommerville, R.; Middleton, B.; Goodship, V.; Kendrick, E. Disassembly of Li ion cells—Characterization and safety considerations of a recycling scheme. Metals 2020, 10, 773. [Google Scholar] [CrossRef]

- Wu, Z.; Zhu, H.; Bi, H.; He, P.; Gao, S. Recycling of electrode materials from spent lithium-ion power batteries via thermal and mechanical treatments. Waste Manag. Res. 2021, 39, 607–619. [Google Scholar] [CrossRef]

- Bi, H.; Zhu, H.; Zu, L.; Gao, Y.; Gao, S.; Wu, Z. Eddy current separation for recovering aluminium and lithium-iron phosphate components of spent lithium-iron phosphate batteries. Waste Manag. Res. 2019, 37, 1217–1228. [Google Scholar] [CrossRef]

- Zhao, Y.; Kang, Y.; Fan, M.; Li, T.; Wozny, J.; Zhou, Y.; Wang, X.; Chueh, Y.-L.; Liang, Z.; Zhou, G.; et al. Precise separation of spent lithium-ion cells in water without discharging for recycling. Energy Storage Mater. 2022, 45, 1092–1099. [Google Scholar] [CrossRef]

- Pražanová, A.; Míka, M.H.; Knap, V. Lithium-ion battery module-to-cell: Disassembly and material analysis. J. Phys. Conf. Ser. 2022, 2382, 012002. [Google Scholar] [CrossRef]

- Schmitt, J.; Haupt, H.; Kurrat, M.; Raatz, A. Disassembly automation for lithium-ion battery systems using a flexible gripper. In Proceedings of the IEEE 15th International Conference on Advanced Robotics: New Boundaries for Robotics, ICAR, Tallinn, Estonia, 20–23 June 2011; pp. 291–297. [Google Scholar] [CrossRef]

- Herrmann, C.; Raatz, A.; Mennenga, M.; Schmitt, J.; Andrew, S. Assessment of automation potentials for the disassembly of automotive lithium ion battery systems. In Leveraging Technology for a Sustainable World.; Dornfeld, D., Linke, B., Eds.; Springer: Berlin, Heidelberg, 2012; pp. 149–154. ISBN 978-3-642-29069-5. [Google Scholar] [CrossRef]

- Herrmann, C.; Raatz, A.; Andrew, S.; Schmitt, J. Scenario-based development of disassembly systems for automotive lithium ion battery systems. Adv. Mater. Res. 2014, 907, 391–401. [Google Scholar] [CrossRef]

- Hellmuth, J.F.; DiFilippo, N.M.; Jouaneh, M.K. Assessment of the automation potential of electric vehicle battery disassembly. J. Manuf. Syst. 2021, 59, 398–412. [Google Scholar] [CrossRef]

- Wegener, K.; Chen, W.H.; Dietrich, F.; Dröder, K.; Kara, S. Robot Assisted Disassembly for the Recycling of Electric Vehicle Batteries. Procedia CIRP 2015, 29, 716–721. [Google Scholar] [CrossRef]

- Garg, A.; Zhou, L.; Zheng, J.; Gao, L. Qualitative framework based on intelligent robotics for safe and efficient disassembly of battery modules for recycling purposes. IOP Conf. Ser.: Earth Environ. Sci. 2020, 463, 12159. [Google Scholar] [CrossRef]

- Zhou, L.; Garg, A.; Zheng, J.; Gao, L.; Oh, K.-Y. Battery pack recycling challenges for the year 2030: Recommended solutions based on intelligent robotics for safe and efficient disassembly, residual energy detection, and secondary utilization. Energy Storage 2021, 3, e190. [Google Scholar] [CrossRef]

- Fleischer, J.; Gerlitz, E.; Rieß, S.; Coutandin, S.; Hofmann, J. Concepts and Requirements for Flexible Disassembly Systems for Drive Train Components of Electric Vehicles. Procedia CIRP 2021, 98, 577–582. [Google Scholar] [CrossRef]

- Rastegarpanah, A.; Gonzalez, H.C.; Stolkin, R. Semi-autonomous behaviour tree-based framework for sorting electric vehicle batteries components. Robotics 2021, 10, 82. [Google Scholar] [CrossRef]

- Yin, H.; Xiao, J.; Wang, G. Human-Robot Collaboration Re-Manufacturing for Uncertain Disassembly in Retired Battery Recycling. In Proceedings of the 2022 5th World Conference on Mechanical Engineering and Intelligent Manufacturing, WCMEIM, Ma’anshan, China, 18–20 November 2022; pp. 595–598. [Google Scholar] [CrossRef]

- Blankemeyer, S.; Wiens, D.; Wiese, T.; Raatz, A.; Kara, S. Investigation of the potential for an automated disassembly process of BEV batteries. Procedia CIRP 2021, 98, 559–564. [Google Scholar] [CrossRef]

- Tan, W.J.; Chin, C.; Garg, A.; Gao, L. A hybrid disassembly framework for disassembly of electric vehicle batteries. Int. J. Energy Res. 2021, 45, 8073–8082. [Google Scholar] [CrossRef]

- Weyrich, M.; Natkunarajah, N. Conception of an automated plant for the disassembly of lithium-ion batteries. In Proceedings of the Conference: 6th International Conference on Life Cyle Management (LCM), Gothenburg, Sweden, 25–28 August 2013. [Google Scholar]

- Gerbers, R.; Wegener, K.; Dietrich, F.; Dröder, K. Safe, Flexible and Productive Human-Robot-Collaboration for Disassembly of Lithium-Ion Batteries. In Recycling of Lithium-Ion Batteries. Sustainable Production, Life Cycle Engineering and Management; Kwade, A., Diekmann, J., Eds.; Springer International Publishing: Cham, Germany, 2018; pp. 99–126. ISBN 978-3-319-70572-9. [Google Scholar] [CrossRef]

- Gerbers, R.; Mücke, M.; Dietrich, F.; Dröder, K. Simplifying Robot Tools by Taking Advantage of Sensor Integration in Human Collaboration Robots. Procedia CIRP 2016, 44, 287–292. [Google Scholar] [CrossRef]