Investigation on the Air Stability of P2-Layered Transition Metal Oxides by Nb Doping in Sodium Ion Batteries

Abstract

1. Introduction

2. Experimental Section

2.1. Synthesis of Materials

2.2. Humid Environment Setting

2.3. Material Characterization

2.4. Electrochemical Measurement

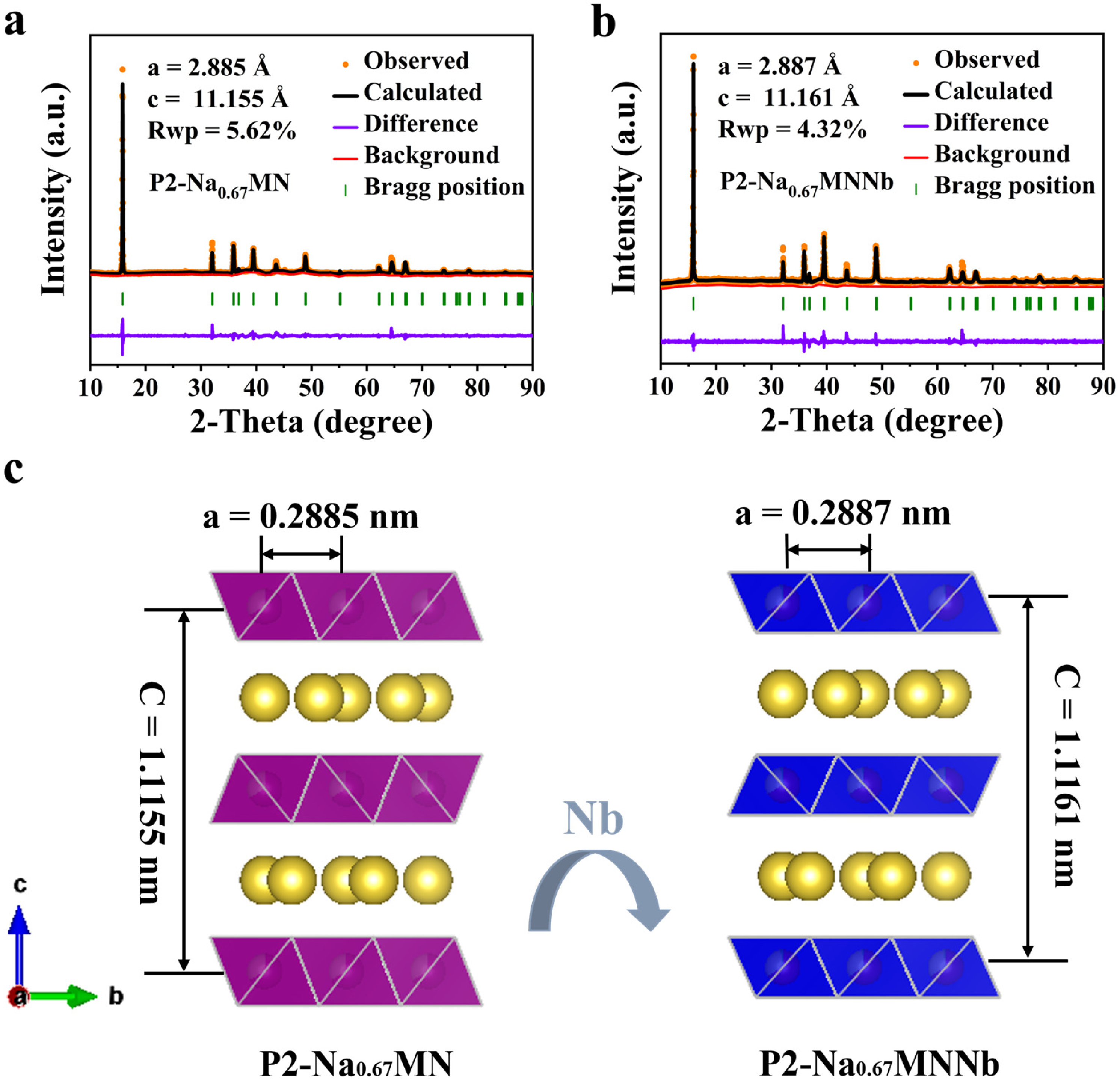

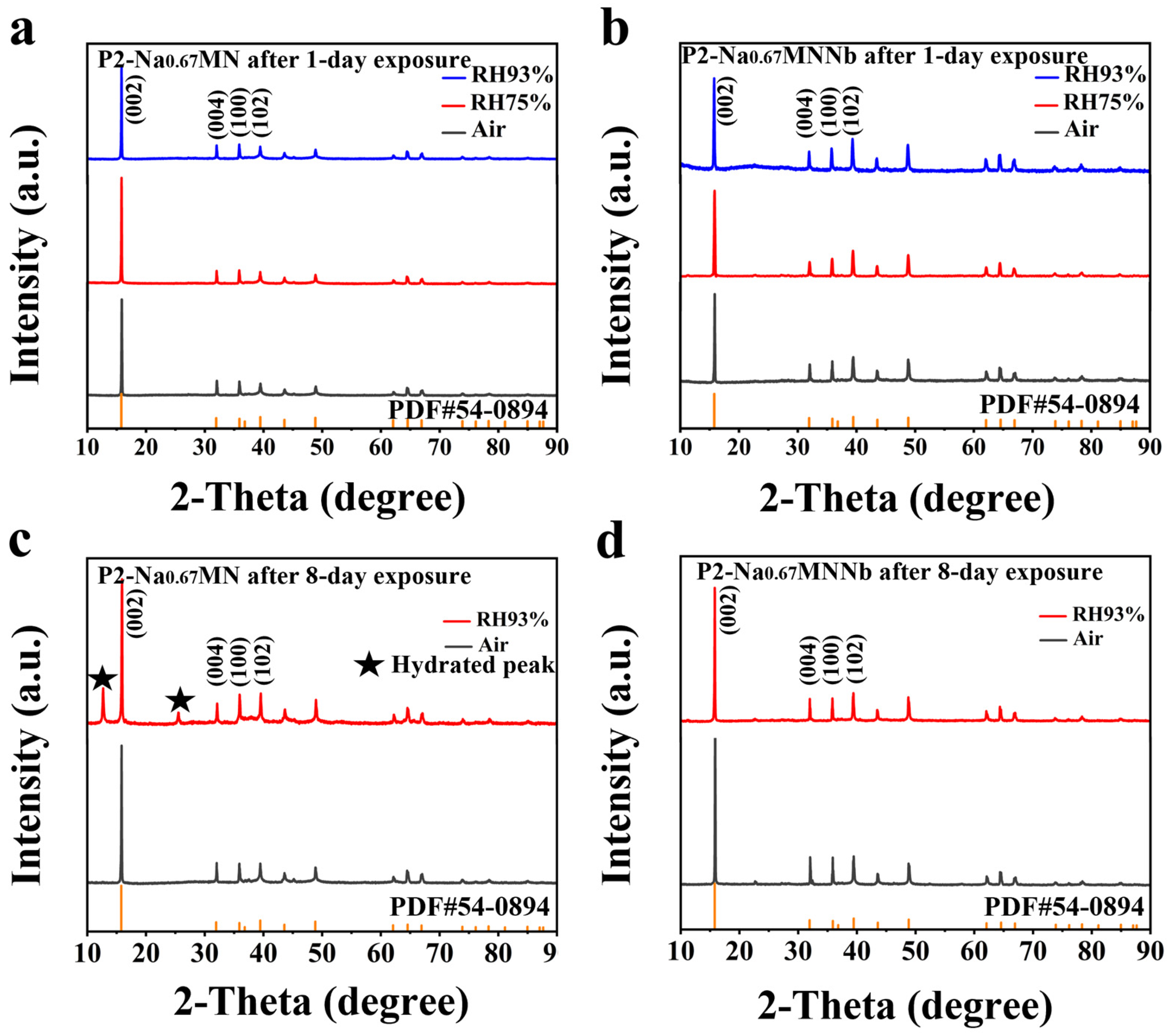

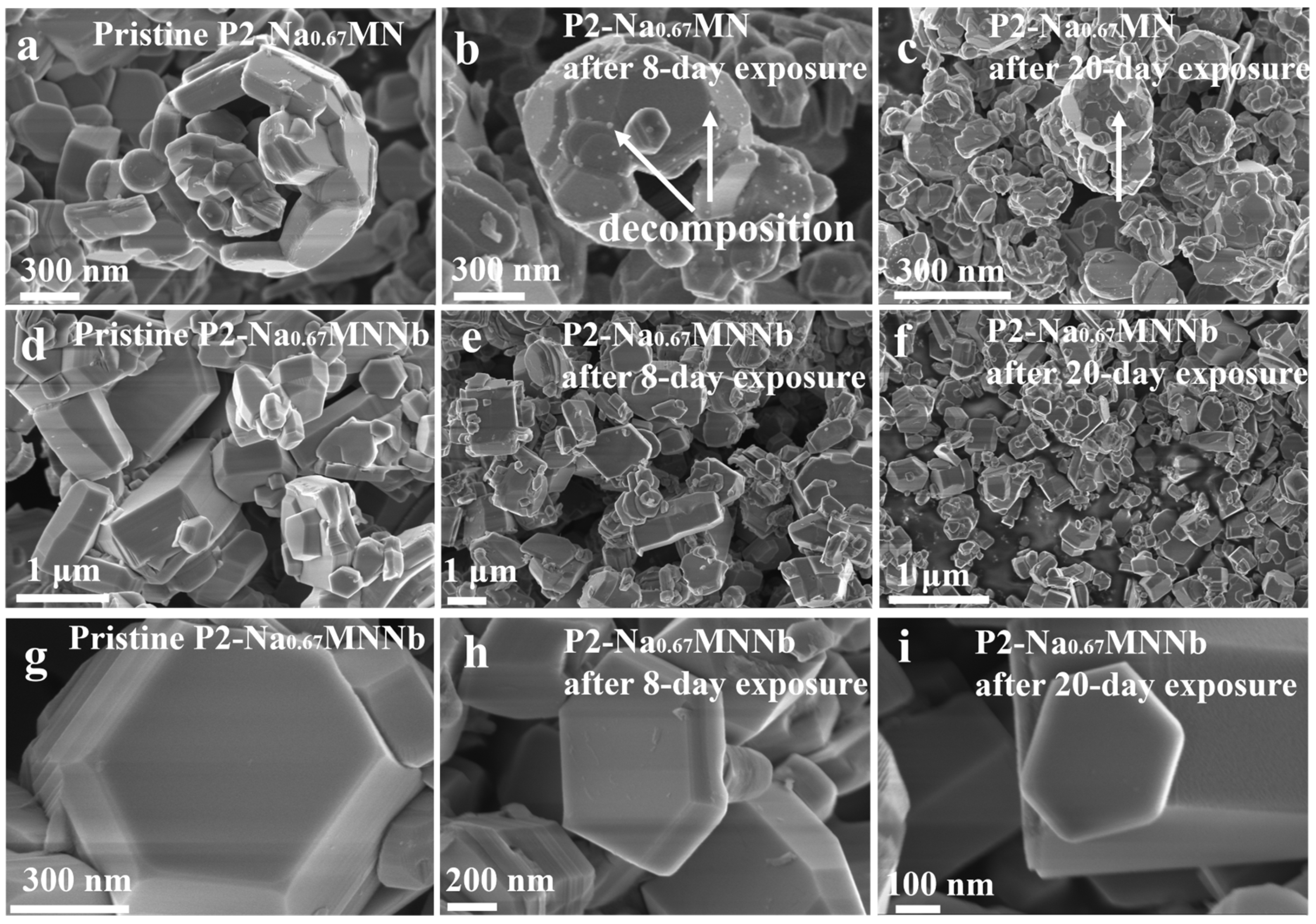

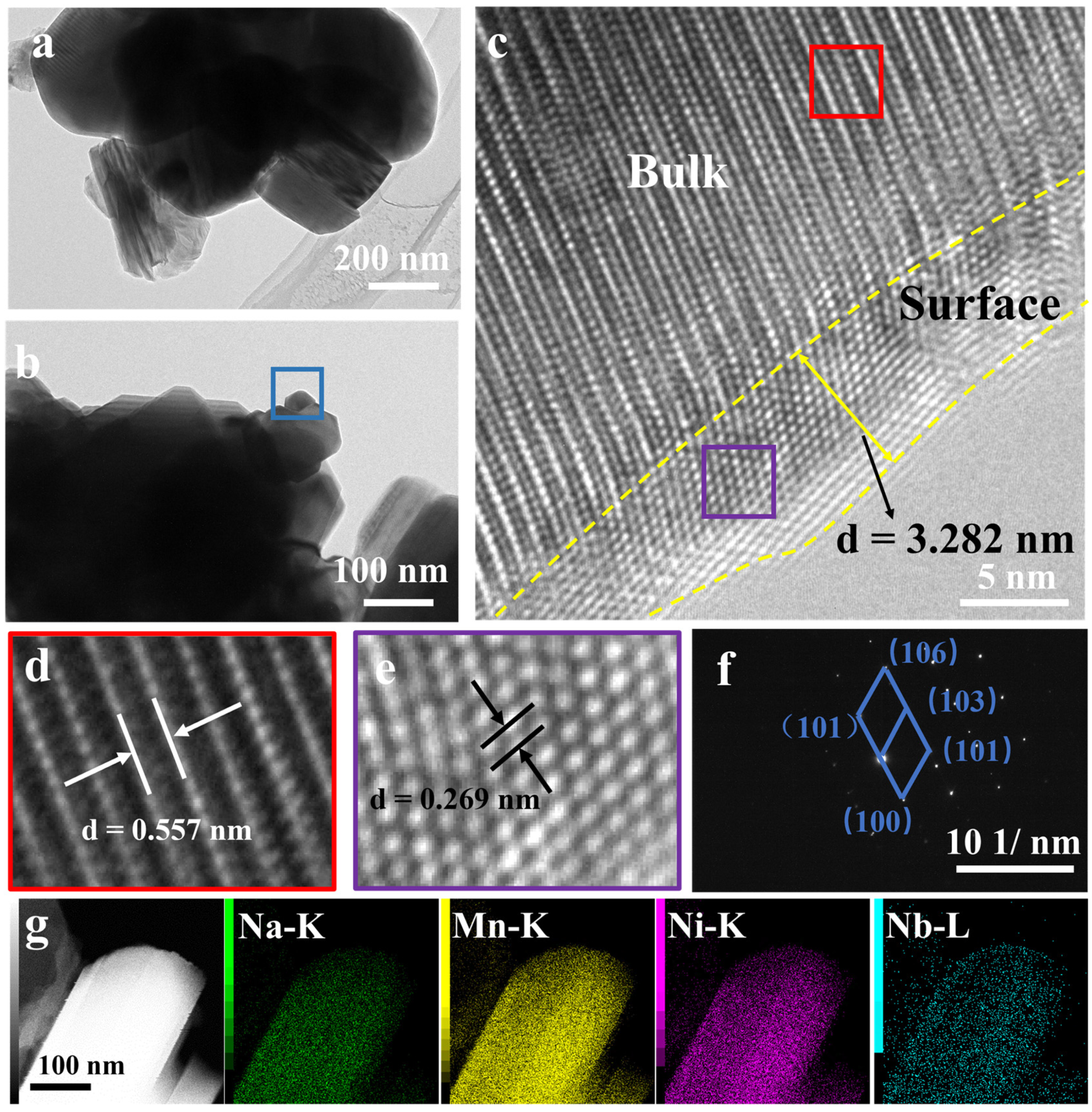

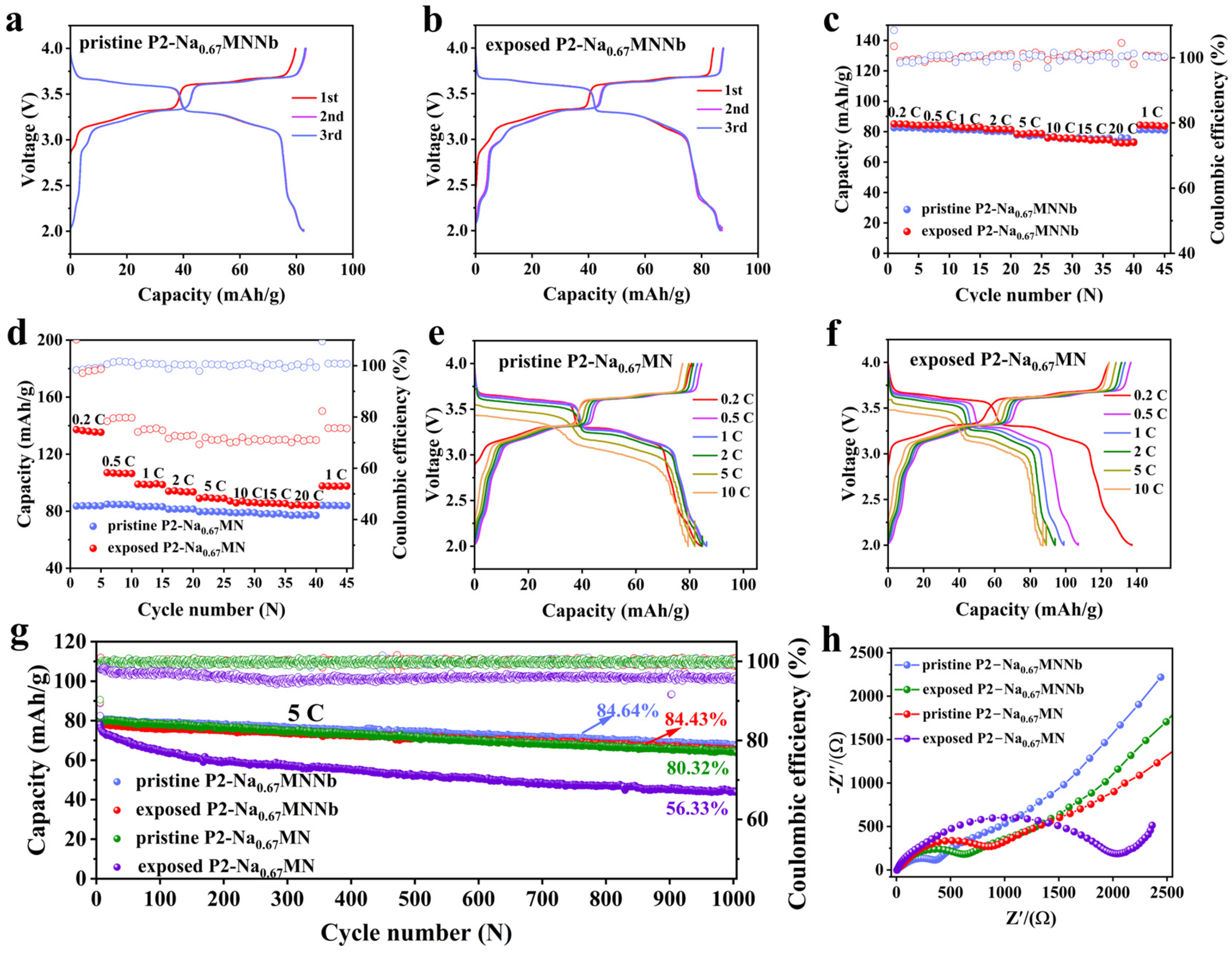

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zuo, W.; Xiao, Z.; Zarrabeitia, M.; Xue, X.; Yang, Y.; Passerini, S. Guidelines for Air-Stable Lithium/Sodium Layered Oxide Cathodes. ACS Mater. Lett. 2022, 4, 1074–1086. [Google Scholar] [CrossRef]

- Zhang, R.; Yang, S.; Li, H.; Zhai, T.; Li, H. Air sensitivity of electrode materials in Li/Na ion batteries: Issues and strategies. InfoMat 2022, 4, e12305. [Google Scholar] [CrossRef]

- Yao, H.-R.; Zheng, L.; Xin, S.; Guo, Y.-G. Air-stability of sodium-based layered-oxide cathode materials. Sci. China Chem. 2022, 65, 1076–1087. [Google Scholar] [CrossRef]

- Chen, T.R.; Sheng, T.; Wu, Z.G.; Li, J.T.; Wang, E.H.; Wu, C.J.; Li, H.T.; Guo, X.D.; Zhong, B.H.; Huang, L.; et al. Cu(2+) Dual-Doped Layer-Tunnel Hybrid Na(0.6)Mn(1−x)Cu (x)O(2) as a Cathode of Sodium-Ion Battery with Enhanced Structure Stability, Electrochemical Property, and Air Stability. ACS Appl. Mater Interfaces 2018, 10, 10147–10156. [Google Scholar] [CrossRef]

- Boyd, S.; Augustyn, V. Transition metal oxides for aqueous sodium-ion electrochemical energy storage. Inorg. Chem. Front. 2018, 5, 999–1015. [Google Scholar] [CrossRef]

- Guo, S.; Li, Q.; Liu, P.; Chen, M.; Zhou, H. Environmentally stable interface of layered oxide cathodes for sodium-ion batteries. Nat. Commun. 2017, 8, 135. [Google Scholar] [CrossRef]

- Xu, C.; Cai, H.; Chen, Q.; Kong, X.; Pan, H.; Hu, Y.-S. Origin of Air-Stability for Transition Metal Oxide Cathodes in Sodium-Ion Batteries. ACS Appl. Mater. Interfaces 2022, 14, 5338–5345. [Google Scholar] [CrossRef]

- Buchholz, D.; Chagas, L.G.; Vaalma, C.; Wu, L.; Passerini, S. Water sensitivity of layered P2/P3-NaxNi0.22Co0.11Mn0.66O2 cathode material. J. Mater. Chem. A 2014, 2, 13415–13421. [Google Scholar] [CrossRef]

- Zuo, W.; Liu, X.; Qiu, J.; Zhang, D.; Xiao, Z.; Xie, J.; Ren, F.; Wang, J.; Li, Y.; Ortiz, G.F.; et al. Engineering Na(+)-layer spacings to stabilize Mn-based layered cathodes for sodium-ion batteries. Nat. Commun. 2021, 12, 4903. [Google Scholar] [CrossRef]

- Zheng, L.; Li, J.; Obrovac, M.N. Crystal Structures and Electrochemical Performance of Air-Stable Na2/3Ni1/3–xCuxMn2/3O2 in Sodium Cells. Chem. Mater. 2017, 29, 1623–1631. [Google Scholar] [CrossRef]

- Whittingham, M.S. Ultimate Limits to Intercalation Reactions for Lithium Batteries. Chem. Rev. 2014, 114, 11414–11443. [Google Scholar] [CrossRef] [PubMed]

- Zuo, W.; Qiu, J.; Liu, X.; Zheng, B.; Zhao, Y.; Li, J.; He, H.; Zhou, K.; Xiao, Z.; Li, Q.; et al. Highly-stable P2–Na0.67MnO2 electrode enabled by lattice tailoring and surface engineering. Energy Storage Mater. 2019, 26, 503–512. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, R.; Huang, Y. Air-Stable Na (x) TMO(2) Cathodes for Sodium Storage. Front. Chem. 2019, 7, 335. [Google Scholar] [CrossRef]

- Wang, P.-F.; You, Y.; Yin, Y.-X.; Guo, Y.-G. Layered Oxide Cathodes for Sodium-Ion Batteries: Phase Transition, Air Stability, and Performance. Adv. Energy Mater. 2018, 8, 1701912. [Google Scholar] [CrossRef]

- Boyd, S.; Dhall, R.; LeBeau, J.M.; Augustyn, V. Charge storage mechanism and degradation of P2-type sodium transition metal oxides in aqueous electrolytes. J. Mater. Chem. A 2018, 6, 22266–22276. [Google Scholar] [CrossRef]

- Yabuuchi, N.; Kubota, K.; Dahbi, M.; Komaba, S. Research Development on Sodium-Ion Batteries. Chem. Rev. 2014, 114, 11636–11682. [Google Scholar] [CrossRef] [PubMed]

- You, Y.; Dolocan, A.; Li, W.; Manthiram, A. Understanding the Air-Exposure Degradation Chemistry at a Nanoscale of Layered Oxide Cathodes for Sodium-Ion Batteries. Nano Lett. 2019, 19, 182–188. [Google Scholar] [CrossRef]

- Han, M.H.; Sharma, N.; Gonzalo, E.; Pramudita, J.C.; Brand, H.E.A.; del Amo, J.M.L.; Rojo, T. Moisture exposed layered oxide electrodes as Na-ion battery cathodes. J. Mater. Chem. A 2016, 4, 18963–18975. [Google Scholar] [CrossRef]

- Duffort, V.; Talaie, E.; Black, R.; Nazar, L.F. Uptake of CO2 in Layered P2-Na0.67Mn0.5Fe0.5O2: Insertion of Carbonate Anions. Chem. Mater. 2015, 27, 2515–2524. [Google Scholar] [CrossRef]

- Pritzl, D.; Teufl, T.; Freiberg, A.T.S.; Strehle, B.; Sicklinger, J.; Sommer, H.; Hartmann, P.; Gasteiger, H.A. Editors’ Choice—Washing of Nickel-Rich Cathode Materials for Lithium-Ion Batteries: Towards a Mechanistic Understanding. J. Electrochem. Soc. 2019, 166, A4056–A4066. [Google Scholar] [CrossRef]

- Grey, C.P.; Tarascon, J.M. Sustainability and in situ monitoring in battery development. Nat. Mater. 2016, 16, 45–56. [Google Scholar] [CrossRef]

- Kim, H.; Hong, J.; Park, K.-Y.; Kim, H.; Kim, S.-W.; Kang, K. Aqueous Rechargeable Li and Na Ion Batteries. Chem. Rev. 2014, 114, 11788–11827. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Feng, X.; Cui, S.; Shi, Q.; Mi, L.; Chen, W. From α-NaMnO2to crystal water containing Na-birnessite: Enhanced cycling stability for sodium-ion batteries. Cryst. Eng. Comm. 2016, 18, 3136–3141. [Google Scholar] [CrossRef]

- Delmas, C.; Fouassier, C.; Hagenmuller, P. Structural classification and properties of the layered oxides. Phys. B+C 1980, 99, 81–85. [Google Scholar] [CrossRef]

- You, Y.; Song, B.; Jarvis, K.; Huq, A.; Manthiram, A. Insights into the Improved Chemical Stability against Water of LiF-Incorporated Layered Oxide Cathodes for Sodium-Ion Batteries. ACS Mater. Lett. 2019, 1, 89–95. [Google Scholar] [CrossRef]

- Liang, X.; Sun, Y.-K. A Novel Pentanary Metal Oxide Cathode with P2/O3 Biphasic Structure for High-Performance Sodium-Ion Batteries. Adv. Funct. Mater. 2022, 32, 2206154. [Google Scholar] [CrossRef]

- Wang, J.E.; Kim, H.; Jung, Y.H.; Kim, D.K.; Kim, D.J. Designing High Energy Sodium-Ion Battery Cathodes by Utilizing P2/O3 Biphasic Structure and Lithium Honeycomb Ordering. Small 2021, 17, 2100146. [Google Scholar] [CrossRef]

- Zhou, Y.-N.; Wang, P.-F.; Zhang, X.-D.; Huang, L.-B.; Wang, W.-P.; Yin, Y.-X.; Xu, S.; Guo, Y.-G. Air-Stable and High-Voltage Layered P3-Type Cathode for Sodium-Ion Full Battery. ACS Appl. Mater. Interfaces 2019, 11, 24184–24191. [Google Scholar] [CrossRef]

- Zheng, Y.-M.; Huang, X.-B.; Meng, X.-M.; Xu, S.-D.; Chen, L.; Liu, S.-B.; Zhang, D. Copper and Zirconium Codoped O3-Type Sodium Iron and Manganese Oxide as the Cobalt/Nickel-Free High-Capacity and Air-Stable Cathode for Sodium-Ion Batteries. ACS Appl. Mater. Interfaces 2021, 13, 45528–45537. [Google Scholar] [CrossRef]

- Qi, R.; Chu, M.; Zhao, W.; Chen, Z.; Liao, L.; Zheng, S.; Chen, X.; Xie, L.; Liu, T.; Ren, Y.; et al. A highly-stable layered Fe/Mn-based cathode with ultralow strain for advanced sodium-ion batteries. Nano Energy 2021, 88, 106206. [Google Scholar] [CrossRef]

- Zhou, P.; Che, Z.; Ma, F.; Zhang, J.; Weng, J.; Wu, X.; Miao, Z.; Lin, H.; Zhou, J.; Zhuo, S. Designing water/air-stable P2-layered cathodes with delayed P2–O2 phase transition by composition and structure engineering for sodium-ion batteries at high voltage. Chem. Eng. J. 2021, 420, 127667. [Google Scholar] [CrossRef]

- Jiang, J.; He, H.-C.; Cheng, C.; Yan, T.; Xia, X.; Ding, M.; He, L.; Chan, T.-S.; Zhang, L. Improving Structural and Moisture Stability of P2-Layered Cathode Materials for Sodium-Ion Batteries. ACS Appl. Energy Mater. 2022, 5, 1252–1261. [Google Scholar] [CrossRef]

- Li, X.; Shen, X.; Zhao, J.; Yang, Y.; Zhang, Q.; Ding, F.; Han, M.; Xu, C.; Yang, C.; Liu, H.; et al. O3-NaFe(1/3–x)Ni1/3Mn1/3AlxO2 Cathodes with Improved Air Stability for Na-Ion Batteries. ACS Appl. Mater. Interfaces 2021, 1, 33015–33023. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Dahn, J.R. Intercalation of Water in P2, T2 and O2 Structure Az[CoxNi1/3-xMn2/3]O2. Chem. Mater. 2001, 13, 1252–1257. [Google Scholar] [CrossRef]

- Wang, X.; Yin, X.; Feng, X.; Li, Y.; Dong, X.; Shi, Q.; Zhao, Y.; Zhang, J. Rational Design of Na0.67Ni0.2Co0.2Mn0.6O2 Microsphere Cathode Material for Stable and Low Temperature Sodium Ion Storage. Chem. Eng. J. 2022, 428, 130990. [Google Scholar] [CrossRef]

- Yao, H.-R.; Wang, P.-F.; Gong, Y.; Zhang, J.; Yu, X.; Gu, L.; OuYang, C.; Yin, Y.-X.; Hu, E.; Yang, X.-Q.; et al. Designing Air-Stable O3-Type Cathode Materials by Combined Structure Modulation for Na-Ion Batteries. J. Am. Chem. Soc. 2017, 139, 8440–8443. [Google Scholar] [CrossRef]

- Kubota, K.; Komaba, S. Review—Practical Issues and Future Perspective for Na-Ion Batteries. J. Electrochem. Soc. 2015, 162, A2538–A2550. [Google Scholar] [CrossRef]

- Zuo, W.; Qiu, J.; Liu, X.; Ren, F.; Liu, H.; He, H.; Luo, C.; Li, J.; Ortiz, G.F.; Duan, H.; et al. The stability of P2-layered sodium transition metal oxides in ambient atmospheres. Nat. Commun. 2020, 11, 3544. [Google Scholar] [CrossRef]

- Wang, X.; Dong, X.; Feng, X.; Shi, Q.; Wang, J.; Yin, X.; Zhang, J.; Zhao, Y. In-Plane BO3 Configuration in P2 Layered Oxide Enables Outstanding Long Cycle Performance for Sodium Ion Batteries. Small Methods 2023, 7, 2201201. [Google Scholar] [CrossRef] [PubMed]

- Nam, K.W.; Kim, S.; Yang, E.; Jung, Y.; Levi, E.; Aurbach, D.; Choi, J.W. Critical Role of Crystal Water for a Layered Cathode Material in Sodium Ion Batteries. Chem. Mater. 2015, 27, 3721–3725. [Google Scholar] [CrossRef]

- Chu, S.; Jia, X.; Wang, J.; Liao, K.; Zhou, W.; Wang, Y.; Shao, Z. Reduced air sensitivity and improved electrochemical stability of P2–Na2/3Mn1/2Fe1/4Co1/4O2 through atomic layer deposition-assisted Al2O3 coating. Compos. Part B 2019, 173, 106913. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, K.; Li, X.; Yu, R.; Zhang, X.; Huang, Y.; Chen, G.; Jamil, S.; Cao, S.; Xie, X.; et al. Improved cycle and air stability of P3-Na0.65Mn0.75Ni0.25O2 electrode for sodium-ion batteries coated with metal phosphates. Chem. Eng. J. 2019, 372, 1066–1076. [Google Scholar] [CrossRef]

- Lamb, J.; Manthiram, A. Surface-Modified Na(Ni0.3Fe0.4Mn0.3)O2 Cathodes with Enhanced Cycle Life and Air Stability for Sodium-Ion Batteries. ACS Appl. Energy Mater. 2021, 4, 11735–11742. [Google Scholar] [CrossRef]

- Zheng, L.; Li, L.; Shunmugasundaram, R.; Obrovac, M.N. Effect of Controlled-Atmosphere Storage and Ethanol Rinsing on NaNi0.5Mn0.5O2 for Sodium-Ion Batteries. ACS Appl. Mater. Interfaces 2018, 10, 38246–38254. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, D.Y. Stabilizing Na0.7MnO2 cathode for Na-ion battery via a single-step surface coating and doping process. J. Power Sources 2018, 391, 106–112. [Google Scholar] [CrossRef]

- Feng, X.; Li, Y.; Shi, Q.; Wang, X.; Yin, X.; Wang, J.; Xia, Z.; Xiao, H.; Chen, A.; Yang, X.; et al. A comprehensive modification enables the high rate capability of P2-Na0.75Mn0.67Ni0.33O2 for sodium-ion cathode materials. J. Energy Chem. 2022, 69, 442–449. [Google Scholar] [CrossRef]

- Shi, Q.; Qi, R.; Feng, X.; Wang, J.; Li, Y.; Yao, Z.; Wang, X.; Li, Q.; Lu, X.; Zhang, J.; et al. Niobium-doped layered cathode material for high-power and low-temperature sodium-ion batteries. Nat. Commun. 2022, 13, 3205. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Shi, Q.; Zhao, S.; Feng, W.; Liu, Y.; Yang, X.; Wang, Z.; Zhao, Y. Investigation on the Air Stability of P2-Layered Transition Metal Oxides by Nb Doping in Sodium Ion Batteries. Batteries 2023, 9, 183. https://doi.org/10.3390/batteries9030183

Chen Y, Shi Q, Zhao S, Feng W, Liu Y, Yang X, Wang Z, Zhao Y. Investigation on the Air Stability of P2-Layered Transition Metal Oxides by Nb Doping in Sodium Ion Batteries. Batteries. 2023; 9(3):183. https://doi.org/10.3390/batteries9030183

Chicago/Turabian StyleChen, Yanyan, Qinhao Shi, Shengyu Zhao, Wuliang Feng, Yang Liu, Xinxin Yang, Zhenwei Wang, and Yufeng Zhao. 2023. "Investigation on the Air Stability of P2-Layered Transition Metal Oxides by Nb Doping in Sodium Ion Batteries" Batteries 9, no. 3: 183. https://doi.org/10.3390/batteries9030183

APA StyleChen, Y., Shi, Q., Zhao, S., Feng, W., Liu, Y., Yang, X., Wang, Z., & Zhao, Y. (2023). Investigation on the Air Stability of P2-Layered Transition Metal Oxides by Nb Doping in Sodium Ion Batteries. Batteries, 9(3), 183. https://doi.org/10.3390/batteries9030183