Gravure Printing for Lithium-Ion Batteries Manufacturing: A Review

Abstract

:1. Introduction

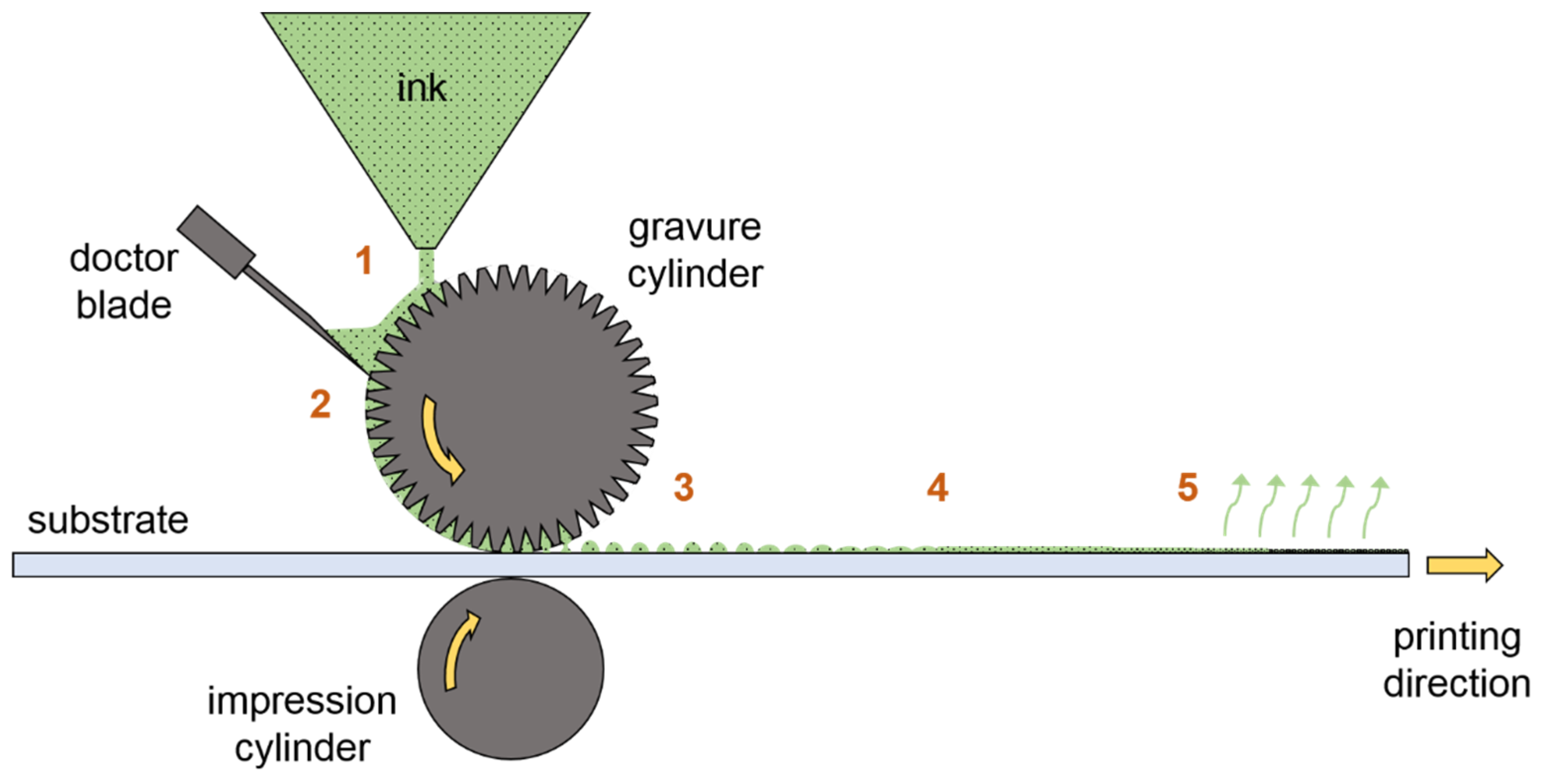

2. Gravure Printing Process

2.1. Overview of Gravure Printing

2.2. Operating Rules for High Quality Gravure Printing Films

2.3. Ink Formulation for Gravure Printed Batteries

3. Main Results

3.1. Gravure Printing Cathodes

3.1.1. LFP-Based Gravure Printed Cathodes

3.1.2. LMO-Based Gravure Printed Cathodes

3.1.3. CAM-Based Gravure Printing Anodes

3.1.4. Graphite-Based Gravure Printing Anodes

4. Discussion

5. Future Prospective

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Roth, B.; Søndergaard, R.R.; Krebs, F.C. Roll-to-roll printing and coating techniques for manufacturing large-area flexible organic electronics. In Handbook of Flexible Organic Electronics, Materials, Manufacturing and Applications, 1st ed.; Logothetidis, S., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 171–197. [Google Scholar]

- Abbel, R.; Galagan, Y.; Groen, P. Roll-to-Roll Fabrication of Solution Processed Electronics. Adv. Eng. Mater. 2018, 20, 1701190. [Google Scholar] [CrossRef]

- Costa, C.M.; Gonçalves, R.; Lanceros-Méndez, S. Recent advances and future challenges in printed batteries. Energy Storage Mater. 2020, 28, 216–234. [Google Scholar] [CrossRef]

- Lyu, Z.; Lim, G.J.H.; Koh, J.J.; Li, Y.; Ma, Y.; Ding, J.; Wang, J.; Hu, Z.; Wang, J.; Chen, W.; et al. Design and Manufacture of 3D-Printed Batteries. Joule 2021, 5, 89–114. [Google Scholar] [CrossRef]

- Oliveira, J.; Costa, C.M.; Lanceros-Méndez, S. Printed Batteries Materials, Technologies and Applications; John Wiley & Sons Ltd.: Chichester, UK, 2018. [Google Scholar]

- Tong, C. Printed Flexible Electrochemical Energy Storage Devices. In Advanced Materials for Printed Flexible Electronics, 1st ed.; Springer Series in Materials Science; Springer: Cham, Switzerland, 2022; Volume 317, pp. 433–521. [Google Scholar]

- Zhu, M.; Shmidt, O.G. Tiny robots and sensors need tiny batteries—Here’s how to do it. Nature 2021, 589, 195. [Google Scholar] [CrossRef] [PubMed]

- You, C.-Y.; Hu, B.-F.; Xu, B.-R.; Zhang, Z.-Y.; Wu, B.-M.; Huang, G.-S.; Song, E.-M.; Mei, Y.-F. Foldable-circuit-enabled miniaturized multifunctional sensor for smart digital dust. Chip 2022, 1, 100034. [Google Scholar] [CrossRef]

- Jung, M.; Kim, J.; Koo, H.; Lee, W.; Subramanian, V.; Cho, G. Roll-to-roll gravure with nanomaterials for printing smart packaging. J. Nanosci. Nanotechnol. 2014, 14, 1303–1317. [Google Scholar] [CrossRef] [PubMed]

- Grau, G.; Kitsomboonloha, R.; Subramanian, V. Fabrication of a high-resolution roll for gravure printing of 2 µm features. In Proceedings of the SPIE Organic Photonics + Electronics, San Diego, CA, USA, 9–13 August 2015. [Google Scholar]

- Tiara, A.M.; Moon, H.; Cho, G.; Lee, J. Fully roll-to-roll gravure printed electronics: Challenges and the way to integrating logic gates. Jpn. J. Appl. Phys. 2022, 61, SE0802. [Google Scholar]

- Hwang, S.S.; Cho, C.G.; Park, K.-S. Stabilizing LiCoO2 electrode with an overlayer of LiNi0.5Mn1.5O4 by using a Gravure printing method. Electrochem. Commun. 2011, 13, 279–283. [Google Scholar] [CrossRef]

- Rassek, P.; Wendler, M.; Krebs, M. Industrial Perspective on Printed Batteries. In Printed Batteries Materials, Technologies and Applications, 1st ed.; Lanceros-Méndez, S., Costa, C.M., Eds.; John Wiley & Sons Ltd.: Chichester, UK, 2018; pp. 185–192. [Google Scholar]

- Szentgyörgyvölgyi, R. Gravure printing. In Printing on Polymers, 1st ed.; Izdebska, J., Thomas, S., Eds.; William Andrew: Waltham, MA, USA, 2016; pp. 199–215. [Google Scholar]

- Romano, F. Printing processes. In Professional Prepress, Printing, and Publishing, 1st ed.; Romano, F., Ed.; Prentice Hall PTR: Hoboken, NJ, USA, 1999; pp. 89–186. [Google Scholar]

- Xia, Z.; Cai, T.; Li, X.; Zhang, Q.; Shuai, J.; Liu, S. Recent Progress of Printing Technologies for High-Efficient Organic Solar Cells. Catalysts 2023, 13, 156. [Google Scholar] [CrossRef]

- Lee, W.; Koo, H.; Sun, J.; Noh, J.; Kwon, K.-S.; Yeom, C.; Choi, Y.; Chen, K.; Javey, A.; Cho, G. A fully roll-to-roll gravure-printed carbon nanotube-based active matrix for multi-touch sensors. Sci. Rep. 2015, 5, 17707. [Google Scholar] [CrossRef] [PubMed]

- Tekoglu, S.; Hernandez-Sosa, G.; Kluge, E.; Lemmer, U.; Mechau, N. Gravure printed flexible small-molecule organic light emitting diodes. Org. Electron. 2013, 14, 3493–3499. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, L.; Chang, Q.; Shi, W.; Shen, L.; Chen, Q. Gravure-printed interdigital microsupercapacitors on a flexible polyimide substrate using crumpled graphene ink. Nanotechnology 2016, 27, 105401. [Google Scholar] [CrossRef]

- Montanino, M.; De Girolamo Del Mauro, A.; Tesoro, M.; Ricciardi, R.; Diana, R.; Morvillo, P.; Nobile, G.; Imparato, A.; Sico, G.; Minarini, C. Gravure-printed PEDOT:PSS on flexible PEN substrate as ITO-free anode for polymer solar cells. Polym. Compos. 2015, 36, 1104–1109. [Google Scholar] [CrossRef]

- Montanino, M.; Sico, G.; Prontera, C.T.; De Girolamo Del Mauro, A.; Aprano, S.; Maglione, M.G.; Minarini, C. Gravure printed PEDOT:PSS as anode for flexible ITO-free organic light emitting diodes. Express Polym. Lett. 2017, 11, 518–523. [Google Scholar] [CrossRef]

- Sico, G.; Montanino, M.; Loffredo, F.; Borriello, C.; Miscioscia, R. Gravure Printing for PVDF Thin-Film Pyroelectric Device Manufacture. Coatings 2022, 12, 1020. [Google Scholar] [CrossRef]

- Sico, G.; Montanino, M.; Prontera, C.T.; De Girolamo Del Mauro, A.; Minarini, C. Gravure printing for thin film ceramics manufacturing from nanoparticles. Ceram. Int. 2018, 44, 19526–19534. [Google Scholar] [CrossRef]

- Garcia, A.J.L.; Sico, G.; Montanino, M.; Defoor, V.; Pusty, M.; Mescot, X.; Loffredo, F.; Villani, F.; Nenna, G.; Ardila, G. Low-Temperature Growth of ZnO Nanowires from Gravure-Printed ZnO Nanoparticle Seed Layers for Flexible Piezoelectric Devices. Nanomaterials 2021, 11, 1430. [Google Scholar] [CrossRef]

- Hennig, G.; Selbmann, K.-H.; Brockelt, A. Laser engraving in gravure industry. In Proceedings of the SPIE 6157, EPIC/SPIE Workshop on Laser Applications in Europe, Dresden, Germany, 9 December 2005. [Google Scholar]

- Sankaran, A.K.; Rothstein, J.P. Effect of viscoelasticity on liquid transfer during gravure printing. J. Non-Newton. Fluid Mech. 2012, 175, 64–75. [Google Scholar] [CrossRef]

- Lee, J.A.; Rothstein, J.P.; Pasquali, M. Computational study of viscoelastic effects on liquid transfer during gravure printing. J. Non-Newton. Fluid Mech. 2013, 199, 1–11. [Google Scholar] [CrossRef]

- Grau, G.; Cen, J.; Kang, H.; Kitsomboonloha, R.; Scheideler, W.J.; Subramanian, V. Gravure-printed electronics: Recent progress in tooling development, understanding of printing physics, and realization of printed devices. Flex. Print. Electron. 2016, 1, 023002. [Google Scholar] [CrossRef]

- Walsh, J.J. A Review of the Graphic Arts Industry. IEEE Trans. Aerosp. Electron. Syst. 1970, AES-6, 422–431. [Google Scholar] [CrossRef]

- Michels, J.J.; de Winter, S.H.P.M.; Symonds, L.H.G. Process optimization of gravure printed light-emitting polymer layers by a neural network approach. Org. Electron. 2009, 10, 1495–1504. [Google Scholar] [CrossRef]

- Kapur, N. A parametric study of direct gravure coating. Chem. Eng. Sci. 2003, 58, 2875–2882. [Google Scholar] [CrossRef]

- Ahn, S.; Na, Y. On the Ink Transfer Process in Gravure Printing. In Proceedings of the Computational Science and Its Applications—ICCSA 2007 International Conference, Kuala Lumpur, Malaysia, 26–29 August 2007. [Google Scholar]

- Kumar, S. Liquid Transfer in Printing Processes: Liquid Bridges with Moving Contact Lines. Annu. Rev. Fluid Mech. 2015, 47, 67–94. [Google Scholar] [CrossRef]

- Hewson, R.W.; Kapur, N.; Gaskell, P.H. A two-scale model for discrete cell gravure roll coating. Chem. Eng. Sci. 2011, 66, 3666–3674. [Google Scholar] [CrossRef]

- Nguyen, H.A.D.; Shin, K.; Lee, C. Effect of nip force on ink transfer in high resolution roll-to-roll printing. Int. J. Precis. Eng. Manuf. 2015, 16, 517–523. [Google Scholar] [CrossRef]

- Nguyen, H.A.D.; Lee, C.; Shin, K.-H.; Lee, D. An Investigation of the Ink-Transfer Mechanism During the Printing Phase of High-Resolution Roll-to-Roll Gravure Printing. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 1516–1524. [Google Scholar] [CrossRef]

- Campana, D.M.; Ubal, S.; Giavedoni, M.D.; Saita, F.A.; Carvalho, M.S. Three dimensional flow of liquid transfer between a cavity and a moving roll. Chem. Eng. Sci. 2016, 149, 169–180. [Google Scholar] [CrossRef]

- Wu, J.-T.; Carvalho, M.S.; Kumar, S. Emptying of gravure cavities containing shear-thinning and shear-thickening liquids. J. Non-Newton. Fluid Mech. 2019, 268, 46–55. [Google Scholar] [CrossRef]

- Grau, G. Gravure-Printed Electronics: Devices, Technology Development and Design. Ph.D. Thesis, University of California, Berkeley, CA, USA, 1 May 2017. [Google Scholar]

- Huang, Q.; Zhu, Y. Printing conductive nanomaterials for flexible and stretchable electronics: A review of materials, processes, and applications. Adv. Mater. Technol. 2019, 4, 1800546. [Google Scholar] [CrossRef]

- Grau, G.; Scheideler, W.J.; Subramanian, V. High-resolution gravure printed lines: Proximity effects and design rules. In Proceedings of the SPIE 9569, SPIE Organic Photonics + Electronics, San Diego, CA, USA, 17 September 2015. [Google Scholar]

- Zavanelli, N.; Kim, J.; Yeo, W.H. Recent Advances in High-Throughput Nanomaterial Manufacturing for Hybrid Flexible Bioelectronics. Materials 2021, 14, 2973. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Lorenzelli, L.; Dahiya, R.S. Technologies for printing sensors and electronics over large flexible substrates: A review. IEEE Sens. J. 2014, 15, 3164–3185. [Google Scholar] [CrossRef]

- Maddipatla, D.; Narakathu, B.B.; Atashbar, M. Recent Progress in Manufacturing Techniques of Printed and Flexible Sensors: A Review. Biosensors 2020, 10, 199. [Google Scholar] [CrossRef] [PubMed]

- Hu, G.; Kang, J.; Ng, L.W.T.; Zhu, X.; Howe, R.C.T.; Jones, C.G.; Hersam, M.C.; Hasan, T. Functional inks and printing of two-dimensional materials. Chem. Soc. Rev. 2018, 47, 3265–3300. [Google Scholar] [CrossRef] [PubMed]

- Secor, E.B.; Lim, S.; Zhang, H.; Frisbie, C.D.; Francis, L.F.; Hersam, M.C. Gravure Printing of Graphene for Large-area Flexible Electronics. Adv. Mater. 2014, 26, 4533–4538. [Google Scholar] [CrossRef] [PubMed]

- Schlisske, S.; Rosenauer, C.; Rödlmeier, T.; Giringer, K.; Michels, J.J.; Kremer, K.; Lemmer, U.; Morsbach, S.; Daoulas, K.C.; Hernandez-Sosa, G. Ink Formulation for Printed Organic Electronics: Investigating Effects of Aggregation on Structure and Rheology of Functional Inks Based on Conjugated Polymers in Mixed Solvents. Adv. Mater. Technol. 2020, 6, 2000335. [Google Scholar] [CrossRef]

- Glasser, A.; Cloutet, E.; Hadziioannou, G.; Kellay, H. Tuning the rheology of conductiong polymer inks for various deposition processes. Chem. Mater. 2019, 31, 6936–6944. [Google Scholar] [CrossRef]

- Chang, Q.; Cao, C.; Qiao, H.; Hu, Y.; Xiao, G.; Shi, W. Ink transfer for printed flexible microsupercapacitors. Carbon 2021, 178, 285–293. [Google Scholar] [CrossRef]

- Stamm, J.; Daume, D.; Hartwig, T.; Oschmann, M.; Schäfer, J.; Sauer, H.M.; Dörsam, E. Dynamic interferometric imaging of the thickness distribution of evaporating thin liquid films. J. Coat. Technol. Res. 2019, 16, 1663–1671. [Google Scholar] [CrossRef]

- Hernandez-Sosa, G.; Bornemann, N.; Ringle, I.; Agari, M.; Dörsam, E.; Mechau, N.; Lemmer, U. Rheological and drying considerations for uniformly gravure printed layers: Towards large-area flexible organic light-emitting diodes. Adv. Funct. Mater. 2013, 23, 3164–3171. [Google Scholar] [CrossRef]

- Montanino, M.; Sico, G.; De Girolamo Del Mauro, A.; Moreno, M. LFP-Based Gravure Printed Cathodes for Lithium-Ion Printed batteries. Membranes 2019, 9, 71. [Google Scholar] [CrossRef] [PubMed]

- Montanino, M.; Sico, G.; De Girolamo Del Mauro, A.; Asenbauer, J.; Binder, J.R.; Bresser, D.; Passerini, S. Gravure-Printed Conversion/Alloying Anodes for Lithium-Ion Batteries. Energy Technol. 2021, 9, 2100315. [Google Scholar] [CrossRef]

- Montanino, M.; De Girolamo Del Mauro, A.; Paoletti, C.; Sico, G. Gravure Printing of Graphite-Based Anodes for Lithium-Ion Printed Batteries. Membranes 2022, 12, 999. [Google Scholar] [CrossRef] [PubMed]

- Montanino, M.; Paoletti, C.; De Girolamo Del Mauro, A.; Sico, G. The Influence of the Gravure Printing Quality on the Layer Functionality: The Study Case of LFP Cathode for Li-Ion Batteries. Coatings 2023, 13, 1214. [Google Scholar] [CrossRef]

- Montanino, M.; Paoletti, C.; De Girolamo Del Mauro, A.; Sico, G. Gravure printed composites based on Lithium Manganese Oxide: A study case for Li-ion batteries manufacturing. Macromol. Symp. 2023; submitted. [Google Scholar]

- Sousa, R.E.; Oliveira, J.; Gören, A.; Miranda, D.; Silva, M.M.; Hilliou, L.; Costa, C.M.; Lanceros-Mendez, S. High performance screen printable lithium-ion battery cathode ink based on C-LiFePO4. Electrochim. Acta 2016, 196, 92–100. [Google Scholar] [CrossRef]

- Gören, A.; Mendes, J.; Rodrigues, H.M.; Sousa, R.E.; Oliveira, J.; Hilliou, L.; Costa, C.M.; Silva, M.M.; Lanceros-Méndez, S. High performance screen-printed electrodes prepared by a green solvent approach for lithium-ion batteries. J. Power Source 2016, 334, 65–77. [Google Scholar] [CrossRef]

- Deiner, L.J.; Jenkins, T.; Powell, A.; Howell, T.; Rottmayer, M. High capacity rate capable aerosol jet printed Li-ion battery cathode. Adv. Eng. Mater. 2019, 21, 1801281. [Google Scholar] [CrossRef]

- Lee, S.H.; Li, K.; Huang, C.; Evans, J.D.; Grant, P.S. Spray-printed and self-assembled honeycomb electrodes of silicon-decorated carbon nanofibers for Li-ion batteries. ACS Appl. Mater. Interfaces 2019, 11, 603–612. [Google Scholar] [CrossRef]

- Mateo, J.V.; Matthew, K.; Pekarovicova, A.; Fleming, P.D. Inks for Li-ion battery anodes printed by rotogravure. Adv. Print. Media Technol. 2022, 47, 171–176. [Google Scholar]

- Pekarovicova, A.; Matthew, K.; Mateo, J.V.; Al-Ajlouni, K.; Fleming, P.D. Li-ion battery anodes printed by rotogravure. J. Print Media Technol. Res. 2023, 12, 7–14. [Google Scholar]

- Jin, Y.; Yu, H.; Liang, X. Simple approach: Heat treatment to improve the electrochemical performance of commonly used anode electrodes for Lithium-ion batteries. ACS Appl. Mater. Interfaces 2020, 12, 41368–41380. [Google Scholar] [CrossRef] [PubMed]

- Cusola, O.; Kivistö, S.; Vierros, S.; Batys, P.; Ago, M.; Tardy, B.L.; Greca, L.G.; Roncero, M.B.; Sammalkorpi, M.; Rojas, O.J. Particulate coatings via evaporation-induced self-assembly of polydisperse colloidal lignin on solid interface. Langmuir 2018, 34, 5759. [Google Scholar] [CrossRef] [PubMed]

- Vesaratchanon, S.; Nikolov, A.; Wasan, D.T. Sedimentation in nano-colloidal dispersions: Effects of collective interactions and particle charge. Adv. Colloid Interface Sci. 2007, 134–135, 268. [Google Scholar] [CrossRef] [PubMed]

- Aimar, P.; Bacchin, P. Concentrated phases of colloids or nanoparticles: Solid pressure and dynamics of concentration processes. In Nano-Science: Colloidal and Interfacial Aspect; Starov, V.M., Ed.; CRC Press: Boca Raton, FL, USA; Taylor and Francis Group: Oxfordshire, UK, 2010. [Google Scholar]

- Schulz, M.; Keddie, J.L. A critical and quantitative review of the stratification of particles during the drying of colloidal films. Soft Matter 2018, 14, 6181. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Brady, J.F. Microstructures and mechanics in the colloidal film drying process. Soft Matter 2017, 13, 8156. [Google Scholar] [CrossRef] [PubMed]

- Trueman, R.E.; Lago Domingues, E.; Emmett, S.N.; Murray, M.W.; Routh, A.F. Auto-stratification in drying colloidal dispersions: A diffusive model. J. Colloid Interface Sci. 2012, 377, 207. [Google Scholar] [CrossRef]

- Choi, K.-H.; Ahn, D.B.; Lee, S.-Y. Current status and challenges in printed batteries: Toward form factor-free monolithic integrated power sources. ACS Energy Lett. 2018, 3, 200–236. [Google Scholar] [CrossRef]

- Jiang, Z.; Chen, G. Research Progress and Prospect of Printed Batteries. In Proceedings of the China Academic Conference on Printing and Packaging CACPP 2022, Jian, China, 11–13 November 2022. [Google Scholar]

| Gravure Cylinder | Process | Ink | Substrate |

|---|---|---|---|

| cell geometry | printing force | viscosity | surface energy |

| cell density | printing speed | surface tension | roughness |

| surface energy | web tension | solvent evaporation rate | porosity |

| diameter | solid content |

| Ink | Printing | Electrode | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| dry solid content [wt%] | ball milling | viscosity [mPa s] | surface tension [mN m−1] | printing speed [m s−1] | printing force [N] | Ca | number of layer | massloading [mg cm−2] | thickness [µm] | apparent density [g cm−3] |

| 15 | No | 74 | 30 | 0.6 | 700 | 1.5 | 10 | 1.8 | 20 ± 1 | 0.9 |

| 15 | Yes | 43 | 30 | 0.6 | 700 | 0.9 | 10 | 1.4 | 15 ± 1 | 0.9 |

| Ink | Printing | Electrode | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| dry solid content [wt%] | ball milling | viscosity [mPa s] | surface tension [mN m−1] | printing speed [m s−1] | printing force [N] | Ca | number of layer | mass loading [mg cm−2] | thickness [µm] | apparent density [g cm−3] |

| 18 | No | 78 | 42 | 0.6 | 700 | 1.1 | 7 | 0.7 | 19 ± 4 | 0.4 |

| 18 | Yes | 86 | 42 | 0.6 | 700 | 1.2 | 7 | 2.0 | 24 ± 2 | 0.8 |

| Ink | Printing | Electrode | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| dry solid content [wt%] | ball milling | viscosity [mPa s] | surface tension [mN m−1] | printing speed [m s−1] | printing force [N] | Ca | number of layer | mass loading [mg cm−2] | thickness [µm] | apparent density [g cm−3] |

| 14 | Yes | 100 | 30 | 0.6 | 700 | 2.0 | 10 | 1.3 | 22 ± 2 | 0.6 |

| 14 | Yes | 100 | 30 | 0.6 | 700 | 2.0 | 15 | 1.7 | 30 ± 3 | 0.6 |

| Ink | Printing | Electrode | ||||||

|---|---|---|---|---|---|---|---|---|

| dry solid content [wt%] | ball milling | surface tension [mN m−1] | printing speed [m s−1] | printing force [N] | number of layer | mass loading [mg cm−2] | thickness [µm] | apparent density [g cm−3] |

| 18 | Yes | 42 | 0.6 | 700 | 6 | 0.9 | 18 | 0.5 |

| Printing Technique | ELECTRODE TYPE | Active Material | Binder | Solvent | Cell Type | Specific Capacity [mAh g−1] | Ref. |

|---|---|---|---|---|---|---|---|

| gravure | cathode | LFP | CMC | water + 2-propanol | half | 168 @ C/10 | [56] |

| gravure | cathode | LMO | CMC | water + 2-propanol | half | 110 @ C/10 | [57] |

| gravure | anode | CAM | CMC | water + 2-propanol | half | 600 @ C/10 | [54] |

| gravure | anode | graphite | CMC | water + 2-propanol | half | 355 @ C/10 | [55] |

| gravure | anode | graphite | PVDF/PVDF + PVP | NMP | half | 340 | [62,63] |

| screen printing | cathode | LFP | PVDF | NMP | half | 48 @ 5C | [58] |

| aerosol | cathode | LFP | Kynar | 2-butanol | half | 151 @ C/15 | [60] |

| spray | cathode | LFP | CMC | water + 2-propanol | full | 150 @ 4A g−1 | [61] |

| screen printing | anode | graphite | PVDF | NMP | full | 81 | [59] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montanino, M.; Sico, G. Gravure Printing for Lithium-Ion Batteries Manufacturing: A Review. Batteries 2023, 9, 535. https://doi.org/10.3390/batteries9110535

Montanino M, Sico G. Gravure Printing for Lithium-Ion Batteries Manufacturing: A Review. Batteries. 2023; 9(11):535. https://doi.org/10.3390/batteries9110535

Chicago/Turabian StyleMontanino, Maria, and Giuliano Sico. 2023. "Gravure Printing for Lithium-Ion Batteries Manufacturing: A Review" Batteries 9, no. 11: 535. https://doi.org/10.3390/batteries9110535

APA StyleMontanino, M., & Sico, G. (2023). Gravure Printing for Lithium-Ion Batteries Manufacturing: A Review. Batteries, 9(11), 535. https://doi.org/10.3390/batteries9110535