Boosting the Lithium Storage Properties of a Flexible Li4Ti5O12/Graphene Fiber Anode via a 3D Printing Assembly Strategy

Abstract

:1. Introduction

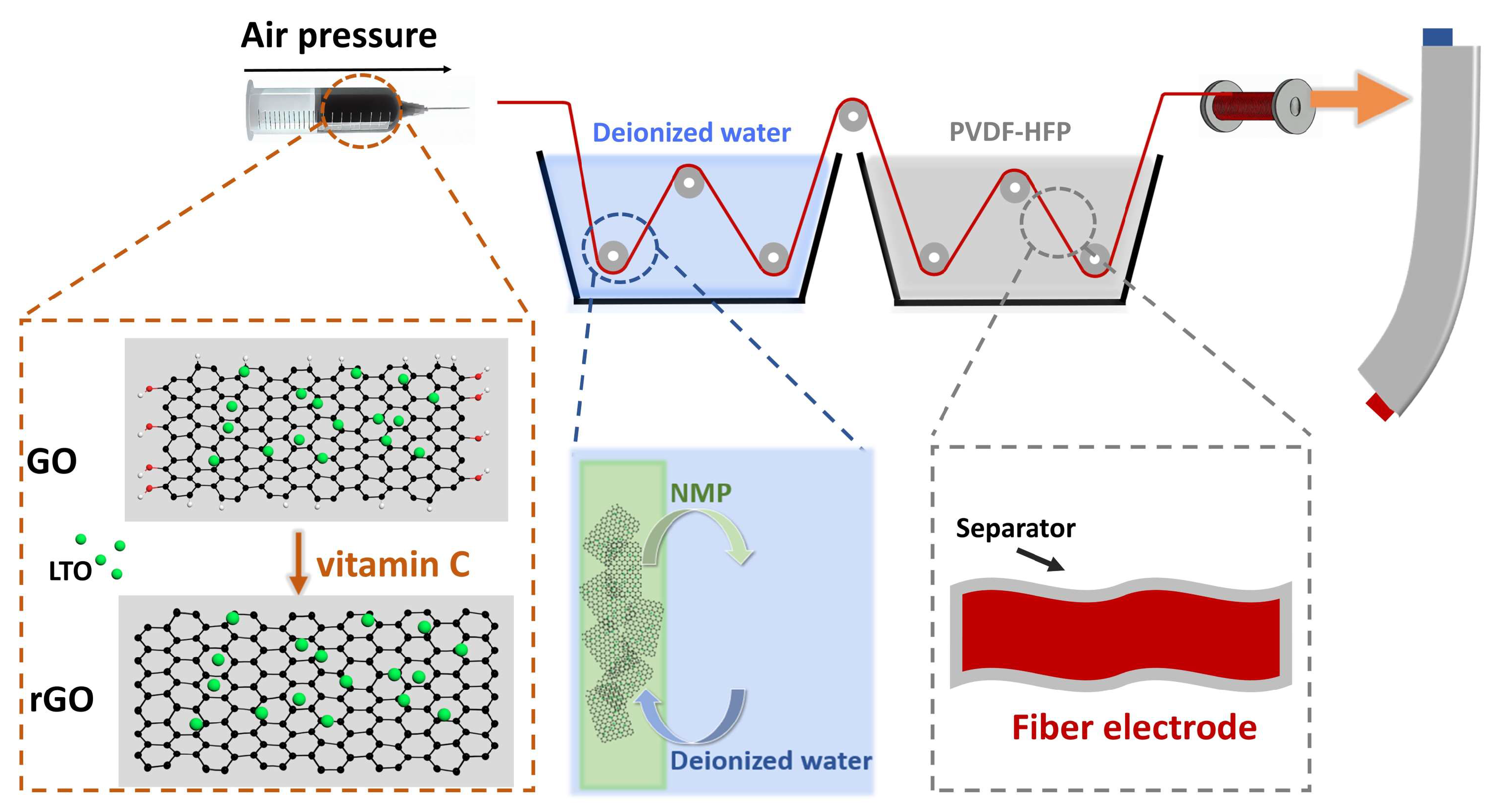

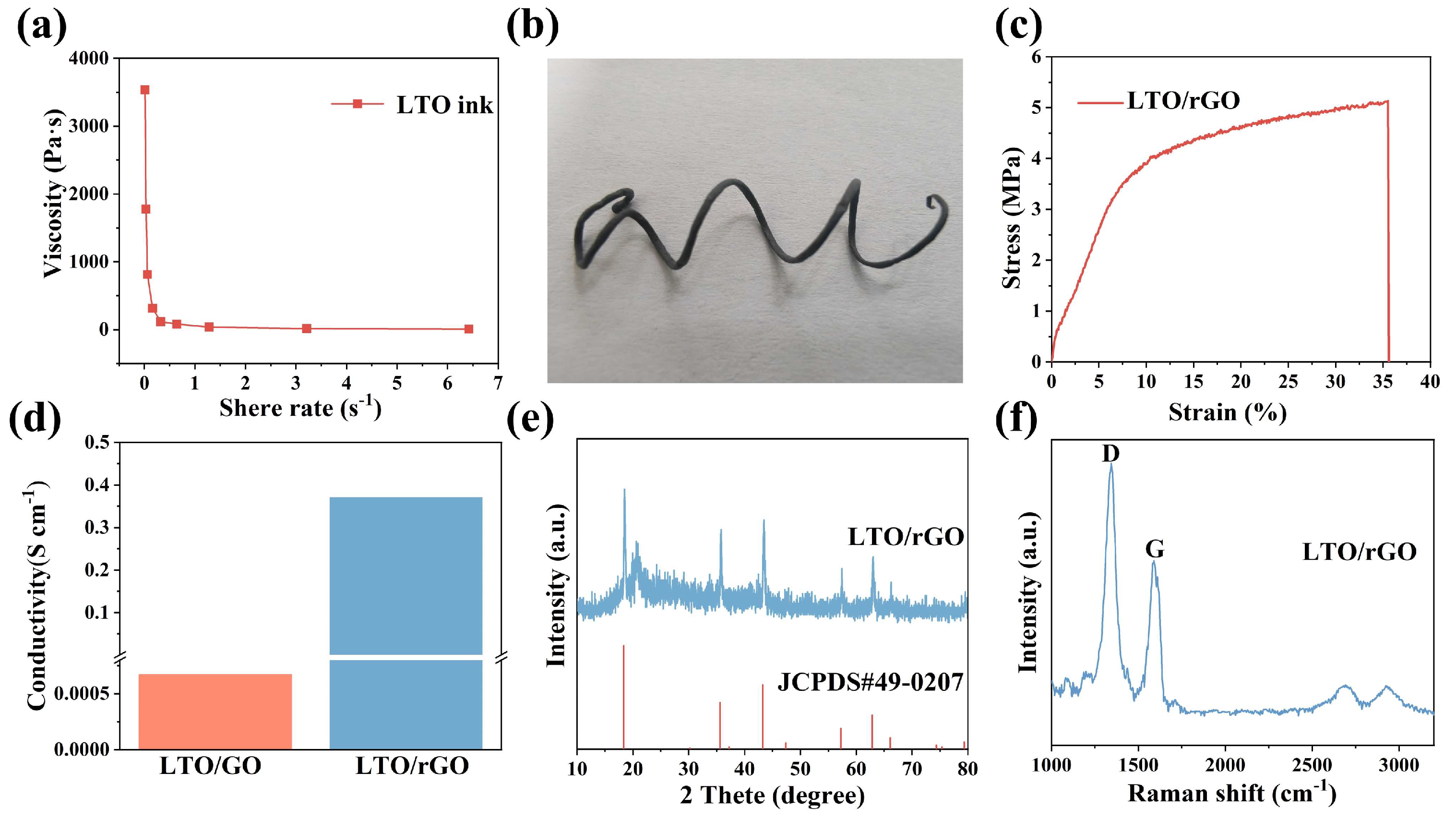

2. Materials and Methods

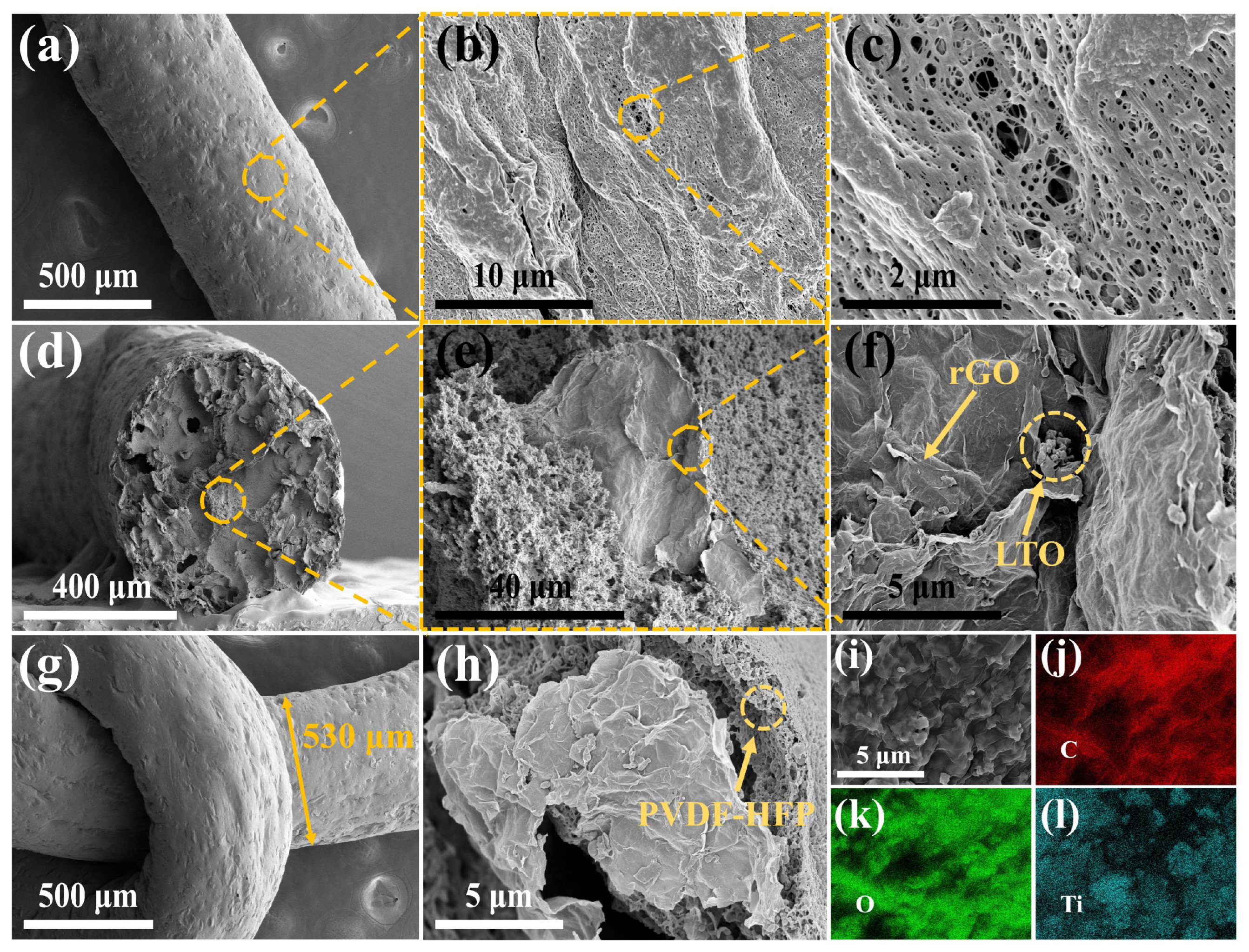

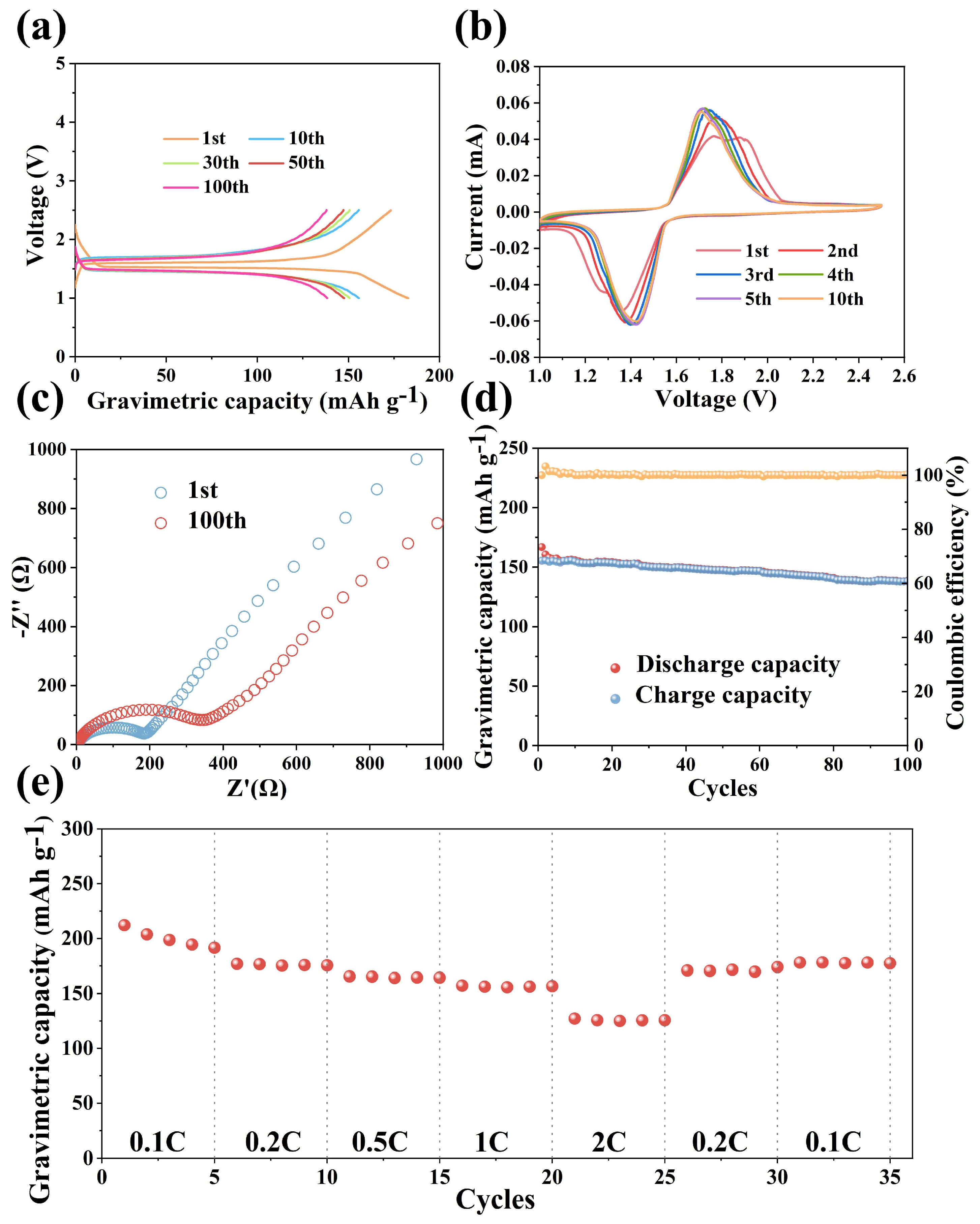

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, X.-L.; Chen, W.-Y.; Zhang, T.; Zou, J.; Chen, Z.-G. Fiber-based thermoelectrics for solid, portable, and wearable electronics. Energy Environ. Sci. 2021, 14, 729–764. [Google Scholar] [CrossRef]

- Tu, J.; Torrente-Rodríguez, R.M.; Wang, M.; Gao, W. The era of digital health: A review of portable and wearable affinity biosensors. Adv. Funct. Mater. 2020, 30, 1906713. [Google Scholar] [CrossRef]

- Rahman, M.T.; Rana, S.S.; Salauddin, M.; Maharjan, P.; Bhatta, T.; Park, J.Y. Biomechanical energy-driven hybridized generator as a universal portable power source for smart/wearable electronics. Adv. Energy Mater. 2020, 10, 1903663. [Google Scholar] [CrossRef]

- Chen, X. Making electrodes stretchable. Small Methods 2017, 1, 1600029. [Google Scholar] [CrossRef]

- Lv, Z.; Li, W.; Yang, L.; Loh, X.J.; Chen, X. Custom-made electrochemical energy storage devices. ACS Energy Lett. 2019, 4, 606–614. [Google Scholar] [CrossRef]

- Song, W.-J.; Lee, S.; Song, G.; Park, S. Stretchable aqueous batteries: Progress and prospects. ACS Energy Lett. 2019, 4, 177–186. [Google Scholar] [CrossRef]

- Song, Z.; Ma, T.; Tang, R.; Cheng, Q.; Wang, X.; Krishnaraju, D.; Panat, R.; Chan, C.K.; Yu, H.; Jiang, H. Origami lithium-ion batteries. Nat. Commun. 2014, 5, 3140. [Google Scholar] [CrossRef]

- Bao, Y.; Zhang, X.; Zhang, X.; Yang, L.; Zhang, X.; Chen, H.; Yang, M.; Fang, D. Free-standing and flexible LiMnTiO4/carbon nanotube cathodes for high performance lithium ion batteries. J. Power Sources 2016, 321, 120–125. [Google Scholar] [CrossRef]

- Fu, K.K.; Cheng, J.; Li, T.; Hu, L. Flexible batteries: From mechanics to devices. ACS Energy Lett. 2016, 1, 1065–1079. [Google Scholar] [CrossRef]

- Bao, Y.; Hong, G.; Chen, Y.; Chen, J.; Chen, H.; Song, W.-L.; Fang, D. Customized kirigami electrodes for flexible and deformable lithium-ion batteries. ACS Appl. Mater. Interfaces 2020, 12, 780–788. [Google Scholar] [CrossRef]

- Li, J.; Zhao, J.; Rogers, J.A. Materials and designs for power supply systems in skin-interfaced electronics. Acc. Chem. Res. 2019, 52, 53–62. [Google Scholar] [CrossRef] [PubMed]

- Armand, M.; Tarascon, J.-M. Building better batteries. Nature 2008, 451, 652–657. [Google Scholar] [CrossRef] [PubMed]

- Liao, M.; Wang, C.; Hong, Y.; Zhang, Y.; Cheng, X.; Sun, H.; Huang, X.; Ye, L.; Wu, J.; Shi, X.; et al. Industrial scale production of fibre batteries by a solution-extrusion method. Nat. Nanotechnol. 2022, 17, 372–377. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Lou, Z.; Jiang, K.; Shen, G. Device configurations and future prospects of flexible/stretchable lithium-ion batteries. Adv. Funct. Mater. 2018, 28, 1805596. [Google Scholar] [CrossRef]

- Mackanic, D.G.; Kao, M.; Bao, Z. Enabling deformable and stretchable batteries. Adv. Energy Mater. 2020, 10, 2001424. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, Y.; Zhang, J.; Sun, X.; Peng, H. Energy harvesting and storage in 1D devices. Nat. Rev. Mater. 2017, 2, 17023. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, F.; Yu, M.; Zhuang, X.; Feng, X. Two-dimensional materials for miniaturized energy storage devices: From individual devices to smart integrated systems. Chem. Soc. Rev. 2018, 47, 7426–7451. [Google Scholar] [CrossRef]

- Ren, J.; Bai, W.; Guan, G.; Zhang, Y.; Peng, H. Flexible and weaveable capacitor wire based on a carbon nanocomposite fiber. Adv. Mater. 2013, 25, 5965–5970. [Google Scholar] [CrossRef]

- Kwon, Y.H.; Woo, S.-W.; Jung, H.-R.; Yu, H.K.; Kim, K.; Oh, B.H.; Ahn, S.; Lee, S.-Y.; Song, S.-W.; Cho, J.; et al. Cable-type flexible lithium ion battery based on hollow multi-helix electrodes. Adv. Mater. 2012, 24, 5192–5197. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, W.; Ren, J.; Weng, W.; Lin, H.; Zhang, Z.; Peng, H. Super-stretchy lithium-ion battery based on carbon nanotube fiber. J. Mater. Chem. A 2014, 2, 11054–11059. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, Y.; Zhang, Y.; Fan, W.; Liu, T. Three-dimensional nanoporous graphene-carbon nanotube hybrid frameworks for confinement of SnS2 nanosheets: Flexible and binder-free papers with highly reversible lithium storage. ACS Appl. Mater. Interfaces 2015, 7, 27823–27830. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Jin, J.; Fan, Z.; Li, C.; Shi, Z.; Sun, J.; Liu, Z. 3D printing of a V8C7–VO2 bifunctional scaffold as an effective polysulfide immobilizer and lithium stabilizer for Li–S batteries. Adv. Mater. 2020, 32, 2005967. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Ahn, D.B.; Kim, J.; Cha, E.; Bae, B.-S.; Lee, S.-Y.; Park, J.-U. Printing of wirelessly rechargeable solid-state supercapacitors for soft, smart contact lenses with continuous operations. Sci. Adv. 2019, 5, eaay0764. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Liu, X.; Yan, J.; Guan, C.; Wang, J. Electrospun nanofibers for new generation flexible energy storage. Energy Environ. Mater. 2021, 4, 502–521. [Google Scholar] [CrossRef]

- Selvaraj, A.R.; Raja, I.S.; Chinnadurai, D.; Rajendiran, R.; Cho, I.; Han, D.-W.; Prabakar, K. Electrospun one dimensional (1D) pseudocapacitive nanorods embedded carbon nanofiber as positrode and graphene wrapped carbon nanofiber as negatrode for enhanced electrochemical energy storage. J. Energy Storage 2022, 46, 103731. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, K.; Qi, Y.; Liu, Z. Chemical vapor deposition method for graphene fiber materials. Acta Phys.-Chim. Sin. 2020, 38, 2006046. [Google Scholar] [CrossRef]

- Sun, C.; Chen, S.; Li, Z. Controllable synthesis of Fe2O3-carbon fiber composites via a facile sol-gel route as anode materials for lithium ion batteries. Appl. Surf. Sci. 2018, 427, 476–484. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, C.; Xie, H.; Gao, T.; Yao, Y.; Pastel, G.; Han, X.; Li, Y.; Zhao, J.; Fu, K.; et al. 3D-printed all-fiber li-ion battery toward wearable energy storage. Adv. Funct. Mater. 2017, 27, 1703140. [Google Scholar] [CrossRef]

- Praveen, S.; Sim, G.S.; Ho, C.W.; Lee, C.W. 3D-printed twisted yarn-type Li-ion battery towards smart fabrics. Energy Storage Mater. 2021, 41, 748–757. [Google Scholar] [CrossRef]

- De Castro Motta, J.; Qaderi, S.; Farina, I.; Singh, N.; Amendola, A.; Fraternali, F. Experimental characterization and mechanical modeling of additively manufactured TPU components of innovative seismic isolators. Acta Mech. 2022, 1–12. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, T.; Qian, F.; Chen, W.; Chandrasekaran, S.; Yao, B.; Song, Y.; Duoss, E.B.; Kuntz, J.D.; Spadaccini, C.M.; et al. 3D printed functional nanomaterials for electrochemical energy storage. Nano Today 2017, 15, 107–120. [Google Scholar] [CrossRef]

- Zhang, F.; Wei, M.; Viswanathan, V.V.; Swart, B.; Shao, Y.; Wu, G.; Zhou, C. 3D printing technologies for electrochemical energy storage. Nano Energy 2017, 40, 418–431. [Google Scholar] [CrossRef]

- Sousa, R.E.; Costa, C.M.; Lanceros-Méndez, S. Advances and future challenges in printed batteries. ChemSusChem 2015, 8, 3539–3555. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Jin, J.; Yuan, S.; Chua, C.K.; Tor, S.B.; Zhou, K. Emerging 3D-printed electrochemical energy storage devices: A critical review. Adv. Energy Mater. 2017, 7, 1700127. [Google Scholar] [CrossRef]

- Pei, M.; Shi, H.; Yao, F.; Liang, S.; Xu, Z.; Pei, X.; Wang, S.; Hu, Y. 3D printing of advanced lithium batteries: A designing strategy of electrode/electrolyte architectures. J. Mater. Chem. A 2021, 9, 25237–25257. [Google Scholar] [CrossRef]

- Truby, R.L.; Lewis, J.A. Printing soft matter in three dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef]

- Wang, L.-C.; Song, W.-L.; Fang, D. Twistable Origami and Kirigami: From structure-guided smartness to mechanical energy storage. ACS Appl. Mater. Interfaces 2019, 11, 3450–3458. [Google Scholar] [CrossRef]

- Rocha, V.G.; Saiz, E.; Tirichenko, I.S.; García-Tuñón, E. Direct ink writing advances in multi-material structures for a sustainable future. J. Mater. Chem. A 2020, 8, 15646–15657. [Google Scholar] [CrossRef]

- Mohammadpourfazeli, S.; Arash, S.; Ansari, A.; Yang, S.; Mallick, K.; Bagherzadeh, R. Future prospects and recent developments of polyvinylidene fluoride (PVDF) piezoelectric polymer; fabrication methods, structure, and electro-mechanical properties. RSC Adv. 2023, 13, 370–387. [Google Scholar] [CrossRef]

- Houis, S.; Engelhardt, E.M.; Wurm, F.; Gries, T. Application of polyvinylidene fluoride (PVDF) as a biomaterial in medical textiles. Med. Healthc. Text. 2010, 342–352. [Google Scholar] [CrossRef]

- Liao, C.; Li, Y.; Tjong, S.C. Graphene nanomaterials: Synthesis, biocompatibility, and cytotoxicity. Int. J. Mol. Sci. 2018, 19, 3564. [Google Scholar] [CrossRef] [PubMed]

- Trück, J.; Wang, P.; Buch, E.; Groos, J.; Niesen, S.; Buchmeiser, M.R. Communication—Lithium titanate as mg-ion insertion anode for mg-ion sulfur batteries based on sulfurated poly(acrylonitrile) composite. J. Electrochem. Soc. 2022, 169, 010505. [Google Scholar] [CrossRef]

- Carvalho, D.V.; Loeffler, N.; Kim, G.-T.; Marinaro, M.; Wohlfahrt-Mehrens, M.; Passerini, S. Study of water-based lithium titanate electrode processing: The role of pH and binder molecular structure. Polymers 2016, 8, 276. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Tao, R.; Li, F.; Lu, X.; Liu, F.; Xu, J.; Kong, D.; Zhang, C.; Tan, X.; Ma, S.; Shi, W.; et al. High-conductivity–dispersibility graphene made by catalytic exfoliation of graphite for lithium-ion battery. Adv. Funct. Mater. 2021, 31, 2007630. [Google Scholar] [CrossRef]

- Wang, P.; Ye, Y.; Liang, D.; Sun, H.; Liu, J.; Tian, Z.; Liang, C. Layered mesoporous Mg(OH)2/GO nanosheet composite for efficient removal of water contaminants. RSC Adv. 2016, 6, 26977–26983. [Google Scholar] [CrossRef]

- Zhang, D.; Chi, B.; Li, B.; Gao, Z.; Du, Y.; Guo, J.; Wei, J. Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth. Met. 2016, 217, 79–86. [Google Scholar] [CrossRef]

- Gómez-Navarro, C.; Weitz, R.T.; Bittner, A.M.; Scolari, M.; Mews, A.; Burghard, M.; Kern, K. Electronic transport properties of individual chemically reduced graphene oxide sheets. Nano Lett. 2007, 7, 3499–3503. [Google Scholar] [CrossRef]

- De Silva, K.K.H.; Huang, H.-H.; Yoshimura, M. Progress of reduction of graphene oxide by ascorbic acid. Appl. Surf. Sci. 2018, 447, 338–346. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Ivanova, R.; Tabakova, S.; Ivanov, E.; Kotsilkova, R.; Cimmino, S.; Di Maio, R.; Silvestre, C. Rheological and electrical behaviour of nanocarbon/poly(lactic) acid for 3D printing applications. Compos. Part B Eng. 2019, 167, 467–476. [Google Scholar] [CrossRef]

- Ponnamma, D.; Sadasivuni, K.K.; Cabibihan, J.-J.; Yoon, W.J.; Kumar, B. Reduced graphene oxide filled poly(dimethyl siloxane) based transparent stretchable, and touch-responsive sensors. Appl. Phys. Lett. 2016, 108, 171906. [Google Scholar] [CrossRef]

- Mo, R.; Lei, Z.; Sun, K.; Rooney, D. Facile Synthesis of anataseTiO2 quantum-dot/graphene-nanosheet composites with enhanced electrochemical performance for lithium-ion batteries. Adv. Mater. 2014, 26, 2084–2088. [Google Scholar] [CrossRef]

- Mo, R.; Li, F.; Tan, X.; Xu, P.; Tao, R.; Shen, G.; Lu, X.; Liu, F.; Shen, L.; Xu, B.; et al. High-quality mesoporous graphene particles as high-energy and fast-charging anodes for lithium-ion batteries. Nat. Commun. 2019, 10, 1474. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Qaderi, S.; Ebrahimi, F. Vibration analysis of polymer composite plates reinforced with graphene platelets resting on two-parameter viscoelastic foundation. Eng. Comput. 2022, 38, 419–435. [Google Scholar] [CrossRef]

- Seyssiecq, I.; Ferrasse, J.-H.; Roche, N. State-of-the-art: Rheological characterisation of wastewater treatment sludge. Biochem. Eng. J. 2003, 16, 41–56. [Google Scholar] [CrossRef]

- Lewis, J.A. Direct ink writing of 3D functional materials. Adv. Funct. Mater. 2006, 16, 2193–2204. [Google Scholar] [CrossRef]

- Clausen, A.; Wang, F.; Jensen, J.S.; Sigmund, O.; Lewis, J.A. Topology optimized architectures with programmable poisson’s ratio over large deformations. Adv. Mater. 2015, 27, 5523–5527. [Google Scholar] [CrossRef]

- Fathy, M.; Gomaa, A.; Taher, F.A.; El-Fass, M.M.; Kashyout, A.E.-H.B. Optimizing the preparation parameters of GO and rGO for large-scale production. J. Mater. Sci. 2016, 51, 5664–5675. [Google Scholar] [CrossRef]

- Hao, Z.; Zhang, Q.; Xu, X.; Zhao, Q.; Wu, C.; Liu, J.; Wang, H. Nanochannels regulating ionic transport for boosting electrochemical energy storage and conversion: A review. Nanoscale 2020, 12, 15923–15943. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Duan, X.; Guo, W.; Li, D.; Zhang, H.; Zheng, W. Electrochemical performances investigation of NiS/rGO composite as electrode material for supercapacitors. Nano Energy 2014, 5, 74–81. [Google Scholar] [CrossRef]

- Zhang, W.; Tu, Z.; Qian, J.; Choudhury, S.; Archer, L.A.; Lu, Y. Design Principles of functional polymer separators for high-energy, metal-based batteries. Small 2018, 14, 1703001. [Google Scholar] [CrossRef]

- Wu, Z.-S.; Ren, W.; Xu, L.; Li, F.; Cheng, H.-M. Doped graphene sheets as anode materials with superhigh rate and large capacity for lithium ion batteries. ACS Nano 2011, 5, 5463–5471. [Google Scholar] [CrossRef]

- Cheng, Q.; Song, Z.; Ma, T.; Smith, B.B.; Tang, R.; Yu, H.; Jiang, H.; Chan, C.K. Folding paper-based lithium-ion batteries for higher areal energy densities. Nano Lett. 2013, 13, 4969–4974. [Google Scholar] [CrossRef]

- Tan, X.; Mo, R.; Xu, J.; Li, X.; Yin, Q.; Shen, L.; Lu, Y. High performance sodium ion anodes based on Sn4P3 encapsulated within amphiphilic graphene tubes. Adv. Energy Mater. 2022, 12, 2102345. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Wang, R.; Fang, B.; Liang, H.; Nie, B.; Wang, R.; Xu, B.; Feng, S.; Li, R.; Li, S.; et al. Boosting the Lithium Storage Properties of a Flexible Li4Ti5O12/Graphene Fiber Anode via a 3D Printing Assembly Strategy. Batteries 2023, 9, 493. https://doi.org/10.3390/batteries9100493

Zhao C, Wang R, Fang B, Liang H, Nie B, Wang R, Xu B, Feng S, Li R, Li S, et al. Boosting the Lithium Storage Properties of a Flexible Li4Ti5O12/Graphene Fiber Anode via a 3D Printing Assembly Strategy. Batteries. 2023; 9(10):493. https://doi.org/10.3390/batteries9100493

Chicago/Turabian StyleZhao, Chenpeng, Rui Wang, Biao Fang, Han Liang, Biyuan Nie, Ruyi Wang, Biao Xu, Songyang Feng, Ruqing Li, Shuaifei Li, and et al. 2023. "Boosting the Lithium Storage Properties of a Flexible Li4Ti5O12/Graphene Fiber Anode via a 3D Printing Assembly Strategy" Batteries 9, no. 10: 493. https://doi.org/10.3390/batteries9100493

APA StyleZhao, C., Wang, R., Fang, B., Liang, H., Nie, B., Wang, R., Xu, B., Feng, S., Li, R., Li, S., Xiong, Y., Shao, Y., & Mo, R. (2023). Boosting the Lithium Storage Properties of a Flexible Li4Ti5O12/Graphene Fiber Anode via a 3D Printing Assembly Strategy. Batteries, 9(10), 493. https://doi.org/10.3390/batteries9100493