State-of-Health Prediction of Lithium-Ion Batteries Based on CNN-BiLSTM-AM

Abstract

1. Introduction

2. Preliminaries

2.1. CNN

2.2. BiLSTM

2.3. AM

3. Dataset Description and Data Preprocessing

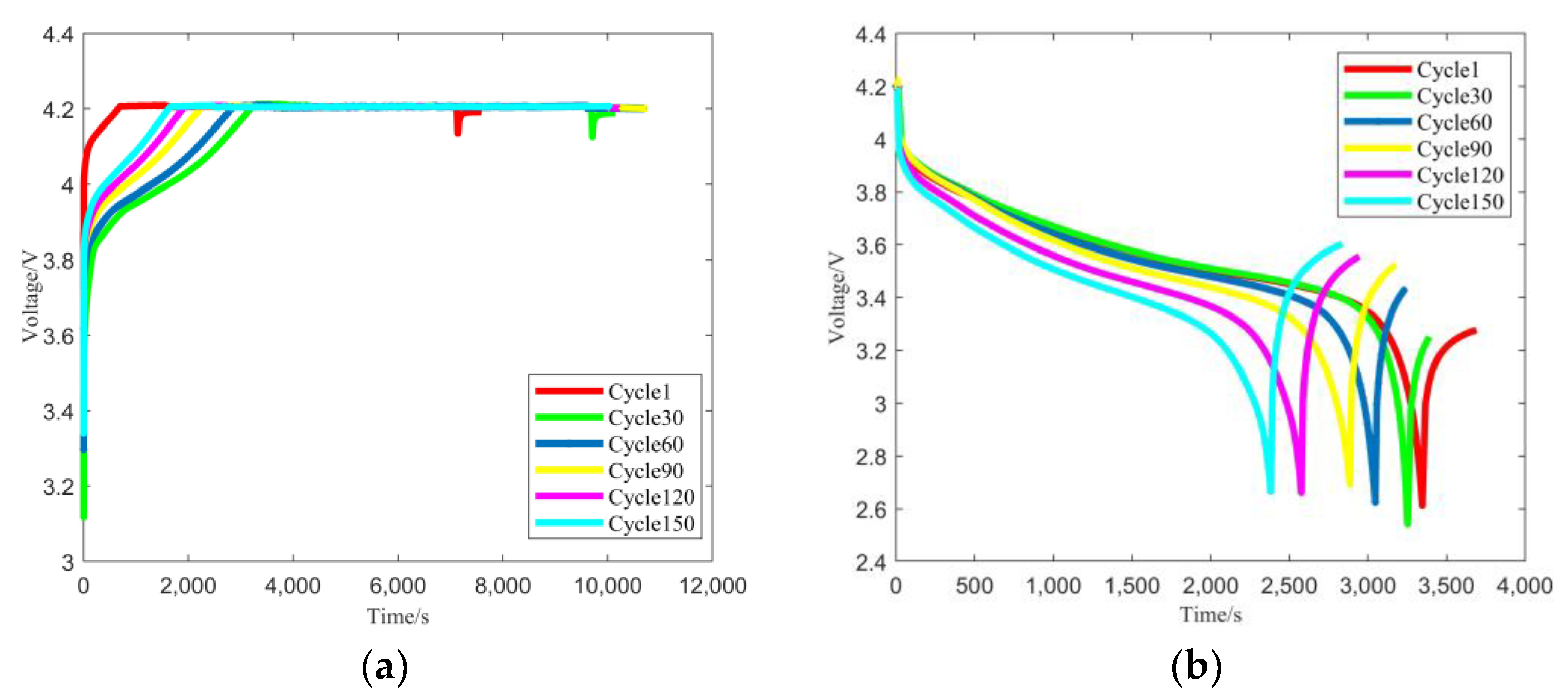

3.1. Dataset Description

3.2. Data Preprocessing

4. Methods

4.1. CNN-BiLSTM-AM Model

- (1)

- Input layer: Firstly, HIs that can characterize the capacity during the charging and discharging process of the lithium-ion battery dataset are extracted, and those that are highly correlated with the capacity are selected as indirect HI; the indirect HI is preprocessed with the data, the processed dataset is divided, and the HI of the training set is used as the input of CNN.

- (2)

- CNN layer: Including innovative concepts such as shared weight and local perceptual fields means CNN has unique benefits in processing battery datasets. In this paper, we use the convolution and pooling operations from the battery time series data to extract features.

- (3)

- BiLSTM layer: The BiLSTM depth model is built, which is made up of forwarding and inverse LSTM. In comparison with the LSTM, the BiLSTM can extract time series in both directions and better collect the forward and reverse dependencies of the data coming from the CNN.

- (4)

- AM layer: AM has been introduced into the hybrid model with the objective of enhancing the accuracy of the prediction model. AM assigns that each feature has a weight, further emphasizing the correlation between the data, which raises the accuracy of the prediction model.

- (5)

- Output layer: The weighted summed prediction results from the AM layer are output and then the testing set is fed into the trained model for prediction to generate SOH prediction results.

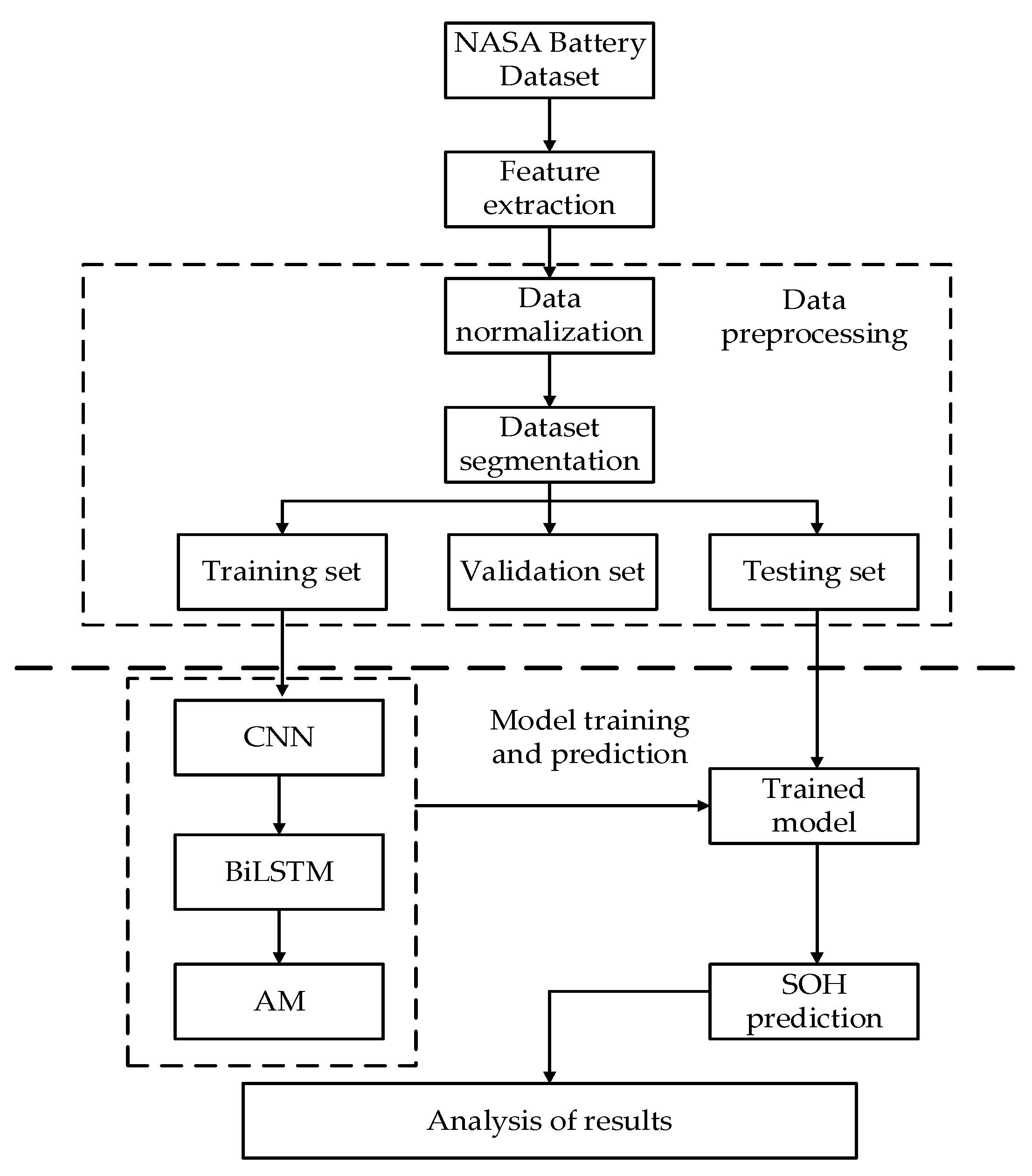

4.2. Prediction Procedure Based on CNN-BiLSTM-AM Model

- Step 1. Feature Extraction: Initially, indirect HIs that reflect battery capacity degeneration are extracted by considering the charge and discharge voltage, current, and temperature curves of lithium-ion batteries, and those that are highly correlated with capacity are selected as indirect HIs.

- Step 2. Data Preprocessing: The extracted HI is normalized as well as followed by segmentation of the dataset.

- Step 3. Build the model and Train: The convolution and pooling operations of the CNN layer are used to extract features, and the bidirectional dependencies of the data coming from CNN are collected by the BiLSTM depth model, followed by the time series data related to SOH weighted by AM, so as to build the CNN-BiLSTM-AM model, and the hyperparameters of the model are determined using the grid search method during the model training process to derive the optimal model.

- Step 4. Model Prediction: The testing set is fed into the trained model for prediction, resulting in SOH prediction results.

- Step 5. Analysis of Results: Lastly, to further verify the validity of the proposed model, three comparison models of CNN, BiLSTM, and CNN-BiLSTM are designed, and the SOH prediction model is quantitatively evaluated using error evaluation metrics.

5. Experimental Settings

5.1. Experimental Equipment and Model Parameter Settings

5.2. Performance Evaluation Indicators

6. Experiment and Result Analysis of SOH Prediction

6.1. HI Extraction

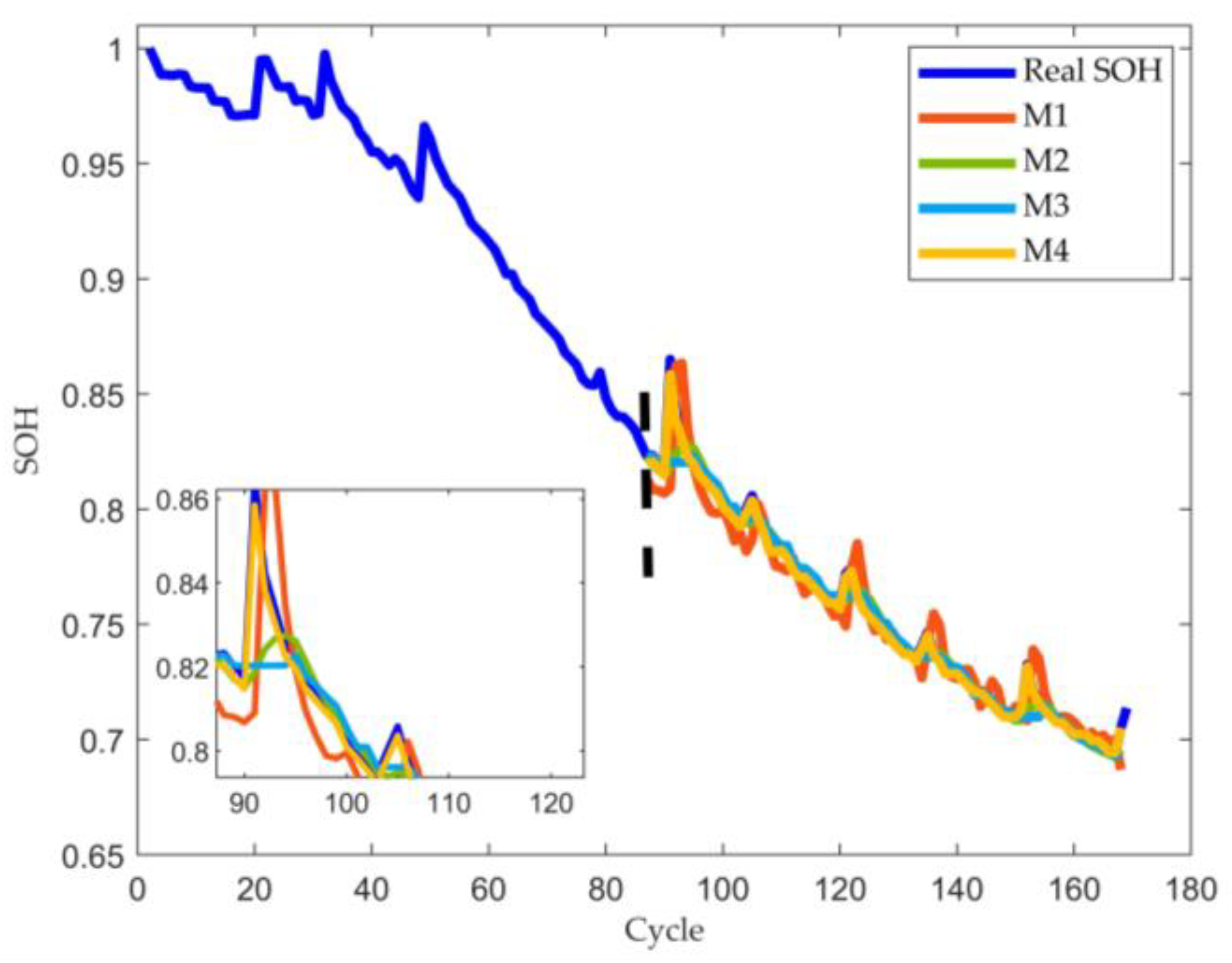

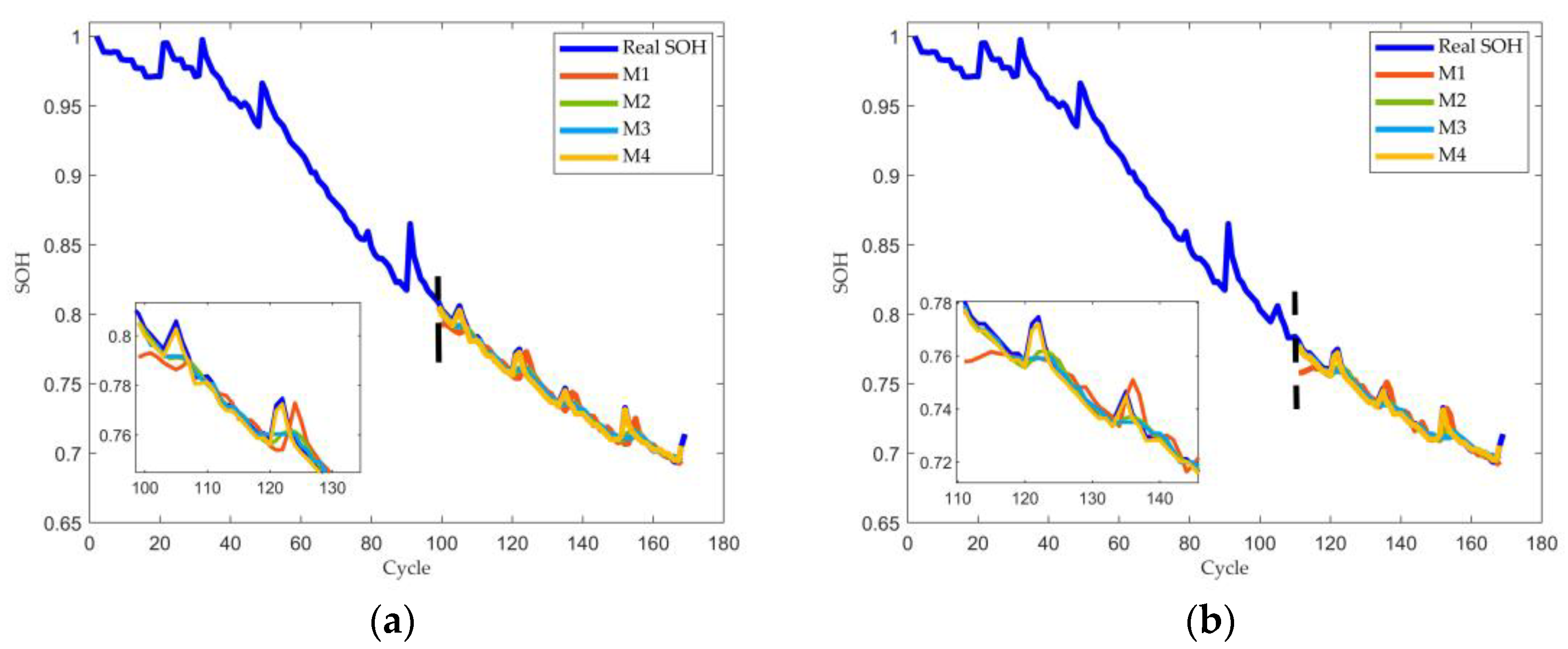

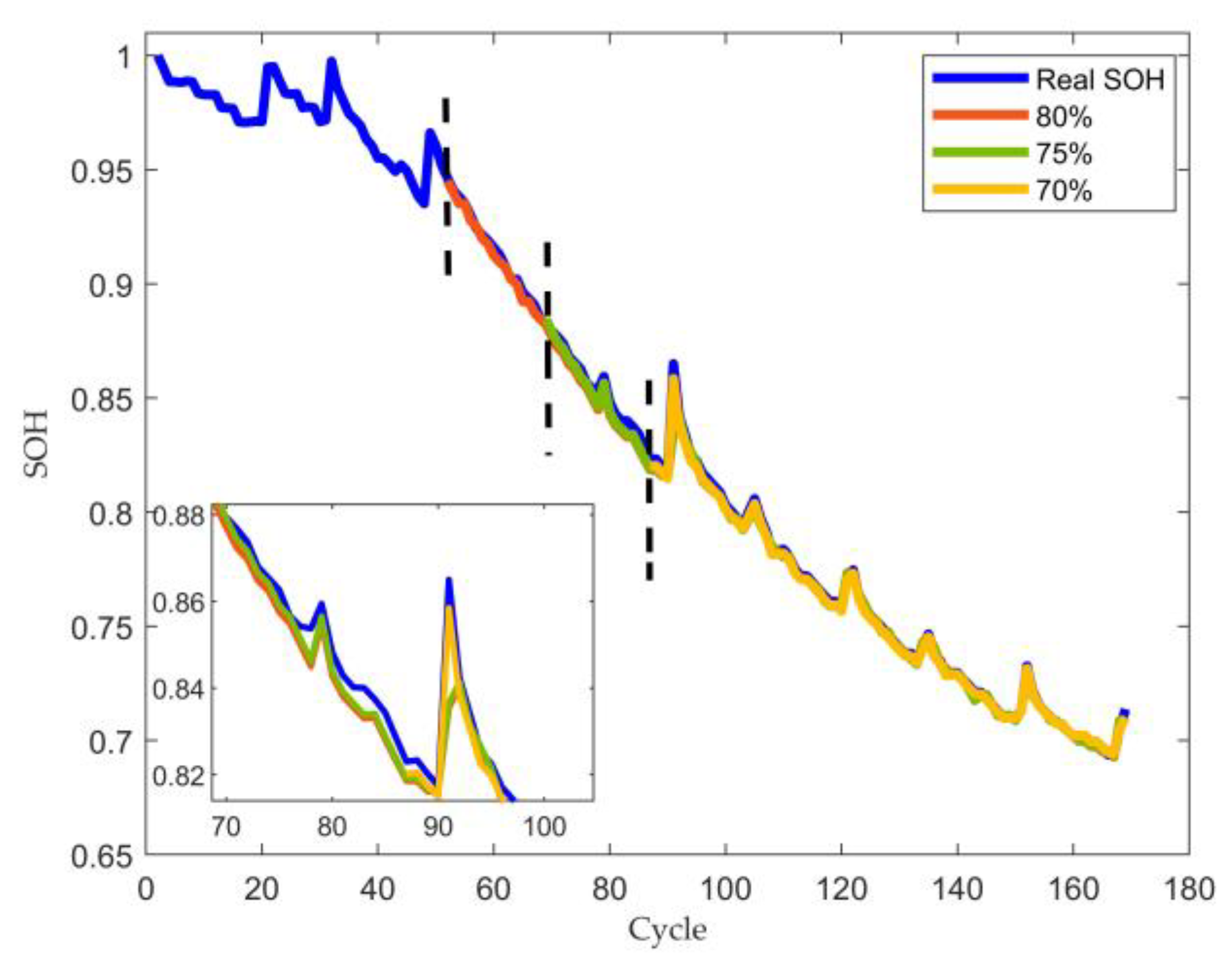

6.2. Results and Analysis of SOH Prediction

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajaeifar, M.A.; Ghadimi, P.; Raugei, M.; Wu, Y.; Heidrich, O. Challenges and recent developments in supply and value chains of electric vehicle batteries: A sustainability perspective. Resour. Conserv. Recycl. 2022, 180, 106144. [Google Scholar] [CrossRef]

- Xiong, R.; Li, L.; Tian, J. Towards a smarter battery management system: A critical review on battery state of health monitoring methods. J. Power Sources 2018, 405, 18–29. [Google Scholar] [CrossRef]

- Shen, M.; Gae, Q. A review on battery management system from the modeling efforts to its multiapplication and integration. Int. J. Energy Res. 2019, 43, 5042–5075. [Google Scholar] [CrossRef]

- Shen, P.; Ouyang, M.; Lu, L.; Li, J.; Feng, X. The co-estimation of state of charge, state of health, and state of function for lithium-ion batteries in electric vehicles. IEEE Trans. Veh. Technol. 2017, 67, 92–103. [Google Scholar] [CrossRef]

- Lai, X.; Gao, W. A comparative study of global optimization methods for parameter identification of different equivalent circuit models for Li-ion batteries. Electrochim. Acta 2019, 295, 1057–1066. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, G.; Li, X.; Chen, Z. A fractional-order model-based state estimation approach for lithium-ion battery and ultra-capacitor hybrid power source system considering load trajectory. J. Power Sources 2020, 449, 227543. [Google Scholar] [CrossRef]

- Cheng, G.; Wang, X.; He, Y. Remaining useful life and state of health prediction for lithium batteries based on empirical mode decomposition and a long and short memory neural network. Energy 2021, 232, 121022. [Google Scholar] [CrossRef]

- Rechkemmer, S.; Zang, X. Empirical Li-ion aging model derived from single particle model. J. Energy Storage 2019, 21, 773–786. [Google Scholar] [CrossRef]

- Li, K.; Wang, Y.; Chen, Z. A comparative study of battery state-of-health estimation based on empirical mode decomposition and neural network. J. Energy Storage 2022, 54, 105333. [Google Scholar] [CrossRef]

- Geng, Z.; Wang, S.; Lacey, M.J.; Brandell, D.; Thiringer, T. Bridging physics-based and equivalent circuit models for lithium-ion batteries. Electrochim. Acta 2021, 372, 137829. [Google Scholar] [CrossRef]

- Xu, N.; Xie, Y.; Liu, Q.; Yue, F.; Zhao, D. A Data-Driven Approach to State of Health Estimation and Prediction for a Lithium-Ion Battery Pack of Electric Buses Based on Real-World Data. Sensors 2022, 22, 5762. [Google Scholar] [CrossRef] [PubMed]

- Ng, M.F.; Zhao, J.; Yan, Q.; Conduit, G.J.; Seh, Z.W. Predicting the state of charge and health of batteries using data-driven machine learning. Nat. Mach. Intell. 2020, 2, 161–170. [Google Scholar] [CrossRef]

- Alipour, M.; Tavallaey, S. Improved Battery Cycle Life Prediction Using a Hybrid Data-Driven Model Incorporating Linear Support Vector Regression and Gaussian. ChemPhysChem 2022, 23, e202100829. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, Z. Prognostic health condition for lithium battery using the partial incremental capacity and Gaussian process regression. J. Power Sources 2019, 421, 56–67. [Google Scholar] [CrossRef]

- Li, Y.; Abdel-Monem, M. A quick on-line state of health estimation method for Li-ion battery with incremental capacity curves processed by Gaussian filter. J. Power Sources 2018, 373, 40–53. [Google Scholar] [CrossRef]

- Ströbel, M.; Pross-Brakhage, J.; Kopp, M.; Birke, K.P. Impedance Based Temperature Estimation of Lithium Ion Cells Using Artificial Neural Networks. Batteries 2021, 7, 85. [Google Scholar] [CrossRef]

- Wu, B.; Han, S.; Shin, K.G.; Lu, W. Application of artificial neural networks in design of lithium-ion batteries. J. Power Sources 2018, 395, 128–136. [Google Scholar] [CrossRef]

- Dai, H.; Zhao, G.; Lin, M.; Wu, J.; Zheng, G. A novel estimation method for the state of health of lithium-ion battery using prior knowledge-based neural network and Markov chain. IEEE Trans. Ind. Electron. 2019, 66, 7706–7716. [Google Scholar] [CrossRef]

- Yang, Y.; Wen, J.; Shi, Y.; Zeng, J. State of Health Prediction of Lithium-Ion Batteries Based on the Discharge Voltage and Temperature. Electronics 2021, 10, 1497. [Google Scholar] [CrossRef]

- Feng, X.; Weng, C.; He, X.; Han, X.; Lu, L.; Ren, D.; Ouyang, M. Online state-of-health estimation for li-ion battery using partial charging segment based on support vector machine. IEEE Trans. Veh. Technol. 2019, 68, 8583–8592. [Google Scholar] [CrossRef]

- Jia, J.; Liang, J.; Shi, Y.; Wen, J.; Pang, X.; Zeng, J. SOH and RUL Prediction of Lithium-Ion Batteries Based on Gaussian Process Regression with Indirect Health Indicators. Energies 2020, 13, 375. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, X.; Pan, R.; Wang, Y.; Chen, Z. A novel Gaussian process regression model for state-of-health estimation of lithium-ion battery using charging curve. J. Power Sources 2018, 384, 387–395. [Google Scholar] [CrossRef]

- Kheirkhah-Rad, E.; Moeini-Aghtaie, M. A novel data-driven SOH prediction model for lithium-ion batteries. In Proceedings of the 2021 31st Australasian Universities Power Engineering Conference (AUPEC), Perth, Australia, 26–30 September 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Tan, Y.; Zhao, G. Transfer Learning With Long Short-Term Memory Network for State-of-Health Prediction of Lithium-Ion Batteries. IEEE Trans. Ind. Electron. 2020, 67, 8723–8731. [Google Scholar] [CrossRef]

- Khumprom, P.; Yodo, N. Data-driven Prognostic Model of Li-ion Battery with Deep Learning Algorithm. In Proceedings of the 2019 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 28–31 January 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Chaoui, H.; Ibe-Ekeocha, C.C. State of Charge and State of Health Estimation for Lithium Batteries Using Recurrent Neural Networks. IEEE Trans. Veh. Technol. 2017, 66, 8773–8783. [Google Scholar] [CrossRef]

- Chen, Z.; Song, X.; Xiao, R.; Shen, J.; Xia, X. State of Health Estimation for Lithium-Ion Battery Based on Long Short Term Memory Networks. In Proceedings of the 2018 Joint International Conference on Energy, Ecology and Environment (ICEEE) and International Conference on Electric and Intelligent Vehicles (ICEIV), Melbourne, Australia, 21–25 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Bezha, M.; Nanahara, T.; Nagaoka, N. Development of Fast SoH Estimation of Li-Ion Battery Pack/Modules Using Multi Series-Parallel based ANN Structure. In Proceedings of the 2021 IEEE 12th Energy Conversion Congress & Exposition-Asia (ECCE-Asia), Singapore, 24–27 May 2021; pp. 1719–1724. [Google Scholar] [CrossRef]

- Qu, J.T.; Liu, F.; Ma, Y.X.; Fan, J.M. A Neural-Network-Based Method for RUL Prediction and SOH Monitoring of Lithium-Ion Battery. IEEE Access 2019, 7, 87178–87191. [Google Scholar] [CrossRef]

- Cai, W.; Wang, Y.; Ma, J.; Jin, Q. CAN: Effective cross features by global attention mechanism and neural network for ad click prediction. Tsinghua Sci. Technol. 2022, 27, 186–195. [Google Scholar] [CrossRef]

- He, M.; Xue, X.; Zhang., X.; Zhou., C. A Bike-sharing Demand Predicting Model with Integrating Temporal Convolutional Network and Self-Attention. In Proceedings of the International Conference on Electronic Information Engineering and Computer Science (EIECS), Changchun, China, 23–26 September 2021; pp. 278–281. [Google Scholar] [CrossRef]

- Feng, A.; Zhang, X.; Song, X. Unrestricted Attention May Not Be All You Need–Masked Attention Mechanism Focuses Better on Relevant Parts in Aspect-Based Sentiment Analysis. IEEE Access 2022, 10, 8518–8528. [Google Scholar] [CrossRef]

- Liu, D.; Liu, J.; Luo, Y.; He, Q.; Lei, D. MGATMDA: Predicting microbe-disease associations via multi-component graph attention network. In IEEE/ACM Transactions on Computational Biology and Bioinformatics; IEEE: Piscataway, NJ, USA, 2021; p. 29. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, C.; Guo, H.; Wang, J.; Zhao, X.; Lu, H. Attention CoupleNet: Fully Convolutional Attention Coupling Network for Object Detection. IEEE Trans. Image Process. 2018, 28, 113–126. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K. Battery Data Set. Available online: http://ti.arc.nasa.gov/tech/dash/pcoe/prognostic-data-repository/ (accessed on 18 February 2020).

- El-Dalahmeh, M.; Al-Greer, M.; El-Dalahmeh, M.; Short, M. Time-Frequency Image Analysis and Transfer Learning for Capacity Prediction of Lithium-Ion Batteries. Energies 2020, 13, 5447. [Google Scholar] [CrossRef]

| Battery | Number of Charges | Number of Discharges | Number of Impedances | Actual Life Expectancy |

|---|---|---|---|---|

| B0005 | 170 | 168 | 278 | 124 |

| B0006 | 170 | 168 | 278 | 108 |

| B0018 | 134 | 132 | 53 | 96 |

| Dataset | Training Set | Validation Set | Testing Set |

|---|---|---|---|

| B0005 | (70%) 50 | 37 | (30%) 37 |

| (80%) 74 | 25 | (20%) 25 | |

| (90%) 99 | 12 | (10%) 13 | |

| B0006 | (70%) 43 | 32 | (30%) 33 |

| (80%) 65 | 22 | (20%) 21 | |

| (90%) 86 | 11 | (10%) 11 | |

| B0018 | (70%) 38 | 29 | (30%) 29 |

| (80%) 58 | 19 | (20%) 19 | |

| (90%) 77 | 10 | (10%) 9 |

| Parameter | Setting Value |

|---|---|

| Optimizer | Adam |

| Loss function | MSE |

| Activation function | RELU |

| Filter size | 10 |

| Batch size | 16 |

| Epochs | 1000 |

| Dropout rate | 0.200 |

| Learning rate | 0.001 |

| Number of neurons | 160 |

| HI | Pearson |

|---|---|

| TIEDVD | 0.9972 |

| Time at which the discharge voltage reaches its minimum point | 0.9928 |

| Maximum gradient of the voltage curve in the initial stage of the discharge process | 0.8050 |

| Discharge power | 0.9132 |

| Time it takes for the temperature to reach the peak value during the discharge process | 0.9886 |

| Battery | Prediction SP | Model | RMSE | MAE | MAPE (%) |

|---|---|---|---|---|---|

| B0005 | 87 (70%) | M1 | 0.00893 | 0.00565 | 0.738 |

| M2 | 0.00867 | 0.00540 | 0.702 | ||

| M3 | 0.00794 | 0.00531 | 0.692 | ||

| M4 | 0.00737 | 0.00382 | 0.496 | ||

| 99 (80%) | M1 | 0.00863 | 0.00661 | 0.886 | |

| M2 | 0.00620 | 0.00432 | 0.582 | ||

| M3 | 0.00595 | 0.00432 | 0.581 | ||

| M4 | 0.00481 | 0.00316 | 0.425 | ||

| 111 (90%) | M1 | 0.00813 | 0.00633 | 0.825 | |

| M2 | 0.00600 | 0.00409 | 0.558 | ||

| M3 | 0.00598 | 0.00408 | 0.558 | ||

| M4 | 0.00487 | 0.00307 | 0.420 | ||

| B0006 | 75 (70%) | M1 | 0.0151 | 0.0101 | 1.49 |

| M2 | 0.0133 | 0.00838 | 1.24 | ||

| M3 | 0.0133 | 0.00846 | 1.25 | ||

| M4 | 0.0114 | 0.00485 | 0.709 | ||

| 87 (80%) | M1 | 0.0134 | 0.00864 | 1.28 | |

| M2 | 0.0129 | 0.00812 | 1.21 | ||

| M3 | 0.0117 | 0.00779 | 1.15 | ||

| M4 | 0.0105 | 0.00491 | 0.727 | ||

| 97 (90%) | M1 | 0.00914 | 0.00708 | 1.11 | |

| M2 | 0.00845 | 0.00617 | 0.963 | ||

| M3 | 0.00759 | 0.00567 | 0.883 | ||

| M4 | 0.00572 | 0.00361 | 0.561 | ||

| B0018 | 67 (70%) | M1 | 0.0145 | 0.0110 | 1.44 |

| M2 | 0.0139 | 0.00997 | 1.30 | ||

| M3 | 0.0138 | 0.0118 | 1.421 | ||

| M4 | 0.0108 | 0.00612 | 0.797 | ||

| 77 (80%) | M1 | 0.0151 | 0.0119 | 1.56 | |

| M2 | 0.0133 | 0.00981 | 1.29 | ||

| M3 | 0.0141 | 0.0109 | 1.44 | ||

| M4 | 0.0109 | 0.00623 | 0.619 | ||

| 87 (90%) | M1 | 0.0153 | 0.0121 | 1.60 | |

| M2 | 0.0141 | 0.0109 | 1.45 | ||

| M3 | 0.0150 | 0.0121 | 1.60 | ||

| M4 | 0.0112 | 0.00627 | 0.828 |

| EOL | Prediction SP | RMSE | MAE | MAPE (%) |

|---|---|---|---|---|

| 70% | 87 (70%) | 0.00737 | 0.00382 | 0.496 |

| 99 (80%) | 0.00481 | 0.00316 | 0.425 | |

| 111 (90%) | 0.00487 | 0.00307 | 0.420 | |

| 75% | 69 (70%) | 0.00660 | 0.00465 | 0.364 |

| 79 (80%) | 0.00665 | 0.00454 | 0.355 | |

| 89 (90%) | 0.00740 | 0.00383 | 0.499 | |

| 80% | 52 (70%) | 0.00621 | 0.00432 | 0.343 |

| 60 (80%) | 0.00627 | 0.00435 | 0.343 | |

| 67 (90%) | 0.00654 | 0.00457 | 0.357 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Wen, J.; Yang, Y.; Shi, Y.; Zeng, J. State-of-Health Prediction of Lithium-Ion Batteries Based on CNN-BiLSTM-AM. Batteries 2022, 8, 155. https://doi.org/10.3390/batteries8100155

Tian Y, Wen J, Yang Y, Shi Y, Zeng J. State-of-Health Prediction of Lithium-Ion Batteries Based on CNN-BiLSTM-AM. Batteries. 2022; 8(10):155. https://doi.org/10.3390/batteries8100155

Chicago/Turabian StyleTian, Yukai, Jie Wen, Yanru Yang, Yuanhao Shi, and Jianchao Zeng. 2022. "State-of-Health Prediction of Lithium-Ion Batteries Based on CNN-BiLSTM-AM" Batteries 8, no. 10: 155. https://doi.org/10.3390/batteries8100155

APA StyleTian, Y., Wen, J., Yang, Y., Shi, Y., & Zeng, J. (2022). State-of-Health Prediction of Lithium-Ion Batteries Based on CNN-BiLSTM-AM. Batteries, 8(10), 155. https://doi.org/10.3390/batteries8100155