State of Charge Estimation of Power Battery Using Improved Back Propagation Neural Network

Abstract

:1. Introduction

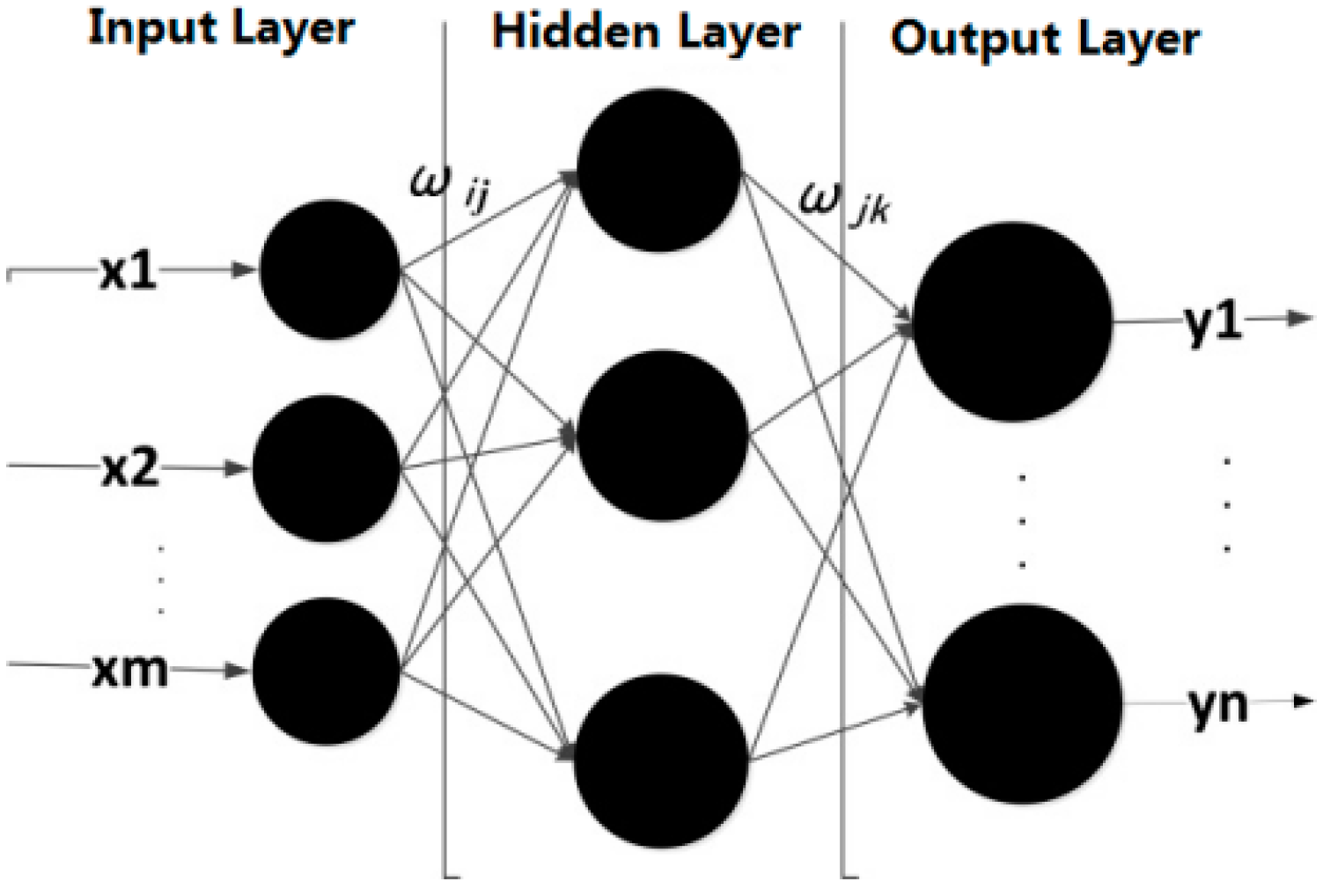

2. Back Propagation Neural Network Principle

3. Improved Back Propagation Neural Network

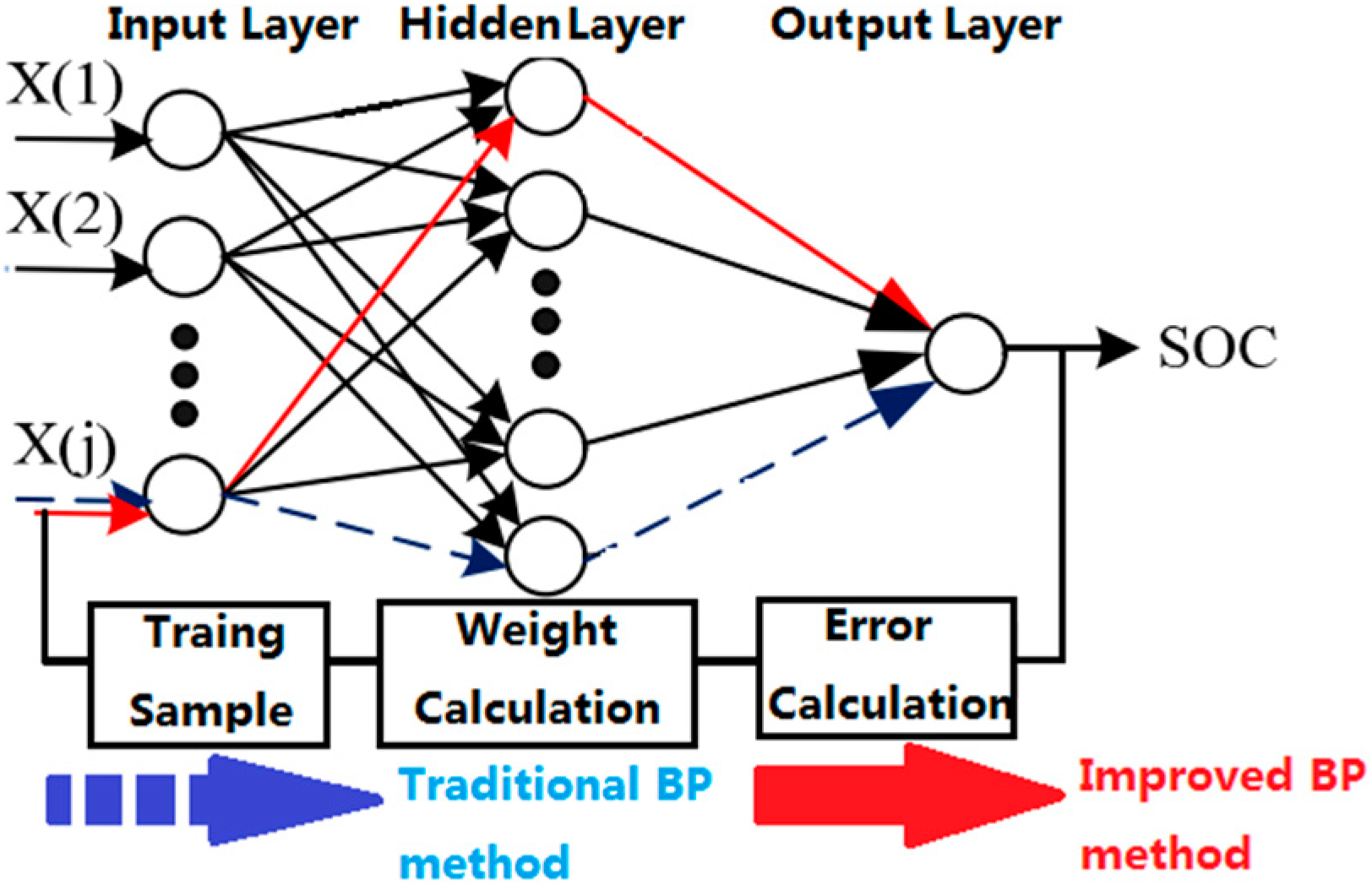

3.1. Improved Back Propagation Neural Network Principle

3.2. Improved Back Propagation Neural Network Modeling

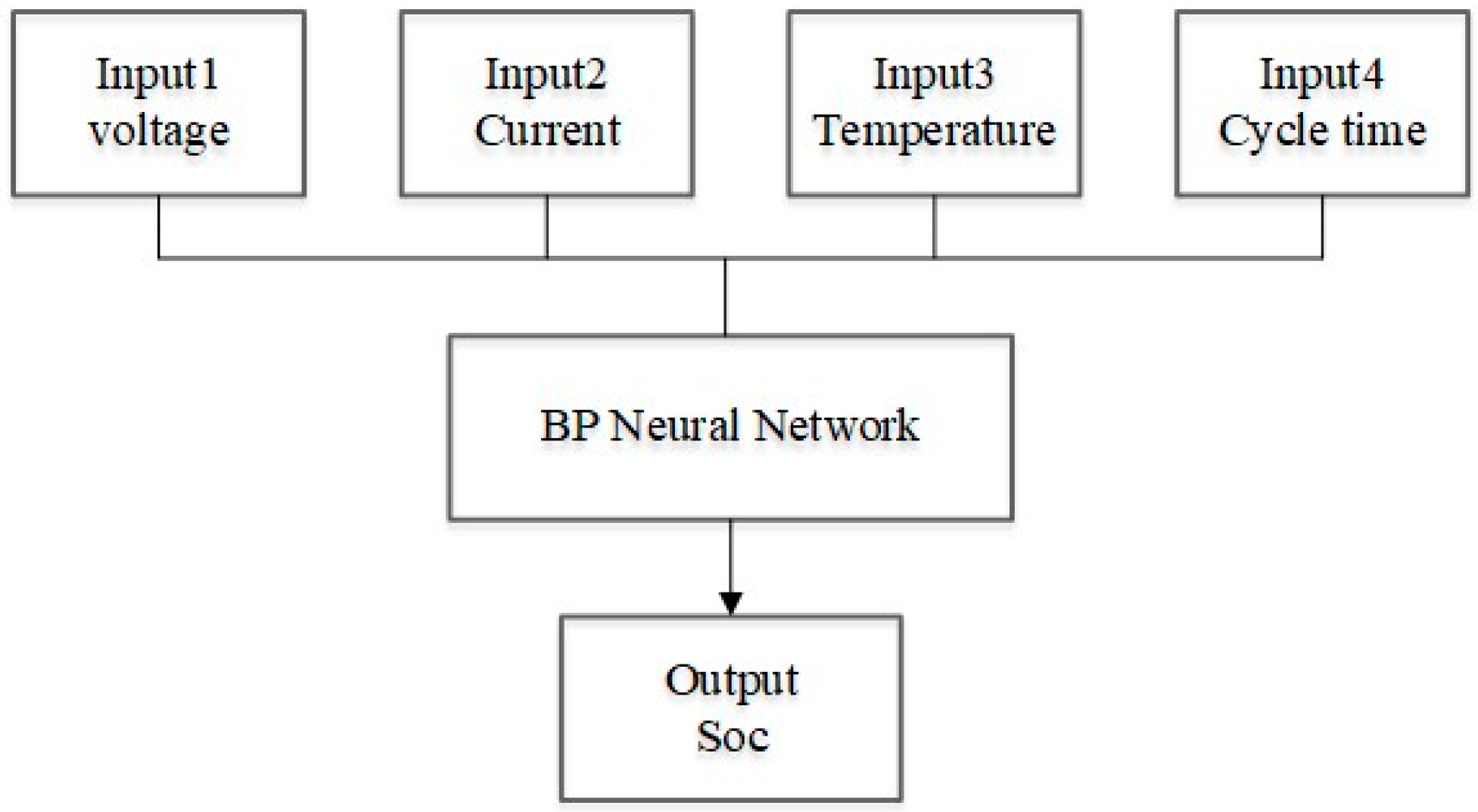

3.2.1. Input Layer Modeling

3.2.2. Hidden Layer Model

3.2.3. Output Layer Model

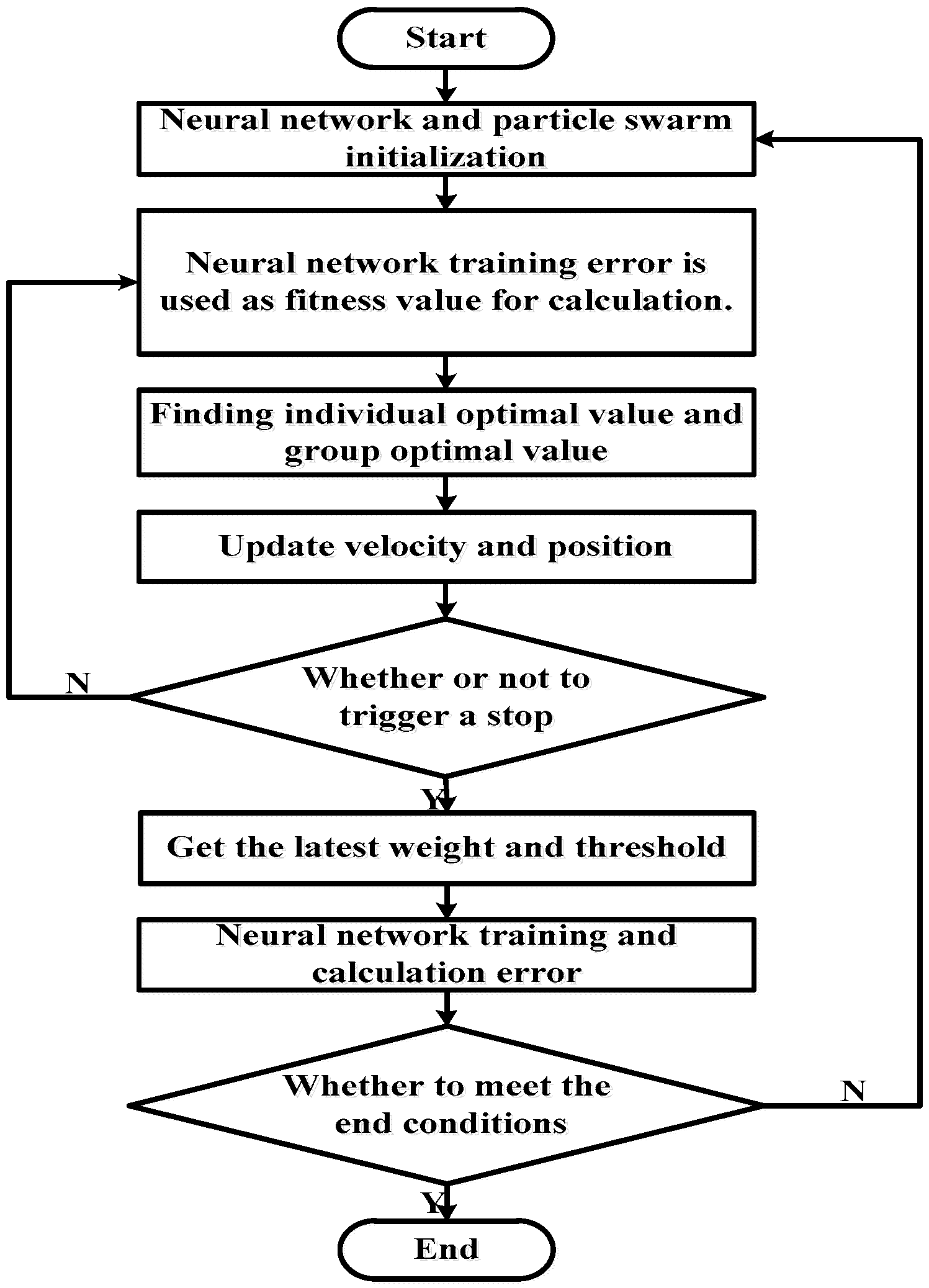

4. Improved Back Propagation Neural Network Algorithm

- (1)

- Initialize: first, the whole model is initialized to determine the particle size, setting particle velocity, location, global extremum, individual extreme value, and maximum number of iterations.

- (2)

- Neural network training: the initial state neural network training is conducted.

- (3)

- Determination of particle fitness: the feedback mean square error is fully utilized in neural network training, and then brought into the calculation as the fitness function value of the particle swarm.

- (4)

- Optimal value finding: the fitness value of each particle is compared with the optimal value of the individual in the current state, leaving the optimal result; in the same way, group optimal values are identified.

- (5)

- Update speed and location: the velocity and position of the particle swarm is updated according to Equations (5) and (6).

- (6)

- The particle algorithm ends: the end condition is the maximum number of iterations that has been set or the point at which N steps is reached, and the mean square error of all samples can meet the requirements. If the end condition is not met, the particle fitness determination step is repeated, and the sequence is carried forward step by step. When the requirements are met, the iteration is stopped and returned to the optimal individual. The optimal value of the individual particle is the improved neural network weight, and the global optimal value is used as the adjustment threshold.

- (7)

- Improved neural network model error analysis: this step determines whether the final mean square error and the SOC estimation error meet the requirements—the training will be finished if they are satisfied; if not, resetting and training is continued until the error requirements are met. The flow chart of the corresponding algorithm is shown in Figure 4.

5. Working Condition Test and Simulation Analysis

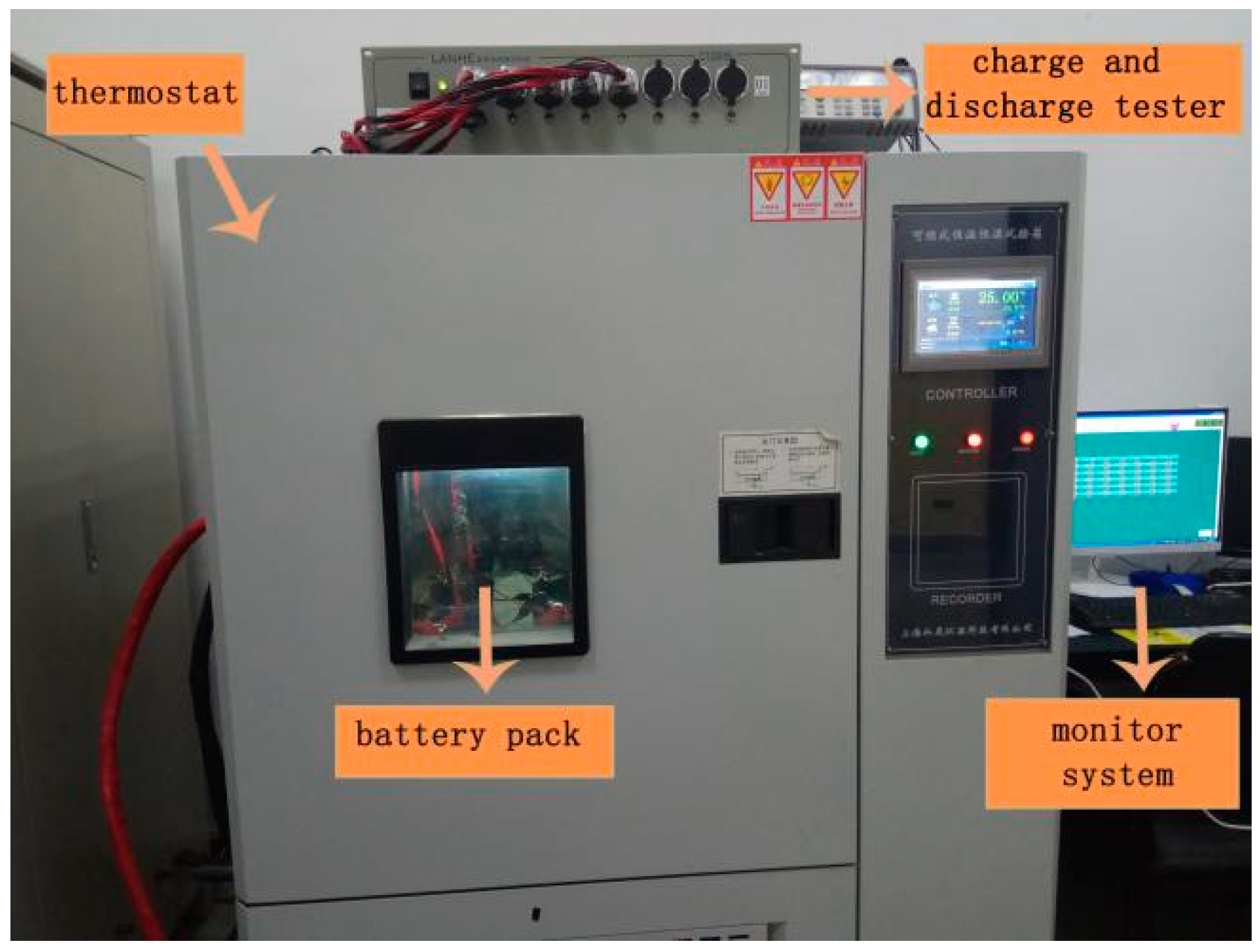

5.1. Construction of Experimental Platform and Training Sample Collection

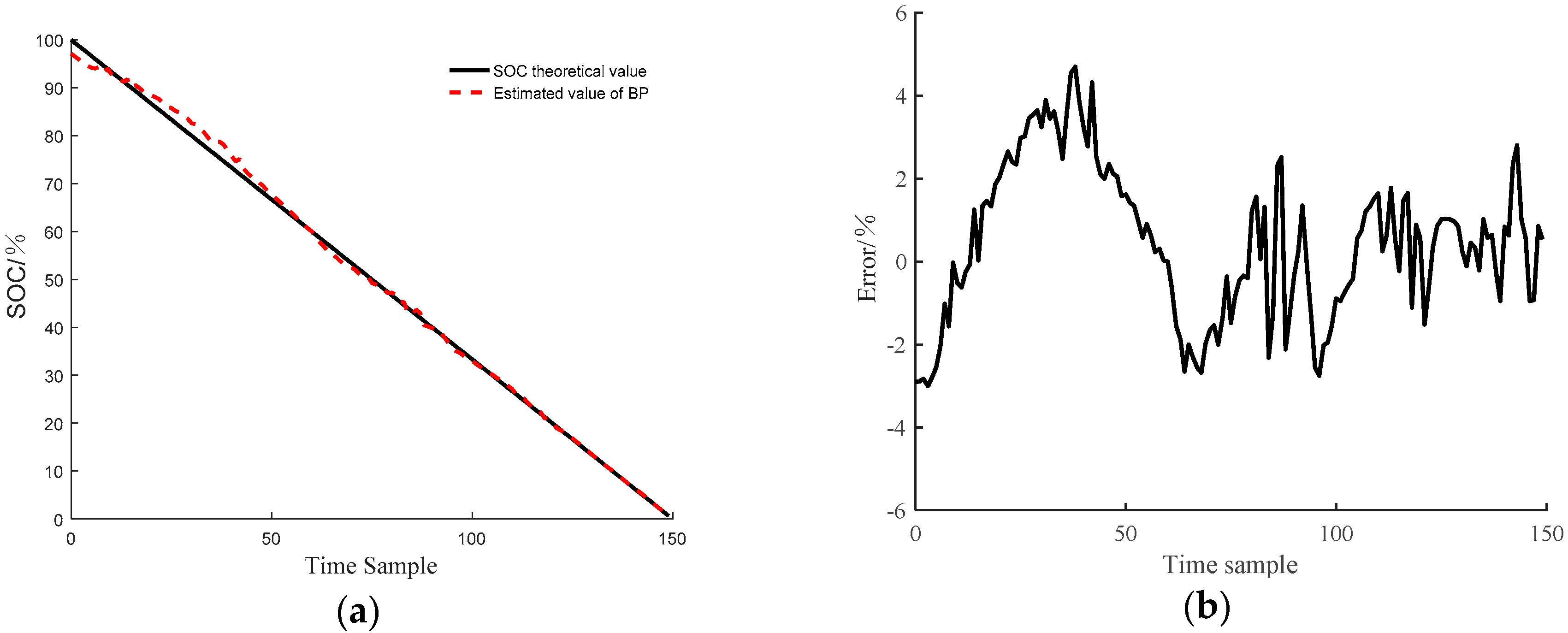

5.2. Back Propagation Neural Network Simulation

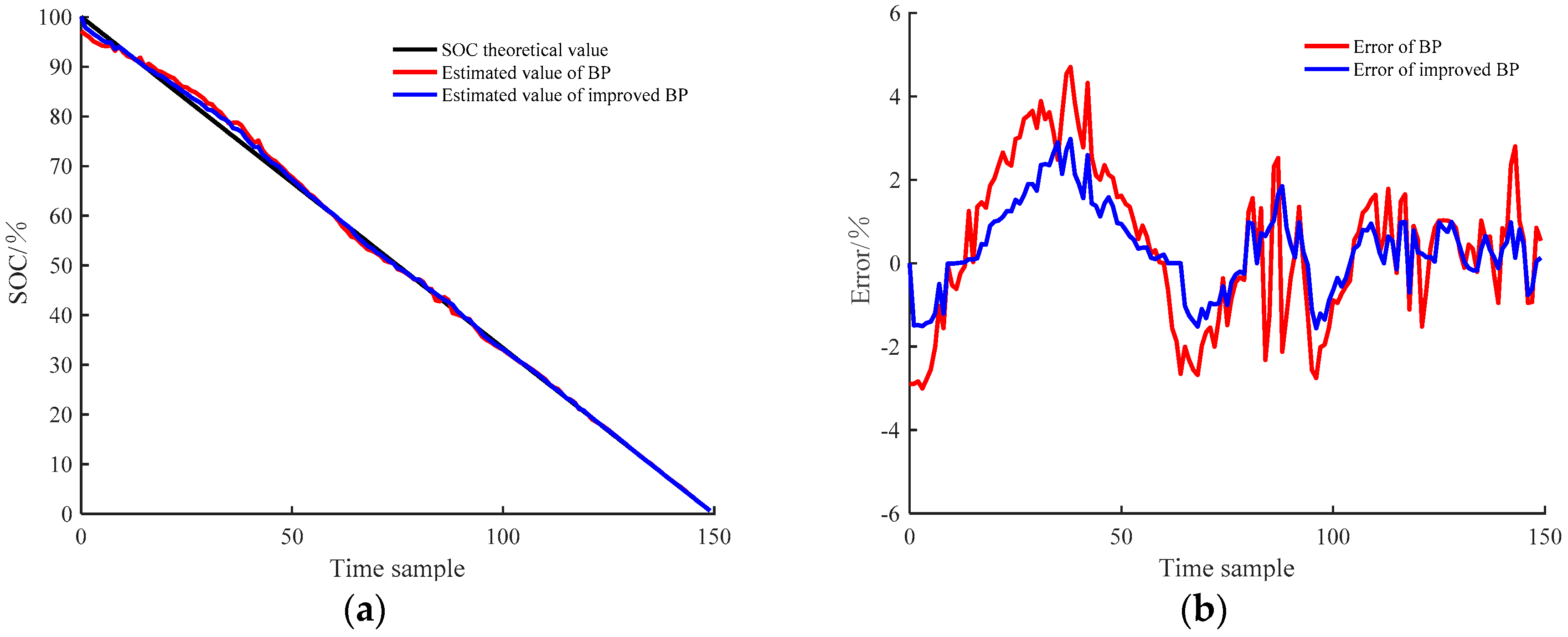

5.3. Improved Back Propagation Neural Network Simulation

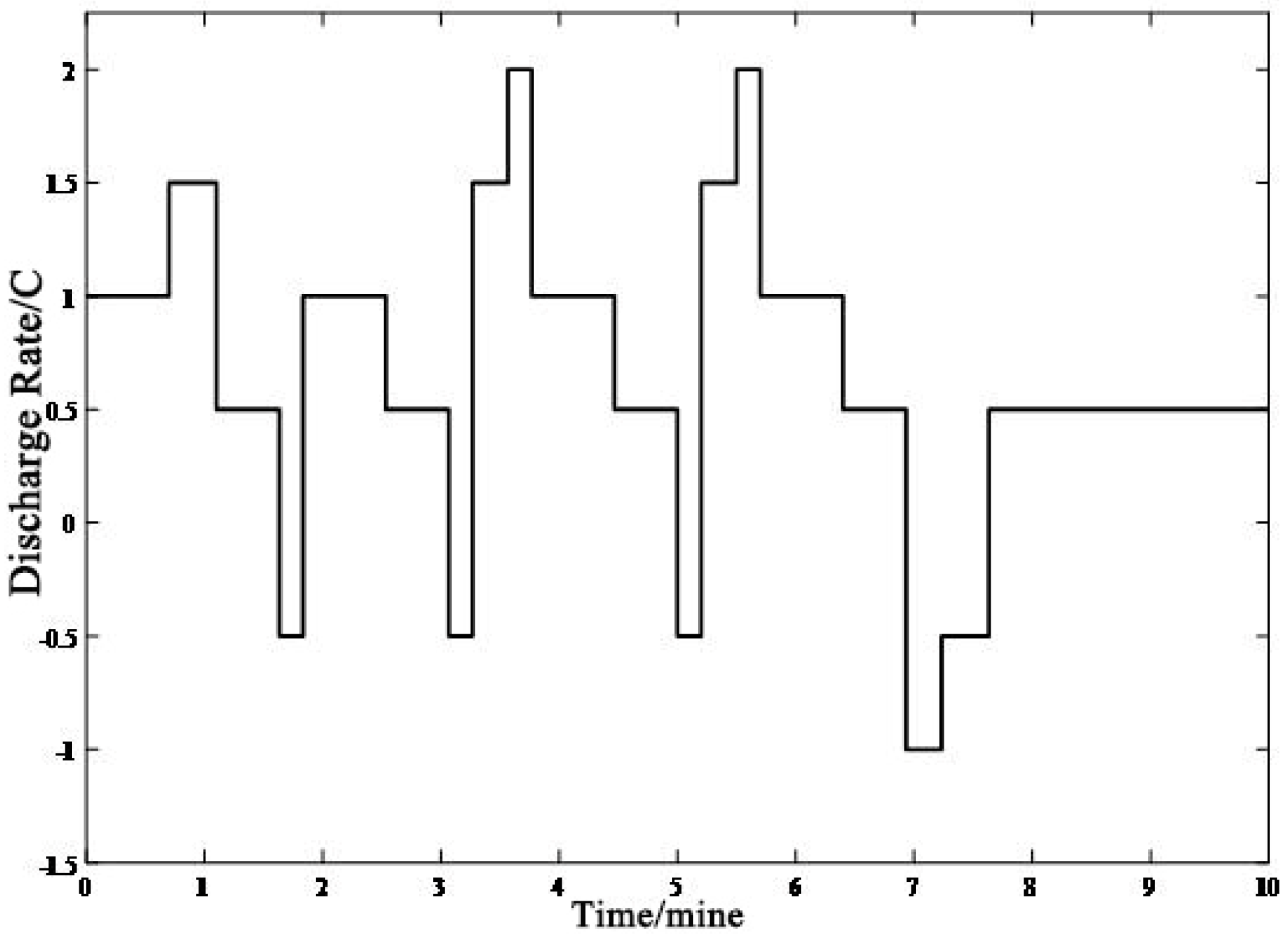

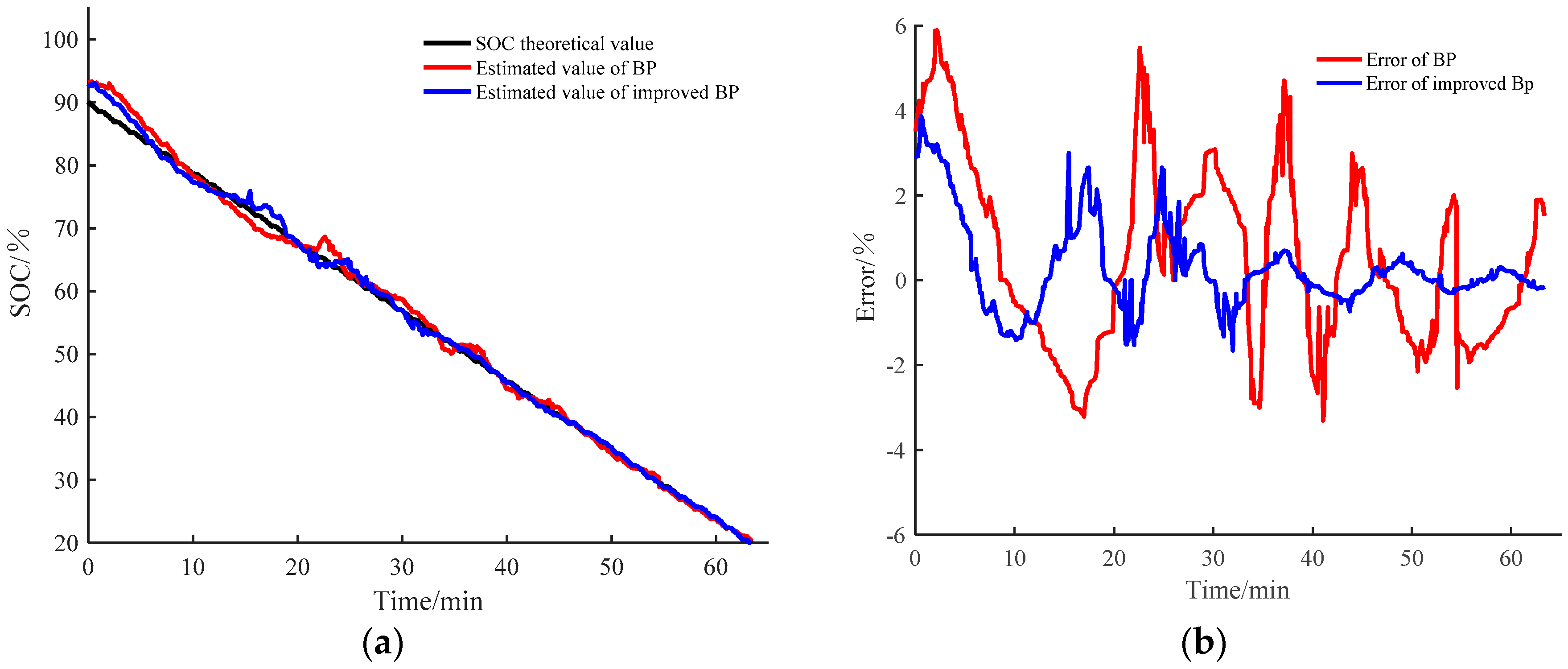

5.4. Working Condition Test

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| BMS | Battery management system |

| SOC | State of charge |

| BP | Back propagation |

| DV | Differential voltage |

| EKF | Extend Kalman filter |

| PF | Particle filter |

| OCV | Open circuit voltage |

| PSO | Particle swarm optimization |

| MSE | Mean square error |

| LM | Levenberg Marquardt |

| CCCV | Constant current constant voltage |

| DST | Dynamic Stress Test |

| USABC | United States Advanced Battery Consortium |

| Pi | Output of the hidden layer |

| Yk | Output of the output layer |

| p | Transfer function of the hidden layer |

| q | Transfer function of the output layer |

| ωij | Connection weight between the input layer and the hidden layer |

| ωjk | Connection weight between the hidden layer and the output layer |

| M | Number of input layers |

| L | Number of hidden layers |

| N | Number of output layers |

| X | Vector of input variables |

| θ | Threshold value |

| E | Mean square error |

| tk | Expected output |

| Yk | Actual output |

| ωa | Current state weight |

| η | Learning rate |

| m | Number of input layer nodes |

| a | Adjustment coefficient |

References

- Safari, M. Battery electric vehicles: Looking behind to move forward. Energy Policy 2018, 115, 54–65. [Google Scholar] [CrossRef]

- Jenn, A.; Springel, K.; Gopal, A.R. Effectiveness of electric vehicle incentives in the United States. Energy Policy 2018, 119, 349–356. [Google Scholar] [CrossRef]

- Kumar, B.; Khare, N.; Chaturvedi, P.K. FPGA-based design of advanced BMS implementing SOC/SOH estimators. Microelectron. Reliab. 2018, 84, 66–74. [Google Scholar] [CrossRef]

- Nembrini, J.; Évéquoz, F.; Baeriswyl, R.; Lalanne, D. Advocating the use of visual analytics in the context of BMS data open access. Energy Procedia 2017, 122, 715–720. [Google Scholar] [CrossRef]

- Xiong, R.; He, H.W.; Ding, Y. Study on identification approach of dynamic model parameters for lithium-ion batteries used in hybrid electric vehicles. J. Power Electron. 2011, 45, 100–104. [Google Scholar]

- Xiong, R.; He, H.W.; Sun, F.C.; Zhao, K. Evaluation on state of charge estimation of batteries with adaptive extended Kalman filter by experiment approach. IEEE Trans. Veh. Technol. 2013, 62, 108–117. [Google Scholar] [CrossRef]

- Awadallah, M.A.; Venkatesh, B. Accuracy improvement of SOC estimation in lithium-ion batteries. J. Energy Storage 2016, 6, 95–104. [Google Scholar] [CrossRef]

- Wu, T.; Wang, M.; Xiao, Q. The SOC estimation of power li-ion battery based on ANFIS model. Smart Grid Renew. Energy 2012, 3, 51–55. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Huang, S.C.; Tseng, K.H.; Liang, J.W. An online SOC and SOH estimation model for lithium-ion batteries. Energies 2017, 10, 512. [Google Scholar] [CrossRef]

- Peng, S.; Zhu, X.L. An adaptive state of charge estimation approach for lithium-ion series-connected battery system. J. Power Sources 2018, 392, 48–59. [Google Scholar] [CrossRef]

- Zheng, F.D.; Xing, Y.J.; Jiang, J.C.; Sun, B.X. Influence of different open circuit voltage tests on state of charge online estimation for lithium-ion batteries. Appl. Energy 2016, 183, 513–525. [Google Scholar] [CrossRef]

- Dang, X.J.; Yan, L.; Xu, K. Open-circuit voltage-Based state of charge estimation of Lithium-ion battery using dual neural network fusion battery model. Electrochim. Acta 2016, 188, 356–366. [Google Scholar] [CrossRef]

- Yang, N.X.; Zhang, X.; Li, G. State of charge estimation for pulse discharge of a LiFePO4 battery by a revised Ah counting. Electrochim. Acta 2015, 151, 63–71. [Google Scholar] [CrossRef]

- Xu, D.P.; Wang, L.F.; Yang, J. Research on Li-ion battery management system. In Proceedings of the 2010 International Conference on Electrical and Control Engineering, Wuhan, China, 25–27 June 2010. [Google Scholar]

- Baba, A.; Adachi, S. State of charge estimation of HEV/EV battery with series Kalman filter. In Proceedings of the 2012 Proceedings of SICE Annual Conference (SICE), Akita, Japan, 20–23 August 2012; pp. 845–850. [Google Scholar]

- Zheng, L.F.; Zhu, J.G. Differential voltage analysis based state of charge estimation methods for lithium-ion batteries using extended Kalman filter and particle filter. Energy 2018, 158, 1028–1037. [Google Scholar] [CrossRef]

- Guo, Y.F.; Zhao, Z.S.; Huang, L.M. SOC Estimation of lithium battery based on improved BP neural network. Energy Procedia 2017, 105, 4153–4158. [Google Scholar] [CrossRef]

- Posewsky, T.; Ziener, D. Throughput optimizations for FPGA-based deep neural network inference. Microprocess. Microsyst. 2018, 60, 151–161. [Google Scholar] [CrossRef]

- Pan, H.H.; Lu, Z.Q.; Lin, W.L.; Li, J.Z.; Chen, L. State of charge estimation of lithium-ion batteries using a grey extended Kalman filter and a novel open-circuit voltage model. Energy 2017, 138, 764–775. [Google Scholar] [CrossRef]

- Li, Z.; Lu, L.G.; Ou, Y. The method of evaluating the accuracy of battery SOC is compared by improving the Ann time integral method. J. Tsinghua Univ. (Nat. Sci.) 2010, 50, 1293–1296. [Google Scholar]

- Mao, H.F.; Wan, G.C.; Wang, L.; Zhang, Q. Battery SOC estimation based on Kalman filter correction algorithm. Chin. J. Power Sources 2014, 38, 298–302. [Google Scholar]

- Afshar, S.; Morris, K.; Khajepour, A. State of charge estimation via extended Kalman filter designed for electrochemical equations. IFAC PapersOnLine 2017, 50, 2152–2157. [Google Scholar] [CrossRef]

- Xiang, Y.; Liu, C.G.; Su, J.Q.; Yang, G.B. Forecast model of battery state of charge based on BP network and its optimization. Chin. J. Power Sources 2013, 137, 963–965. [Google Scholar]

- He, W.; Williard, N.; Chen, C.C.; Pecht, M. State of charge estimation for Li-ion batteries using neural network modeling and unscented Kalman filter-based error cancellation. J. Electr. Power Energy Syst. 2014, 62, 783–791. [Google Scholar] [CrossRef]

- Feng, J. BP neural network predicts the selection of SOC training data for li-ion battery. Chin. J. Power Sources 2016, 140, 283–286. [Google Scholar]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Experimental and theoretical investigation of temperature distributions in a prismatic lithium-ion battery. Int. J. Therm. Sci. 2016, 99, 204–212. [Google Scholar] [CrossRef]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Thermal modeling and validation of temperature distributions in a prismatic lithium-ion battery at different discharge rates and varying boundary conditions. Appl. Therm. Eng. 2016, 96, 190–199. [Google Scholar] [CrossRef]

| Network Parameters | Value | Network Parameters | Value |

|---|---|---|---|

| Maximum number of iterations | 1000 | Learning rate | 0.05 |

| Target mean square error | 4–10 | Optimal number of iterations | 312 |

| Research Methods | BP Neural Network | Improved BP Neural Network |

|---|---|---|

| Maximum estimation error in simulation | 5% | 3% |

| Maximum estimation error in working condition test | 6% | 4% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.-W.; Chen, S.-R.; Gao, H.-B.; Xu, K.-J.; Yang, M.-Y. State of Charge Estimation of Power Battery Using Improved Back Propagation Neural Network. Batteries 2018, 4, 69. https://doi.org/10.3390/batteries4040069

Zhang C-W, Chen S-R, Gao H-B, Xu K-J, Yang M-Y. State of Charge Estimation of Power Battery Using Improved Back Propagation Neural Network. Batteries. 2018; 4(4):69. https://doi.org/10.3390/batteries4040069

Chicago/Turabian StyleZhang, Chuan-Wei, Shang-Rui Chen, Huai-Bin Gao, Ke-Jun Xu, and Meng-Yue Yang. 2018. "State of Charge Estimation of Power Battery Using Improved Back Propagation Neural Network" Batteries 4, no. 4: 69. https://doi.org/10.3390/batteries4040069

APA StyleZhang, C.-W., Chen, S.-R., Gao, H.-B., Xu, K.-J., & Yang, M.-Y. (2018). State of Charge Estimation of Power Battery Using Improved Back Propagation Neural Network. Batteries, 4(4), 69. https://doi.org/10.3390/batteries4040069