System-Level Compact Review of On-Board Charging Technologies for Electrified Vehicles: Architectures, Components, and Industrial Trends

Abstract

1. Introduction

1.1. Motivations

- Control strategies (voltage and current regulation, digital implementation, PFC, grid synchronization) [10];

- Battery pack configurations (cell arrangement, thermal management, high-voltage insulation, modularity) [11];

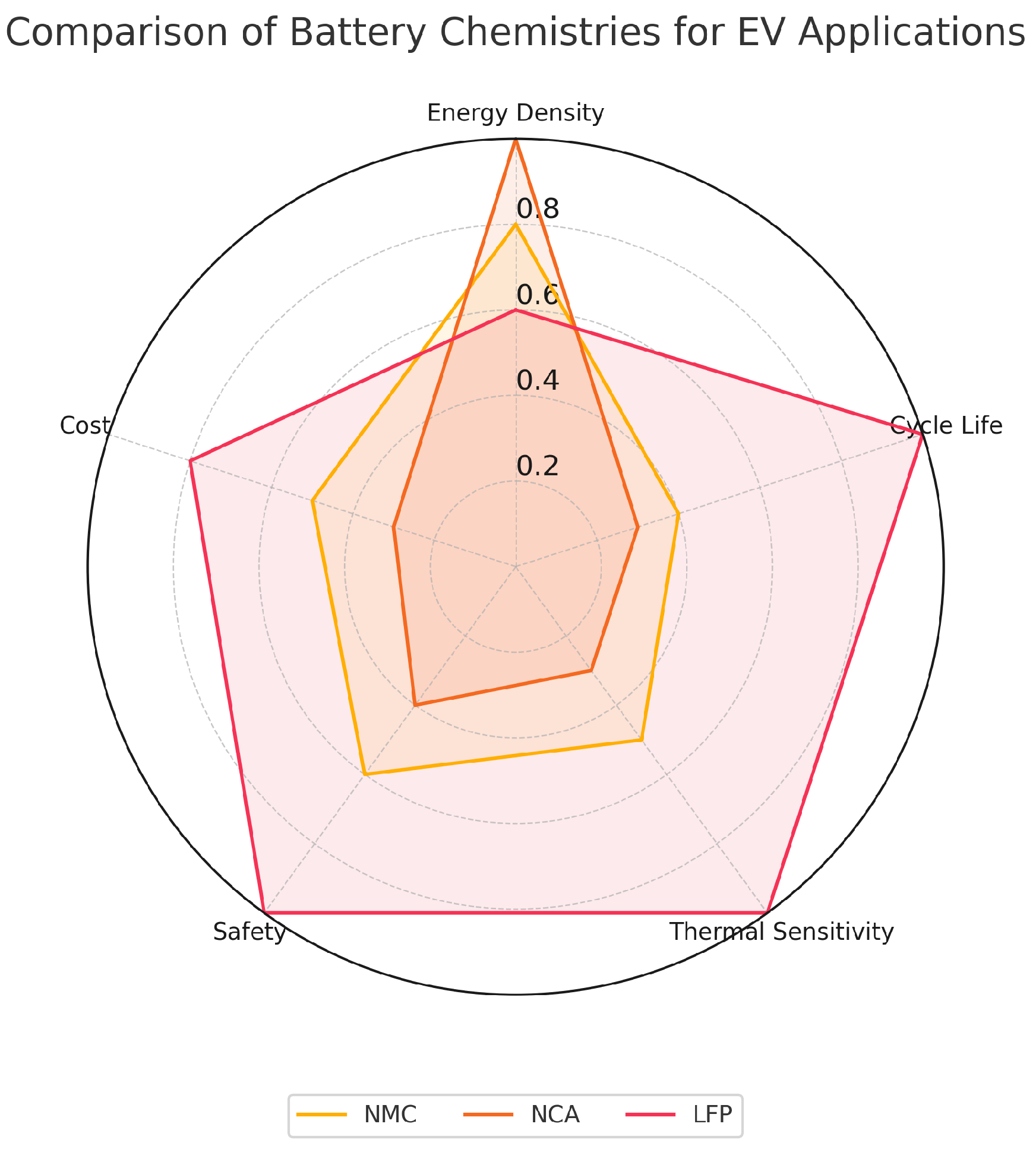

- Lithium-ion battery chemistries (LFP, NMC, NCA), each with trade-offs in energy density, safety, cost, and fast-charging behavior [3];

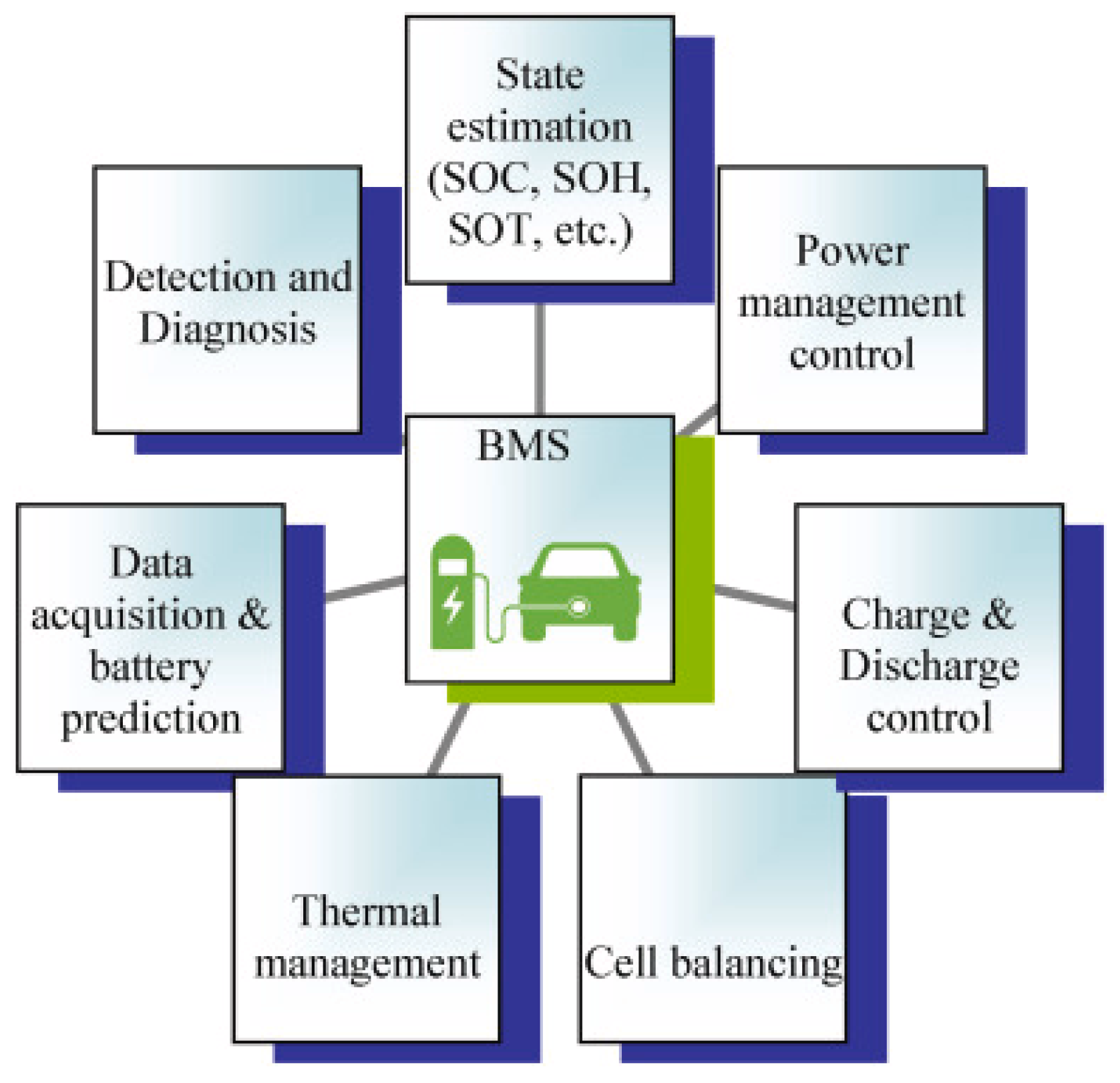

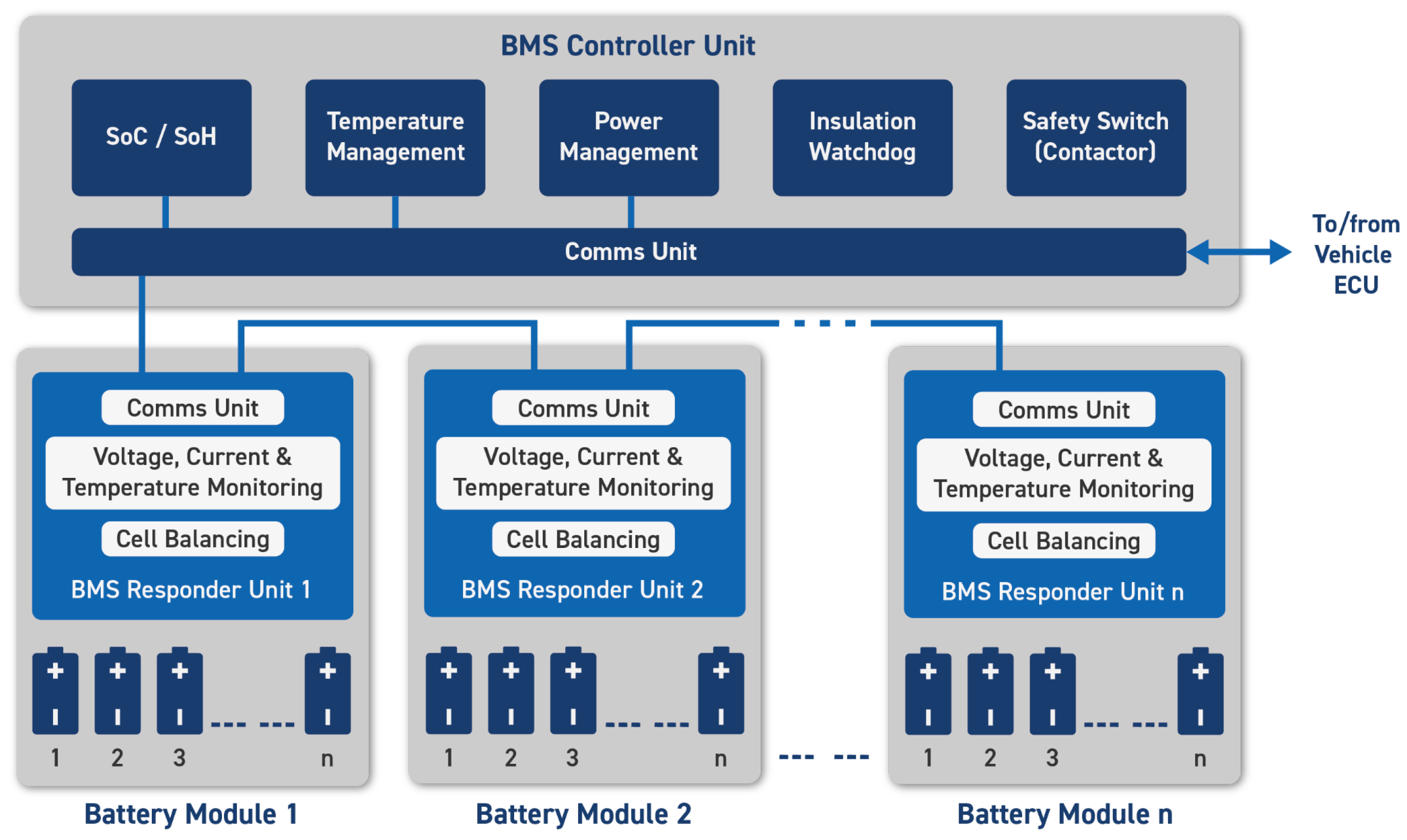

- BMS integration, including balancing algorithms, state estimation, protection features, and charger communication [12];

- Essential aspects of system safety and protection, such as insulation monitoring, fault detection, compliance with standards, and cybersecurity [13].

1.2. Background

- The AC supply interface, connected to single- or three-phase mains;

- An active rectifier stage implementing power factor correction (PFC);

- An isolated DC/DC converter, which adapts the DC bus voltage and provides galvanic isolation;

- The battery pack, composed of lithium-ion cells managed by a BMS to ensure monitoring, protection, and charge control.

1.3. Paper Contribution

- A critical discussion of lithium-ion chemistries, namely LFP, NMC, and NCA, with emphasis on their impact on safety, performance, cost, and charging compatibility [3];

2. Architecture of Automotive Charging Systems

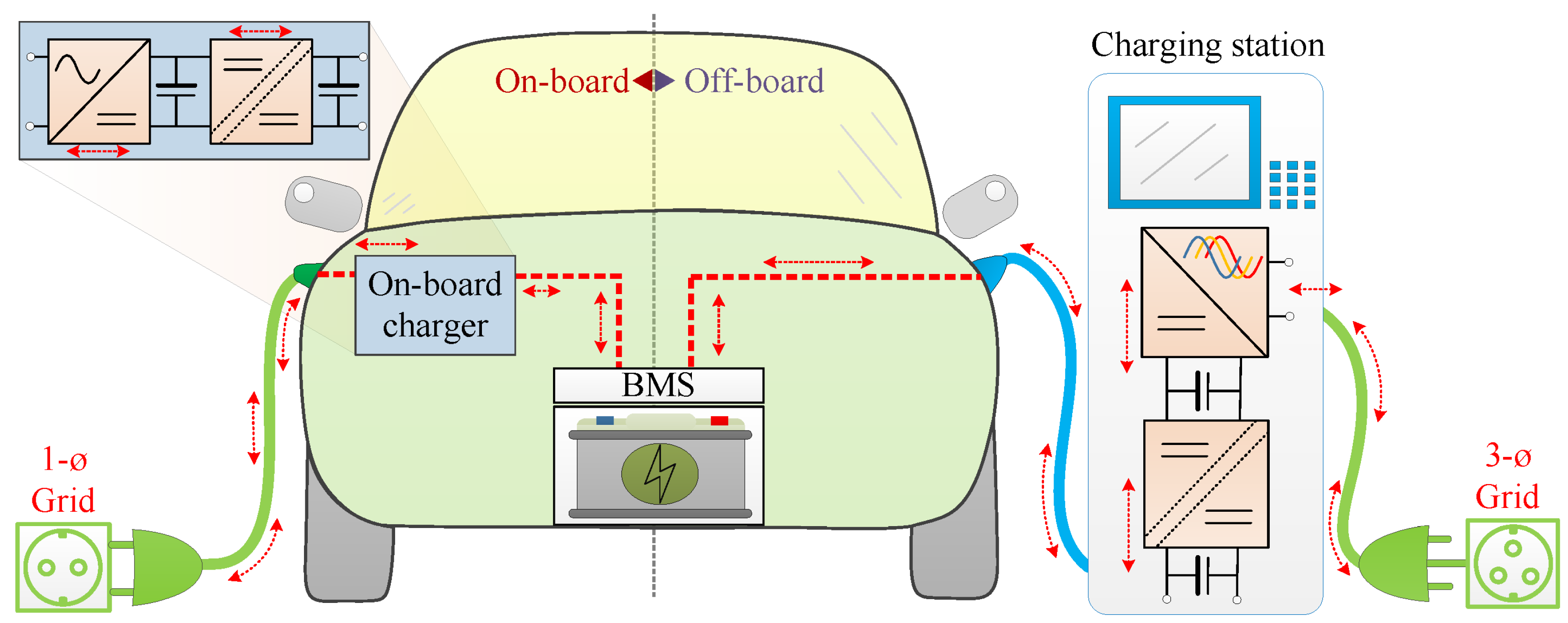

2.1. On-Board vs. Off-Board

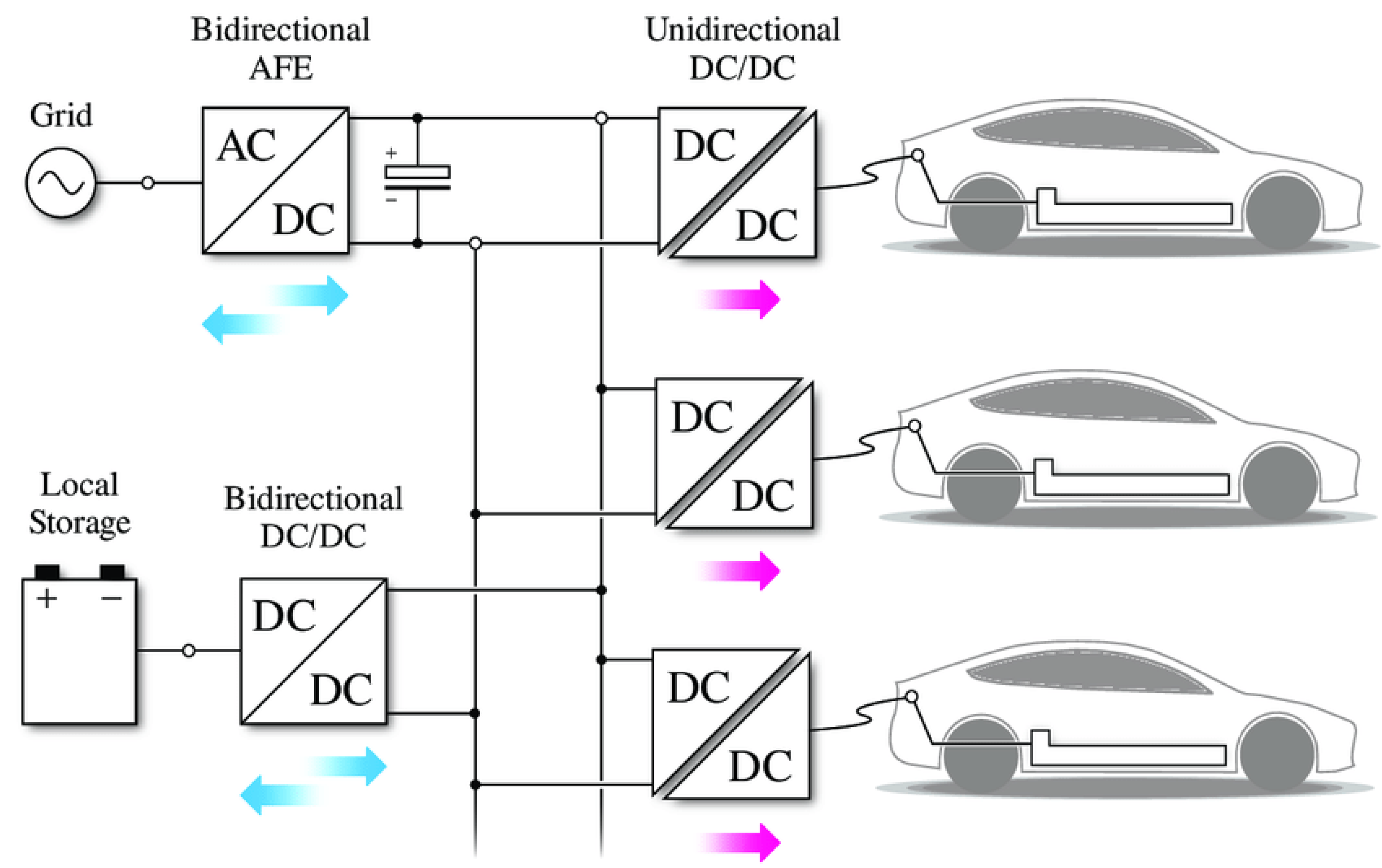

2.2. Unidirectional vs. Bidirectional Charging Systems

Quantitative Outlook and Distribution Scenarios

2.3. Energy Flow and Functional Blocks

- AC interface: Handles physical connection to the grid, incorporating protective devices, EMI filters, and grid sensing. Ensures synchronization and standard compliance.

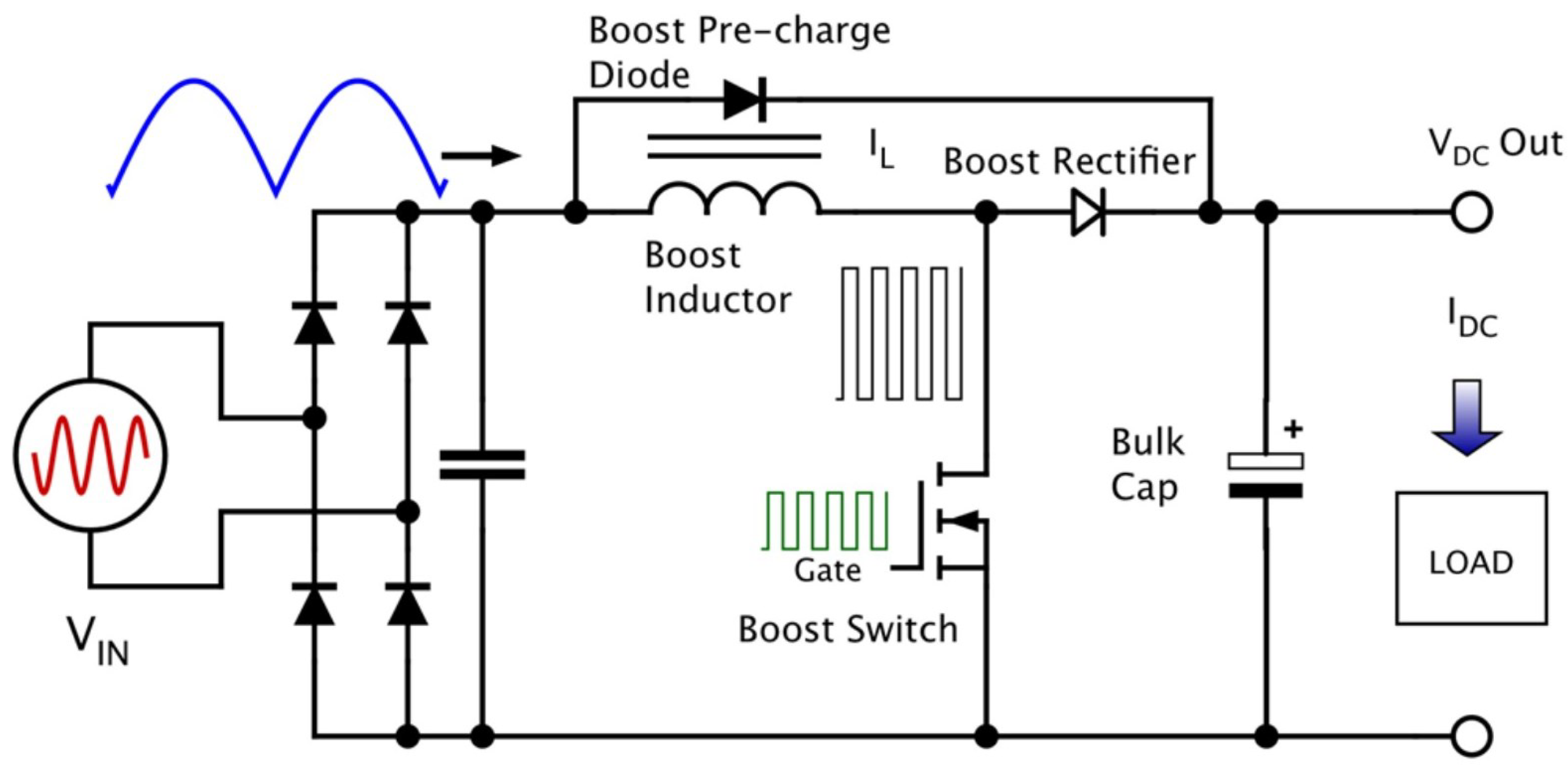

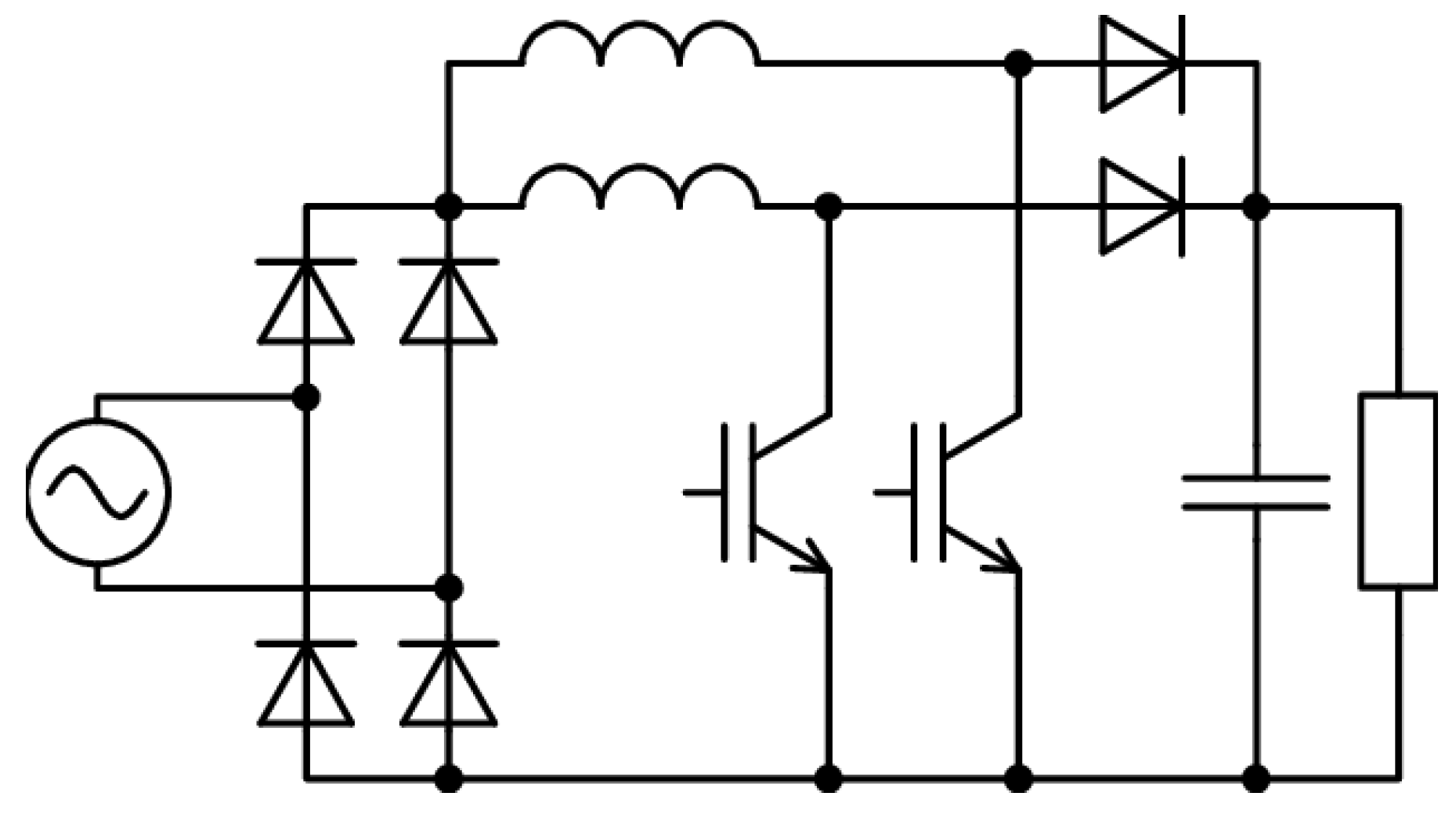

- Active rectifier with PFC: Converts AC to regulated DC with high power factor and low harmonic distortion. Boost and Vienna topologies are common choices.

- Isolated DC/DC converter: Adapts voltage to battery level and provides galvanic isolation. LLC and DAB are widely used, with magnetic design playing a key role [10].

- Control and communication unit: Manages regulation, monitors parameters, and exchanges information with the BMS via protocols such as CAN or ISO 15118 [14].

- Battery and BMS: The battery pack and its management system coordinate SoC/SoH monitoring, balancing, and safety protections during the charging process [12].

- : 96–98%;

- : 96–98%;

- : 98–99%.

2.4. Design Considerations

- Galvanic isolation ensures user protection and limits fault propagation. Isolation coordination and insulation materials shall comply with IEC 60664 [27] for creepage/clearance and PD categories, while EV-specific safety and charging requirements are covered by ISO 6469 [28] (electrical safety on-board) and IEC 61851 (conductive charging). In North America, UL 2202 [29] adds product-level requirements for EV charging equipment. Typical verification includes the following: dielectric withstand (hi-pot) on the HF transformer and DC link barrier; insulation resistance at representative DC stress; partial discharge (PD) tests for reinforced insulation; and impulse/surge immunity on the mains side (IEC 61000-4-x) [30]. In operation, insulation monitoring functions per ISO/UNECE EV safety frameworks are coordinated with the BMS. Industrial practice: Tier-1 OBCs used in 11–22 kW platforms implement reinforced isolation across the HF transformer and DC-link barrier and perform end-of-line hi-pot/PD screening before vehicle-level ISO 6469/UNECE approvals (see Section 9).

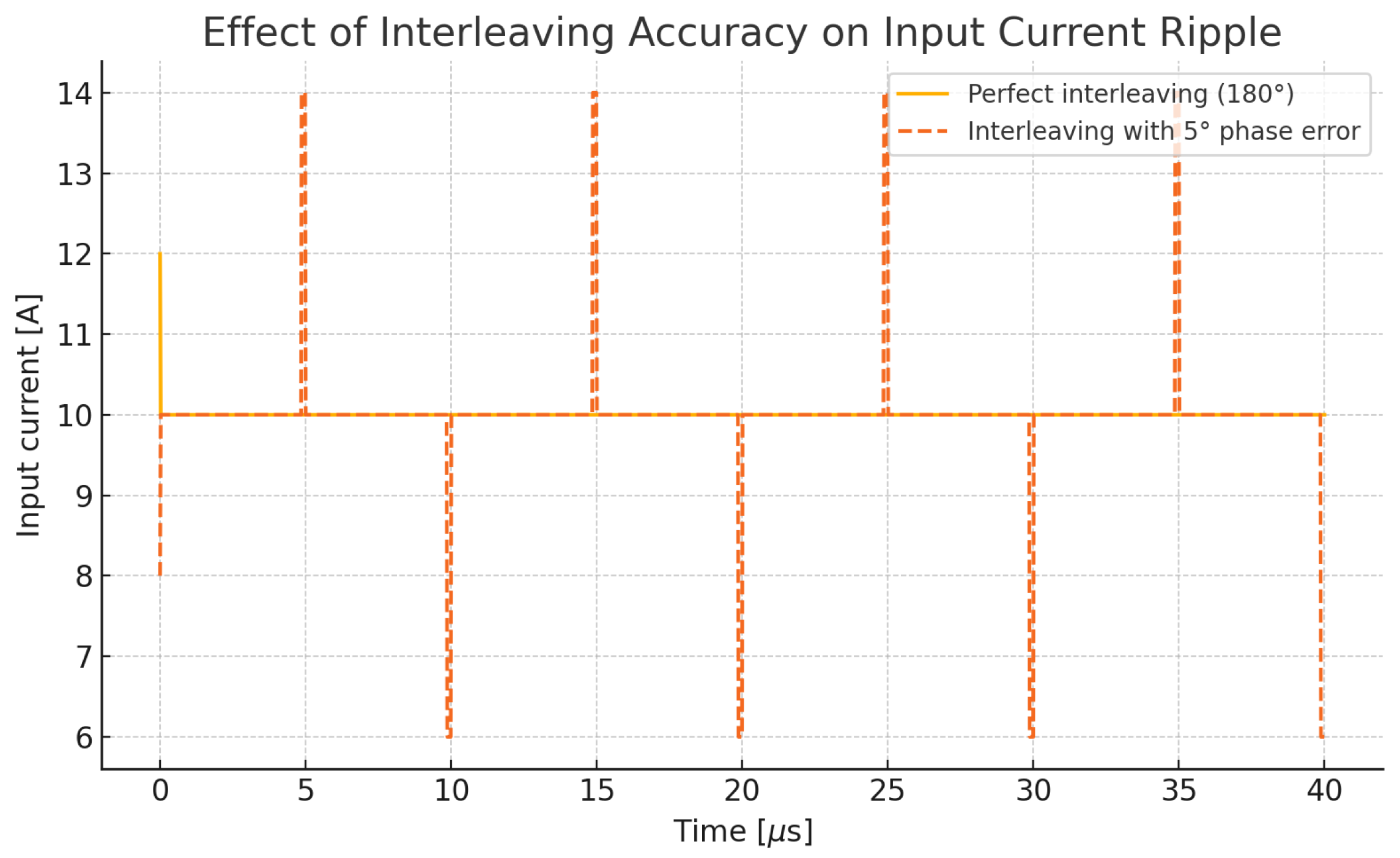

- Power scalability and modularity is essential, especially in infrastructure-level or high-power automotive platforms. Modular architectures (e.g., interleaved multi-phase PFC, parallel DC/DC modules) enable N + 1 redundancy, phase shedding at light load, and serviceability. In three-phase 11–22 kW OBCs, two synchronized 11 kW strings are often packaged together, while off-board stations scale as multi-module racks with shared cooling and supervisory control [20].

- Interoperability and communication relies on standards for the EV–EVSE link and the internal vehicle network. ISO 15118 [31] enables Plug&Charge, certificate-based authentication, and negotiation of charging limits; IEC 61851 defines control pilot/timing; connector interfaces follow IEC 62196/SAE J1772 [32,33]. Inside the vehicle, the OBC exchanges limits, diagnostics, and derating requests with the BMS over CAN/CAN FD; bidirectional/V2G-capable stacks extend this to grid-interactive use cases [14]. Given the connectivity, cybersecurity-by-design (e.g., ISO/SAE 21434) [34] and functional safety (ISO 26262 [35]) are increasingly required in series production.

- Energy efficiency and thermal management affect not only operating cost but also heatsink/coolant design, enclosure volume, and reliability. Achieving stage efficiencies above 96–98% at both AC/DC and DC/DC is a practical target in modern OBCs; system efficiency results from the product of stage efficiencies and battery acceptance [22]. High-efficiency, soft-switched topologies (e.g., bridgeless totem-pole PFC + LLC/PSFB/DAB) operated with SiC/GaN devices reduce switching losses and magnetic size at a given power density. Thermal design (liquid cold plates, TIMs, even heat-spreaders for planar magnetics) must ensure junction and case temperatures within derating limits across ambient/vibration profiles typical of automotive duty.

- EMC/EMI and grid power quality drive front-end filter design and control bandwidth. Automotive EMC is typically validated against UNECE R10/CISPR 25 for radiated/conducted emissions and immunity, while grid-connected behavior (THD, PF, flicker, immunity) follows the relevant IEC 61000 families at equipment or system level. Resonant or three-level front-ends help reduce dv/dt and shrink EMI filters; LCL variants with selective damping are preferred in three-phase designs when acoustic/size constraints are stringent.

- Cost, footprint, and manufacturability are crucial for on-board systems, where space, mass, and BOM must be minimized without compromising EMC or thermal performance [1,15]. While WBG devices increase device cost versus Si/IGBT, they typically enable smaller magnetics/filters and lower cooling overhead, improving total cost of ownership at scale. Integration trends (shared coolant loops, co-packaging OBC with HV DC/DC or traction inverter power modules) further reduce volume and parts count in series production.

- Reliability and environmental robustness require qualification against automotive stressors (thermal cycling, humidity, corrosive atmospheres, mechanical shock/vibration). Design of the HF transformer, busbars, and large passives should consider mechanical fixation, potting/impregnation, and material choices resilient to vibration-induced fatigue (e.g., per ISO 16750 [36] test profiles), as well as insulation life models versus thermal hotspots.

3. AC/DC Front-End in Automotive Charging Systems

3.1. Boost Power Factor Correction Converter

3.1.1. Operating Regimes and Practical Trade-Offs

3.1.2. Efficiency Sensitivity to Switching Frequency ()

3.1.3. Design Notes for WBG-Based Boost PFC

- Inductor: Choosing and fixes L; with higher , the copper AC losses and core loss terms may dominate unless the winding and core material are optimized (e.g., litz wire, low-loss ferrites).

- Switch/diode: SiC MOSFET + SiC diode (or synchronous MOSFET) reduces recovery and improves high-line ZVS margin in BCM; gate-driver layout and management are crucial for EMI.

- EMI: Higher narrows the spectrum but increases common-mode noise due to faster edges; input EMI filters (L, LC/LCL with damping) must be co-designed with layout to avoid peaking near the control bandwidth.

- Light-load: Frequency foldback and phase-shedding (in multi-phase variants) help maintain efficiency when the mains current is small near the zero crossings.

3.1.4. Efficiency Versus Switching Frequency: Comparative Outlook

3.2. Interleaved Boost PFC

3.2.1. Current Balancing Methods (Design Guidelines)

- Passive droop (series R or DCR emulation). A small effective resistance introduces a proportional droop, so that higher current phases see a reduced voltage reference. The droop coefficient can be expressed aswhere is the physical (or emulated) sense resistance and is the current-loop gain. Typical design targets set such that current sharing error remains across load and temperature.

- Average current-mode control. Each phase tracks , enforced via digital averaging of measured currents. Provides excellent accuracy at the cost of higher sensing and control effort.

- Master–slave bus. A single master phase defines current reference; slave phases synchronize via a dedicated bus. Simpler but slower dynamic equalization.

- Inductor coupling or Interphase transformer (IPT). Magnetic coupling naturally enforces current sharing and further suppresses ripple.

- Digital calibration and trimming. Compensation of offsets and mismatches in sensors, gate drivers, and dead-times via firmware, improving long-term balance.

3.2.2. Implementation Notes to Avoid Practical Errors

- Match inductor values across phases (<±3%).

- Use symmetric PCB layout to equalize parasitics and minimize circulating currents.

- Synchronize sampling to PWM edges to avoid sensing skew (see Figure 5).

- Apply phase-shedding under fault/thermal stress to maintain stable operation.

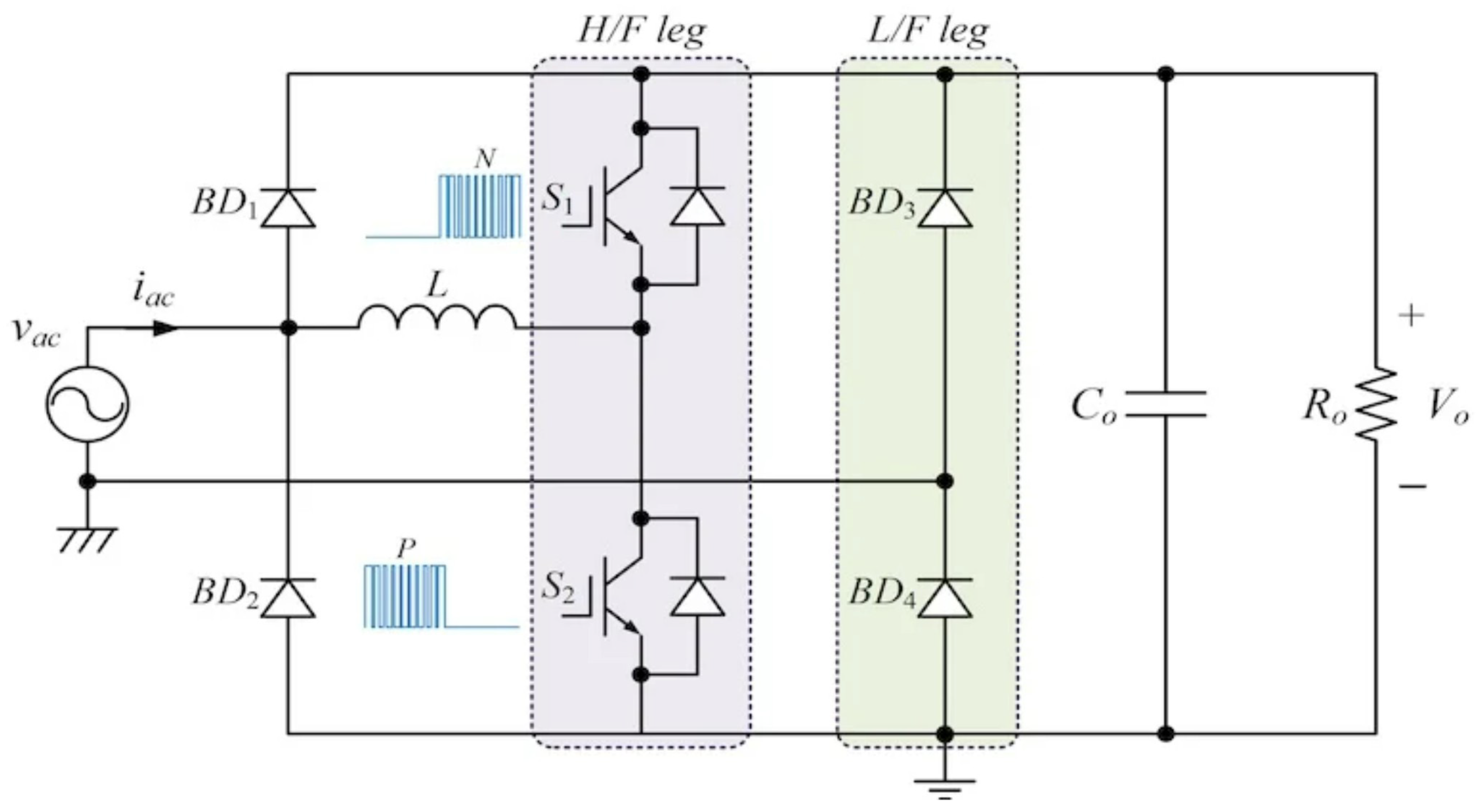

3.3. Bridgeless Totem-Pole PFC

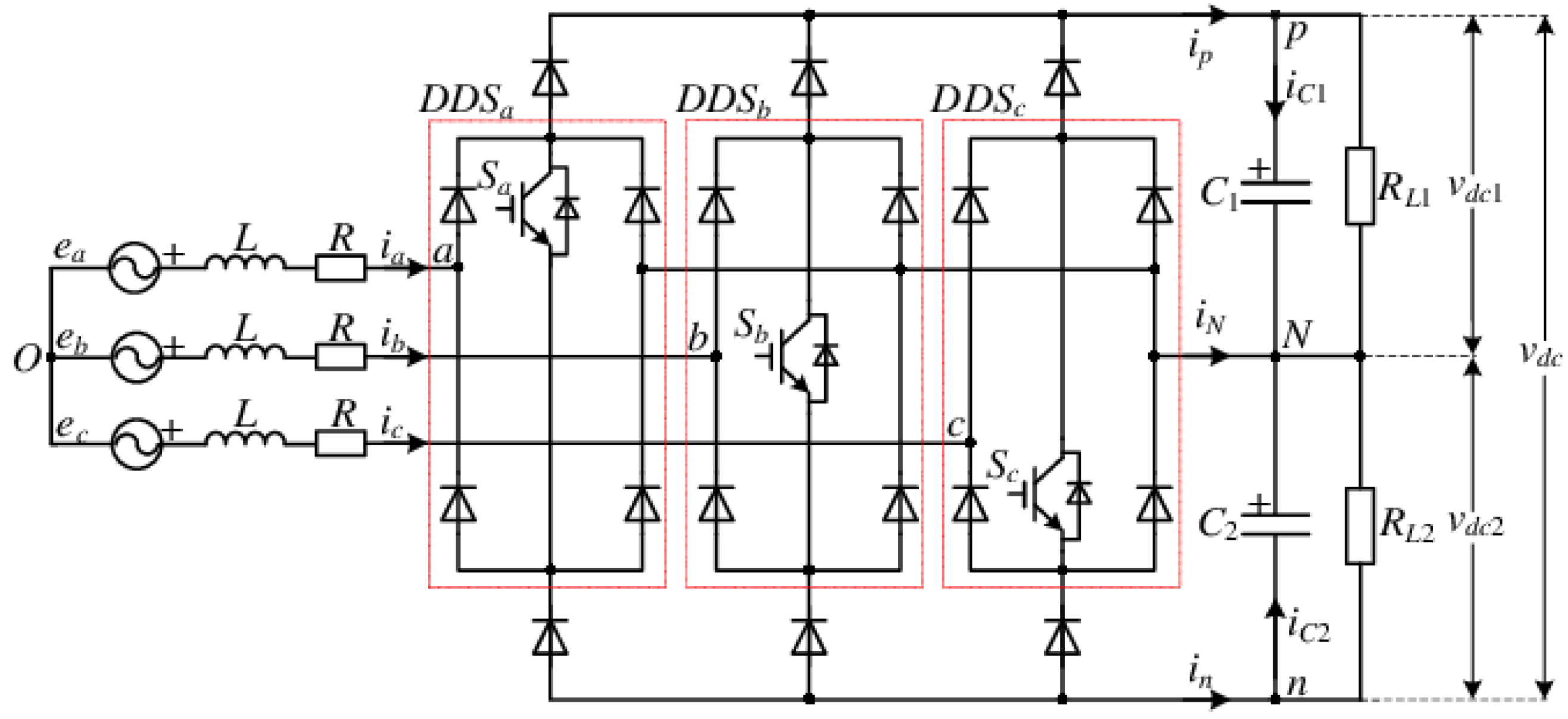

3.4. Vienna Rectifier

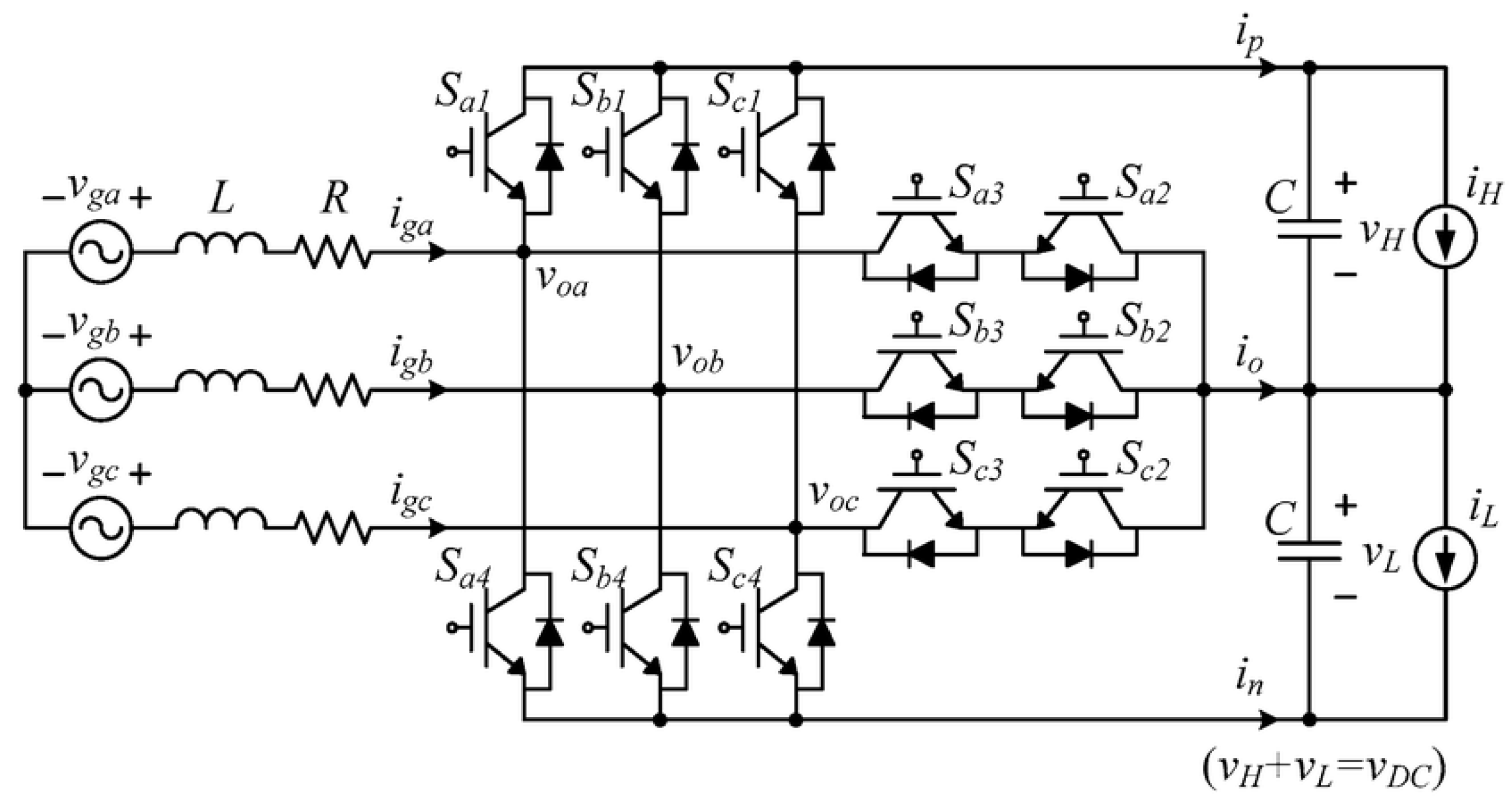

3.5. T-Type PFC Converters

3.6. Comparison of AC/DC Front-End Topologies: Key Metrics

4. AC-Grid Interface in Automotive Charging Systems

4.1. Pure Inductive Filter

4.2. LC Filter

4.3. LCL Filter

4.4. LCL with Series or Parallel Damping

4.5. Resonant Traps and Selective Filters

4.6. Discussion

5. DC/DC Converters in Automotive Charging Systems

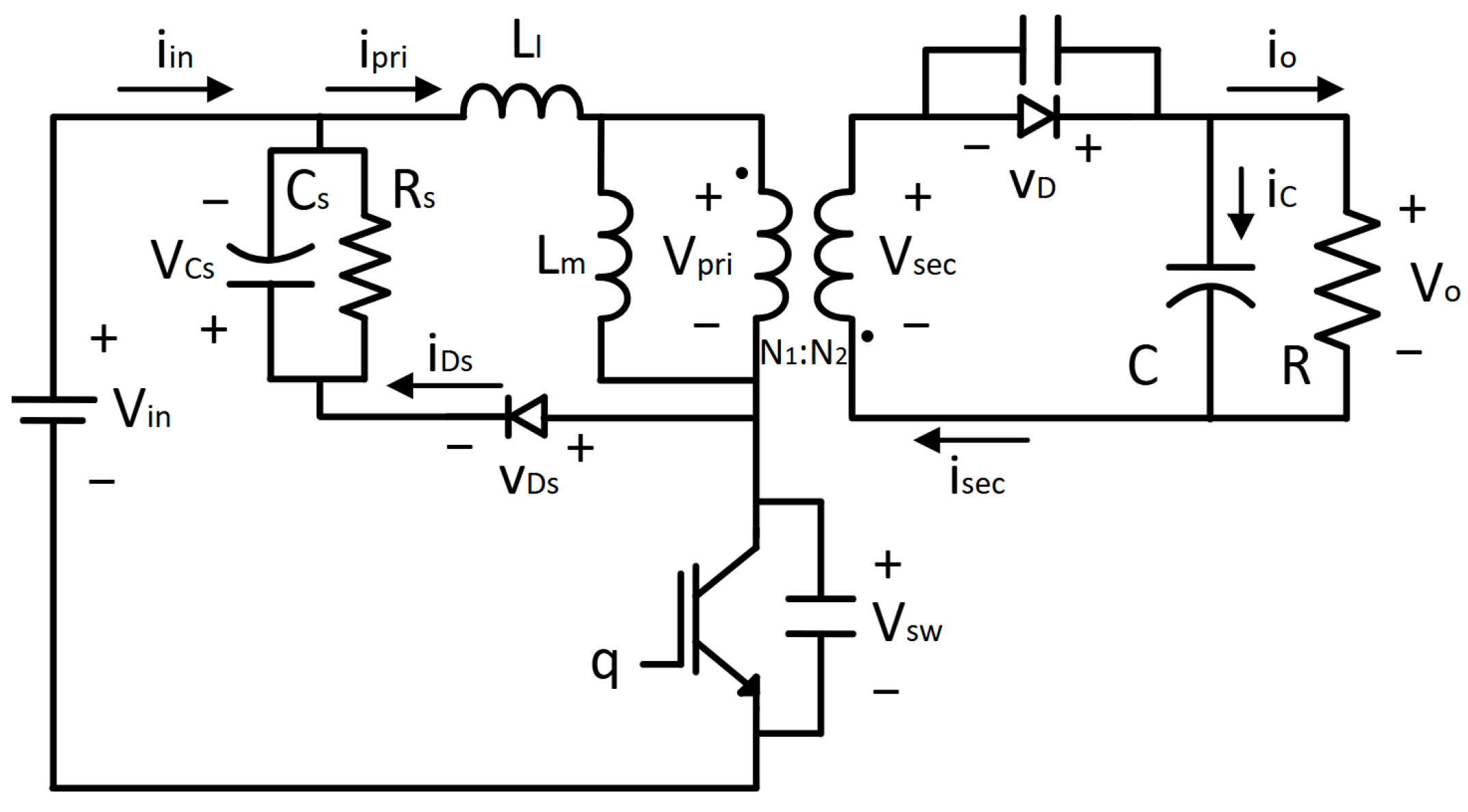

5.1. Flyback Converter

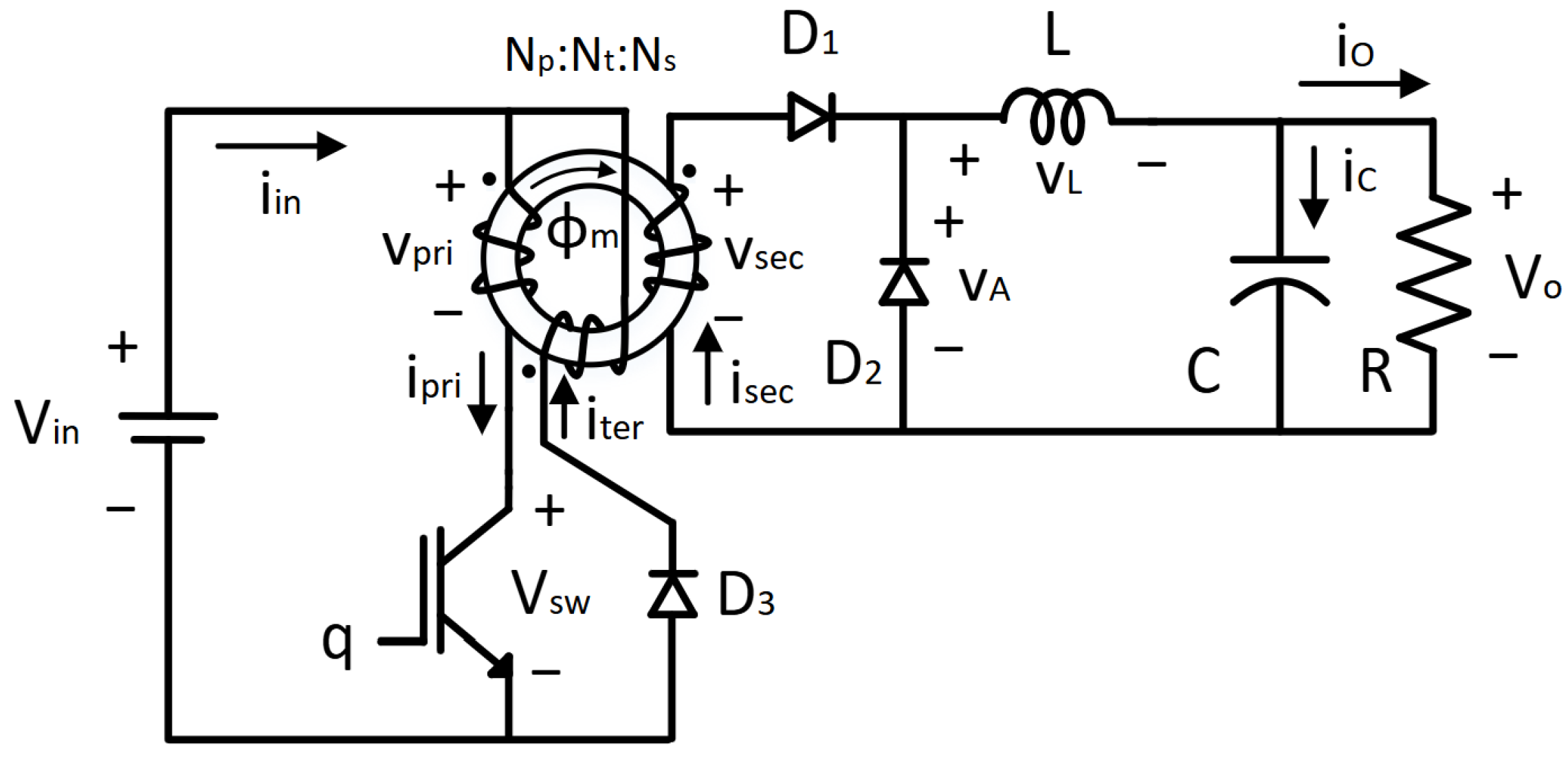

5.2. Forward Converter

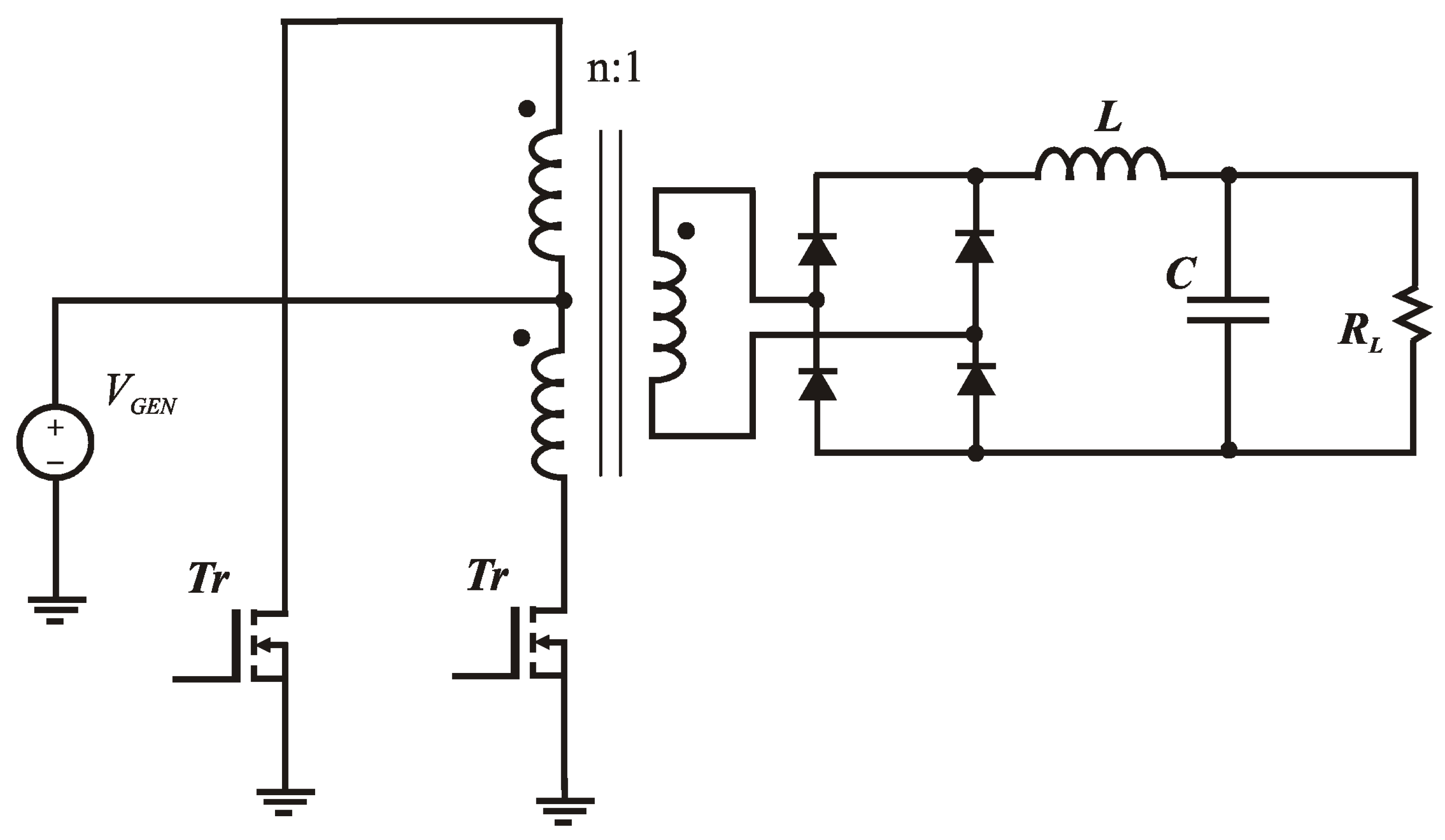

5.3. Push–Pull Converter

5.4. LLC Resonant Converter

5.4.1. Temperature Dependence of Q and Resonant Parameters

5.4.2. Thermal-Aware Tuning and Verification

- Hot-corner gain and ZVS: Ensure that at still covers the required regulation window with the available frequency excursion and that magnetizing current remains sufficient for ZVS when decreases.

- Frequency shift: With , pre-allocate frequency headroom so that limits are not exceeded at hot/cold drift. A practical bound is to design for ±few-% drift of across the qualified temperature span.

- Loss-constrained Q: Dimension and so that does not fall below the minimum value needed to meet gain and efficiency targets; conversely, avoid overly high Q at that would raise circulating energy.

5.4.3. Component and Magnetics Guidelines

- Resonant capacitor : Prefer film capacitors with low loss tangent and stable capacitance over temperature; evaluate and its impact on .

- Inductors/transformer: Select core materials with controlled permeability drift and adequate saturation margin at ; optimize winding for reduced AC losses at the chosen ; and consider impregnation/potting and mechanical fixtures for automotive vibration.

- Primary devices: WBG switches reduce switching loss and mitigate growth at temperature; match dead-time and gate network across T to preserve ZVS.

5.4.4. Control and Re-Tuning Strategies

- Extended frequency modulation: Enlarge the range to accommodate the reduced peak gain.

- Adaptive control: Temperature-aware scheduling of the control law (e.g., gain/limit tables vs. T) and dead-time adjustment.

- Parameter re-centering: Slight re-tuning of or (and thus ) at design time so that the hot-corner falls near the intended operating knee.

5.4.5. Characterization Workflow

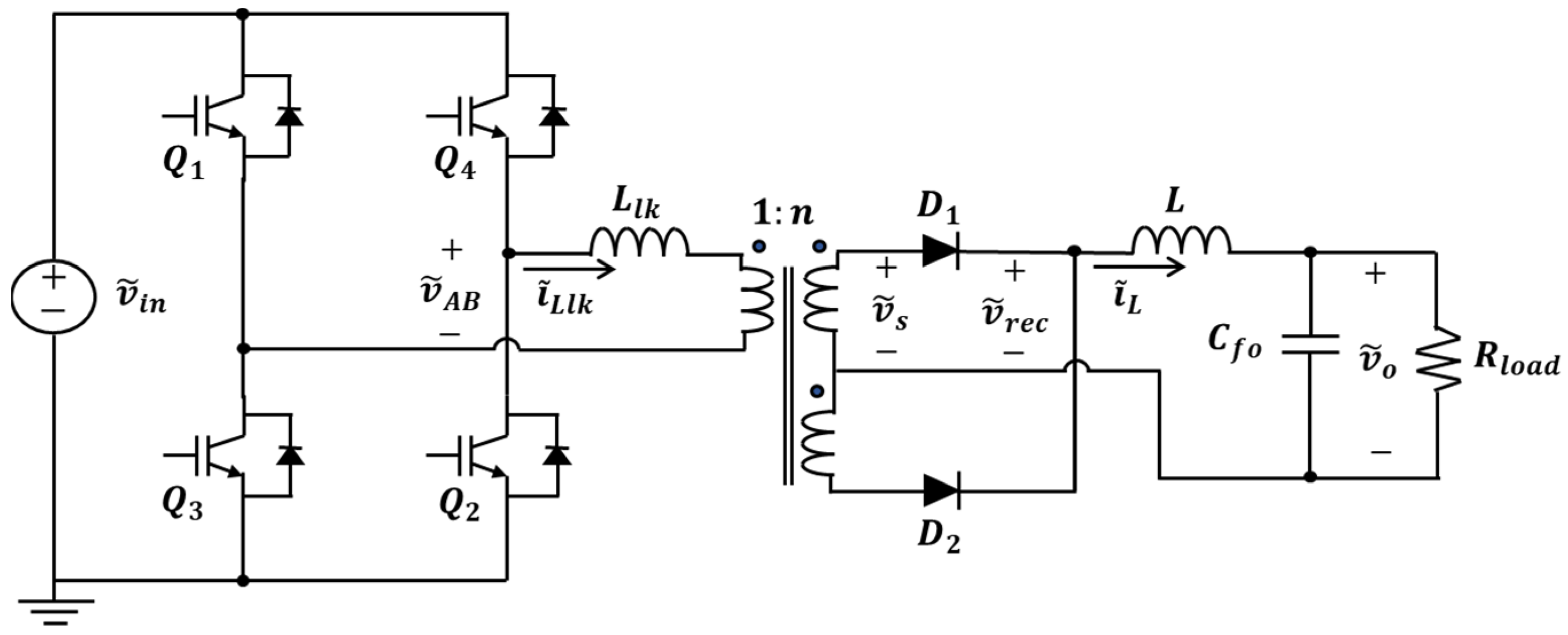

5.5. Phase-Shifted Full-Bridge (PSFB) Converter

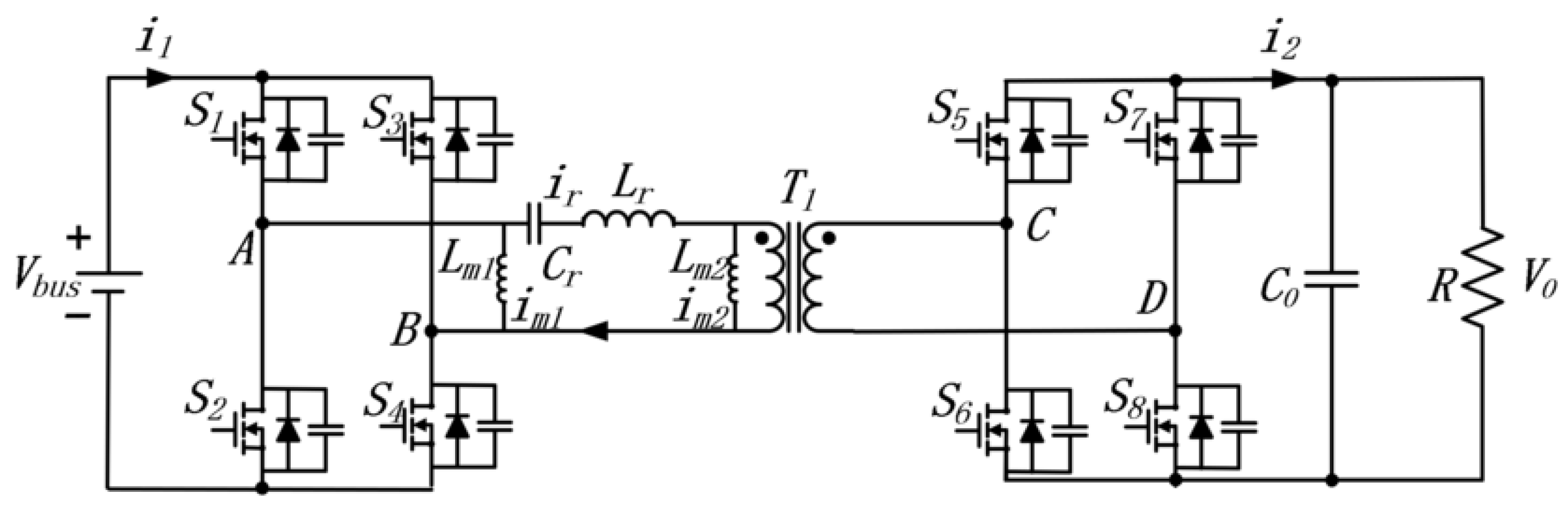

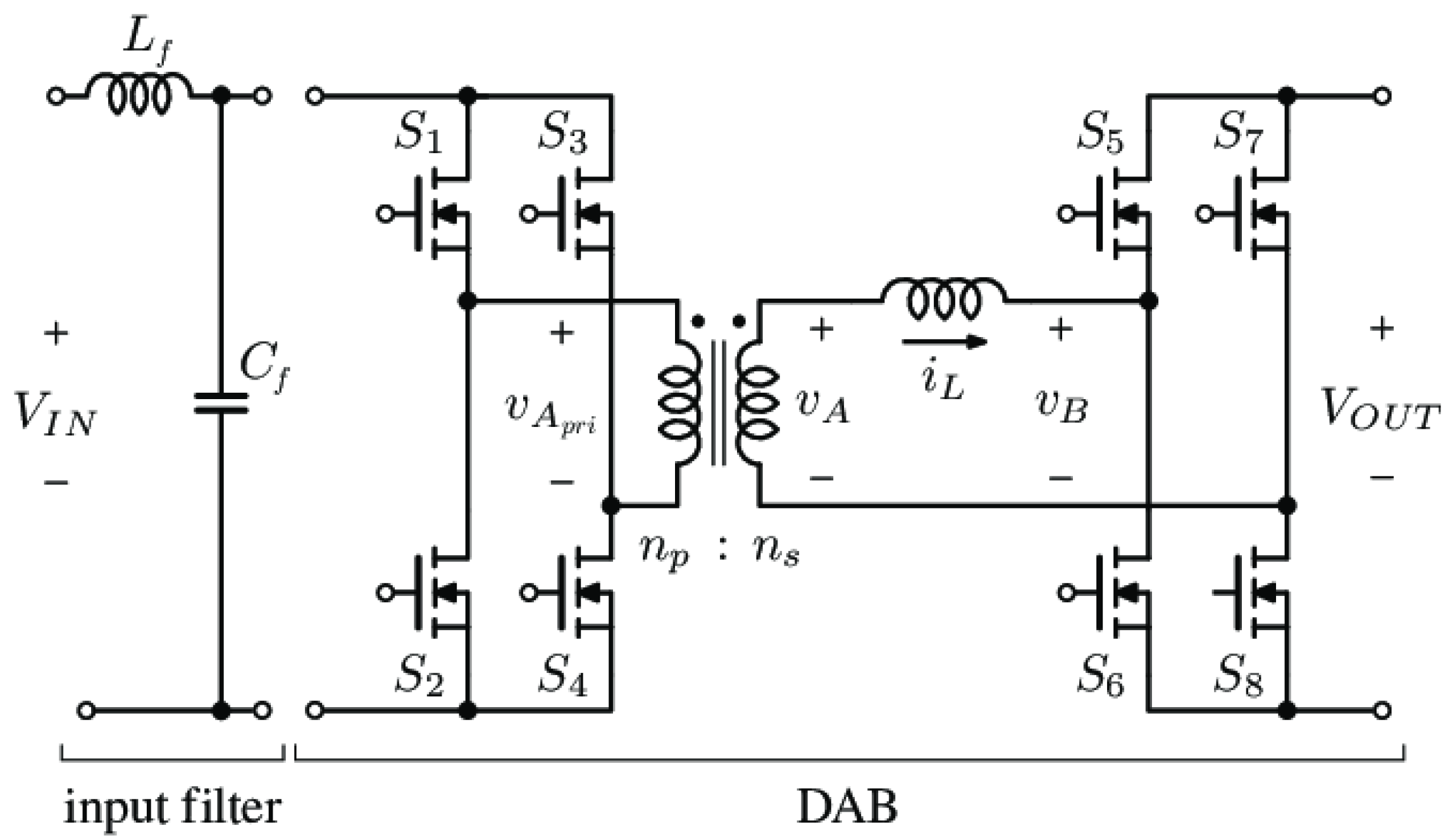

5.6. Dual Active Bridge (DAB) Converter

5.6.1. Battery Degradation Under Frequent Reverse Cycling

5.6.2. Ripple Currents and Battery Stress

5.6.3. Mitigation Strategies

5.7. Comparison of DC/DC Converter Topologies

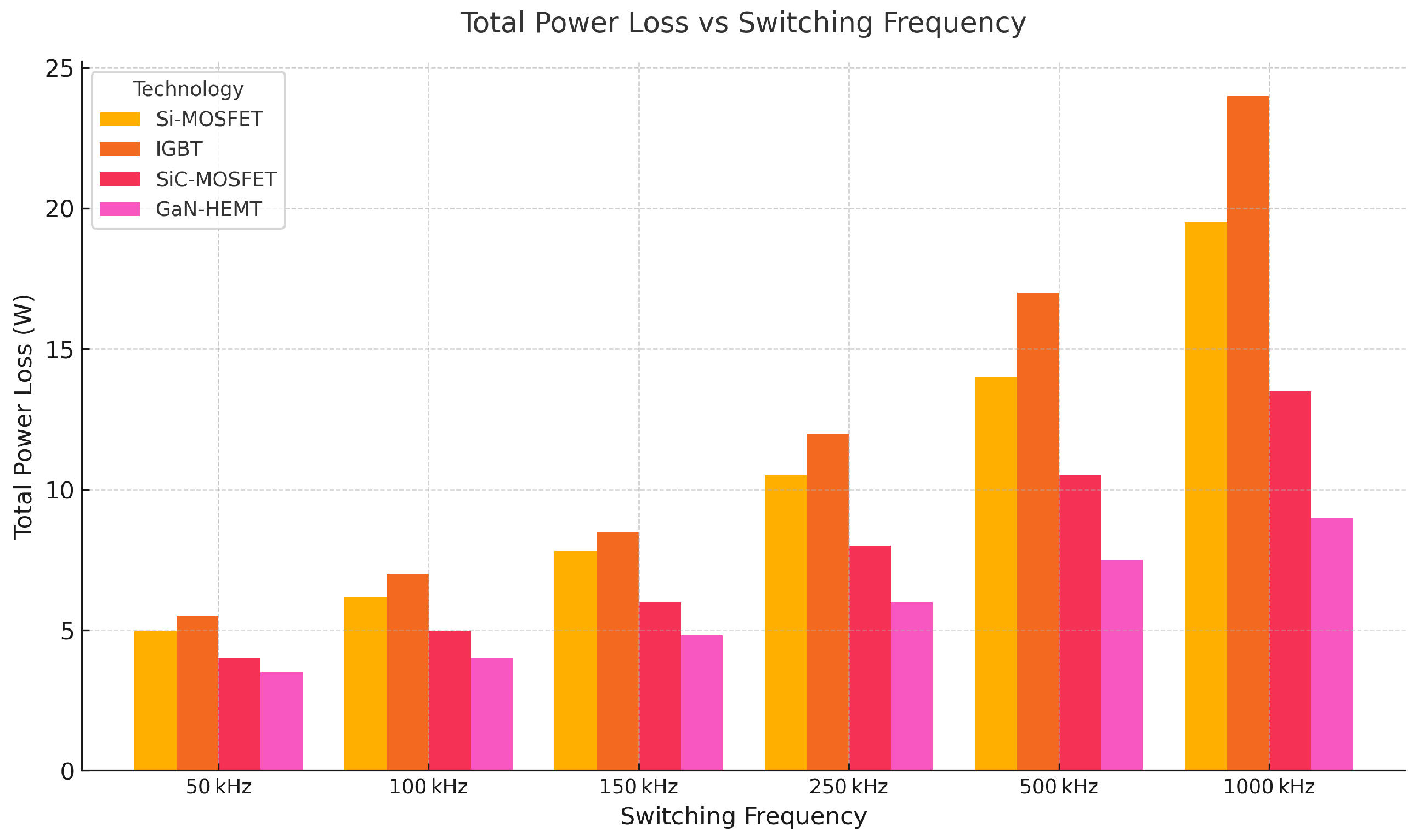

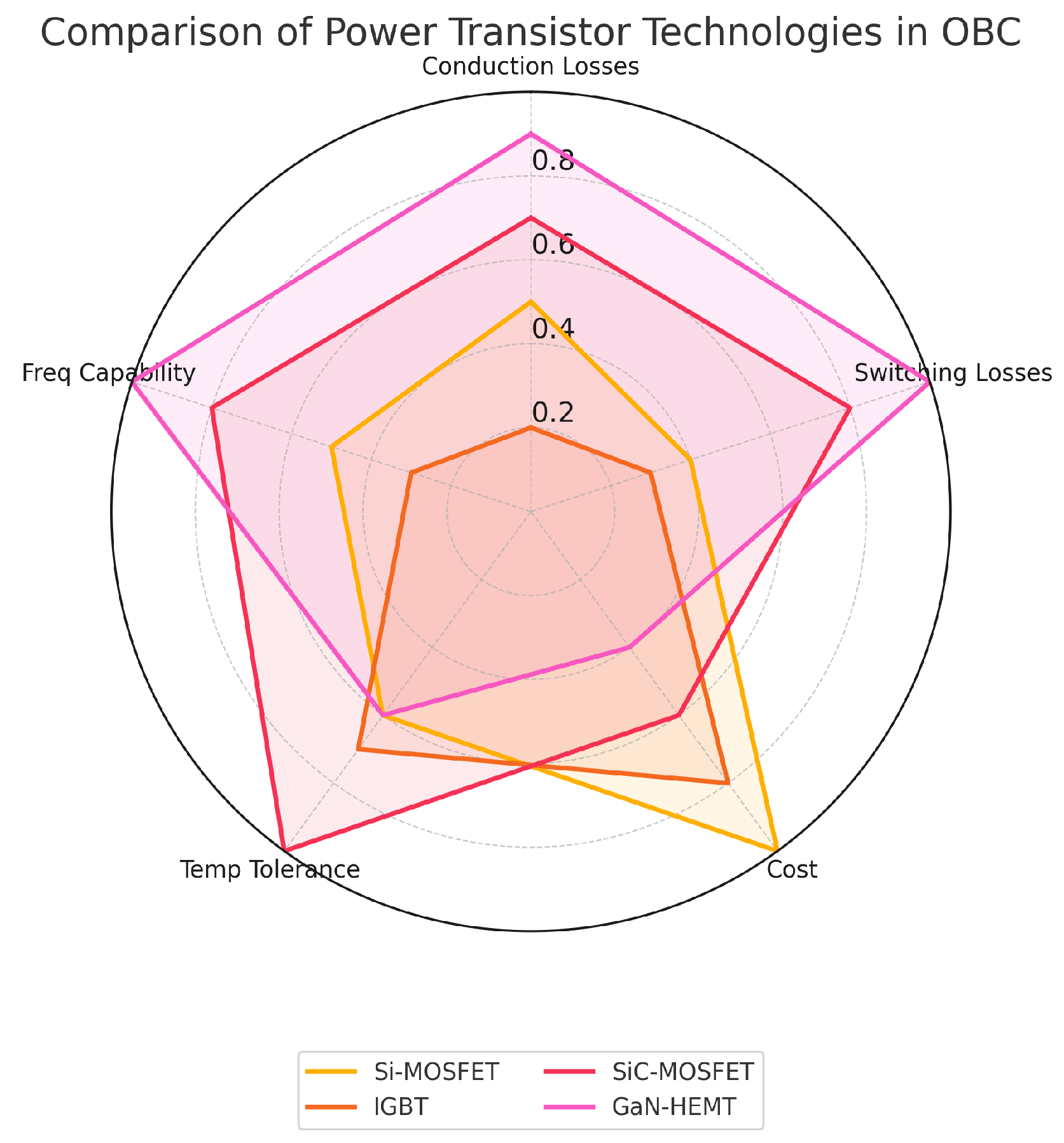

6. Power Switch Technologies in On-Board Chargers

6.1. Mathematical Model for Losses

6.2. Qualitative Performance Trade-Offs

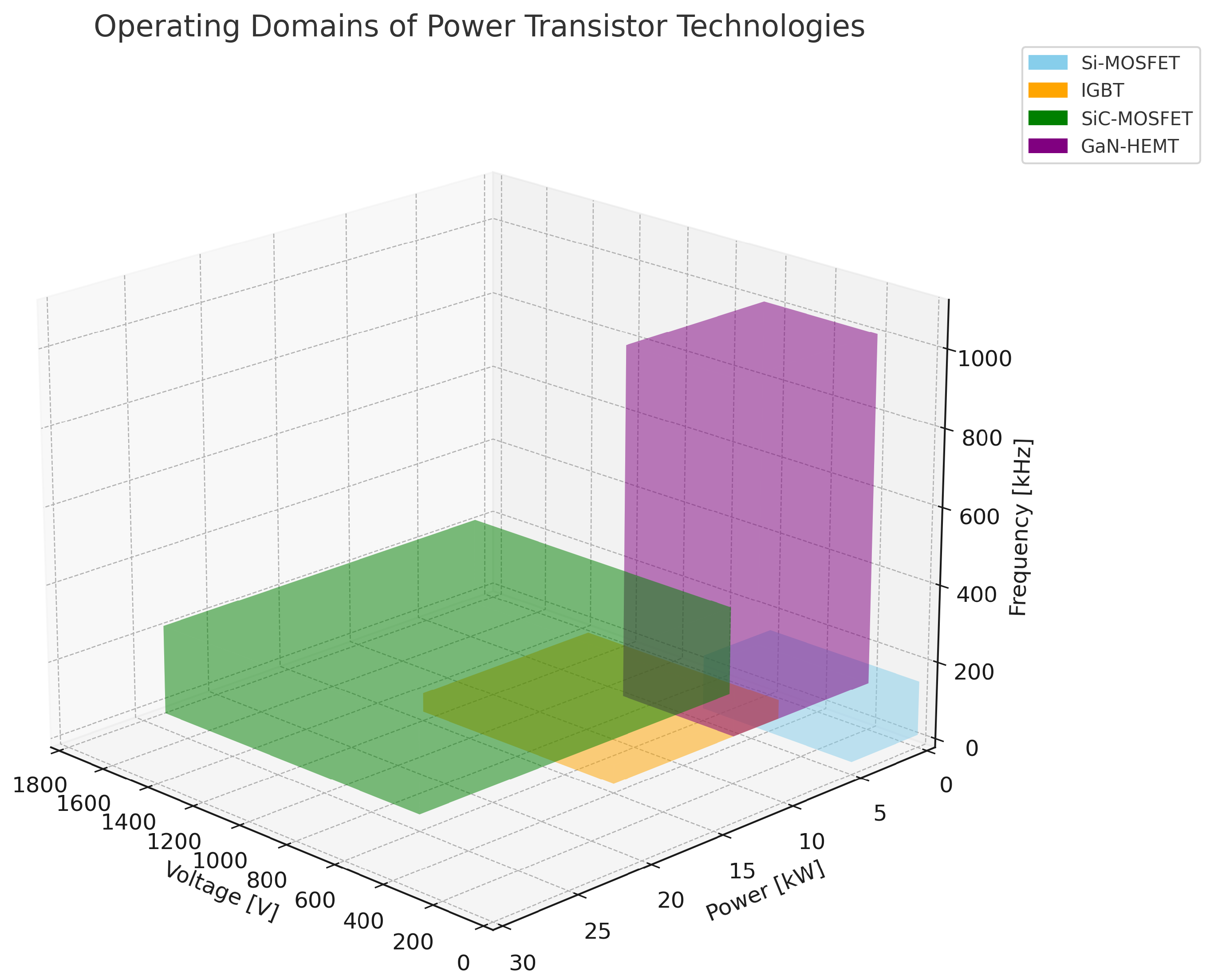

- GaN excels in switching losses and high-frequency operation (up to MHz), making it ideal for resonant converters.

- SiC dominates in thermal capability and high-voltage endurance (up to 1.7 kV+), favored in PFC stages.

- Si and IGBT remain suitable for cost-driven or legacy applications operating at low frequencies.

6.3. System-Level Considerations and Integration

- GaN: High frequency (up to MHz), low-to-mid voltage (up to 650 V), power range up to approx. 10 kW.

- SiC: Medium-to-high frequency (up to 500 kHz), high voltage (up to 1700 V), power up to over 100 kW.

- IGBT: Low frequency (below 50 kHz), mid-to-high voltage, power above 100 kW.

- Si: Cost-effective, low-power (below 1 kW), low-frequency solutions.

6.4. Summary Table

6.5. Trends and Outlook

7. Transformers in Automotive Charging Systems

7.1. Functional Requirements

- Galvanic isolation between input and output domains;

- Voltage scaling across a wide range (e.g., 300–900 V battery vs. 230–400 V bus);

- EMI suppression via coupling geometry and winding symmetry;

- Thermal robustness under high-frequency, high-power conditions.

7.2. Ideal Model and Deviations

- Winding resistances , ;

- Leakage inductances , ;

- Magnetizing inductance ;

- Core loss resistance .

7.3. Thermal Interactions and Loss Modeling

- Copper losses:

- Core losses (for ferrites):where , are material constants, and . These losses grow steeply with frequency and B.

7.3.1. Frequency-Dependent Efficiency Outlook

7.3.2. Impact of Vibrations in Automotive Environments

7.4. Design Evolution and Integration Trends

7.5. Architectural Comparison

7.6. Final Remarks

8. Battery Pack

8.1. Cell Technology and Chemistry

8.1.1. Chemistry Overview (Automotive Li-Ion)

- NMC (LiNiMnCoO2): Balanced energy/power with tunable Ni/Mn/Co ratios; wide deployment across formats (prismatic, pouch, cylindrical). Good energy density, moderate abuse tolerance, fast-charging limited by Li plating risk at low temperature/high SOC.

- NCA (LiNiCoAlO2): Among the highest gravimetric energy; widely used in cylindrical and pouch. Higher thermal sensitivity and stricter fast-charge management (temperature/SOC control) are typically required to mitigate aging and safety risk.

- LFP (LiFePO4): Lower nominal voltage and energy density but markedly higher thermal/chemical stability, flat OCV curve, and long cycle life; prevalent in prismatic format for high-volume packs, with growing adoption in alternative formats. Tolerant to high C-rate at moderate temperatures when appropriately cooled.

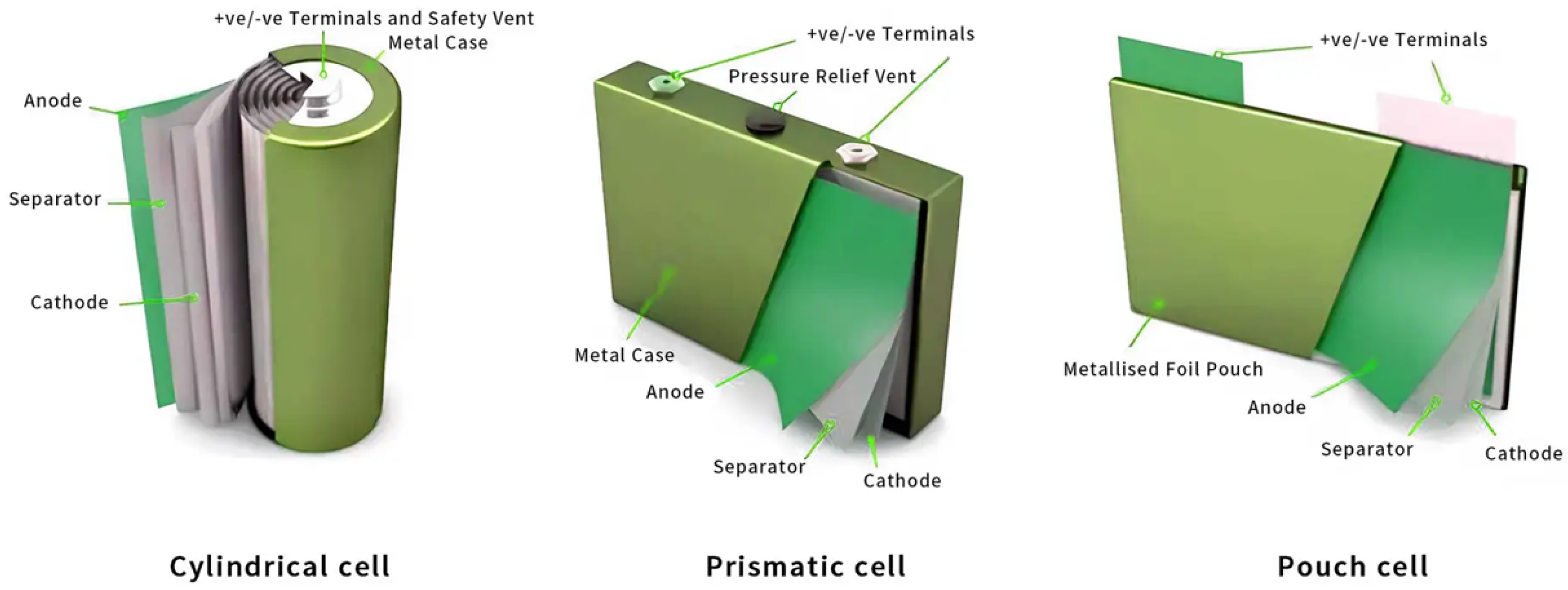

8.1.2. Format Overview (Mechanical/Thermal Integration)

- Cylindrical: Robust “jelly-roll”, excellent mechanical integrity and venting control, high line-speed manufacturing; historically lower packing factor due to interstitial voids, mitigated by large-format designs (e.g., 46xx) and tabless current collectors that reduce ohmic gradients and promote fast charge.

- Prismatic: High volumetric efficiency, flat interfaces for baseplate/side cooling, straightforward series/parallel busbar integration; requires attention to through-plane thermal gradients and shell expansion management.

- Pouch: Highest gravimetric efficiency and short thermal path; requires compressive fixture to control swelling and to maintain interfacial contact; mechanical protection and gas management are critical for abuse robustness.

8.1.3. Chemistry Metrics (Typical Cell-Level Ranges)

8.1.4. Format Attributes (Integration-Centric)

8.1.5. Chemistry–Format Interplay Without Conflation

8.1.6. From Cell to Pack: Implications for OBC Design

8.1.7. Pack-Level Ranges (Indicative)

8.2. Battery Pack Architecture and OBC Interface

- Insulation requirements (e.g., 1–2.5 kV isolation levels);

- Ripple current tolerance and filter sizing;

- Transient overshoot and reverse recovery behavior;

- Pack inductance and loop parasitics.

8.2.1. Filter Examples to Meet Battery Ripple Specifications

- (A)

- Low-frequency (2) ripple decoupling

- (B)

- High-frequency ripple (switching) shaping

8.2.2. Worked Example 1 (6.6 kW, 400 V, 50 Hz): 2 Decoupling

8.2.3. Worked Example 2 (6.6 kW, 400 V, kHz): HF LC Filter

8.2.4. LCL Filters and Damping

8.2.5. Integration Notes

8.3. Battery Management System: Functions and Control Integration

- 1.

- State Estimation (SOC, SOH, SOT)

- 2.

- Charge and Discharge Control

- 3.

- Power Management and Thermal Control

- 4.

- Cell Monitoring and Balancing

- 5.

- Fault Detection and Isolation

- Sensor drift;

- Isolation loss;

- Overtemperature or overvoltage;

- Short circuits.

- 6.

- Communication and Control Integration

9. Commercial Aspects and Trends

- Hyundai Ioniq 5: OBC by Hyundai Mobis with totem-pole PFC and LLC DC/DC, operating at high frequency to minimize passive size.

- Porsche Taycan: Bosch system combining interleaved totem-pole PFC and PSFB with ZVS control, based on SiC switches.

- Fiat 500e: Marelli OBC using a bridgeless PFC with LLC converter, optimized for cost and compactness at 400 V.

9.1. Tier 2: Semiconductors, Magnetics, and Control ICs

9.2. Tier 3: Materials and Passive Component Suppliers

9.3. System-Level Outlook

10. Conclusions and Future Perspectives

- Multi-functional power stages, combining traction, charging, and auxiliary conversion in a unified architecture;

- Digital twin and predictive models for battery-pack-aware charging, real-time diagnostics, and lifetime optimization [129];

- Advanced materials and packaging, including embedded magnetics, thermal composites, and co-encapsulated modules;

- Cybersecure and over-the-air upgradable platforms, aligned with evolving V2X standards and functional safety requirements.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| AFE | Active Front-End |

| BMS | Battery Management System |

| CCM | Continuous Conduction Mode |

| DC | Direct Current |

| DCM | Discontinuous Conduction Mode |

| DAB | Dual Active Bridge |

| EMC | Electromagnetic Compatibility |

| EMI | Electromagnetic Interference |

| EV | Electric Vehicle |

| GaN | Gallium Nitride |

| IGBT | Insulated Gate Bipolar Transistor |

| LLC | Inductor–Inductor–Capacitor (resonant converter) |

| MOSFET | Metal–Oxide–Semiconductor Field-Effect Transistor |

| NCA | Nickel Cobalt Aluminum |

| NMC | Nickel Manganese Cobalt |

| OBC | On-Board Charger |

| OEM | Original Equipment Manufacturer |

| PCB | Printed Circuit Board |

| PCC | Point of Common Coupling |

| PDU | Power Distribution Unit |

| PFC | Power Factor Correction |

| PLL | Phase-Locked Loop |

| PSFB | Phase-Shifted Full Bridge |

| PWM | Pulse Width Modulation |

| RMS | Root Mean Square |

| Si | Silicon |

| SiC | Silicon Carbide |

| SOC | State of Charge |

| SOH | State of Health |

| SOT | State of Temperature |

| THD | Total Harmonic Distortion |

| UPS | Uninterruptible Power Supply |

| V2G | Vehicle-to-Grid |

| V2L | Vehicle-to-Load |

| V2H | Vehicle-to-Home |

| VOC | Open Circuit Voltage |

| WBG | Wide Bandgap |

| ZCS | Zero Current Switching |

| ZVS | Zero Voltage Switching |

References

- Shahjalal, M.; Shams, T.; Tasnim, M.N.; Ahmed, M.R.; Ahsan, M.; Haider, J. A critical review on charging technologies of electric vehicles. Energies 2022, 15, 8239. [Google Scholar] [CrossRef]

- Tejeida-Padilla, R.; Berdeja-Rocha, E.M.; Badillo-Piña, I.; Pérez-Matamoros, Z.; Amador-Santiago, J.E. A Comprehensive Review of Electric Charging Stations with a Systemic Approach. World Electr. Veh. J. 2024, 15, 571. [Google Scholar] [CrossRef]

- Dini, P.; Saponara, S.; Colicelli, A. Overview on battery charging systems for electric vehicles. Electronics 2023, 12, 4295. [Google Scholar] [CrossRef]

- Rachid, A.; El Fadil, H.; Gaouzi, K.; Rachid, K.; Lassioui, A.; El Idrissi, Z.; Koundi, M. Electric vehicle charging systems: Comprehensive review. Energies 2022, 16, 255. [Google Scholar] [CrossRef]

- Nkembi, A.A.; Cova, P.; Sacchi, E.; Coraggioso, E.; Delmonte, N. A comprehensive review of power converters for E-mobility. Energies 2023, 16, 1888. [Google Scholar] [CrossRef]

- Nasr Esfahani, F.; Darwish, A.; Ma, X.; Twigg, P. Non-integrated and integrated on-board battery chargers (iOBCs) for electric vehicles (EVs): A critical review. Energies 2024, 17, 2285. [Google Scholar] [CrossRef]

- Jaman, S.; Chakraborty, S.; Tran, D.D.; Geury, T.; El Baghdadi, M.; Hegazy, O. Review on integrated on-board charger-traction systems: V2G topologies, control approaches, standards and power density state-of-the-art for electric vehicle. Energies 2022, 15, 5376. [Google Scholar] [CrossRef]

- Dar, A.R.; Haque, A.; Khan, M.A.; Kurukuru, V.S.B.; Mehfuz, S. On-board chargers for electric vehicles: A comprehensive performance and efficiency review. Energies 2024, 17, 4534. [Google Scholar] [CrossRef]

- Bay, O.; Tran, M.T.; El Baghdadi, M.; Chakraborty, S.; Hegazy, O. A comprehensive review of gan-based bi-directional on-board charger topologies and modulation methods. Energies 2023, 16, 3433. [Google Scholar] [CrossRef]

- Al Attar, H.; Hamida, M.A.; Ghanes, M.; Taleb, M. Review on modeling and control strategies of DC–DC LLC converters for bidirectional electric vehicle charger applications. Energies 2023, 16, 3946. [Google Scholar] [CrossRef]

- Ria, A.; Dini, P. A compact overview on Li-ion batteries characteristics and battery management systems integration for automotive applications. Energies 2024, 17, 5992. [Google Scholar] [CrossRef]

- Gaona-Cárdenas, L.F.; Vázquez-Nava, N.; Ruíz-Martínez, O.F.; Espinosa-Calderón, A.; Barranco-Gutiérrez, A.I.; Rodríguez-Licea, M.A. An overview on fault management for electric vehicle onboard chargers. Electronics 2022, 11, 1107. [Google Scholar] [CrossRef]

- Polat, H.; Hosseinabadi, F.; Hasan, M.M.; Chakraborty, S.; Geury, T.; El Baghdadi, M.; Wilkins, S.; Hegazy, O. A review of DC fast chargers with BESS for electric vehicles: Topology, battery, reliability oriented control and cooling perspectives. Batteries 2023, 9, 121. [Google Scholar] [CrossRef]

- Arif, S.M.; Lie, T.T.; Seet, B.C.; Ayyadi, S.; Jensen, K. Review of electric vehicle technologies, charging methods, standards and optimization techniques. Electronics 2021, 10, 1910. [Google Scholar] [CrossRef]

- Sousa, T.J.; Pedrosa, D.; Monteiro, V.; Afonso, J.L. A review on integrated battery chargers for electric vehicles. Energies 2022, 15, 2756. [Google Scholar] [CrossRef]

- Shahir, F.M.; Gheisarnejad, M.; Sadabadi, M.S.; Khooban, M.H. A new off-board electrical vehicle battery charger: Topology, analysis and design. Designs 2021, 5, 51. [Google Scholar] [CrossRef]

- Neto, R.C.; Bandeira, C.M.; Azevedo, G.M.; Limongi, L.R.; de Carvalho, M.R.; Castro, J.F.; Rosas, P.A.; Venerando, A.C.; Spader, N.; Bueno, E. Mobile charging stations: A comprehensive review of converter topologies and market solutions. Energies 2024, 17, 5931. [Google Scholar] [CrossRef]

- Zhou, K.; Wu, Y.; Wu, X.; Sun, Y.; Teng, D.; Liu, Y. Research and development review of power converter topologies and control technology for electric vehicle fast-charging systems. Electronics 2023, 12, 1581. [Google Scholar] [CrossRef]

- Alrubaie, A.J.; Swadi, M.; Salem, M.; Richelli, A.; Bughneda, A.; Kamarol, M. Systematic review of bidirectional, multiport converter structures and their derivatives: A case study of bidirectional dual input dual output converters. Energies 2024, 17, 1575. [Google Scholar] [CrossRef]

- Kilicoglu, H.; Tricoli, P. Technical review and survey of future trends of power converters for fast-charging stations of electric vehicles. Energies 2023, 16, 5204. [Google Scholar] [CrossRef]

- Afonso, J.L.; Cardoso, L.A.L.; Pedrosa, D.; Sousa, T.J.; Machado, L.; Tanta, M.; Monteiro, V. A review on power electronics technologies for electric mobility. Energies 2020, 13, 6343. [Google Scholar] [CrossRef]

- Akhtar, M.F.; Raihan, S.R.S.; Rahim, N.A.; Akhtar, M.N.; Abu Bakar, E. Recent developments in DC-DC converter topologies for light electric vehicle charging: A critical review. Appl. Sci. 2023, 13, 1676. [Google Scholar] [CrossRef]

- Islam, R.; Rafin, S.S.H.; Mohammed, O.A. Comprehensive review of power electronic converters in electric vehicle applications. Forecasting 2022, 5, 22–80. [Google Scholar] [CrossRef]

- Santos, J.B.; Francisco, A.M.B.; Cabrita, C.; Monteiro, J.; Pacheco, A.; Cardoso, P.J.S. Development and implementation of a smart charging system for electric vehicles based on the ISO 15118 standard. Energies 2024, 17, 3045. [Google Scholar] [CrossRef]

- Monteiro, V.; Afonso, J.A.; Afonso, J.L. Bidirectional power converters for ev battery chargers. Energies 2023, 16, 1694. [Google Scholar] [CrossRef]

- ElMenshawy, M.; Massoud, A. Medium-voltage dc-dc converter topologies for electric bus fast charging stations: State-of-the-art review. Energies 2022, 15, 5487. [Google Scholar] [CrossRef]

- IEC 60664-1; Insulation Coordination for Equipment within Low-Voltage Systems—Part 1: Principles, Requirements and Tests. International Electrotechnical Commission: Geneva, Switzerland, 2021.

- ISO 6469; Electrically Propelled Road Vehicles—Safety Specifications. International Organization for Standardization: Geneva, Switzerland, 2022.

- UL 2202; Standard for Electric Vehicle (EV) Charging System Equipment. Underwriters Laboratories: Northbrook, IL, USA, 2019.

- IEC 61000-4-x; Electromagnetic Compatibility (EMC)—Part 4: Testing and Measurement Techniques. International Electrotechnical Commission: Geneva, Switzerland, 2020.

- ISO 15118; Road Vehicles—Vehicle to Grid Communication Interface. International Organization for Standardization: Geneva, Switzerland, 2019.

- IEC 62196; Plugs, Socket-Outlets, Vehicle Connectors and Vehicle Inlets—Conductive Charging of Electric Vehicles. International Electrotechnical Commission: Geneva, Switzerland, 2022.

- SAE J1772; Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Coupler. Society of Automotive Engineers: Warrendale, PA, USA, 2020.

- ISO/SAE 21434; Road Vehicles—Cybersecurity Engineering. International Organization for Standardization and Society of Automotive Engineers: Geneva, Switzerland; Warrendale, PA, USA, 2021.

- ISO 26262; Road Vehicles—Functional Safety. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 16750; Road Vehicles—Environmental Conditions and Testing for Electrical and Electronic Equipment. International Organization for Standardization: Geneva, Switzerland, 2023.

- Zhaksylyk, A.; Rasool, H.; Abramushkina, E.; Chakraborty, S.; Geury, T.; El Baghdadi, M.; Hegazy, O. Review of active front-end rectifiers in ev dc charging applications. Batteries 2023, 9, 150. [Google Scholar] [CrossRef]

- Nikolaev, A.; Maklakov, A.; Bulanov, M.; Gilemov, I.; Denisevich, A.; Afanasev, M. Current electromagnetic compatibility problems of high-power industrial electric drives with active front-end rectifiers connected to a 6–35 kV power grid: A comprehensive overview. Energies 2022, 16, 293. [Google Scholar] [CrossRef]

- Piasecki, S.; Zaleski, J.; Jasinski, M.; Bachman, S.; Turzyński, M. Analysis of AC/DC/DC converter modules for direct current fast-charging applications. Energies 2021, 14, 6369. [Google Scholar] [CrossRef]

- Monteiro, V.; Monteiro, L.F.; Franco, F.L.; Mandrioli, R.; Ricco, M.; Grandi, G.; Afonso, J.L. The role of front-end AC/DC converters in hybrid AC/DC smart homes: Analysis and experimental validation. Electronics 2021, 10, 2601. [Google Scholar] [CrossRef]

- Ortiz-Castrillón, J.R.; Mejía-Ruíz, G.E.; Muñoz-Galeano, N.; López-Lezama, J.M.; Saldarriaga-Zuluaga, S.D. PFC single-phase AC/DC boost converters: Bridge, semi-bridgeless, and bridgeless topologies. Appl. Sci. 2021, 11, 7651. [Google Scholar] [CrossRef]

- Dini, P.; Saponara, S. Electro-thermal model-based design of bidirectional on-board chargers in hybrid and full electric vehicles. Electronics 2021, 11, 112. [Google Scholar] [CrossRef]

- Gonçalves, J.T.; Valtchev, S.; Melicio, R.; Gonçalves, A.; Blaabjerg, F. Hybrid three-phase rectifiers with active power factor correction: A systematic review. Electronics 2021, 10, 1520. [Google Scholar] [CrossRef]

- Sayed, K.; Gabbar, H.A. Electric vehicle to power grid integration using three-phase three-level AC/DC converter and PI-fuzzy controller. Energies 2016, 9, 532. [Google Scholar] [CrossRef]

- Azeem, O.; Ali, M.; Abbas, G.; Uzair, M.; Qahmash, A.; Algarni, A.; Hussain, M.R. A comprehensive review on integration challenges, optimization techniques and control strategies of hybrid AC/DC Microgrid. Appl. Sci. 2021, 11, 6242. [Google Scholar] [CrossRef]

- Monteiro, V.; Martins, J.S.; Aparicio Fernandes, J.C.; Afonso, J.L. Review of a disruptive vision of future power grids: A new path based on hybrid AC/DC grids and solid-state transformers. Sustainability 2021, 13, 9423. [Google Scholar] [CrossRef]

- Sarwar, S.; Kirli, D.; Merlin, M.M.; Kiprakis, A.E. Major challenges towards energy management and power sharing in a hybrid AC/DC microgrid: A review. Energies 2022, 15, 8851. [Google Scholar] [CrossRef]

- Rehman, B.; Rehman, A.u.; Khan, W.A.; Sami, I.; Ro, J.S. Operation and challenges of multi-infeed lcc–hvdc system: Commutation failure, ac/dc power flow, and voltage stability. Appl. Sci. 2021, 11, 8637. [Google Scholar] [CrossRef]

- Hollweg, G.V.; Khan, S.A.; Chaturvedi, S.; Fan, Y.; Wang, M.; Su, W. Grid-connected converters: A brief survey of topologies, output filters, current control, and weak grids operation. Energies 2023, 16, 3611. [Google Scholar] [CrossRef]

- Beres, R.N.; Wang, X.; Liserre, M.; Blaabjerg, F.; Bak, C.L. A review of passive power filters for three-phase grid-connected voltage-source converters. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 4, 54–69. [Google Scholar] [CrossRef]

- Das, S.R.; Ray, P.K.; Sahoo, A.K.; Ramasubbareddy, S.; Babu, T.S.; Kumar, N.M.; Elavarasan, R.M.; Mihet-Popa, L. A comprehensive survey on different control strategies and applications of active power filters for power quality improvement. Energies 2021, 14, 4589. [Google Scholar] [CrossRef]

- Fang, J.; Li, X.; Tang, Y. A review of passive power filters for voltage-source converters. In Proceedings of the 2016 Asian Conference on Energy, Power and Transportation Electrification (ACEPT), Singapore, 25–27 October 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–6. [Google Scholar]

- Nguyen, M.K. Power Converters in Power Electronics: Current Research Trends. Electronics 2020, 9, 654. [Google Scholar] [CrossRef]

- Beres, R.; Wang, X.; Blaabjerg, F.; Bak, C.L.; Liserre, M. A review of passive filters for grid-connected voltage source converters. In Proceedings of the 2014 IEEE Applied Power Electronics Conference and Exposition-APEC 2014, Fort Worth, TX, USA, 16–20 March 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 2208–2215. [Google Scholar]

- Zhang, Y.; Song, C.; Wang, T.; Wang, K. Optimization of Passive Damping for LCL-Filtered AC Grid-Connected PV-Storage Integrated Systems. Electronics 2025, 14, 801. [Google Scholar] [CrossRef]

- Adamas-Pérez, H.; Ponce-Silva, M.; Mina-Antonio, J.D.; Claudio-Sánchez, A.; Rodríguez-Benítez, O.; Rodríguez-Benítez, O.M. A New LCL Filter Design Method for Single-Phase Photovoltaic Systems Connected to the Grid via Micro-Inverters. Technologies 2024, 12, 89. [Google Scholar] [CrossRef]

- Al-Barashi, M.; Zou, A.; Wang, Y.; Luo, W.; Shao, N.; Tang, Z.; Lu, B. Magnetic Integrated Multi-Trap Filters Using Mutual Inductance to Mitigate Current Harmonics in Grid-Connected Power Electronics Converters. Energies 2025, 18, 423. [Google Scholar] [CrossRef]

- Mustafa, U.; Ahmed, R.; Watson, A.; Wheeler, P.; Ahmed, N.; Dahele, P. A comprehensive review of machine-integrated electric vehicle chargers. Energies 2022, 16, 129. [Google Scholar] [CrossRef]

- Raghavendra, K.V.G.; Zeb, K.; Muthusamy, A.; Krishna, T.; Kumar, S.V.P.; Kim, D.H.; Kim, M.S.; Cho, H.G.; Kim, H.J. A comprehensive review of DC–DC converter topologies and modulation strategies with recent advances in solar photovoltaic systems. Electronics 2019, 9, 31. [Google Scholar] [CrossRef]

- Kotb, R.; Chakraborty, S.; Tran, D.D.; Abramushkina, E.; El Baghdadi, M.; Hegazy, O. Power electronics converters for electric vehicle auxiliaries: State of the art and future trends. Energies 2023, 16, 1753. [Google Scholar] [CrossRef]

- Litrán, S.P.; Durán, E.; Semião, J.; Díaz-Martín, C. Multiple-output DC–DC Converters: Applications and solutions. Electronics 2022, 11, 1258. [Google Scholar] [CrossRef]

- Ivanovic, Z.; Knezic, M. Modeling push–pull converter for efficiency improvement. Electronics 2022, 11, 2713. [Google Scholar] [CrossRef]

- Habumugisha, D.; Chowdhury, S.; Chowdhury, S. A DC-DC interleaved forward converter to step-up DC voltage for DC Microgrid applications. In Proceedings of the 2013 IEEE Power & Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 1–5. [Google Scholar]

- Vivas, F.J.; Segura, F.; Andújar, J.M. Generalized, Complete and Accurate Modeling of Non-Ideal Push–Pull Converters for Power System Analysis and Control. Appl. Sci. 2023, 13, 10982. [Google Scholar] [CrossRef]

- Tai, Y.K.; Hwu, K.I. A novel ZVS/ZCS push-pull LC resonant DC-DC converter for energy sources. Energies 2023, 16, 2892. [Google Scholar] [CrossRef]

- Vivas, F.J.; Andújar, J.M.; Segura, F. Non-Ideal Push–Pull Converter Model: Trade-Off between Complexity and Practical Feasibility in Terms of Topology, Power and Operating Frequency. Appl. Sci. 2024, 14, 6224. [Google Scholar] [CrossRef]

- Mortazavizadeh, S.A.; Palazzo, S.; Amendola, A.; De Santis, E.; Di Ruzza, D.; Panariello, G.; Sanseverino, A.; Velardi, F.; Busatto, G. High frequency, high efficiency, and high power density GaN-based LLC resonant converter: State-of-the-art and perspectives. Appl. Sci. 2021, 11, 11350. [Google Scholar] [CrossRef]

- Alatai, S.; Salem, M.; Alhamrouni, I.; Ishak, D.; Bughneda, A.; Kamarol, M. Design methodology and analysis of five-level LLC resonant converter for battery chargers. Sustainability 2022, 14, 8255. [Google Scholar] [CrossRef]

- Rocha, J.; Amin, S.; Coelho, S.; Rego, G.; Afonso, J.L.; Monteiro, V. Design and Implementation of a DC–DC resonant LLC converter for electric vehicle fast chargers. Energies 2025, 18, 1099. [Google Scholar] [CrossRef]

- Faizan, M.; Wang, X.; Yousaf, M.Z. Design and comparative analysis of an ultra-highly efficient, compact half-bridge LLC resonant GaN converter for low-power applications. Electronics 2023, 12, 2850. [Google Scholar] [CrossRef]

- Sayed, K.; Ali, Z.M.; Aldhaifallah, M. Phase-shift PWM-controlled DC–DC converter with secondary-side current doubler rectifier for on-board charger application. Energies 2020, 13, 2298. [Google Scholar] [CrossRef]

- Escudero, M.; Kutschak, M.A.; Meneses, D.; Rodriguez, N.; Morales, D.P. A practical approach to the design of a highly efficient PSFB DC-DC converter for server applications. Energies 2019, 12, 3723. [Google Scholar] [CrossRef]

- Gocen, F.E.; Ozturk, S.B.; Aksit, M.H.; Dugan, G.; Cakmak, B.; Demir, C. Design and Implementation of a Full SiC-Based Phase-Shifted Full-Bridge DC-DC Converter with Nanocrystalline-Cored Magnetics for Railway Battery Charging Applications. Energies 2025, 18, 3945. [Google Scholar] [CrossRef]

- Benites Quispe, J.B.; Mezaroba, M.; Batschauer, A.L.; de Souza Ribeiro, J.M. A Reconfigurable Phase-Shifted Full-Bridge DC–DC Converter with Wide Range Output Voltage. Energies 2024, 17, 3483. [Google Scholar] [CrossRef]

- He, J.; Chen, Y.; Lin, J.; Chen, J.; Cheng, L.; Wang, Y. Review of modeling, modulation, and control strategies for the dual-active-bridge DC/DC converter. Energies 2023, 16, 6646. [Google Scholar] [CrossRef]

- Oh, H.S.; Hong, S.Y.; Lee, J.; Lee, J.B. Comparison of Bi-Directional Topologies for On-Board Charger: A 10.9 kW High-Efficiency High Power Density of DC-DC Stage. Energies 2024, 17, 5496. [Google Scholar] [CrossRef]

- Ataullah, H.; Iqbal, T.; Khalil, I.U.; Ali, U.; Blazek, V.; Prokop, L.; Ullah, N. Analysis of the dual active bridge-based DC-DC converter topologies, high-frequency transformer, and control techniques. Energies 2022, 15, 8944. [Google Scholar] [CrossRef]

- Moonem, M.; Pechacek, C.; Hernandez, R.; Krishnaswami, H. Analysis of a multilevel dual active bridge (ML-DAB) DC-DC converter using symmetric modulation. Electronics 2015, 4, 239–260. [Google Scholar] [CrossRef]

- Jiang, T.; Chen, M.; Parastar, A.; Beza, M. Comparison of Full-Bridge and T-type DC/DC Converters for Electric Vehicle Applications. In Proceedings of the 2024 6th International Conference on Electrical, Control and Instrumentation Engineering (ICECIE), Pattaya, Thailand, 23–23 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–11. [Google Scholar]

- Guzmán, P.; Vázquez, N.; Liserre, M.; Orosco, R.; Vaquero, J.; Hernández, C. AC-DC DAB converter with power factor correction. Energies 2022, 16, 320. [Google Scholar] [CrossRef]

- Dini, P.; Ariaudo, G.; Botto, G.; Greca, F.L.; Saponara, S. Real-time electro-thermal modelling and predictive control design of resonant power converter in full electric vehicle applications. IET Power Electron. 2023, 16, 2045–2064. [Google Scholar] [CrossRef]

- Kumar, A.; Moradpour, M.; Losito, M.; Franke, W.T.; Ramasamy, S.; Baccoli, R.; Gatto, G. Wide band gap devices and their application in power electronics. Energies 2022, 15, 9172. [Google Scholar] [CrossRef]

- Chaudhary, O.S.; Denaï, M.; Refaat, S.S.; Pissanidis, G. Technology and applications of wide bandgap semiconductor materials: Current state and future trends. Energies 2023, 16, 6689. [Google Scholar] [CrossRef]

- Rasul, A.; Teixeira, R.; Baptista, J. Silicon Carbide Converter Design: A Review. Energies 2025, 18, 2140. [Google Scholar] [CrossRef]

- Buffolo, M.; Favero, D.; Marcuzzi, A.; De Santi, C.; Meneghesso, G.; Zanoni, E.; Meneghini, M. Review and outlook on GaN and SiC power devices: Industrial state-of-the-art, applications, and perspectives. IEEE Trans. Electron Devices 2024, 71, 1344–1355. [Google Scholar] [CrossRef]

- Ma, C.T.; Gu, Z.H. Review of GaN HEMT applications in power converters over 500 W. Electronics 2019, 8, 1401. [Google Scholar] [CrossRef]

- Akbar, G.; Di Fatta, A.; Rizzo, G.; Ala, G.; Romano, P.; Imburgia, A. Comprehensive Review of Wide-Bandgap (WBG) Devices: SiC MOSFET and Its Failure Modes Affecting Reliability. Physchem 2025, 5, 10. [Google Scholar] [CrossRef]

- Spejo, L.B.; Thekemuriyil, T.; Minamisawa, R.A. Estimation of Energy-Saving Potential Using Commercial SiC Power Converters. Energies 2024, 17, 4570. [Google Scholar] [CrossRef]

- Dini, P.; Basso, G.; Saponara, S.; Romano, C. Real-time monitoring and ageing detection algorithm design with application on SiC-based automotive power drive system. IET Power Electron. 2024, 17, 690–710. [Google Scholar] [CrossRef]

- Dini, P.; Saponara, S. Modeling and control simulation of power converters in automotive applications. Appl. Sci. 2024, 14, 1227. [Google Scholar] [CrossRef]

- La Via, F.; Alquier, D.; Giannazzo, F.; Kimoto, T.; Neudeck, P.; Ou, H.; Roncaglia, A.; Saddow, S.E.; Tudisco, S. Emerging SiC applications beyond power electronic devices. Micromachines 2023, 14, 1200. [Google Scholar] [CrossRef]

- Dini, P.; Basso, G.; Saponara, S.; Chakraborty, S.; Hegazy, O. Real-Time AMPC for Loss Reduction in 48 V Six-Phase Synchronous Motor Drives. IET Power Electron. 2025, 18, e70072. [Google Scholar] [CrossRef]

- Dini, P.; Saponara, S.; Basso, G.; Romano, C. Model-Based Design and AI for Monitoring Systems in Automotive Power Electronics. In Proceedings of the Annual Meeting of the Italian Electronics Society, Genoa, Italy, 26–28 June 2024; Springer: Cham, Switzerland, 2024; pp. 351–361. [Google Scholar]

- Son, W.J.; Lee, B.K. Design of Planar Transformers for LLC Converters in High Power Density On-Board Chargers for Electric Vehicles. Energies 2023, 16, 6757. [Google Scholar] [CrossRef]

- Lee, D.W.; Lim, J.H.; Lee, D.I.; Youn, H.S. A high-power-density active-clamp converter with integrated planar transformer. Energies 2022, 15, 5609. [Google Scholar] [CrossRef]

- Wouters, H.; Martinez, W. Bidirectional onboard chargers for electric vehicles: State-of-the-art and future trends. IEEE Trans. Power Electron. 2023, 39, 693–716. [Google Scholar] [CrossRef]

- Wang, C.S.; Li, W.; Meng, Z.; Wang, Y.F.; Zhou, J.G. Three-Phase High-Power and Zero-Current-Switching OBC for Plug-In Electric Vehicles. Energies 2015, 8, 6672–6704. [Google Scholar] [CrossRef]

- Valedsaravi, S.; El Aroudi, A.; Martínez-Salamero, L. Review of solid-state transformer applications on electric vehicle DC ultra-fast charging station. Energies 2022, 15, 5602. [Google Scholar] [CrossRef]

- Wouters, H.; Martinez, W. Integrated Inductor-Transformers for High-Frequency Converters: An Overview. IEEE Trans. Power Electron. 2025, 40, 13157–13176. [Google Scholar] [CrossRef]

- Tabrez, M.; Sadhu, P.K.; Hossain Lipu, M.S.; Iqbal, A.; Husain, M.A.; Ansari, S. Power conversion techniques using multi-phase transformer: Configurations, applications, issues and recommendations. Machines 2021, 10, 13. [Google Scholar] [CrossRef]

- Yang, Z.; Tahir, M.; Hu, S.; Huang, Q.; Zhu, H. Transformer Leakage Inductance Calculation Method with Experimental Validation for CLLLC Converter Topology. Energies 2022, 15, 6801. [Google Scholar] [CrossRef]

- Choi, C.W.; Ko, J.S.; Yoon, K.Y.; Park, Y.U.; Kang, Y.S.; Kim, D.K. A Novel Structure of Variable Inductance High-Frequency Transformer for Power Level Enhancement in Dual-Active-Bridge Converters. Energies 2025, 18, 1043. [Google Scholar] [CrossRef]

- Pavlićević, A.; Mujović, S. Impact of reactive power from public electric vehicle stations on transformer aging and active energy losses. Energies 2022, 15, 7085. [Google Scholar] [CrossRef]

- IEC 60068; Environmental Testing. International Electrotechnical Commission: Geneva, Switzerland, 2017.

- Alzuguren, I.; Garcia-Bediaga, A.; Avila, A.; Vasic, M.; Rujas, A. Ultra-Versatile Power Converter based on a Multi-Winding Flyback Transformer for EV Application. In Proceedings of the 2021 IEEE Vehicle Power and Propulsion Conference (VPPC), Gijon, Spain, 25–28 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Noh, J.H.; Song, S.i.; Hur, D.J. Numerical Analysis of the Cooling Performance in a 7.2 kW Integrated Bidirectional OBC/LDC Module. Appl. Sci. 2019, 10, 270. [Google Scholar] [CrossRef]

- Zou, D.; Sun, X.; Quan, H.; Yin, J.; Peng, Q.; Wang, S.; Dai, W.; Hong, Z. Power transformer on-load capacity-regulating control and optimization based on load forecasting and hesitant fuzzy control. Symmetry 2024, 16, 679. [Google Scholar] [CrossRef]

- Sang, V.T.D.; Duong, Q.H.; Zhou, L.; Arranz, C.F. Electric vehicle battery technologies and capacity prediction: A comprehensive literature review of trends and influencing factors. Batteries 2024, 10, 451. [Google Scholar] [CrossRef]

- Grebtsov, D.K.; Kubasov, M.K.; Bernatskii, E.R.; Beliauski, P.A.; Kokorenko, A.A.; Isokjanov, S.S.; Kazikov, S.P.; Kashin, A.M.; Itkis, D.M.; Morozova, S.M. Electric Vehicle Battery Technologies: Chemistry, Architectures, Safety, and Management Systems. World Electr. Veh. J. 2024, 15, 568. [Google Scholar] [CrossRef]

- Stampatori, D.; Raimondi, P.P.; Noussan, M. Li-ion batteries: A review of a key technology for transport decarbonization. Energies 2020, 13, 2638. [Google Scholar] [CrossRef]

- Houache, M.S.; Yim, C.H.; Karkar, Z.; Abu-Lebdeh, Y. On the current and future outlook of battery chemistries for electric vehicles—Mini review. Batteries 2022, 8, 70. [Google Scholar] [CrossRef]

- Baazouzi, S.; Feistel, N.; Wanner, J.; Landwehr, I.; Fill, A.; Birke, K.P. Design, properties, and manufacturing of cylindrical li-ion battery cells—A generic overview. Batteries 2023, 9, 309. [Google Scholar] [CrossRef]

- Ghani, F.; An, K.; Lee, D. A review on design parameters for the full-cell lithium-ion batteries. Batteries 2024, 10, 340. [Google Scholar] [CrossRef]

- Itani, K.; De Bernardinis, A. Review on new-generation batteries technologies: Trends and future directions. Energies 2023, 16, 7530. [Google Scholar] [CrossRef]

- Dini, P.; Colicelli, A.; Saponara, S. Review on modeling and soc/soh estimation of batteries for automotive applications. Batteries 2024, 10, 34. [Google Scholar] [CrossRef]

- Dini, P.; Paolini, D.; Saponara, S.; Minossi, M. Leaveraging digital twin & artificial intelligence in consumption forecasting system for sustainable luxury yacht. IEEE Access 2024, 12, 160700–160714. [Google Scholar] [CrossRef]

- Bubulinca, C.; Kazantseva, N.E.; Pechancova, V.; Joseph, N.; Fei, H.; Venher, M.; Ivanichenko, A.; Saha, P. Development of all-solid-state Li-ion batteries: From key technical areas to commercial use. Batteries 2023, 9, 157. [Google Scholar] [CrossRef]

- Dini, P.; Paolini, D. Exploiting Artificial Neural Networks for the State of Charge Estimation in EV/HV Battery Systems: A Review. Batteries 2025, 11, 107. [Google Scholar] [CrossRef]

- Begni, A.; Dini, P.; Saponara, S. Design and test of an lstm-based algorithm for li-ion batteries remaining useful life estimation. In Proceedings of the International Conference on Applications in Electronics Pervading Industry, Environment and Society, Genova, Italy, 26–27 September 2022; Springer: Berlin/Heidelberg, Germany, 2022; pp. 373–379. [Google Scholar]

- Saldarini, A.; Longo, M.; Brenna, M.; Zaninelli, D. Battery Electric Storage Systems: Advances, Challenges, and Market Trends. Energies 2023, 16, 7566. [Google Scholar] [CrossRef]

- Memon, M.; Rossi, C. A Review of EV Adoption, Charging Standards, and Charging Infrastructure Growth in Europe and Italy. Batteries 2025, 11, 229. [Google Scholar] [CrossRef]

- Alaee, P.; Bems, J.; Anvari-Moghaddam, A. A Review of the Latest Trends in Technical and Economic Aspects of EV Charging Management. Energies 2023, 16, 3669. [Google Scholar] [CrossRef]

- Dimitriadou, K.; Rigogiannis, N.; Fountoukidis, S.; Kotarela, F.; Kyritsis, A.; Papanikolaou, N. Current Trends in Electric Vehicle Charging Infrastructure; Opportunities and Challenges in Wireless Charging Integration. Energies 2023, 16, 2057. [Google Scholar] [CrossRef]

- Alrubaie, A.J.; Salem, M.; Yahya, K.; Mohamed, M.; Kamarol, M. A comprehensive review of electric vehicle charging stations with solar photovoltaic system considering market, technical requirements, network implications, and future challenges. Sustainability 2023, 15, 8122. [Google Scholar] [CrossRef]

- Ali, A.; Shakoor, R.; Raheem, A.; Muqeet, H.A.u.; Awais, Q.; Khan, A.A.; Jamil, M. Latest energy storage trends in multi-energy standalone electric vehicle charging stations: A comprehensive study. Energies 2022, 15, 4727. [Google Scholar] [CrossRef]

- Asef, P.; Milan, M.; Lapthorn, A.; Padmanaban, S. Future Trends and Aging Analysis of Battery Energy Storage Systems for Electric Vehicles. Sustainability 2021, 13, 13779. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Mamun, A.A.; Ansari, S.; Miah, M.S.; Hasan, K.; Meraj, S.T.; Abdolrasol, M.G.M.; Rahman, T.; Maruf, M.H.; Sarker, M.R.; et al. Battery Management, Key Technologies, Methods, Issues, and Future Trends of Electric Vehicles: A Pathway toward Achieving Sustainable Development Goals. Batteries 2022, 8, 119. [Google Scholar] [CrossRef]

- Osman, M.G.; Lazaroiu, G.; Hamad, S.A.; Messaoud, H.; Mohammed, D.; Stoica, D. Analysis of Photovoltaic Systems with Battery Storage, Electric Vehicle Charging, and Smart Energy Management. Sustainability 2025, 17, 3887. [Google Scholar] [CrossRef]

- Carrasco Ortega, P.; Durán Gomez, P.; Merida Sanchez, J.C.; Echevarria Camarero, F.; Pardinas, A.A. Battery Energy Storage Systems for the New Electricity Market Landscape: Modeling, State Diagnostics, Management, and Viability—A Review. Energies 2023, 16, 6334. [Google Scholar] [CrossRef]

- Muna, Y.B.; Kuo, C.C. Feasibility and techno-economic analysis of electric vehicle charging of PV/wind/diesel/battery hybrid energy system with different battery technology. Energies 2022, 15, 4364. [Google Scholar] [CrossRef]

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A review on battery market trends, second-life reuse, and recycling. Sustain. Chem. 2021, 2, 167–205. [Google Scholar] [CrossRef]

- Rotella Junior, P.; Rocha, L.C.S.; Morioka, S.N.; Bolis, I.; Chicco, G.; Mazza, A.; Janda, K. Economic analysis of the investments in battery energy storage systems: Review and current perspectives. Energies 2021, 14, 2503. [Google Scholar] [CrossRef]

| Metric (New Deployments) | 2024 (Baseline) | 2030 (Reference) | 2035 (Accelerated) |

|---|---|---|---|

| EVs with bidirectional-capable OBCs [% of new EVs] | 2–6% | 15–25% | 35–55% |

| Home AC chargers bidirectional-capable [% of new AC] | <1% | 5–10% | 10–20% |

| Public DC chargers bidirectional-capable [% of new DC] | <1% | 3–8% | 8–15% |

| Technology | Typical Optimal | Efficiency Trend with | Design Implication |

|---|---|---|---|

| Si MOSFET/IGBT | 20–50 kHz | Sharp drop above 50 kHz due to switching losses | Large inductors/capacitors required |

| SiC MOSFET | 50–150 kHz | Flat efficiency up to ∼150 kHz; mild drop at higher | Reduced passive size, good thermal margin |

| GaN HEMT | 100–500 kHz | High efficiency sustained up to MHz-class operation | Enables compact magnetics, tighter EMI design |

| Method | Balancing Accuracy | Loss/Cost Impact | Complexity |

|---|---|---|---|

| Passive droop (series R/DCR) | Medium | Efficiency penalty (on R) | Low |

| Average current-mode (equal refs) | High | Minimal (sensing required) | Medium–High |

| Master–slave (share bus) | Medium–High | Minimal | Medium |

| Coupled inductors/IPT | High | Magnetics cost/volume | Medium–High |

| Digital calibration/trimming | Complements above | Negligible (runtime) | Medium (FW/test) |

| Topology | Power | Input | ISO | Bi-dir | PFC | Eff. | Ripple | THD | Passive | Control |

|---|---|---|---|---|---|---|---|---|---|---|

| Boost PFC | 1–3 kW | 1 | No | No | Yes | 97% | Medium | <5% | Medium | Low |

| Interleaved Boost | 3–6 kW | 1 | No | No | Yes | 97% | Low | <5% | Small–Med | Med |

| Totem-Pole PFC | 1.8–7 kW | 1 | No | Optional | Yes | 97–99% | Very low | <5% (even <2%) | Small | High |

| Vienna Rectifier | 10–20 kW | 3 | No | No | Yes | >97% | Low | <5% | Medium | Med–High |

| T-Type PFC | 10–30 kW | 3 | No | No | Yes | >97% | Low | <5% | Medium | High |

| Filter Type | Power Rating | Attenuation @ | Grid Current THD | Efficiency Impact |

|---|---|---|---|---|

| L (2.5 mH) | 3.3 kW, 1 | ∼15 dB | ∼7% | <0.5% loss |

| (1.5 mH + 5 μF) | 6.6 kW, 1 | >25 dB | ∼4% | ∼0.3% loss |

| LCL (0.7 mH + 6 μF + 0.7 mH) | 11 kW, 3 | ∼40 dB | <2%, PF > 0.99 | <0.5% loss (with damping) |

| LCL + trap (tuned at 100 kHz) | 22 kW, 3 | 20 dB narrowband | <2%, CISPR 25 Class 5 | ∼0.5–1% loss |

| Parameter | Typical Guideline | Rationale | Impact on Degradation |

|---|---|---|---|

| SOC window | 30–70% | Avoids high-SOC stress and low-SOC deep cycles | Reduces SEI growth, Li plating risk |

| C-rate | ≤0.3–0.5C | Limits cycling stress and heat generation | Extends cycle life |

| Temperature | 20–35 °C | Optimal range for Li-ion chemistry | Minimizes thermal aging |

| Ripple current | <1–2% | Use DC-link and LC filters | Prevents local heating, impedance rise |

| Power ramp rate | ≤0.2/s | Controlled transients | Avoids high instantaneous C-rate |

| BMS scheduling | SOH- and T-aware | Adaptive derating of V2G service | Preserves long-term capacity |

| Topology | Power Range | ZVS/ZCS | Bidirectional | EMI/THD | Freq. (kHz) | Complexity | WBG Ready |

|---|---|---|---|---|---|---|---|

| Flyback | <300 W | No | No | High | 50–100 | Low | Yes |

| Forward | <1 kW | No | No | Medium | 50–150 | Medium | Yes |

| Push–Pull | 1–2 kW | Partial | No | High | 50–150 | Medium | Yes |

| Half-Bridge | 1–6.6 kW | ZVS | No | Low | 100–300 | Medium | Yes |

| LLC | 3–22 kW | ZVS/ZCS | No | Very Low | 150–500 | High | Yes |

| PSFB | 6–22 kW | ZVS | No | Medium | 100–250 | High | Yes |

| DAB | 3–22 kW | ZVS/ZCS | Yes | Low | 100–500 | Very High | Yes |

| Parameter | Si | IGBT | SiC MOSFET | GaN HEMT |

|---|---|---|---|---|

| Bandgap (eV) | 1.1 | 1.1 | 3.2 | 3.4 |

| Breakdown Voltage (V) | <600 | 600–1700 | 600–3300 | up to 650 |

| On-Resistance at 25C (mOhm) | Low | Medium | Very Low | Low |

| Switching Frequency | <100 kHz | <50 kHz | <500 kHz | >1 MHz |

| Switching Losses | High | Very High | Low | Very Low |

| Thermal Conductivity (W/mK) | 150 | 150 | 490 | 130 |

| Max Junction Temp (C) | up to 150 | up to 175 | above 200 | above 200 |

| Gate Drive Complexity | Low | Medium | Medium | High |

| Relative Cost | 1× | 1.5× | 3–4× | 4–5× |

| Technology Maturity | High | High | Medium | Low |

| Architecture | 50–150 kHz | 150–300 kHz | 300–500 kHz | Notes (Materials and Winding Options) |

|---|---|---|---|---|

| LLC (two-stage AC/DC + DC/DC) | 99.3–99.7% | 98.9–99.5% | 98.3–99.1% | Ferrite E/EI/ER cores; litz for round-wire, planar viable >200 kHz; efficiency mildly drops with f as and core losses grow. |

| PSFB (hard/soft-switched) | 99.3–99.7% | 98.8–99.4% | 98.0–98.8% | Often run at lower f for lower ; leakage tailored for ZVS energy. Planar feasible with careful window utilization. |

| DAB (bidirectional) | 99.2–99.6% | 98.8–99.4% | 98.2–99.0% | Leakage intentionally used as series L; circulating current drives copper loss sensitivity. Planar helps repeatability of leakage. |

| Single-stage resonant (LLC-like) | – | 98.7–99.3% | 98.0–99.0% | Higher f to reduce bulk; planar preferred; tighter EMI/thermal co-design. |

| HV–LV auxiliary (HV→12 V) | 99.0–99.5% | 98.6–99.2% | 98.0–98.8% | High secondary currents; prioritize low- windings and short paths. |

| Architecture | Transformer Location | Freq. | Function | Advantages | Challenges |

|---|---|---|---|---|---|

| AC/DC + DC/DC | After PFC | 50–250 kHz | Isolation and scaling | Modular, flexible | Two stages, volume |

| Single-stage LLC | After rectified AC | 150–500 kHz | Resonant isolation | High efficiency | Complex regulation |

| DAB | Between bridges | 100–400 kHz | Bidirectional energy | V2G-ready, modular | Synchronization |

| HV–LV auxiliary | Between HV/12 V rails | 100–300 kHz | Voltage reduction | Compact, efficient | High |

| Modular/interleaved | One per module | 200–500 kHz | Isolation + filtering | Scalable thermal load | Magnetic complexity |

| Metric | NMC | NCA | LFP |

|---|---|---|---|

| Nominal voltage [V] | 3.6–3.7 | 3.6–3.7 | 3.2–3.3 |

| Gravimetric energy density [Wh/kg] | 150–220 | 200–260 | 100–160 |

| Volumetric energy density [Wh/L] | 350–600 | 450–700 | 250–450 |

| Continuous C-rate [] | 1–2 | 1–2.5 | 1–3 |

| 10 s peak C-rate [] | 3–5 | 5–7 | 5–10 |

| Typical cycle life (full cycles) [–] | 1000–2000 | 1000–1500 | 2000–5000 |

| Thermal stability/abuse tolerance [qual.] | Moderate | Lower | Higher |

| Fast-charge sensitivity (plating risk) [qual.] | Moderate–High | High | Moderate |

| OCV slope for SOC estimation [qual.] | Favorable | Moderate | Flat (needs high-res BMS) |

| Indicative cost [USD/kWh, rel.] | Medium–High | High | Low–Medium |

| Attribute | Cylindrical | Prismatic | Pouch |

|---|---|---|---|

| Packing efficiency [qual.] | Medium (voids) | High | Medium–High |

| Thermal path | Radial/axial (1D) | Through-plane + in-plane (2D) | Short path; needs preload |

| Mechanical robustness | High (shell) | High (rigid can) | Lower; needs fixture |

| Swelling management | Minimal | Shell expansion management | Requires compressive frame |

| Manufacturing throughput | High | Medium–High | Medium |

| Serviceability/module design | Mature busbars | Straightforward stacking | Requires careful clamping |

| Typical chemistry pairings (non-exclusive) | NMC/NCA | LFP/NMC/NCA | NMC/NCA/LFP |

| Symbol | Unit | Meaning |

|---|---|---|

| – | Number of cells in series (defines pack voltage) | |

| – | Number of parallel cell strings (defines pack current capability) | |

| V | Open-circuit voltage of a cell (or pack) | |

| V | Pack voltage under operating conditions | |

| Ah | Nominal cell capacity at reference conditions | |

| C-rate | Normalized current: (e.g., 1C = full charge in 1 h) | |

| SOC | % or – | State of charge (fraction of available capacity) |

| SOH | % or – | State of health (capacity or impedance relative to beginning of life) |

| Internal resistance (cell or pack) |

| Design Constraint | NMC/NCA | LFP | High-Voltage Packs | Legacy Low-Voltage Packs |

|---|---|---|---|---|

| OBC output voltage range [V] | 250–850 | 220–700 | 500–1000 | 48–150 |

| Required output power [kW] | 6.6–22 | 3.3–11 | 11–43 | <3.3 |

| Voltage regulation resolution | Medium | High | Very high | Low |

| Current ripple tolerance | <1% peak | <2% peak | <0.5% peak | <5% peak |

| Insulation level | Standard (1+ kVDC) | Standard (1+ kVDC) | Enhanced (2.5+ kVDC) | Optional |

| Control loop dynamics | Fast (VOC slope) | Slower (flat VOC) | Fast with stability constraints | Slow |

| Feedback bandwidth required | Medium–high | Medium | Very high | Low |

| Balancing and BMS coordination | Standard | High-accuracy needed | Critical for safety | Simplified |

| Thermal derating interface | Temperature-dependent limits | SOC–T joint profiling | Active derating enforced | Passive |

| OBC-to-BMS communication | CAN FD/ISO 15118 | CAN FD/ISO 15118 | Dual bus, high-res updates | Basic CAN |

| V2G readiness (bidirectional) | Supported | Supported | Required | Not applicable |

| Option | Typical Use | Sizing Highlights | Pros/Cons |

|---|---|---|---|

| Passive LC filter | High-frequency ripple () | ; L from ; low-ESR film capacitors | Simple, robust, low cost/large C for very low ripple; potential resonance with control loop |

| LCL filter with damping | HF + pack/line interactions | chosen for staged cutoff; for damping | High attenuation with smaller L/Requires damping, more complex stability design |

| Active Ripple Port (ARP) | Low-frequency decoupling; V2G services | from oscillation energy and allowed | Drastically reduces HV capacitance; scalable/Extra stage and cost |

| Hybrid (LC + ARP) | HF + LF ripple in high-density OBCs | Design LC for , ARP for ; coordinate control loops | Superior performance/Highest integration complexity |

| Supplier | Product Type | Customers | Power [kW] | Voltage [V] | Highlights |

|---|---|---|---|---|---|

| Bosch | OBC, inverter | VW, BMW, Mercedes | 3.3–22 | 400–800 | Bidirectional charging, ISO 26262 compliance |

| Marelli | OBC, inverter | Stellantis, Hyundai | 6.6–22 | 400–800 | GaN-based topologies, compact form factor |

| Hyundai Mobis | OBC | Hyundai, Kia | 11–22 | 800 | Integrated HV power module |

| Denso | OBC, PDU | Toyota, Honda | 3.3–6.6 | 400 | High reliability, compact integration |

| Company | Component Type | Application | Package | Notes |

|---|---|---|---|---|

| Infineon | SiC/GaN power modules | OBC, inverter | EasyPACK, CoolSiC | Automotive-qualified, high efficiency |

| STMicroelectronics | Controllers, drivers | OBC, DC/DC | QFN, TSSOP | PFC and LLC stage control |

| Würth Elektronik | Magnetics, chokes | EMI filters, transformers | Custom/standard | Designed for high-frequency resonant topologies |

| Texas Instruments | Gate drivers, monitors | All stages | SOIC, QFN | Isolated drivers with fault detection |

| Supplier | Material Type | Application Area | Key Property |

|---|---|---|---|

| Henkel | Thermal pastes and adhesives | Power modules, PCBs | High thermal conductivity |

| Luvata | Copper wire and strips | Magnetics, busbars | High purity, low resistance |

| Ferroglobe | Metallurgical silicon | Semiconductor base | Source for Si/SiC production |

| Sumitomo Electric | Enameled wire, insulators | HV magnetics | Automotive-grade insulation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dini, P.; Saponara, S.; Chakraborty, S.; Hegazy, O. System-Level Compact Review of On-Board Charging Technologies for Electrified Vehicles: Architectures, Components, and Industrial Trends. Batteries 2025, 11, 341. https://doi.org/10.3390/batteries11090341

Dini P, Saponara S, Chakraborty S, Hegazy O. System-Level Compact Review of On-Board Charging Technologies for Electrified Vehicles: Architectures, Components, and Industrial Trends. Batteries. 2025; 11(9):341. https://doi.org/10.3390/batteries11090341

Chicago/Turabian StyleDini, Pierpaolo, Sergio Saponara, Sajib Chakraborty, and Omar Hegazy. 2025. "System-Level Compact Review of On-Board Charging Technologies for Electrified Vehicles: Architectures, Components, and Industrial Trends" Batteries 11, no. 9: 341. https://doi.org/10.3390/batteries11090341

APA StyleDini, P., Saponara, S., Chakraborty, S., & Hegazy, O. (2025). System-Level Compact Review of On-Board Charging Technologies for Electrified Vehicles: Architectures, Components, and Industrial Trends. Batteries, 11(9), 341. https://doi.org/10.3390/batteries11090341