A Comprehensive Review of Thermal Management Challenges and Safety Considerations in Lithium-Ion Batteries for Electric Vehicles

Abstract

1. Introduction

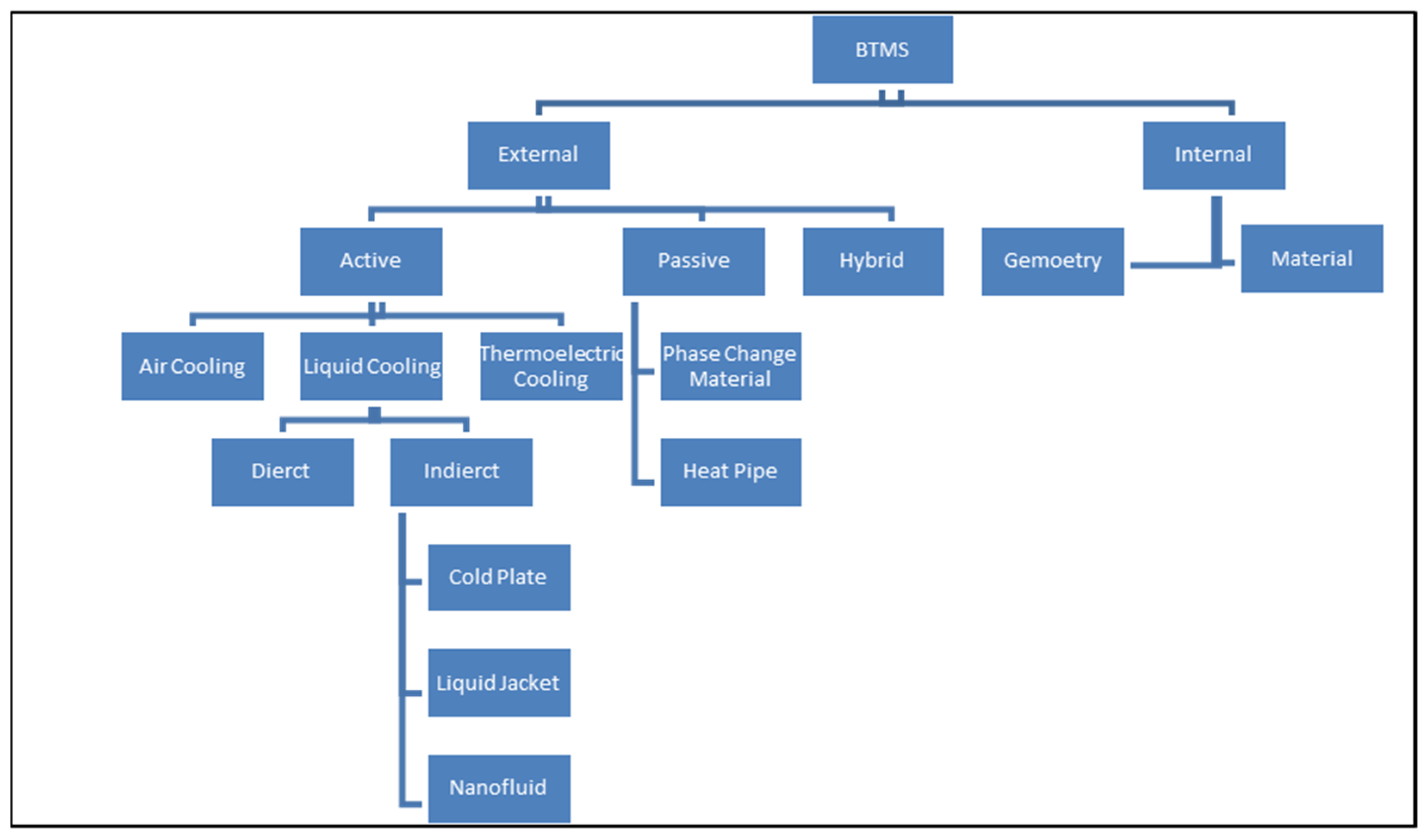

2. Battery Thermal Management Systems

2.1. Design Parameters of LIBs

2.2. Performance Parameters of LIBs

2.2.1. State of Charge (SoC)

2.2.2. State of Health (SoH)

2.2.3. Internal Resistance (Ri)

2.2.4. Self-Discharge

2.2.5. Coulombic Efficiency (CE)

2.2.6. Energy Efficiency

2.3. Thermal Model

3. Types of Battery Thermal Management Systems (BTMSs)

3.1. Active Cooling Technique

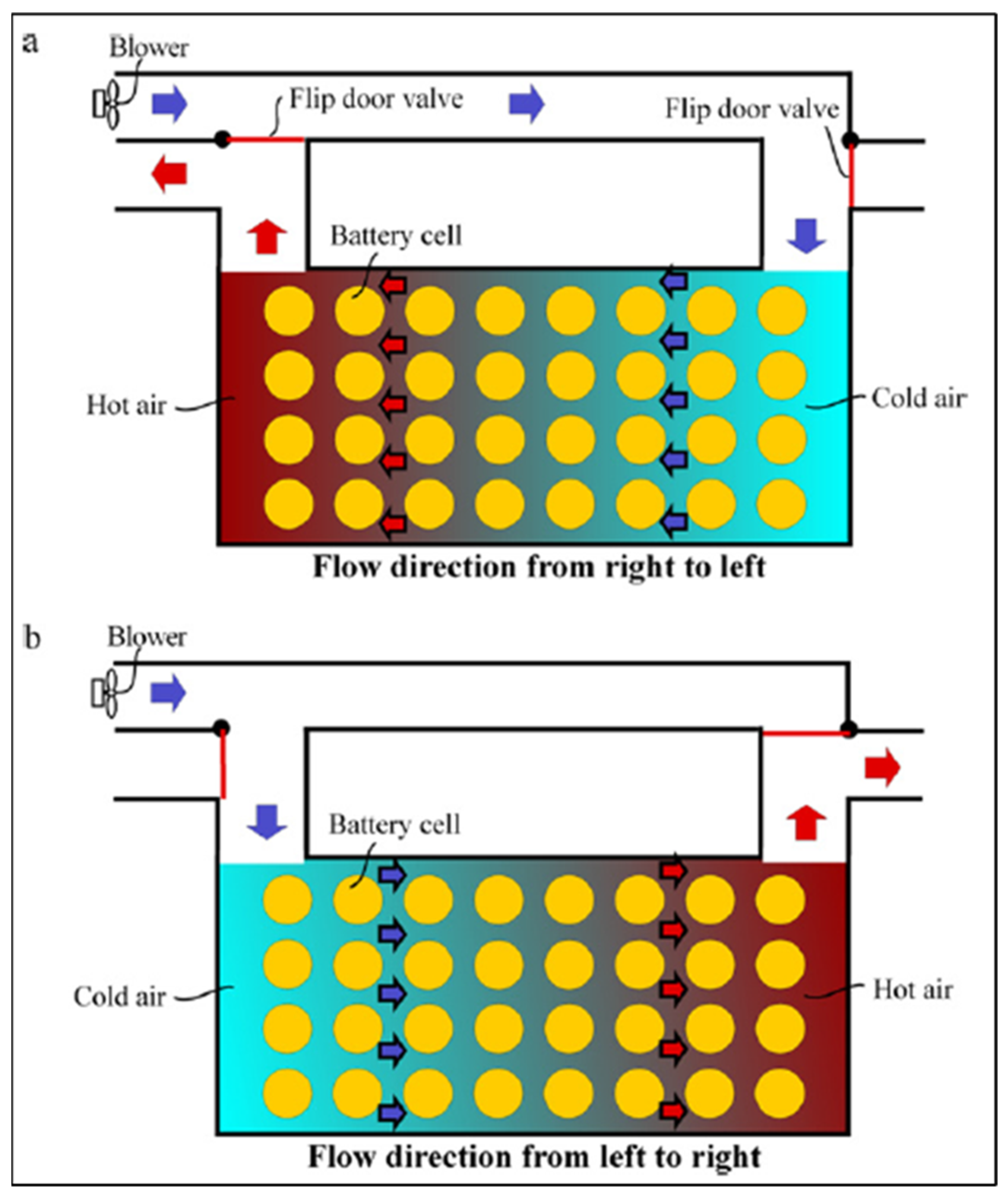

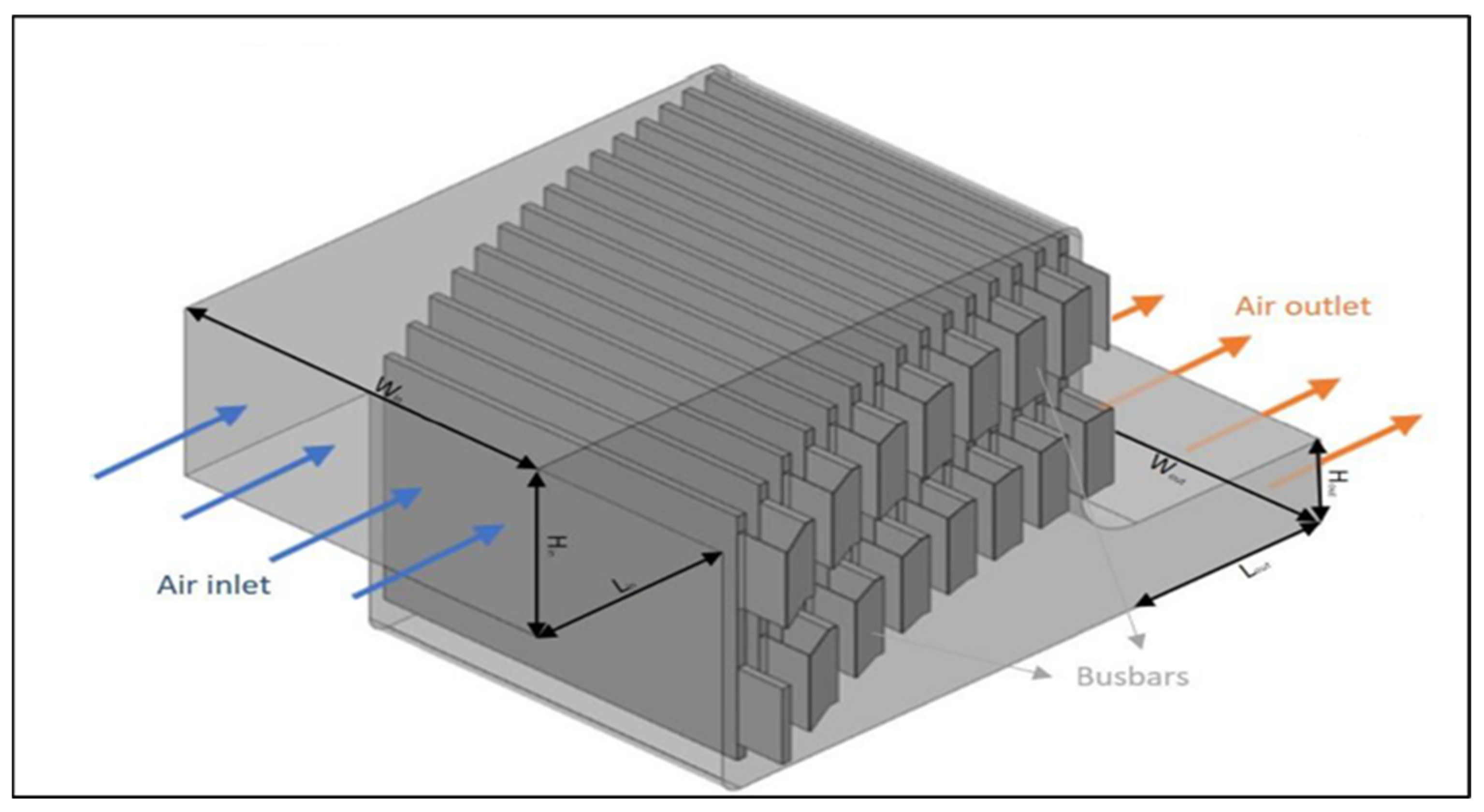

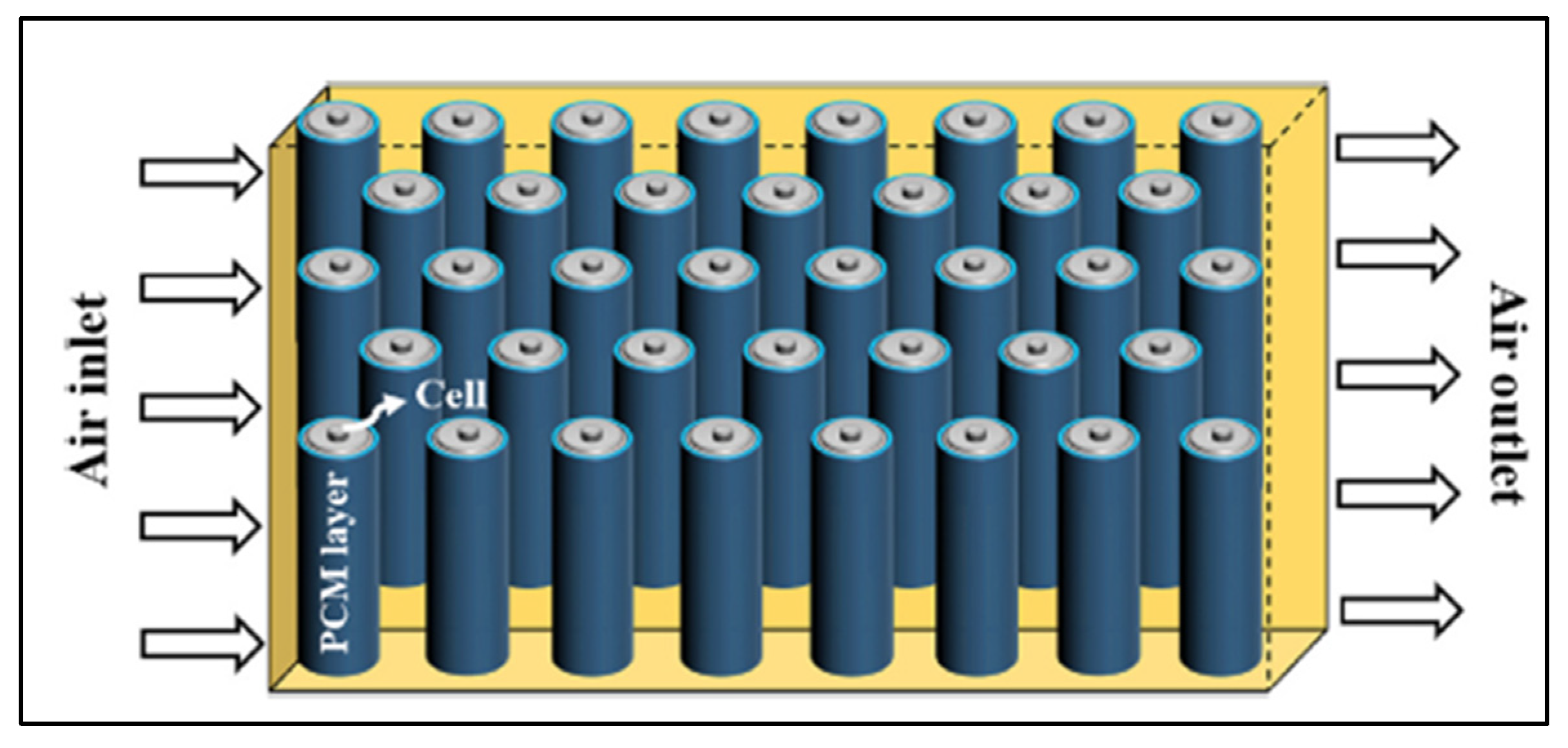

3.1.1. Air Cooling

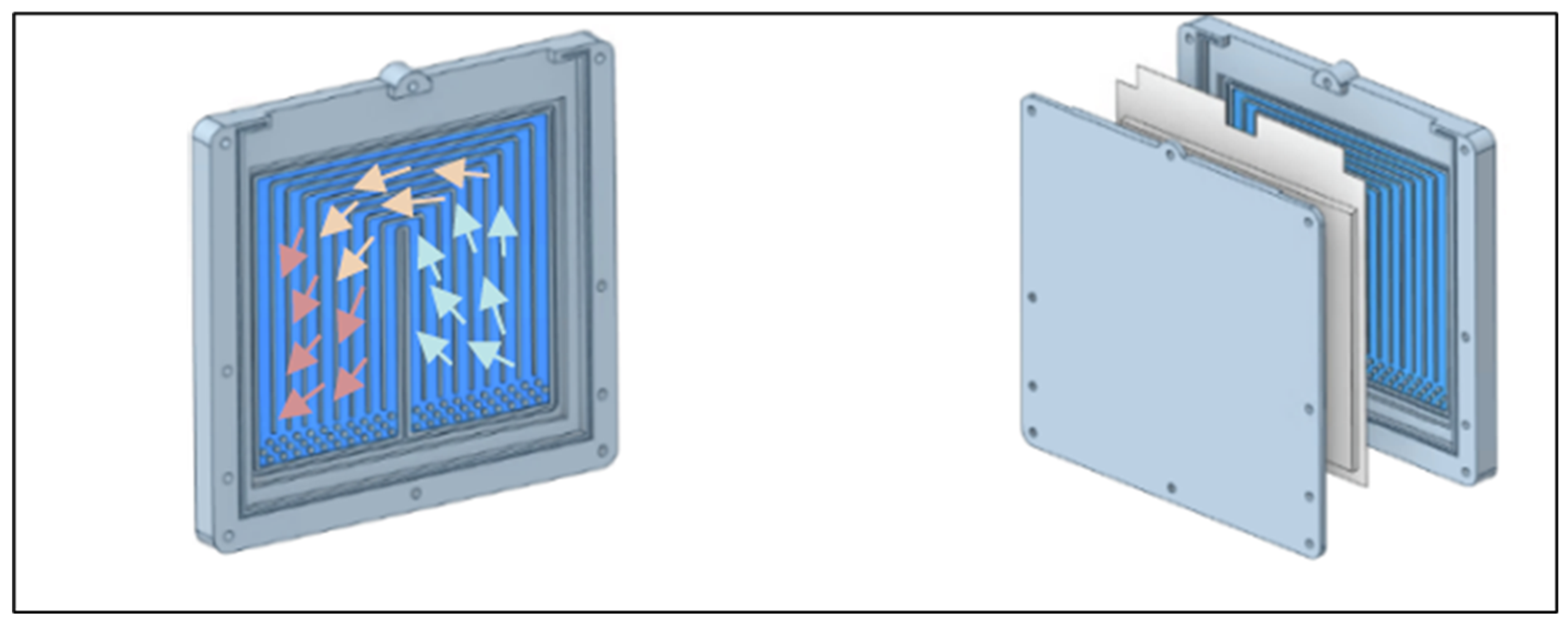

3.1.2. Liquid Cooling

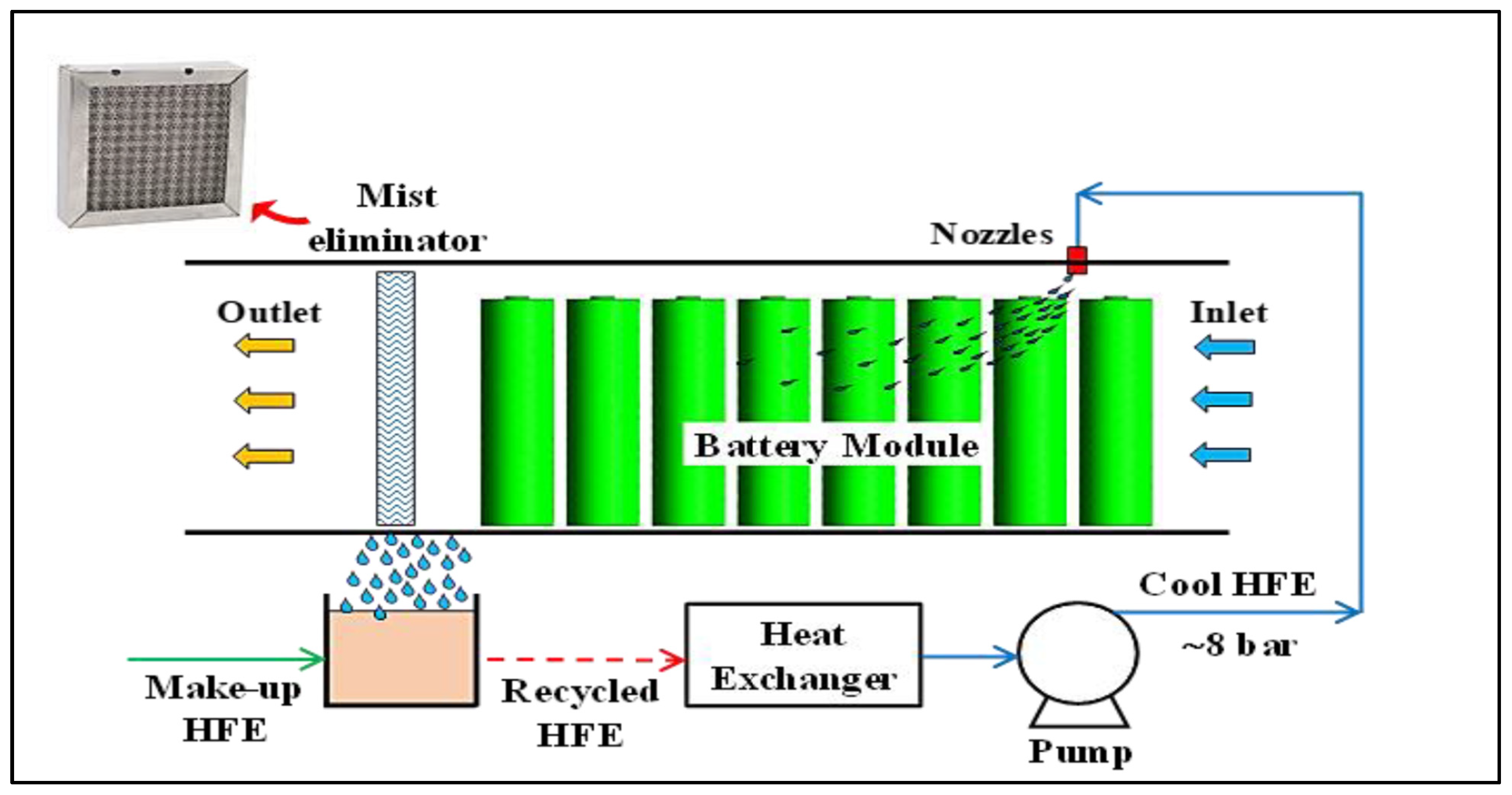

- Direct Cooling

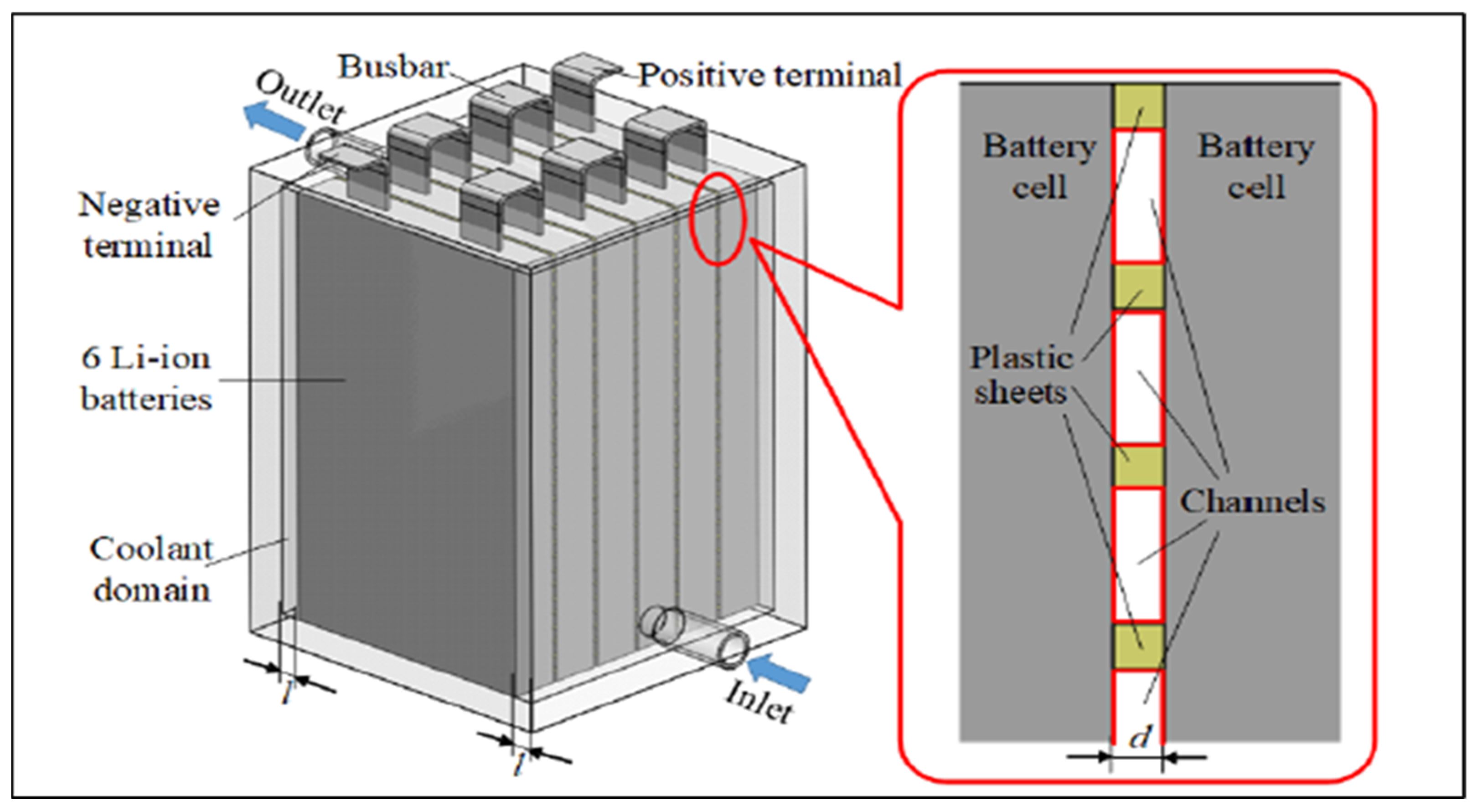

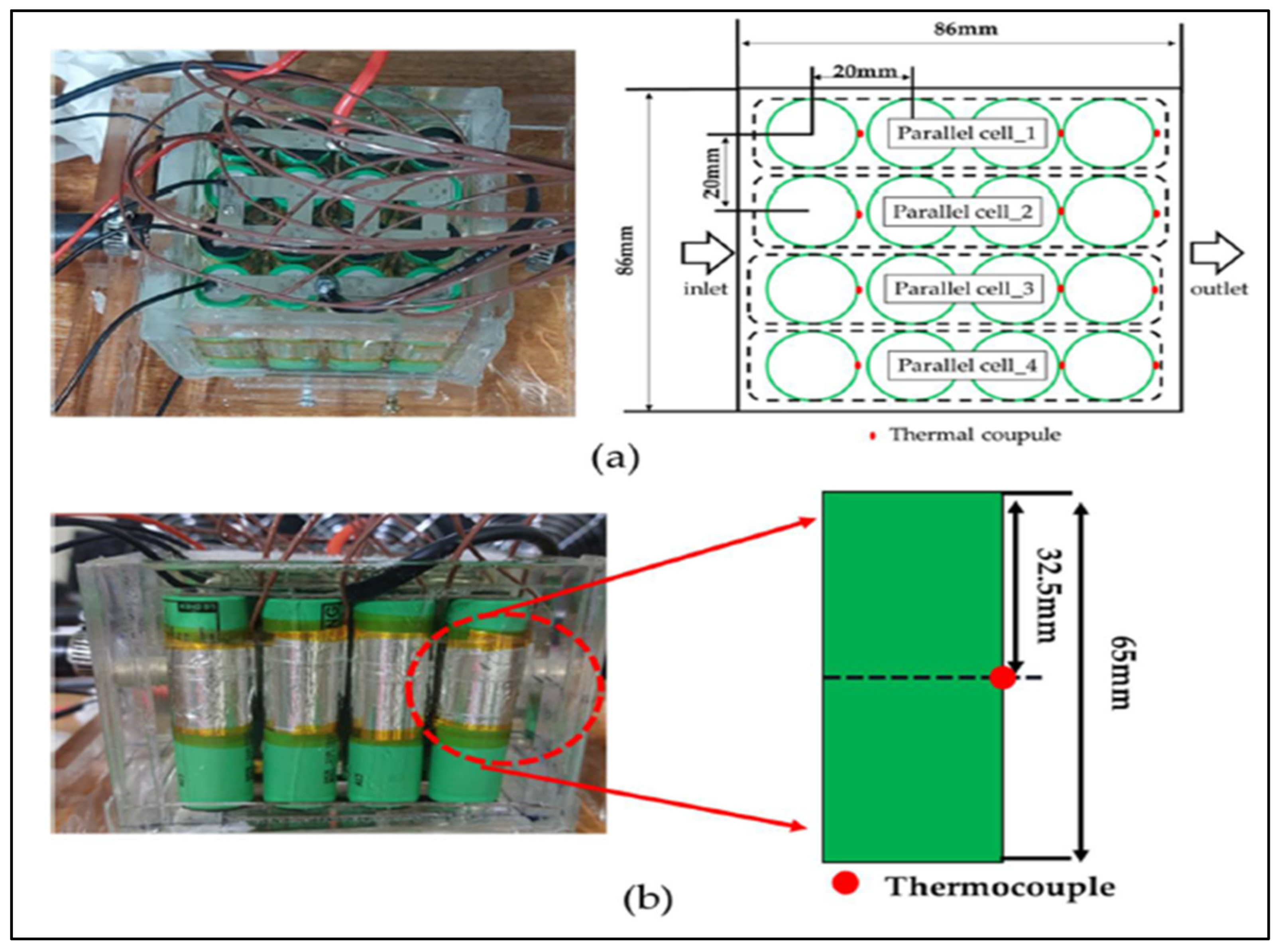

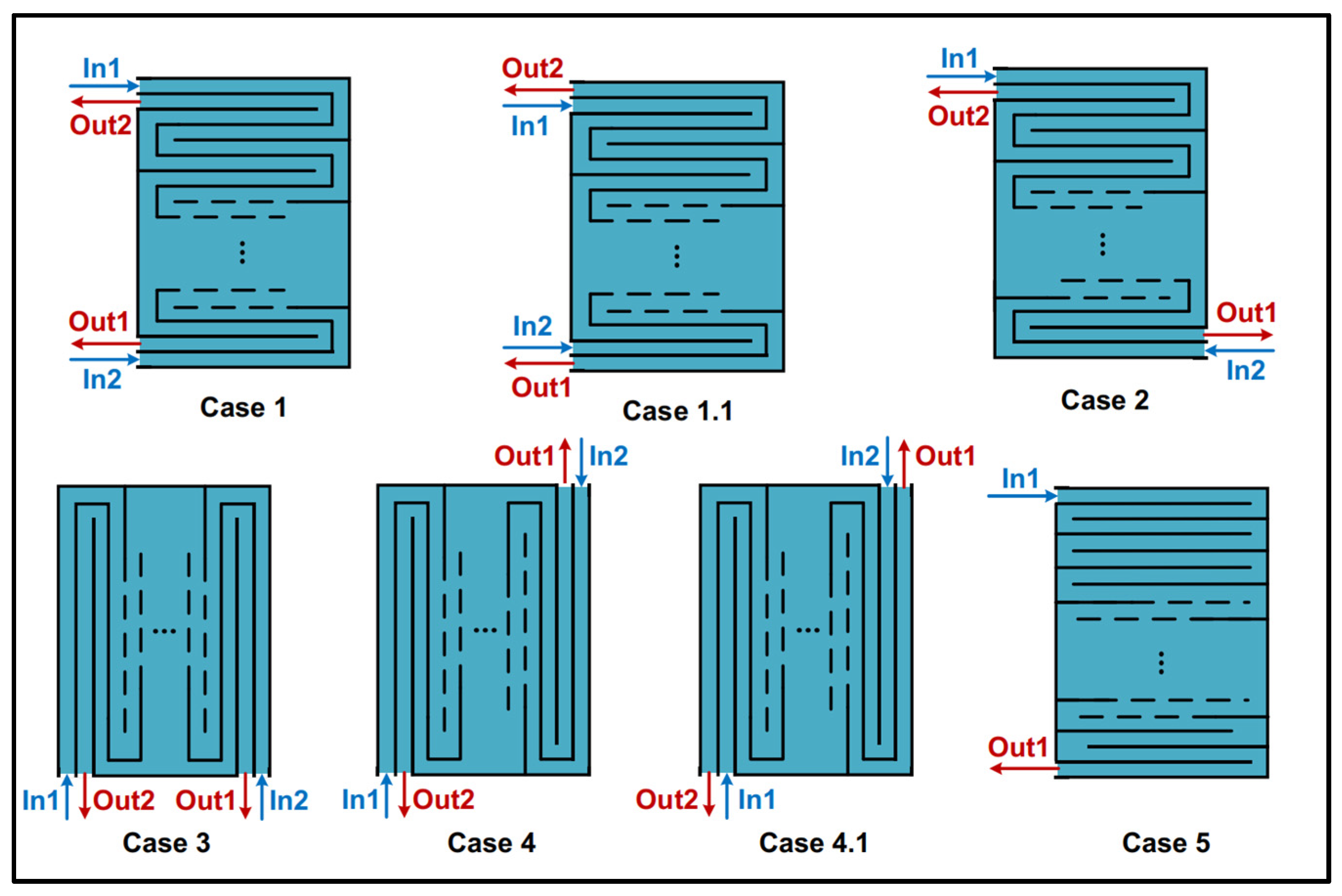

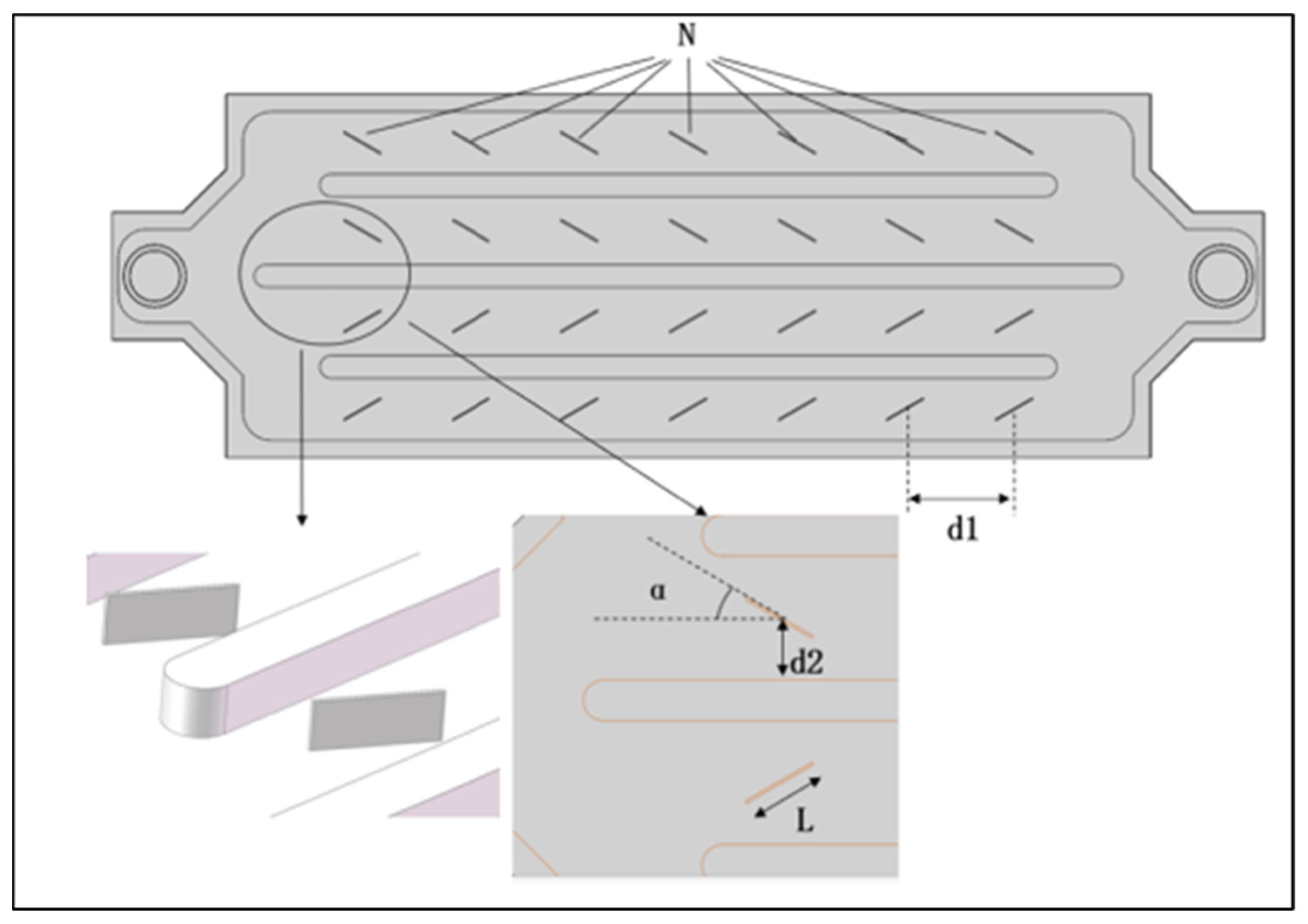

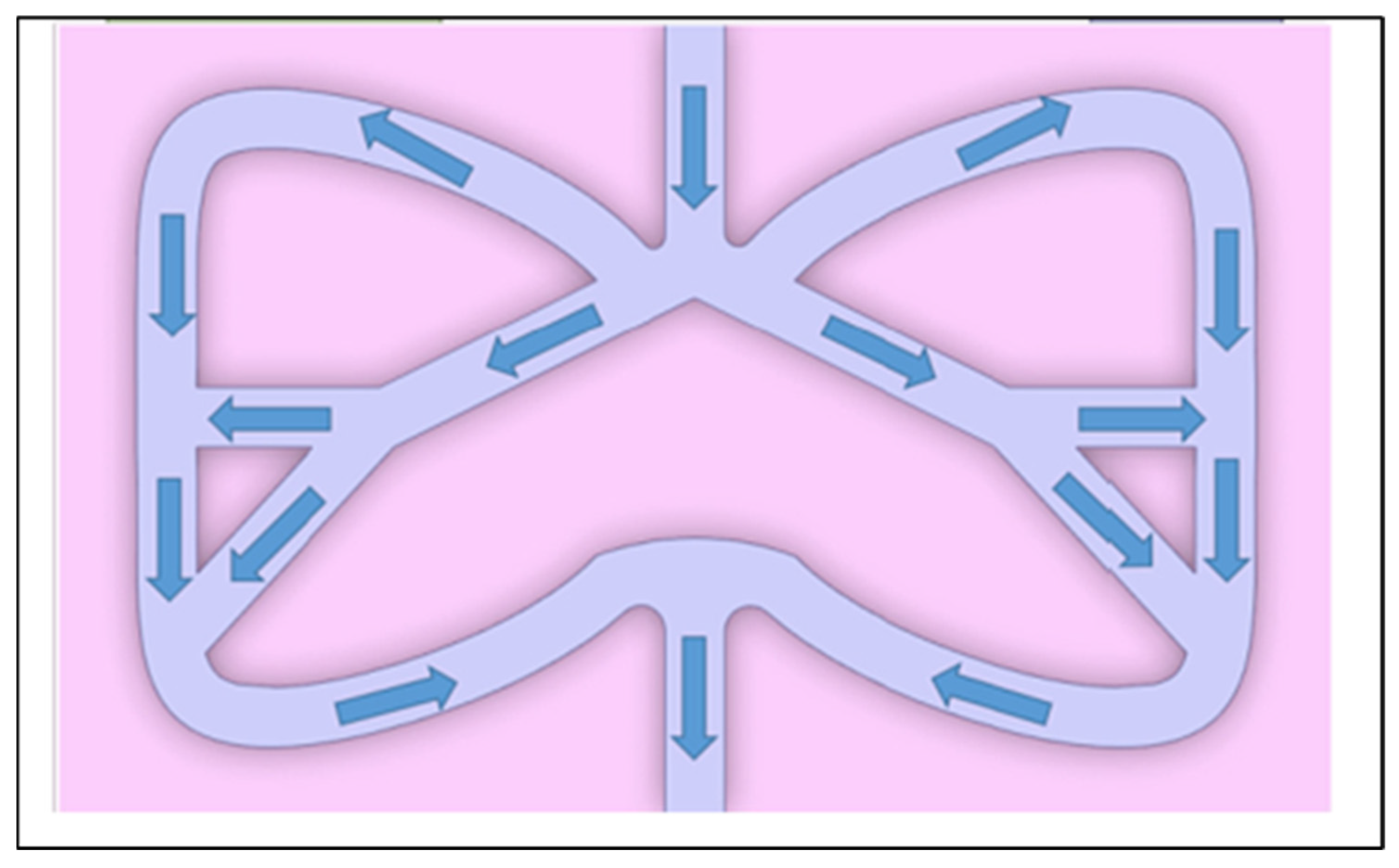

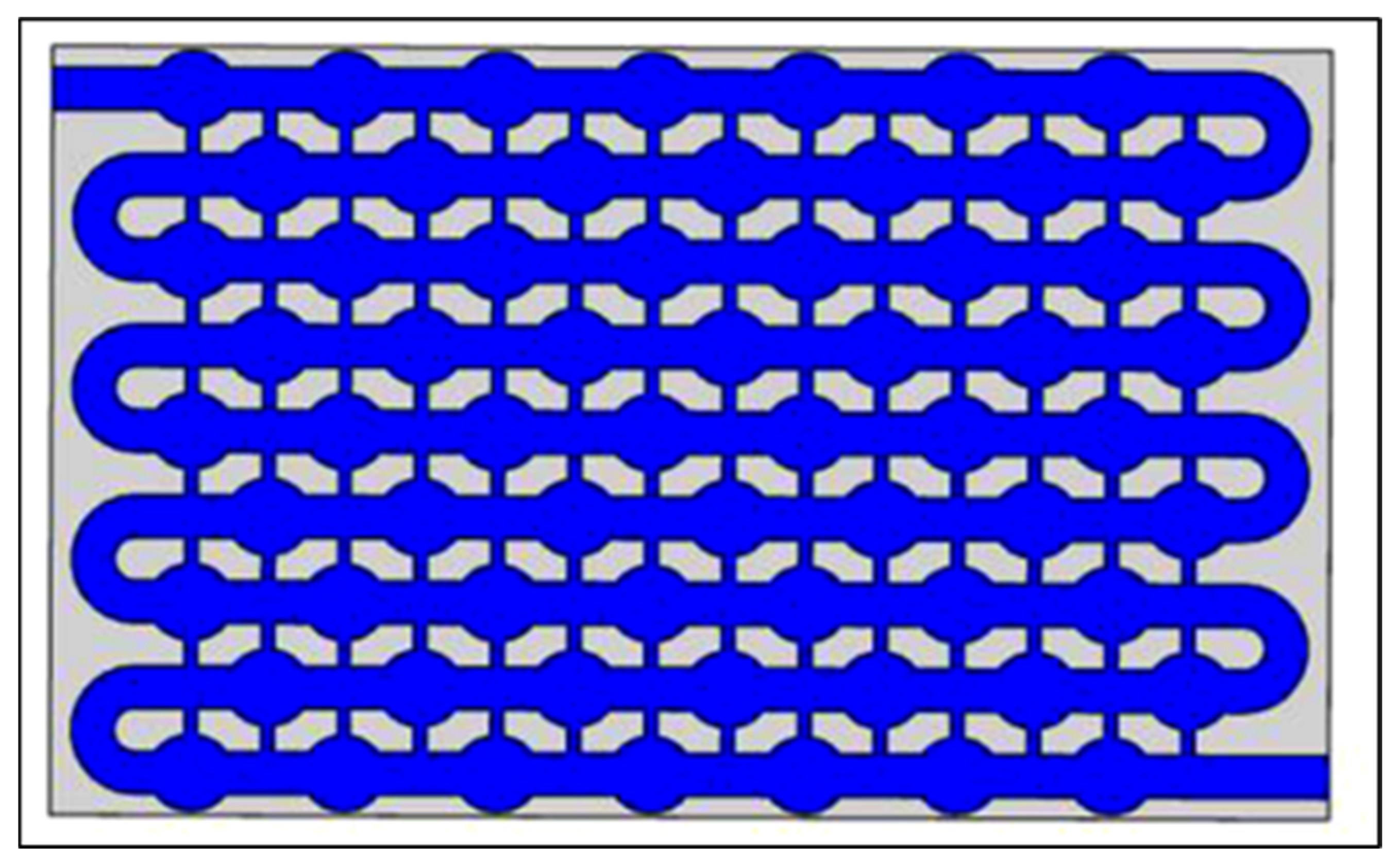

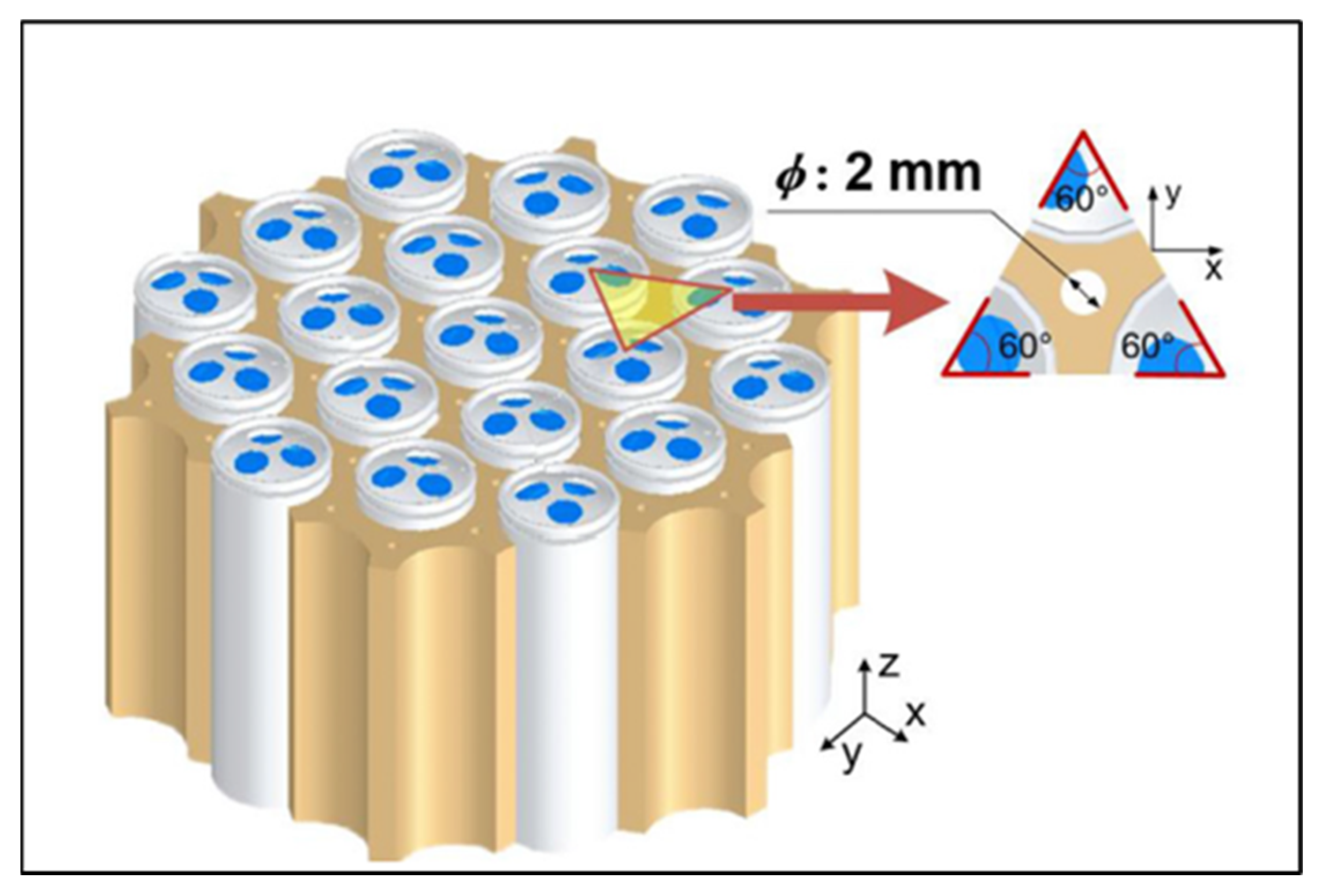

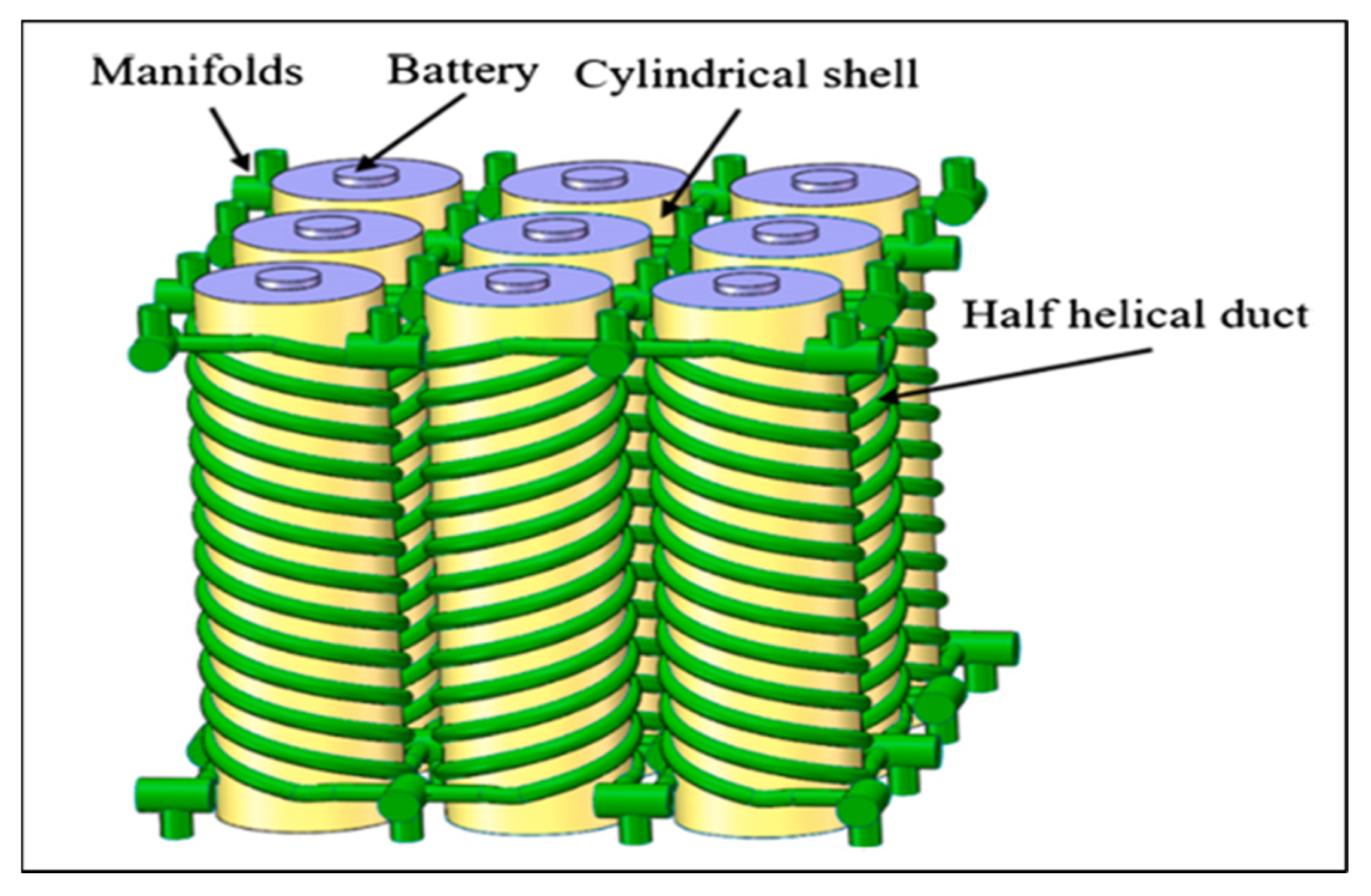

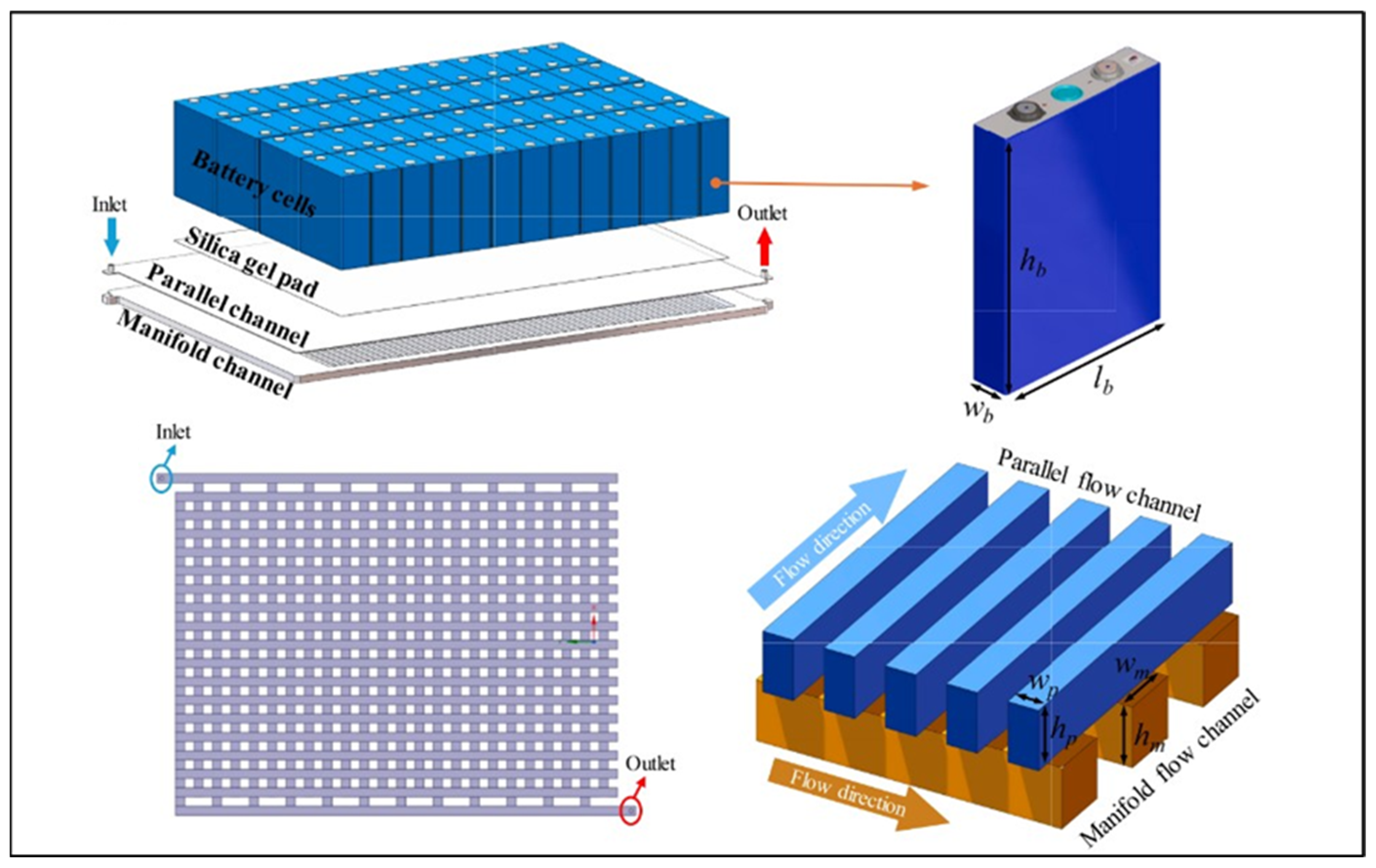

- Indirect Liquid Cooling

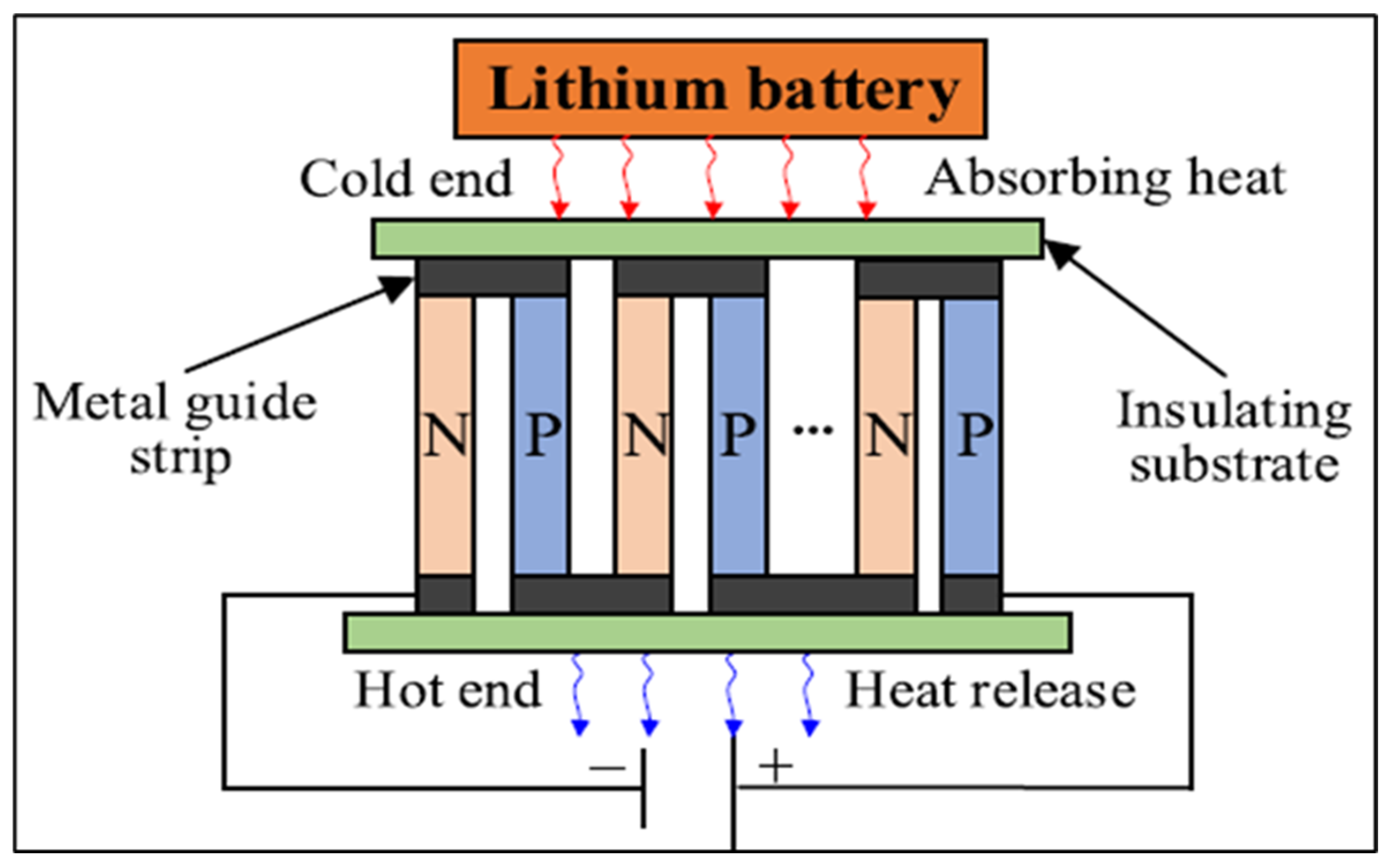

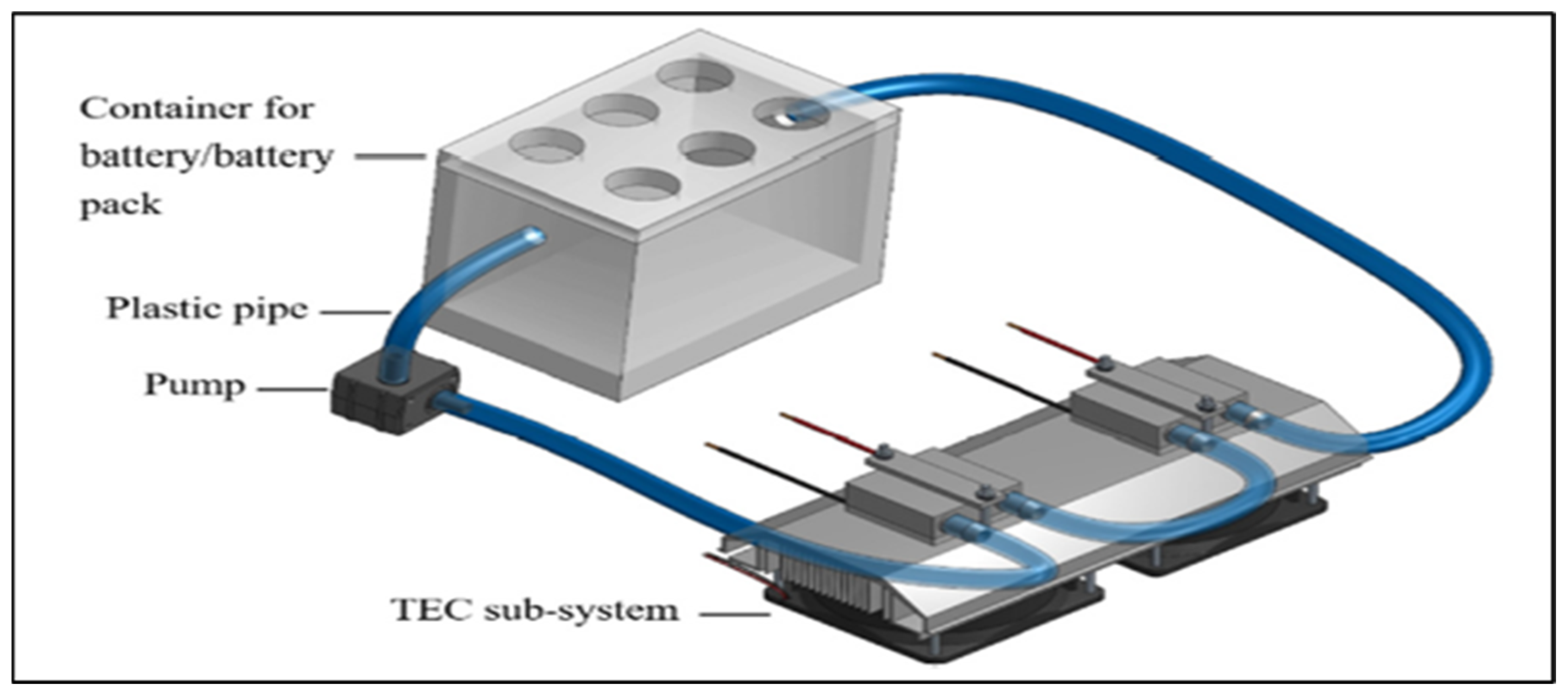

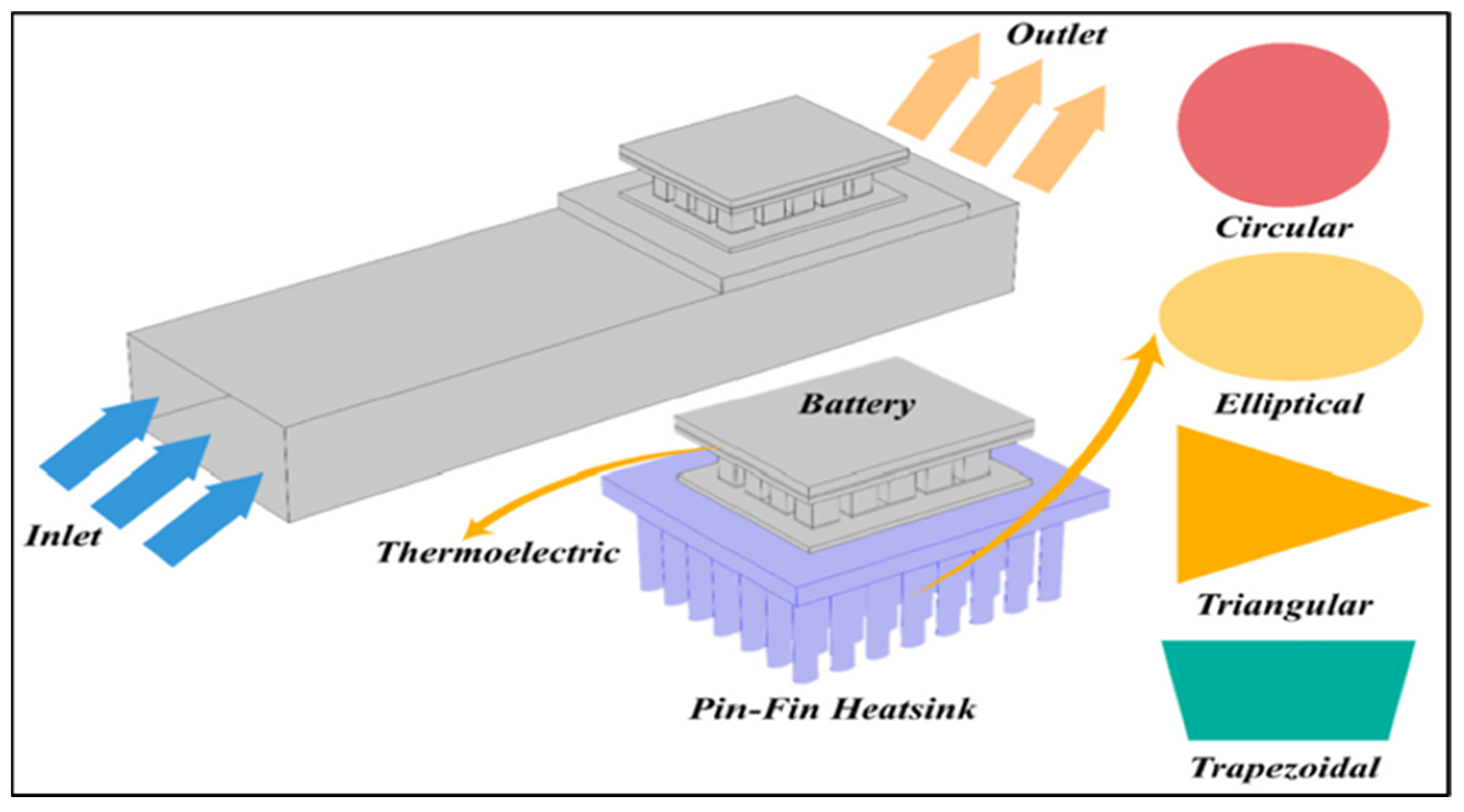

3.1.3. Thermoelectric Cooling

3.2. Passive Cooling

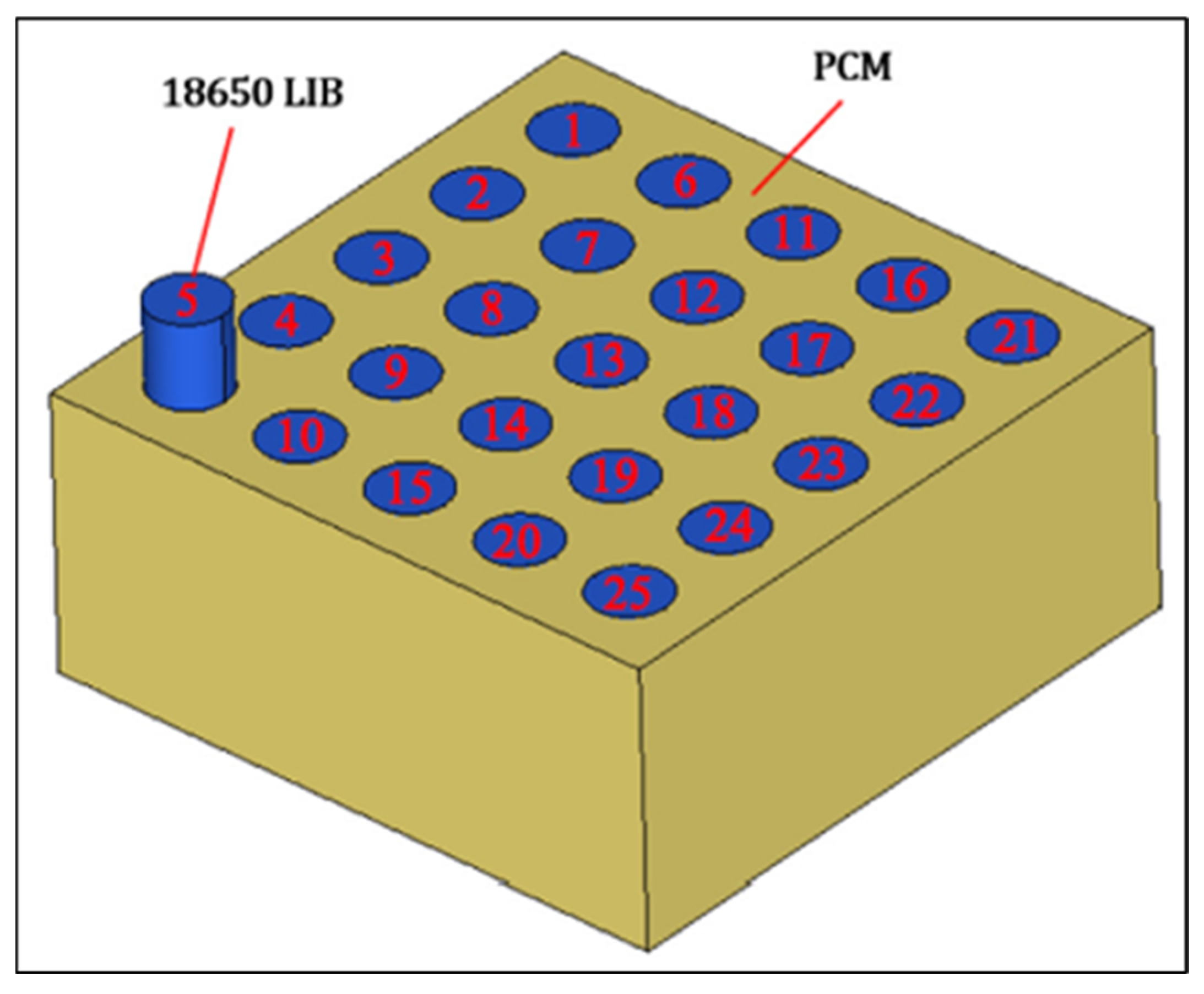

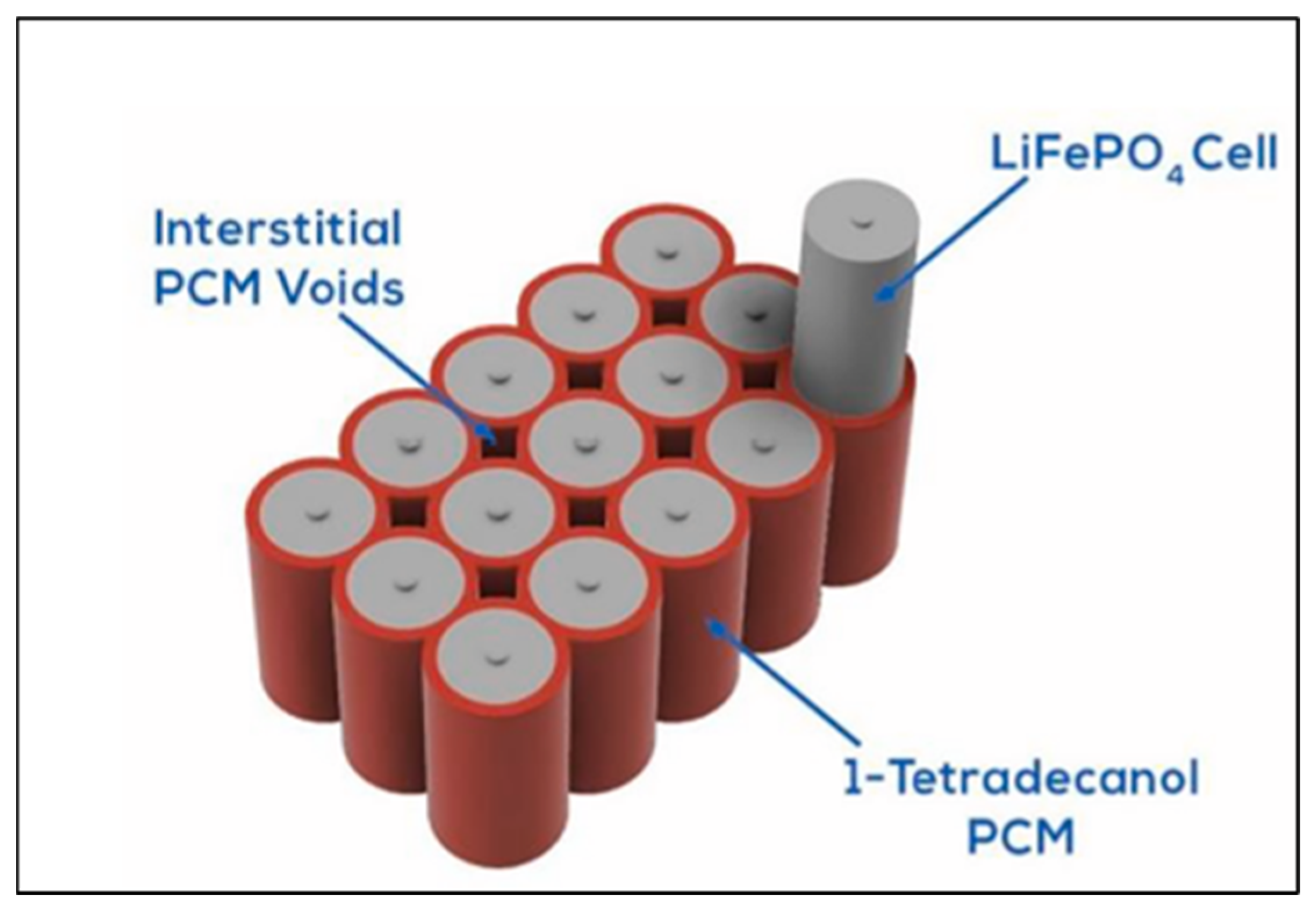

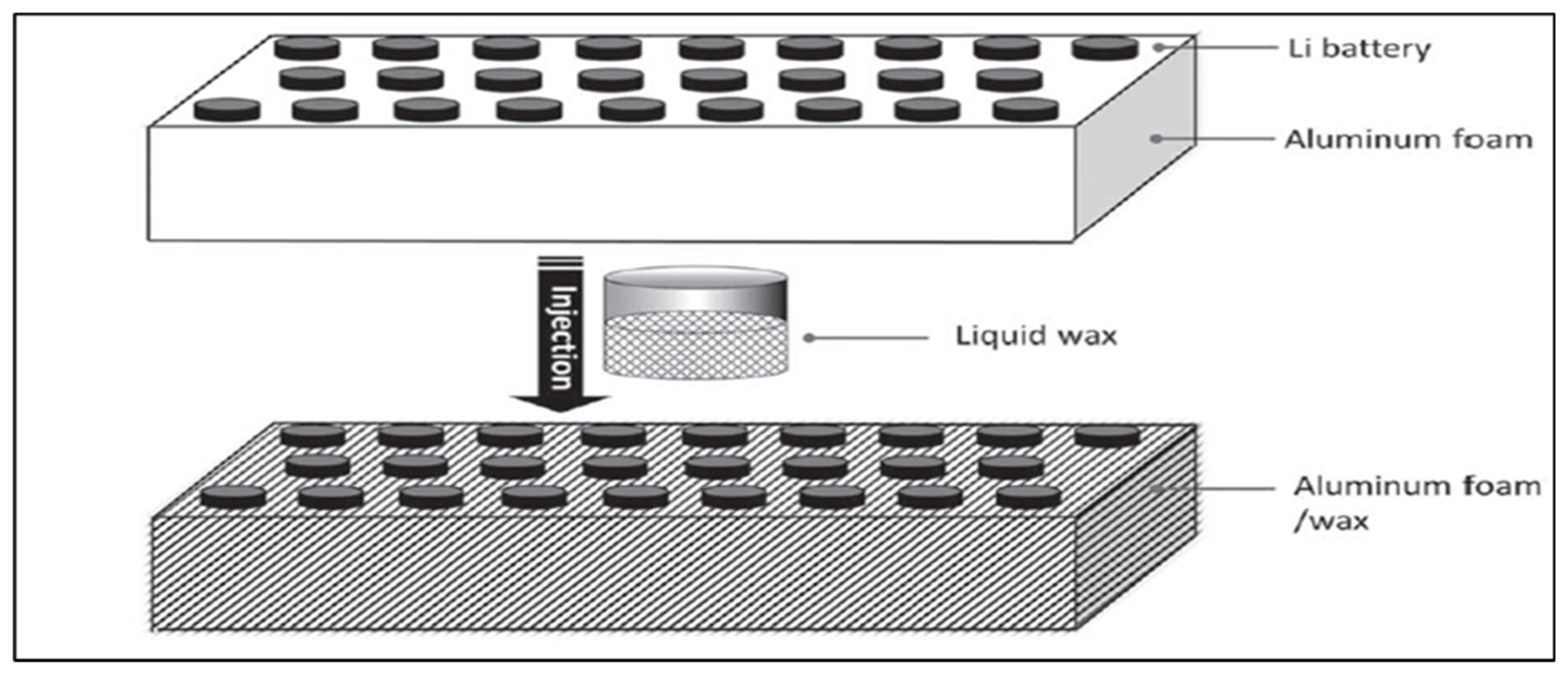

3.2.1. Phase Change Material (PCM)

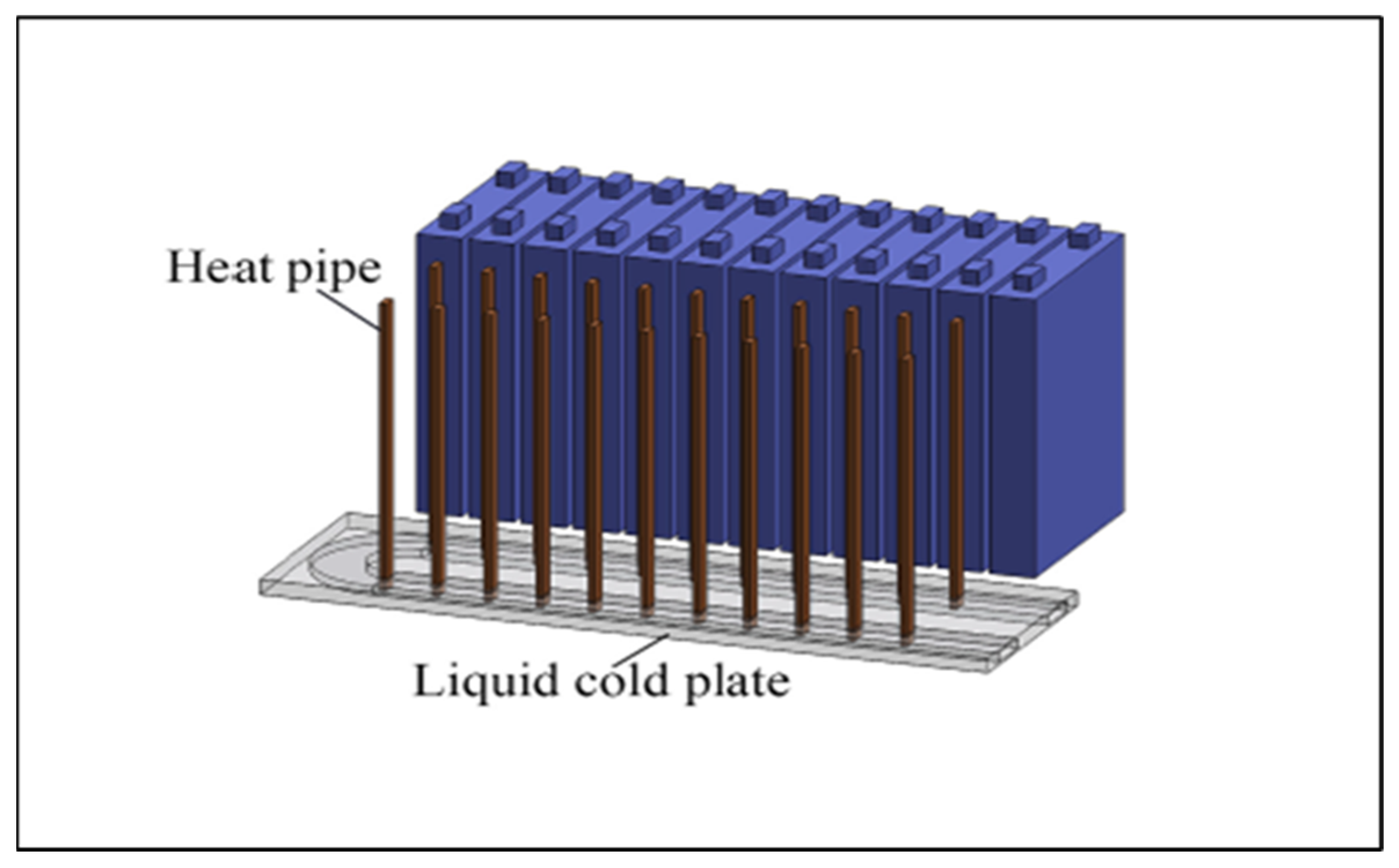

3.2.2. Heat Pipe

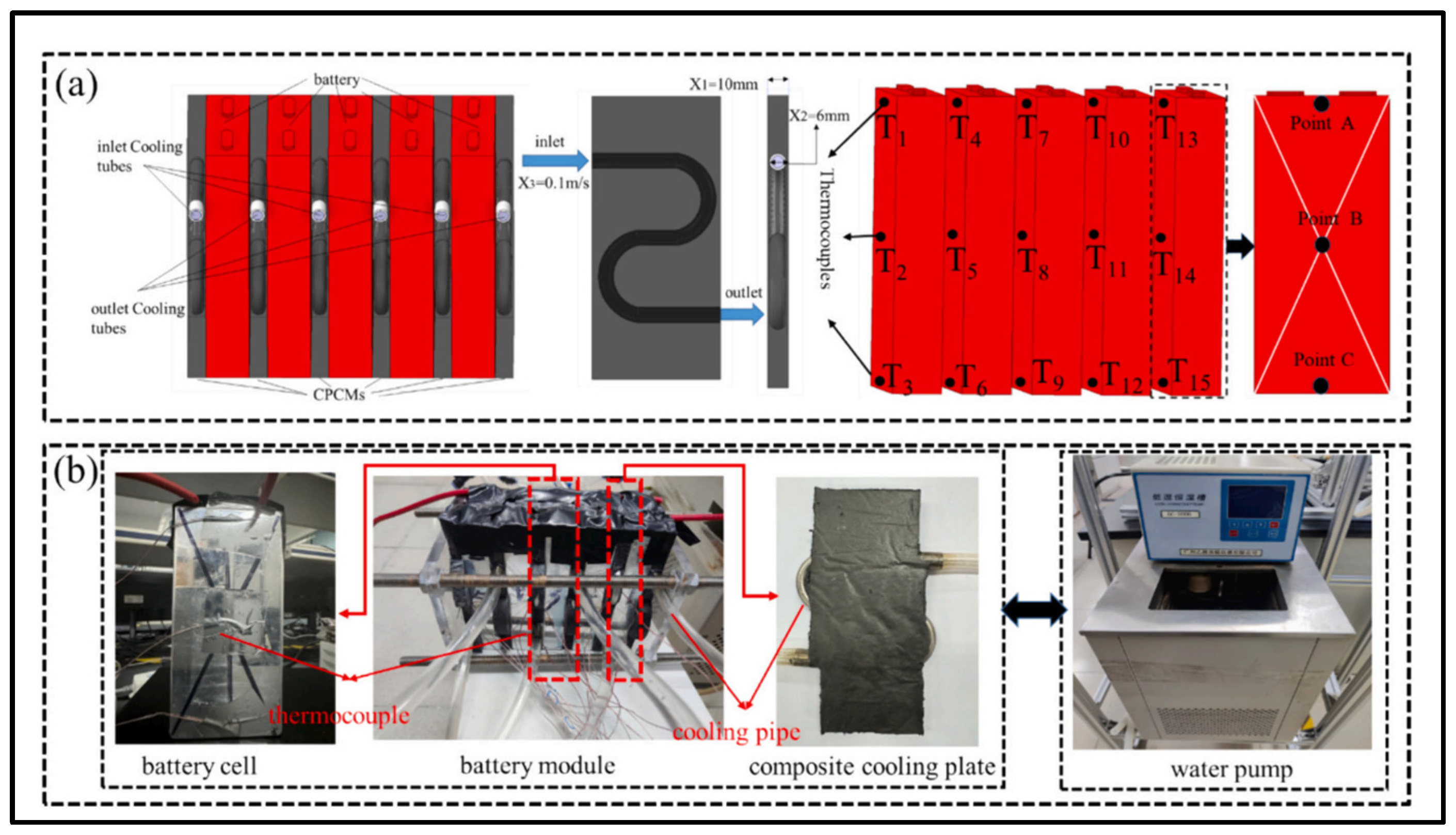

3.3. Hybrid Cooling

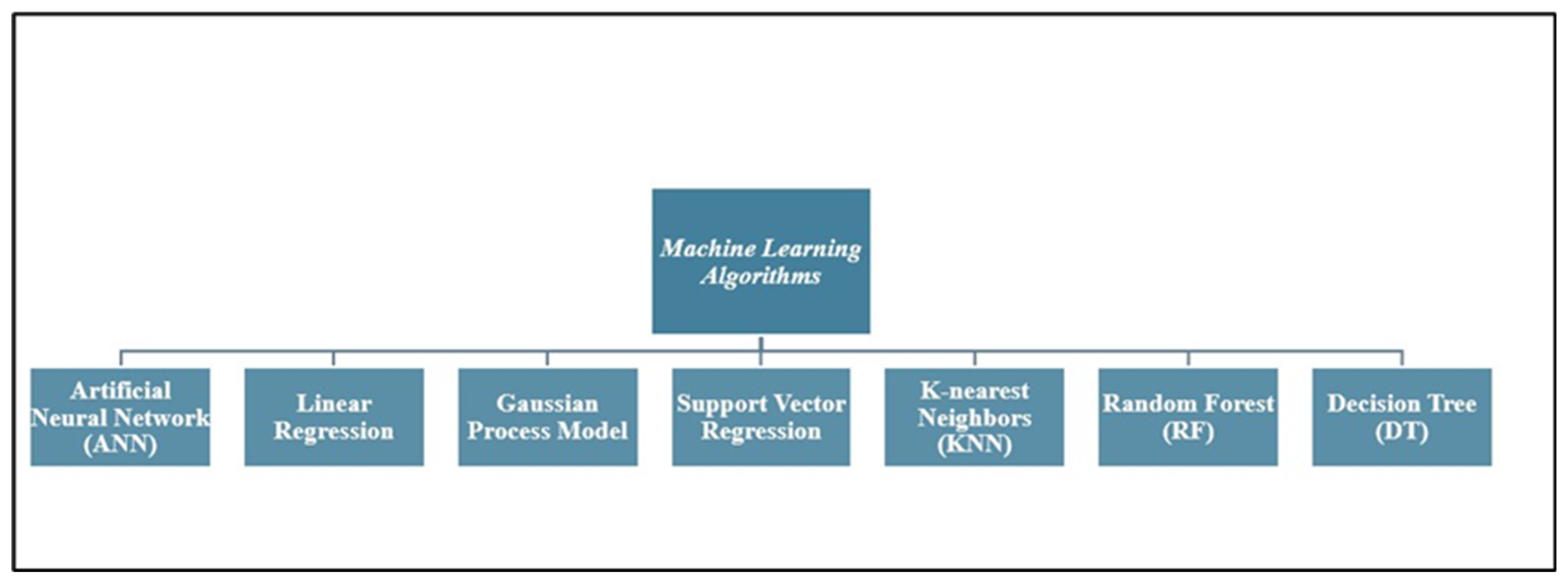

4. BTMSs Using AI and ML

4.1. Active BTMSs

4.2. Passive BTMSs

4.3. Hybrid BTMSs

| No. | Authors | Year | BTMS | AI/ML Used | Input Parameters | Goal/Target | Major Findings | Gaps |

|---|---|---|---|---|---|---|---|---|

| 1 | Monika et al. [159] | 2024 | Liquid–BTMS | Kriging Model/NSGA II | , | , , h | increased by 0.07%, decreased by 62.32%, and h was enhanced by 64.41% |

|

| 2 | Zheng et al. [160] | 2024 | Liquid–BTMS | Artificial Neural Network/NSGA–II | α, β, X1, X2, X3, Y1, Y2, Y3 |

| ||

| 3 | Yuan et al. [161] | 2024 | Refrigerant–BTMS | Artificial Neural Networks (Elman–NN) | Compressor speed, ambient temperature, discharge rate, and state of charge | Minimum, maximum, and difference temperature cell | For unexpected condition, predicted model of Elman–NN had maximum prediction error of 0.94 °C, and maximum MSE and minimum R2 were 0.2275 and 94.48% |

|

| 4 | Li et al. [162] | 2024 | Liquid–BTMS | Kriging Model/MOGA | F, Hc, Wb, WL, WS, WIO |

| ||

| 5 | Al-Haddad et al. [163] | 2024 | Air–BTMS | Neural Networks | Tamb, cell length | Predicted heat flux | Accurate prediction of heat flux and less computational time |

|

| 6 | Bacak [164] | 2024 | Air–BTMS | Levenberg–Marquardt | Tamb, C-rate, hconvection, nominal capacity | Surface temperature | ML predicted accurate surface temperature compared with experimental and numerical methods |

|

| 7 | Sukkam et al. [165] | 2024 | Liquid–BTMS | Multilayer Perceptron/GridSearchCV | MaxCh, CR, I, V, SoC, SoH, BT, v, s, H, W, BCL, CL, AC. | Battery health factor | SoC, MaxCh, and BT have a vital influence on battery health factor |

|

| 8 | Jiang et al. [166] | 2024 | Liquid–BTMS | Bayesian Multi–Objective Optimization Algorithm/NSGA–II | w, d, r | , PP | PP reduced by 71%, reduced slightly |

|

| 9 | Li et al. [167] | 2023 | Air–BTMS | Genetic Programming and Response/NSGA–II and MOGA Surface Model | v, d1, d2, d3, d4, d5 | Maximum temperature and cyclical cost | Higher temperature operating condition significantly decreased battery life cycle |

|

| 10 | Zhang et al. [168] | 2023 | Liquid–BTMS | NSGA–II | i, f, j, β, θ | is reduced by 64.72%, and Tavg was decreased by 1.01% of Arcing channel |

| |

| 11 | Fan er al. [169] | 2023 | Liquid–BTMS | Genetic Algorithm | Charging current trajectories | Trade–off between temperature difference and charging time | Temperature difference and charging time are decreased by 37.9% and 11.9%, respectively, using optimized charging strategy |

|

| 12 | Fan et al. [170] | 2023 | Liquid–BTMS | Kriging Model/NCGA | G, W, Re | Thermal performance of optimized MSTV was enhanced by 17.3% |

| |

| 13 | Fan et al. [171] | 2022 | Air–BTMS | MOE/NSGA–II | X1, X2, X3, Xh | Optimized design decreased by 9%, 17.6%, and 8.9%, respectively. |

| |

| 14 | Çolak [172] | 2022 | Liquid–BTMS | Levenberg–Marquardt, Bayesian Regularization, and Scaled Conjugate Gradient | Discharge rate, flow rate, and inlet temperature | Average temperature of battery surface and maximum temperature difference | Levenberg–Marquardt has highest accuracy of prediction |

|

| 15 | Yalçın et al. [173] | 2022 | Liquid–BTMS | CNN–ABC Model | Heat generation rate and voltage variables | Heat generation rate and voltage estimations | CNN–ABC model showed best prediction compared with LR, MLR, DT, RF, SVM, LSTN, and CNN |

|

| 16 | Liao et al. [174] | 2021 | Air/Liquid–BTMS | RSM/NSGA–II | Wh, Wv, Dc, Dh, Dv, Th, H | , , Pmax | Optimized design decreased to 304.5, to 0.88 K, and Pmax to 710.01 Pa |

|

| 17 | Chen et al. [175] | 2021 | Liquid–BTMS | Artificial Neural Network | I1, I2, I3, Q | , TSD, W | , TSD, and W were decreased to 33.35 °C, 0.8 °C, and 0.02 J, respectively |

|

| 18 | Deng et al. [176] | 2020 | Liquid–BTMS | NSGA–II | D1, ω, γ, dc, qm | h, f | h was enhanced by 17.19% and f was decreased by 85.5% |

|

| 19 | Garg et al. [177] | 2020 | Air–BTMS | ANS/NSGA II | X1, X2, X3, X4, V | V, , TSD | V, , and TSD were decreased by 29.21, 35.66%, and 78.69%, respectively |

|

| 20 | Lei et al. [178] | 2024 | Air–BTMS | NSGA II | Coolant temperature, air flow rate, and engine speed | Engine fuel consumption and battery SOH | Fuel consumption was reduced by 4.85% and SOH was improved by 3.7% |

|

| No. | Authors | Year | BTMS | AI/ML Used | Input Parameters | Goal/Target | Major Findings | Gaps |

|---|---|---|---|---|---|---|---|---|

| 1 | Amba et al. [179] | 2024 | PCM-BTMS | Linear Regression, Support Vector Regression (SVR), Decision Trees, and Polynomial Regression | PCM thickness, discharge rate, ambient temperature, and PCM type | Battery temperatures | Polynomial regression had a higher R2 of 0.997 and a lower RSME of 0.629. Moreover, the optimal thickness was 5 mm, and the higher thermal conductivity of the inorganic types has shown better thermal performance than the organic types. |

|

| 2 | Goud et al. [180] | 2023 | PCM-BTMS | Adaptive Neuro-Fuzzy Inference System | Type of cooling, battery module C-rate, and time | Maximum surface temperature of the battery | The PCM-BTMS decreased the maximum surface temperature by 31.72%, with a discharge rate of up to 5 C. The ANFIS model had higher accuracy with an R-value of 0.99. |

|

| 3 | Boonma et al. [181] | 2022 | HP-BTMS | Pattern-Based Machine Learning | Geometry of CBHP (pairs and clusters), initial battery and heat pipe conditions, temperature profiles during charge/discharge cycles, and variables affecting boiling/condensation processes | Battery temperature profiles, HP temperature, condensation ratio, thermal conductivity variations, and overall BTMS efficiency | Increasing the condensation surface area and optimizing pair/cluster configurations decreased the maximum surface temperature and the difference temperature by 27% and 13.43%, respectively. |

|

| 4 | Muthya Goud et al. [182] | 2022 | PCM-BTMS | Adaptive Neuro-Fuzzy Inference System | PCM type, sample heating rate, and temperature | Predicted heat flow rate of PCM | PCM-BC24, with 24% biochar and 1% MWCNT, enhanced the thermal conductivity and effusivity by 458.72% and 146.25%, respectively. |

|

| 5 | Kolodziejczyk et al. [183] | 2021 | PCM-BTMS | Convolutional Neural Networks | Images of CPCM microstructures | Thermal conductivity of CPCMs and electrochemical model output heat generation rates | The proposed model had a 5% mean absolute percentage error in predicting the thermal conductivities. |

|

| No. | Authors | Year | BTMS | AI/ML Used | Input Parameters | Goal/Target | Major Findings |

|---|---|---|---|---|---|---|---|

| 1 | Zhang et al. [184] | 2024 | PCM and air cooling with cantor fractal fin | Backpropagation (BP) neural network | SoC, n of cantor fractal fin, PCM combination, PCM proportion, air flow direction, discharge rate, ambient temperature | and ∆Tmax |

|

| 2 | Fini et al. [185] | 2023 | Water cooling with PCM | ANN | Re, volume fraction of microencapsulated PCM (ϕ), average temperature, temperature standard deviation | Nu and ∆P |

|

| 3 | Wang et al. [186] | 2023 | Two-phase nanofluid with PCM | AI technique | Horizontal distance, vertical distance, nanofluid input size | Heat transfer coefficient and |

|

| 4 | Xie et al. [187] | 2024 | Liquid cooling with PCM | Random forest (RF), neural networks (NNs), and gradient boosting (GB). | Battery arrangement structure (e.g., single row or double row), liquid flow direction (e.g., upper nozzle inflow, staggered inflow), mass flow rate, liquid cooling startup temperature, PCM melting point, discharge rate (3C or 5C), initial battery temperature | , ∆Tmax, and energy consumption |

|

| 5 | Chen et al. [188] | 2022 | Liquid cooling with PCM | ANN | Charging current rate (2C, 2.5C, and 3C), mass flow rate, PCM thickness | and temperature standard deviation (TSD) |

|

| 6 | Liu et al. [189] | 2022 | Airflow with PCM | ANN | Battery temperature and ∆P |

| |

| 7 | Alqaed et al. [190] | 2024 | Air cooling with PCM | ANN | Battery pack arrangement, airflow velocity, PCM properties, temperature change over 2500 s |

| |

| 8 | Yang et al. [191] | 2021 | Bionic liquid mini-channel in cooling plate with PCM | Back propagation (BP) neural network | Ambient temperature, , ∆Tmax, discharge current, cycle conditions | Inlet flow rate |

|

5. Discussion

- The active cooling, including air–BTMS and liquid–BTMS using AI and ML, has shown superior thermal behavior. Both reduced the maximum surface temperature, enhanced the homogeneity of the temperature inside the battery pack, and reduced energy consumption by optimizing the dimensions of the cooling system, coolant flow rate, and discharge rate. One of the significant multi-objective optimization methods that has been intensively used is NSGA-II, with a higher R2 value of up to 0.99. Moreover, genetic algorithms, Kriging models, and artificial neural networks are frequently utilized in numerous studies due to their high efficiency in handling nonlinear relationships between variables and their reduced computational time requirements. On the other hand, there are still limitations with active cooling using AI and ML, such as the need to optimize the effect of the nanofluid on the battery pack. It is well known that working fluid plays a key role in influencing the ion thermal behavior of the battery. Furthermore, most of the studies had challenges with validating the results with experimental tests; numerous studies have been conducted on the specified type of battery cells. In addition, there is a vital need to observe and study the health monitoring of the battery (SoH). Also, most investigations have studied and optimized the BTMS with a constant ambient temperature and constant discharge/charging rate.

- Passive cooling, including PCM-BTMS and HP-BTMS using AI and ML, has shown more significant potential to enhance uniformity and reduce the battery’s surface temperature. As a result, most of the proposed predictive models (SVR, ANFIS, and CNN) had an R2 value of up to 0.99, and the maximum surface temperature reduction was 31.72%; in addition, the thickness of the PCM had a significant influence on the thermal performance of the PCM-BTMS. However, due to their lower thermal conductivity, the PCM-BTMS still struggled with maintaining the temperature in the optimal operating range. Furthermore, the PCM-BTMS relies on mass, resulting in bulky and heavy systems. On the other hand, there is still a limitation of passive BTMSs, such as the HP-BTMS using AI and ML, which has not been intensively investigated. Moreover, the PCM-BTMS using AI and ML has not been studied and verified with experimental tests, especially for the operating cycle (while driving) compared with charging and discharging cycles. Furthermore, the nano PCM-BTMS should be considered in future work.

- According to the literature for hybrid BTMSs with AI/ML, they have demonstrated significant success in improving cooling efficiency, energy consumption, and thermal stability in LIBs. Multi-objective optimization approaches like NSGA-II have provided balanced cooling performance and minimum pressure drops, resulting in optimal flow rates and channel designs. ANN models have allowed for more accurate temperature predictions in PCM-enhanced BTMS settings, greatly lowering temperature variance. Furthermore, models such as backpropagation neural networks (BPNNs) and LSTM have been utilized to anticipate temperature distribution and manage system responses, resulting in high prediction accuracy and enhanced thermal uniformity while using less energy. However, limitations remain, since many models are designed for specific situations, and expansion to other battery applications remains difficult. Further study might extend these methodologies to cover a broader range of configurations, materials, and operating conditions for hybrid BTMS optimization. Furthermore, extra LIB parameters, such as SoH and internal resistance increase, must be investigated. Additionally, more experimental work is needed to simulate actual situations for BTMSs.

- AI and ML can significantly enhance BTMSs by enabling real-time thermal prediction, adaptive cooling control, and degradation mitigation, thereby extending battery lifespan and maintaining optimal operating conditions (15–35 °C). AI and ML offer substantial advantages, including high-accuracy temperature prediction (R2 = 0.99 for ANN), optimized cooling efficiency, and adaptive control strategies that enhance safety and prolong battery lifespan. Techniques such as ANN, LSTM, and reinforcement learning enable real-time thermal monitoring, as well as a reduction in maximum temperatures and temperature differences, ensuring a homogeneous thermal distribution inside the battery system. AI-driven multi-objective optimization, such as NSGA II, MOGA, and NCGA models, also improves energy efficiency by significantly lowering cooling demands by reducing the pressure drop, heat transfer coefficient, and power consumption. However, these methods present notable challenges, including high computational costs, complex model development, and a heavy reliance on extensive, high-quality training datasets. Scalability remains a concern, particularly when transitioning from lab-scale models to real-world battery packs, where diverse operating conditions and pack configurations complicate implementation. Additionally, deep learning approaches, while powerful encountered issues like overfitting require significant expertise for fine-tuning. Hybrid approaches that integrate experimental-based data and CFD-based data with AI/ML show promise in balancing accuracy with practicality, offering a viable path forward for robust and efficient BTMSs.

6. Conclusions and Future Work

- Establish extensive experimental setups that simulate real BTMS operational situations to optimize model outputs, improve system design, and include realistic scenarios for the experimental study, such as charging and discharging rates.

- Extending the study to include additional variables such as SoH and internal resistance increase in LIBs to better understand how AI/ML affects battery longevity and performance.

- Extending studies beyond specific cell types or configurations to evaluate the flexibility and adaptiveness of AI/ML applications across an extensive range of battery technologies.

- Intensify research on nanofluid and nanocomposite PCMs to improve the thermal performance of BTMSs and integrate this technology with the input parameters to AI/ML.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| ANN | Artificial Neural Network |

| BEV | Battery Electric Vehicle |

| BTMS | Battery Thermal Management System |

| CFD | Computational Fluid Dynamics |

| COP | Coefficient of Performance |

| CNN | Convolutional Neural Network |

| DCIR | Direct Current Internal Resistance |

| EV | Electric Vehicle |

| GHG | Greenhouse Gas |

| HEV | Hybrid Electric Vehicle |

| HP | Heat Pipe |

| HPACS | Heat Pump Air Conditioning System |

| ICE | Internal Combustion Engine |

| LCP | Liquid Cold Plate |

| LIB | Lithium-Ion Battery |

| LSTM | Long Short-Term Memory |

| ML | Machine Learning |

| MOGA | Multi-Objective Genetic Algorithm |

| NSGA-II | Non-Dominated Sorting Genetic Algorithm II |

| PCM | Phase-Change Material |

| PHEV | Plug-in Hybrid Electric Vehicle |

| PSO | Particle Swarm Optimization |

| RF | Random Forest |

| RSM | Response Surface Methodology |

| SEI | Solid–Electrolyte Interface |

| SoC | State of Charge |

| SoH | State of Health |

| SVR | Support Vector Regression |

| TEC | Thermoelectric Cooler |

| TR | Thermal Runaway |

| XGB | X-Gradient Boosting |

| Nomenclature: | |

| I | Current |

| Heat Generation | |

| Internal Resistance | |

| |T | Battery Temperature |

| Maximum Temperature | |

| Temperature Difference | |

| Open Circuit Voltage | |

| V | Nominal Voltage |

References

- Morfeldt, J.; Davidsson Kurland, S.; Johansson, D.J.A. Carbon Footprint Impacts of Banning Cars with Internal Combustion Engines. Transp. Res. D Transp. Environ. 2021, 95, 102807. [Google Scholar] [CrossRef]

- Leach, F.; Kalghatgi, G.; Stone, R.; Miles, P. The Scope for Improving the Efficiency and Environmental Impact of Internal Combustion Engines. Transp. Eng. 2020, 1, 100005. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, H.; Yuan, H.; Chu, X. How Does Adoption of Electric Vehicles Reduce Carbon Emissions? Evidence from China. Heliyon 2023, 9, e20296. [Google Scholar] [CrossRef] [PubMed]

- Veza, I.; Asy’ari, M.Z.; Idris, M.; Epin, V.; Rizwanul Fattah, I.M.; Spraggon, M. Electric Vehicle (EV) and Driving towards Sustainability: Comparison between EV, HEV, PHEV, and ICE Vehicles to Achieve Net Zero Emissions by 2050 from EV. Alex. Eng. J. 2023, 82, 459–467. [Google Scholar] [CrossRef]

- Dobó, Z.; Dinh, T.; Kulcsár, T. A Review on Recycling of Spent Lithium-Ion Batteries. Energy Rep. 2023, 9, 6362–6395. [Google Scholar] [CrossRef]

- Sasaki, T.; Ukyo, Y.; Novák, P. Memory Effect in a Lithium-Ion Battery. Nat. Mater. 2013, 12, 569–575. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Singh, V.; Goel, R. Strategic Forecasting for Electric Vehicle Sales: A Cutting Edge Holistic Model Leveraging Key Factors and Machine Learning Technique. Transp. Dev. Econ. 2024, 10, 23. [Google Scholar] [CrossRef]

- Ali, H.M. Thermal Management Systems for Batteries in Electric Vehicles: A Recent Review. Energy Rep. 2023, 9, 5545–5564. [Google Scholar] [CrossRef]

- Zou, B.; Zhang, L.; Xue, X.; Tan, R.; Jiang, P.; Ma, B.; Song, Z.; Hua, W. A Review on the Fault and Defect Diagnosis of Lithium-Ion Battery for Electric Vehicles. Energies 2023, 16, 5507. [Google Scholar] [CrossRef]

- Shen, D.; Lyu, C.; Yang, D.; Hinds, G.; Ma, K.; Xu, S.; Bai, M. Concurrent Multi-Fault Diagnosis of Lithium-Ion Battery Packs Using Random Convolution Kernel Transformation and Gaussian Process Classifier. Energy 2024, 306, 132467. [Google Scholar] [CrossRef]

- Amba Prasad Rao, G.; Shravan Kumar, S.R. A Review of Integrated Battery Thermal Management Systems for Lithium-Ion Batteries of Electric Vehicles. E-Prime—Adv. Electr. Eng. Electron. Energy 2024, 8, 100526. [Google Scholar] [CrossRef]

- Al Miaari, A.; Ali, H.M. Batteries Temperature Prediction and Thermal Management Using Machine Learning: An Overview. Energy Rep. 2023, 10, 2277–2305. [Google Scholar] [CrossRef]

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature Effect and Thermal Impact in Lithium-Ion Batteries: A Review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666. [Google Scholar] [CrossRef]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A Review of Lithium-Ion Battery Safety Concerns: The Issues, Strategies, and Testing Standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Alipour, M.; Ziebert, C.; Conte, F.V.; Kizilel, R. A Review on Temperature-Dependent Electrochemical Properties, Aging, and Performance of Lithium-Ion Cells. Batteries 2020, 6, 35. [Google Scholar] [CrossRef]

- Thomas, E.V.; Case, H.L.; Doughty, D.H.; Jungst, R.G.; Nagasubramanian, G.; Roth, E.P. Accelerated Power Degradation of Li-Ion Cells. J. Power Sources 2003, 124, 254–260. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. Temperature-Dependent Electrochemical Heat Generation in a Commercial Lithium-Ion Battery. J. Power Sources 2014, 247, 618–628. [Google Scholar] [CrossRef]

- Saeed, A.; Alshehri, A.; Munteshari, O. Calendar Aging of Commercial Lithium Ion Batteries under Realistic Conditions. Therm. Sci. Eng. Prog. 2024, 49, 102436. [Google Scholar] [CrossRef]

- Gao, T.; Bai, J.; Ouyang, D.; Wang, Z.; Bai, W.; Mao, N.; Zhu, Y. Effect of Aging Temperature on Thermal Stability of Lithium-Ion Batteries: Part A—High-Temperature Aging. Renew. Energy 2023, 203, 592–600. [Google Scholar] [CrossRef]

- Chen, S.; Wei, X.; Zhang, G.; Wang, X.; Zhu, J.; Feng, X.; Dai, H.; Ouyang, M. All-Temperature Area Battery Application Mechanism, Performance, and Strategies. Innovation 2023, 4, 100465. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Wang, Y.; Feng, Y.H.; Fan, X.Y.; Han, X.; Wang, P.F. Lithium-Ion Batteries under Low-Temperature Environment: Challenges and Prospects. Materials 2022, 15, 8166. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.; Zhao, H.; Ping, P.; Zhang, Y.; Wang, G. Effect of Low Temperature on Thermal Runaway and Fire Behaviors of 18650 Lithium-Ion Battery: A Comprehensive Experimental Study. Process Saf. Environ. Prot. 2023, 174, 448–459. [Google Scholar] [CrossRef]

- Smart, M.C.; Ratnakumar, B.V.; Whitcanack, L.D.; Chin, K.B.; Surampudi, S.; Croft, H.; Tice, D.; Staniewicz, R. Improved Low-Temperature Performance of Lithium-Ion Cells with Quaternary Carbonate-Based Electrolytes. J. Power Sources 2003, 119–121, 349–358. [Google Scholar] [CrossRef]

- Gharehghani, A.; Rabiei, M.; Mehranfar, S.; Saeedipour, S.; Mahmoudzadeh Andwari, A.; García, A.; Reche, C.M. Progress in Battery Thermal Management Systems Technologies for Electric Vehicles. Renew. Sustain. Energy Rev. 2024, 202, 114654. [Google Scholar] [CrossRef]

- Fan, L.; Khodadadi, J.M.; Pesaran, A.A. A Parametric Study on Thermal Management of an Air-Cooled Lithium-Ion Battery Module for Plug-in Hybrid Electric Vehicles. J. Power Sources 2013, 238, 301–312. [Google Scholar] [CrossRef]

- Hossain, M.H.; Chowdhury, M.A.; Hossain, N.; Islam, M.A.; Mobarak, M.H. Advances of Lithium-Ion Batteries Anode Materials—A Review. Chem. Eng. J. Adv. 2023, 16, 100569. [Google Scholar] [CrossRef]

- Rojas, O.E.; Khan, M.A. A Review on Electrical and Mechanical Performance Parameters in Lithium-Ion Battery Packs. J. Clean. Prod. 2022, 378, 134381. [Google Scholar] [CrossRef]

- Amer, M.; Masri, J.; Dababat, A.; Sajjad, U.; Hamid, K. Electric Vehicles: Battery Technologies, Charging Standards, AI Communications, Challenges, and Future Directions. Energy Convers. Manag. X 2024, 24, 100751. [Google Scholar] [CrossRef]

- Borah, R.; Hughson, F.R.; Johnston, J.; Nann, T. On Battery Materials and Methods. Mater. Today Adv. 2020, 6, 100046. [Google Scholar] [CrossRef]

- Gao, Y.; Pan, Z.; Sun, J.; Liu, Z.; Wang, J. High-Energy Batteries: Beyond Lithium-Ion and Their Long Road to Commercialisation. Nano-Micro Lett. 2022, 14, 94. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Jin, M.; Cai, Y.; Lian, Y.; Zhao, X.; Wang, R.; Qiao, S.; Chen, L.; Yan, X. Construction of Electrochemical Model for High C-Rate Conditions in Lithium-Ion Battery Based on Experimental Analogy Method. Energy 2023, 279, 128073. [Google Scholar] [CrossRef]

- Gao, Z.; Xie, H.; Yang, X.; Niu, W.; Li, S.; Chen, S. The Dilemma of C-Rate and Cycle Life for Lithium-Ion Batteries under Low Temperature Fast Charging. Batteries 2022, 8, 234. [Google Scholar] [CrossRef]

- Wu, C.; Sun, Y.; Tang, H.; Zhang, S.; Yuan, W.; Zhu, L.; Tang, Y. A Review on the Liquid Cooling Thermal Management System of Lithium-Ion Batteries. Appl. Energy 2024, 375, 124173. [Google Scholar] [CrossRef]

- Yang, L.; Liu, F.; Li, F.; Chen, Z.; Wang, J.; Gao, L.; Xiao, F.; Sun, J.; Romagnoli, A. Thermal Runaway Prevention and Mitigation for Lithium-Ion Battery-Powered Electric Aircraft: Challenges and Perspectives. Aerosp. Traffic Saf. 2024, 1, 103–118. [Google Scholar] [CrossRef]

- Ren, Z.; Du, C.; Wu, Z.; Shao, J.; Deng, W. A Comparative Study of the Influence of Different Open Circuit Voltage Tests on Model-Based State of Charge Estimation for Lithium-Ion Batteries. Int. J. Energy Res. 2021, 45, 13692–13711. [Google Scholar] [CrossRef]

- Suganya, R.; Joseph, L.M.I.L.; Kollem, S. Understanding Lithium-Ion Battery Management Systems in Electric Vehicles: Environmental and Health Impacts, Comparative Study, and Future Trends: A Review. Results Eng. 2024, 24, 103047. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, M.; Ding, Y.; Wu, S.; Li, Y.; Liang, G.; Li, H.; Pan, H. Estimation the Internal Resistance of Lithium-Ion-Battery Using a Multi-Factor Dynamic Internal Resistance Model with an Error Compensation Strategy. Energy Rep. 2021, 7, 3050–3059. [Google Scholar] [CrossRef]

- Heiskanen, S.K.; Kim, J.; Lucht, B.L. Generation and Evolution of the Solid Electrolyte Interphase of Lithium-Ion Batteries. Joule 2019, 3, 2322–2333. [Google Scholar] [CrossRef]

- Zimmerman, A.H. Self-Discharge Losses in Lithium-Ion Cells. IEEE Aerosp. Electron. Syst. Mag. 2004, 2, 19–24. [Google Scholar] [CrossRef]

- Birkl, C.R.; Roberts, M.R.; McTurk, E.; Bruce, P.G.; Howey, D.A. Degradation Diagnostics for Lithium Ion Cells. J. Power Sources 2017, 341, 373–386. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, B.; Han, P.; Hao, C.; Li, S.; You, Z.; Wang, M. Optimization of an Air-Based Thermal Management System for Lithium-Ion Battery Packs. J. Energy Storage 2021, 44, 103314. [Google Scholar] [CrossRef]

- Wang, A.; Kadam, S.; Li, H.; Shi, S.; Qi, Y. Review on Modeling of the Anode Solid Electrolyte Interphase (SEI) for Lithium-Ion Batteries. NPJ Comput. Mater. 2018, 4, 15. [Google Scholar] [CrossRef]

- Meister, P.; Jia, H.; Li, J.; Kloepsch, R.; Winter, M.; Placke, T. Best Practice: Performance and Cost Evaluation of Lithium Ion Battery Active Materials with Special Emphasis on Energy Efficiency. Chem. Mater. 2016, 28, 7203–7217. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Luo, L.; Fan, Y.; Du, Z. A Review on Thermal Management of Lithium-Ion Batteries for Electric Vehicles. Energy 2022, 238, 121652. [Google Scholar] [CrossRef]

- Jaguemont, J.; Boulon, L.; Dube, Y.; Martel, F. Thermal Management of a Hybrid Electric Vehicle in Cold Weather. IEEE Trans. Energy Convers. 2016, 31, 1110–1120. [Google Scholar] [CrossRef]

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A Critical Review of Battery Thermal Performance and Liquid Based Battery Thermal Management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Tete, P.R.; Gupta, M.M.; Joshi, S.S. Developments in Battery Thermal Management Systems for Electric Vehicles: A Technical Review. J. Energy Storage 2021, 35, 102255. [Google Scholar] [CrossRef]

- Bernardi, D.; Pawlikowski, E.; Newman, J. A General Energy Balance for Battery Systems. J. Electorchemical Socity 1985, 132, 5. [Google Scholar] [CrossRef]

- Hwang, F.S.; Confrey, T.; Reidy, C.; Picovici, D.; Callaghan, D.; Culliton, D.; Nolan, C. Review of Battery Thermal Management Systems in Electric Vehicles. Renew. Sustain. Energy Rev. 2024, 192, 114171. [Google Scholar] [CrossRef]

- Sheng, L.; Su, L.; Zhang, H.; Li, K.; Fang, Y.; Ye, W.; Fang, Y. Numerical Investigation on a Lithium Ion Battery Thermal Management Utilizing a Serpentine-Channel Liquid Cooling Plate Exchanger. Int. J. Heat Mass Transf. 2019, 141, 658–668. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, X.; Liu, Z.; Kong, J.; Zhai, Q.; Zakaria, H.; Wang, Q.; Zhou, F.; Wei, H. Optimization of Liquid Cooling for Prismatic Battery with Novel Cold Plate Based on Butterfly-Shaped Channel. J. Energy Storage 2023, 73, 109161. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Li, B.; Yan, Y. A Critical Review of Thermal Management Models and Solutions of Lithium-Ion Batteries for the Development of Pure Electric Vehicles. Renew. Sustain. Energy Rev. 2016, 64, 106–128. [Google Scholar] [CrossRef]

- Kim, J.; Oh, J.; Lee, H. Review on Battery Thermal Management System for Electric Vehicles. Appl. Therm. Eng. 2019, 149, 192–212. [Google Scholar] [CrossRef]

- Gozdur, R.; Guzowski, B.; Dimitrova, Z.; Noury, A.; Mitukiewicz, G.; Batory, D. An Energy Balance Evaluation in Lithium-Ion Battery Module under High Temperature Operation. Energy Convers. Manag. 2021, 227, 113565. [Google Scholar] [CrossRef]

- Liao, C.; Wang, W.; Wang, J.; Han, L.; Qiu, S.; Song, L.; Gui, Z.; Kan, Y.; Hu, Y. Magnetron Sputtering Deposition of Silicon Nitride on Polyimide Separator for High-Temperature Lithium-Ion Batteries. J. Energy Chem. 2021, 56, 1–10. [Google Scholar] [CrossRef]

- Ma, Z.; Chen, J.; Vatamanu, J.; Borodin, O.; Bedrov, D.; Zhou, X.; Zhang, W.; Li, W.; Xu, K.; Xing, L. Expanding the Low-Temperature and High-Voltage Limits of Aqueous Lithium-Ion Battery. Energy Storage Mater. 2022, 45, 903–910. [Google Scholar] [CrossRef]

- Zhang, S.S.; Xu, K.; Jow, T.R. The Low Temperature Performance of Li-Ion Batteries. J. Power Sources 2003, 115, 137–140. [Google Scholar] [CrossRef]

- Akbarzadeh, M.; Kalogiannis, T.; Jaguemont, J.; Jin, L.; Behi, H.; Karimi, D.; Beheshti, H.; Van Mierlo, J.; Berecibar, M. A Comparative Study between Air Cooling and Liquid Cooling Thermal Management Systems for a High-Energy Lithium-Ion Battery Module. Appl. Therm. Eng. 2021, 198, 117503. [Google Scholar] [CrossRef]

- Deng, Y.; Feng, C.; E, J.; Zhu, H.; Chen, J.; Wen, M.; Yin, H. Effects of Different Coolants and Cooling Strategies on the Cooling Performance of the Power Lithium Ion Battery System: A Review. Appl. Therm. Eng. 2018, 142, 10–29. [Google Scholar] [CrossRef]

- Yang, Y.; Li, W.; Xu, X.; Tong, G. Heat Dissipation Analysis of Different Flow Path for Parallel Liquid Cooling Battery Thermal Management System. Int. J. Energy Res. 2020, 44, 5165–5176. [Google Scholar] [CrossRef]

- Zhang, C.-W.; Xu, K.-J.; Li, L.-Y.; Yang, M.-Z.; Gao, H.-B.; Chen, S.-R. Study on a Battery Thermal Management System Based on a Thermoelectric Effect. Energies 2018, 11, 279. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, X.; Tran, M.-K.; Fowler, M.; Ouyang, M.; Burke, A.F. Battery Safety: Fault Diagnosis from Laboratory to Real World. J. Power Sources 2024, 598, 234111. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, X.; Pang, Q.; Fowler, M.; Lian, Y.; Ouyang, M.; Burke, A.F. Battery Safety: Machine Learning-Based Prognostics. Prog. Energy Combust. Sci. 2024, 102, 101142. [Google Scholar] [CrossRef]

- Mahamud, R.; Park, C. Reciprocating Air Flow for Li-Ion Battery Thermal Management to Improve Temperature Uniformity. J. Power Sources 2011, 196, 5685–5696. [Google Scholar] [CrossRef]

- Wang, T.; Tseng, K.J.; Zhao, J.; Wei, Z. Thermal Investigation of Lithium-Ion Battery Module with Different Cell Arrangement Structures and Forced Air-Cooling Strategies. Appl. Energy 2014, 134, 229–238. [Google Scholar] [CrossRef]

- Chen, K.; Song, M.; Wei, W.; Wang, S. Structure Optimization of Parallel Air-Cooled Battery Thermal Management System with U-Type Flow for Cooling Efficiency Improvement. Energy 2018, 145, 603–613. [Google Scholar] [CrossRef]

- Wang, Y.-W.; Jiang, J.-M.; Chung, Y.-H.; Chen, W.-C.; Shu, C.-M. Forced-Air Cooling System for Large-Scale Lithium-Ion Battery Modules during Charge and Discharge Processes. J. Therm. Anal. Calorim. 2019, 135, 2891–2901. [Google Scholar] [CrossRef]

- Gocmen, S.; Cetkin, E. Emergence of Elevated Battery Positioning in Air Cooled Battery Packs for Temperature Uniformity in Ultra-Fast Dis/Charging Applications. J. Energy Storage 2022, 45, 103516. [Google Scholar] [CrossRef]

- Lazim, A.A.; Ismael, M.A. Cooling of Lithium-Ion Battery Pack Using Different Configurations of Flexible Baffled Channels. Heat Transf. 2024, 53, 1267–1291. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Yang, B.; Cai, S. A Review of Battery Thermal Management Systems Using Liquid Cooling and PCM. J. Energy Storage 2024, 76, 109836. [Google Scholar] [CrossRef]

- Jithin, K.V.; Rajesh, P.K. Numerical Analysis of Single-Phase Liquid Immersion Cooling for Lithium-Ion Battery Thermal Management Using Different Dielectric Fluids. Int. J. Heat Mass Transf. 2022, 188, 122608. [Google Scholar] [CrossRef]

- Tan, X.; Lyu, P.; Fan, Y.; Rao, J.; Ouyang, K. Numerical Investigation of the Direct Liquid Cooling of a Fast-Charging Lithium-Ion Battery Pack in Hydrofluoroether. Appl. Therm. Eng. 2021, 196, 117279. [Google Scholar] [CrossRef]

- Wu, S.; Lao, L.; Wu, L.; Liu, L.; Lin, C.; Zhang, Q. Effect Analysis on Integration Efficiency and Safety Performance of a Battery Thermal Management System Based on Direct Contact Liquid Cooling. Appl. Therm. Eng. 2022, 201, 117788. [Google Scholar] [CrossRef]

- Larrañaga-Ezeiza, M.; Vertiz, G.; Arroiabe, P.F.; Martinez-Agirre, M.; Berasategi, J. A Novel Direct Liquid Cooling Strategy for Electric Vehicles Focused on Pouch Type Battery Cells. Appl. Therm. Eng. 2022, 216, 118869. [Google Scholar] [CrossRef]

- Giammichele, L.; D’Alessandro, V.; Falone, M.; Ricci, R. Experimental Study of a Direct Immersion Liquid Cooling of a Li-Ion Battery for Electric Vehicles Applications. Int. J. Heat Technol. 2022, 40, 1–8. [Google Scholar] [CrossRef]

- Guo, Z.; Xu, J.; Xu, Z.; Mubashir, M.; Wang, H.; Mei, X. A Lightweight Multichannel Direct Contact Liquid-Cooling System and Its Optimization for Lithium-Ion Batteries. IEEE Trans. Transp. Electrif. 2022, 8, 2334–2345. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Z.; Su, L.; Bai, M.; Gao, L.; Li, Y.; Liu, X.; Li, Y.; Song, Y. Numerical Simulations for Indirect and Direct Cooling of 54 V LiFePO4 Battery Pack. Energies 2022, 15, 4581. [Google Scholar] [CrossRef]

- Han, J.-W.; Garud, K.S.; Hwang, S.G.; Lee, M.-Y. Experimental Study on Dielectric Fluid Immersion Cooling for Thermal Management of Lithium-Ion Battery. Symmetry 2022, 14, 2126. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Wen, X.; Cai, W.; Jiang, Y.; Wen, C.; Wang, Y.; Hu, L.; Yu, H.; Zhu, H.; et al. Experimental Studies on Two-Phase Immersion Liquid Cooling for Li-Ion Battery Thermal Management. J. Energy Storage 2023, 72, 108748. [Google Scholar] [CrossRef]

- Xu, X.; Tong, G.; Li, R. Numerical Study and Optimizing on Cold Plate Splitter for Lithium Battery Thermal Management System. Appl. Therm. Eng. 2020, 167, 114787. [Google Scholar] [CrossRef]

- Wang, G.; Gao, Q.; Yan, Y.; Wang, Y. Thermal Management Optimization of a Lithium-Ion Battery Module with Graphite Sheet Fins and Liquid Cold Plates. Automot. Innov. 2020, 3, 336–346. [Google Scholar] [CrossRef]

- Rabiei, M.; Gharehghani, A.; Andwari, A.M. Enhancement of Battery Thermal Management System Using a Novel Structure of Hybrid Liquid Cold Plate. Appl. Therm. Eng. 2023, 232, 121051. [Google Scholar] [CrossRef]

- Fan, L.; Li, J.; Chen, Y.; Zhou, D.; Jiang, Z.; Sun, J. Study on the Cooling Performance of a New Secondary Flow Serpentine Liquid Cooling Plate Used for Lithium Battery Thermal Management. Int. J. Heat Mass Transf. 2024, 218, 124711. [Google Scholar] [CrossRef]

- Wei, L.; Zou, Y.; Cao, F.; Ma, Z.; Lu, Z.; Jin, L. An Optimization Study on the Operating Parameters of Liquid Cold Plate for Battery Thermal Management of Electric Vehicles. Energies 2022, 15, 9180. [Google Scholar] [CrossRef]

- Sheng, L.; Zhang, H.; Su, L.; Zhang, Z.; Zhang, H.; Li, K.; Fang, Y.; Ye, W. Effect Analysis on Thermal Profile Management of a Cylindrical Lithium-Ion Battery Utilizing a Cellular Liquid Cooling Jacket. Energy 2021, 220, 119725. [Google Scholar] [CrossRef]

- Zhou, H.; Zhou, F.; Zhang, Q.; Wang, Q.; Song, Z. Thermal Management of Cylindrical Lithium-Ion Battery Based on a Liquid Cooling Method with Half-Helical Duct. Appl. Therm. Eng. 2019, 162, 114257. [Google Scholar] [CrossRef]

- Li, P.; Zhao, J.; Zhou, S.; Duan, J.; Li, X.; Zhang, H.; Yuan, J. Design and Optimization of a Liquid Cooling Thermal Management System with Flow Distributors and Spiral Channel Cooling Plates for Lithium-Ion Batteries. Energies 2023, 16, 2196. [Google Scholar] [CrossRef]

- Sun, Y.; Bai, R.; Ma, J. Development and Analysis of a New Cylindrical Lithium-Ion Battery Thermal Management System. Chin. J. Mech. Eng. (Engl. Ed.) 2022, 35, 100. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Maghrabie, H.M.; Abo-Khalil, A.G.; Adhari, O.H.K.; Sayed, E.T.; Radwan, A.; Elsaid, K.; Wilberforce, T.; Olabi, A.G. Battery Thermal Management Systems Based on Nanofluids for Electric Vehicles. J. Energy Storage 2022, 50, 104385. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, Applications and Toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Awais, M.; Ullah, N.; Ahmad, J.; Sikandar, F.; Ehsan, M.M.; Salehin, S.; Bhuiyan, A.A. Heat Transfer and Pressure Drop Performance of Nanofluid: A State-of- the-Art Review. Int. J. Thermofluids 2021, 9, 100065. [Google Scholar] [CrossRef]

- Apmann, K.; Fulmer, R.; Soto, A.; Vafaei, S. Thermal Conductivity and Viscosity: Review and Optimization of Effects of Nanoparticles. Materials 2021, 14, 1291. [Google Scholar] [CrossRef] [PubMed]

- Li, C.H.; Peterson, G.P. Mixing Effect on the Enhancement of the Effective Thermal Conductivity of Nanoparticle Suspensions (Nanofluids). Int. J. Heat Mass Transf. 2007, 50, 4668–4677. [Google Scholar] [CrossRef]

- Al Shdaifat, M.Y.; Zulkifli, R.; Sopian, K.; Salih, A.A. Effect of CuO/Water Nanofluid as a Coolant for Liquid Cold Plate on Electric Vehicle Battery Cells. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 2270–2283. [Google Scholar] [CrossRef]

- Thorat, P.; Sanap, S.; Gawade, S. A Comparative Study of Thermo-Physical Properties of Different Nanofluids for Effective Heat Transfer Leading to Li-Ion Battery Pack Cooling. Energy Storage 2024, 6, e566. [Google Scholar] [CrossRef]

- Morali, U.; Yetik, O.; Karakoc, T.H. Nanofluid-Based Cooling of Prismatic Lithium-Ion Battery Packs: An Integrated Numerical and Statistical Approach. J. Therm. Anal. Calorim. 2024, 149, 799–811. [Google Scholar] [CrossRef]

- Dhanasekaran, A.; Dhanasekaran, R.; Subramanian, Y.; Gubendiren, R.K.; Ali, M.; Raj, V.; Yassin, H.; Azad, A.K. Silver Nanofluid-Based Thermal Management for Effective Cooling of Batteries in Electric Vehicle Systems. Arab. J. Sci. Eng. 2024, 49, 14711–14728. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Mahmud, S.; Heyst, B.V. A Comprehensive Review on a Passive (Phase Change Materials) and an Active (Thermoelectric Cooler) Battery Thermal Management System and Their Limitations. J. Power Sources 2018, 401, 224–237. [Google Scholar] [CrossRef]

- Cui, X.; Jiang, S. A Novel Temperature Distribution Modeling Method for Thermoelectric Cooler with Application to Battery Thermal Management System. Energy 2024, 306, 132426. [Google Scholar] [CrossRef]

- Cui, X.; Hu, T. Robust Predictive Thermal Management Strategy for Lithium-Ion Battery Based on Thermoelectric Cooler. Appl. Therm. Eng. 2023, 221, 119833. [Google Scholar] [CrossRef]

- Lyu, Y.; Siddique, A.R.M.; Gadsden, S.A.; Mahmud, S. Experimental Investigation of Thermoelectric Cooling for a New Battery Pack Design in a Copper Holder. Results Eng. 2021, 10, 100214. [Google Scholar] [CrossRef]

- Sait, H. Cooling a Plate Lithium-Ion Battery Using a Thermoelectric System and Evaluating the Geometrical Impact on the Performance of Heatsink Connected to the System. J. Energy Storage 2022, 52, 104692. [Google Scholar] [CrossRef]

- Kharabati, S.; Saedodin, S. A Systematic Review of Thermal Management Techniques for Electric Vehicle Batteries. J. Energy Storage 2024, 75, 109586. [Google Scholar] [CrossRef]

- Patel, J.R.; Rathod, M.K. Phase Change Material Selection Using Simulation-Oriented Optimization to Improve the Thermal Performance of Lithium-Ion Battery. J. Energy Storage 2022, 49, 103974. [Google Scholar] [CrossRef]

- Verma, A.; Shashidhara, S.; Rakshit, D. A Comparative Study on Battery Thermal Management Using Phase Change Material (PCM). Therm. Sci. Eng. Prog. 2019, 11, 74–83. [Google Scholar] [CrossRef]

- Huang, R.; Li, Z.; Hong, W.; Wu, Q.; Yu, X. Experimental and Numerical Study of PCM Thermophysical Parameters on Lithium-Ion Battery Thermal Management. Energy Rep. 2020, 6, 8–19. [Google Scholar] [CrossRef]

- Rajan, J.T.; Jayapal, V.S.; Krishna, M.J.; Mohammed Firose, K.A.; Vaisakh, S.; John, A.K.; Suryan, A. Analysis of Battery Thermal Management System for Electric Vehicles Using 1- Tetradecanol Phase Change Material. Sustain. Energy Technol. Assess. 2022, 51, 101943. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.K.; Song, Y.; Lai, W.; Zheng, L. Thermal Management System for Stable EV Battery Operation with Composite Phase Change Materials. Phys. Scr. 2024, 99, 6. [Google Scholar] [CrossRef]

- El Idi, M.M.; Karkri, M.; Abdou Tankari, M. A Passive Thermal Management System of Li-Ion Batteries Using PCM Composites: Experimental and Numerical Investigations. Int. J. Heat Mass Transf. 2021, 169, 120894. [Google Scholar] [CrossRef]

- Jilte, R.; Afzal, A.; Panchal, S. A Novel Battery Thermal Management System Using Nano-Enhanced Phase Change Materials. Energy 2021, 219, 119564. [Google Scholar] [CrossRef]

- Behi, H.; Karimi, D.; Behi, M.; Nargesi, N.; Aminian, M.; Ghanbarpour, A.; Mirmohseni, F.; Van Mierlo, J.; Berecibar, M. An Enhanced Phase Change Material Composite for Electrical Vehicle Thermal Management. Designs 2022, 6, 70. [Google Scholar] [CrossRef]

- Hussain, A.; Shahid, H.; Ali, I.; Ali, H.M. Passive Thermal Management System of Lithium-Ion Batteries Employing Metal Foam/ Pcm Composite for the Development of Electric Vehicles. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 505–522. [Google Scholar] [CrossRef]

- Budiman, A.C.; Azzopardi, B.; Sudirja; Perdana, M.A.P.; Kaleg, S.; Hadiastuti, F.S.; Hasyim, B.A.; Amin; Ristiana, R.; Muharam, A.; et al. Phase Change Material Composite Battery Module for Thermal Protection of Electric Vehicles: An Experimental Observation. Energies 2023, 16, 3896. [Google Scholar] [CrossRef]

- Nithin, V.K. A Comprehensive Review of Opportunities and Challenges in Heat Pipe Application: A Numerical Modeling. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 45. [Google Scholar] [CrossRef]

- Weragoda, D.M.; Tian, G.; Burkitbayev, A.; Lo, K.H.; Zhang, T. A Comprehensive Review on Heat Pipe Based Battery Thermal Management Systems. Appl. Therm. Eng. 2023, 224, 120070. [Google Scholar] [CrossRef]

- Brennan, P.J.; Kroliczek, E.J. Heat Pipe Design Handbook. B & K Engineering, Inc.: Towson, MD, USA, 1979. [Google Scholar]

- Abdelkareem, M.A.; Maghrabie, H.M.; Abo-Khalil, A.G.; Adhari, O.H.K.; Sayed, E.T.; Radwan, A.; Rezk, H.; Jouhara, H.; Olabi, A.G. Thermal Management Systems Based on Heat Pipes for Batteries in EVs/HEVs. J. Energy Storage 2022, 51, 104384. [Google Scholar] [CrossRef]

- Behi, H.; Karimi, D.; Behi, M.; Jaguemont, J.; Ghanbarpour, M.; Behnia, M.; Berecibar, M.; Van Mierlo, J. Thermal Management Analysis Using Heat Pipe in the High Current Discharging of Lithium-Ion Battery in Electric Vehicles. J. Energy Storage 2020, 32, 101893. [Google Scholar] [CrossRef]

- Vachhani, M.; Sagar, K.R.; Patel, V.M.; Mehta, H.B. Novel Integration of Dual Evaporator Loop Heat Pipe for Improved Electric Vehicle Battery Thermal Regulation. Appl. Therm. Eng. 2024, 236, 121832. [Google Scholar] [CrossRef]

- Zheng, M.; Liu, Y.; Ma, Z.; Li, Y.; Li, D.; Lu, Z.; Song, H.; Guo, X.; Shao, W. Numerical Study on Power Battery Thermal Management System Based on Heat Pipe Technology. Energy Rep. 2023, 9, 350–361. [Google Scholar] [CrossRef]

- Nasir, F.M.; Abdullah, M.Z.; Ismail, M.A. Effect of Heat Pipe’s Configuration in Managing the Temperature of EV Battery. CFD Lett. 2023, 15, 22–34. [Google Scholar] [CrossRef]

- Liu, H.; Ahmad, S.; Shi, Y.; Zhao, J. A Parametric Study of a Hybrid Battery Thermal Management System That Couples PCM/Copper Foam Composite with Helical Liquid Channel Cooling. Energy 2021, 231, 120869. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, Z.; Xiong, X.; Zhu, J.; Gao, Q.; Wang, H.; Wu, H. Novel Concept Design of Low Energy Hybrid Battery Thermal Management System Using PCM and Multistage Tesla Valve Liquid Cooling. Appl. Therm. Eng. 2023, 220, 119680. [Google Scholar] [CrossRef]

- Hekmat, S.; Molaeimanesh, G.R. Hybrid Thermal Management of a Li-Ion Battery Module with Phase Change Material and Cooling Water Pipes: An Experimental Investigation. Appl. Therm. Eng. 2020, 166, 114759. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, Z.; Zhang, B.; Yang, H.; Bao, R.; Xiong, S.; Du, X.; Min, R. Performance Investigation of Battery Thermal Management System Based on L-Shaped Heat Pipe Coupled Cold Plate and Optimization of Controllable Liquid Cooling. Eng. Appl. Comput. Fluid Mech. 2024, 18, 2370941. [Google Scholar] [CrossRef]

- Jang, D.S.; Yun, S.; Hong, S.H.; Cho, W.; Kim, Y. Performance Characteristics of a Novel Heat Pipe-Assisted Liquid Cooling System for the Thermal Management of Lithium-Ion Batteries. Energy Convers. Manag. 2022, 251, 115001. [Google Scholar] [CrossRef]

- Cheng, J.; Shuai, S.; Zhao, R.; Tang, Z. Numerical Analysis of Heat-Pipe-Based Battery Thermal Management System for Prismatic Lithium-Ion Batteries. J. Therm. Sci. Eng. Appl. 2022, 14, 081008. [Google Scholar] [CrossRef]

- Singh, L.K.; Kumar, R.; Gupta, A.K.; Sharma, A.K.; Panchal, S. Computational Study on Hybrid Air-PCM Cooling inside Lithium-Ion Battery Packs with Varying Number of Cells. J. Energy Storage 2023, 67, 107649. [Google Scholar] [CrossRef]

- Chen, X.; Yang, W.; Shen, J.; Xu, X.; Zhou, F. Thermal Performance of Hybrid Battery Thermal Management System with Air Cooling and Phase Change Material Embedding Biomimetic Variable Section Fins. Appl. Therm. Eng. 2023, 231, 120985. [Google Scholar] [CrossRef]

- Carbajal, G. Study of Different Flow Configurations and Heat Pipe Combination Effects in Air Cooling Systems. In Proceedings of the ASME 2022 International Mechanical Engineering Congress and Exposition, Columbus, OH, USA, 30 October–3 November 2022. V008T11A041. [Google Scholar]

- Saechan, P.; Dhuchakallaya, I.; Al Zahrah Mohd Saat, F. Thermal Performance Improvement of Forced-Air Cooling System Combined with Liquid Spray for Densely Packed Batteries of Electric Vehicle. Eng. Sci. 2023, 24, 886. [Google Scholar] [CrossRef]

- Al Tahhan, A.B.; AlKhedher, M.; Ramadan, M.; ElCheikh, A.; Choi, D.S.; Ghazal, M. Experimental and Numerical Analysis of a Liquid-Air Hybrid System for Advanced Battery Thermal Management. Appl. Therm. Eng. 2024, 253, 123754. [Google Scholar] [CrossRef]

- Andersson, M.; Streb, M.; Ko, J.Y.; Löfqvist Klass, V.; Klett, M.; Ekström, H.; Johansson, M.; Lindbergh, G. Parametrization of Physics-Based Battery Models from Input–Output Data: A Review of Methodology and Current Research. J. Power Sources 2022, 521, 230859. [Google Scholar] [CrossRef]

- Zou, L. Meta-Learning Basics and Background. In Meta-Learning; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–22. [Google Scholar]

- Wang, Y.; Seo, B.; Wang, B.; Zamel, N.; Jiao, K.; Adroher, X.C. Fundamentals, Materials, and Machine Learning of Polymer Electrolyte Membrane Fuel Cell Technology. Energy AI 2020, 1, 100014. [Google Scholar] [CrossRef]

- Smiti, A. When Machine Learning Meets Medical World: Current Status and Future Challenges. Comput. Sci. Rev. 2020, 37, 100280. [Google Scholar] [CrossRef]

- Hasan, M.M.; Ali Pourmousavi, S.; Jahanbani Ardakani, A.; Saha, T.K. A Data-Driven Approach to Estimate Battery Cell Temperature Using a Nonlinear Autoregressive Exogenous Neural Network Model. J. Energy Storage 2020, 32, 101879. [Google Scholar] [CrossRef]

- Quazi, M.M.; Jaliliantabar, F.; Kumarasamy, S.; Ezazi, M. Future of Battery Thermal Management Systems (BTMS): Role of Advanced Technologies, Artificial Intelligence and Sustainability. Next Sustain. 2025, 6, 100114. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Li, C. An Up-to-Date Review on the Design Improvement and Optimization of the Liquid-Cooling Battery Thermal Management System for Electric Vehicles. Appl. Therm. Eng. 2023, 219, 119626. [Google Scholar] [CrossRef]

- Ghalkhani, M.; Habibi, S. Review of the Li-Ion Battery, Thermal Management, and AI-Based Battery Management System for EV Application. Energies 2023, 16, 185. [Google Scholar] [CrossRef]

- Ghafoor, U.; Yaqub, M.W.; Qureshi, M.U.; Aslam Khan, M.N. Thermal Optimization of Li-Ion Battery Pack Using Genetic Algorithm Integrated with Machine Learning. Therm. Sci. Eng. Prog. 2023, 44, 102069. [Google Scholar] [CrossRef]

- Qian, X.; Xuan, D.; Zhao, X.; Shi, Z. Heat Dissipation Optimization of Lithium-Ion Battery Pack Based on Neural Networks. Appl. Therm. Eng. 2019, 162, 114289. [Google Scholar] [CrossRef]

- Xu, Y.; Zhao, J.; Chen, J.; Zhang, H.; Feng, Z.; Yuan, J. Performance Analyses on the Air Cooling Battery Thermal Management Based on Artificial Neural Networks. Appl. Therm. Eng. 2024, 252, 123567. [Google Scholar] [CrossRef]

- Shi, Y.; Ahmad, S.; Liu, H.; Lau, K.T.; Zhao, J. Optimization of Air-Cooling Technology for LiFePO4 Battery Pack Based on Deep Learning. J. Power Sources 2021, 497, 229894. [Google Scholar] [CrossRef]

- Jin, L.; Xi, H. Multi-Objective Parameter Optimization of the Z-Type Air-Cooling System Based on Artificial Neural Network. J. Energy Storage 2024, 86, 111284. [Google Scholar] [CrossRef]

- Liu, Z.; Kabirzadeh, P.; Wu, H.; Fu, W.; Qiu, H.; Miljkovic, N.; Li, Y.; Wang, P. Machine Learning Enhanced Control Co-Design Optimization of an Immersion Cooled Battery Thermal Management System. J. Appl. Phys. 2024, 136, 025001. [Google Scholar] [CrossRef]

- Tang, X.; Guo, Q.; Li, M.; Wei, C.; Pan, Z.; Wang, Y. Performance Analysis on Liquid-Cooled Battery Thermal Management for Electric Vehicles Based on Machine Learning. J. Power Sources 2021, 494, 229727. [Google Scholar] [CrossRef]

- Zhou, X.; Guo, W.; Shi, X.; She, C.; Zheng, Z.; Zhou, J.; Zhu, Y. Machine Learning Assisted Multi-Objective Design Optimization for Battery Thermal Management System. Appl. Therm. Eng. 2024, 253, 123826. [Google Scholar] [CrossRef]

- Kanti, P.K.; Yang, E.S.J.; Wanatasanappan, V.V.; Sharma, P.; Said, N.M. Impact of Hybrid and Mono Nanofluids on the Cooling Performance of Lithium-Ion Batteries: Experimental and Machine Learning Insights. J. Energy Storage 2024, 101, 113613. [Google Scholar] [CrossRef]

- Afzal, A.; Alahmadi, A.A.; Abdul Razak, R.K.; Alwetaishi, M.; Alzaed, A.N.; Shaik, S. Machine Learning Prediction and Study of Hotspots and Hotspots Location for Sustainable Battery Energy System. Int. J. Energy Res. 2022, 46, 21045–21065. [Google Scholar] [CrossRef]

- Jaliliantabar, F.; Mamat, R.; Kumarasamy, S. Prediction of Lithium-Ion Battery Temperature in Different Operating Conditions Equipped with Passive Battery Thermal Management System by Artificial Neural Networks. Mater. Today Proc. 2021, 48, 1796–1804. [Google Scholar] [CrossRef]

- Najafi Khaboshan, H.; Jaliliantabar, F.; Abdullah, A.A.; Panchal, S.; Azarinia, A. Parametric Investigation of Battery Thermal Management System with Phase Change Material, Metal Foam, and Fins; Utilizing CFD and ANN Models. Appl. Therm. Eng. 2024, 247, 123080. [Google Scholar] [CrossRef]

- Arif, A.; Reddy, V.S.N.; Srividya, K.; Mallampalli, U.T. Utilizing Multilayer Perceptron for Machine Learning Diagnosis in Phase Change Material-Based Thermal Management Systems. Heat Transf. 2024, 53, 4922–4947. [Google Scholar] [CrossRef]

- Anooj, G.V.S.; Marri, G.K.; Balaji, C. A Machine Learning Methodology for the Diagnosis of Phase Change Material-Based Thermal Management Systems. Appl. Therm. Eng. 2023, 222, 119864. [Google Scholar] [CrossRef]

- Sui, Z.; Lin, H.; Sun, Q.; Dong, K.; Wu, W. Multi-Objective Optimization of Efficient Liquid Cooling-Based Battery Thermal Management System Using Hybrid Manifold Channels. Appl. Energy 2024, 371, 123766. [Google Scholar] [CrossRef]

- Ye, L.; Li, C.; Wang, C.; Zheng, J.; Zhong, K.; Wu, T. A Multi-Objective Optimization Approach for Battery Thermal Management System Based on the Combination of BP Neural Network Prediction and NSGA-II Algorithm. J. Energy Storage 2024, 99, 113212. [Google Scholar] [CrossRef]

- Guo, C.Y.; Muhieldeen, M.W.; Teng, K.H.; Ang, C.K.; Lim, W.H. A Novel Thermal Management System for Lithium-Ion Battery Modules Combining Indirect Liquid-Cooling with Forced Air-Cooling: Deep Learning Approach. J. Energy Storage 2024, 94, 112434. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Z.; Ayed, H.; Alhoee, J. Incorporating Nickel Foam with Nano-Encapsulated Phase Change Material and Water Emulsion for Battery Thermal Management: Coupling CFD and Machine Learning. Case Stud. Therm. Eng. 2024, 60, 104672. [Google Scholar] [CrossRef]

- Monika, K.; Punnoose, E.M.; Datta, S.P. Multi-Objective Optimization of Cooling Plate with Hexagonal Channel Design for Thermal Management of Li-Ion Battery Module. Appl. Energy 2024, 368, 123423. [Google Scholar] [CrossRef]

- Zheng, A.; Gao, H.; Jia, X.; Cai, Y.; Yang, X.; Zhu, Q.; Jiang, H. Deep Learning-Assisted Design for Battery Liquid Cooling Plate with Bionic Leaf Structure Considering Non-Uniform Heat Generation. Appl. Energy 2024, 373, 123898. [Google Scholar] [CrossRef]

- Yuan, L.; Li, W.; Deng, W.; Sun, W.; Huang, M.; Liu, Z. Cell Temperature Prediction in the Refrigerant Direct Cooling Thermal Management System Using Artificial Neural Network. Appl. Therm. Eng. 2024, 254, 123852. [Google Scholar] [CrossRef]

- Li, W.; Wang, Y.; Yang, W.; Zhang, K. Design and Optimization of an Integrated Liquid Cooling Thermal Management System with a Diamond-Type Channel. Therm. Sci. Eng. Prog. 2024, 47, 102325. [Google Scholar] [CrossRef]

- Al-Haddad, L.A.; Ibraheem, L.; EL-Seesy, A.I.; Jaber, A.A.; Al-Haddad, S.A.; Khosrozadeh, R. Thermal Heat Flux Distribution Prediction in an Electrical Vehicle Battery Cell Using Finite Element Analysis and Neural Network. Green Energy Intell. Transp. 2024, 3, 100155. [Google Scholar] [CrossRef]

- Bacak, A. Investigation of Maximum Temperatures in Lithium-Ion Batteries by CFD and Machine Learning. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2024, 239, 2461–2471. [Google Scholar] [CrossRef]

- Sukkam, N.; Katongtung, T.; Suttakul, P.; Mona, Y.; Achariyaviriya, W.; Tippayawong, K.Y.; Tippayawong, N. Machine Learning Prediction of a Battery’s Thermal-Related Health Factor in a Battery Electric Vehicle Using Real-World Driving Data. Information 2024, 15, 553. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, Y.; Liu, Y.; Xu, R.; Zhu, J.; Wang, J. Structural Optimization of Serpentine Channel Water-Cooled Plate for Lithium-Ion Battery Modules Based on Multi-Objective Bayesian Optimization Algorithm. J. Energy Storage 2024, 91, 112136. [Google Scholar] [CrossRef]

- Li, W.; Wang, N.; Garg, A.; Gao, L. Multi-Objective Optimization of an Air Cooling Battery Thermal Management System Considering Battery Degradation and Parasitic Power Loss. J. Energy Storage 2023, 58, 106382. [Google Scholar] [CrossRef]

- Zhang, F.; He, Y.; Wang, C.; Liang, B.; Zhu, Y.; Gou, H.; Xiao, K.; Lu, F. A New Type of Liquid-Cooled Channel Thermal Characteristics Analysis and Optimization Based on the Optimal Characteristics of 24 Types of Channels. Int. J. Heat Mass Transf. 2023, 202, 123734. [Google Scholar] [CrossRef]

- Fan, Z.; Fu, Y.; Liang, H.; Gao, R.; Liu, S. A Module-Level Charging Optimization Method of Lithium-Ion Battery Considering Temperature Gradient Effect of Liquid Cooling and Charging Time. Energy 2023, 265, 126331. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, Z.; Xiong, X.; Panchal, S.; Fraser, R.; Fowler, M. Multi-Objective Optimization Design and Experimental Investigation for a Prismatic Lithium-Ion Battery Integrated with a Multi-Stage Tesla Valve-Based Cold Plate. Processes 2023, 11, 1618. [Google Scholar] [CrossRef]

- Fan, Y.; Lyu, P.; Zhan, D.; Ouyang, K.; Tan, X.; Li, J. Surrogate Model-Based Multiobjective Design Optimization for Air-Cooled Battery Thermal Management Systems. Eng. Appl. Comput. Fluid Mech. 2022, 16, 1031–1047. [Google Scholar] [CrossRef]

- Çolak, A.B. Comparative Investigation of the Usability of Different Machine Learning Algorithms in the Analysis of Battery Thermal Performances of Electric Vehicles. Int. J. Energy Res. 2022, 46, 21104–21126. [Google Scholar] [CrossRef]

- Yalçın, S.; Panchal, S.; Herdem, M.S. A CNN-ABC Model for Estimation and Optimization of Heat Generation Rate and Voltage Distributions of Lithium-Ion Batteries for Electric Vehicles. Int. J. Heat Mass Transf. 2022, 199, 123486. [Google Scholar] [CrossRef]

- Liao, X.; Ma, C.; Peng, X.; Li, Y.; Duan, L.; Garg, A.; Gao, L. A Framework of Optimal Design of Thermal Management System for Lithium-Ion Battery Pack Using Multi-Objectives Optimization. J. Electrochem. Energy Convers. Storage 2021, 18, 021005. [Google Scholar] [CrossRef]

- Chen, S.; Bao, N.; Garg, A.; Peng, X.; Gao, L. A Fast Charging–Cooling Coupled Scheduling Method for a Liquid Cooling-Based Thermal Management System for Lithium-Ion Batteries. Engineering 2021, 7, 1165–1176. [Google Scholar] [CrossRef]

- Deng, T.; Ran, Y.; Yin, Y.; Liu, P. Multi-Objective Optimization Design of Thermal Management System for Lithium-Ion Battery Pack Based on Non-Dominated Sorting Genetic Algorithm II. Appl. Therm. Eng. 2020, 164, 114394. [Google Scholar] [CrossRef]

- Garg, A.; Ruhatiya, C.; Cui, X.; Peng, X.; Bhalerao, Y.; Gao, L. A Novel Approach for Enhancing Thermal Performance of Battery Modules Based on Finite Element Modeling and Predictive Modeling Mechanism. J. Electrochem. Energy Convers. Storage 2020, 17, 021103. [Google Scholar] [CrossRef]

- Lei, N.; Zhang, H.; Li, R.; Yu, J.; Wang, H.; Wang, Z. Physics-Informed Data-Driven Modeling Approach for Commuting-Oriented Hybrid Powertrain Optimization. Energy Convers. Manag. 2024, 299, 117814. [Google Scholar] [CrossRef]

- Amba, G.; Rao, P.; Karthik, S.; Student, V.G.; Saurav, G.V.S.; Student, G.; Swetha, A. Numerical and Machine Learning Approaches for Effective Thermal Management with Phase Change Materials. Appl. Therm. Eng. 2022, 222. [Google Scholar] [CrossRef]

- Goud, V.M.; Satyanarayana, G.; Ramesh, J.; Pathanjali, G.A.; Ruben Sudhakar, D. An Experimental Investigation and Hybrid Neural Network Modelling of Thermal Management of Lithium-Ion Batteries Using a Non-Paraffinic Organic Phase Change Material, Myristyl Alcohol. J. Energy Storage 2023, 72, 108395. [Google Scholar] [CrossRef]

- Boonma, K.; Mesgarpour, M.; NajmAbad, J.M.; Alizadeh, R.; Mahian, O.; Dalkılıç, A.S.; Ahn, H.S.; Wongwises, S. Prediction of Battery Thermal Behaviour in the Presence of a Constructal Theory-Based Heat Pipe (CBHP): A Multiphysics Model and Pattern-Based Machine Learning Approach. J. Energy Storage 2022, 48, 103963. [Google Scholar] [CrossRef]

- Muthya Goud, V.; Raval, F.; Ruben Sudhakar, D. A Sustainable Biochar-Based Shape Stable Composite Phase Change Material for Thermal Management of a Lithium-Ion Battery System and Hybrid Neural Network Modeling for Heat Flow Prediction. J. Energy Storage 2022, 56, 106163. [Google Scholar]

- Kolodziejczyk, F.; Mortazavi, B.; Rabczuk, T.; Zhuang, X. Machine Learning Assisted Multiscale Modeling of Composite Phase Change Materials for Li-Ion Batteries’ Thermal Management. Int. J. Heat Mass Transf. 2021, 172, 121199. [Google Scholar] [CrossRef]

- Zhang, N.; Zhang, Z.; Li, J.; Cao, X. Performance Analysis and Prediction of Hybrid Battery Thermal Management System Integrating PCM with Air Cooling Based on Machine Learning Algorithm. Appl. Therm. Eng. 2024, 257, 124474. [Google Scholar] [CrossRef]

- Fini, A.T.; Fattahi, A.; Musavi, S. Machine Learning Prediction and Multiobjective Optimization for Cooling Enhancement of a Plate Battery Using the Chaotic Water-Microencapsulated PCM Fluid Flows. J. Taiwan Inst. Chem. Eng. 2023, 148, 104680. [Google Scholar] [CrossRef]

- Wang, D.; Ali, M.A.; Alizadeh, A.; Chaturvedi, R.; Ali, M.R.; Sohail, M. A Numerical Investigation of a Two-Phase Nanofluid Flow with Phase Change Materials in the Thermal Management of Lithium Batteries and Use of Machine Learning in the Optimization of the Horizontal and Vertical Distances between Batteries. Case Stud. Therm. Eng. 2023, 41, 102582. [Google Scholar] [CrossRef]

- Xie, S.; Xu, C.; Li, W.; Kang, Y.; Feng, X.; Wu, W. Machine Learning Accelerated the Performance Analysis on PCM-Liquid Coupled Battery Thermal Management System. J. Energy Storage 2024, 100, 113479. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, G.; Qiao, D.; Wang, X.; Jiang, B.; Dai, H.; Zhu, J.; Wei, X. A Neural Network-Based Regression Study for a Hybrid Battery Thermal Management System under Fast Charging. SAE Int. J. Electrified Veh. 2022, 11, 189–202. [Google Scholar] [CrossRef]

- Liu, J.; Tavakoli, F.; Sajadi, S.M.; Mahmoud, M.Z.; Heidarshenas, B.; Aybar, H. Numerical Evaluation and Artificial Neural Network Modeling of the Effect of Oval PCM Compartment Dimensions around a Triple Lithium-Ion Battery Pack despite Forced Airflow. Eng. Anal. Bound. Elem. 2022, 142, 71–92. [Google Scholar] [CrossRef]

- Alqaed, S.; Mustafa, J.; Mohammad Sajadi, S.; Ali Hamdan Alajmi, S.; Saleh Alsnan, M.; Aybar, H. Enhancing Thermal Performance of Cylindrical Li-Ion Battery Packs: A 3D Simulation with Strategic Phase Change Material Integration and Airflow Control. Arab. J. Chem. 2024, 17, 105835. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, F.; Liu, Y.; Xu, S.; Chen, X. Thermal Performance of Honeycomb-like Battery Thermal Management System with Bionic Liquid Mini-Channel and Phase Change Materials for Cylindrical Lithium-Ion Battery. Appl. Therm. Eng. 2021, 188, 116649. [Google Scholar] [CrossRef]

| Parameters | Air Cooling (Forced/Natural) | Direct Liquid Cooling | Indirect Liquid Cooling | PCM (Pure/Composite/Metal Foam) | Heat Pipe (Single/Dual Evaporator) | Thermoelectric (TEC + Liquid/Air) |

|---|---|---|---|---|---|---|

| Cooling Efficiency | Low | Moderate | High | Low | High | Low |

| Temperature Uniformity | Poor | Moderate | High | High | High | Good |

| Energy Consumption | High | Low | Low | None | Low | High |

| Weight | Light | High | High | High | High | Light |

| Cost | Cheap | Medium | Medium | High | High | High |

| Complexity | Simple | Complex | Complex | Complex | Complex | Moderate |

| Leakage Risk | None | High risk | High risk | Low | Low | None |

| Maintenance | Low | High | Medium | High | Low | Low |

| Thermal Conductivity | Low | High | High | Low | High | Moderate |

| Compactness | High | Low | Low | Low | Low | Moderate |

| Key Limitations | Low heat capacity | Leakage, corrosion | Leakage, corrosion | Low conductivity, bulkiness | High cost, design constraints | Low COP, high power |

| Cooling Method | Advantages | Disadvantages | |

| Active | Air-based |

|

|

| Liquid-based |

|

| |

| Based on thermoelectric method |

|

| |

| Passive | Free convection |

|

|

| PCM-based |

|

| |

| HP-based |

|

| |

| Hybrid |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alawi, A.; Saeed, A.; Sharqawy, M.H.; Al Janaideh, M. A Comprehensive Review of Thermal Management Challenges and Safety Considerations in Lithium-Ion Batteries for Electric Vehicles. Batteries 2025, 11, 275. https://doi.org/10.3390/batteries11070275

Alawi A, Saeed A, Sharqawy MH, Al Janaideh M. A Comprehensive Review of Thermal Management Challenges and Safety Considerations in Lithium-Ion Batteries for Electric Vehicles. Batteries. 2025; 11(7):275. https://doi.org/10.3390/batteries11070275

Chicago/Turabian StyleAlawi, Ali, Ahmed Saeed, Mostafa H. Sharqawy, and Mohammad Al Janaideh. 2025. "A Comprehensive Review of Thermal Management Challenges and Safety Considerations in Lithium-Ion Batteries for Electric Vehicles" Batteries 11, no. 7: 275. https://doi.org/10.3390/batteries11070275

APA StyleAlawi, A., Saeed, A., Sharqawy, M. H., & Al Janaideh, M. (2025). A Comprehensive Review of Thermal Management Challenges and Safety Considerations in Lithium-Ion Batteries for Electric Vehicles. Batteries, 11(7), 275. https://doi.org/10.3390/batteries11070275