Environmental Assessment of Lithium-Ion Battery Lifecycle and of Their Use in Commercial Vehicles

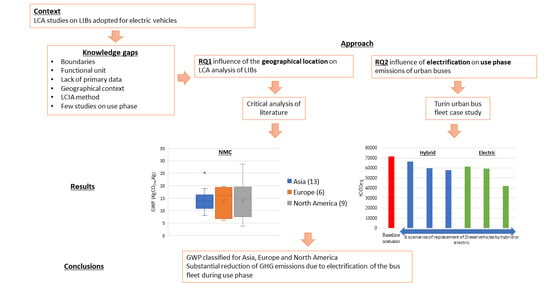

Abstract

1. Introduction

2. Methodology

2.1. Literature Review of LCA Studies on LIB Lifecycle

- (i)

- Survey of Scopus and Science Direct databases to pre-screen the review studies and research papers published in English from 2011 to 2023. The keywords “Lithium-ion” (or Li-ion), “battery” (or batteries), “LCA”, “environmental assessment”, and “recycling” have been used in various combinations. Only the references related to cells involving NMC and LFP cathodes and graphite anodes have been selected, as they are the most common in LIBs used in electric vehicles [16].

- (ii)

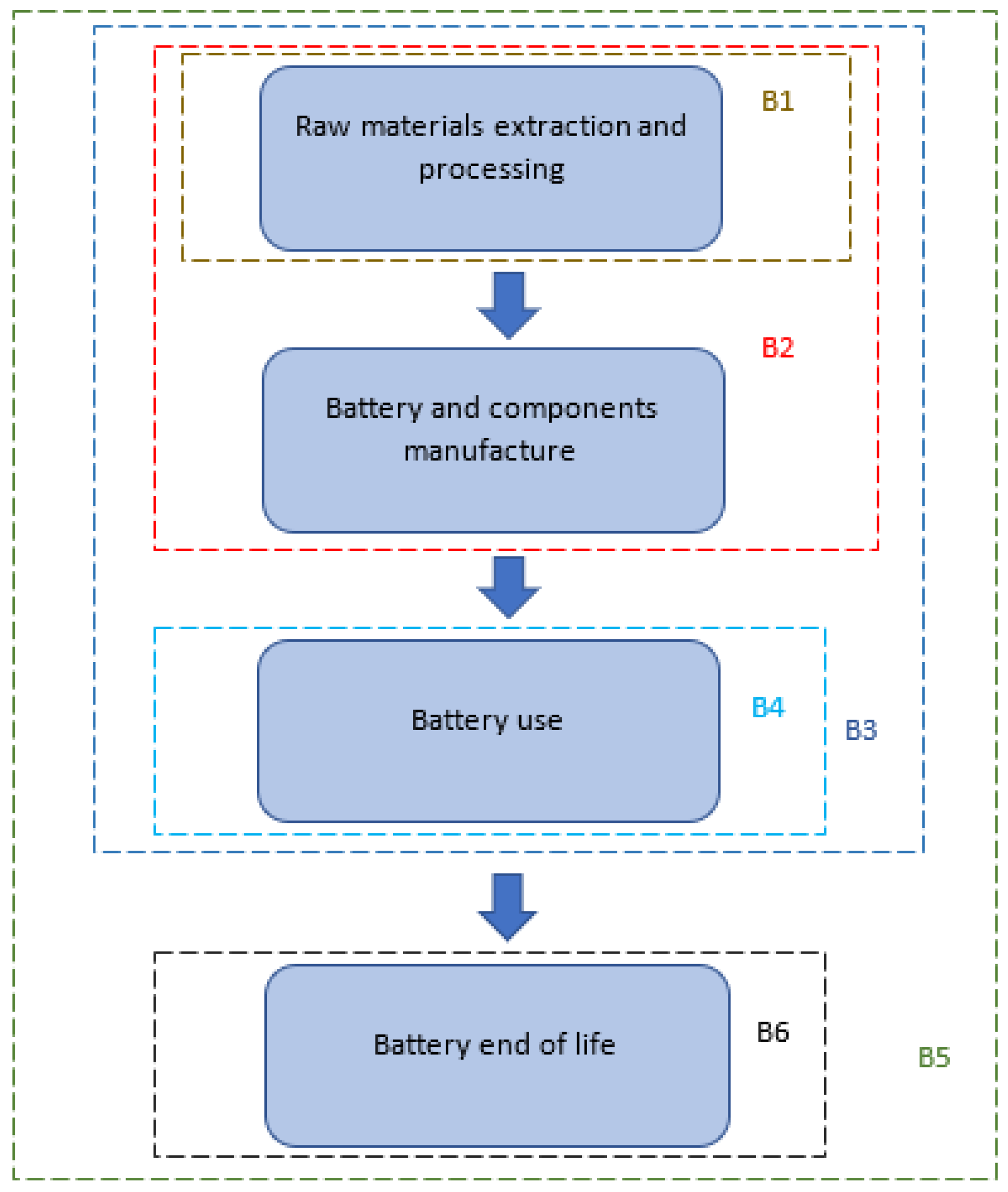

- Selection of the pre-screened references based on the consistency of title and abstract with the scope of this study, and inventory according to the following categories: article type (review or research); specific focus (the reference considers only the LIB or the whole passenger/commercial vehicle); approach (complete LCA or assessment of GHG emissions); phase of lifecycle (depending on boundary conditions); geographical context (Asia, Europe, or the USA); functional unit. Specifically, to assign the phase of the LIB lifecycle associated to the boundary conditions defined in the selected references, the whole lifecycle was considered (Figure 1): raw material extraction and processing, cradle to gate, cradle to gate including use, use, cradle to grave, cradle to grave excluding use, and end of life. This analysis considered hybrid passenger and commercial vehicles, plug-in hybrid, and fully electric-type LIBs; only for the use phase were plug-in hybrid vehicles excluded. Fuel cell electric vehicles were not considered in this work.

- (iii)

- Extraction of global warming potential (GWP) values associated to each lifecycle phase from the inventoried references. To achieve consistency, the GWP values have been normalized to refer to the same unit, i.e., 1 kg of battery. NMC-graphite and LFP-graphite cell compositions have been based on [35], considering graphite and Li, Co, Ni, Mn, Cu, and Al for NMC and Li, Fe, Cu, and Al for LFP. The specifications reported for NMC [28] and LFP [16] were as follows: total capacity 23.5 kWh, weight 165 kg (119.77 kg of cells) for NMC and 203.1 kg (147.59 kg of cells) for LFP.

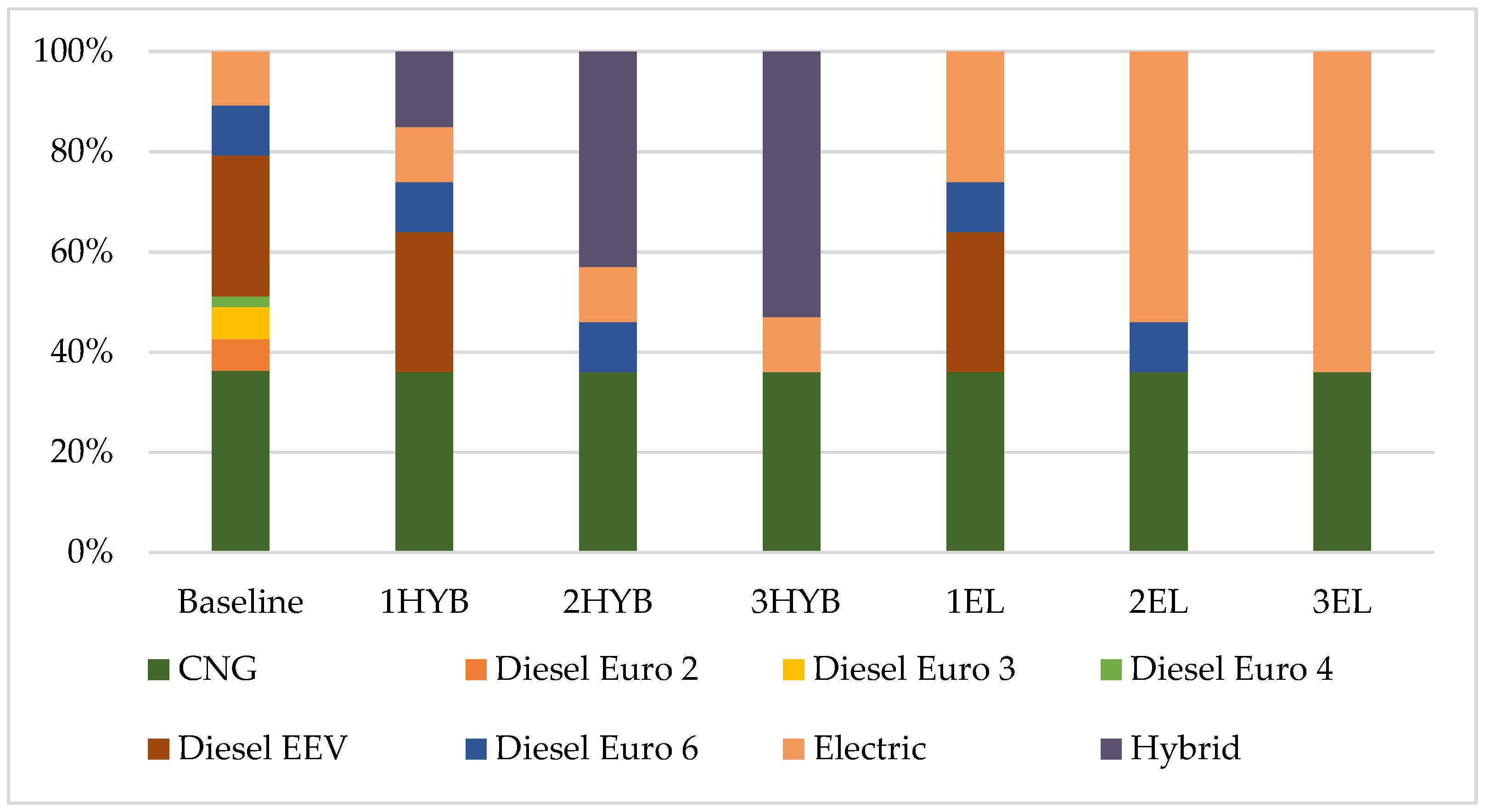

2.2. Assessment of the Emissions of Turin Urban Bus Fleet

- (iv) GHG emissions (GWPuse, for all types of vehicles), expressed as tonnes of CO2eq, considering the GWP100 of each pollutant contributing to the GHG effect according to Equation (1):

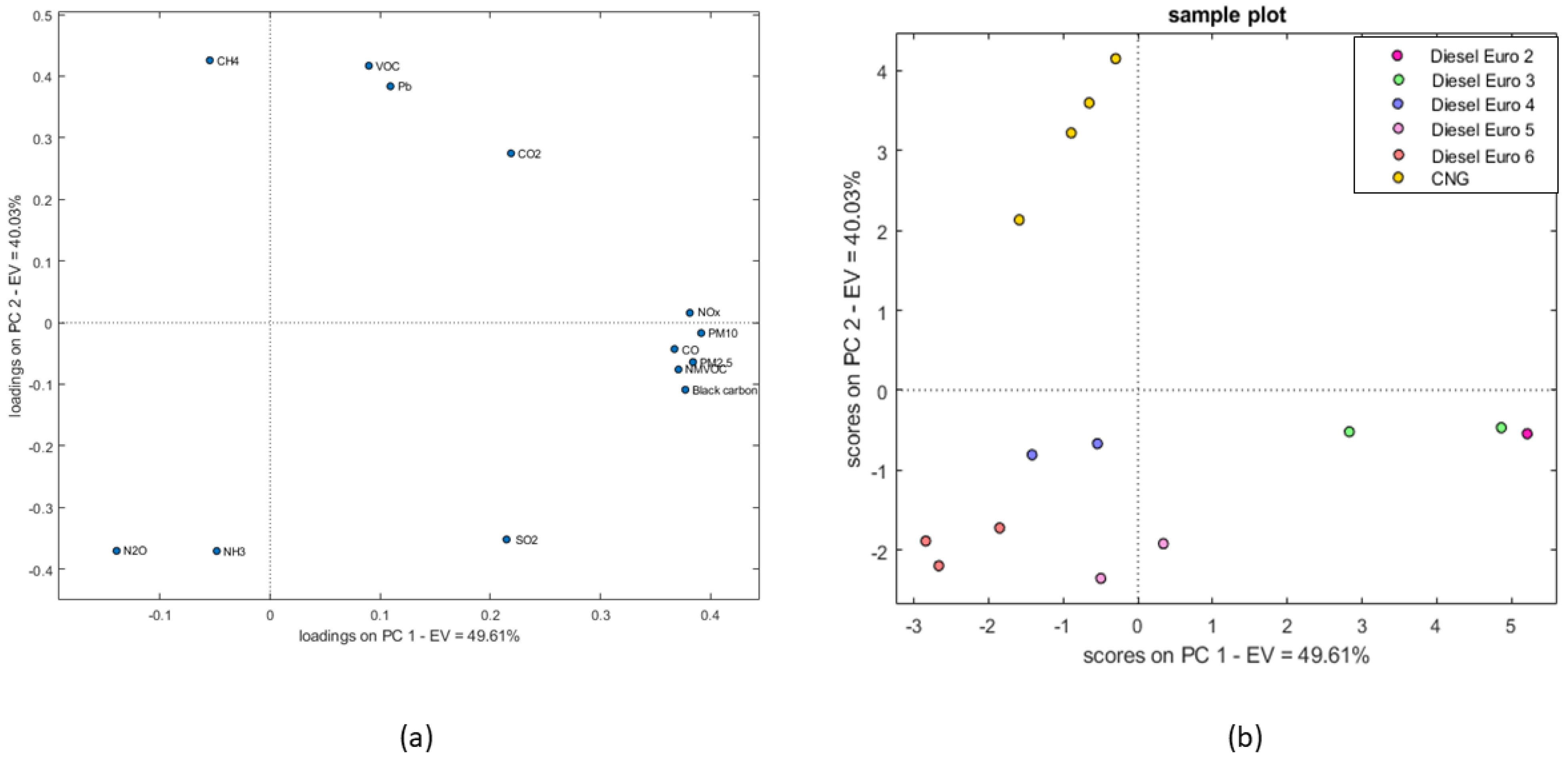

- (v) Emissions from 13 single pollutants (for diesel and CNG buses), considering CO2, CO, NOx, PM (including black carbon and organic carbon), VOC, CH4, SO2 and NH3, N2O, Pb, and non-methane volatile organic compounds (NMVOCs). The calculation was based on Equation (2), where the emission factor (EF) is multiplied to the number of km/y covered by each bus (50,000 km) and the number of buses in the fleet.

3. Results and Discussion

3.1. Overview of Literature Review

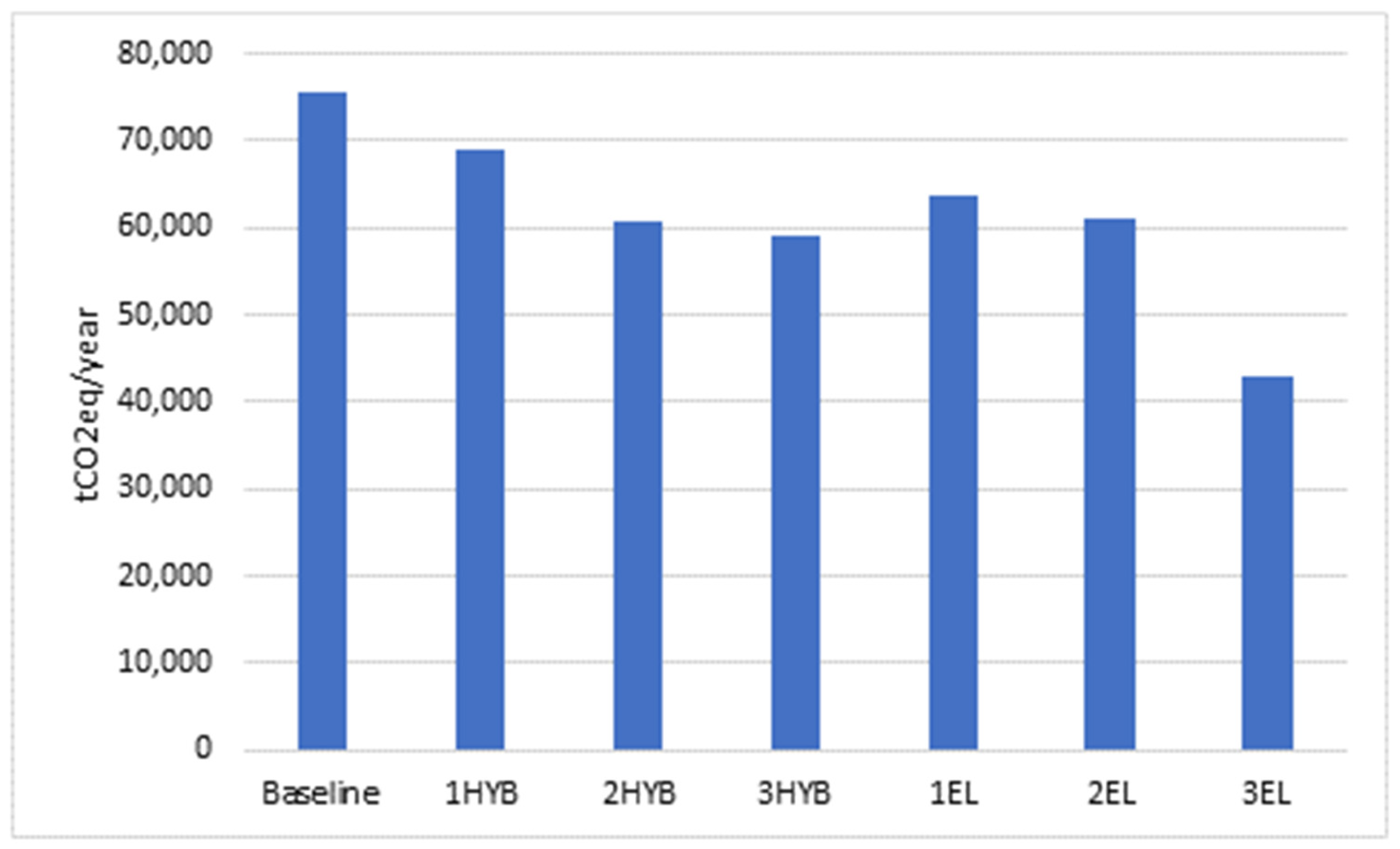

3.2. Emission Assessment of the Turin Urban Bus Fleet—Use Phase

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions—The European Green Deal. 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 30 March 2022).

- IEA. Tracking Transport 2020—Analysis—IEA. Available online: https://www.iea.org/reports/tracking-transport-2020 (accessed on 17 January 2022).

- IEA. Global EV Outlook 2021. Accelerating Ambitions Despite the Pandemic. 2021. Available online: www.iea.org/t&c/ (accessed on 17 January 2022).

- European Commission. Committee of the Regions and the European Investment Bank on the Implementation of the Strategic Action Plan on Batteries: Building a Strategic Battery Value Chain in Europe. 2019. Available online: https://eur-lex.europa.eu/legal-content/en/TXT/?uri=CELEX%3A52019DC0176 (accessed on 17 January 2022).

- Arshad, F.; Lin, J.; Manurkar, N.; Fan, E.; Ahmad, A.; Tariq, M.N.; Wu, F.; Chen, R.; Li, L. Life Cycle Assessment of Lithium-ion Batteries: A Critical Review. Resour. Conserv. Recycl. 2022, 180, 106164. [Google Scholar] [CrossRef]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Bouter, A.; Guichet, X. The greenhouse gas emissions of automotive lithium-ion batteries: A statistical review of life cycle assessment studies. J. Clean. Prod. 2022, 344, 130994. [Google Scholar] [CrossRef]

- Aichberger, C.; Jungmeier, G. Environmental Life Cycle Impacts of Automotive Batteries Based on a Literature Review. Energies 2020, 13, 6345. [Google Scholar] [CrossRef]

- Zhong, C.; Weng, S.; Wang, Z.; Zhan, C.; Wang, X. Kinetic limits and enhancement of graphite anode for fast-charging lithium-ion batteries. Nano Energy 2023, 117, 108894. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Ren, D.; Wang, L.; He, X. Graphite as anode materials: Fundamental mechanism, recent progress and advances. Energy Storage Mater. 2021, 36, 147–170. [Google Scholar] [CrossRef]

- Zhao, E.; Walker, D.; Surawski, N.C.; Bennett, N.S. Assessing the life cycle cumulative energy demand and greenhouse gas emissions of lithium-ion batteries. J. Energy Storage 2021, 43, 103193. [Google Scholar] [CrossRef]

- Yang, Y.; Okonkwo, E.G.; Huang, G.; Xu, S.; Sun, W.; He, Y. On the sustainability of lithium ion battery industry—A review and perspective. Energy Storage Mater. 2021, 36, 186–212. [Google Scholar] [CrossRef]

- Lai, X.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Guo, Y.; Bhagat, R.; Zheng, Y. Critical review of life cycle assessment of lithium-ion batteries for electric vehicles: A lifespan perspective. eTransportation 2022, 12, 100169. [Google Scholar] [CrossRef]

- Ellingsen, L.A.W.; Hung, C.R.; Strømman, A.H. Identifying key assumptions and differences in life cycle assessment studies of lithium-ion traction batteries with focus on greenhouse gas emissions. Transp. Res. D Transp. Environ. 2017, 55, 82–90. [Google Scholar] [CrossRef]

- Crenna, E.; Gauch, M.; Widmer, R.; Wäger; Hischier, R. Towards more flexibility and transparency in life cycle inventories for Lithium-ion batteries. Resour. Conserv. Recycl. 2021, 170, 105619. [Google Scholar] [CrossRef]

- Quan, J.; Zhao, S.; Song, D.; Wang, T.; He, W.; Li, G. Comparative life cycle assessment of LFP and NCM batteries including the secondary use and different recycling technologies. Sci. Total Environ. 2022, 819, 153105. [Google Scholar] [CrossRef] [PubMed]

- Kallitsis, E.; Korre, A.; Kelsall, G.H. Life cycle assessment of recycling options for automotive Li-ion battery packs. J. Clean. Prod. 2022, 371, 133636. [Google Scholar] [CrossRef]

- Sun, X.; Luo, X.; Zhang, Z.; Meng, F.; Yang, J. Life cycle assessment of lithium nickel cobalt manganese oxide (NCM) batteries for electric passenger vehicles. J. Clean. Prod. 2020, 273, 123006. [Google Scholar] [CrossRef]

- Wang, F.; Deng, Y.; Yuan, C. Life cycle assessment of lithium oxygen battery for electric vehicles. J. Clean. Prod. 2020, 264, 121339. [Google Scholar] [CrossRef]

- Deng, Y.; Li, J.; Li, T.; Gao, X.; Yuan, C. Life cycle assessment of lithium sulfur battery for electric vehicles. J. Power Sources 2017, 343, 284–295. [Google Scholar] [CrossRef]

- Mohr, M.; Peters, J.F.; Baumann, M.; Weil, M. Toward a cell-chemistry specific life cycle assessment of lithium-ion battery recycling processes. J. Ind. Ecol. 2020, 24, 1310–1322. [Google Scholar] [CrossRef]

- Guo, W.; Feng, T.; Li, W.; Hua, L.; Meng, Z.; Li, K. Comparative life cycle assessment of sodium-ion and lithium iron phosphate batteries in the context of carbon neutrality. J. Energy Storage 2023, 72, 108589. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, Z.; Wu, B.; Tang, Y.; Evans, S. Environmental life cycle assessment of recycling technologies for ternary lithium-ion batteries. J. Clean. Prod. 2023, 389, 136008. [Google Scholar] [CrossRef]

- Feng, T.; Guo, W.; Li, Q.; Meng, Z.; Liang, W. Life cycle assessment of lithium nickel cobalt manganese oxide batteries and lithium iron phosphate batteries for electric vehicles in China. J. Energy Storage 2022, 52, 104767. [Google Scholar] [CrossRef]

- Lai, X.; Gu, H.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Han, X.; Guo, Y.; Bhagat, R.; Zheng, Y. Investigating greenhouse gas emissions and environmental impacts from the production of lithium-ion batteries in China. J. Clean. Prod. 2022, 372, 133756. [Google Scholar] [CrossRef]

- Abdelbaky, M.; Schwich, L.; Crenna, E.; Peeters, J.R.; Hischier, R.; Friedrich, B.; Dewulf, W. Comparing the environmental performance of industrial recycling routes for lithium nickel-cobalt-manganese oxide 111 vehicle batteries. Procedia CIRP 2021, 98, 97–102. [Google Scholar] [CrossRef]

- Dai, Q.; Kelly, J.C.; Gaines, L.; Wang, M. Life cycle analysis of lithium-ion batteries for automotive applications. Batteries 2019, 5, 48. [Google Scholar] [CrossRef]

- Qiao, Q.; Zhao, F.; Liu, Z.; Jiang, S.; Hao, H. Cradle-to-gate greenhouse gas emissions of battery electric and internal combustion engine vehicles in China. Appl. Energy 2017, 204, 1399–1411. [Google Scholar] [CrossRef]

- Hao, H.; Mu, Z.; Jiang, S.; Liu, Z.; Zhao, F. GHG Emissions from the Production of Lithium-Ion Batteries for Electric Vehicles in China. Sustainability 2017, 9, 504. [Google Scholar] [CrossRef]

- Ambrose, H.; Kendall, A. Effects of battery chemistry and performance on the life cycle greenhouse gas intensity of electric mobility. Transp. Res. D Transp. Environ. 2016, 47, 182–194. [Google Scholar] [CrossRef]

- Zackrisson, M.; Avellán, L.; Orlenius, J. Life cycle assessment of lithium-ion batteries for plug-in hybrid electric vehicles—Critical issues. J. Clean. Prod. 2010, 18, 1519–1529. [Google Scholar] [CrossRef]

- ISTAT. Popolazione Residente al 1° Gennaio: Piemonte. Available online: http://dati.istat.it/Index.aspx?QueryId=18540 (accessed on 18 January 2022).

- Minutolo, A.; Laurenti, M.A. Poggio di Legambiente, Mal’aria di città. 2021. [Google Scholar]

- Comune di Torino. Città di Torino-Limitazioni Alla Circolazione. Available online: http://www.comune.torino.it/emergenzaambientale/ (accessed on 18 January 2022).

- Gaines, L.; Richa, K.; Spangenberger, J. Key issues for Li-ion battery recycling. MRS Energy Sustain. 2018, 5, E14. [Google Scholar] [CrossRef]

- Nuss, P.; Eckelman, M.J. Life Cycle Assessment of Metals: A Scientific Synthesis. PLoS ONE 2014, 9, e101298. [Google Scholar] [CrossRef]

- Manjong, N.B.; Usai, L.; Burheim, O.S.; Strømman, A.H. Life cycle modelling of extraction and processing of battery minerals—A parametric approach. Batteries 2021, 7, 57. [Google Scholar] [CrossRef]

- European Commission. Critical Raw Materials. Available online: https://ec.europa.eu/growth/sectors/raw-materials/areas-specific-interest/critical-raw-materials_it (accessed on 18 February 2022).

- U.S. Geological Survey. Mineral Commodity Summaries. 2021. Available online: https://pubs.usgs.gov/periodicals/mcs2021/mcs2021.pdf (accessed on 15 February 2022).

- Xiong, S.; Ji, J.; Ma, X. Comparative Life Cycle Energy and GHG Emission Analysis for BEVs and PhEVs: A Case Study in China. Energies 2019, 12, 834. [Google Scholar] [CrossRef]

- GTT. Parco Veicoli-Schede Tecniche. 2021. Available online: https://www.gtt.to.it/cms/risorse/gruppo/veicoli/parco_veicoli_tpl.pdf (accessed on 18 January 2022).

- GTT. Bilancio di Sostenibilità. 2018. Available online: https://www.gtt.to.it/cms/risorse/gruppo/bilancio_sostenibilit%C3%A0_2018.pdf (accessed on 18 January 2022).

- Climate Transparency. Brown to Green Report. Available online: https://www.climate-transparency.org/g20-climate-performance/g20report2018#1531904263713-04b62b8d-e708 (accessed on 16 February 2022).

- European Environmental Agency. Greenhouse Gas Emission Intensity of Electricity Generation by Country. Available online: https://www.eea.europa.eu/data-and-maps/daviz/co2-emission-intensity-9#tab-googlechartid_googlechartid_googlechartid_chart_1111 (accessed on 16 February 2022).

- ISPRA. La Banca Dati dei Fattori di Emissione Medi per il Parco Circolante in Italia. Available online: https://fetransp.isprambiente.it/#/ (accessed on 10 March 2022).

- Jollife, I.T.; Cadima, J. Principal component analysis: A review and recent developments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150202. [Google Scholar] [CrossRef]

- Ballabio, D. A MATLAB toolbox for Principal Component Analysis and unsupervised exploration of data structure. Chemom. Intell. Lab. Syst. 2015, 149, 1–9. [Google Scholar] [CrossRef]

- Song, Q.; Wang, Z.; Wu, Y.; Li, J.; Yu, D.; Duan, H.; Yuan, W. Could urban electric public bus really reduce the GHG emissions: A case study in Macau? J. Clean. Prod. 2018, 172, 2133–2142. [Google Scholar] [CrossRef]

- IPPC. Fifth Assessment Report-AR5. 2014. Available online: https://www.ipcc.ch/ (accessed on 18 January 2022).

- Fuglestvedt, J.S.; Shine, K.P.; Berntsen, T.; Cook, J.; Lee, D.S.; Stenke, A.; Skeie, R.B.; Velders, G.J.M.; Waitz, I.A. Transport impacts on atmosphere and climate: Metrics. Atmos. Environ. 2010, 44, 4648–4677. [Google Scholar] [CrossRef]

- Lammel, G.; Graßl, H. Greenhouse effect of NOX. Environ. Sci. Pollut. Res. 1995, 2, 40–45. [Google Scholar] [CrossRef]

- Sustainable Bus. 15 Iveco Urbanway Hybrids for Bruxelles. The First Group of a 141 Units Order. Available online: https://www.sustainable-bus.com/hybrid-bus/15-iveco-urbanway-hybrids-for-bruxelles-the-first-group-of-a-141-units-order/ (accessed on 23 November 2023).

- International Energy Agency. Trends in Batteries. Available online: https://www.iea.org/reports/global-ev-outlook-2023/trends-in-batteries (accessed on 23 November 2023).

- ecoQuery. Available online: https://ecoquery.ecoinvent.org/Account/LogOn?ReturnUrl=%2f (accessed on 16 February 2022).

- EEA. Explaining Road Transport Emissions. EEA Report; European Environment Agency: Copenhagen, Denmark, 2016; pp. 1–31. Available online: https://www.eea.europa.eu/publications/explaining-road-transport-emissions (accessed on 8 January 2024).

- Statista. Italy: Energy mix 2021 | Statista. Available online: https://www.statista.com/statistics/873552/energy-mix-in-italy/ (accessed on 27 November 2023).

| NMC | LFP | Source | |

|---|---|---|---|

| Battery weight (kg) | 444 | 494 | [40] |

| Battery capacity (kWh) | 17.1 | 47.5 | [40] |

| Fuel efficiency (electricity) (kWh/100 km) | 15 | 15.3 | [40] |

| Charging efficiency (%) | 90 | 90 | [14] |

| Total lifetime mileage (km) | 120,000 | 160,000 | [40] |

| Pollutant | Total Annual Emissions (t) |

|---|---|

| CO | 102.12 |

| VOC | 33.97 |

| NOx | 358.04 |

| NMVOC | 5.78 |

| CH4 | 29.85 |

| N2O | 0.84 |

| NH3 | 0.29 |

| PM 2.5 | 7.48 |

| PM10 | 10.78 |

| SO2 | 0.15 |

| Pb | 0.01 |

| Black carbon | 2.38 |

| CO2 | 69,016.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nastasi, L.; Fiore, S. Environmental Assessment of Lithium-Ion Battery Lifecycle and of Their Use in Commercial Vehicles. Batteries 2024, 10, 90. https://doi.org/10.3390/batteries10030090

Nastasi L, Fiore S. Environmental Assessment of Lithium-Ion Battery Lifecycle and of Their Use in Commercial Vehicles. Batteries. 2024; 10(3):90. https://doi.org/10.3390/batteries10030090

Chicago/Turabian StyleNastasi, Livia, and Silvia Fiore. 2024. "Environmental Assessment of Lithium-Ion Battery Lifecycle and of Their Use in Commercial Vehicles" Batteries 10, no. 3: 90. https://doi.org/10.3390/batteries10030090

APA StyleNastasi, L., & Fiore, S. (2024). Environmental Assessment of Lithium-Ion Battery Lifecycle and of Their Use in Commercial Vehicles. Batteries, 10(3), 90. https://doi.org/10.3390/batteries10030090