Reducing Energy Consumption and Greenhouse Gas Emissions of Industrial Drying Processes in Lithium-Ion Battery Cell Production: A Qualitative Technology Benchmark

Abstract

1. Introduction

1.1. Environmental Impact of Automotive Battery Cell Production

1.2. Existing Literature on Drying in LIB Cell Production

1.3. Focus and Goal of This Study

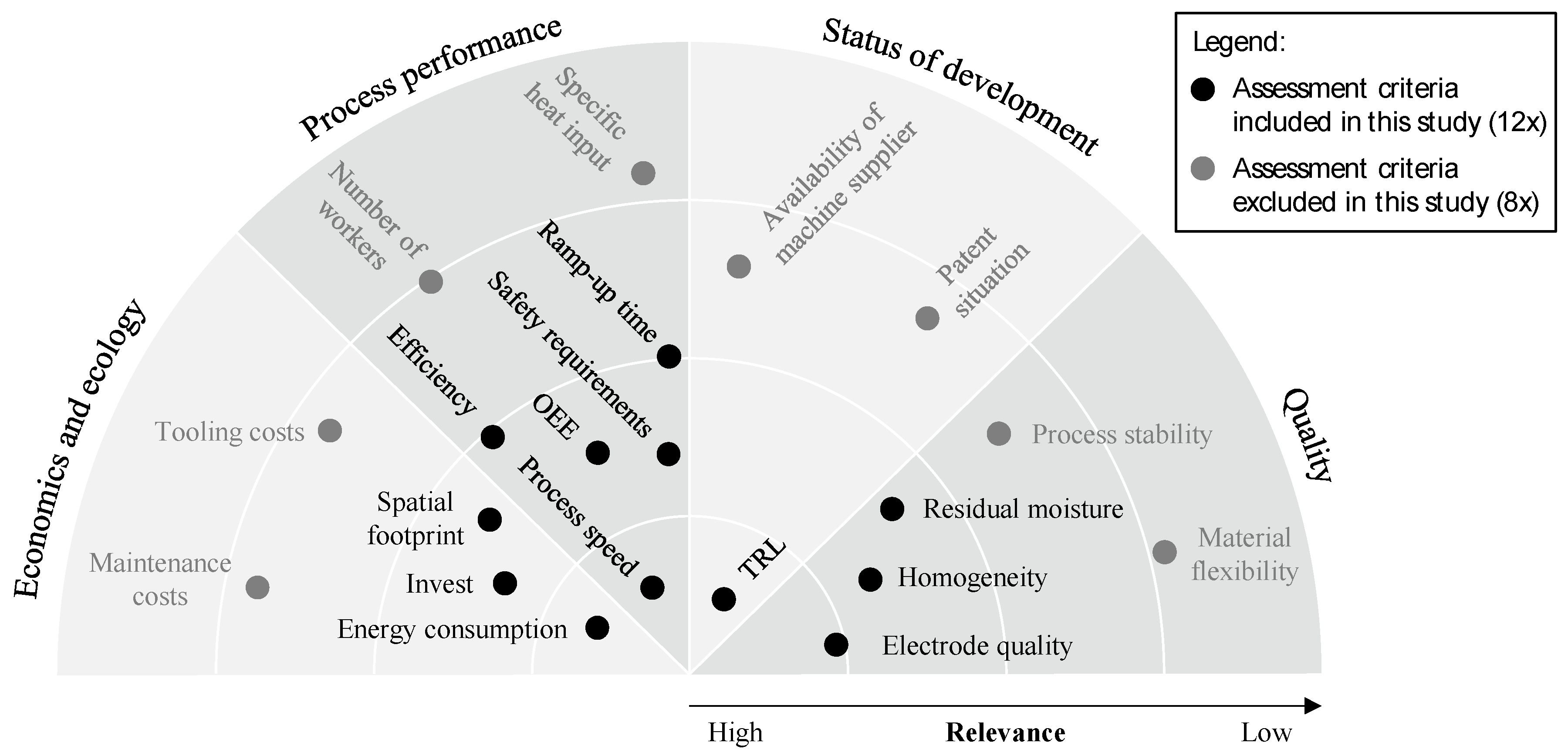

- Economics and ecology (e.g., investment and energy consumption);

- Process performance (e.g., process speed, efficiency and ramp-up time);

- Technological maturity (e.g., technology readiness level (TRL), patent situation);

- Quality (e.g., homogeneity of drying and residual moisture).

2. Methods and Data

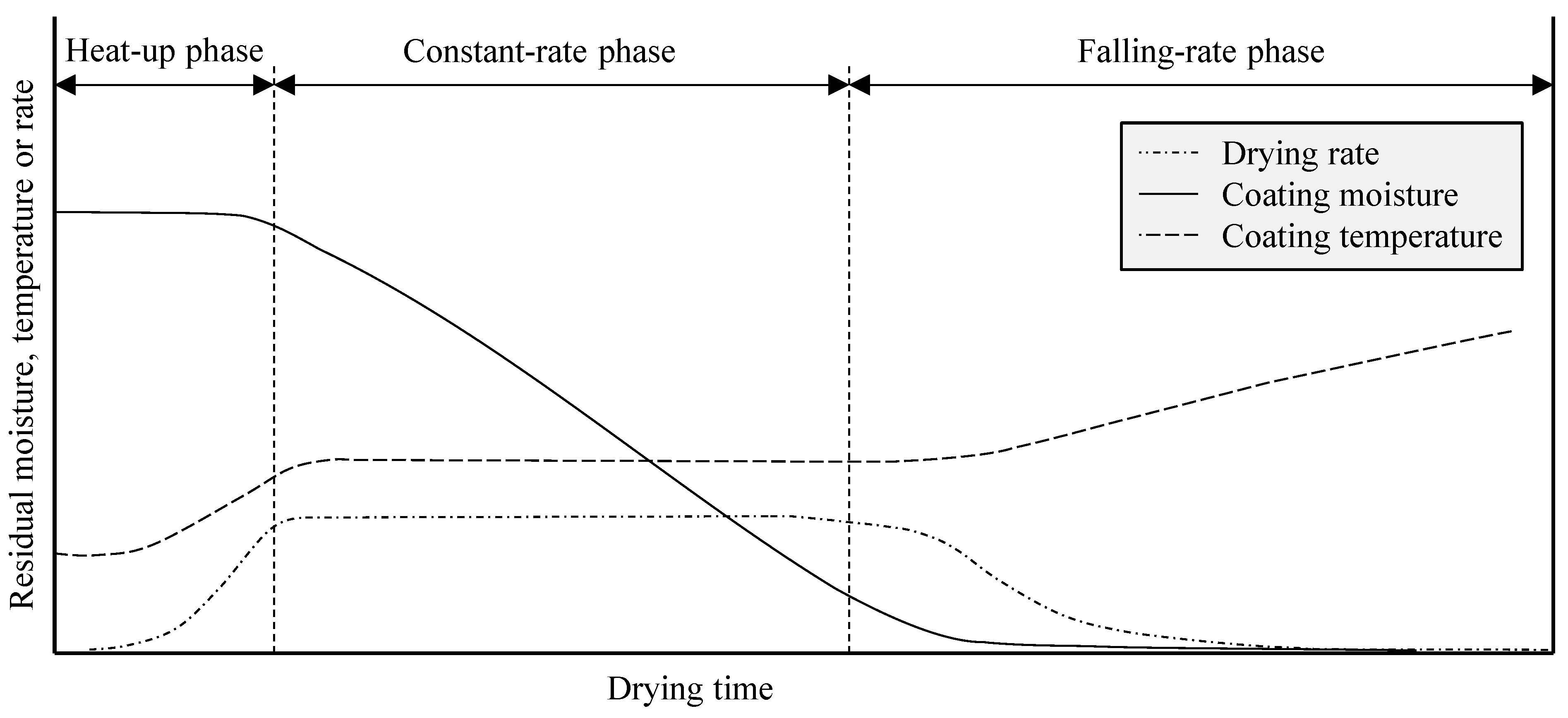

2.1. Physics of LIB Electrode Drying

- The type of solvent used;

- The thickness of the coating;

- The solid content of the coating;

- The dew point of the supply air.

2.2. Methodology

2.2.1. Conceptualisation of the Study and Determination of Key Performance Indicators

- Status of development indicator: The KPI reflects current progress in the development of the technology. The only assessment criterion here was the TRL.

- Economic and ecology indicator: KPI expressing financial and ecological means or use of resources. The key influences on this KPI are investment costs, energy consumption (or energy-related costs) and spatial footprint (space demand in factory layout).

- Process performance indicator: The KPI is related to the technological performance of the process, expressed by process speed, overall equipment effectiveness (OEE), efficiency, safety requirements and ramp-up time.

- Quality indicator: KPI expressing how well electrodes can be dried repeatedly. The main aspects of this KPI are electrode quality, homogeneity of drying and residual moisture.

2.2.2. Data Acquisition and Evaluation

3. Results and Discussion

3.1. Overview of Identified Technological Approaches

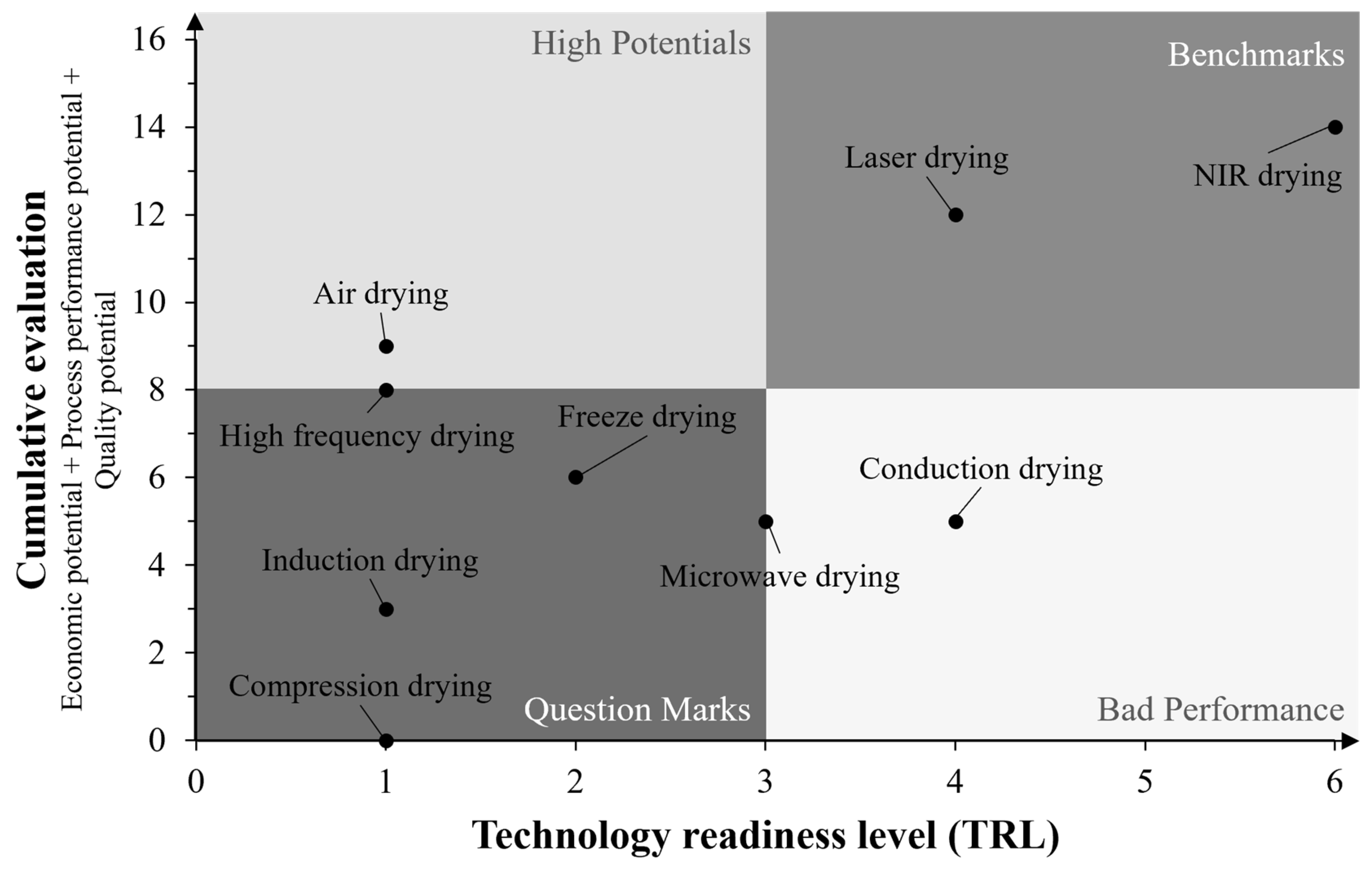

3.2. Analysis of the Most Promising Approaches

3.3. Impact of Different LIB Drying Technologies on Energy Consumption and GHG Emissions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| No. | Education Level | Educational Background | Field of Expertise Relevant to This Study | Work Experience |

|---|---|---|---|---|

| 1 | Doctoral degree | Mechanical Engineering | Battery production | 20–29 years |

| 2 | Doctoral degree | Material Science | Battery technology | 10–19 years |

| 3 | Doctoral degree | Process Engineering | Drying technology | 20–29 years |

| 4 | Doctoral degree | Electrochemistry | Battery chemistry | 10–19 years |

| 5 | Doctoral degree | Electrochemistry | Battery chemistry | 10–19 years |

| 6 | Master of Science | Mechanical Engineering | Battery production | 20–29 years |

| 7 | Master of Science | Mechanical Engineering | Battery production | 10–19 years |

| 8 | Master of Science | Mechanical Engineering | Drying technology | 6–10 years |

| 9 | Master of Science | Mechanical Engineering | Energy technology | 6–10 years |

| 10 | Master of Science | Electrochemistry | Battery chemistry | 6–10 years |

| 11 | Master of Science | Electrochemistry | Battery chemistry | 2–5 years |

| 12 | Master of Science | Environmental Sciences | Environmental technology | 2–5 years |

Appendix B

| Data Type | Database | Search Terms in Boolean Operators | Total Hits | Remaining after First Screening | Final Number of Sources |

|---|---|---|---|---|---|

| Scientific Publications (published between 2016 and 2022) | ScienceDirect | li-ion AND (battery OR batteries) AND (manufacturing OR production) AND drying | 19,904 | 38 | 28 |

| TITLE-ABS-KEY li-ion AND (battery OR batteries) AND drying | 320 | 12 | |||

| IEEExplore | li-ion AND (battery OR batteries) AND drying | 6 | 1 | ||

| TITLE-ABS-KEY li-ion AND (battery OR batteries) AND drying | 3 | 0 | |||

| Wiley | li-ion AND (battery OR batteries) AND (manufacturing OR production) AND drying | 17,164 | 6 | ||

| TITLE-ABS-KEY li-ion AND (battery OR batteries) AND drying | 10 | 3 | |||

| Taylor & Francis | li-ion AND (battery OR batteries) AND (manufacturing OR production) AND drying | 2030 | 1 | ||

| TITLE-ABS-KEY li-ion AND (battery OR batteries) AND drying | 1 | 0 | |||

| Springer | li-ion AND (battery OR batteries) AND (manufacturing OR production) AND drying | 4521 | 2 | ||

| TITLE-ABS-KEY li-ion AND (battery OR batteries) AND drying | 0 | 0 | |||

| Patents (published until 2022) | Espacenet | li-ion AND (battery OR batteries) AND drying AND technology | 28 | 7 | 5 |

| industrial AND drying AND technology | 15,176 | 274 | |||

| Patbase | li-ion AND (battery OR batteries) AND drying AND technology | 79 | 11 | ||

| industrial AND drying AND technology | 3989 | 41 | |||

| R&D projects (launched in 2022 or before) | li-ion battery electrode drying | 9 | 6 | 6 |

- (1)

- First screening of ‘Total Hits’:

- (2)

- Second screening to arrive at the ‘Final number of sources’:

Appendix C

| No. | Education Level | Educational Background | Industry Sector | Work Experience |

|---|---|---|---|---|

| 1 | Doctoral degree | Mechanical Engineering | Equipment manufacturing | 30–39 years |

| 2 | Doctoral degree | Process Engineering | R&D in production technology | 20–29 years |

| 3 | Master of Science | Electronics and test systems | R&D in battery technology | 10–19 years |

| 4 | Master of Science | Electrochemistry | R&D in battery production | 6–10 years |

| 5 | Master of Science | Process Engineering | R&D in battery production | 6–10 years |

| 6 | Bachelor of Science | Mechanical Engineering | Equipment manufacturing | 20–29 years |

| 7 | Master of Science | Mechanical Engineering | Equipment manufacturing | 10–19 years |

| 8 | Doctoral degree | Mechanical Engineering | Equipment manufacturing | 20–29 years |

| 9 | Master of Science | Process Engineering | Battery production | 6–10 years |

| 10 | Master of Science | Mechanical Engineering | Equipment manufacturing | 20–29 years |

| 11 | Doctoral degree | Process Engineering | Equipment manufacturing | 20–29 years |

| 12 | Master of Science | Electrochemistry | R&D in Battery production | 10–19 years |

| 13 | Master of Science | Mechanical Engineering | R&D in Battery production | 6–10 years |

| 14 | Doctoral degree | Electrochemistry | R&D in battery technology | 10–19 years |

| 15 | Master of Science | Electrochemistry | R&D in battery technology | 6–10 years |

Appendix D

| Topic | Question |

|---|---|

| Technology overview | How would you briefly explain the technology? |

| How would you explain the underlying physical principle? | |

| Which partners or institutions participate in the development of this technology? | |

| How would you assess the technological maturity? | |

| What are the major advantages of the technology? | |

| What are the major disadvantages currently and in the long term? | |

| Competence of expert | In which way are you involved with the technology? |

| How many years of expertise do you have regarding this technology? | |

| Process details | What process steps are involved in the technology? |

| How does the technology differ from other drying technologies? | |

| How is the process performance regarding | |

| Drying speed? | |

| OEE? | |

| Process robustness? | |

| What are requirements/restrictions? | |

| safety requirements | |

| area requirements (spatial footprint) | |

| infrastructure requirements | |

| product limitations (e.g., anode or cathode excluded) | |

| Economic details | How does the technology compare (qualitative) to state-of-the-art drying with |

| operating cost and invest? | |

| energy consumption? | |

| maintenance? | |

| personnel expenses? | |

| Quality details | Does the technology (in comparison to state-of-the-art drying) positively or negatively affect |

| drying homogeneity? | |

| porosity? | |

| residual moisture? | |

| other quality parameters? | |

| Outlook | How would you estimate the amount of time and costs to reach marketability? |

| How much effort is required to integrate the technology into a production line (pilot and industrial scale)? | |

| What plans do you have for the further development of the technology? | |

| Do you know alternative technologies currently in development? | |

| How can these be described and how do they differ? |

References

- Sommerville, R.; Zhu, P.; Rajaeifar, M.A.; Heidrich, O.; Goodship, V.; Kendrick, E. A qualitative assessment of lithium ion battery recycling processes. Resour. Conserv. Recycl. 2021, 165, 105219. [Google Scholar] [CrossRef]

- Wessel, J.; Turetskyy, A.; Cerdas, F.; Herrmann, C. Integrated Material-Energy-Quality Assessment for Lithium-ion Battery Cell Manufacturing. Procedia CIRP 2021, 98, 388–393. [Google Scholar] [CrossRef]

- Scheller, C.; Schmidt, K.; Spengler, T.S. Effects of CO2-Penalty Costs on the Production and Recycling Planning of Lithium-Ion Batteries. Procedia CIRP 2021, 98, 643–647. [Google Scholar] [CrossRef]

- IEA. I.E.A. Global EV Outlook 2021. Available online: https://iea.blob.core.windows.net/assets/ed5f4484-f556-4110-8c5c-4ede8bcba637/GlobalEVOutlook2021.pdf (accessed on 23 June 2022).

- Statista Research Department. Projected Demand for Lithium-Ion Batteries Worldwide in EVs 2019–2030. 2021. Available online: https://www.statista.com/statistics/309570/lithium-ion-battery-market-in-electric-vehicles/ (accessed on 13 June 2022).

- World Economic Forum. A Vision for a Sustainable Battery Value Chain in 2030: Unlocking the Full Potential to Power Sustainable Development and Climate Change Mitigation. Available online: https://www3.weforum.org/docs/WEF_A_Vision_for_a_Sustainable_Battery_Value_Chain_in_2030_Report.pdf (accessed on 20 September 2022).

- Kosai, S.; Takata, U.; Yamasue, E. Natural resource use of a traction lithium-ion battery production based on land disturbances through mining activities. J. Clean. Prod. 2021, 280, 124871. [Google Scholar] [CrossRef]

- Degen, F.; Schütte, M. Life cycle assessment of the energy consumption and GHG emissions of state-of-the-art automotive battery cell production. J. Clean. Prod. 2022, 330, 129798. [Google Scholar] [CrossRef]

- Yuan, C.; Deng, Y.; Li, T.; Yang, F. Manufacturing energy analysis of lithium ion battery pack for electric vehicles. CIRP Ann. 2017, 66, 53–56. [Google Scholar] [CrossRef]

- Jinasena, A.; Burheim, O.S.; Strømman, A.H. A Flexible Model for Benchmarking the Energy Usage of Automotive Lithium-Ion Battery Cell Manufacturing. Batteries 2021, 7, 14. [Google Scholar] [CrossRef]

- Degen, F. Lithium-ion battery cell production in Europe: Scenarios for reducing energy consumption and greenhouse gas emissions until 2030. J Ind. Ecol. 2023, 27, 964–976. [Google Scholar] [CrossRef]

- Von Drachenfels, N.; Husmann, J.; Khalid, U.; Cerdas, F.; Herrmann, C. Life Cycle Assessment of the Battery Cell Production: Using a Modular Material and Energy Flow Model to Assess Product and Process Innovations. Energy Tech. 2023, 11, 2200673. [Google Scholar] [CrossRef]

- Degen, F.; Krätzig, O. Future in Battery Production: An Extensive Benchmarking of Novel Production Technologies as Guidance for Decision Making in Engineering. IEEE Trans. Eng. Manag. 2024, 71, 1038–1056. [Google Scholar] [CrossRef]

- Simić, S.; Orašanin, G.; Golubović, D.; Milić, D.; Batinić, K. Consideration of Opportunities for the Optimization of Heat Energy Consumption in Industry and Energetics. In New Technologies, Development and Application II; Karabegović, I., Ed.; Springer International Publishing: Cham, Germany, 2020; pp. 494–503. ISBN 978-3-030-18071-3. [Google Scholar]

- Susarla, N.; Ahmed, S.; Dees, D.W. Modeling and analysis of solvent removal during Li-ion battery electrode drying. J. Power Sources 2018, 378, 660–670. [Google Scholar] [CrossRef]

- Wood, D.L.; Quass, J.D.; Li, J.; Ahmed, S.; Ventola, D.; Daniel, C. Technical and economic analysis of solvent-based lithium-ion electrode drying with water and NMP. Dry. Technol. 2018, 36, 234–244. [Google Scholar] [CrossRef]

- Von Horstig, M.-W.; Schoo, A.; Loellhoeffel, T.; Mayer, J.K.; Kwade, A. A Perspective on Innovative Drying Methods for Energy-Efficient Solvent-Based Production of Lithium-Ion Battery Electrodes. Energy Tech. 2022, 10, 2200689. [Google Scholar] [CrossRef]

- Chojnacka, K.; Mikula, K.; Izydorczyk, G.; Skrzypczak, D.; Witek-Krowiak, A.; Moustakas, K.; Ludwig, W.; Kułażyński, M. Improvements in drying technologies—Efficient solutions for cleaner production with higher energy efficiency and reduced emission. J. Clean. Prod. 2021, 320, 128706. [Google Scholar] [CrossRef]

- Barrozo, M.A.S.; Mujumdar, A.; Freire, J.T. Air-Drying of Seeds: A Review. Dry. Technol. 2014, 32, 1127–1141. [Google Scholar] [CrossRef]

- Ahmed, S.; Nelson, P.A.; Gallagher, K.G.; Dees, D.W. Energy impact of cathode drying and solvent recovery during lithium-ion battery manufacturing. J. Power Sources 2016, 322, 169–178. [Google Scholar] [CrossRef]

- Bichon, M.; Sotta, D.; Dupré, N.; de Vito, E.; Boulineau, A.; Porcher, W.; Lestriez, B. Study of Immersion of LiNi0.5Mn0.3Co0.2O2 Material in Water for Aqueous Processing of Positive Electrode for Li-Ion Batteries. ACS Appl. Mater. Interfaces 2019, 11, 18331–18341. [Google Scholar] [CrossRef]

- Ford, D. Develop your Technology Strategy. Long Range Plan. 1988, 21, 85–95. [Google Scholar] [CrossRef]

- Gregory, M.J. Technology Management: A Process Approach. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1995, 209, 347–356. [Google Scholar] [CrossRef]

- Hamzeh, R.; Xu, X. Technology selection methods and applications in manufacturing: A review from 1990 to 2017. Comput. Ind. Eng. 2019, 138, 106123. [Google Scholar] [CrossRef]

- Efstathiades, A.; Tassou, S.A.; Oxinos, G.; Antoniou, A. Advanced manufacturing technology transfer and implementation in developing countries. Technovation 2000, 20, 93–102. [Google Scholar] [CrossRef]

- Huang, G.Q.; Mak, K.L. Current practices of engineering change management in UK manufacturing industries. Int. J. Oper. Prod. Manag. 1999, 19, 21–37. [Google Scholar] [CrossRef]

- Fleischer, T.; Decker, M.; Fiedeler, U. Assessing emerging technologies—Methodological challenges and the case of nanotechnologies. Technol. Forecast. Soc. Change 2005, 72, 1112–1121. [Google Scholar] [CrossRef]

- Gavankar, S.; Suh, S.; Keller, A.A. The Role of Scale and Technology Maturity in Life Cycle Assessment of Emerging Technologies: A Case Study on Carbon Nanotubes. J. Ind. Ecol. 2015, 19, 51–60. [Google Scholar] [CrossRef]

- United States Department of Defence. Manufacturing Readiness Level (MRL) Deskbook—Version 2.0. Available online: https://www.dodmrl.com/MRL_Deskbook_V2.pdf (accessed on 20 March 2023).

- Bell, S.; Morse, S. Groups and facilitators within problem structuring processes. J. Oper. Res. Soc. 2013, 64, 959–972. [Google Scholar] [CrossRef]

- Nino, J.; Nelwan, L.O.; Purwanto, Y.A. Application of Natural Air Drying on Shelled Corn in Timor. IOP Conf. Ser. Earth Environ. Sci. 2018, 147, 12024. [Google Scholar] [CrossRef]

- Neb, D.; Kim, S.; Clever, H.; Dorn, B.; Kampker, A. Current advances on laser drying of electrodes for lithium-ion battery cells. Procedia CIRP 2022, 107, 1577–1587. [Google Scholar] [CrossRef]

- Heindl, A. Praxisbuch Horden- und Flächentrocknung; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 978-3-662-60432-8. [Google Scholar]

- Bryntesen, S.N.; Strømman, A.H.; Tolstorebrov, I.; Shearing, P.R.; Lamb, J.J.; Stokke Burheim, O. Opportunities for the State-of-the-Art Production of LIB Electrodes—A Review. Energies 2021, 14, 1406. [Google Scholar] [CrossRef]

- Font, F.; Protas, B.; Richardson, G.; Foster, J.M. Binder migration during drying of lithium-ion battery electrodes: Modelling and comparison to experiment. J. Power Sources 2018, 393, 177–185. [Google Scholar] [CrossRef]

- Jaiser, S.; Müller, M.; Baunach, M.; Bauer, W.; Scharfer, P.; Schabel, W. Investigation of film solidification and binder migration during drying of Li-Ion battery anodes. J. Power Sources 2016, 318, 210–219. [Google Scholar] [CrossRef]

- Westphal, B.; Bockholt, H.; Günther, T.; Haselrieder, W.; Kwade, A. Influence of Convective Drying Parameters on Electrode Performance and Physical Electrode Properties. ECS Trans. 2015, 64, 57–68. [Google Scholar] [CrossRef]

- Umweltbundesamt. Carbon Dioxide Emissions for the German Atmospheric Emission Reporting 1990–2020. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/361/dokumente/co2_ef_liste_2022_brennstoffe_und_industrie_final.xlsx (accessed on 15 March 2023).

- European Environment Agency. Greenhouse Gas Emission Intensity of Electricity Generation by Country. Available online: https://www.eea.europa.eu/data-and-maps/daviz/co2-emission-intensity-9#tab-googlechartid_googlechartid_googlechartid_googlechartid_chart_11111 (accessed on 10 June 2022).

| ++ | Much higher potential than reference | (5 points) |

| + | Higher potential than reference | (4 points) |

| 0 | Same potential as the reference | (3 points) |

| - | Lower potential than reference | (2 points) |

| -- | Much lower potential than the reference | (1 point) |

| ? | Not enough reliable information available for a rating | (0 points) |

| n/a | Technology serves as a reference and is, therefore, not rated |

| Physical Mechanism | Technology | Rating | |||

|---|---|---|---|---|---|

| TRL | Economic and Ecological Potential | Process Performance Potential | Quality Potential | ||

| Convection | Hot air drying | 9 | n/a | n/a | n/a |

| Air drying | 1 | + | -- | + | |

| Electromagnetic waves | Microwave drying | 3 | ? | + | -- |

| Near-infrared drying (NIR) | 6 | ++ | ++ | + | |

| Laser drying | 4 | + | + | + | |

| Others | Conduction drying | 4 | 0 | - | ? |

| Induction drying | 1 | 0 | ? | ? | |

| High-frequency drying | 1 | - | + | -- | |

| Freeze drying | 2 | -- | -- | + | |

| Compression drying | 1 | ? | ? | ? | |

| Drying Technology | Energy Saving Potential | Energy Consumption (kWh/kWh Cell Capacity) | GHG Emissions in 2030 (Metric Ton CO2eq/a) |

|---|---|---|---|

| Hot air drying (status quo) | 0% | 10.09 kWh natural gas | 3.400 million Mt CO2eq/a |

| 0.92 kWh electricity | |||

| NIR drying | 80% | 2.204 kWh electricity | 0.773 million Mt CO2eq/a |

| Laser drying | 50% | 5.51 kWh electricity | 1.933 million Mt CO2eq/a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schütte, M.; Degen, F.; Walter, H. Reducing Energy Consumption and Greenhouse Gas Emissions of Industrial Drying Processes in Lithium-Ion Battery Cell Production: A Qualitative Technology Benchmark. Batteries 2024, 10, 64. https://doi.org/10.3390/batteries10020064

Schütte M, Degen F, Walter H. Reducing Energy Consumption and Greenhouse Gas Emissions of Industrial Drying Processes in Lithium-Ion Battery Cell Production: A Qualitative Technology Benchmark. Batteries. 2024; 10(2):64. https://doi.org/10.3390/batteries10020064

Chicago/Turabian StyleSchütte, Marius, Florian Degen, and Hendrik Walter. 2024. "Reducing Energy Consumption and Greenhouse Gas Emissions of Industrial Drying Processes in Lithium-Ion Battery Cell Production: A Qualitative Technology Benchmark" Batteries 10, no. 2: 64. https://doi.org/10.3390/batteries10020064

APA StyleSchütte, M., Degen, F., & Walter, H. (2024). Reducing Energy Consumption and Greenhouse Gas Emissions of Industrial Drying Processes in Lithium-Ion Battery Cell Production: A Qualitative Technology Benchmark. Batteries, 10(2), 64. https://doi.org/10.3390/batteries10020064