1. Introduction

Lithium-ion batteries are extensively used in various aspects of modern life and industrial manufacturing, owing to their numerous benefits, such as high energy density [

1], low self-discharge rate [

2], elevated voltage, lightweight nature, and prolonged lifespan [

3]. However, lithium-ion batteries are prone to performance degradation during usage and storage [

4], which may lead to a decrease in system operating capacity, cause a battery to stop working, or even result in catastrophic failures [

5]. Therefore, it is necessary to propose an effective health assessment method for lithium-ion batteries to strengthen battery management and maintenance and reduce risks.

At present, health assessment methods for lithium-ion batteries encompass model-based, data-driven, and hybrid approaches. These techniques are used to evaluate battery condition and performance, aiming to maximize their efficiency and functionality [

6].

Model-based methods can be broadly categorized into physical models, electrochemical models, and mathematical models, each serving a different purpose in various fields of study. Yang et al. proposed an online battery SOH estimation method based on the quantitative correlation between normalized battery capacity and the current time constant [

7]. Zhang et al. proposed a quantitative electrochemical aging model for lithium-ion batteries considering the side reactions [

8]. Madani et al. proposed a practical, simple, and reliable method for estimating battery capacity based on two parameters [

9]. However, model-based methods often involve intricate modeling processes, in which only the mathematical, physical, and chemical mechanisms and characteristics of batteries are considered, while other perturbations and complexities in engineering applications are ignored, resulting in inaccurate assessment results.

In comparison with model-based methods, data-driven methods offer greater flexibility and accuracy. Data-driven methods can directly extract models based on historical data without analyzing internal mechanisms. Long et al. proposed an improved data-driven particle swarm optimization model for predicting the remaining useful life of lithium-ion batteries [

10]. Yu proposed a novel method for estimating and predicting the state of health (SOH) of lithium-ion batteries [

11]. Wassiliadis et al. proposed the application of the dual extended Kalman filtering method to the charging state and health state assessment of batteries, which improved the accuracy of the assessment [

12]. However, data-driven methods lack understanding of knowledge and interpretability of results and belong to the black-box model, which greatly affects the assessment results.

Hybrid methods, compared with single model-based or data-driven methods, typically demonstrate superior accuracy and performance. Zhi et al. developed a method for estimating battery SOH, integrating the GA-PSO-SVR algorithm to estimate the health status of lithium-ion batteries in electric vehicles [

13]. Yao et al. developed a novel prediction model that integrated particle swarm optimization (PSO), extreme learning machine (ELM), and correlation vector machine (RVM) to provide an accurate prediction for the remaining lifespan of lithium-ion batteries. [

14]. However, hybrid methods still possess certain limitations, including high computational costs and the challenge of uncertainty fusion.

Compared with the methods mentioned above, evidence reasoning (ER) rules not only effectively handle ambiguity and uncertainty but also provide a transparent and interpretable reasoning process [

15,

16,

17]. The method effectively combines quantitative information and qualitative knowledge to yield comprehensive assessment results [

18]. Zhang et al. introduced a novel approach to the health assessment of lithium-ion batteries by utilizing the evidential reasoning rule [

19]. Zhao et al. developed an online security evaluation model that incorporates the ER method [

20]. Wang et al. introduced an enhanced ER rule-based performance assessment model for an aerospace relay, which incorporates distributed referential points [

21]. The above literature supports the efficacy of ER rules in health assessment.

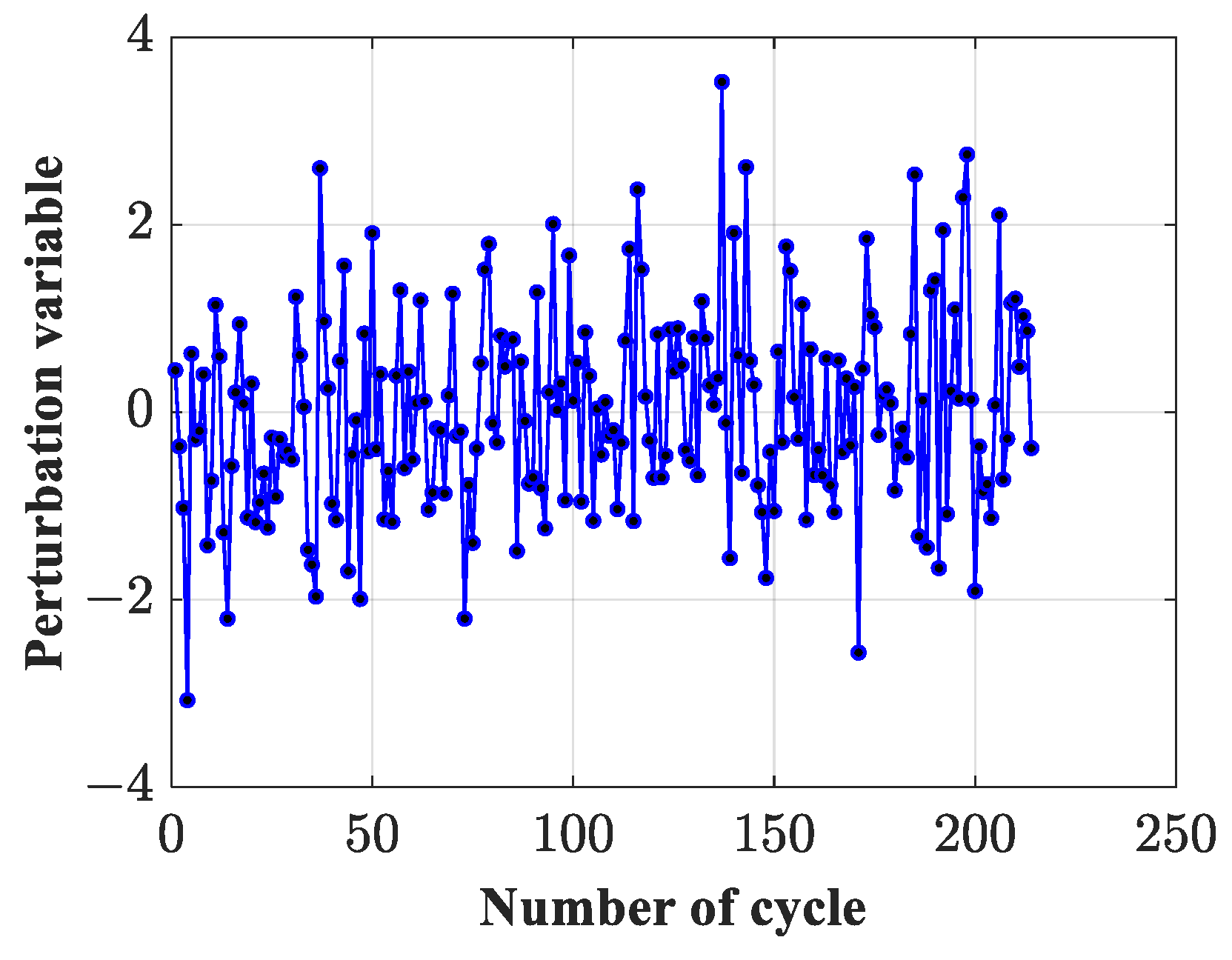

However, when developing a model to assess the health of a lithium-ion battery based on ER rules, the following issues still persist. First, while lithium-ion batteries are being charged and discharged, some observation indicators gathered will possess uncertainty factors. Therefore, it is essential for the health assessment model to be capable of addressing uncertainty. Second, the accuracy of the assessment model is greatly influenced by the level of reference values set by expert knowledge. Consequently, it is necessary to develop an optimization method to adjust the level reference values of the model to improve assessment accuracy. Third, lithium-ion batteries are susceptible to various perturbations during operation, which can result in a decline in the reliability [

22,

23]. Thus, to analyze the suitability of lithium-ion batteries for various perturbations, it is necessary to develop a method to simulate these perturbations. Then, this method can be used to analyze the robustness of the lithium-ion battery health assessment model.

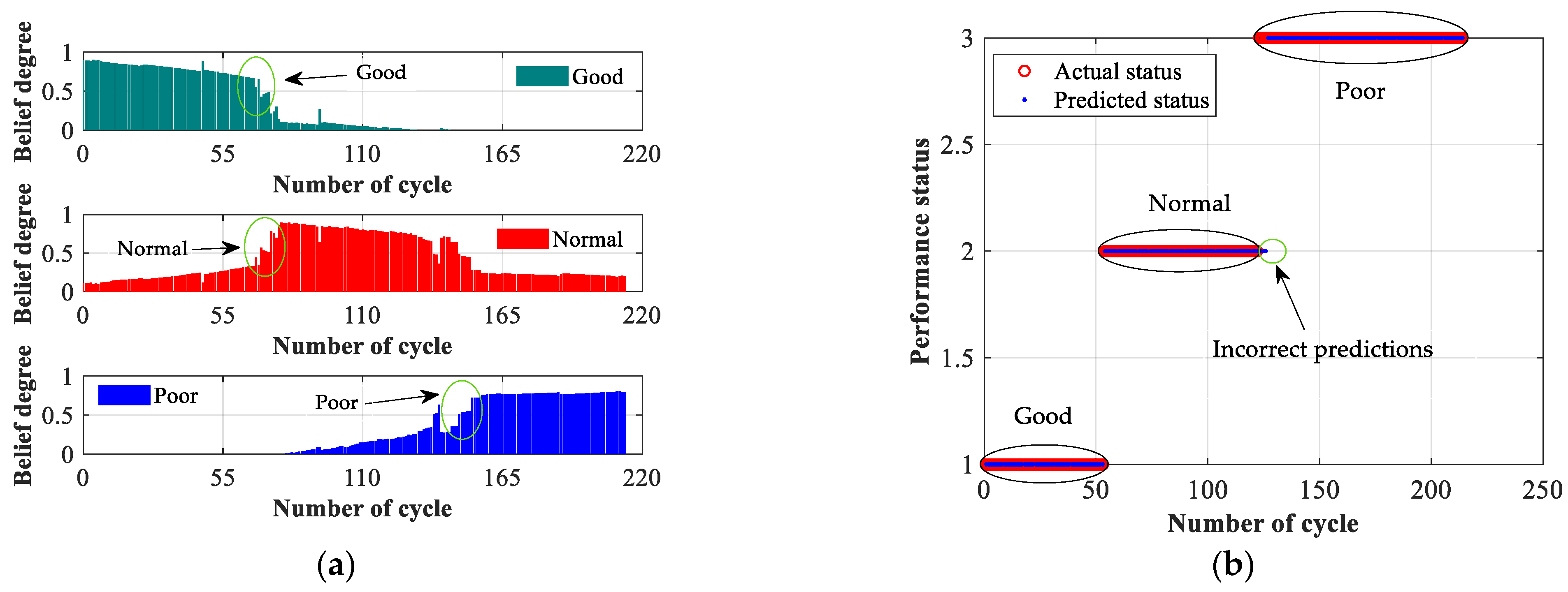

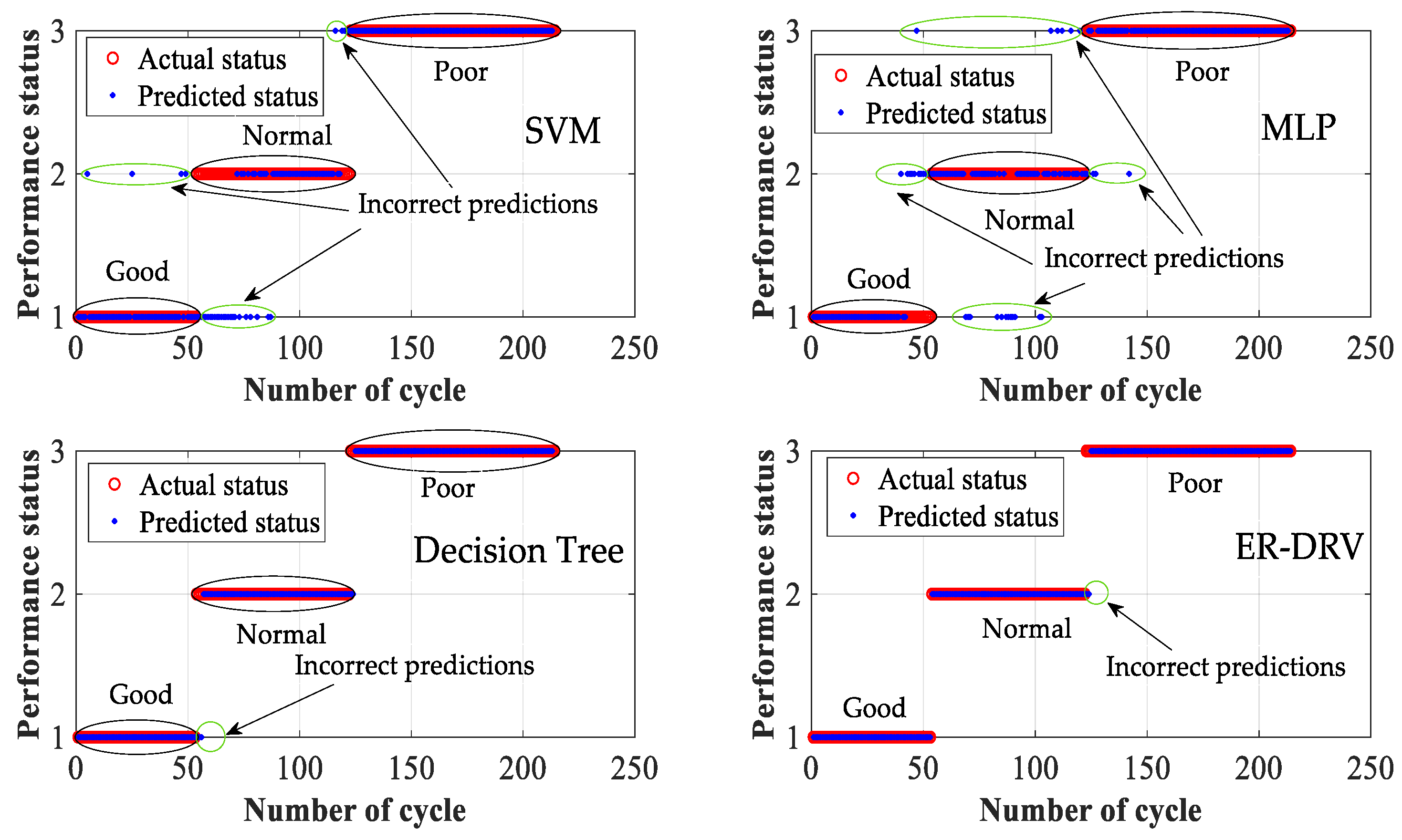

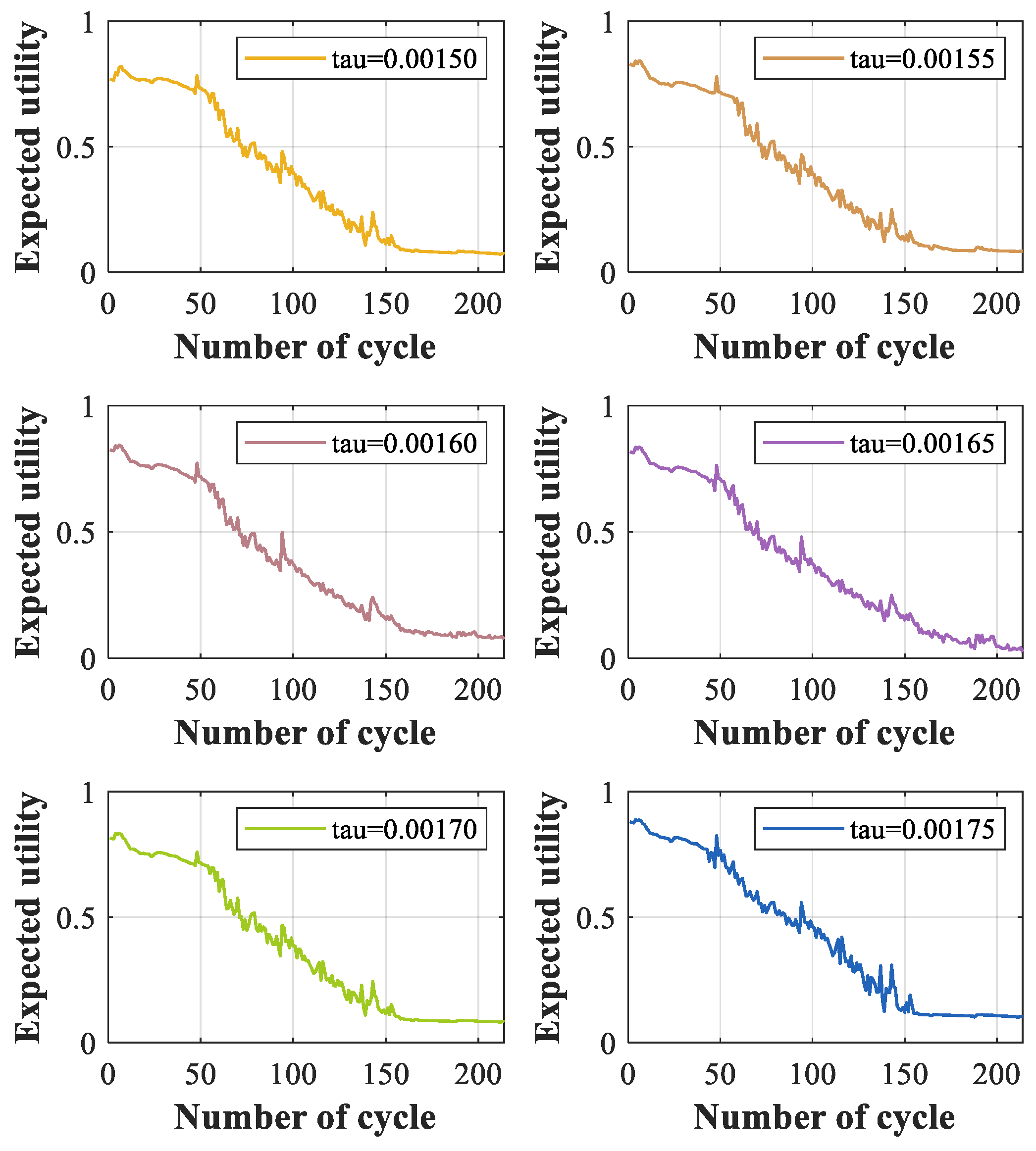

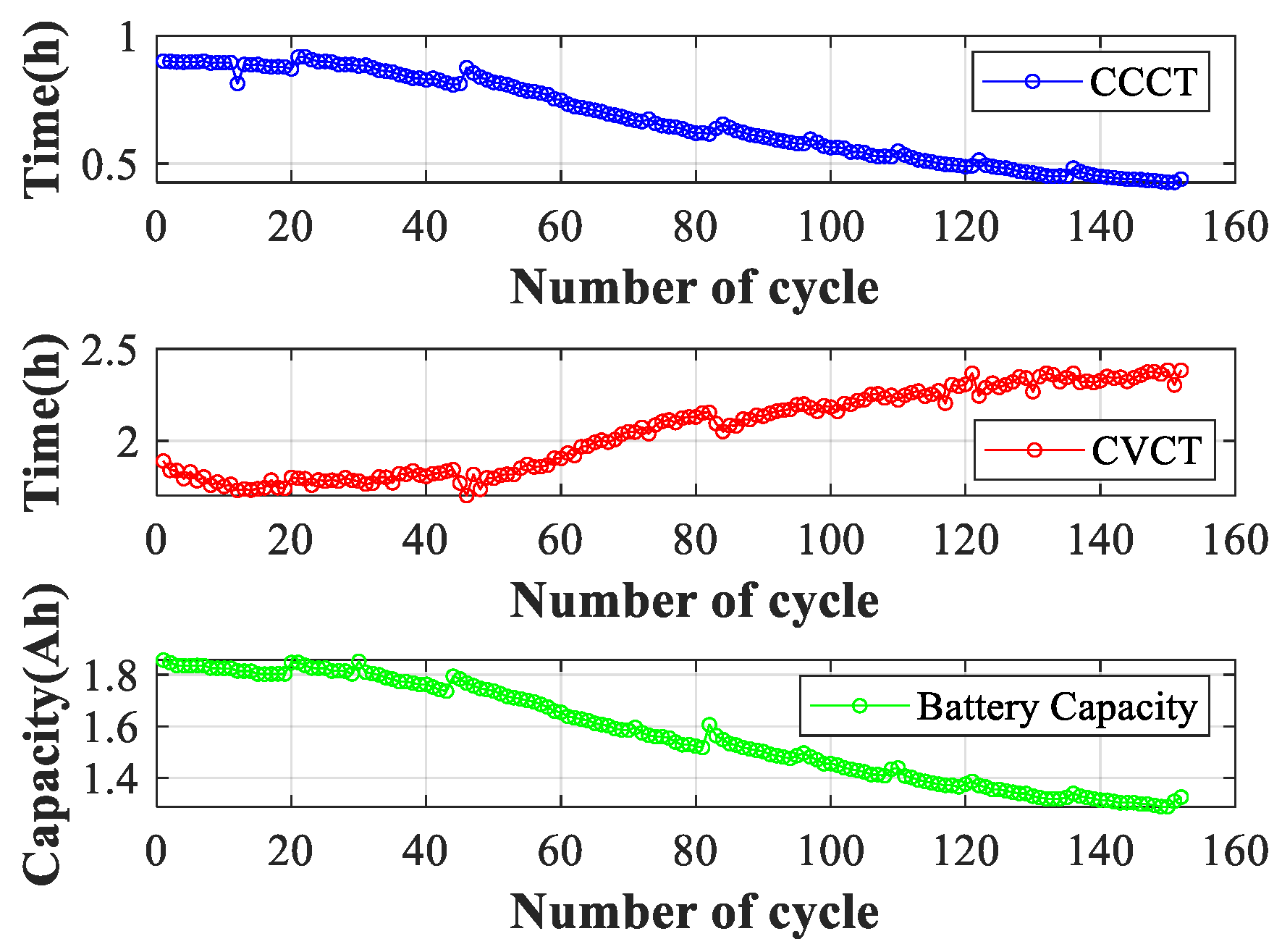

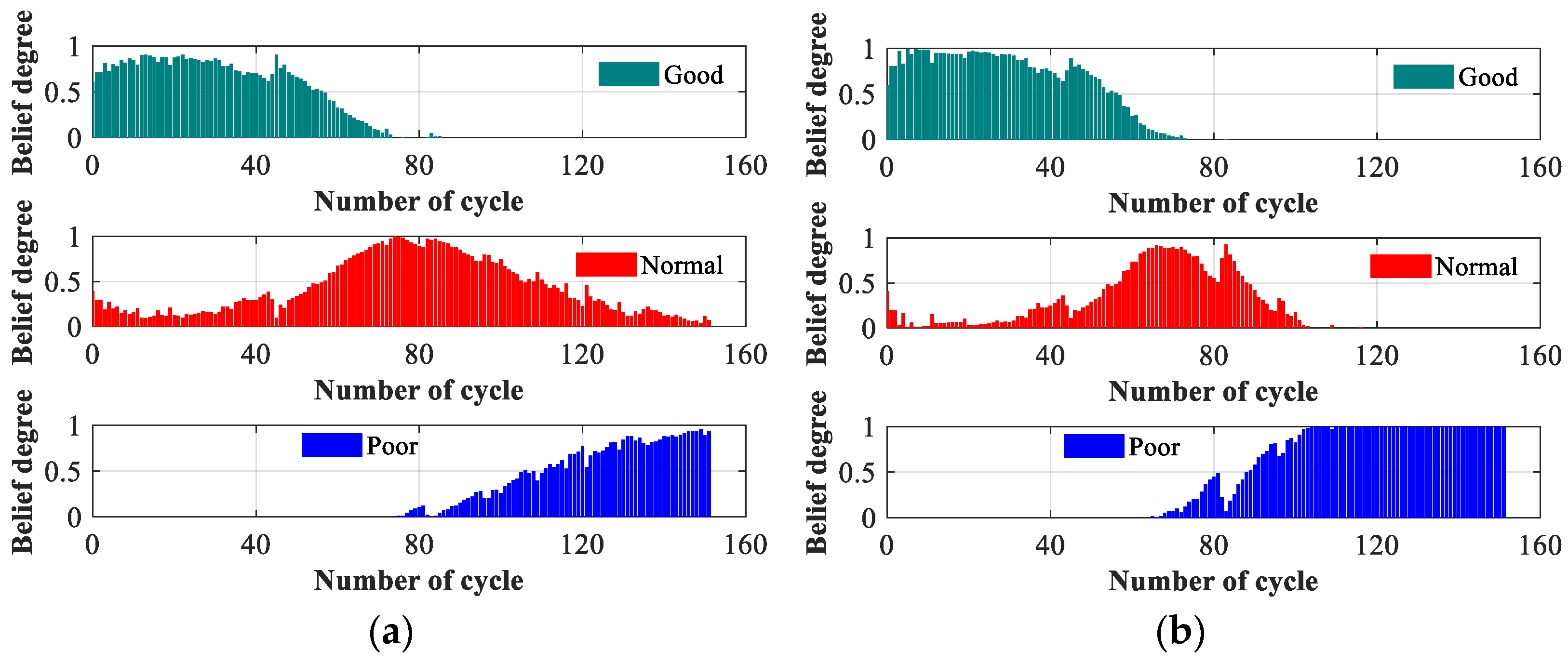

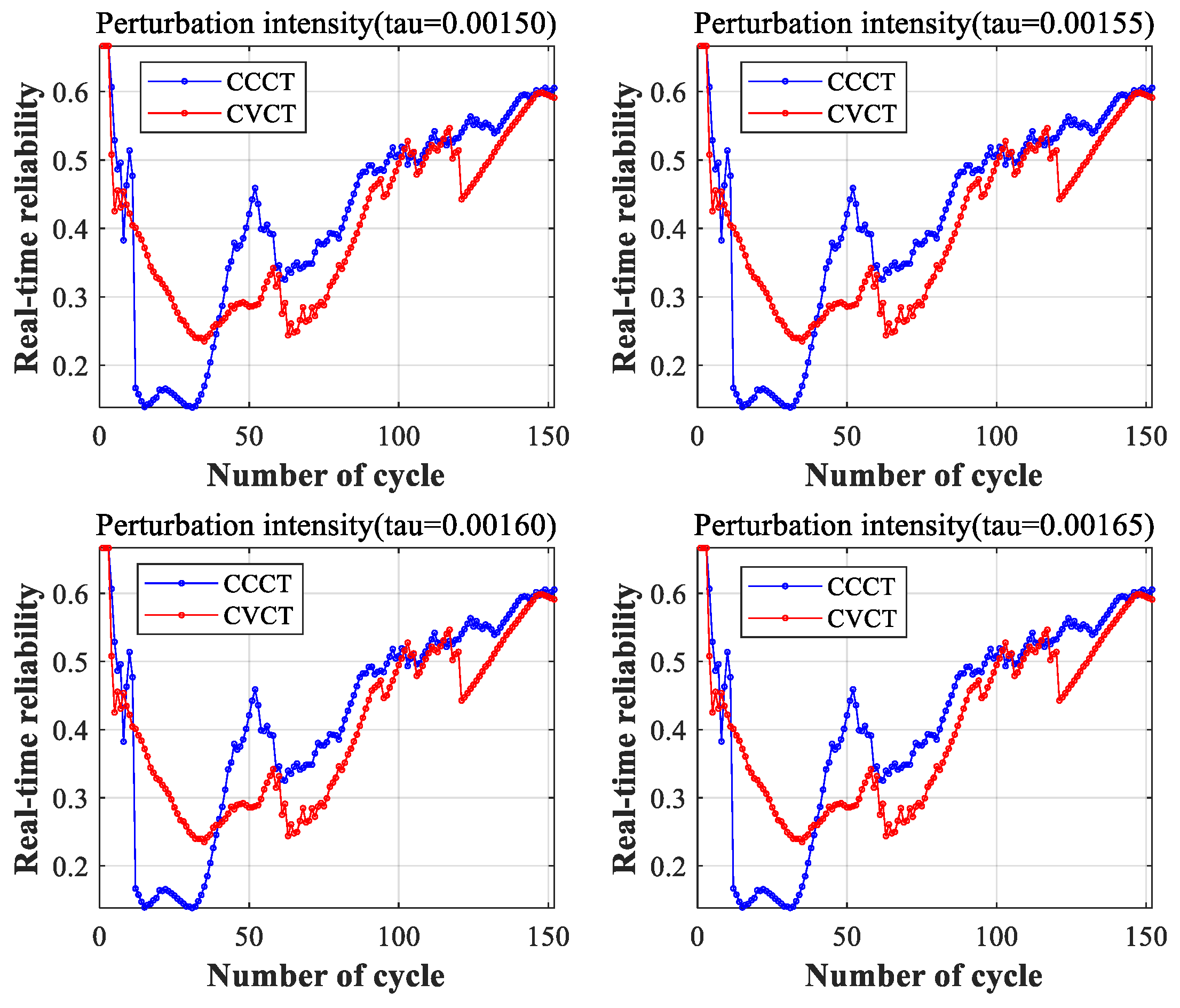

To address the above-mentioned issues, a lithium-ion battery health assessment method based on ER rules with a dynamic reference value (ER-DRV) is proposed. In the ER-DRV model, to deal with the uncertainty of observation indicators, the real-time weights and real-time reliability of evidence are introduced. Additionally, an improved optimization method based on WOA is proposed, which can enhance the search capability of the WOA. This improved WOA (IWOA) optimizes the dynamic reference value of the assessment model. Then, the accuracy of the lithium-ion battery health assessment model is improved by incorporating dynamic reference values, real-time weights, and real-time reliability. Finally, the perturbation analysis method is utilized to analyze the robustness of the health assessment model.

The main contributions of this article are as follows:

- (1)

An ER-DRV model is proposed to evaluate the health state of lithium-ion batteries.

- (2)

In order to enhance the accuracy of the ER-DRV model, an improved WOA optimization method is proposed.

- (3)

The perturbation analysis method is introduced into the ER-DRV model to explore its robustness.

The rest of this article provides a summary of its contents.

Section 2 describes the problems and construction of the ER-DRV health assessment model.

Section 3 explains the inference and optimization process of the ER-DRV health assessment model.

Section 4 provides a detailed description of the perturbation analysis mechanism. Experimental analysis is conducted on an open dataset of lithium-ion batteries in

Section 5. Finally,

Section 6 concludes this article.

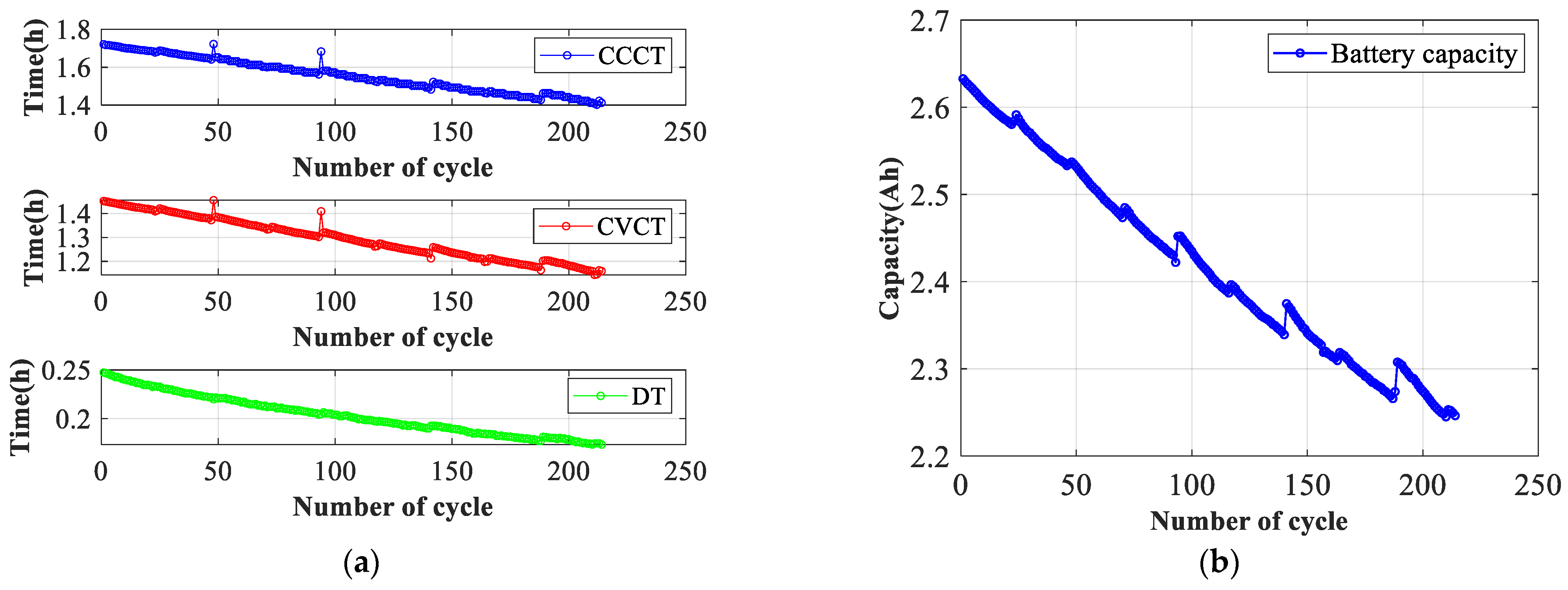

3. The Inference and Optimization Process of the ER-DRV Model

The ER-DRV health assessment model is proposed in this section. In the model, the weight and reliability can be dynamically adjusted in real time to enhance its accuracy and effectiveness. The initial level reference values of the indicator are determined by experts in some models [

19]. However, the accuracy of the model may be compromised due to the limitations of expert knowledge. Therefore, the IWOA is used to optimize the level reference values of the ER-DRV model’s indicators. The optimization goal of the ER-DRV model is to maximize assessment accuracy.

Section 3.1 provides an introduction to the inference process for indicator reliability. In

Section 3.2, the inference process for indicator weight is discussed.

Section 3.3 focuses on the standardization of indicators. In

Section 3.4, a fusion method based on ER rules is introduced.

Section 3.5 describes the optimization process of the ER-DRV model.

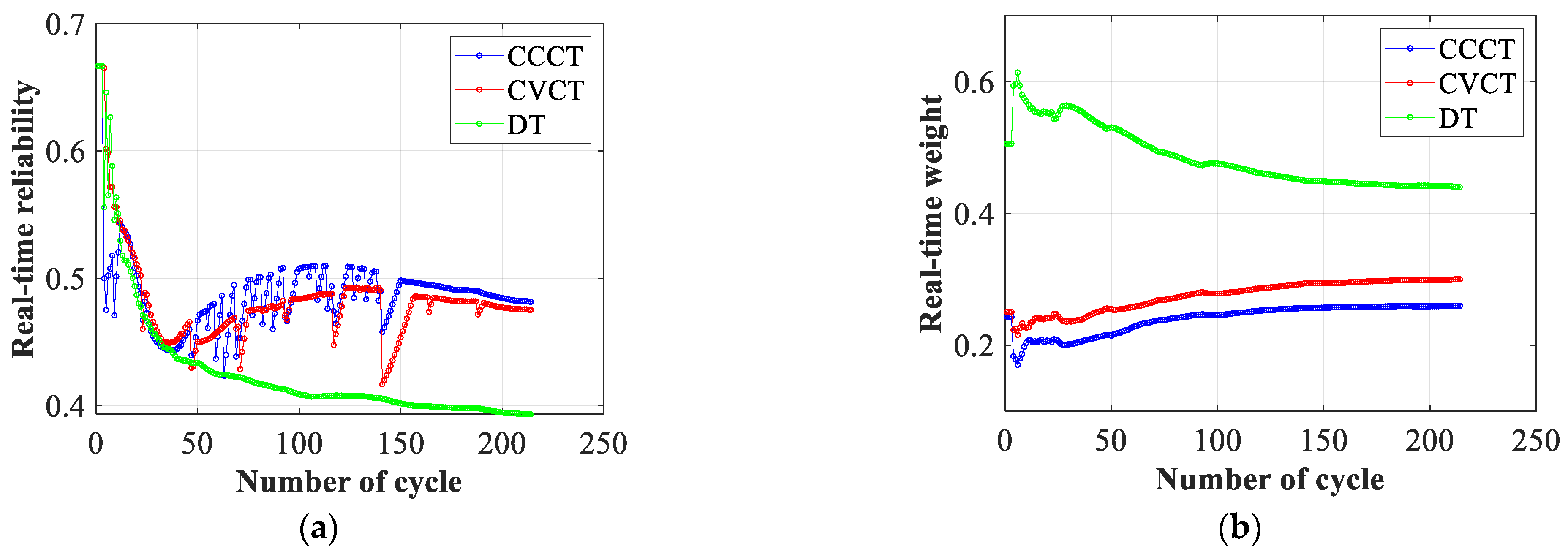

3.1. Indicator Reliability

Reliability is objective and demonstrates an information source’s capacity to provide precise or reliable information [

26]. In engineering applications, observation indicators may be influenced by some disturbance factors, resulting in fluctuations in testing data. Then, the reliability of observation indicators and model accuracy may be affected [

27]. Therefore, when integrating observation indicators, reliability must be considered. Some of the literature has discussed the calculation of reliability using the distance-based method [

19,

20,

26]. Therefore, the indicator reliability is obtained using the distance-based method in this article [

26]. Meanwhile, real-time reliability is applied to improve the effectiveness and accuracy of the health assessment models.

Assume there are

observation indicators, which are represented by

. The total number of cycles is given as

, and

represents the

observation indicator data at cycle

. The average value of the observation indicator

within

is calculated as follows:

The distance between

and

is determined using the following formula:

To determine the mean distance among all indicator data values within

cycles, we use the following formula:

The reliability of indicators can be expressed as

where

is the maximum value of

. The larger

, the more unreliable the indicators. Therefore, it is reasonable to calculate reliability using distance-based methods.

3.2. Indicator Weight

The weight of each indicator reflects its relative importance in the process of evidence fusion. Due to the diversity of indicator data, we set real-time weights based on various conditions. In this article, the coefficient of variation (COV) method is utilized to determine the weight [

19,

20].

The average value of

within

cycles is denoted by

and can be calculated using Formula (4). The mean square error of

within

cycles is denoted by

and can be obtained with the following equation:

The weight of the indicator

can be obtained with the following equation:

where

represents the degree of volatility in

. Volatility refers to how well the indicator responds to unusual data. A higher volatility for an indicator results in a higher weight. As a result, the weight derived using the COV method is deemed to be reasonable.

3.3. Indicator Standardization

There is much uncertain information during the assessment process. Therefore, to quantitatively describe this uncertain information, rule-based methods are used to convert indicator data into the form of belief degrees [

26,

28]. Before the conversion process, it is important to establish a reasonable input indicator health level and a level reference value. This will ensure that the conversion yields accurate and meaningful results.

where the reference value of indicator

is denoted by

. Indicator

is dependent on input data

. The number of assessment levels is represented by the variable

.

is the belief degree, and it satisfies

and

.

3.4. Fusion Method

The ER rule serves as a fusion scheme for integrating indicator information and evidence parameters to effectively represent the health state of batteries. This is achieved using a belief distribution, which combines multiple sources of information to provide a comprehensive depiction of a battery’s condition.

Each input indicator is a piece of independent evidence, which can be represented as

.

can be expressed as evidence

.

represents

reference levels. The evidence is represented in the form of a distribution of belief.

where

represents the belief degree of evidence

within the framework of identification

, which is global ignorance.

Observation indicators are transformed into initial evidence by assigning a belief degree. The reliability of indicators is determined using the method described in

Section 3.1. The calculation method described in

Section 3.2 is utilized to determine the weight of each indicator. Then, ER rules are used to aggregate multiple indicators and obtain the union belief degree

, as follows [

16]:

where the amount of evidence can be expressed as

, and

is used to indicate the number of assessment levels.

represents the combined weight taking into account both the reliability and weight of the evidence. The initial belief degree assigned to the assessment level is represented by

, and

is used to represent the belief degree in the assessment result

, which is the comprehensive assessment result.

The fused belief distribution can be expressed as follows:

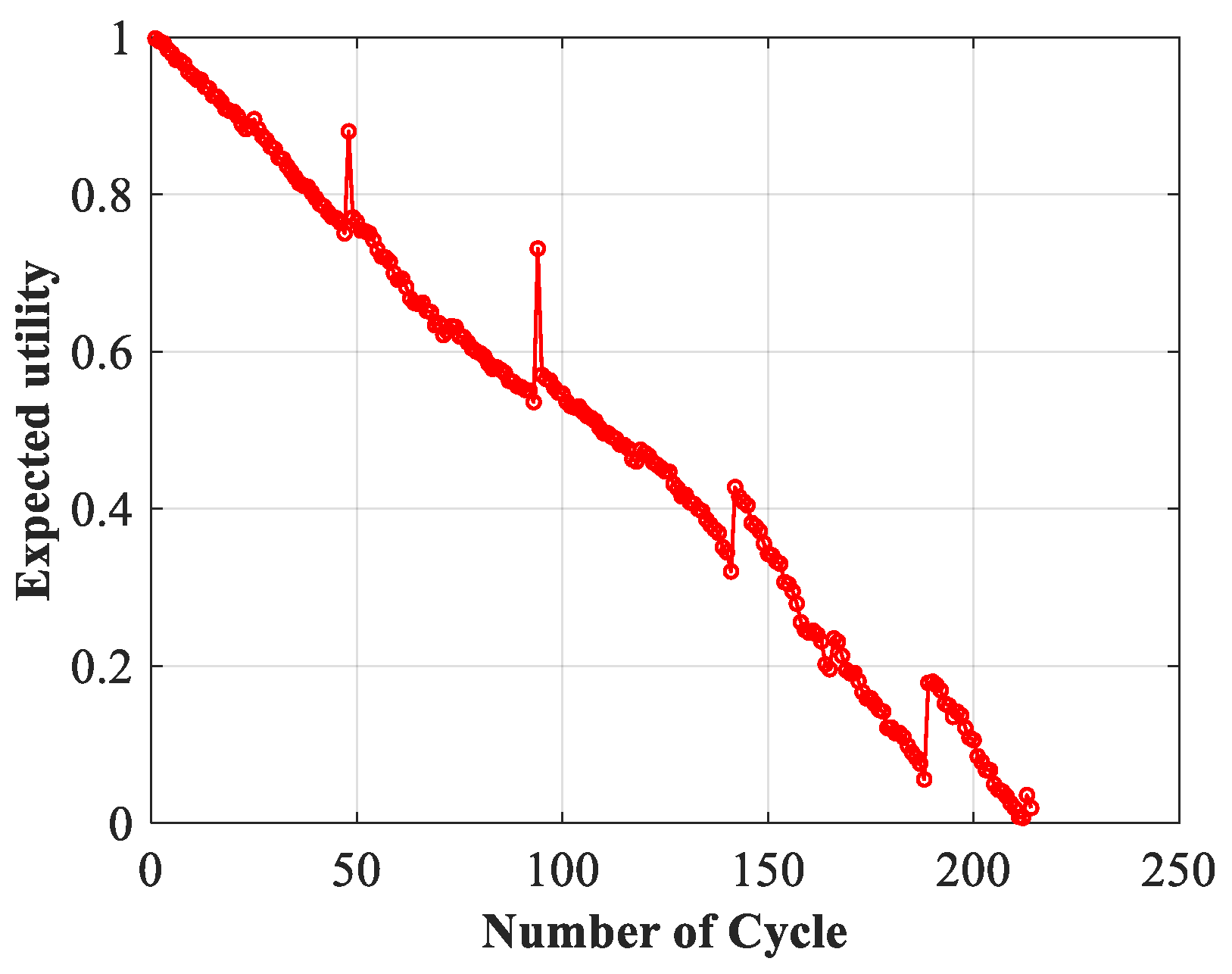

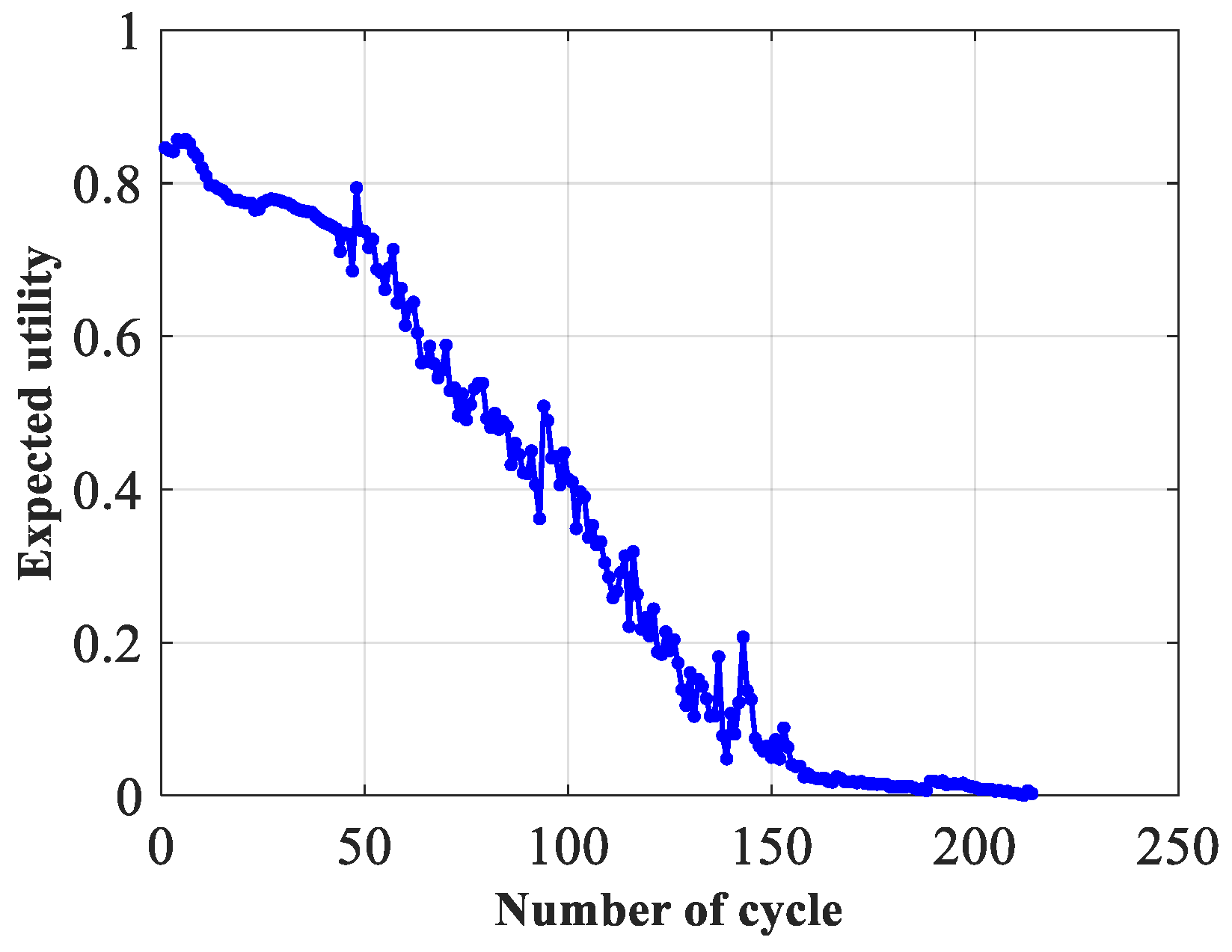

In engineering applications, transforming the belief degree of fused results into expected utility is a useful approach to obtain numerical output results that can be analyzed and interpreted. This transformation allows engineers to quantify the usefulness or value of the fused results, which is essential for decision-making processes.

Once we determine the expected utility values

for all assessment levels, we can calculate the expected utility of the fused results [

24]. By considering the expected utility, we can effectively evaluate and compare the various health assessment results. The way to express the expected utility

of the health assessment results is as follows:

3.5. Optimization of the ER-DRV Model Parameters

The level reference values of indicators play a critical role in determining the aggregate outcome of ER rules [

21]. However, the level reference values of indicators are often given by experts, which leads to unreasonable assessment results. Thus, in this section, we introduce an improved whale optimization algorithm (IWOA). The IWOA is designed to optimize the level reference values of the ER-DRV model.

3.5.1. Improved Whale Optimization Algorithm (IWOA)

The purpose of optimizing level reference values is to improve assessment accuracy, which is the objective function of optimization. Thus, based on the WOA, two strategies are proposed in the IWOA.

Strategy 1: Improve the convergence factor.

The global and local search capabilities of the WOA depend on changes in the convergence factors to strike a balance between exploration and exploitation, ultimately improving the algorithm’s optimization efficiency and effectiveness [

29]. The convergence factor

in the original WOA linearly decreases from 2 to 0, with the same decreasing speed throughout the entire algorithm. However, the newly designed convergence factor decreases non-linearly, which is more suitable for optimizing the level reference values of the ER-DRV model. An improved nonlinear convergence factor

is displayed in Equation (17) and illustrated in

Figure 2a.

where

denotes the convergence factor, reflecting the speed of convergence,

represents the minimum allowable value for the convergence factor, and

represents the maximum allowable value that the convergence factor can reach.

is a variable set by expert knowledge, which can change the convergence speed of the convergence factor.

represents the current iteration count, and

indicates the maximum number of iterations allowed in the process.

In

Figure 2a, it can be seen that the nonlinear convergence factor

decreases nonlinearly with an increasing number of iterations. In the initial stage, the convergence factor

decreases slowly, allowing whales to make larger strides in their movement. This enables them to effectively explore a wide range of possibilities and increase the chance of finding the global optimal solution. However, as the search progresses into the later stage, the convergence factor

decreases rapidly. This means that the whales need to make smaller, more precise strides to fine-tune their search and home in on the optimal solution. Furthermore, it can also be observed that the larger the value of

, the greater the decrease in the convergence factor

. The smaller the value of

, the smaller the decrease in the convergence factor

. The value of

should be reasonably set by experts to ensure good experimental results. Overall, this two-stage process allows whales to first explore broadly and then narrow down their search to find the most accurate and optimal solution.

Strategy 2: Disturbances are introduced.

In the prey encirclement stage of the WOA algorithm, the movement of whale individuals is based on the position of the current population leader in the search space, which can easily lead to the algorithm falling into local optima. To enhance the global convergence accuracy of the algorithm and prevent it from becoming stuck in local optima, disturbances

with uniform distributions

were added after updating the position of whale individuals during the prey encirclement stage. This enhances the algorithm’s ability to overcome local optima and achieve better search optimization in both the initial and final stages. The disturbance formulas are as follows:

where

represents a whale individual before a disturbance,

represents the whale individual after adding the disturbance,

represents the relative error level set by expert knowledge, where

, and

is a randomly selected number from a uniform distribution

.

The disturbance value obtained increases as the relative error level increases, as shown in

Figure 2b. In the experiment, it is necessary to set the relative error level

reasonably to ensure better experimental results.

3.5.2. The Optimization Process of the ER-DRV Model’s Parameters

In recent research, various optimization algorithms have been utilized to enhance the health assessment of lithium-ion batteries [

6]. Among them, the WOA is used across multiple fields, including classification tasks, robot trajectories, image processing applications, networks, and task scheduling, due to its simplicity of operation, few adjustable parameters, and strong ability to escape local optima [

29,

30,

31].

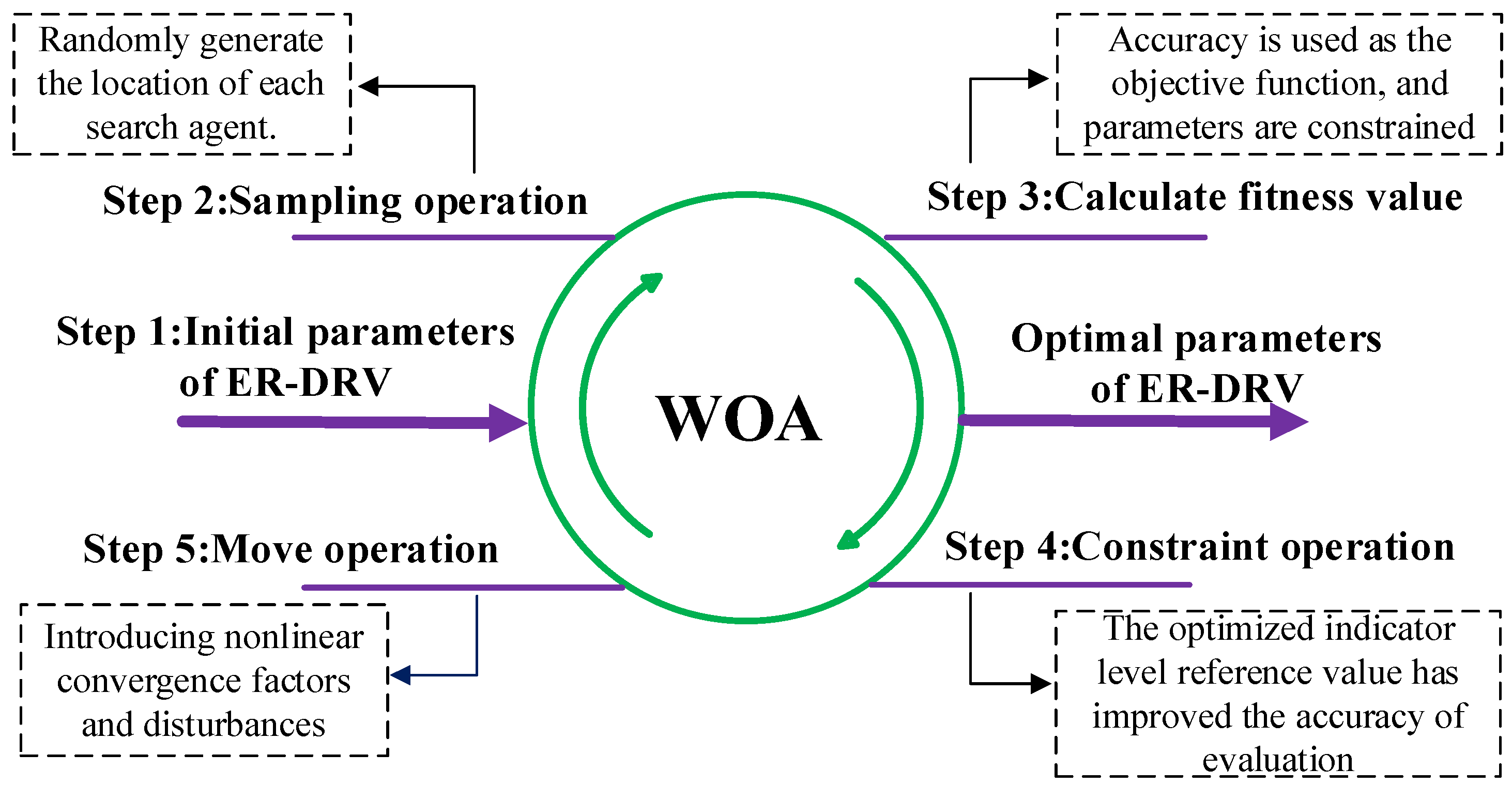

This article presents an improved version of the WOA, as depicted in

Figure 3, with the following specific steps:

Step 1 (Initialization): The variable represents the initial population of whales. The number of iterations of the search algorithm is denoted by the variable . The maximum number of iterations allowed is denoted by the variable . The dimensions of the search space, which represent the number of variables in the optimization problem, are denoted by the variable .

Step 2 (Sample operations): Randomly generate the location of each search agent .

Step 3 (Determine fitness): The objective of this article is to enhance the assessment accuracy of the model. To achieve this, an objective function for optimization was developed and is explained as follows:

where

is the accuracy of the assessment without perturbations.

represents the number of assessed lithium-ion battery statuses that match the actual status.

represents the total number of performance statuses.

is the accuracy of the assessment under perturbations.

represents the number of assessed lithium-ion battery statuses that match the actual status under perturbations.

represents the total number of the performance statuses under perturbations.

Step 4 (Constraint operation): Combining indicator data and expert knowledge, the upper and lower limits of constraint conditions were set.

where

represents the initial level reference value, and

and

represent the lower and upper bounds of

.

represents the coefficient that limits excessive overlap between different levels. The values of (

,

,

) are determined by expert knowledge and the observational indicator data.

Step 5 (Exploration and exploitation): When

and

, humpback whales can capture prey and surround them. Because the exact location of the optimal solution in the search space is uncertain, the WOA operates under the assumption that the current best candidate solution represents the target prey or is in close proximity to the optimal solution. This assumption helps guide the search toward potentially better solutions and reduces the chances of becoming stuck in suboptimal regions. Once the best search agent is determined, other search agents strive to adjust their positions to match that of the best search agent. This process is described by the following two formulas:

where

and

denote the coefficient vector, the current whale’s position can be expressed as vector

, and

represents the current iteration number. The vectors

and

can also be expressed using the following equation:

where

is a random vector on the interval

.

represents the upper limit of the number of iterations, and the linear convergence factor of the WOA can be expressed as

. To improve the balance between exploration and exploitation in optimizing the ER-DRV model, a transformation is applied to convert

into a convergent decreasing form that is nonlinear.

To prevent the WOA from becoming trapped in local optima during optimization, random disturbances are introduced. This process is described in (18) and (19).

When

and

, humpback whales exhibit a unique foraging behavior that can be described as “randomly searching for prey”. This process can also be expressed using the following equation:

where

denotes the position of randomly selected whales. When

, the positions of other whales are updated based on the randomly selected whale positions, forcing the whales to stay away from their prey and find more suitable prey. This can enhance the algorithm’s exploration ability and enable the WOA to conduct global searches.

When

, humpback whales use a distinct hunting strategy in which they encircle their prey in a spiral formation of bubbles. They then utilize a spiral contraction approach to efficiently capture their intended target. This process can be represented by the following formula:

where

represents the distance separating a humpback whale from its prey,

denotes the constant of the spiral motion trajectory, and

represents random numbers between intervals

.

6. Conclusions

In this article, a health assessment model based on evidence reasoning rules with dynamic reference values for lithium-ion batteries is proposed. Meanwhile, an improved WOA method is used to optimize the level reference value of the model for improving assessment accuracy. Moreover, the robustness of the model was studied using perturbation analysis methods. The effectiveness and generalization ability of the model is illustrated using two open lithium-ion battery datasets as examples.

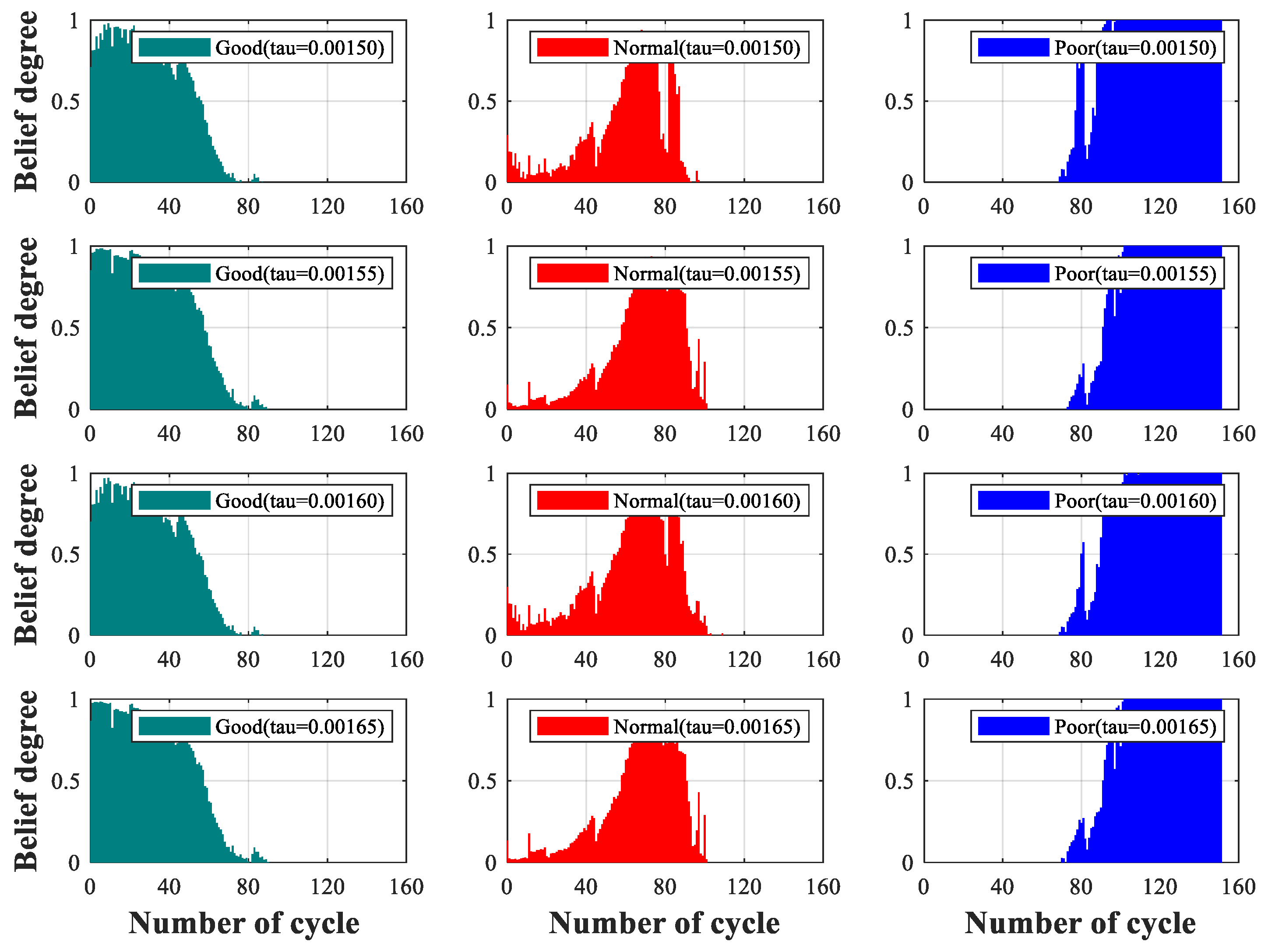

There are three main contributions of this paper. Firstly, the nonlinear convergence factor and disturbances are introduced into the WOA, and an improved WOA is proposed for optimizing level reference values. Secondly, the distance-based method and the coefficient of variation method are used to obtain real-time reliability and real-time weight. Then, the IWOA is used to obtain dynamic level reference values. Therefore, the accuracy of the model assessment is improved. Thirdly, to study the robustness of the ER-DRV model, perturbation variables and perturbation intensities are added to the observation indicators. Using experiments, it was found that perturbations can lead to a decrease of about 2% in model’s accuracy. The experimental results demonstrate that the proposed ER-DRV model effectively evaluates the health state of lithium-ion batteries. Furthermore, it exhibits remarkable robustness and generalization capability.

In the future, it is necessary to develop a reasonable method to reduce the impact of perturbation on the assessment results and improve assessment accuracy. It is important to focus future work on addressing these challenges.