Fabrication and Magneto-Optical Property of (Dy0.7Y0.25La0.05)2O3 Transparent Ceramics by PLSH Technology

Abstract

:1. Introduction

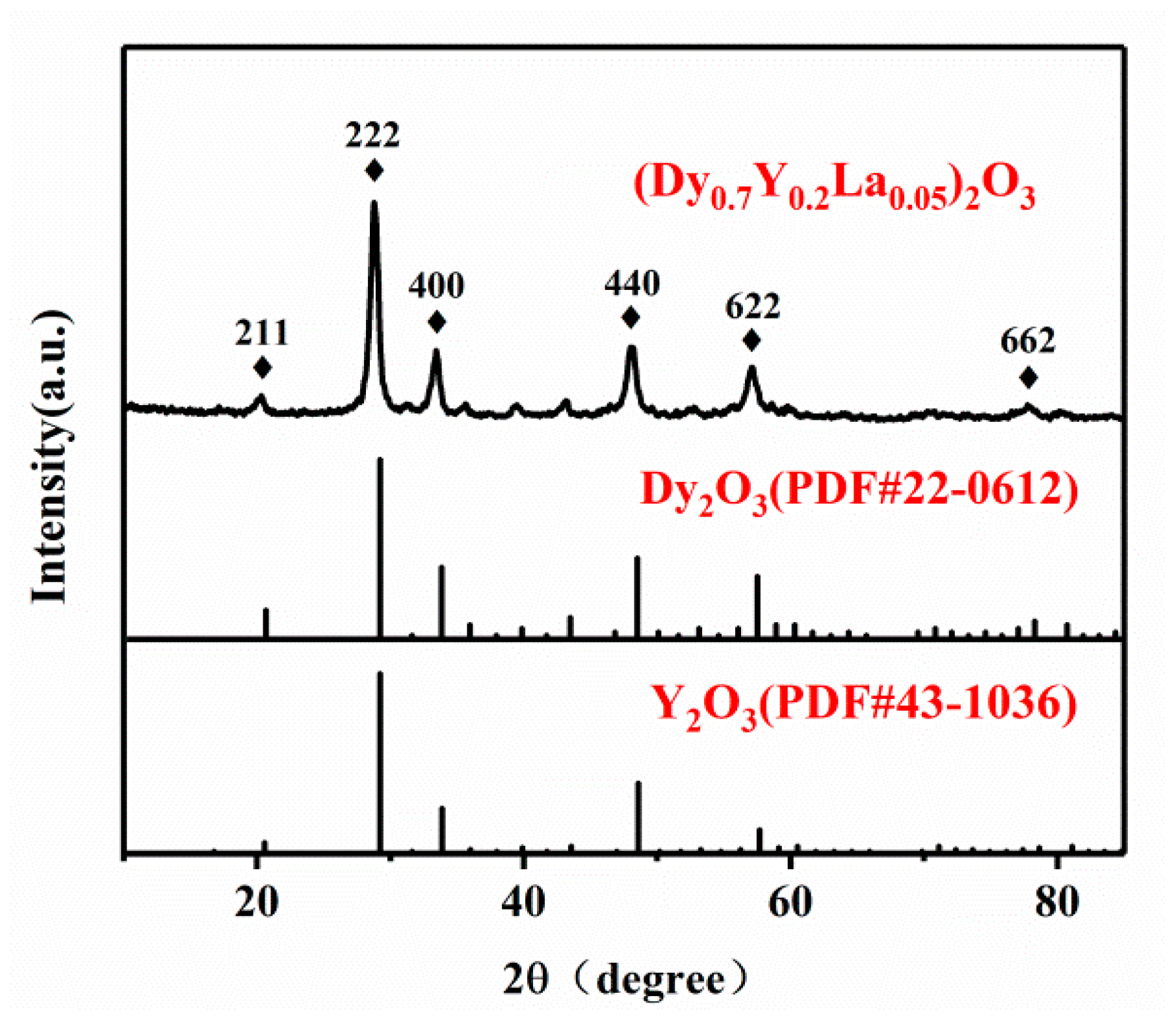

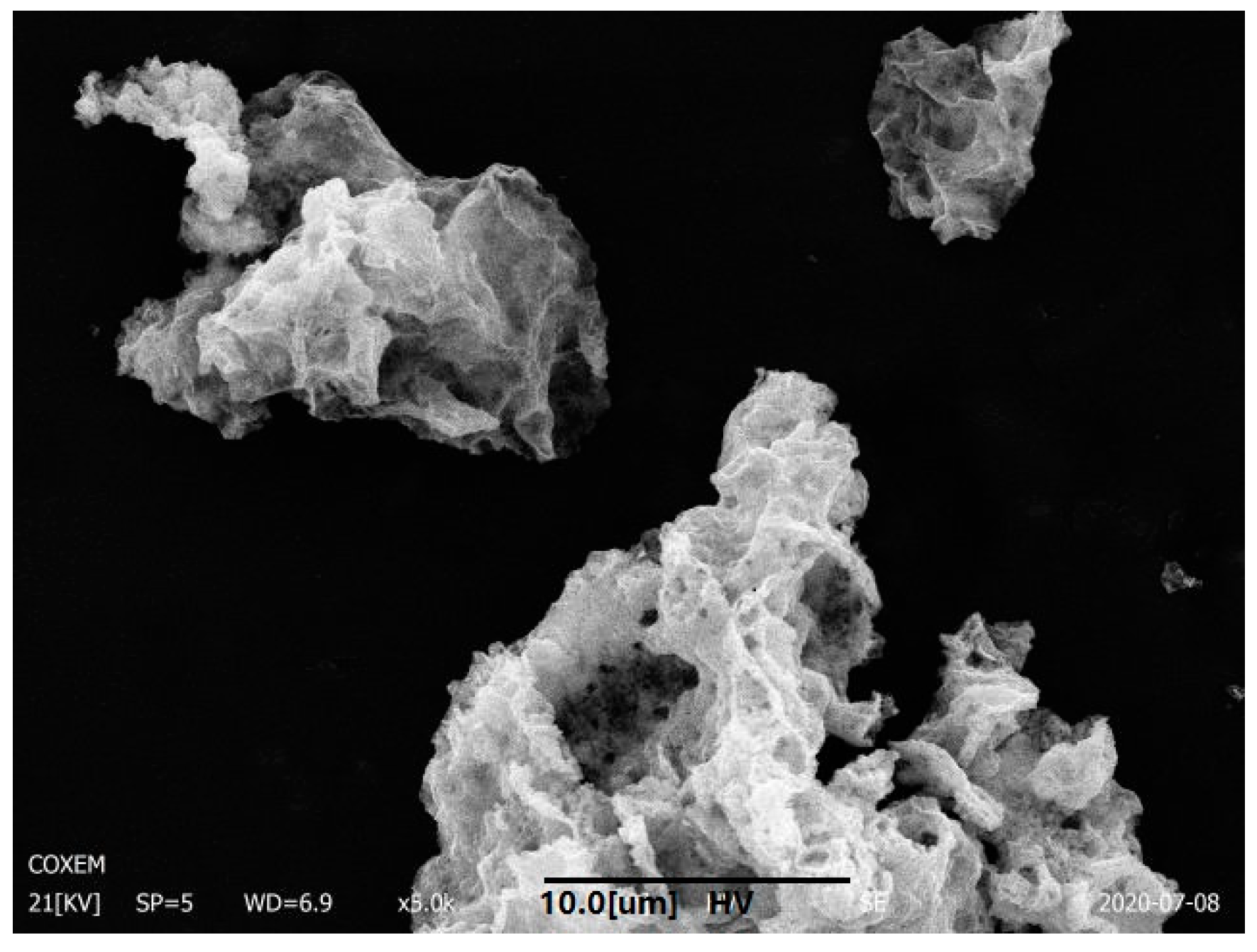

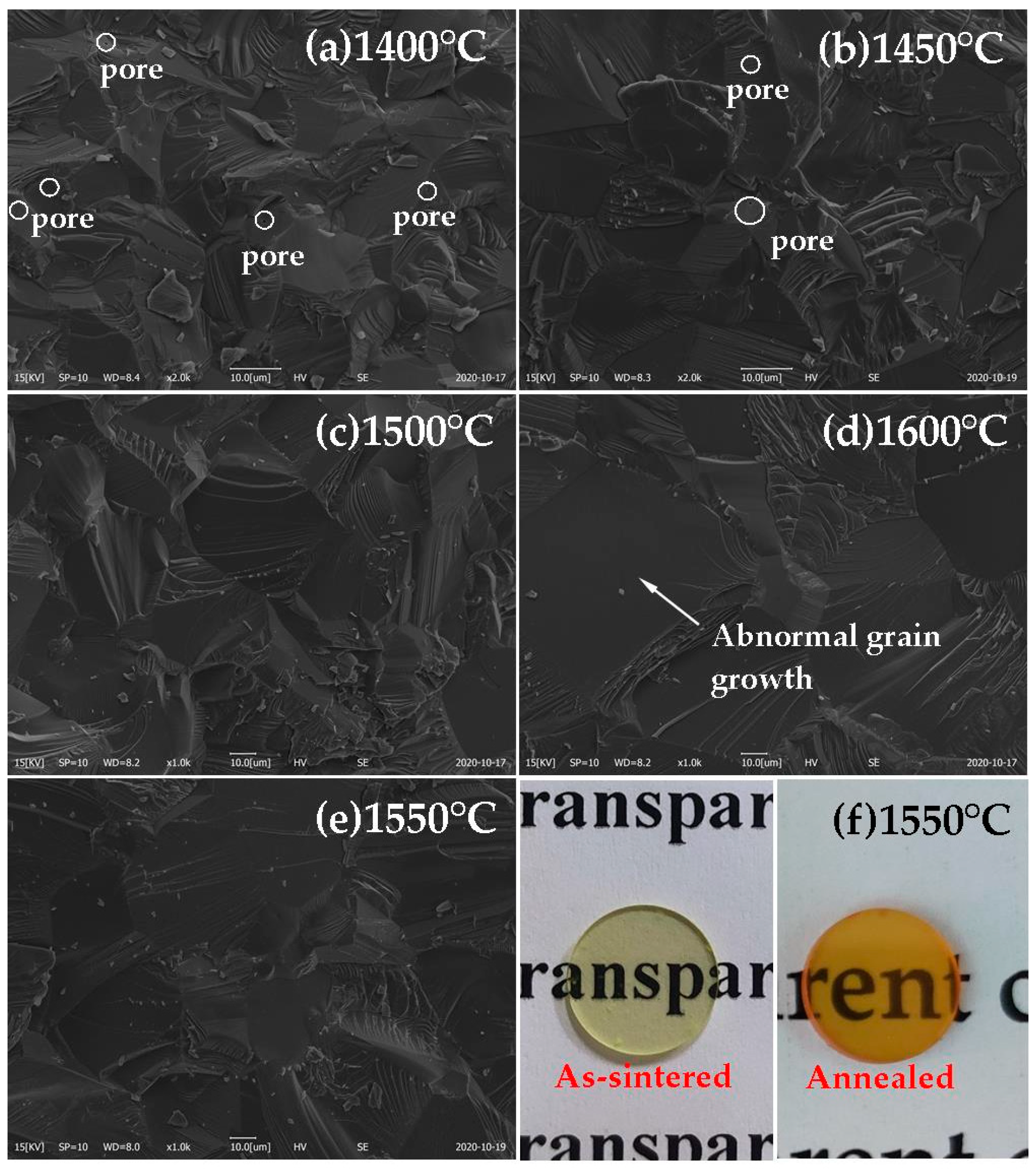

2. Results and Discussion

3. Materials and Methods

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dai, J.W.; Li, J. Promising magneto-optical ceramics for high power Faraday isolators. Scr. Mater. 2018, 155, 78–84. [Google Scholar] [CrossRef]

- Yang, M.; Zhou, D.; Xu, J.; Tian, T.; Jia, R.; Wang, Z. Fabrication and magneto-optical property of yttria stabilized Tb2O3 transparent ceramics. J. Eur. Ceram. Soc. 2019, 39, 5005–5009. [Google Scholar] [CrossRef]

- Banerjee, S.; Ertel, K.; Mason, P.D.; Phillips, P.J.; Siebold, M.; Loeser, M.; Hernandez-Gomez, C.; Collier, J.L. High-efficiency 10 J diode pumped cryogenic gas cooled Yb:YAG multislab amplifier. Opt. Lett. 2012, 37, 2175–2177. [Google Scholar] [CrossRef] [PubMed]

- Kaminskii, A.A.; Eichler, H.J.; Reiche, P.; Uecker, R. SRS risk potential in Faraday rotator Tb3Ga5O12 crystals for high-peak power lasers. Laser Phys. Lett. 2005, 2, 489–492. [Google Scholar] [CrossRef]

- Balabanov, S.S.; Permin, D.A.; Rostokina, E.Y.; Palashov, O.V.; Snetkov, I.L. Characterizations of REE: Tb2O3 Magneto-Optical Ceramics. Phys. Status Solidi B 2020, 257, 1900474. [Google Scholar] [CrossRef]

- Veber, P.; Velázquez, M.; Gadret, G.; Rytz, D.; Peltz, M.; Decourt, R. Flux growth at 1230 °C of cubic Tb2O3 single crystals and characterization of their optical and magnetic properties. CrystEngComm 2015, 17, 492–497. [Google Scholar] [CrossRef]

- Furuse, H.; Yasuhara, R. Magneto-optical characteristics of holmium oxide (Ho2O3) ceramics. Opt. Mater. Express 2017, 7, 827–833. [Google Scholar] [CrossRef]

- Morales, J.R.; Amos, N.; Khizroev, S.; Garay, J.E. Magneto-optical Faraday effect in nanocrystalline oxides. J. Appl. Phys. 2011, 109, 093110. [Google Scholar] [CrossRef]

- Snetkov, I.L.; Yakovlev, A.I.; Permin, D.A.; Balabanov, S.S.; Palashov, O.V. Magneto-optical Faraday effect in dysprosium oxide (Dy2O3) based ceramics obtained by vacuum sintering. Opt. Lett. 2018, 43, 4041–4044. [Google Scholar] [CrossRef] [PubMed]

- Aung, Y.L.; Ikesue, A.; Yasuhara, R.; Iwamoto, Y. Magneto-optical Dy2O3 ceramics with optical grade. Opt. Lett. 2020, 45, 4615–4617. [Google Scholar] [CrossRef] [PubMed]

- Balabanov, S.; Filofeev, S.; Ivanov, M.; Kaigorodov, A.; Krugovykh, A.; Kuznetsov, D.; Permin, D.; Popov, P.; Rostokina, E. Fabrication and characterizations of erbium oxide based optical ceramics. Opt. Mater. 2020, 101, 109732. [Google Scholar] [CrossRef]

- Permin, D.A.; Balabanov, S.S.; Novikova, A.V.; Snetkov, I.L.; Palashov, O.V.; Sorokin, A.A.; Ivanov, M.G. Fabrication of Yb-doped Lu2O3-Y2O3-La2O3 solid solutions transparent ceramics by self-propagating high-temperature synthesis and vacuum sintering. Ceram. Int. 2019, 45, 522–529. [Google Scholar] [CrossRef]

- Permin, D.A.; Boldin, M.S.; Belyaev, A.V.; Balabanov, S.S.; Novikova, A.V.; Koshkin, V.A.; Murashov, A.A.; Ladenkov, I.V.; Popov, A.A.; Lantsev, E.A.; et al. IR-transparent MgO-Y2O3 ceramics by self-propagating high-temperature synthesis and spark plasma sintering. Ceram. Int. 2020, 46, 15786–15792. [Google Scholar] [CrossRef]

- Permin, D.A.; Balabanov, S.S.; Snetkov, I.L.; Palashov, O.V.; Novikova, A.V.; Klyusik, O.N.; Ladenkov, I.V. Hot pressing of Yb:Sc2O3 laser ceramics with LiF sintering aid. Opt. Mater. 2020, 100, 109701. [Google Scholar] [CrossRef]

- Kruk, A.; Brylewski, T.; Mrózek, M. Optical and magneto-optical properties of Nd0.1La0.1Y1.8O3 transparent ceramics. J. Lumin. 2019, 209, 333–339. [Google Scholar] [CrossRef]

- Permin, D.A.; Novikova, A.V.; Gavrishchuk, E.M.; Balabanov, S.S.; Sorokin, A.A. Self-Propagating High-Temperature Synthesis of Lu2O3 Powders for Optical Ceramics. Inorg. Mater. 2017, 53, 1330–1335. [Google Scholar] [CrossRef]

- Permin, D.A.; Gavrishchuk, E.M.; Klyusik, O.N.; Novikova, A.V.; Sorokin, A.A. Preparation of optical ceramics based on highly dispersed powders of scandium oxide. J. Opt. Technol. 2018, 85, 58–62. [Google Scholar] [CrossRef]

- Permin, D.A.; Kurashkin, S.V.; Novikova, A.V.; Savikin, A.P.; Gavrishchuk, E.M.; Balabanov, S.S.; Khamaletdinovaa, N.M. Synthesis and luminescence properties of Yb-doped Y2O3, Sc2O3 and Lu2O3 solid solutions nanopowders. Opt. Mater. 2018, 77, 240–245. [Google Scholar] [CrossRef]

- Balabanov, S.S.; Permin, D.A.; Rostokina, E.Y.; Egorov, S.V.; Sorokin, A.A.; Kuznetsov, D.D. Synthesis and structural characterization of ultrafine terbium oxide powders. Ceram. Int. 2017, 43, 16569–16574. [Google Scholar] [CrossRef]

- Babayevskaya, N.V.; Deyneka, T.G.; Mateychenko, P.V.; Matveevskaya, N.A.; Tolmachev, A.V.; Yavetskiy, R.P. Fabrication and characterization of Lu2O3:Eu3+ nanopowders and X-ray films. J. Alloys Compd. 2010, 507, L26–L31. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, D.; Li, X.; Wang, T.; Xu, J.; Wang, Z.; Shi, Y.; Permin, D.; Balabanov, S.S. Fabrication and Magneto-Optical Property of (Dy0.7Y0.25La0.05)2O3 Transparent Ceramics by PLSH Technology. Magnetochemistry 2020, 6, 70. https://doi.org/10.3390/magnetochemistry6040070

Zhou D, Li X, Wang T, Xu J, Wang Z, Shi Y, Permin D, Balabanov SS. Fabrication and Magneto-Optical Property of (Dy0.7Y0.25La0.05)2O3 Transparent Ceramics by PLSH Technology. Magnetochemistry. 2020; 6(4):70. https://doi.org/10.3390/magnetochemistry6040070

Chicago/Turabian StyleZhou, Ding, Xiaohui Li, Tun Wang, Jiayue Xu, Zhanyong Wang, Ying Shi, Dmitry Permin, and Stanislav S. Balabanov. 2020. "Fabrication and Magneto-Optical Property of (Dy0.7Y0.25La0.05)2O3 Transparent Ceramics by PLSH Technology" Magnetochemistry 6, no. 4: 70. https://doi.org/10.3390/magnetochemistry6040070

APA StyleZhou, D., Li, X., Wang, T., Xu, J., Wang, Z., Shi, Y., Permin, D., & Balabanov, S. S. (2020). Fabrication and Magneto-Optical Property of (Dy0.7Y0.25La0.05)2O3 Transparent Ceramics by PLSH Technology. Magnetochemistry, 6(4), 70. https://doi.org/10.3390/magnetochemistry6040070