Postharvest Preservation of Thai Mango var. Chok-Anan by the Combination of Pulsed Electric Field and Chemical Pickling

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mango Fruit and Sucrose Solutions Preparations

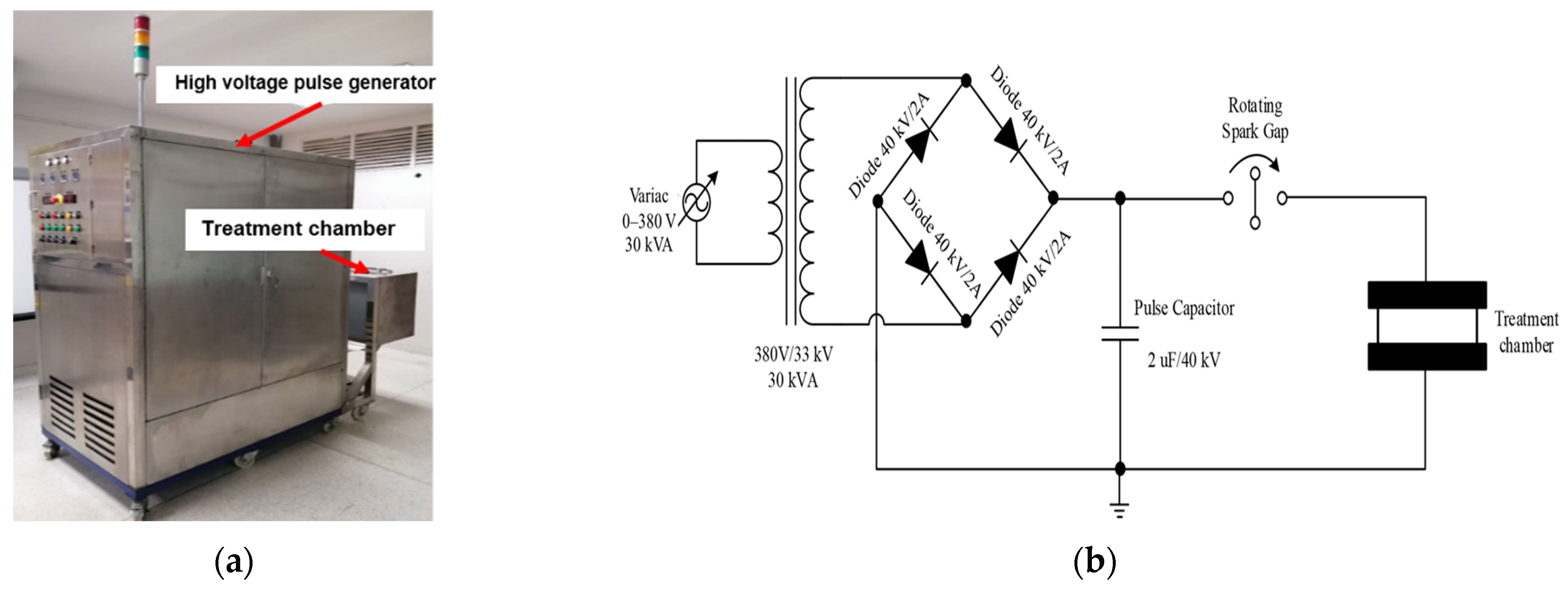

2.2. PEF Equipment

2.3. PEF-Assisted Pickling Process

2.4. Conventional Pickling Process

2.5. Water Loss, Solids Gain, and Effective Diffusivity

2.6. Physicochemical Analysis

2.6.1. Moisture Content, Water Activity, and pH

2.6.2. Surface Color of the Mango

2.6.3. Beta-Carotene Content

2.6.4. Ascorbic Acid Content

2.7. Texture Analysis

2.8. Electrical Conductivity Disintegration Index (Z)

2.9. Surface Morphology

2.10. Statistical Analysis

3. Results and Discussion

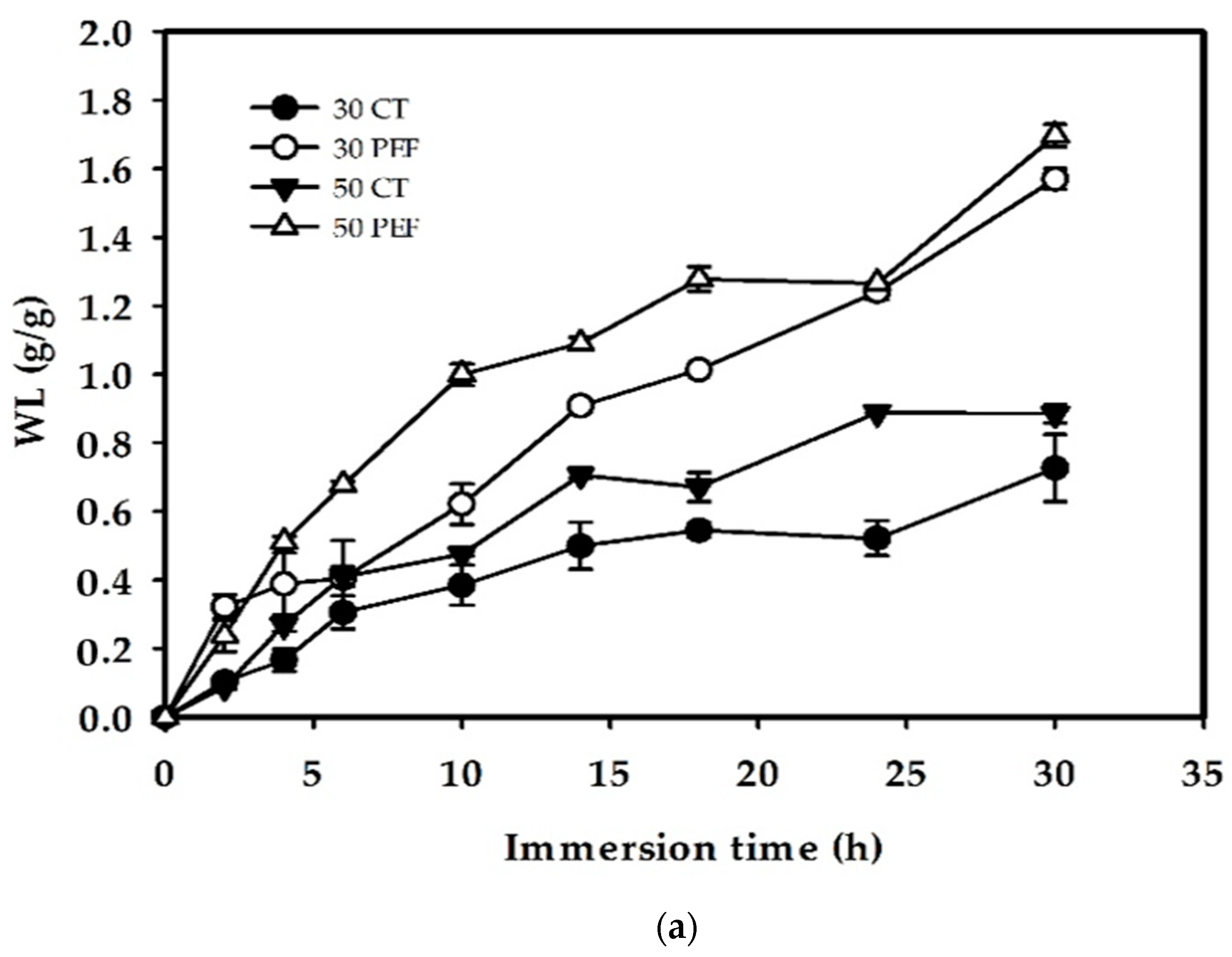

3.1. Effect of PEF-Assisted Pickling Process on Water Loss, Solids Gain, and Diffusion Efficiency

3.2. Effect of the PEF-Assisted Pickling Process on Moisture Content, Water Activity, and pH

3.3. Effect of the PEF-Assisted Pickling Process on Appearance and Color

3.4. Effect of PEF-Assisted Pickling Process on Texture Properties

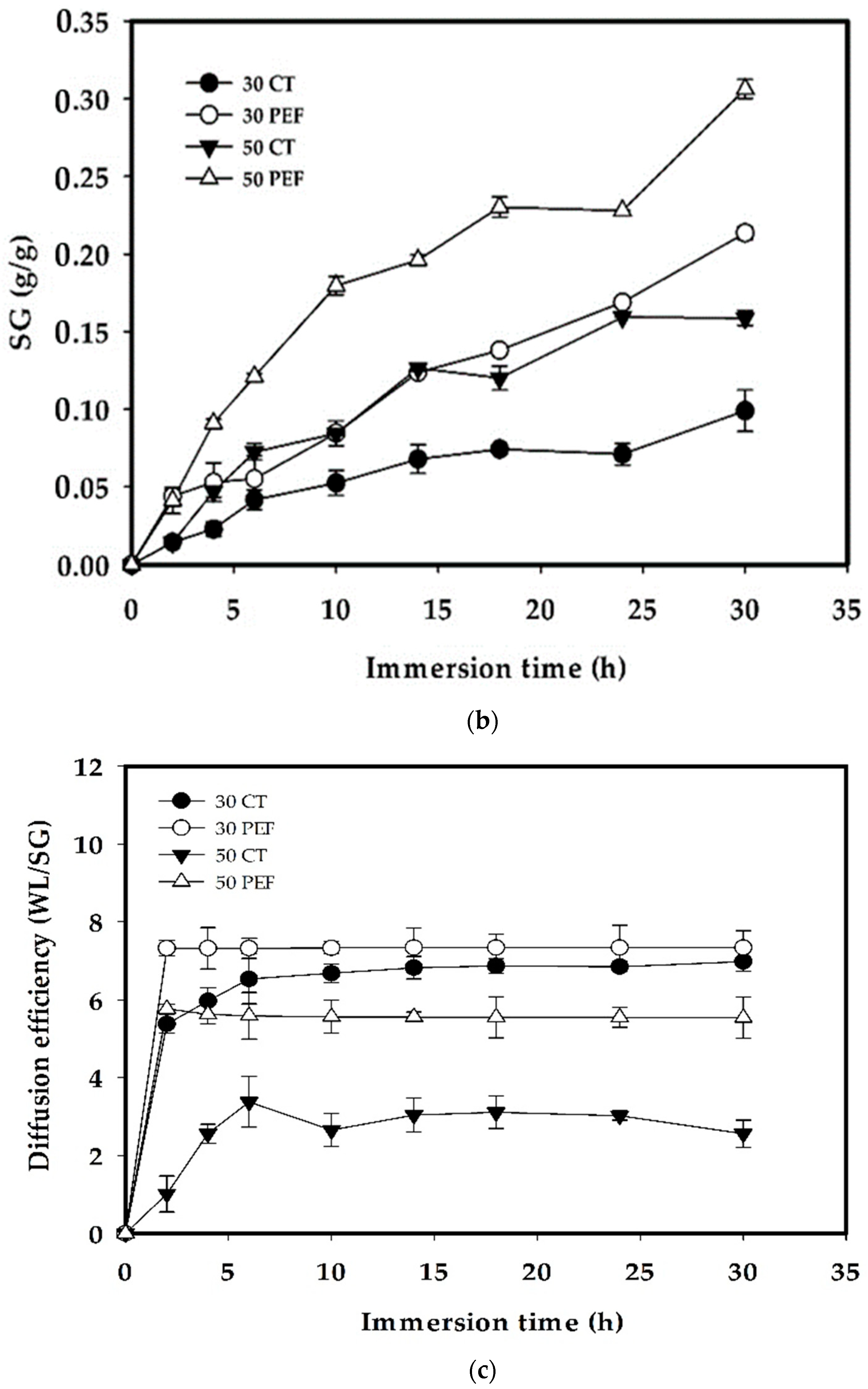

3.5. Effect of the PEF-Assisted Pickling Process on Beta-Carotene and Ascorbic Acid Content

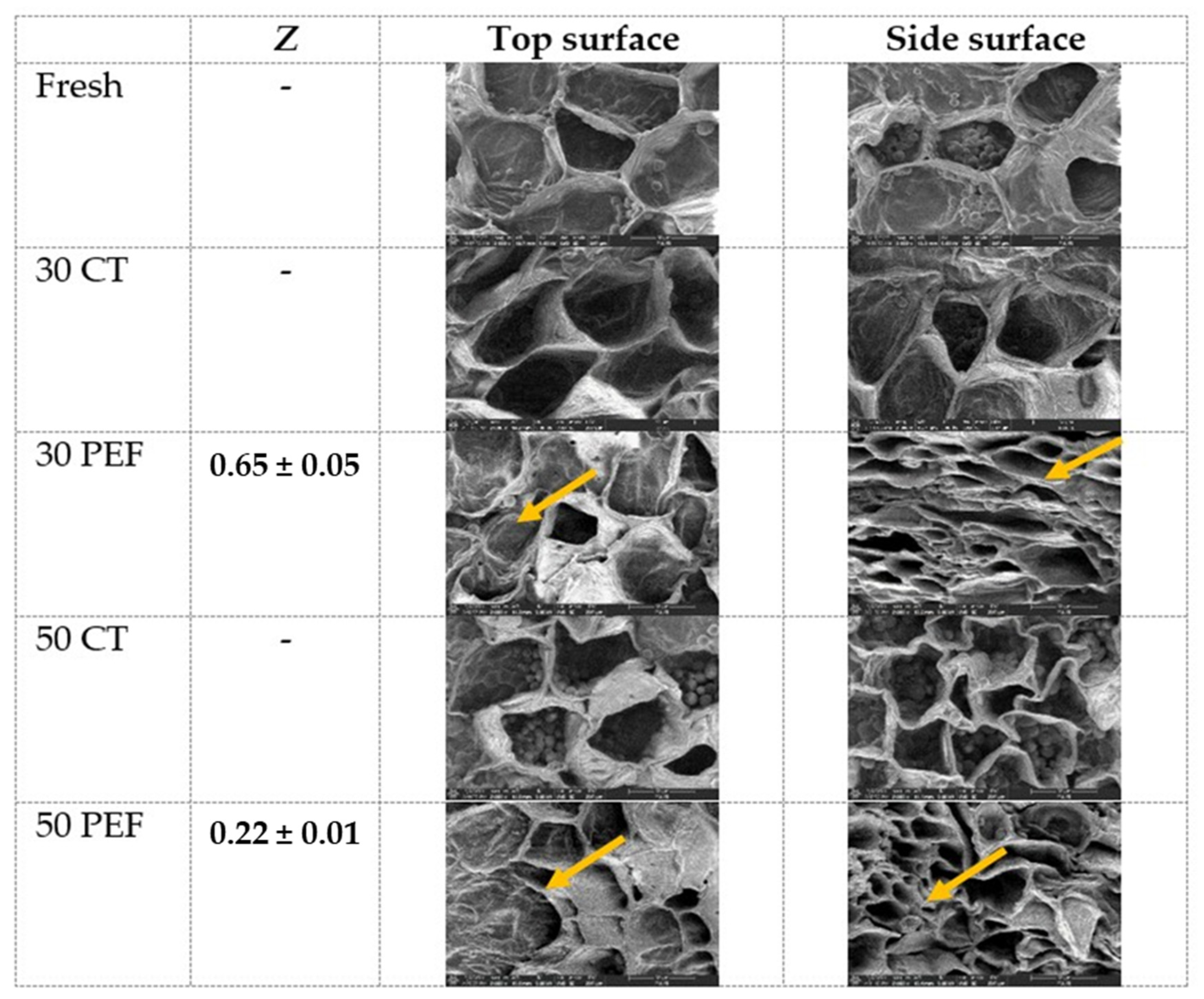

3.6. Effect of the PEF-Assisted Pickling Process on Microstructure and Cell Disintegration (Z)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Muchiri, D.R.; Mahungu, S.M.; Gituanja, S.N. Studies on mango (Mangifera indica L.) kernel fat of some Kenyan varieties in Meru. J. Am. Oil Chem. Soc. 2012, 89, 1567–1575. [Google Scholar] [CrossRef]

- Pérez Pulido, R.; Grande Burgos, M.J.; Gálvez, A.; Lucas, R. Changes in bacterial diversity of refrigerated mango pulp before and after treatment by high hydrostatic pressure. LWT 2017, 78, 289–295. [Google Scholar] [CrossRef]

- Tharanathan, R.N.; Yashoda, H.M.; Prabha, T.N. Mango (Mangifera indica L.),“The king of fruits”—An overview. Food Rev. Int. 2006, 22, 95–123. [Google Scholar] [CrossRef]

- Wongkaew, M.; Sangta, J.; Chansakaow, S.; Jantanasakulwong, K.; Rachtanapun, P.; Sommano, S.R. Volatile profiles from over-ripe purée of Thai mango varieties and their physiochemical properties during heat processing. PLoS ONE 2021, 16, e0248657. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Yeoh, W.K.; Forney, C.; Siddiqui, M.W. Advances in postharvest technologies to extend the storage life of minimally processed fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2018, 58, 2632–2649. [Google Scholar] [CrossRef] [PubMed]

- Khaliq, G.; Mohamed, M.T.M.; Ding, P.; Ghazali, H.M.; Ali, A. Storage behaviour and quality responses of mango (Mangifera indica L.) fruit treated with chitosan and gum arabic coatings during cold storage conditions. Int. Food Res. J. 2016, 23, S141–S148. [Google Scholar]

- Owino, W.O.; Ambuko, J.L. Mango fruit processing: Options for small-scale processors in developing countries. Agriculture 2021, 11, 1105. [Google Scholar] [CrossRef]

- Ashwani, K.; Amarjeet, S.; Monika, S. Standardization of recipe and method for mango chutney. Haryana J. Hortic. Sci. 2010, 39, 247–249. [Google Scholar]

- Montaño, A.; Sánchez, A.H.; Beato, V.M.; López-López, A.; de Castro, A. Pickling; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 369–374. ISBN 978-0-12-384953-3. [Google Scholar]

- Kumari, A.; Angmo, K.; Bhalla, T.C. Traditional Pickles of Himachal Pradesh. Indian J. Tradit. Knowl. 2016, 15, 330–336. [Google Scholar]

- Acosta, O.; Gao, X.; Sullivan, E.K.; Padilla-Zakour, O.I. Pickled egg production: Effect of brine acetic acid concentration and packing conditions on acidification rate. J. Food Prot. 2014, 77, 788–795. [Google Scholar] [CrossRef]

- Behera, S.S.; El Sheikha, A.F.; Hammami, R.; Kumar, A. Traditionally fermented pickles: How the microbial diversity associated with their nutritional and health benefits? J. Funct. Foods 2020, 70, 103971. [Google Scholar] [CrossRef]

- Indrati, N.; Sumpavapol, P.; Samakradhamrongthai, R.S.; Phonsatta, N.; Poungsombat, P.; Khoomrung, S.; Panya, A. Volatile and non-volatile compound profiles of commercial sweet pickled mango and its correlation with consumer preference. Int. J. Food Sci. Technol. 2022, 57, 3760–3770. [Google Scholar] [CrossRef]

- Uthairungsri, N.; Kijroongrojana, K.; Sumpavapol, P. Development of sorbet from sweet pickled mango syrup. Veridian E-J. Sci. Technol. Silpakorn Univ. 2019, 6, 85–97. [Google Scholar]

- Zhang, Y.; Zielinska, M.; Vidyarthi, S.K.; Zhao, J.-H.; Pei, Y.-P.; Li, G.; Zheng, Z.-A.; Wu, M.; Gao, Z.-J.; Xiao, H.-W. Pulsed pressure pickling enhances acetic acid transfer, thiosulfinates degradation, color and ultrastructure changes of “Laba” garlic. Innov. Food Sci. Emerg. Technol. 2020, 65, 102438. [Google Scholar] [CrossRef]

- Zhang, Y.; Zielinska, M.; Li, G.-F.; Deng, L.-Z.; Sun, B.-H.; Zheng, Z.-A.; Gao, Z.-J.; Xiao, H.-W. Pulsed vacuum pickling (PVP) of garlic cloves: Mass transfer kinetics and quality attributes. Dry. Technol. 2020, 38, 712–723. [Google Scholar] [CrossRef]

- Li, J.; Shi, J.; Wang, T.; Huang, X.; Zou, X.; Li, Z.; Zhang, D.; Zhang, W.; Xu, Y. Effects of pulsed electric field pretreatment on mass transfer kinetics of pickled lotus root (Nelumbo nucifera Gaertn.). LWT 2021, 151, 112205. [Google Scholar] [CrossRef]

- Arshad, R.N.; Abdul-Malek, Z.; Munir, A.; Buntat, Z.; Ahmad, M.H.; Jusoh, Y.M.M.; Bekhit, A.E.-D.; Roobab, U.; Manzoor, M.F.; Aadil, R.M. Electrical systems for pulsed electric field applications in the food industry: An engineering perspective. Trends Food Sci. Technol. 2020, 104, 1–13. [Google Scholar] [CrossRef]

- Dermesonlouoglou, E.; Zachariou, I.; Andreou, V.; Taoukis, P.S. Effect of pulsed electric fields on mass transfer and quality of osmotically dehydrated kiwifruit. Food Bioprod. Process. 2016, 100, 535–544. [Google Scholar] [CrossRef]

- Tylewicz, U.; Tappi, S.; Mannozzi, C.; Romani, S.; Dellarosa, N.; Laghi, L.; Ragni, L.; Rocculi, P.; Dalla Rosa, M. Effect of pulsed electric field (PEF) pre-treatment coupled with osmotic dehydration on physico-chemical characteristics of organic strawberries. J. Food Eng. 2017, 213, 2–9. [Google Scholar] [CrossRef]

- Tedjo, W.; Taiwo, K.A.; Eshtiaghi, M.N.; Knorr, D. Comparison of pretreatment methods on water and solid diffusion kinetics of osmotically dehydrated mangos. J. Food Eng. 2002, 53, 133–142. [Google Scholar] [CrossRef]

- Amami, E.; Vorobiev, E.; Kechaou, N. Modelling of mass transfer during osmotic dehydration of apple tissue pre-treated by pulsed electric field. LWT-Food Sci. Technol. 2006, 39, 1014–1021. [Google Scholar] [CrossRef]

- Nazari, A.; Salehi, M.A.; Abbasi Souraki, B. Experimental investigation of effective factors of pulsed electric field in osmotic dehydration of apple. Heat Mass Transf. 2019, 55, 2049–2059. [Google Scholar] [CrossRef]

- Taiwo, K.A.; Angersbach, A.; Knorr, D. Effects of pulsed electric field on quality factors and mass transfer during osmotic dehydration of apples. J. Food Process Eng. 2003, 26, 31–48. [Google Scholar] [CrossRef]

- Bazhal, M.I.; Ngadi, M.O.; Raghavan, G.S.V.; Nguyen, D.H. Textural changes in apple tissue during pulsed electric field treatment. J. Food Sci. 2003, 68, 249–253. [Google Scholar] [CrossRef]

- Dermesonlouoglou, E.; Chalkia, A.; Dimopoulos, G.; Taoukis, P. Combined effect of pulsed electric field and osmotic dehydration pre-treatments on mass transfer and quality of air dried goji berry. Innov. Food Sci. Emerg. Technol. 2018, 49, 106–115. [Google Scholar] [CrossRef]

- Santhirasegaram, V.; Razali, Z.; Somasundram, C. Effects of thermal treatment and sonication on quality attributes of Chokanan mango (Mangifera indica L.) juice. Ultrason. Sonochem. 2013, 20, 1276–1282. [Google Scholar] [CrossRef]

- Kantala, C.; Supasin, S.; Intra, P.; Rattanadecho, P. Evaluation of Pulsed Electric Field and Conventional Thermal Processing for Microbial Inactivation in Thai Orange Juice. Foods 2022, 11, 1102. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International; AOAC International: Rockville, MD, USA, 2005; ISBN 0935584757. [Google Scholar]

- Utama-ang, N.; Kuatrakul, I.; Klangpetch, W.; Walter, P.; Kawee-ai, A. Comparative evaluation of physicochemical, functional and texture properties and sensory acceptance of different instant rice varieties coated with Spirulina and edible polymers. Int. J. Food Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Wihong, P.; Songsri, P.; Suriharn, B.; Lomthaisong, K.; Lertrat, K. Rapid assessment of lycopene and β-carotene in spiny bitter gourd (Momordica cochinchinensis (lour.) spreng). Pak. J. Bot 2017, 49, 493–497. [Google Scholar]

- Kanphet, W.; National Bureau of Agricultural Commodity and Food Standards. Compendium of Methods for Food Analysis; Department of Medical Sciences and National Bureau of Agriculture Commodity and Food Standards: Chatuchak, Thailand, 2003; ISBN 9789744220158.

- Lebovka, N.I.; Shynkaryk, N.V.; Vorobiev, E. Pulsed electric field enhanced drying of potato tissue. J. Food Eng. 2007, 78, 606–613. [Google Scholar] [CrossRef]

- Bchir, B.; Sebii, H.; Danthine, S.; Blecker, C.; Besbes, S.; Attia, H.; Bouaziz, M.A. Efficiency of Osmotic Dehydration of Pomegranate Seeds in Polyols Solutions Using Response Surface Methodology. Horticulturae 2021, 7, 268. [Google Scholar] [CrossRef]

- Barat, J.M.; Fito, P.; Chiralt, A. Modeling of simultaneous mass transfer and structural changes in fruit tissues. J. Food Eng. 2001, 49, 77–85. [Google Scholar] [CrossRef]

- Wiktor, A.; Śledź, M.; Nowacka, M.; Chudoba, T.; Witrowa-Rajchert, D. Pulsed electric field pretreatment for osmotic dehydration of apple tissue: Experimental and mathematical modeling studies. Dry. Technol. 2014, 32, 408–417. [Google Scholar] [CrossRef]

- Mendonça, K.; Correa, J.; Junqueira, J.; Angelis-Pereira, M.; Cirillo, M. Mass transfer kinetics of the osmotic dehydration of yacon slices with polyols. J. Food Process. Preserv. 2017, 41, e12983. [Google Scholar] [CrossRef] [Green Version]

- Shynkaryk, M.V.; Lebovka, N.I.; Vorobiev, E. Pulsed electric fields and temperature effects on drying and rehydration of red beetroots. Dry. Technol. 2008, 26, 695–704. [Google Scholar] [CrossRef]

- Escriche, I.; Chiralt, A.; Moreno, J.; Serra, J.A. Influence of blanching-osmotic dehydration treatments on volatile fraction of strawberries. J. Food Sci. 2000, 65, 1107–1111. [Google Scholar] [CrossRef]

- Moreno, J.; Simpson, R.; Sayas, M.; Segura, I.; Aldana, O.; Almonacid, S. Influence of ohmic heating and vacuum impregnation on the osmotic dehydration kinetics and microstructure of pears (cv. Packham’s Triumph). J. Food Eng. 2011, 104, 621–627. [Google Scholar] [CrossRef]

- Cserhalmi, Z.; Sass-Kiss, Á.; Tóth-Markus, M.; Lechner, N. Study of pulsed electric field treated citrus juices. Innov. Food Sci. Emerg. Technol. 2006, 7, 49–54. [Google Scholar] [CrossRef]

- Chiralt, A.; Talens, P. Physical and chemical changes induced by osmotic dehydration in plant tissues. J. Food Eng. 2005, 67, 167–177. [Google Scholar] [CrossRef]

- Bot, F.; Verkerk, R.; Mastwijk, H.; Anese, M.; Fogliano, V.; Capuano, E. The effect of pulsed electric fields on carotenoids bioaccessibility: The role of tomato matrix. Food Chem. 2018, 240, 415–421. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Zeng, X.-A.; Brennan, C.S.; Brennan, M.; Han, Z.; Xiong, X.-Y. Effects of pulsed electric fields (PEF) on vitamin C and its antioxidant properties. Int. J. Mol. Sci. 2015, 16, 24159–24173. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oms-Oliu, G.; Odriozola-Serrano, I.; Soliva-Fortuny, R.; Martín-Belloso, O. Effects of high-intensity pulsed electric field processing conditions on lycopene, vitamin C and antioxidant capacity of watermelon juice. Food Chem. 2009, 115, 1312–1319. [Google Scholar] [CrossRef]

- Johra, F.T.; Bepari, A.K.; Bristy, A.T.; Reza, H.M. A mechanistic review of β-carotene, lutein, and zeaxanthin in eye health and disease. Antioxidants 2020, 9, 1046. [Google Scholar] [CrossRef] [PubMed]

| Conditions | Parameters | |||

|---|---|---|---|---|

| Moisture (%) | Water Activity | pH (Pulp) ns3 | pH (Solution) | |

| Fresh mango | 84.63 ± 0.54 a2 | 0.990 ± 0.001 a | 3.01 ± 0.01 | - |

| Conventional pickling | ||||

| 80.94 ± 0.49 b | 0.964 ± 0.002 b | 3.05 ± 0.04 | 4.77 ± 0.10 a |

| 68.41 ± 0.01 c | 0.977 ± 0.001 b | 3.21 ± 1.66 | 3.34 ± 0.21 c |

| PEF-assisted pickling | ||||

| 71.16 ± 0.21 c | 0.958 ± 0.000 c | 3.03 ± 0.34 | 3.80 ± 0.05 b |

| 61.54 ± 0.03 d | 0.969 ± 0.007 b | 3.10 ± 0.19 | 3.32 ± 0.01 c |

| Fresh Mango | Conventional Pickling | PEF-Assisted Pickling | |||

|---|---|---|---|---|---|

| 30 °Brix | 50 °Brix | 30 °Brix | 50 °Brix | ||

| Appearance | |||||

|  |  |  |  |  |

|  |  |  |  |  |

| L* | 54.63 ± 2.08 ab2 | 52.27 ± 1.84 b | 55.55 ± 1.58 ab | 58.29 ± 3.40 ab | 55.41 ± 2.50 ab |

| a * | −3.14 ± 0.25 d | −0.77 ± 0.06 b | −1.13 ± 0.05 c | 1.95 ± 0.02 a | 2.09 ± 0.14 a |

| b * | 29.81 ± 1.41 b | 33.65 ± 4.52 a | 33.43 ± 4.60 a | 28.43 ± 0.93 b | 29.41 ± 1.53 b |

| ΔE ns3 | 0 | 5.83 ± 2.66 | 5.51 ± 2.58 | 7.03 ± 1.64 | 5.92 ± 0.51 |

| BI | 70.05 ± 1.55 bc | 94.34 ± 14.54 a | 84.77 ± 13.99 ab | 66.98 ± 2.37 c | 75.12 ± 0.76 bc |

| Conditions | Texture Properties | |

|---|---|---|

| Hardness (N) | Toughness (mJ/m3) | |

| Fresh mango | 51.27 ± 0.98 b2 | 189.13 ± 45.48 a |

| Conventional pickling | ||

| 38.03 ± 3.71 c | 98.67 ± 8.12 c |

| 63.80 ± 0.07 b | 136.98 ± 13.26 b |

| PEF-assisted pickling | ||

| 23.36 ± 1.93 d | 30.36 ± 4.82 d |

| 72.65 ± 1.98 a | 114.82 ± 1.19 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Supasin, S.; Kantala, C.; Intra, P.; Rattanadecho, P. Postharvest Preservation of Thai Mango var. Chok-Anan by the Combination of Pulsed Electric Field and Chemical Pickling. Horticulturae 2022, 8, 584. https://doi.org/10.3390/horticulturae8070584

Supasin S, Kantala C, Intra P, Rattanadecho P. Postharvest Preservation of Thai Mango var. Chok-Anan by the Combination of Pulsed Electric Field and Chemical Pickling. Horticulturae. 2022; 8(7):584. https://doi.org/10.3390/horticulturae8070584

Chicago/Turabian StyleSupasin, Supakiat, Chatchawan Kantala, Panich Intra, and Phadungsak Rattanadecho. 2022. "Postharvest Preservation of Thai Mango var. Chok-Anan by the Combination of Pulsed Electric Field and Chemical Pickling" Horticulturae 8, no. 7: 584. https://doi.org/10.3390/horticulturae8070584

APA StyleSupasin, S., Kantala, C., Intra, P., & Rattanadecho, P. (2022). Postharvest Preservation of Thai Mango var. Chok-Anan by the Combination of Pulsed Electric Field and Chemical Pickling. Horticulturae, 8(7), 584. https://doi.org/10.3390/horticulturae8070584