Shelf Life Prediction and Kinetics of Quality Changes in Pineapple (Ananas comosus) Varieties at Different Storage Temperatures

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Determination of Physicochemical Properties

2.2.1. Total Soluble Solids

2.2.2. pH

2.2.3. Firmness

2.2.4. Moisture Content

2.2.5. Colour Evaluation

2.3. Kinetic Model Development

2.4. Statistical Analysis

3. Results and Discussion

3.1. Effect of Storage Temperature on TSS, pH, Firmness, and Moisture Content

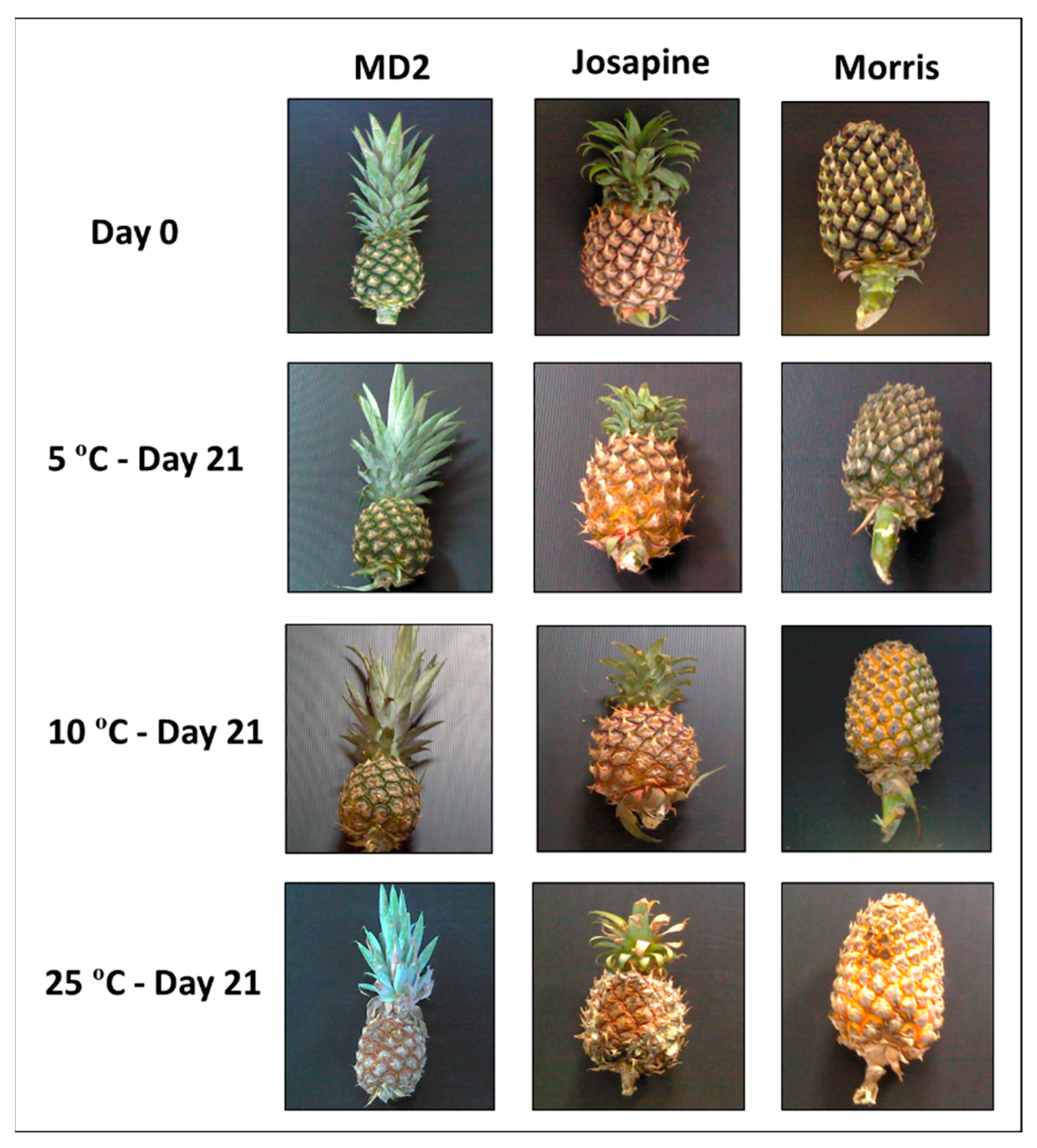

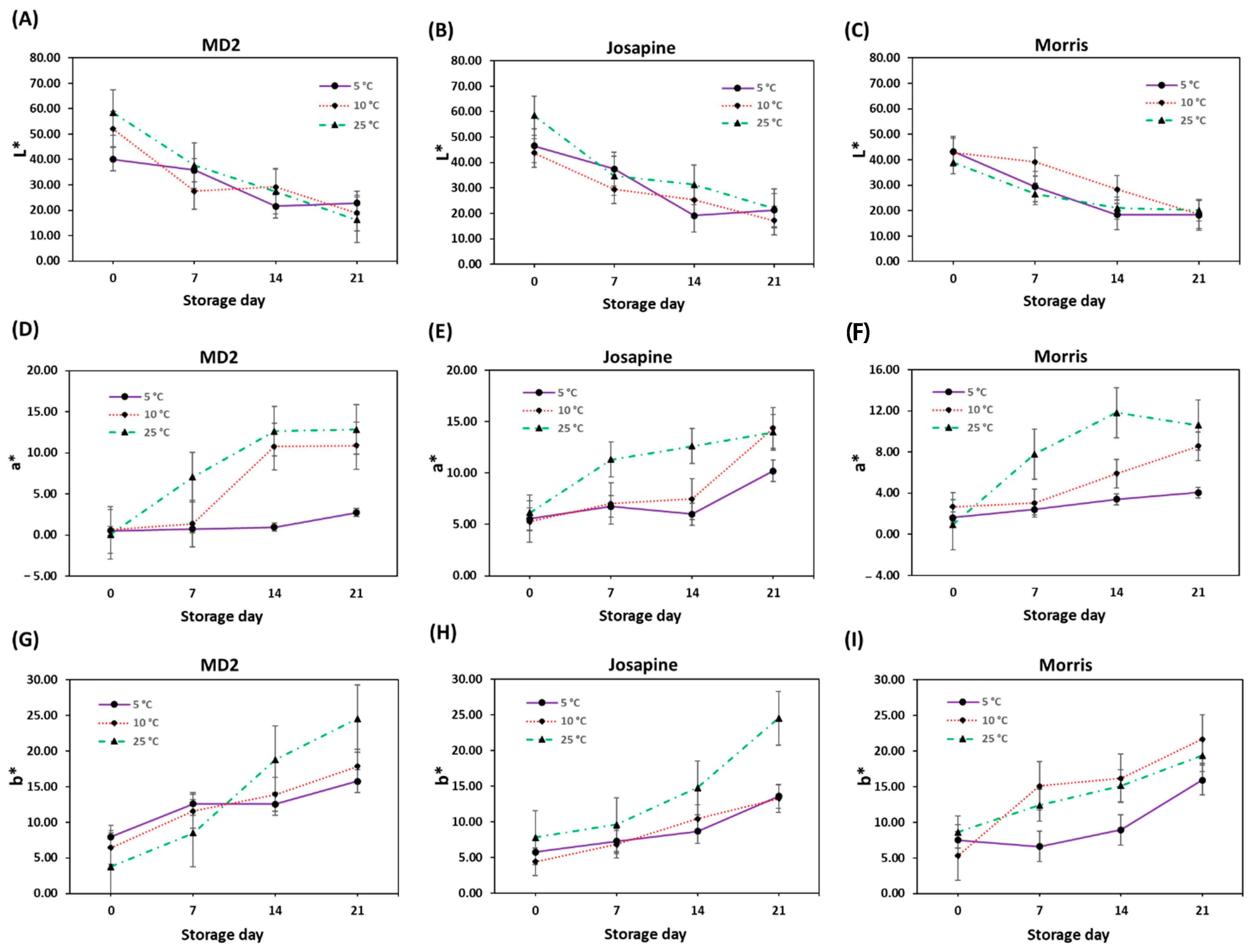

3.2. Effect of Storage Temperature on Colour Parameters

3.3. Kinetics of Quality Changes in Pineapples

3.4. Determination of Shelf Life

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAOSTAT. Pineapple Production in 2019, Crops/Regions/World List/Production Quantity. UN Food and Agriculture Organization, Corporate Statistical Database. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 20 January 2021).

- Amuah, C.L.Y.; Teye, E.; Lamptey, F.P.; Nyandey, K.; Opoku-Ansah, J.; Adueming, P.O.W. Feasibility Study of the Use of Handheld NIR Spectrometer for Simultaneous Authentication and Quantification of Quality Parameters in Intact Pineapple Fruits. J. Spectrosc. 2019, 2019, 5975461. [Google Scholar] [CrossRef]

- Mohd Ali, M.; Hashim, N.; Abd Aziz, S.; Lasekan, O. Pineapple (Ananas comosus): A Comprehensive Review of Nutritional Values, Volatile Compounds, Health Benefits, and Potential Food Products. Food Res. Int. 2020, 137, 109675. [Google Scholar] [CrossRef]

- Padrón-Mederos, M.; Rodríguez-Galdón, B.; Díaz-Romero, C.; Lobo-Rodrigo, M.G.; Rodríguez-Rodríguez, E.M. Quality Evaluation of Minimally Fresh-Cut Processed Pineapples. LWT-Food Sci. Technol. 2020, 129, 109607. [Google Scholar] [CrossRef]

- Guimarães, G.H.C.; Silva, R.S.; Madruga, M.S.; Sousa, A.S.B.; Brito, A.L.; Lima, R.P.; Mendonça, R.M.N.; Beaudry, R.M.; Silva, S.M. Effect of Plant-Based Coatings on the Volatile Profile of “Pérola” Pineapple. Acta Hortic. 2018, 1194, 1519–1526. [Google Scholar] [CrossRef]

- Steingass, C.B.; Carle, R.; Schmarr, H.G. Ripening-Dependent Metabolic Changes in the Volatiles of Pineapple (Ananas comosus (L.) Merr.) Fruit: I. Characterization of Pineapple Aroma Compounds by Comprehensive Two-Dimensional Gas Chromatography-Mass Spectrometry. Anal. Bioanal. Chem. 2015, 407, 2591–2608. [Google Scholar] [CrossRef]

- Dolhaji, N.H.; Muhamad, I.I.; Ya’akub, H.; Abd Aziz, A. Evaluation of Chilling Injury and Internal Browning Condition on Quality Attributes, Phenolic Content, and Antioxidant Capacity during Sub-Optimal Cold Storage of Malaysian Cultivar Pineapples. Malays. J. Fundam. Appl. Sci. 2019, 14, 456–461. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Samapundo, S.; Rademaker, M.; Noseda, B.; Denon, Q.; de Baenst, I.; Sürengil, G.; De Baets, B.; Devlieghere, F. Effect of Initial Headspace Oxygen Level on Growth and Volatile Metabolite Production by the Specific Spoilage Microorganisms of Fresh-Cut Pineapple. LWT-Food Sci. Technol. 2014, 55, 224–231. [Google Scholar] [CrossRef]

- Mohd Ali, M.; Hashim, N.; Bejo, S.K.; Shamsudin, R. Quality Evaluation of Watermelon Using Laser-Induced Backscattering Imaging during Storage. Postharvest Biol. Technol. 2017, 123, 51–59. [Google Scholar] [CrossRef]

- Zhi, N.N.; Zong, K.; Thakur, K.; Qu, J.; Shi, J.J.; Yang, J.L.; Yao, J.; Wei, Z.J. Development of a Dynamic Prediction Model for Shelf-Life Evaluation of Yogurt by Using Physicochemical, Microbiological and Sensory Parameters. CYTA-J. Food 2018, 16, 42–49. [Google Scholar] [CrossRef]

- Hartono, M.T.; Rahayoe, S.; Bintoro, N. Kinetics of Physical Quality of Pineapple Fruit (Ananas comosus L.) with Crown during Storage with Temperature Variation. IOP Conf. Ser. Earth Environ. Sci. 2019, 355, 012039. [Google Scholar] [CrossRef]

- George, D.S.; Razali, Z.; Somasundram, C. Physiochemical Changes during Growth and Development of Pineapple (Ananas comosus L. Merr. Cv. Sarawak). J. Agric. Sci. Technol. 2016, 18, 491–503. [Google Scholar]

- Ismail, N.A.M.; Abdullah, N.; Muhammad, N. Effect of Microwave-Assisted Processing on Quality Characteristics of Pineapple Jam. J. Adv. Res. Fluid Mech. Therm. Sci. 2018, 42, 24–30. [Google Scholar]

- Leneveu-jenvrin, C.; Quentin, B.; Assemat, S.; Hoarau, M.; Meile, J.C.; Remize, F. Changes of Quality of Minimally-Processed Pineapple (Ananas comosus, Var. ‘Queen Victoria’) during Cold Storage: Fungi in the Leading Role. Microorganisms 2020, 8, 185. [Google Scholar] [CrossRef] [PubMed]

- Sakač, M.; Pestorić, M.; Mandić, A.; Mišan, A.; Nedeljković, N.; Jambrec, D.; Jovanov, P.; Lazić, V.; Pezo, L.; Sedej, I. Shelf-Life Prediction of Gluten-Free Rice-Buckwheat Cookies. J. Cereal Sci. 2016, 69, 336–343. [Google Scholar] [CrossRef]

- Niu, Y.; Yun, J.; Bi, Y.; Wang, T.; Zhang, Y.; Liu, H.; Zhao, F. Predicting the Shelf Life of Postharvest Flammulina Velutipes at Various Temperatures Based on Mushroom Quality and Specific Spoilage Organisms. Postharvest Biol. Technol. 2020, 167, 111235. [Google Scholar] [CrossRef]

- Tan, S.L.; Sulaiman, R.; Rukayadi, Y.; Ramli, N.S. Physical, Chemical, Microbiological Properties and Shelf Life Kinetic of Spray-Dried Cantaloupe Juice Powder during Storage. LWT-Food Sci. Technol. 2021, 140, 110597. [Google Scholar] [CrossRef]

- Wanakamol, W.; Poonlarp, P. Effects of Frying Temperature, Frying Time and Cycles on Physicochemical Properties of Vacuum Fried Pineapple Chips and Shelf Life Prediction. Int. Food Res. J. 2018, 25, 2681–2688. [Google Scholar]

- Montero-Calderón, M.; Rojas-Graü, M.A.; Martín-Belloso, O. Effect of Packaging Conditions on Quality and Shelf-Life of Fresh-Cut Pineapple (Ananas comosus). Postharvest Biol. Technol. 2008, 50, 182–189. [Google Scholar] [CrossRef]

- Gómez, J.M.; Mendoza, S.M.; Herrera, A.O.; Castellanos, D.A. Evaluation and Modeling of Changes in Color, Firmness, and Physicochemical Shelf Life of Cut Pineapple (Ananas comosus) Slices in Equilibrium-Modified Atmosphere Packaging. J. Food Sci. 2020, 85, 3899–3908. [Google Scholar] [CrossRef]

- Chakraborty, S.; Rao, P.S.; Mishra, H.N. Changes in Quality Attributes During Storage of High-Pressure and Thermally Processed Pineapple Puree. Food Bioprocess Technol. 2016, 9, 768–791. [Google Scholar] [CrossRef]

- Song, Y.; Hu, Q.; Wu, Y.; Pei, F.; Kimatu, B.M.; Su, A.; Yang, W. Storage Time Assessment and Shelf-Life Prediction Models for Postharvest Agaricus Bisporus. LWT-Food Sci. Technol. 2019, 101, 360–365. [Google Scholar] [CrossRef]

- Shamsudin, R.; Daud, W.R.W.; Takriff, M.S.; Hassan, O. Physicochemical Properties of the Josapine Variety of Pineapple Fruit. Int. J. Food Eng. 2007, 3, 1–12. [Google Scholar] [CrossRef]

- da Silva, E.P.; Cardoso, A.F.L.; Fante, C.; Rosell, C.M.; Vilas Boas, E.V.D.B. Effect of Postharvest Temperature on the Shelf Life of Gabiroba Fruit (Campomanesia pubescens). Food Sci. Technol. 2013, 33, 632–637. [Google Scholar] [CrossRef]

- Siti Rashima, R.; Maizura, M.; Wan Nur Hafzan, W.M.; Hazzeman, H. Physicochemical Properties and Sensory Acceptability of Pineapples of Different Varieties and Stages of Maturity. Food Res. 2019, 3, 491–500. [Google Scholar] [CrossRef]

- Nadzirah, K.Z.; Zainal, S.; Noriham, A.; Normah, I.; Siti Roha, A.M.; Nadya, H. Physico- Chemical Properties of Pineapple Variety N36 Harvested and Stored at Different Maturity Stages. Int. Food Res. J. 2013, 20, 225–231. [Google Scholar]

- Antoniolli, L.R.; Benedetti, B.C.; de Souza Filho, M.D.S.M.; dos Santos Garutti, D.; de Fatima Borges, M. Shelf Life of Minimally Processed Pineapples Treated with Ascorbic and Citric Acids. Bragantia 2012, 71, 447–453. [Google Scholar] [CrossRef]

- Siow, L.-F.; Lee, K.-H. Determination of Physicochemical Properties of Osmo-Dehydrofrozen Pineapples. Borneo Sci. 2012, 31, 71–84. [Google Scholar]

- Montero-Calderón, M.; Rojas-Graü, M.A.; Martín-Belloso, O. Aroma Profile and Volatiles Odor Activity Along Gold Cultivar Pineapple Flesh. J. Food Sci. 2010, 75, 506–512. [Google Scholar] [CrossRef]

- Ancos, B.; Sánchez-Moreno, C.; González-Aguilar, G.A. Pineapple Composition and Nutrition. Handb. Pineapple Technol. Postharvest Sci. Process. Nutr. 2016, 221–239. [Google Scholar] [CrossRef]

- Chaudhary, V.; Kumar, V.; Kumar, A.A.; Kumar, V.; Kumar, R. Impact of Different Drying Temperatures and Osmotic Treatments on Quality of Pineapple Slices during Storage. Food Process. Nutr. Sci. 2020, 1, 80–85. [Google Scholar]

- Pulissery, S.K.; Boregowda, S.K.; Suseela, S.; Jaganath, B. A Comparative Study on the Textural and Nutritional Profile of High Pressure and Minimally Processed Pineapple. J. Food Sci. Technol. 2020, 58, 3734–3742. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, F.; Sousa-Gallagher, M.J.; Mahajan, P.V.; Teixeira, J.A. Development of Shelf-Life Kinetic Model for Modified Atmosphere Packaging of Fresh Sliced Mushrooms. J. Food Eng. 2012, 111, 466–473. [Google Scholar] [CrossRef]

- Bizura Hasida, M.R.; Nur Aida, M.P.; Zaipun, M.Z.; Hairiyah, M. Quality Evaluation of Fresh-Cut “Josapine” Pineapple Coated with Hydrocolloid Based Edible Coating Using Gelatin. Acta Hortic. 2013, 1012, 1037–1042. [Google Scholar] [CrossRef]

- Lima, R.P.; Silva, S.M.; Dantas, R.L.; Dantas, A.L.; Sousa, A.S.B.; Pereira, W.E.; Mendonça, R.M.N.; Guimarães, G.H.C. Using Digital Image Processing for Evaluation of Translucency in Fresh-Cut “Pérola” Pineapple Coated with Biofilms. Acta Hortic. 2016, 1141, 311–318. [Google Scholar] [CrossRef]

- Kaewtathip, T.; Charoenrein, S. Changes in Volatile Aroma Compounds of Pineapple (Ananas comosus) during Freezing and Thawing. Int. J. Food Sci. Technol. 2012, 47, 985–990. [Google Scholar] [CrossRef]

- Chutintrasri, B.; Noomhorm, A. Color Degradation Kinetics of Pineapple Puree during Thermal Processing. LWT-Food Sci. Technol. 2007, 40, 300–306. [Google Scholar] [CrossRef]

- Zardetto, S.; Barbanti, D. Shelf Life Assessment of Fresh Green Pesto Using an Accelerated Test Approach. Food Packag. Shelf Life 2020, 25, 100524. [Google Scholar] [CrossRef]

- Zhang, W.; Luo, Z.; Wang, A.; Gu, X.; Lv, Z. Kinetic Models Applied to Quality Change and Shelf Life Prediction of Kiwifruits. LWT-Food Sci. Technol. 2021, 138, 110610. [Google Scholar] [CrossRef]

- Dermesonluoglu, E.; Katsaros, G.; Tsevdou, M.; Giannakourou, M.; Taoukis, P. Kinetic Study of Quality Indices and Shelf Life Modelling of Frozen Spinach under Dynamic Conditions of the Cold Chain. J. Food Eng. 2015, 148, 13–23. [Google Scholar] [CrossRef]

- Ziabakhsh Deylami, M.; Abdul Rahman, R.; Tan, C.P.; Bakar, J.; Olusegun, L. Effect of Blanching on Enzyme Activity, Color Changes, Anthocyanin Stability and Extractability of Mangosteen Pericarp: A Kinetic Study. J. Food Eng. 2016, 178, 12–19. [Google Scholar] [CrossRef]

- Dak, M.; Sagar, V.R.; Jha, S.K. Shelf-Life and Kinetics of Quality Change of Dried Pomegranate Arils in Flexible Packaging. Food Packag. Shelf Life 2014, 2, 1–6. [Google Scholar] [CrossRef]

- Melih Secer, O.; Guneser, B.A.; Guneser, O. Prediction of Shelf-Life and Kinetics of Quality Changes in Canned Stuffed Grape Leaves. LWT-Food Sci. Technol. 2020, 132, 109850. [Google Scholar] [CrossRef]

- Tomac, A.; Mascheroni, R.H.; Yeannes, M.I. Modelling the Effect of Gamma Irradiation on the Inactivation and Growth Kinetics of Psychrotrophic Bacteria in Squid Rings during Refrigerated Storage. Shelf-Life Predictions. J. Food Eng. 2013, 117, 211–216. [Google Scholar] [CrossRef]

- Vaishnav, J.; Adiani, V.; Variyar, P.S. Radiation Processing for Enhancing Shelf Life and Quality Characteristics of Minimally Processed Ready-to-Cook (RTC) Cauliflower (Brassica oleracea). Food Packag. Shelf Life 2015, 5, 50–55. [Google Scholar] [CrossRef]

| Temperature | Day | MD2 | Josapine | Morris | |||

|---|---|---|---|---|---|---|---|

| TSS (%) | pH | TSS (%) | pH | TSS (%) | pH | ||

| 5 °C | 0 | 10.71 ± 0.04 a | 3.00 ± 0.11 b | 10.10 ± 0.84 b | 2.80 ± 1.02 a | 3.60 ± 0.74 ab | 3.20 ± 1.39 a |

| 7 | 13.50 ± 1.48 ab | 2.90 ± 0.01 a | 12.30 ± 1.16 ab | 2.90 ± 0.92 b | 8.20 ± 0.54 a | 3.00 ± 0.07 b | |

| 14 | 15.34 ± 0.13 b | 2.40 ± 0.07 ab | 14.10 ± 0.03 a | 2.60 ± 0.97 c | 9.40 ± 0.02 b | 2.70 ± 1.29 c | |

| 21 | 14.60 ± 0.64 c | 2.60 ± 0.48 c | 12.73 ± 0.16 c | 2.40 ± 0.96 ab | 8.00 ± 0.16 c | 2.50 ± 1.04 ab | |

| 10 °C | 0 | 11.30 ± 0.54 a | 3.00 ± 0.39 ab | 12.20 ± 0.25 a | 3.00 ± 1.04 b | 9.20 ± 0.04 a | 2.90 ± 1.03 b |

| 7 | 12.10 ± 0.26 b | 2.80 ± 0.16 b | 12.50 ± 0.95 ab | 2.90 ± 0.03 a | 9.70 ± 0.42 b | 2.70 ± 0.36 a | |

| 14 | 13.70 ± 0.92 ab | 2.70 ± 0.49 a | 13.10 ± 0.22 b | 2.90 ± 0.38 a | 10.01 ± 1.82 ab | 2.50 ± 0.64 ab | |

| 21 | 11.40 ± 0.02 c | 2.60 ± 1.467 c | 11.80 ± 0.19 c | 2.70 ± 0.26 ab | 7.60 ± 0.05 c | 2.60 ± 0.02 c | |

| 25 °C | 0 | 10.10 ± 0.16 a | 3.30 ± 0.16 a | 9.40 ± 0.02 a | 4.10 ± 0.73 b | 7.80 ± 0.16 a | 3.60 ± 1.36 b |

| 7 | 11.20 ± 0.07 ab | 3.20 ± 0.85 b | 14.70 ± 0.74 ab | 4.00 ± 0.05 ab | 9.80 ± 0.21 ab | 2.90 ± 0.83 a | |

| 14 | 15.60 ± 0.26 b | 3.10 ± 0.01 c | 16.60 ± 0.26 c | 3.10 ± 0.36 a | 10.10 ± 0.94 ac | 2.70 ± 1.06 ab | |

| 21 | 9.40 ± 0.85 a | 2.90 ± 0.74 ab | 10.70 ± 0.02 b | 2.80 ± 0.02 c | 8.40 ± 0.21 b | 2.70 ± 0.17 c | |

| Temperature | Day | MD2 | Josapine | Morris | |||

|---|---|---|---|---|---|---|---|

| Firmness (N) | Moisture Content (%) | Firmness (N) | Moisture Content (%) | Firmness (N) | Moisture Content (%) | ||

| 5 °C | 0 | 1.48 ± 0.89 a | 84.93 ± 0.22 a | 1.39 ± 0.16 a | 86.88 ± 1.26 a | 1.59 ± 0.73 a | 90.35 ± 1.26 b |

| 7 | 1.43 ± 0.58 b | 85.72 ± 0.84 b | 1.01 ± 0.06 b | 90.76 ± 0.68 ab | 1.47 ± 0.93 b | 91.75 ± 0.01 a | |

| 14 | 1.23 ± 0.06 c | 87.82 ± 1.83 bc | 0.90 ± 0.03 c | 91.58 ± 1.04 b | 1.40 ± 0.03 ab | 92.85 ± 1.15 c | |

| 21 | 1.15 ± 0.93 bc | 89.52 ± 0.03 c | 0.83 ± 0.14 ab | 93.66 ± 1.84 b | 1.31 ± 0.18 c | 90.39 ± 1.35 ab | |

| 10 °C | 0 | 1.48 ± 1.63 a | 86.93 ± 0.26 a | 1.45 ± 0.02 a | 85.56 ± 0.36 b | 2.92 ± 0.03 a | 68.87 ± 2.25 b |

| 7 | 1.01 ± 0.05 ab | 88.78 ± 0.89 b | 0.63 ± 0.52 ab | 87.27 ± 0.39 a | 2.47 ± 0.15 a | 70.72 ± 1.94 b | |

| 14 | 0.80 ± 0.16 b | 89.50 ± 0.12 c | 0.61 ± 0.25 b | 91.39 ± 1.82 c | 2.49 ± 0.74 a | 81.48 ± 1.16 a | |

| 21 | 0.62 ± 0.05 ac | 91.08 ± 0.84 bc | 0.55 ± 0.07 bc | 92.86 ± 0.28 bc | 1.17 ± 0.15 b | 89.95 ± 1.54 b | |

| 25 °C | 0 | 1.47 ± 1.87 a | 85.25 ± 0.36 a | 1.63 ± 0.26 a | 85.67 ± 0.15 b | 1.27 ± 0.14 a | 84.07 ± 1.06 b |

| 7 | 1.51 ± 0.75 b | 87.52 ± 0.07 ab | 1.44 ± 0.14 ab | 89.15 ± 0.64 a | 0.77 ± 0.06 ab | 86.15 ± 0.38 a | |

| 14 | 0.68 ± 0.65 ab | 90.47 ± 0.03 b | 1.05 ± 1.66 c | 92.83 ± 0.20 ab | 0.65 ± 1.53 b | 87.69 ± 0.02 ab | |

| 21 | 0.33 ± 1.03 c | 91.27 ± 0.15 a | 0.92 ± 0.13 b | 95.26 ± 0.03 c | 0.45 ± 0.04 ab | 89.66 ± 0.17 c | |

| Variety | Quality Indices | Temperature (°C) | Zero-Order | First-Order | ||||

|---|---|---|---|---|---|---|---|---|

| k | R2 | RMSE | k | R2 | RMSE | |||

| MD2 | Total soluble solids | 5 | −0.025 | 0.915 | 1.962 | −0.006 | 0.925 | 0.986 |

| 10 | −0.014 | 0.893 | 0.506 | −0.003 | 0.910 | 1.582 | ||

| 25 | 0.085 | 0.894 | 0.963 | 0.007 | 0.902 | 3.959 | ||

| pH | 5 | 0.026 | 0.909 | 1.156 | 0.018 | 0.911 | 1.863 | |

| 10 | −0.011 | 0.911 | 0.849 | −0.016 | 0.928 | 1.479 | ||

| 25 | −0.056 | 0.882 | 0.252 | −0.099 | 0.899 | 0.960 | ||

| Firmness | 5 | 0.068 | 0.936 | 0.056 | 0.005 | 0.948 | 2.066 | |

| 10 | 0.157 | 0.932 | 0.084 | 0.022 | 0.946 | 0.042 | ||

| 25 | 0.186 | 0.926 | 0.969 | −0.001 | 0.973 | 0.068 | ||

| Moisture content | 5 | 0.266 | 0.942 | 0.263 | −0.003 | 0.964 | 1.964 | |

| 10 | 0.005 | 0.946 | 1.642 | 0.002 | 0.978 | 0.485 | ||

| 25 | 0.047 | 0.969 | 1.859 | 0.095 | 0.985 | 0.958 | ||

| Josapine | Total soluble solids | 5 | −0.003 | 0.884 | 0.857 | −0.002 | 0.899 | 1.435 |

| 10 | −0.016 | 0.911 | 0.854 | −0.007 | 0.923 | 0.645 | ||

| 25 | 0.025 | 0.872 | 0.234 | 0.007 | 0.893 | 0.658 | ||

| pH | 5 | −0.096 | 0.901 | 3.648 | −0.002 | 0.921 | 2.543 | |

| 10 | −0.019 | 0.925 | 1.074 | −0.001 | 0.955 | 0.125 | ||

| 25 | −0.026 | 0.919 | 1.532 | −0.001 | 0.909 | 0.643 | ||

| Firmness | 5 | 0.218 | 0.936 | 1.525 | 0.002 | 0.943 | 1.353 | |

| 10 | 0.005 | 0.973 | 0.094 | 0.005 | 0.982 | 0.032 | ||

| 25 | 0.233 | 0.926 | 0.252 | −0.005 | 0.951 | 0.943 | ||

| Moisture content | 5 | 0.095 | 0.973 | 1.524 | −0.001 | 0.992 | 3.545 | |

| 10 | 0.250 | 0.988 | 0.043 | −0.002 | 0.991 | 0.245 | ||

| 25 | 0.464 | 0.930 | 0.524 | 0.001 | 0.956 | 1.352 | ||

| Morris | Total soluble solids | 5 | −0.053 | 0.908 | 0.069 | −0.003 | 0.921 | 0.385 |

| 10 | −0.059 | 0.915 | 0.958 | −0.009 | 0.920 | 0.589 | ||

| 25 | 0.068 | 0.904 | 1.849 | 0.029 | 0.938 | 0.596 | ||

| pH | 5 | 0.003 | 0.877 | 0.038 | 0.001 | 0.911 | 0.591 | |

| 10 | 0.258 | 0.889 | 2.842 | 0.048 | 0.948 | 1.106 | ||

| 25 | −0.524 | 0.900 | 0.153 | −0.027 | 0.947 | 0.859 | ||

| Firmness | 5 | 0.025 | 0.893 | 2.597 | −0.006 | 0.924 | 0.058 | |

| 10 | 0.170 | 0.921 | 0.296 | −0.009 | 0.963 | 0.472 | ||

| 25 | 0.219 | 0.928 | 1.110 | 0.024 | 0.947 | 0.859 | ||

| Moisture content | 5 | 0.058 | 0.919 | 0.307 | −0.008 | 0.934 | 0.285 | |

| 10 | 0.188 | 0.899 | 0.253 | −0.086 | 0.902 | 0.297 | ||

| 25 | 0.048 | 0.934 | 0.069 | 0.003 | 0.989 | 0.059 | ||

| Variety | Colour Parameter | Temperature (°C) | Zero-Order | First-Order | ||||

|---|---|---|---|---|---|---|---|---|

| k | R2 | RMSE | k | R2 | RMSE | |||

| MD2 | L* | 5 | 0.064 | 0.924 | 0.030 | 0.004 | 0.901 | 0.495 |

| 10 | 0.269 | 0.895 | 0.096 | 0.002 | 0.921 | 1.489 | ||

| 25 | 0.053 | 0.896 | 1.856 | 0.024 | 0.899 | 0.948 | ||

| a* | 5 | −0.266 | 0.911 | 1.382 | −0.007 | 0.879 | 1.859 | |

| 10 | −0.832 | 0.890 | 0.789 | −0.263 | 0.932 | 0.083 | ||

| 25 | 0.063 | 0.932 | 0.356 | 0.006 | 0.924 | 1.489 | ||

| b* | 5 | 0.025 | 0.899 | 0.598 | 0.004 | 0.921 | 0.968 | |

| 10 | 0.028 | 0.925 | 1.056 | 0.008 | 0.927 | 0.257 | ||

| 25 | 0.053 | 0.924 | 0.859 | 0.002 | 0.935 | 0.585 | ||

| Josapine | L* | 5 | 0.021 | 0.875 | 0.343 | 0.001 | 0.892 | 2.437 |

| 10 | 0.763 | 0.949 | 0.032 | 0.002 | 0.934 | 1.242 | ||

| 25 | −0.004 | 0.868 | 0.521 | −0.004 | 0.890 | 0.654 | ||

| a* | 5 | −0.847 | 0.872 | 2.520 | −0.012 | 0.888 | 1.435 | |

| 10 | −0.598 | 0.911 | 0.345 | −0.046 | 0.925 | 0.743 | ||

| 25 | 0.558 | 0.884 | 0.824 | 0.017 | 0.886 | 0.422 | ||

| b* | 5 | 0.957 | 0.884 | 1.252 | 0.002 | 0.889 | 0.867 | |

| 10 | 0.484 | 0.879 | 0.245 | 0.001 | 0.897 | 0.079 | ||

| 25 | 0.638 | 0.875 | 0.522 | 0.004 | 0.890 | 0.243 | ||

| Morris | L* | 5 | 0.042 | 0.885 | 0.085 | 0.002 | 0.899 | 0.396 |

| 10 | 0.068 | 0.895 | 0.964 | 0.003 | 0.906 | 0.396 | ||

| 25 | 0.146 | 0.904 | 1.396 | 0.042 | 0.921 | 2.853 | ||

| a* | 5 | −0.047 | 0.914 | 0.842 | −0.024 | 0.922 | 0.252 | |

| 10 | −0.385 | 0.911 | 0.078 | −0.059 | 0.914 | 0.963 | ||

| 25 | 0.004 | 0.895 | 2.954 | 0.023 | 0.896 | 2.953 | ||

| b* | 5 | 0.003 | 0.885 | 0.021 | 0.009 | 0.915 | 0.085 | |

| 10 | 0.001 | 0.907 | 0.528 | 0.003 | 0.932 | 0.389 | ||

| 25 | 0.002 | 0.918 | 0.953 | 0.005 | 0.920 | 0.958 | ||

| Variety | Physicochemical Properties | Ea (kJ/mol) | kref (day−1) | R2 | RMSE |

|---|---|---|---|---|---|

| MD2 | TSS | 35.856 | 0.425 | 0.892 | 1.524 |

| pH | 35.647 | 0.873 | 0.921 | 0.043 | |

| Firmness | 34.934 | 1.464 | 0.909 | 0.645 | |

| Moisture content | 36.352 | 1.929 | 0.946 | 0.658 | |

| L* | 35.067 | 0.472 | 0.931 | 0.046 | |

| a* | 35.679 | 0.643 | 0.948 | 0.422 | |

| b* | 34.974 | 0.174 | 0.927 | 0.854 | |

| Josapine | TSS | 35.656 | 0.246 | 0.935 | 0.234 |

| pH | 35.175 | 0.247 | 0.933 | 0.079 | |

| Firmness | 35.675 | 1.094 | 0.992 | 0.243 | |

| Moisture content | 36.896 | 1.549 | 0.989 | 0.743 | |

| L* | 35.680 | 0.892 | 0.951 | 0.422 | |

| a* | 35.935 | 0.218 | 0.907 | 0.043 | |

| b* | 34.793 | 0.094 | 0.935 | 0.524 | |

| Morris | TSS | 35.969 | 0.137 | 0.918 | 0.343 |

| pH | 35.159 | 0.794 | 0.914 | 0.884 | |

| Firmness | 35.553 | 1.487 | 0.952 | 0.884 | |

| Moisture content | 34.895 | 1.118 | 0.927 | 0.879 | |

| L* | 36.594 | 0.638 | 0.929 | 0.643 | |

| a* | 35.585 | 0.867 | 0.920 | 1.353 | |

| b* | 35.797 | 0.488 | 0.923 | 0.032 |

| Variety | Physicochemical Properties | Temperature (°C) | Regression Equation | R2 | Predicted Shelf Life (Days) |

|---|---|---|---|---|---|

| MD2 | Firmness | 5 | ln k = −0.053(1/T) + 4.45 | 0.8930 | 31.57 |

| 10 | ln k = −0.063(1/T) + 4.95 | 0.9232 | 39.52 | ||

| 25 | ln k = −0.065(1/T) + 3.91 | 0.8942 | 26.52 | ||

| Moisture content | 5 | ln k = 2.044(1/T) + 74.04 | 0.9421 | 33.58 | |

| 10 | ln k = 3.592(1/T) + 72.98 | 0.9884 | 38.76 | ||

| 25 | ln k = 2.824(1/T) + 79.87 | 0.9138 | 28.41 | ||

| Josapine | Firmness | 5 | ln k = −0.089(1/T) + 3.00 | 0.8970 | 21.52 |

| 10 | ln k = −0.096(1/T) + 3.05 | 0.9996 | 27.77 | ||

| 25 | ln k = −0.082(1/T) + 3.13 | 0.9317 | 16.68 | ||

| Moisture content | 5 | ln k = 1.239(1/T) + 63.69 | 0.8840 | 25.83 | |

| 10 | ln k = 1.121(1/T) + 64.76 | 0.8980 | 29.26 | ||

| 25 | ln k = 1.079(1/T) + 66.38 | 0.8812 | 21.19 | ||

| Morris | Firmness | 5 | ln k = −0.095(1/T) + 4.92 | 0.9233 | 32.53 |

| 10 | ln k = −1.026(1/T) + 5.90 | 0.9535 | 34.12 | ||

| 25 | ln k = −1.115(1/T) + 5.24 | 0.9014 | 28.53 | ||

| Moisture content | 5 | ln k = 3.636(1/T) + 79.35 | 0.8836 | 29.18 | |

| 10 | ln k = 3.852(1/T) + 73.36 | 0.9323 | 32.96 | ||

| 25 | ln k = 3.954(1/T) + 69.60 | 0.8968 | 28.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Ali, M.; Hashim, N.; Abd Aziz, S.; Lasekan, O. Shelf Life Prediction and Kinetics of Quality Changes in Pineapple (Ananas comosus) Varieties at Different Storage Temperatures. Horticulturae 2022, 8, 992. https://doi.org/10.3390/horticulturae8110992

Mohd Ali M, Hashim N, Abd Aziz S, Lasekan O. Shelf Life Prediction and Kinetics of Quality Changes in Pineapple (Ananas comosus) Varieties at Different Storage Temperatures. Horticulturae. 2022; 8(11):992. https://doi.org/10.3390/horticulturae8110992

Chicago/Turabian StyleMohd Ali, Maimunah, Norhashila Hashim, Samsuzana Abd Aziz, and Ola Lasekan. 2022. "Shelf Life Prediction and Kinetics of Quality Changes in Pineapple (Ananas comosus) Varieties at Different Storage Temperatures" Horticulturae 8, no. 11: 992. https://doi.org/10.3390/horticulturae8110992

APA StyleMohd Ali, M., Hashim, N., Abd Aziz, S., & Lasekan, O. (2022). Shelf Life Prediction and Kinetics of Quality Changes in Pineapple (Ananas comosus) Varieties at Different Storage Temperatures. Horticulturae, 8(11), 992. https://doi.org/10.3390/horticulturae8110992