A Theory of Planned Behavior-Informed Evaluation of Growers’ Intent to Use Automated Nursery Technologies

Abstract

1. Introduction

1.1. Theoretical Framework

1.2. Overview of Nursery Automation

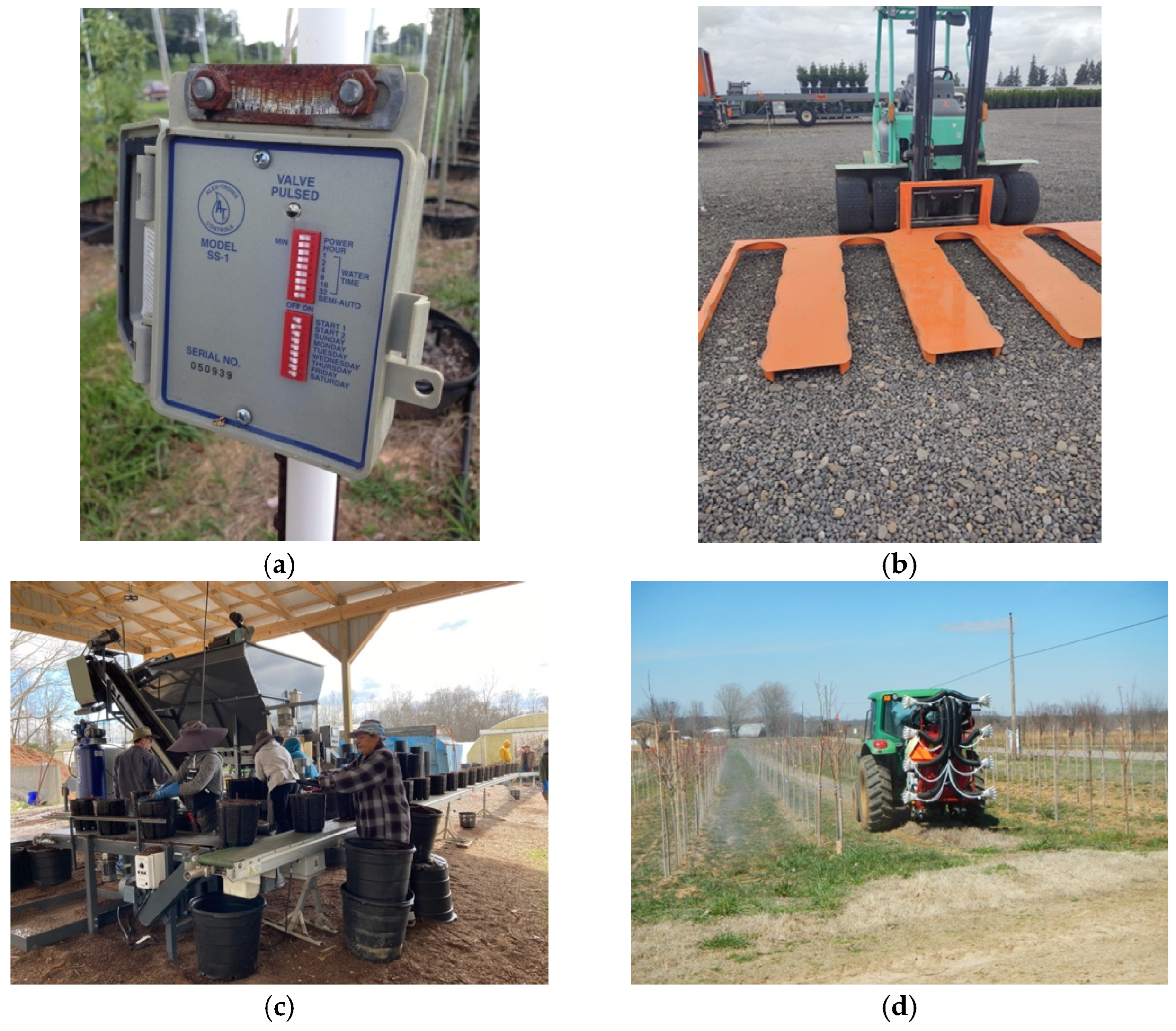

1.2.1. Irrigation Application

1.2.2. Plant Transport

1.2.3. Plant Handling

1.2.4. Agrochemical Application

2. Materials and Methods

2.1. Participant Characteristics and Sample Size

2.2. Measures and Instrumentation

2.3. Quality of Measurements

2.4. Data Analysis

2.5. Limitations

3. Results

3.1. Objective One: (1) Describe Theory of Planned Behavior and Normative Variables to Characterize the Present State of ANT Adoption

3.2. Objective Two: Identify Factors Related to the Likelihood of Future Adoption of Each of the Four ANT Categories

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hall, C.R.; Hodges, A.W.; Khachatryan, H.; Palma, M.A. Economic contributions of the green industry in the United States in 2018. J. Environ. Hortic. 2020, 38, 73–79. [Google Scholar] [CrossRef]

- Cruz, F.; Kostandini, G.; Mykerezi, E.; Jordan, J.; Tanellari, E. The effects of E-Verify on the share of labor-intensive and capital-intensive crops: Evidence from farm-level data. Agribus. Int. J. 2022, 38, 660–678. [Google Scholar] [CrossRef]

- Richards, T.J. Immigration reform and farm labor markets. Am. J. Agric. Econ. 2018, 100, 1051–1071. [Google Scholar] [CrossRef]

- Hall, C.R.; Ingram, D. Production costs of field-grown Cercis canadensis L. ‘Forest Pansy’ identified during life cycle assessment analysis. HortScience 2014, 49, 622–627. [Google Scholar] [CrossRef]

- Mathers, H.M.; Acuña, A.A.; Long, D.R.; Behe, B.K.; Hodges, A.W.; Haydu, J.J.; Schuch, U.K.; Barton, S.S.; Dennis, J.H.; Maynard, B.K.; et al. Nursery worker turnover and language proficiency. HortScience 2010, 45, 71–77. [Google Scholar] [CrossRef]

- Caplan, S.; Tilt, B.; Hoheisel, G.; Baugher, T.A. Specialty crop growers’ perspective on adopting new technologies. HortTechnology 2014, 24, 81–87. [Google Scholar] [CrossRef]

- Ling, P.P. From mechanization to the information highway. Greenhouse systems: Automation, culture and environment. In Proceedings of the Greenhouse Systems International Conference, New Brunswick, NJ, USA, 20–22 July 1994; pp. 5–7. [Google Scholar]

- Pan, M.; Linner, T.; Pan, W.; Cheng, H.; Bock, T. A framework of indicators for assessing construction automation and robotics in the sustainability context. J. Clean. Prod. 2018, 182, 82–95. [Google Scholar] [CrossRef]

- Posadas, B.C. Economic impacts of mechanization or automation on horticulture production firms sales, employment, and workers’ earnings, safety, and retention. HortTechnology 2012, 22, 388–401. [Google Scholar] [CrossRef]

- Hu, R. Garden-Related Behaviour and Invasive Plants: A Case Study in Wollongong LGA, New South Wales. Master’s Thesis, School of Earth and Environmental Sciences, University of Wollongong, Wollongong, Australia, 2014. Available online: https://ro.uow.edu.au/theses/4202/ (accessed on 2 September 2022).

- Shaw, B.R.; Radler, B.R.; Chenoweth, B.T.; Heiberger, R.; Dearlove, P. Predicting intent to install a rain garden to protect a local lake: An application of the theory of planned behavior. J. Ext. 2011, 49, 4FEA6. [Google Scholar]

- Dalvi-Esfahani, M.; Alaedini, Z.; Nilashi, M.; Samad, S.; Asadi, S.; Mohammadi, M. Students’ green information technology behavior: Beliefs and personality traits. J. Clean. Prod. 2020, 257, 120406. [Google Scholar] [CrossRef]

- Moons, I.; de Pelsmacker, P.; Pijnenburg, A.; Daems, K.; van de Velde, L.L.J. Growers’ adoption intention of innovations is crucial to establish a sustainable greenhouse horticultural industry: An empirical study in Flanders and the Netherlands. J. Clean. Prod. 2022, 330, 129752. [Google Scholar] [CrossRef]

- Hall, T.J.; Dennis, J.H.; Lopez, R.G.; Marshall, M.I. Factors affecting growers’ willingness to adopt sustainable floriculture practices. HortScience 2009, 44, 1346–1351. [Google Scholar] [CrossRef]

- Clark, W.A.; Finley, J.C. Determinants of water conservation intention in Blagoevgrad, Bulgaria. Soc. Nat. Resour. 2007, 20, 613–627. [Google Scholar] [CrossRef]

- Kumar Chaudhary, A.; Warner, L.A.; Lamm, A.J.; Israel, G.D.; Rumble, J.N.; Cantrell, R.A. Using the theory of planned behavior to encourage water conservation among extension clients. J. Agric. Educ. 2017, 58, 185–202. [Google Scholar] [CrossRef]

- Warner, L.A. Who conserves and who approves? Predicting water conservation intentions in urban landscapes with referent groups beyond the traditional ‘important others’. Urban For. Urban Green. 2021, 60, 127070. [Google Scholar] [CrossRef]

- Hattam, C. Adopting organic agriculture: An investigation using the theory of planned behaviour. In Proceedings of the International Association of Agricultural Economics Conference, Gold Coast, Australia, 12–18 August 2006. No. 1004-2016-78538. [Google Scholar] [CrossRef]

- Ajzen, I. The theory of planned behavior. Organ. Behav. Hum. Decis. Process. 1991, 50, 179–211. [Google Scholar] [CrossRef]

- Cialdini, R.B.; Reno, R.R.; Kallgren, C.A. A focus theory of normative conduct: Recycling the concept of norms to reduce littering in public places. J. Personal. Soc. Psychol. 1990, 58, 1015–1026. [Google Scholar] [CrossRef]

- Lapinski, M.K.; Rimal, R.N. An explication of social norms. Commun. Theory 2005, 15, 127–147. [Google Scholar] [CrossRef]

- Bicchieri, C. Norms in the Wild. How to Diagnose, Measure, and Change Social Norms; Oxford University Press: New York, NY, USA, 2017. [Google Scholar]

- Eisenstadt, S.M. Reference group behavior and social integration: An explorative study. Am. Sociol. Rev. 1954, 19, 175–185. [Google Scholar] [CrossRef]

- Warner, L.A.; Hobbs, W.H. Examining the potential role of descriptive norms in landscape water conservation programs. J. Ext. 2020, 58, 26. [Google Scholar]

- Uren, H.V.; Dzidic, P.L.; Bishop, B.J. Exploring social and cultural norms to promote ecologically sensitive residential garden design. Landsc. Urban Plan. 2015, 137, 76–84. [Google Scholar] [CrossRef]

- Warner, L.A.; Turner, S.; Lundy, L. Comparing linkages between descriptive norms and current and intended outdoor water conservation. J. Ext. 2020, 58, 16. [Google Scholar]

- Zhllima, E.; Shahu, E.; Xhoxhi, O.; Gjika, I. Understanding farmers’ intentions to adopt organic farming in Albania. New Medit 2021, 20, 97–111. [Google Scholar] [CrossRef]

- Lynne, G.D.; Casey, C.F.; Hodges, A.; Rahmani, M. Conservation technology adoption decisions and the theory of planned behavior. J. Econ. Psychol. 1995, 16, 581–598. [Google Scholar] [CrossRef]

- Lamm, A.J.; Warner, L.A.; Martin, E.; White, S.A.; Fischer, P. Enhancing extension programs by discussing water conservation technology adoption with growers. J. Agric. Educ. 2017, 58, 251–266. [Google Scholar] [CrossRef]

- Tama, R.A.Z.; Ying, L.; Yu, M.; Hoque, M.M.; Adnan, K.M.M.; Sarker, S.A. Assessing farmers’ intention towards conservation agriculture by using the extended theory of planned behavior. J. Environ. Manag. 2021, 280, 111654. [Google Scholar] [CrossRef]

- Ataei, P.; Gholamrezai, S.; Movahedi, R.; Aliabadi, V. An analysis of farmers’ intention to use green pesticides: The application of the extended theory of planned behavior and health belief model. J. Rural Stud. 2021, 81, 374–384. [Google Scholar] [CrossRef]

- Semuroh, J.; Sumin, V. Factors affecting the intention of sustainable agriculture practices among pepper farmers in Sarawak, Malaysia. Food Res. 2021, 5, 92–100. [Google Scholar] [CrossRef]

- Galati, A.; Sabatino, L.; Prinzivalli, C.S.; D’Anna, F.; Scalenghe, R. Strawberry fields forever: That is, how many grams of plastics are used to grow a strawberry? J. Environ. Manag. 2020, 276, 111313. [Google Scholar] [CrossRef]

- McKenzie-Mohr, D. Fostering Sustainable Behavior: An Introduction to Community-Based Social Marketing; New Society Publishers: Gabriola Island, BC, Canada, 2011. [Google Scholar]

- Rihn, A.L.; Velandia, M.; Warner, L.A.; Fulcher, A.; Schexnayder, S.; LeBude, A.V. Factors correlated with the propensity to use automation and mechanization by the U.S. nursery industry. Agribusiness 2022. [Google Scholar] [CrossRef]

- Warner, L.A.; Rihn, A.L.; Fulcher, A.; Schexnayder, S.; LeBude, A.V. Relating grower perceptions and adoption of automated nursery technologies to address labor needs. J. Agric. Educ. 2022, 63, 146–164. [Google Scholar] [CrossRef]

- Rogers, E.M. Diffusion of Innovations, 3rd ed.; Simon and Schuster: New York, NY, USA, 2003. [Google Scholar]

- LeaP for Sustainability Nursery Labor and Automation [LEAP]. LEAP Nursery Labor and Automation Survey; University of Tennessee: Knoxville, TN, USA, 2020. [Google Scholar]

- Yeary, W.; Fulcher, A.; Leib, B. Nursery Irrigation: A Guide for Reducing Risk and Improving Production. University of Tennessee Extension Publication PB 1836. 2016. Available online: https://extension.tennessee.edu/publications/Documents/PB1836.pdf (accessed on 20 August 2022).

- Belayneh, B.E.; Lea-Cox, J.D.; Lichtenberg, E. Costs and benefits of implementing sensor-controlled irrigation in a commercial pot-in-pot container nursery. HortTechnology 2013, 23, 760–769. [Google Scholar] [CrossRef]

- Cypher, Q.; Wright, W.C.; Sun, X.; Fessler, L.; Fulcher, A. Automated leachating fraction-based system reduces leaching, conserves water, and supports crop growth in a commercial nursery. Appl. Eng. Agric. 2022, 38, 807–816. [Google Scholar] [CrossRef]

- Fang, W.; Ting, K.C.; Giacomelli, G.A. Animated simulation of greenhouse internal transport using SIMAN/CINEMA. Trans. Agric. 1990, 33, 336–340. [Google Scholar] [CrossRef]

- Zhu, H.; Rosetta, R.; Reding, M.E.; Zondag, R.H.; Ranger, C.M.; Canas, L.; Fulcher, A.; Derksen, R.C.; Ozkan, H.E.; Krause, C.R. Validation of a laser-guided variable-rate sprayer for managing insects in ornamental nurseries. Trans. ASABE 2017, 60, 337–345. Available online: https://elibrary.asabe.org/abstract.asp?aid=47709 (accessed on 1 March 2022).

- Chen, L.; Zhu, H.; Horst, L.; Wallhead, M.; Reding, R.; Fulcher, A. Management of pest insects and plant diseases in fruit and nursery production with laser-guided variable-rate sprayers. HortScience 2021, 56, 94–100. [Google Scholar] [CrossRef]

- Fessler, L.; Fulcher, A.; Schneider, L.; Wright, W.; Zhu, H. Reducing the nursery pesticide footprint with laser-guided, variable-rate spray application technology. HortScience 2021, 56, 1572–1584. [Google Scholar] [CrossRef]

- Manandhar, A.; Zhu HOzkan, E.; Shah, A. Techno-economic impacts of using a laser-guided variable-rate spraying system to retrofit conventional constant-rate sprayers. Precis. Agric. 2020, 21, 1156–1171. [Google Scholar] [CrossRef]

- Lowenberg-DeBoer, J.; Huang, I.Y.; Grigoriadis, V.; Blackmore, S. Economics of robots and automation in field crop production. Precis. Agric. 2020, 21, 278–299. [Google Scholar] [CrossRef]

- Vaske, J.J. Survey Research and Analysis: Applications in Parks, Recreation and Human Dimensions; Venture Publishing: State College, PA, USA, 2008. [Google Scholar]

- AAPOR American Association for Public Opinion Research (AAPOR). Survey Outcome Rate Calculator 4.1. 2020. Available online: https://www.aapor.org/Education-Resources/For-Researchers/Poll-Survey-FAQ/Response-Rates-An-Overview.aspx (accessed on 1 March 2022).

- Ary, D.; Jacobs, L.C.; Irvine, C.K.S.; Walker, D. Introduction to Research in Education, 10th ed.; Cengage Learning: Boston, MA, USA, 2019. [Google Scholar]

| Irrigation application |

| Irrigation scheduling technology (e.g., leaching fraction, moisture probes; do not consider a rain delay feature) |

| Time-based irrigation controller |

| Hose and gun or center pivot irrigation |

| Permanent, rigid irrigation (such as PVC, field or container) |

| Drip irrigation |

| Plant transport |

| B&B tree handler: Tree Boss, Tree Jaws®, etc. to move B&B |

| Forklift to move and space product |

| Forklift to move B&B |

| Trike to move and space product |

| Tractor/truck/wagon to move product |

| Conveyer belts |

| Plant handling |

| Mechanical liner setter/planter (field) |

| Potting machine |

| Mechanical stake installer |

| Lifter or shaker |

| Tree spade |

| Pneumatic c-ring fastener for burlapping |

| Tying machine (during production; e.g., Max Tapener, etc.) |

| Mechanical bundler or tying machine (post-harvest) |

| Robotic plant spacers |

| Agrochemical application |

| Pesticide application technology (e.g., GPS tracking, crop sensing) |

| Granular fertilizer applicator |

| Liquid fertilizer injector |

| Variable | M (SD) |

|---|---|

| Intent to adopt | |

| Irrigation application ANT | −0.188 (1.238) |

| Plant transport ANT | −0.257 (1.218) |

| Plant handling ANT | −0.379 (1.104) |

| Agrochemical application ANT | −0.112 (1.305) |

| Attitude | 1.252 (0.885) |

| Perceived behavioral control | 0.274 (0.745) |

| Injunctive norms | |

| Growers | 0.630 (0.831) |

| Industry | 0.688 (0.821) |

| Customers | 0.695 (0.770) |

| Family | 0.935 (0.814) |

| Descriptive norms | |

| Growers | 0.029 (1.010) |

| Industry | 0.117 (0.907) |

| Constant | AIC | R2 | B | β | p | |

|---|---|---|---|---|---|---|

| Overall model * | −0.897 | 33.114 | 0.207 | 0.012 | ||

| Attitude * | 0.532 | 0.383 | 0.017 | |||

| Perceived behavioral control | ||||||

| Injunctive norms | −0.058 | −0.037 | 0.804 | |||

| Growers | 0.362 | 0.269 | 0.072 | |||

| Industry | −0.325 | −0.234 | 0.098 | |||

| Customers | −0.359 | −0.246 | 0.129 | |||

| Family | 0.293 | 0.209 | 0.143 | |||

| Descriptive norms | ||||||

| Growers * | −0.388 | −0.335 | 0.007 | |||

| Industry | −0.016 | −0.012 | 0.917 |

| Constant | AIC | R2 | B | β | p | |

|---|---|---|---|---|---|---|

| Overall model * | −1.004 | 44.515 | 0.184 | 0.001 | ||

| Attitude * | 0.655 | 0.429 | 0.001 | |||

| Perceived behavioral control | 0.032 | 0.019 | 0.865 | |||

| Injunctive norms | ||||||

| Growers | 0.233 | 0.161 | 0.157 | |||

| Industry | −0.276 | −0.188 | 0.112 | |||

| Customers | −0.215 | −0.135 | 0.295 | |||

| Family | 0.132 | 0.088 | 0.440 | |||

| Descriptive norms | ||||||

| Growers | −0.186 | −0.149 | 0.137 | |||

| Industry | −0.084 | −0.061 | 0.533 |

| Constant | AIC | R2 | B | β | p | |

|---|---|---|---|---|---|---|

| Overall model * | −0.824 | 14.237 | 0.163 | 0.002 | ||

| Attitude | 0.305 | 0.229 | 0.054 | |||

| Perceived behavioral control | 0.282 | 0.185 | 0.095 | |||

| Injunctive norms | ||||||

| Growers * | 0.299 | 0.232 | 0.040 | |||

| Industry | −0.155 | −0.119 | 0.285 | |||

| Customers * | −0.440 | −0.316 | 0.013 | |||

| Family | 0.191 | 0.143 | 0.194 | |||

| Descriptive norms | ||||||

| Growers | −0.069 | −0.064 | 0.519 | |||

| Industry | −0.048 | −0.040 | 0.675 |

| Constant | AIC | R2 | B | β | p | |

|---|---|---|---|---|---|---|

| Overall model * | −0.675 | 53.805 | 0.191 | 0.001 | ||

| Attitude * | 0.410 | 0.264 | 0.047 | |||

| Perceived behavioral control | 0.256 | 0.145 | 0.240 | |||

| Injunctive norms | ||||||

| Growers * | 0.410 | 0.277 | 0.024 | |||

| Industry | −0.203 | −0.132 | 0.275 | |||

| Customers * | −0.483 | −0.299 | 0.031 | |||

| Family | 0.255 | 0.163 | 0.185 | |||

| Descriptive norms | ||||||

| Growers | −0.071 | −0.055 | 0.627 | |||

| Industry | −0.155 | −0.110 | 0.310 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warner, L.A.; Rihn, A.L.; Fulcher, A.; LeBude, A.V.; Schexnayder, S.; Joshi, A. A Theory of Planned Behavior-Informed Evaluation of Growers’ Intent to Use Automated Nursery Technologies. Horticulturae 2022, 8, 1028. https://doi.org/10.3390/horticulturae8111028

Warner LA, Rihn AL, Fulcher A, LeBude AV, Schexnayder S, Joshi A. A Theory of Planned Behavior-Informed Evaluation of Growers’ Intent to Use Automated Nursery Technologies. Horticulturae. 2022; 8(11):1028. https://doi.org/10.3390/horticulturae8111028

Chicago/Turabian StyleWarner, Laura A., Alicia L. Rihn, Amy Fulcher, Anthony V. LeBude, Susan Schexnayder, and Arati Joshi. 2022. "A Theory of Planned Behavior-Informed Evaluation of Growers’ Intent to Use Automated Nursery Technologies" Horticulturae 8, no. 11: 1028. https://doi.org/10.3390/horticulturae8111028

APA StyleWarner, L. A., Rihn, A. L., Fulcher, A., LeBude, A. V., Schexnayder, S., & Joshi, A. (2022). A Theory of Planned Behavior-Informed Evaluation of Growers’ Intent to Use Automated Nursery Technologies. Horticulturae, 8(11), 1028. https://doi.org/10.3390/horticulturae8111028