Application of Room Cooling and Thermal Insulation Materials to Maintain Quality of Okra during Storage and Transportation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Properties

2.2. Plant Materials

2.3. Experimental Treatments and Heat from Respiration Rate (RR)

2.3.1. Handling Procedures

2.3.2. Determination of Respiration Rate

100 × (fruit weight (kg)) × (closing time (h))

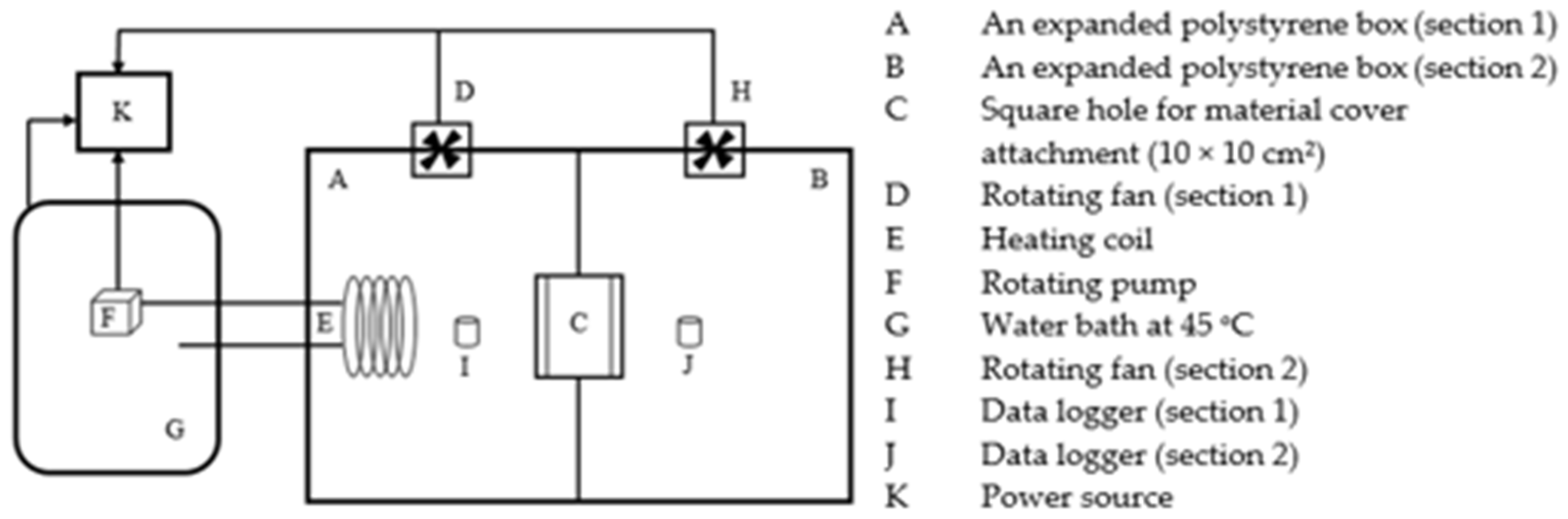

2.4. Temperature and Relative Humidity Monitoring

2.5. Mass Loss Determination

2.6. Determination of Decay Incidence

2.7. Statistical Analysis

3. Results and Discussion

3.1. Materials Properties

3.2. Respiration Rate, Q10 Value, and Heat from Respiration Rate

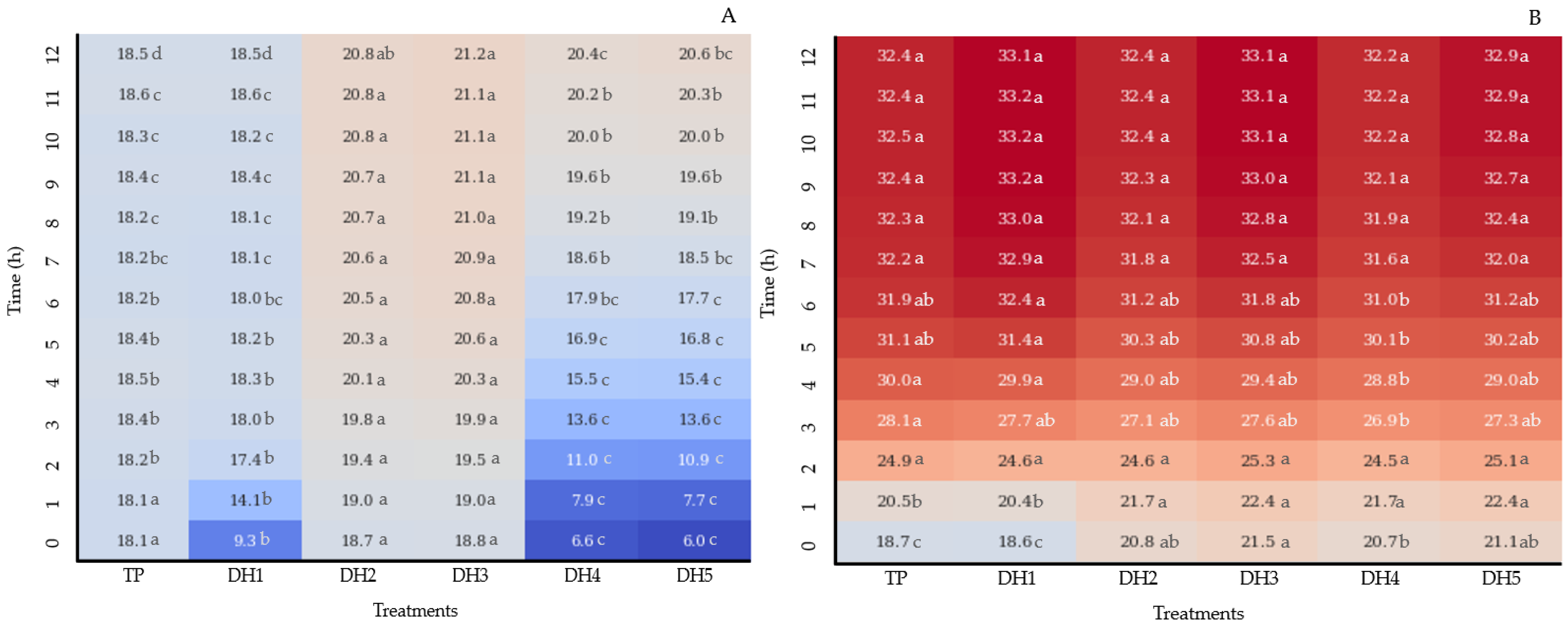

3.3. Air and Pulp Temperature Levels of Okra

3.4. Relative Humidity inside Covering Materials

3.5. Mass Loss of Okra

3.6. Incidence of Decay (ID)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Tripathi, K.K.; Govila, O.P.; Warrier, R.; Ahuja, V. Biology of Abelmoschus esculentus L. (Okra). In Series of Crop Specific Biology Documents; Department of Biotechnology, Ministry of Science & Technology & Ministry of Environment and Forest, Govt. of India: New Delhi, India, 2011; 26p. [Google Scholar]

- Thai Customs. Statistic Report 2020. 2020. Available online: http://www.customs.go.th/statistic_report.php?lang=en&tariff_code=07099990003 (accessed on 14 August 2020).

- Tsado, E.K. Quality of postharvest handling of marketable okra fruits sold in Minna, Niger State, Nigeria. Eur. J. Agric. For. Res. 2015, 3, 33–45. [Google Scholar]

- Okra: Postharvest Care and Market Preparation; Publications in the Postharvest Handling Technical Bulletin Series No.10. 2003. Available online: http://agriculture.gov.gy/wp-content/uploads/2016/01/Okra.pdf (accessed on 10 November 2020).

- Perkins-Veazie, P.; Collins, J.K. Cultivar, packing and storage temperature differences in postharvest shelf life of okra. HortTechnogy 1992, 2, 350–352. [Google Scholar] [CrossRef] [Green Version]

- Taain, D.A.; Jasim, A.M.; Al-Hij, M.J.H.H. A study of storage behavior of okra fruits (Abelmoschus esculuntus L. Moenth cv. Khnesri). Int. J. Farming Allied Sci. 2014, 3, 760–766. [Google Scholar]

- Okra: The Commercial Storage of Fruits. Vegetables and Florist and Nursery Stocks. USDA-ARS Agriculture Handbook #66 (Revised). 2016. Available online: https://www.ars.usda.gov/arsuserfiles/oc/np/commercialstorage/commercialstorage.pdf (accessed on 10 November 2020).

- Cheng, Z.; Gong, X.; Jing, W.; Peng, Z.; Li, J. Quality change of postharvest okra at different storage temperatures. J. Food Eng. Technol. 2018, 7, 43. [Google Scholar]

- Kader, A.A. Postharvest Technology of Horticultural Crops, 3rd ed.; University of California Agriculture and Natural Resources: Davis, CA, USA, 2002; pp. 39–47. [Google Scholar]

- Huang, S.; Li, T.; Jiang, G.; Xie, W.; Chang, S.; Jiang, Y.; Duan, X. 1-Methylcyclopropene reduces chilling injury of harvested okra (Hibiscus esculentus L.) pods. Sci. Hortic. 2012, 141, 42–46. [Google Scholar] [CrossRef]

- Saltviet, M.E. Measuring Respiration. 2015. Available online: http://ucce.ucdavis.edu/files/datastore/234-20.pdf (accessed on 10 June 2020).

- Kienholz, J.; Edeogu, I. Fresh Fruit and Vegetable Pre-Cooling for Market Gardeners in Alberta; Alberta Agriculture, Food and Rural Development: Edmonton, AB, Canada, 2002; pp. 1–4. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). Good Practice in the Design Management and Operation of a Fresh Produce Packing-House; FAO Region Office for Asia and the Pacific: Bangkok, Thailand, 2012; pp. 44–47. [Google Scholar]

- Dhall, R.K.; Sharma, S.R.; Mahajan, B.V.C. Development of post-harvest protocol of okra for export marketing. J. Food Sci. Technol. 2014, 51, 1622–1625. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Ma, Z.; Zhao, C.; Chen, Y. Study on forced-air pre-cooling of Longan. In 2007 ASAE Annual Meeting 076267, Minneapolis, MN, 17–20 June 2007; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007. [Google Scholar]

- Wang, Z.; Chen, L.; Yang, H.; Wang, A. Effect of exogenous glycine betaine on qualities of button mushrooms (Agaricus bisporus) during postharvest storage. Eur. Food Res. Technol. 2015, 240, 41–48. [Google Scholar] [CrossRef]

- Deshmukh, G.; Birwal, P.; Datir, R.; Patel, S. Thermal insulation materials: A tool for energy conservation. J. Food Process Technol. 2017, 8, 670. [Google Scholar] [CrossRef]

- Wheeler, L.; Kitinoja, L.; Barrett, D. Use of insulated covers over product crates to reduce losses in amaranth during shipping delays. Agriculture 2015, 5, 1204–1223. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.P.; Burgess, G.; Singh, J. Performance comparison of thermal insulated packaging boxes, bags and refrigerants for single-parcel shipments. Packag. Technol. Sci. 2008, 21, 25–35. [Google Scholar] [CrossRef] [Green Version]

- Harding, K.G. Heat Transfer Introduction; University of the Witwatersrand: Johannesburg, South Africa, 2018; pp. 1–62. [Google Scholar]

- Harvey, B.V. Mild Chilling Injury of Banana (Cavendish cv. Williams) and Its Control in the Field. Ph.D. Thesis, The University of Adelaide, Adelaide, Australia, September 2005. [Google Scholar]

- Desjarlais, A.O.; Zarr, R.R. (Eds.) Insulation Materials, Testing and Applications, 4th Volume (Vol. 1426); ASTM International: West Conshohocken, PA, USA, 2002; 417p. [Google Scholar]

- Chaiwong, S.; Bishop, C.F.H. Use of an insulated bag from the supermarket to maintain ‘Elsanta’ strawberry temperature to households. Acta Hortic. 2014, 1079, 187–192. [Google Scholar] [CrossRef]

- Melis, R.B. New Techniques and Methods for Cold Chain Monitoring and Tracking in Perishable Products. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2016; pp. 134–146. [Google Scholar]

- Liu, Y.B. Low-temperature phosphine fumigation of chilled lettuce under insulated cover for postharvest control of western flower thrips, Frankliniella occidentalis (Pergande) (Thysanoptera: Thripidae). J. Asia Pac. Entomol. 2011, 14, 323–325. [Google Scholar] [CrossRef]

- ASTM. (96). Standard Test Methods for Water Vapor Transmission of Materials; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- ASTM. Standard Test Method for Air Permeability of Textile Fabrics; D737-96; ASTM International: West Conshohocken, PA, USA, 1996; pp. 230–234. [Google Scholar]

- Kader, A.A.; Saltveit, M.E. Respiration and gas exchange. Post. Physio. Patho. Veg. 2003, 2, 7–29. [Google Scholar]

- Patel, B.B.; Roy, F.S.; Saiyad, M.J.S.; Joshi, D.C. Respiration behaviour and heat of respiration of mango (cv. Langdo) under different storage conditions. Int. J. Agric. Environ. Biotechnol. 2016, 9, 855–859. [Google Scholar] [CrossRef]

- Ngure, J.W.; Aguyoh, J.N.; Gaoquiong, L. Interactive effects of packaging and storage temperatures on the shelf-life of okra. ARPN J. Agric. Biol. Sci. 2009, 4, 43–52. [Google Scholar]

- Mangaraj, S.; Goswami, T.K.; Panda, D.K. Modeling of gas transmission properties of polymeric films used for MA packaging of fruits. J. Food Sci. Technol. 2015, 52, 5456–5469. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tripathi, P.C.; Lawande, K.E. Temperature-related changes in respiration and Q10 coefficient in different varieties of onion. Progress. Hortic. 2010, 42, 88–90. [Google Scholar]

- Murata, S.; Miyauchi, K.; Wang, Y. Measurement of respiration of fresh vegetables. J. Jpn. Soc. Agric. Mach. 1993, 55, 69–75. [Google Scholar]

- Yasunaga, E.; Tomita, K.; Hamanaka, D.; Hu, W.; Uchino, T. Effect of temperature on the respiration rate of some vegetables. IFAC Proc. Vol. 2001, 34, 205–210. [Google Scholar]

- Bollen, F.; Bycroft, B.L.; Brash, D.W. Using insulation and cooling to improve the asparagus cool chain. Acta Hortic. 1993, 415, 323–332. [Google Scholar]

- Paternoster, A.; Van Camp, J.; Vanlanduit, S.; Weeren, A.; Springael, J.; Braet, J. The performance of beer packaging: Vibration damping and thermal insulation. Food Packag. Shelf Life 2017, 11, 91–97. [Google Scholar] [CrossRef]

- Dieckmann, E.; Nagy, B.; Yiakoumetti, K.; Sheldrick, L.; Cheeseman, C. Thermal insulation packaging for cold-chain deliveries made from feathers. Food Packag. Shelf Life 2019, 21, 100360. [Google Scholar] [CrossRef]

- Lim, B.S.; Lim, C.I.; Gross, K.C. High relative humidity under pallet coverage maintained ‘Niitaka’ pear fruit (Pyruspyrifolia Nakai) quality during low temperature storage. Korean J. Hortic. Sci. Technol. 2005, 23, 135–139. [Google Scholar]

- Macnish, A.J.; Padda, M.S.; Pupin, F.; Tsouvaltzis, P.I.; Deltsidis, A.I.; Sims, C.A.; Brecht, J.K.; Mitcham, E.J. Comparison of pallet cover systems to maintain strawberry fruit quality during transport. HortTechnology 2012, 22, 493–501. [Google Scholar] [CrossRef] [Green Version]

- Moureh, J.; Laguerre, O.; Flick, D.; Commere, B. Analysis of use of insulating pallet covers for shipping heat-sensitive foodstuffs in ambient conditions. Comput. Electron. Agric. 2002, 34, 89–109. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mc Carthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Villalba, J.R. New trends in cold chain monitoring applications-A review. Food Control 2018, 86, 170–182. [Google Scholar] [CrossRef]

| Treatment | Description |

|---|---|

| TP (Control) | No room cooling with P-LLDPE covering |

| DH1 | Room cooling with P-LLDPE covering |

| DH2 | No room cooling with HRS+TNNW covering |

| DH3 | No room cooling with MFS covering |

| DH4 | Room cooling with HRS+TNNW covering |

| DH5 | Room cooling with MFS covering |

| Material | Thickness (mm) | Thermal Heat Energy (Qx × 10−4) (J s−1) | R-Value (m2 °C W−1) | Water Vapor Permeability (g h−1 m−2) | Air Permeability (l m−2 s−1) |

|---|---|---|---|---|---|

| P-LLDPE | 0.120 ± 0.03 d | 3.85 ± 0.06 a | 0.153 ± 0.01 d | 0.325 ± 0.04 a | 172.80 ± 12.05 b |

| TNNW | 0.270 ± 0.20 c | 3.23 ± 0.07 b | 0.187 ± 0.01 c | 0.450 ± 0.05 a | 945.60 ± 43.21 a |

| HRS | 1.450 ± 0.43 b | 2.57 ± 0.12 c | 0.211 ± 0.02 b | 0.000003 ± 0.00 b | 0.59 ± 0.01 d |

| MFS | 3.100 ± 0.08 a | 1.53 ± 0.06 d | 0.225 ± 0.01 a | 0.000012 ± 0.00 b | 49.42 ± 0.21 c |

| Temperature (°C) | RCO2 (mg CO2 kg−1 h−1) | Q10 | ||

|---|---|---|---|---|

| Day 2 | Day 3 | Day 2 | Day 3 | |

| 10 | 186.39 | 207.33 | ||

| 1.17 | 1.87 | |||

| 20 | 237.70 | 325.63 | ||

| 1.50 | 1.37 | |||

| 30 | 355.44 | 444.61 | ||

| Treatment | Rc1 (mg CO2 kg−1 h−1) | Vital Heat (J kg−1 h−1) |

|---|---|---|

| TP | 329 ± 0.0 a | 3522 ± 0.1 a |

| DH1 | 329 ± 0.0 a | 3522 ± 0.1 a |

| DH2 | 330 ± 0.8 a | 3529 ± 8.1 a |

| DH3 | 330 ± 0.9 a | 3536 ± 9.3 a |

| DH4 | 214 ± 0.4 b | 2288 ± 4.7 b |

| DH5 | 218 ± 1.9 b | 2329 ± 20.1 b |

| Treatment | Rc2 (mg CO2 kg−1 h−1) at 1 h | Vital Heat (J kg−1 h−1) at 1 h | Rc2 (mg CO2 kg−1 h−1) at 15 h | Vital Heat (J kg−1 h−1) at 15 h |

|---|---|---|---|---|

| TP | 541 ± 4.7 a | 5791 ± 49.0 a | 640 ± 0.3 | 6853 ± 3.1 |

| DH1 | 549 ± 2.6 a | 5873 ± 28.5 a | 646 ± 0.6 | 6914 ± 6.3 |

| DH2 | 486 ± 6.1 b | 5202 ± 66.3 bc | 633 ± 4.0 | 6774 ± 42.5 |

| DH3 | 483 ± 4.7 b | 5167 ± 49.7 bc | 629 ± 8.2 | 6732 ± 87.4 |

| DH4 | 506 ± 2.7 b | 5413 ± 28.0 b | 632 ± 3.2 | 6768 ± 34.3 |

| DH5 | 481 ± 8.4 b | 5148 ± 88.4 c | 645 ± 3.8 | 6900 ± 40.9 |

| Treatment | Rate of Temperature Changes (°Ch−1) | |||

|---|---|---|---|---|

| Air Temperature | Pulp Temperature | |||

| T1–25 °C | 25–30 °C | T1–25 °C | 25–30 °C | |

| TP | 7.54 ± 0.17 b | 1.40 ± 0.02 a | 4.26 ± 0.20 a | 2.64 ± 0.15 a |

| DH1 | 7.34 ± 0.21 b | 1.40 ± 0.01 a | 4.00 ± 0.11 a | 2.58 ± 0.02 ab |

| DH2 | 9.56 ± 0.47 ab | 1.13 ± 0.04 b | 2.55 ± 0.08 b | 2.02 ± 0.05 bc |

| DH3 | 10.30 ± 1.41 ab | 1.32 ± 0.05 a | 2.50 ± 0.08 b | 1.88 ± 0.15 c |

| DH4 | 11.69 ± 0.47 a | 1.14 ± 0.03 b | 2.59 ± 0.10 b | 1.83 ± 0.08 c |

| DH5 | 9.25 ± 0.45 ab | 1.08 ± 0.04 b | 2.75 ± 0.18 b | 1.75 ± 0.15 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rattanakaran, J.; Saengrayap, R.; Prahsarn, C.; Kitazawa, H.; Chaiwong, S. Application of Room Cooling and Thermal Insulation Materials to Maintain Quality of Okra during Storage and Transportation. Horticulturae 2021, 7, 188. https://doi.org/10.3390/horticulturae7070188

Rattanakaran J, Saengrayap R, Prahsarn C, Kitazawa H, Chaiwong S. Application of Room Cooling and Thermal Insulation Materials to Maintain Quality of Okra during Storage and Transportation. Horticulturae. 2021; 7(7):188. https://doi.org/10.3390/horticulturae7070188

Chicago/Turabian StyleRattanakaran, Jutarat, Rattapon Saengrayap, Chureerat Prahsarn, Hiroaki Kitazawa, and Saowapa Chaiwong. 2021. "Application of Room Cooling and Thermal Insulation Materials to Maintain Quality of Okra during Storage and Transportation" Horticulturae 7, no. 7: 188. https://doi.org/10.3390/horticulturae7070188

APA StyleRattanakaran, J., Saengrayap, R., Prahsarn, C., Kitazawa, H., & Chaiwong, S. (2021). Application of Room Cooling and Thermal Insulation Materials to Maintain Quality of Okra during Storage and Transportation. Horticulturae, 7(7), 188. https://doi.org/10.3390/horticulturae7070188