Smallholder Farmer Perceptions of Postharvest Loss and Its Determinants in Fijian Tomato Value Chains

Abstract

1. Introduction

2. Materials and Methods

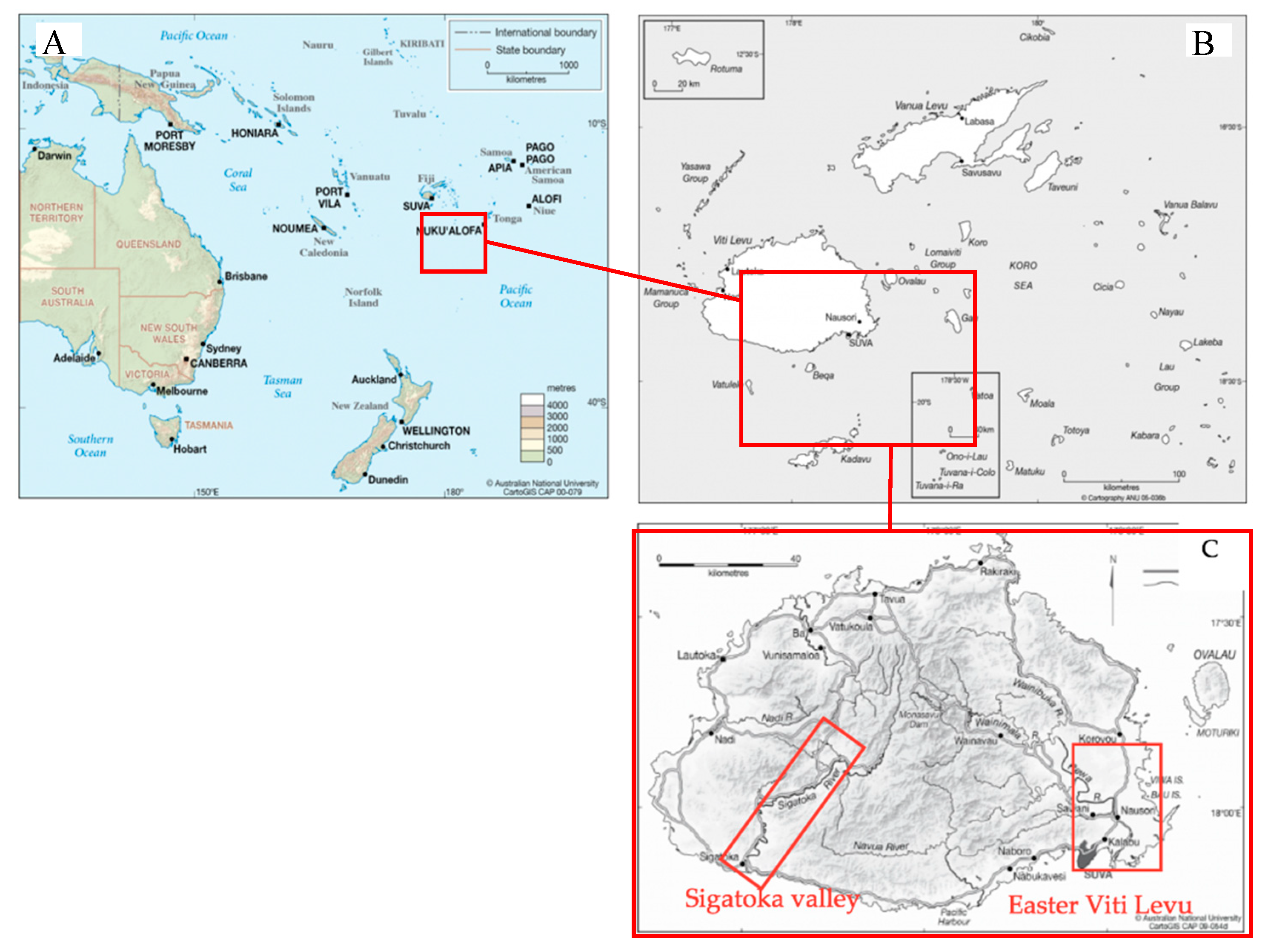

2.1. Location

2.2. Survey Design

2.3. Data Collection

2.4. Data Analysis

3. Results

3.1. Farmer Socio-Demographics and Land Access

3.2. On-Farm Postharvest Infrastructure

3.3. Loss During On-Farm Postharvest Handling Practice

3.4. Postharvest Loss Associated with Specific Types of Postharvest Handling Practice

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Choudhury, M.L. Recent developments in reducing postharvest losses in the Asia-Pacific region. In Postharvest Management of Fruit and Vegetables in the Asia-Pacific Region; Rolle, R., Ed.; Asian Productivity Organization: Tokyo, Japan, 2006; pp. 15–22. ISBN 92-833-7051-1. [Google Scholar]

- Weinberger, K.M.; Easdown, W.J.; Yang, R.Y.; Keatinge, J.D.H. Food crisis in the Asia-Pacific region. Asia Pac. J. Clin. Nutr. 2009, 18, 507–515. [Google Scholar] [PubMed]

- Underhill, S.J.R. Improving the effectiveness of small-holder farm postharvest practices in Fiji. Acta Hort. 2012, 1011, 41–48. [Google Scholar] [CrossRef]

- Underhill, S.J.R.; Kumar, S. Quantifying horticulture postharvest wastage in three municipal fruit and vegetable markets in Fiji. Int. J. Post. Technol. Innov. 2014, 4, 251–261. [Google Scholar] [CrossRef]

- Underhill, S.J.R.; Kumar, S. Quantifying postharvest losses along a commercial tomato supply chain in Fiji. J. Appl. Hort. 2015, 17, 199–204. [Google Scholar]

- Underhill, S.J.R.; Kumar, S. Postharvest handling of tropical fruit in the South Pacific. Fiji Agric. J. 2017, 57, 19–26. [Google Scholar]

- Macheka, L.; Spelt, E.J.; Bakker, E.J.; van der Vorst, J.G.; Luning, P.A. Identification of determinants of postharvest losses in Zimbabwean tomato supply chains as basis for dedicated interventions. Food Control 2018, 87, 135–144. [Google Scholar] [CrossRef]

- Underhill, S.J.R.; Zhou, Y.; Sherzad, S.; Singh-Peterson, L.; Tagoai, S.M. Horticultural postharvest loss in municipal fruit and vegetable markets in Samoa. Food Secur. 2017, 9, 1373–1383. [Google Scholar] [CrossRef]

- Underhill, S.J.R.; Joshua, L.; Zhou, Y. A preliminary assessment of horticultural postharvest market loss in the Solomon Islands. Horticulturae 2019, 5, 5. [Google Scholar] [CrossRef]

- Kitinoja, L.; Kader, A.A. Measuring Postharvest Losses of Fresh Fruits and Vegetables in Developing Countries. The Postharvest Education Foundation White Paper 15-02. 2015. Available online: http://www.postharvest.org/PEF_White_Paper_15-02_PHFVmeasurement.pdf (accessed on 21 April 2019).

- Kumar, V. Fiji. In Postharvest Management of Fruit and Vegetables in the Asia-Pacific Region; Rolle, R., Ed.; Asian Productivity Organization: Tokyo, Japan, 2006; pp. 123–130. ISBN 92-833-7051-1. [Google Scholar]

- Kitinoja, L.; Saran, S.; Roy, S.K.; Kader, A.A. Postharvest technology for developing countries: Challenges and opportunities in research, outreach and advocacy. J. Sci. Food Agric. 2011, 91, 597–603. [Google Scholar] [CrossRef]

- Cocker, E. Postharvest handling status and problems of the Pacific Island countries. In Quality Assurance in Agricultural Produce; Johnson, G.I., Van To, L., Duy Duc, N., Webb, M.C., Eds.; ACIAR Proceedings 100: Canberra, Australia, 2000; pp. 57–59. [Google Scholar]

- Rolle, R.S. Improving postharvest management and marketing in the Asia-Pacific region: Issues and challenges. In Postharvest Management of Fruit and Vegetables in the Asia-Pacific Region; Rolle, R., Ed.; Asian Productivity Organization: Tokyo, Japan, 2006; pp. 23–30. ISBN 92-833-7051-1. [Google Scholar]

- Tibagonzeka, J.E.; Akumu, G.; Kiyimba, F.; Atukwase, A.; Wambete, J.; Bbemba, J.; Muyonga, J.H. Post-harvest handling practice and losses for legumes and starchy staples in Uganda. Agric. Sci. 2018, 9, 141–156. [Google Scholar] [CrossRef]

- Cave, D. Digital Islands: How the Pacific’s ICT Revolution Is Transforming the Region. Lowy Institute for International Policy. Available online: https://www.files.ethz.ch/isn/155343/cave_digital_islands_web.pdf (accessed on 11 February 2019).

- Meese, J.; Chan Mow, I. The regulatory jewel of the South Pacific: Samoa’s decade of telecommunications reform. Mob. Media Commum. 2016, 4, 295–309. [Google Scholar] [CrossRef]

- Salvioni, C.; Serpagli, A. How to make money by feeding the tourists: The case of Fiji. In Proceedings of the 105th EAAE Seminar ‘International Marketing and International Trade of Quality Food Products’, Bologna, Italy, 8–10 March 2007; pp. 157–170. [Google Scholar]

- Fink, A.; Neave, S.; Hickes, A.; Wang, J.F. Vegetable Production, Postharvest Handling and Marketing in Fiji. 2013. Available online: http://203.64.245.61/fulltext_pdf/EB/2011-2015/eb0204.pdf (accessed on 11 February 2019).

- Veit, R. Assessing the viability of collection centres for fruit and vegetables in Fiji: A Value Chain Approach. In All ACP Agricultural Commodities Programme; FAO: Rome, Italy, 2009; Volume 7, pp. 1–117. [Google Scholar]

- Ministry of Agriculture, Fiji. Agricultural Production. Available online: http://www.agriculture.gov.fj/index.php/market-info (accessed on 5 February 2019).

- Ministry of Agriculture. Fiji National Agricultural Census Report; Government Printer: Suva, Fiji, 2009; pp. 1–389.

- LaGra, J.A. Commodity System Assessment Methodology for Problem and Project Identification. Available online: https://books.google.com.au/books?hl=en&lr=&id=2PMOAQAAIAAJ&oi=fnd&pg=PR2&ots=C0nMEGFjCT&sig=BeoOob94SBwpJo0LEKQsIU2Nlz8#v=onepage&q&f=false-10 (accessed on 12 Februray 2019).

- Komen, J.J.; Mutoko, C.; Wanyama, J.; Rono, S.; Mose, L. Economics of postharvest maize grain losses in Trans Nzoia and Uasin Gishu districts of Northwest Kenya. In Proceedings of the 10th KARI Biennial Scientific Conference, Nairobi, Kenya, 12–17 November 2006; pp. 1228–1233. [Google Scholar]

- Bala, B.; Haque, M.; Hossain, A.; Majumdar, S. Post Harvest Loss and Technical Efficiency of Rice, Wheat and Maize Production System: Assessment and Measures for Strengthening Food Security; Final Report; Bangladesh Agricultural University: Mymensingh, Bangladesh, 2010. [Google Scholar]

- Chandra, S. Monoculture, mixed cropping and rotations: Implications for Fiji agriculture. Fiji Agric. J. 1978, 40, 63–70. [Google Scholar]

- Aidoo, R.; Danfoku, R.A.; Mensah, J.O. Determinants of postharvest losses in tomato production in the Offinso Nortn district of Ghana. J. Dev. Agric. Econ. 2014, 6, 338–344. [Google Scholar]

- Alidu, A.; Ali, E.B.; Aminu, H. Determinants of post-harvest losses among tomato farmers in the Navrongo municipality in the Upper East region. J. Biol. Agric. Health 2016, 6, 14–20. [Google Scholar]

- Arah, I.K.; Kumah, E.K.; Anku, E.K.; Amaglo, H. An overview of post-harvest losses in tomato production in Africa: Causes and possible prevention strategies. J. Biol. Agric. Health 2015, 5, 78–88. [Google Scholar]

- Adepoju, A.O. Post-harvest losses and welfare of tomato farmers in Ogbomosho, Osun state, Nigeria. J. Stored Prod. Post. Res. 2014, 5, 8–13. [Google Scholar]

- Musasa, S.T.; Mvumi, B.M.; Manditsera, F.A.; Chinhanga, J.; Musiyandaka, S.; Chigwedere, C. Postharvest orange losses and small-scale farmers’ perceptions on the loss causes in the fruit value chain: A case study of Rusitu Valley, Zimbabwe. Food Sci. Qual. Man. 2013, 18, 1–8. [Google Scholar]

- Mandisvika, G.; Chirisa, I.; Bandauko, E. Post-harvest issues: Rethinking technology for value-addition in food security and food sovereignty in Zim-babwe. Adv. Food Technol. Nutr. Sci. Open J. 2015, SE, 29–37. [Google Scholar] [CrossRef]

- Singh, I.R.; Goswami, S.N.R. Assessment of water quality of river Navua, Fiji for irrigation purpose. Asian J. Soil Sci. 2017, 12, 187–190. [Google Scholar] [CrossRef]

- Litchfield, M.H. Estimates of acute pesticide poisoning in agricultural workers in less developed countries. Toxicol. Rev. 2005, 24, 271–278. [Google Scholar] [CrossRef]

- Underhill, S.J.R.; Zhou, Y.; Kumar, S. Infrared Thermal Imaging: A practical educational tool to improve smallholder farmer postharvest practice in Fiji. J. Agric. Food Inf. 2017, 18, 75–78. [Google Scholar] [CrossRef]

| Socio-Demographic Characteristics | Category | Sigatoka Valley z (%) | Eastern Viti Levu y (%) |

|---|---|---|---|

| Gender | Male | 62 | 70 |

| Female | 38 | 30 | |

| Age of farmer (years) | <35 | 23 | 5 |

| 35–50 | 38 | 40 | |

| 51–65 | 37 | 47 | |

| >66 | 2 | 8 | |

| Farming experience (years) | <10 | 22 | 26 |

| 11–20 | 23 | 42 | |

| 21–30 | 29 | 14 | |

| 31–40 | 22 | 16 | |

| >41 | 6 | 2 | |

| Location of place of residence | On-farm | 83 | 88 |

| Off-farm | 17 | 12 | |

| Mean household size | 4.8 (2.1) a x | 4.3 (1.4) b |

| Land Resource | Category | Sigatoka Valley | Eastern Viti Levu |

|---|---|---|---|

| Land use (ha) | Mean area available for cultivation per farm | 2.1 (1.3) a x | 2.9 (2.5) a |

| Mean area under tomato production | 0.8 (0.3) a | 0.4 (0.3) a | |

| Holding (%) | Leased native land | 54 | 45 |

| Freehold land | 38 | 15 | |

| Leased crown land z | 8 | 35 | |

| Native land (%) | Leased from i-Taukei land trust y | 55 | 67 |

| Tenancy at will | 9 | 5 | |

| Communal | 25 | 8 | |

| Landowner/tenant arrangement | 11 | 20 | |

| Lease period <5 years | 71 | 63 | |

| Crown land (%) | Lease period <5 years | 100 | 40 |

| Variable | Group | Sigatoka Valley (%) | Eastern Viti Levu (%) |

|---|---|---|---|

| Postharvest infrastructure | Dedicated purpose building z | 0 | 0 |

| Multiple purpose building | 100 | 100 | |

| Multiple purpose building | |||

| Structure design | Enclosed shed | 20 | 28 |

| Open shed | 60 | 47 | |

| Vacant space in farm house | 20 | 25 | |

| Roof structure | Corrugated iron (permanent) y | 91 | 70 |

| Corrugated iron (temporary) | 9 | 30 | |

| Sidewall structure | No side walls | 53 | 65 |

| Closed with windows and doors | 35 | 30 | |

| Half-way closed | 12 | 5 | |

| Floor structure | Wooden | 6 | 33 |

| Concrete | 82 | 49 | |

| Bare-ground | 12 | 19 |

| Product Loss z | Sigatoka Valley (%) | Eastern Viti Levu (%) | Reasons for Loss |

|---|---|---|---|

| Pre-harvest | 0.4 a y | 0.1 b | Birds, wind and rain |

| Harvesting | 7.6 a | 8.9 a | Pests, diseases, unable to harvest due to rain, soil contact, unsold |

| Sorting | 6.1 a | 4.4 a | Insect damage, soft fruits |

| Storage | 8.6 a | 10.1 a | Decay, overripe, insect damage |

| Grading and packaging | 3.5 a | 4.0 a | Failed to ripe, overripe, blemishes x, size |

| Total loss w | 26.1 a | 27.6 b |

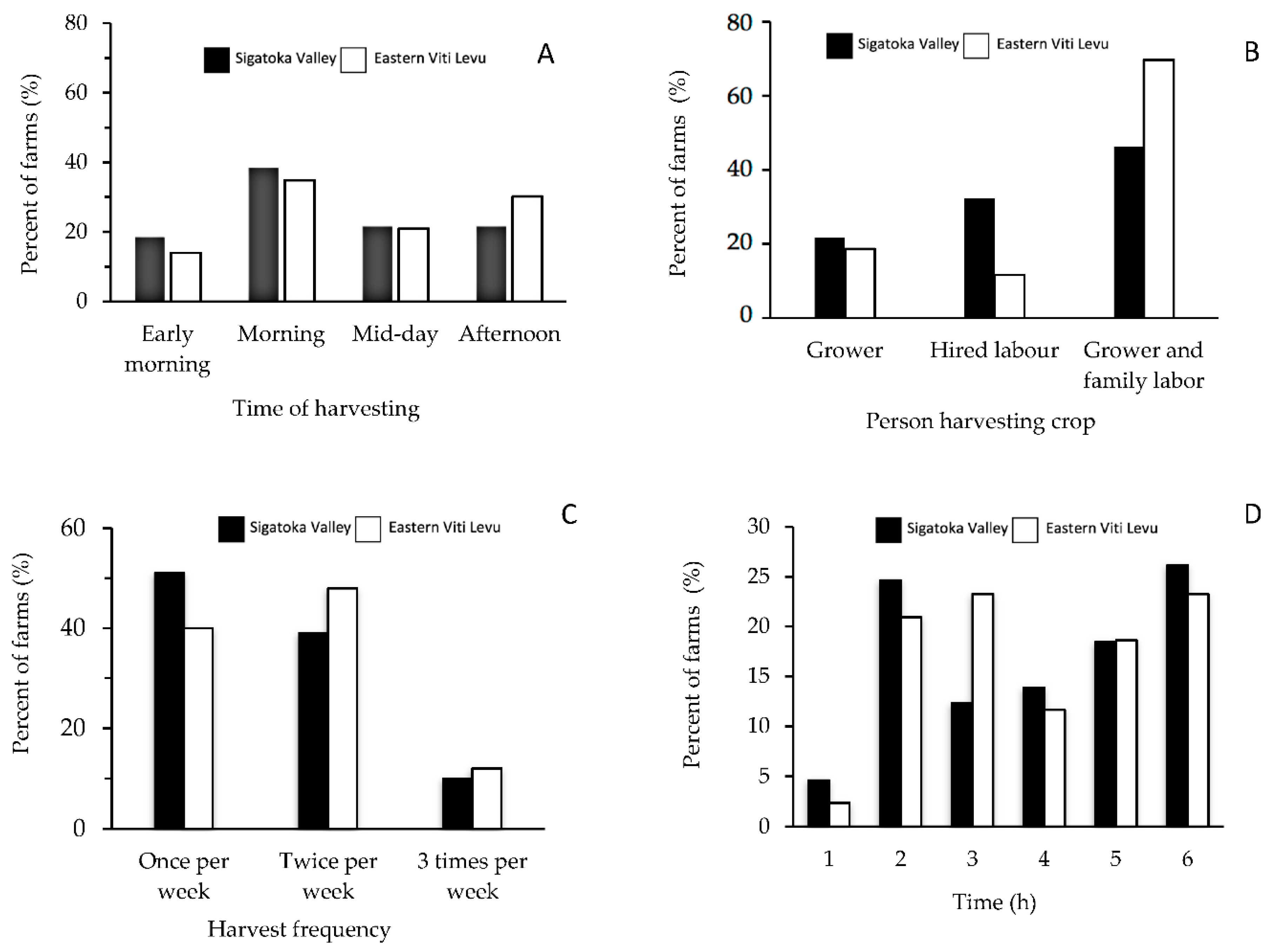

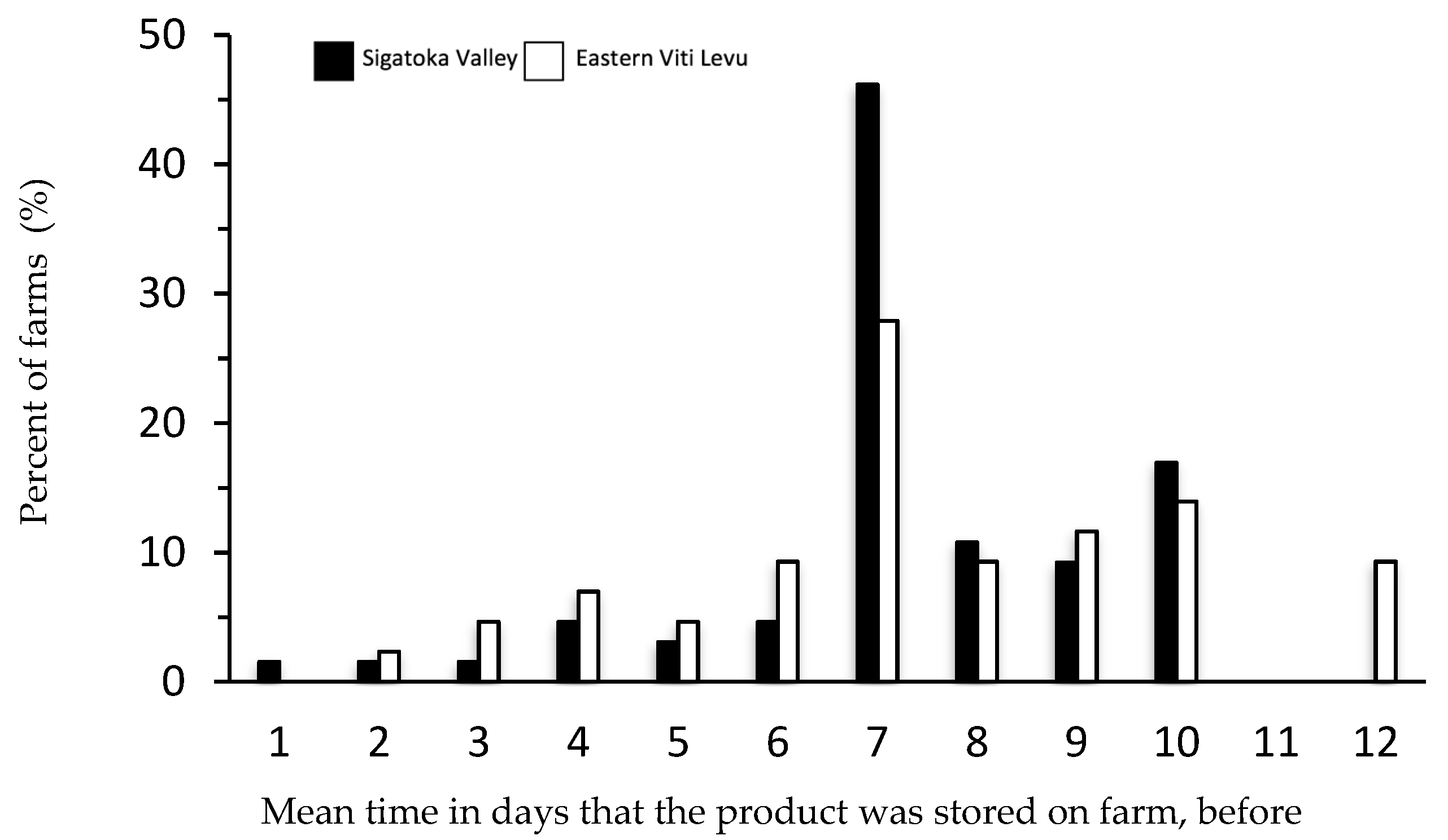

| Harvesting and Postharvest Practice | Variable | Mean Percent Postharvest Loss Per Location z | |

|---|---|---|---|

| Sigatoka Valley | Eastern Viti Levu | ||

| Time of harvest | Early morning (before 7 am) | 30.2 b | 31.4 b |

| Morning | 21.2 c | 21.5 c | |

| Mid-day | 28.6 b | 28.4 b | |

| Afternoon (after 2 pm) | 29.3 b | 32.5 a | |

| Person harvesting | Farmer only | 20.1 f | 25.1 e |

| Hired-labour | 30.6 b | 36.2 a | |

| Farmer and family labour | 26.0 d | 28.8 c | |

| Number of harvests per week | 1 harvest per week | 9.3 a | 10.7 a |

| 2 harvests per week | 7.0 b | 7.8 b | |

| 3 harvests per week | 4.9 b | 6.2 b | |

| Mean time from harvesting to transport to the packing shed | 1 h | 18.7 d | 19.0 d |

| 2 h | 19.9 d | 21.9 d | |

| 3 h | 22.5 cd | 21.9 d | |

| 4 h | 26.8 bc | 23.9 c | |

| 5 h | 29.0 bc | 32.8 b | |

| ≥6 h | 32.8 b | 37.2 a | |

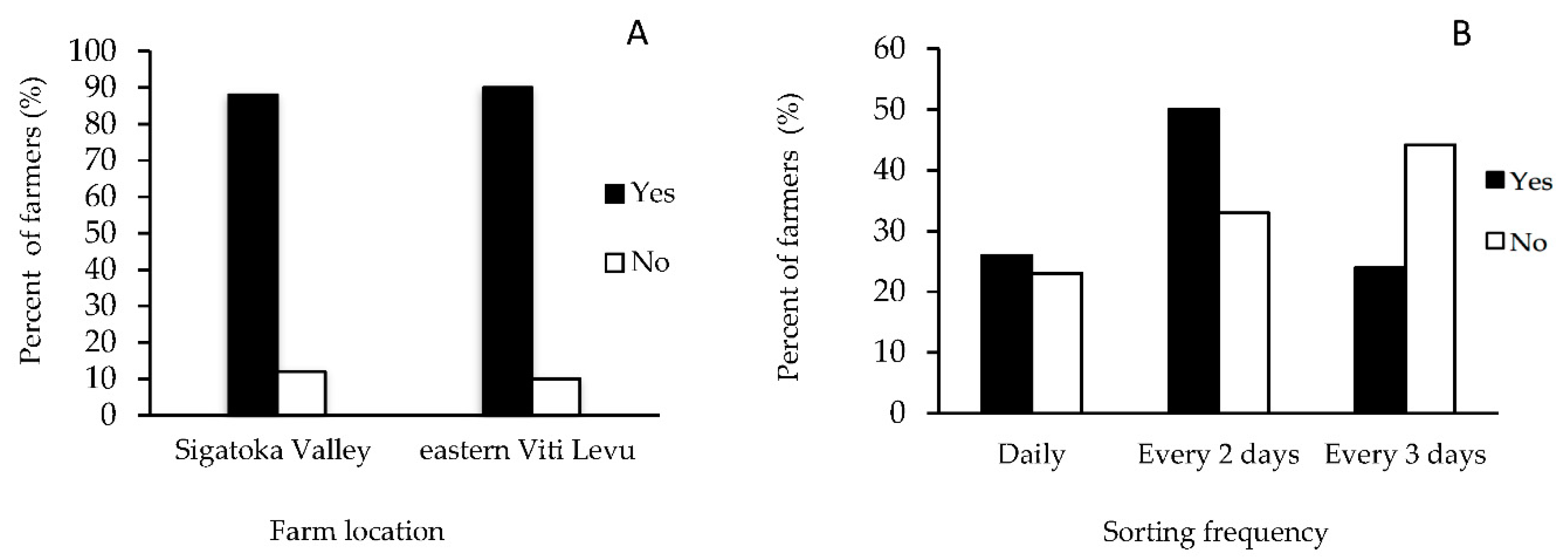

| Sorting undertaken prior to on-farm storage | Yes | 22.2 c | 26.0 c |

| No | 30.6 b | 34.7 a | |

| Frequency of sorting undertaken during on-farm storage/ripening | Daily | 23.3 c | 21.5 c |

| Every second day | 27.2 b | 26.7 b | |

| Every third day | 32.8 a | 33.6 a | |

| On-farm packing or storage shed design | Open shed (no side walls) | 30.2 b | 34.6 a |

| Enclosed shed | 20.8 c | 22.2 c | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, S.; Underhill, S.J.R. Smallholder Farmer Perceptions of Postharvest Loss and Its Determinants in Fijian Tomato Value Chains. Horticulturae 2019, 5, 74. https://doi.org/10.3390/horticulturae5040074

Kumar S, Underhill SJR. Smallholder Farmer Perceptions of Postharvest Loss and Its Determinants in Fijian Tomato Value Chains. Horticulturae. 2019; 5(4):74. https://doi.org/10.3390/horticulturae5040074

Chicago/Turabian StyleKumar, Salesh, and Steven J. R. Underhill. 2019. "Smallholder Farmer Perceptions of Postharvest Loss and Its Determinants in Fijian Tomato Value Chains" Horticulturae 5, no. 4: 74. https://doi.org/10.3390/horticulturae5040074

APA StyleKumar, S., & Underhill, S. J. R. (2019). Smallholder Farmer Perceptions of Postharvest Loss and Its Determinants in Fijian Tomato Value Chains. Horticulturae, 5(4), 74. https://doi.org/10.3390/horticulturae5040074