Suitability of Treated Domestic and Urban Wastewaters for the Hydroponic Cultivation of Rocket (Eruca vesicaria [L.] Cav.)

Abstract

1. Introduction

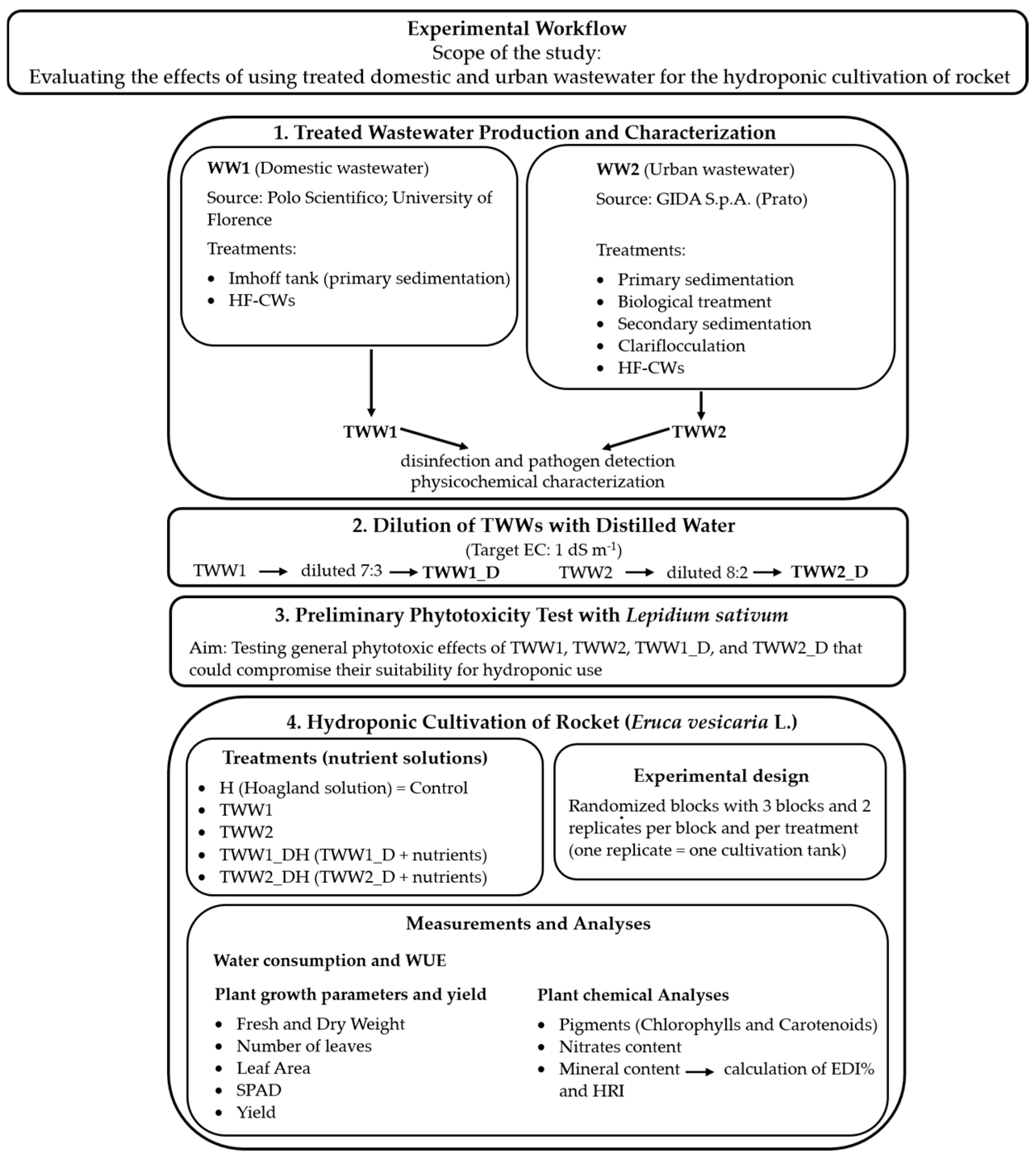

2. Materials and Methods

2.1. Treated Wastewaters Production, Characterization, and Dilution

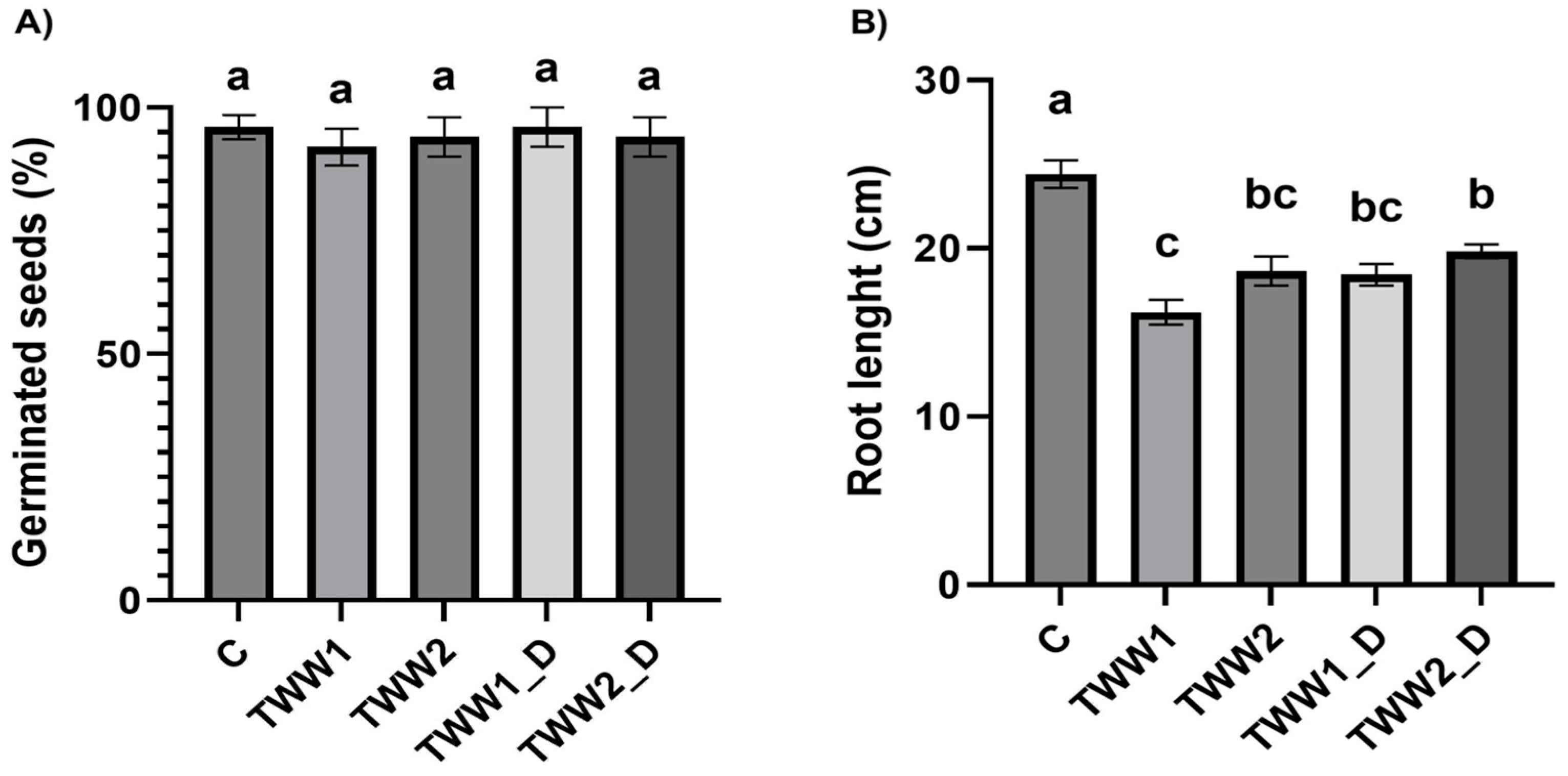

2.2. Phytotoxicity Test

2.3. Plant Material and Growing Conditions

2.4. Plant Growth Parameters and Yield

2.5. Plant Chemical Analysis

2.5.1. Pigment Concentration

2.5.2. Mineral Content

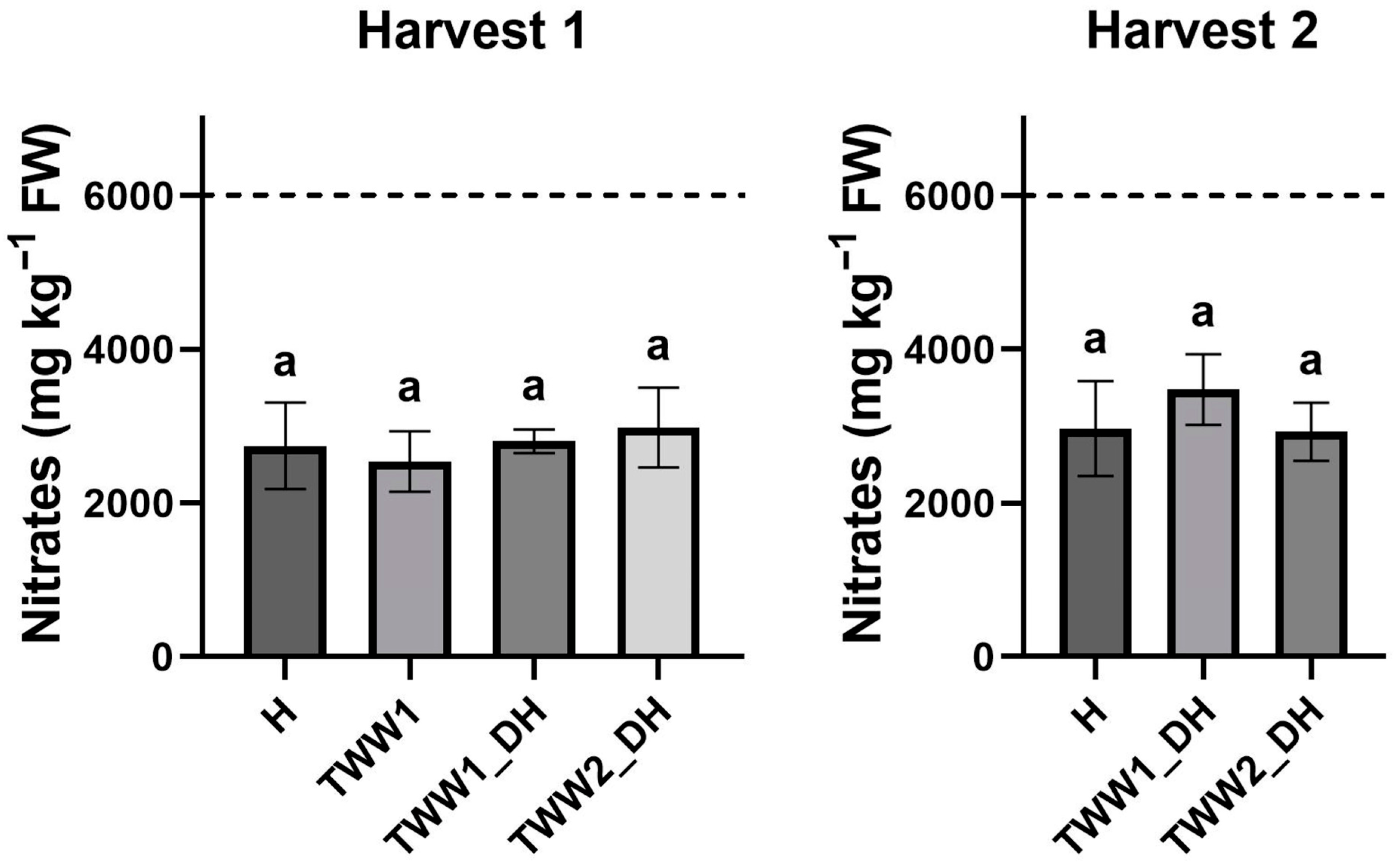

2.5.3. Nitrate Content

2.6. Contribution to Dietary Mineral Intake and Health Risk Assessment

2.7. Statistical Analysis

3. Results

3.1. Phytotoxicity Test

3.2. Plant Growth and Yield

3.3. SPAD and Pigments

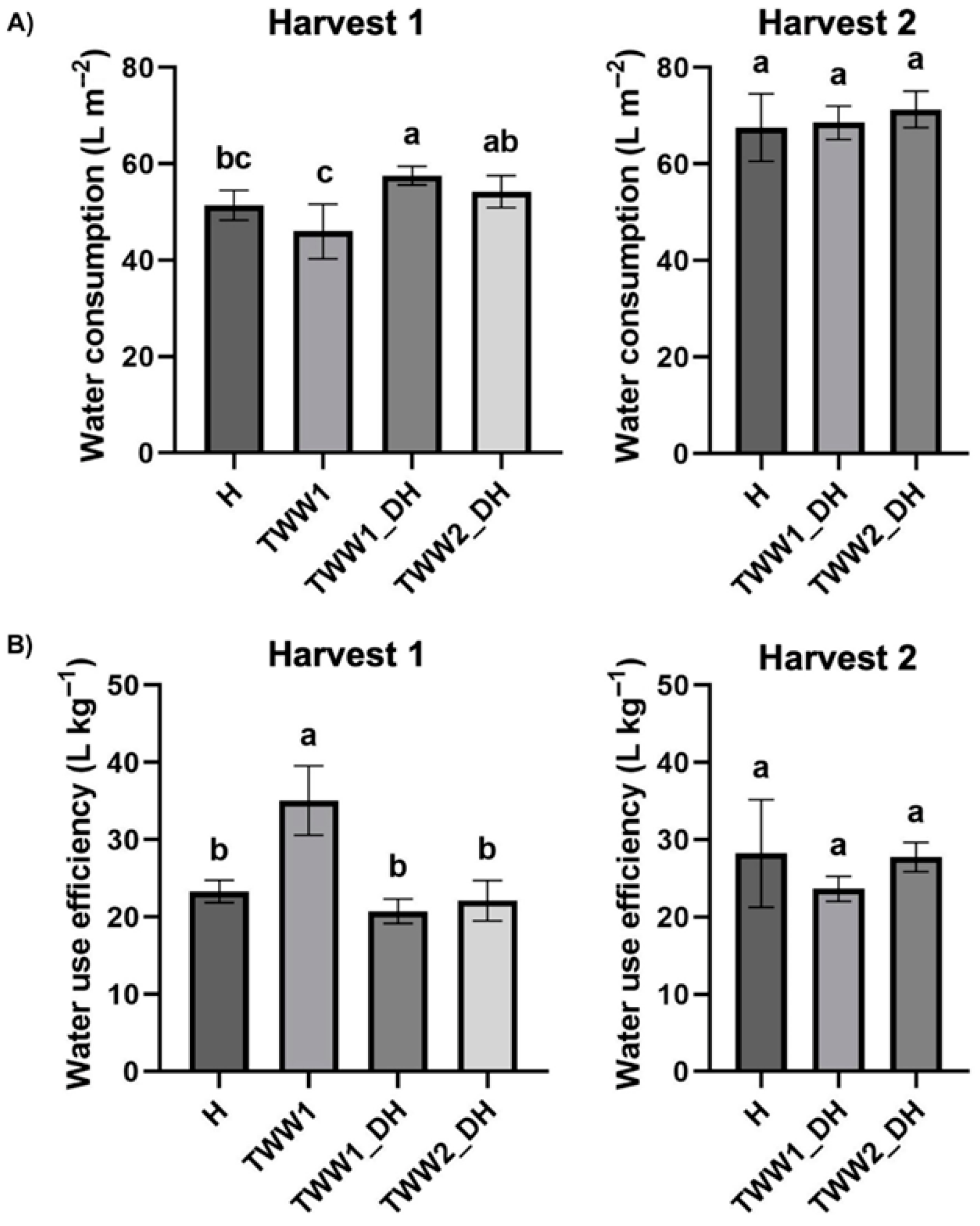

3.4. Consumption of Nutrient Solution and WUE

3.5. Mineral Content and Nitrates

3.6. Contribution to Mineral Dietary Intake and Health Risk Assessment

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mishra, B.K.; Kumar, P.; Saraswat, C.; Chakraborty, S.; Gautam, A. Water Security in a Changing Environment: Concept, Challenges and Solutions. Water 2021, 13, 490. [Google Scholar] [CrossRef]

- Mancosu, N.; Snyder, R.L.; Kyriakakis, G.; Spano, D. Water Scarcity and Future Challenges for Food Production. Water 2015, 7, 975–992. [Google Scholar] [CrossRef]

- Boretti, A.; Rosa, L. Reassessing the Projections of the World Water Development Report. NPJ Clean. Water 2019, 2, 15. [Google Scholar] [CrossRef]

- Tzanakakis, V.A.; Paranychianakis, N.V.; Angelakis, A.N. Water Supply and Water Scarcity. Water 2020, 12, 2347. [Google Scholar] [CrossRef]

- Shemer, H.; Wald, S.; Semiat, R. Challenges and Solutions for Global Water Scarcity. Membranes 2023, 13, 612. [Google Scholar] [CrossRef]

- Jones, E.R.; van Vliet, M.T.H.; Qadir, M.; Bierkens, M.F.P. Country-Level and Gridded Estimates of Wastewater Production, Collection, Treatment and Reuse. Earth Syst. Sci. Data 2021, 13, 237–254. [Google Scholar] [CrossRef]

- Jaramillo, M.F.; Restrepo, I. Wastewater Reuse in Agriculture: A Review about Its Limitations and Benefits. Sustainability 2017, 9, 1734. [Google Scholar] [CrossRef]

- Chatzistathis, T.; Koutsos, T. Olive Mill Wastewater as a Source of Organic Matter, Water and Nutrients for Restoration of Degraded Soils and for Crops Managed with Sustainable Systems. Agric. Water Manag. 2017, 190, 55–64. [Google Scholar] [CrossRef]

- Qadir, M.; Drechsel, P.; Jiménez Cisneros, B.; Kim, Y.; Pramanik, A.; Mehta, P.; Olaniyan, O. Global and Regional Potential of Wastewater as a Water, Nutrient and Energy Source. In Natural Resources Forum; Wiley Online Library: Hoboken, NJ, USA, 2020; Volume 44, pp. 40–51. [Google Scholar] [CrossRef]

- Tymchuk, I.; Shkvirko, O.; Sakalova, H.; Malovanyy, M.; Dabizhuk, T.; Shevchuk, O.; Matviichuk, O.; Vasylinych, T. Wastewater a Source of Nutrients for Crops Growth and Development. J. Ecol. Eng. 2020, 21, 88–96. [Google Scholar] [CrossRef] [PubMed]

- Al-Hazmi, H.E.; Mohammadi, A.; Hejna, A.; Majtacz, J.; Esmaeili, A.; Habibzadeh, S.; Saeb, M.R.; Badawi, M.; Lima, E.C.; Mąkinia, J. Wastewater Reuse in Agriculture: Prospects and Challenges. Environ. Res. 2023, 236, 116711. [Google Scholar] [CrossRef]

- Ofori, S.; Puškáčová, A.; Růžičková, I.; Wanner, J. Treated Wastewater Reuse for Irrigation: Pros and Cons. Sci. Total Environ. 2021, 760, 144026. [Google Scholar] [CrossRef]

- Hashem, M.S.; Qi, X. Treated Wastewater Irrigation—A Review. Water 2021, 13, 1527. [Google Scholar] [CrossRef]

- Karvelas, M.; Katsoyiannis, A.; Samara, C. Occurrence and Fate of Heavy Metals in the Wastewater Treatment Process. Chemosphere 2003, 53, 1201–1210. [Google Scholar] [CrossRef] [PubMed]

- Lazarova, V.; Bahri, A. Water Reuse for Irrigation: Agriculture, Landscapes, and Turf Grass; CRC Press: Boca Raton, FL, USA, 2004; pp. 1–432. ISBN 0203499409. [Google Scholar] [CrossRef]

- Gao, Y.; Shao, G.; Wu, S.; Xiaojun, W.; Lu, J.; Cui, J. Changes in Soil Salinity under Treated Wastewater Irrigation: A Meta-Analysis. Agric. Water Manag. 2021, 255, 106986. [Google Scholar] [CrossRef]

- Akpor, O.B.; Ohiobor, G.O.; Olaolu, D.T. Heavy Metal Pollutants in Wastewater Effluents: Sources, Effects and Remediation. Adv. Biosci. Bioeng. 2014, 2, 37–43. [Google Scholar] [CrossRef]

- Peralta-Videa, J.R.; Lopez, M.L.; Narayan, M.; Saupe, G.; Gardea-Torresdey, J. The Biochemistry of Environmental Heavy Metal Uptake by Plants: Implications for the Food Chain. Int. J. Biochem. Cell Biol. 2009, 41, 1665–1677. [Google Scholar] [CrossRef]

- Tang, C.; Chen, J.; Shindo, S.; Sakura, Y.; Zhang, W.; Shen, Y. Assessment of Groundwater Contamination by Nitrates Associated with Wastewater Irrigation: A Case Study in Shijiazhuang Region, China. Hydrol. Process 2004, 18, 2303–2312. [Google Scholar]

- Muhaidat, R.; Al-Qudah, K.; Al-Taani, A.A.; AlJammal, S. Assessment of Nitrate and Nitrite Levels in Treated Wastewater, Soil, and Vegetable Crops at the Upper Reach of Zarqa River in Jordan. Environ. Monit. Assess. 2019, 191, 153. [Google Scholar] [CrossRef]

- Mora, A.; Torres-Martínez, J.A.; Capparelli, M.V.; Zabala, A.; Mahlknecht, J. Effects of Wastewater Irrigation on Groundwater Quality: An Overview. Curr. Opin. Environ. Sci. Health 2022, 25, 100322. [Google Scholar] [CrossRef]

- Kesari, K.K.; Soni, R.; Jamal, Q.M.S.; Tripathi, P.; Lal, J.A.; Jha, N.K.; Siddiqui, M.H.; Kumar, P.; Tripathi, V.; Ruokolainen, J. Wastewater Treatment and Reuse: A Review of Its Applications and Health Implications. Water Air Soil. Pollut. 2021, 232, 208. [Google Scholar] [CrossRef]

- Cifuentes-Torres, L.; Mendoza-Espinosa, L.G.; Correa-Reyes, G.; Daesslé, L.W. Hydroponics with Wastewater: A Review of Trends and Opportunities. Water Environ. J. 2021, 35, 166–180. [Google Scholar] [CrossRef]

- Sharma, B.; Kothari, R.; Singh, R.P. Growth Performance, Metal Accumulation and Biochemical Responses of Palak (Beta vulgaris L. Var. Allgreen H-1) Grown on Soil Amended with Sewage Sludge-Fly Ash Mixtures. Environ. Sci. Pollut. Res. 2018, 25, 12619–12640. [Google Scholar] [CrossRef]

- AlShrouf, A. Hydroponics, Aeroponic and Aquaponic as Compared with Conventional Farming. Am. Sci. Res. J. Eng. Technol. Sci. 2017, 27, 247–255. [Google Scholar]

- Magwaza, S.T.; Magwaza, L.S.; Odindo, A.O.; Mditshwa, A. Hydroponic Technology as Decentralised System for Domestic Wastewater Treatment and Vegetable Production in Urban Agriculture: A Review. Sci. Total Environ. 2020, 698, 134154. [Google Scholar] [CrossRef]

- da Silva Cuba Carvalho, R.; Bastos, R.G.; Souza, C.F. Influence of the Use of Wastewater on Nutrient Absorption and Production of Lettuce Grown in a Hydroponic System. Agric. Water Manag. 2018, 203, 311–321. [Google Scholar] [CrossRef]

- Shoushtarian, F.; Negahban-Azar, M. Worldwide Regulations and Guidelines for Agricultural Water Reuse: A Critical Review. Water 2020, 12, 971. [Google Scholar] [CrossRef]

- M.D. 185/2003. Regolamento Recante Norme Tecniche per il Riutilizzo delle Acque Reflue in Attuazione Dell’articolo 26, Comma 2, del Decreto Legislativo 11 Maggio 1999, n. 152. Decreto 12 Giugno 2003, n. 185. Available online: https://www.gazzettaufficiale.it/eli/id/2003/07/23/003G0210/Sg (accessed on 23 November 2024).

- Regulation (EU) 2020/741 of the European Parliament and of the Council of 25 May 2020 on Minimum Requirements for Water Reuse. 2020. Available online: https://eur-lex.europa.eu/eli/reg/2020/741/oj (accessed on 22 November 2024).

- Tripodi, P.; Francese, G.; Mennella, G. Rocket Salad: Crop Description, Bioactive Compounds and Breeding Perspectives. Adv. Hortic. Sci. 2017, 31, 107–114. [Google Scholar]

- Santamaria, P. Nitrate in Vegetables: Toxicity, Content, Intake and EC Regulation. J. Sci. Food Agric. 2006, 86, 10–17. [Google Scholar] [CrossRef]

- Kesar, S.; Bhatti, M.S. Chlorination of secondary treated wastewater with sodium hypochlorite (NaOCl): An effective single alternate to other disinfectants. Heliyon 2022, 8, e11162. [Google Scholar] [CrossRef]

- ISO 22743:2006; Water Quality—Determination of Sulfates—Method by Continuous Flow Analysis (CFA). ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38339.html (accessed on 22 November 2024).

- ISO 6878:2004; Water Quality—Determination of Phosphorus—Ammonium Molybdate Spectrometric Method. ISO: Geneva, Switzerland, 2004. Available online: https://www.iso.org/standard/36917.html (accessed on 22 November 2024).

- ISO 10304-1:2007; Water Quality—Determination of Dissolved Anions by Liquid Chromatography of Ions—Part 1: Determination of Bromide, Chloride, Fluoride, Nitrate, Nitrite, Phosphate and Sulfate. ISO: Geneva, Switzerland, 2007. Available online: https://www.iso.org/standard/46004.html (accessed on 22 November 2024).

- Fibbi, D.; Doumett, S.; Colzi, I.; Coppini, E.; Pucci, S.; Gonnelli, C.; Lepri, L.; Del Bubba, M. Total and Hexavalent Chromium Removal in a Subsurface Horizontal Flow (h-SSF) Constructed Wetland Operating as Post-Treatment of Textile Wastewater for Water Reuse. Water Sci. Technol. 2011, 64, 826–831. [Google Scholar] [CrossRef]

- Mañas, P.; De las Heras, J. Phytotoxicity Test Applied to Sewage Sludge Using Lactuca sativa L. and Lepidium sativum L. Seeds. Int. J. Environ. Sci. Technol. 2018, 15, 273–280. [Google Scholar] [CrossRef]

- Palmitessa, O.D.; Renna, M.; De Angelis, D.; Signore, A.; Serio, F.; Summo, C.; Santamaria, P. Moderate saline waters are effective to enhance a landrace of unripe melon cultivated in a “water culture system” with high input efficiency. Sci. Hortic. 2024, 337, 113599. [Google Scholar] [CrossRef]

- Lichtenthaler, H.K.; Buschmann, C. Chlorophylls and Carotenoids: Measurement and Characterization by UV-VIS Spectroscopy. Curr. Protoc. Food Anal. Chem. 2001, 1, F4-3. [Google Scholar] [CrossRef]

- ISO 17294-2:2023; Water Quality—Application of Inductively Coupled Plasma Mass Spectrometry (ICP-MS)—Part 2: Determination of Selected Elements Including Uranium Isotopes. ISO: Geneva, Switzerland, 2023. Available online: https://www.iso.org/standard/82245.html (accessed on 22 November 2024).

- Cataldo, D.A.; Schrader, L.E.; Youngs, V.L. Analysis by Digestion and Colorimetric Assay of Total Nitrogen in Plant Tissues High in Nitrate 1. Crop. Sci. 1974, 14, 854–856. [Google Scholar] [CrossRef]

- Elgueta, S.; Fuentes, M.; Valenzuela, M.; Zhao, G.; Liu, S.; Lu, H.; Correa, A. Pesticide Residues in Ready-to-Eat Leafy Vegetables from Markets of Santiago, Chile, and Consumer’s Risk. Food Addit. Contam. Part B 2019, 12, 259–267. [Google Scholar] [CrossRef]

- Baldi, A.; Truschi, S.; Bruschi, P.; Lenzi, A. Preliminary Assessment of Four Wild Leafy Species to Be Used as Baby Salads. Horticulturae 2023, 9, 650. [Google Scholar] [CrossRef]

- SINU. Livelli Di Assunzione Di Riferimento Di Nutrienti Ed Energia, IV Revisione. Società Italiana Di Nutrizione Umana. Available online: http://www.Sinu.It/Html/Pag/12-MINERALI.Asp (accessed on 18 April 2023).

- Barnes, D.G.; Dourson, M.; Dourson, M.; Preuss, P.; Barnes, D.G.; Bellin, J.; Derosa, C.; Engler, R.; Erdreich, L.; Farber, T.; et al. Reference Dose (RfD): Description and Use in Health Risk Assessments. Regul. Toxicol. Pharmacol. 1988, 8, 471–486. [Google Scholar] [CrossRef]

- Taylor, A.A.; Tsuji, J.S.; McArdle, M.E.; Adams, W.J.; Goodfellow, W.L., Jr. Recommended Reference Values for Risk Assessment of Oral Exposure to Copper. Risk Anal. 2023, 43, 211–218. [Google Scholar] [CrossRef]

- Chang, A.C.; Granato, T.C.; Page, A.L. A Methodology for Establishing Phytotoxicity Criteria for Chromium, Copper, Nickel, and Zinc in Agricultural Land Application of Municipal Sewage Sludges. J. Environ. Qual. 1992, 21, 521–536. [Google Scholar] [CrossRef]

- The European Commission. Commission Regulation (EU) No 1258/2011 of 2 December 2011 Amending Regulation (EC) No 1881/2006 as Regards Maximum Levels for Nitrates in Foodstuffs Text with EEA Relevance. Available online: https://Faolex.Fao.Org/Docs/Pdf/Eur108181.Pdf (accessed on 6 September 2024).

- Kumar, P.; Choudhury, D. Bioremediation of Wastewater Using Hydroponics. In Hydroponics and Environmental Bioremediation: Wastewater Treatment; Kumar, N., Ed.; Springer Nature: Cham, Switzerland, 2024; pp. 27–64. ISBN 978-3-031-53258-0. [Google Scholar]

- Nazir, M.; Roy, K.; Saha, A.; Saha, D. A Sustainable Holistic Approach of Hydroponic Farming for Reclaiming, and Rehabilitating Wastewater: A Review. Water Air Soil. Pollut. 2024, 235, 445. [Google Scholar] [CrossRef]

- Santos, O.; Vaz, D.; Sebastião, F.; Sousa, H.; Vieira, J. Wastewater as a Nutrient Source for Hydroponic Production of Lettuce: Summer and Winter Growth. Agric. Water Manag. 2024, 301, 108966. [Google Scholar] [CrossRef]

- Sheets, J.P.; Yang, L.; Ge, X.; Wang, Z.; Li, Y. Beyond Land Application: Emerging Technologies for the Treatment and Reuse of Anaerobically Digested Agricultural and Food Waste. Waste Manag. 2015, 44, 94–115. [Google Scholar] [CrossRef]

- Egbuikwem, P.N.; Mierzwa, J.C.; Saroj, D.P. Assessment of Suspended Growth Biological Process for Treatment and Reuse of Mixed Wastewater for Irrigation of Edible Crops under Hydroponic Conditions. Agric. Water Manag. 2020, 231, 106034. [Google Scholar] [CrossRef]

- Incrocci, L.; Malorgio, F.; Massa, D.; Pardossi, A. Colture Fuori Suolo. Idroponica e Coltivazione in Substrato; Edagricole-New Business Media srl: Milano, Italy, 2022; pp. 1–330. ISBN 885065572x. [Google Scholar]

- Bożym, M.; Król, A.; Mizerna, K. Leachate and Contact Test with Lepidium sativum L. to Assess the Phytotoxicity of Waste. Int. J. Environ. Sci. Technol. 2021, 18, 1975–1990. [Google Scholar] [CrossRef]

- Mancini, L.; Avellis, L.; Caciolli, S.; Carere, M.; Chiudioni, F.; D’Angelo, A.M.; Figliomeni, M.; Lacchetti, I.; Puccinelli, C.; Marcheggiani, S. Industrial Production of Medical Devices and Decalogue for Water Saving; Istituto Superiore di Sanità: Rome, Italy, 2020. [Google Scholar]

- El-Darier, S.M.; Youssef, R.S. Effect of Soil Type, Salinity, and Allelochemicals on Germination and Seedling Growth of a Medicinal Plant Lepidium sativum L. Ann. Appl. Biol. 2000, 136, 273–279. [Google Scholar] [CrossRef]

- Maathuis, F.J.M. Sodium in Plants: Perception, Signalling, and Regulation of Sodium Fluxes. J. Exp. Bot. 2014, 65, 849–858. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, H.; Song, C.; Zhu, J.-K.; Shabala, S. Mechanisms of Plant Responses and Adaptation to Soil Salinity. Innovation 2020, 1, 100017. [Google Scholar] [CrossRef]

- Krishnasamy, K.; Nair, J.; Bäuml, B. Hydroponic System for the Treatment of Anaerobic Liquid. Water Sci. Technol. 2012, 65, 1164–1171. [Google Scholar] [CrossRef]

- Montoneri, E.; Baglieri, A.; Fascella, G. Biostimulant Effects of Waste Derived Biobased Products in the Cultivation of Ornamental and Food Plants. Agriculture 2022, 12, 994. [Google Scholar] [CrossRef]

- Morillas-España, A.; Ruiz-Nieto, Á.; Lafarga, T.; Acién, G.; Arbib, Z.; González-López, C. V Biostimulant Capacity of Chlorella and Chlamydopodium Species Produced Using Wastewater and Centrate. Biology 2022, 11, 1086. [Google Scholar] [CrossRef]

- Álvarez-González, A.; Greque de Morais, E.; Planas-Carbonell, A.; Uggetti, E. Enhancing Sustainability through Microalgae Cultivation in Urban Wastewater for Biostimulant Production and Nutrient Recovery. Sci. Total Environ. 2023, 904, 166878. [Google Scholar] [CrossRef]

- Farquhar, W.B.; Edwards, D.G.; Jurkovitz, C.T.; Weintraub, W.S. Dietary Sodium and Health: More than Just Blood Pressure. J. Am. Coll. Cardiol. 2015, 65, 1042–1050. [Google Scholar] [CrossRef] [PubMed]

- Webster, J.L.; Dunford, E.K.; Neal, B.C. A Systematic Survey of the Sodium Contents of Processed Foods12. Am. J. Clin. Nutr. 2010, 91, 413–420. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Liu, X.; Wang, Z.; Liang, Z.; Wang, M.; Liu, M.; Suarez, D.L. Interactive Effects of PH, EC and Nitrogen on Yields and Nutrient Absorption of Rice (Oryza sativa L.). Agric. Water Manag. 2017, 194, 48–57. [Google Scholar] [CrossRef]

- Santamaria, P.; Gonnella, M.; Elia, A.; Parente, A.; Serio, F. Ways of Reducing Rocket Salad Nitrate Content. Acta Hortic. 2001, 548, 529–536. [Google Scholar] [CrossRef]

| Parameters | TWW1 | TWW2 | MD 185/2003 |

|---|---|---|---|

| pH | 7.3 | 8.5 | 6–9.5 |

| EC | 3.05 | 4.8 | 3 |

| DO | 6.1 | 5.8 | n.a. |

| HCO3− | 51 | 449 | n.a. |

| COD | 12 | 21 | 100 |

| TSS | 3.5 | 4 | 10 |

| TN | 71 | 0.5 | 15 |

| NH4+-N | 0.001 | 0.002 | 2 |

| NO3−-N | 60.5 | 0.2 | n.a. |

| NO2−-N | 0.28 | 0.1 | n.a. |

| TP | 44 | 1.05 | 2 |

| PO43− | 20.25 | 0.98 | n.a. |

| K | 39 | 7.2 | n.a. |

| SO42− | 62 | 336 | 500 |

| Ca | 157 | 104 | n.a. |

| Mg | 18 | 20 | n.a. |

| Fe | 0.0125 | 0.0125 | 2 |

| Zn | 0.0535 | 0.0515 | 0.1 |

| Cu | <0.05 | <0.05 | 1 |

| Mn | <0.05 | <0.05 | 0.2 |

| B | 0.0905 | 0.1155 | 1 |

| Mo | <0.02 | 0.065 | n.a. |

| Na | 355 | 808 | n.a. |

| Cl | 731 | 1202 | 250 |

| Al | 0.035 | 0.0215 | 1 |

| Pb | <0.05 | <0.05 | 0.1 |

| Cd | <MDL | <MDL | 0.005 |

| Ni | <0.05 | <0.05 | 0.2 |

| As | <0.02 | <0.02 | 0.02 |

| Se | 0.0095 | 0.01 | 0.01 |

| Sn | <0.02 | <0.02 | 3 |

| Ba | 0.1195 | 0.1 | 10 |

| Cr | <0.01 | <0.01 | 0.1 |

| Sb | <0.02 | 0.065 | n.a. |

| Formula | Content (mg L−1) |

|---|---|

| Ca(NO3)2·4H2O | 1180 |

| KNO3 | 505 |

| KH2PO4 | 136 |

| MgSO4·7H2O | 493 |

| Fe-EDDHA | 46.6 |

| H3BO3 | 2.86 |

| MnCl2·4H2O | 1.81 |

| ZnSO4·7H2O | 0.22 |

| CuSO4·7H2O | 0.08 |

| Na2MoO4·2H2O | 0.03 |

| Treatment | GI (%) | I (%) |

|---|---|---|

| TWW1 | 61.7 | 38.3 |

| TWW2 | 74.8 | 25.2 |

| TWW1_D | 75.5 | 24.5 |

| TWW2_D | 79.5 | 20.5 |

| Yield (kg m−2) | Fresh Weight (g Plant−1) | Dry Weight (g Plant−1) | Plant Height (cm) | Number of Leaves | Leaf Area (cm2 Plant−1) | |

|---|---|---|---|---|---|---|

| Harvest 1 | ||||||

| H | 2.21 b | 2.91 a | 0.21 a | 15.22 a | 5.83 a | 71.67 a |

| TWW1 | 1.31 c | 1.68 b | 0.12 b | 11.37 b | 4.83 b | 35.51 b |

| TWW1_DH | 2.78 a | 3.11 a | 0.20 ab | 15.68 a | 5.50 ab | 66.73 a |

| TWW2_DH | 2.47 b | 3.01 a | 0.21 a | 15.73 a | 5.50 ab | 65.10 a |

| Harvest 2 | ||||||

| H | 2.50 a | 3.99 a | 0.33 a | 14.83 a | 6.92 a | 80.61 a |

| TWW1_DH | 2.92 a | 4.50 a | 0.37 a | 15.58 a | 7.08 a | 81.81 a |

| TWW2_DH | 2.58 a | 3.89 a | 0.35 a | 15.21 a | 6.92 a | 76.74 a |

| Treatment | SPAD | Chl a | Chl b | Chl a + b | Carotenoids |

|---|---|---|---|---|---|

| SPAD | (mg g−1 FW) | (mg g−1 FW) | (mg g−1 FW) | (mg g−1 FW) | |

| Harvest 1 | |||||

| H | 35.88 ab | 1.57 a | 0.53 a | 2.10 a | 0.29 a |

| TWW1 | 33.04 b | 1.14 b | 0.39 b | 1.53 b | 0.020 b |

| TWW1_DH | 38.77 a | 1.43 ab | 0.51 a | 1.94 ab | 0.25 ab |

| TWW2_DH | 40.37 a | 1.49 a | 0.52 a | 2.00 a | 0.26 ab |

| Harvest 2 | |||||

| H | 43.02 a | 1.08 a | 0.52 a | 1.62 a | 0.13 a |

| TWW1_DH | 44.13 a | 0.96 a | 0.47 a | 1.44 a | 0.12 a |

| TWW2_DH | 44.31 a | 1.01 a | 0.50 a | 1.53 a | 0.11 a |

| Harvest 1 | Harvest 2 | ||||||

|---|---|---|---|---|---|---|---|

| Element | H | TWW1 | TWW1_DH | TWW2_DH | H | TWW1_DH | TWW2_DH |

| Ca | 44.98 a | 48.43 a | 46.35 a | 42.06 a | 43.96 a | 41.78 a | 40.70 a |

| K | 61.17 a | 34.57 b | 65.87 a | 58.26 a | 60.14 a | 57.15 a | 55.73 a |

| Mg | 17.98 a | 15.25 a | 18.47 a | 16.98 a | 20.81 a | 18.85 a | 18.27 a |

| Na | 0.42 c | 11.52 a | 4.78 b | 5.74 b | 0.60 b | 8.85 a | 10.57 a |

| P | 7.70 a | 4.84 b | 8.01 a | 7.67 a | 7.35 a | 6.42 a | 6.98 a |

| S | 14.72 a | 12.15 a | 15.61 a | 14.98 a | 24.07 a | 20.95 a | 20.50 a |

| B | 52.58 a | 53.48 a | 51.37 a | 46.51 a | 108.55 a | 82.97 b | 81.19 b |

| Cr | 0.66 ab | 3.89 a | 0.61 ab | 0.35 b | 2.22 a | 1.27 b | 0.71 b |

| Cu | 4.79 ab | 6.49 a | 4.65 ab | 4.29 b | 8.88 a | 5.81 b | 5.03 b |

| Fe | 138.75 a | 140.09 a | 129.16 a | 123.22 a | 168.80 a | 180.06 a | 192.97 a |

| Mn | 194.49 a | 143.47 a | 135.29 a | 156.83 a | 196.28 a | 116.27 b | 129.33 b |

| Mo | 2.89 a | 2.97 a | 3.46 a | 3.73 a | 2.62 a | 3.46 a | 2.90 a |

| Zn | 33.52 a | 43.93 a | 35.27 a | 31.82 a | 42.20 a | 31.26 b | 31.01 b |

| Harvest 1 | Harvest 2 | ||||||

|---|---|---|---|---|---|---|---|

| Element | RDI/AI a (mg day−1) | H | TWW1_DH | TWW2_DH | H | TWW1_DH | TWW2_DH |

| Ca | 1000 | 13.8 | 14.0 | 13.3 | 18.5 | 15.7 | 16.8 |

| K | 3900 | 4.8 | 5.1 | 4.7 | 6.5 | 5.5 | 5.9 |

| Mg | 240 | 22.9 | 23.3 | 22.3 | 36.7 | 29.5 | 31.4 |

| Na | 1500 | 0.1 | 1.0 | 1.2 | 0.2 | 2.2 | 2.9 |

| P | 700 | 3.4 | 3.5 | 3.5 | 4.4 | 3.5 | 4.1 |

| Cr | 0.035 | 5.8 | 5.3 | 3.3 | 26.9 | 13.7 | 8.4 |

| Cu | 0.9 | 1.6 | 1.6 | 1.5 | 4.2 | 2.4 | 2.3 |

| Fe | 10 | 4.3 | 3.9 | 3.9 | 7.1 | 6.8 | 8.0 |

| Mn | 2.7 | 22.0 | 15.2 | 18.3 | 30.6 | 16.2 | 19.8 |

| Mo | 0.045 | 13.7 | 16.1 | 18.1 | 17.2 | 20.1 | 18.4 |

| Zn | 11 | 0.9 | 0.9 | 0.8 | 1.5 | 1.0 | 1.1 |

| Element | Harvest 1 | Harvest 2 | |||||

|---|---|---|---|---|---|---|---|

| H | TWW1_DH | TWW2_DH | H | TWW1_DH | TWW2_DH | ||

| B (RfD 0.2) | EDIBW | 2.30 × 10−3 | 2.22 × 10−3 | 2.09 × 10−3 | 6.56 × 10−3 | 4.46 × 10−3 | 4.78 × 10−3 |

| HRI | 1.15 × 10−2 | 1.11 × 10−2 | 1.05 × 10−2 | 3.28 × 10−2 | 2.23 × 10−2 | 2.29 × 10−2 | |

| Cr (RfD 0.0009) | EDIBW | 2.89 × 10−5 | 2.63 × 10−5 | 1.62 × 10−5 | 1.34 × 10−5 | 6.86 × 10−5 | 4.18 × 10−5 |

| HRI | 3.21 × 10−2 | 2.92 × 10−2 | 1.80 × 10−2 | 1.49 × 10−1 | 7.62 × 10−2 | 4.64 × 10−2 | |

| Cu (RfD 0.04) | EDIBW | 2.09 × 10−4 | 2.01 × 10−4 | 1.93 × 10−4 | 5.39 × 10−4 | 3.11 × 10−4 | 2.96 × 10−4 |

| HRI | 5.23 × 10−3 | 5.02 × 10−3 | 4.83 × 10−3 | 1.35 × 10−2 | 7.79 × 10−3 | 7.41 × 10−3 | |

| Fe (RfD 0.7) | EDIBW | 6.08 × 10−3 | 5.58 × 10−3 | 5.57 × 10−3 | 1.02 × 10−2 | 9.70 × 10−3 | 1.14 × 10−2 |

| HRI | 8.68 × 10−3 | 7.96 × 10−3 | 7.96 × 10−3 | 1.45 × 10−2 | 1.39 × 10−2 | 1.63 × 10−2 | |

| Mn (RfD 0.14) | EDIBW | 8.50 × 10−3 | 5.86 × 10−3 | 7.05 × 10−3 | 1.18 × 10−2 | 6.25 × 10−3 | 7.62 × 10−3 |

| HRI | 6.07 × 10−2 | 4.18 × 10−2 | 5.04 × 10−2 | 8.44 × 10−2 | 4.47 × 10−2 | 5.44 × 10−2 | |

| Mo (RfD 0.05) | EDIBW | 1.27 × 10−4 | 1.50 × 10−4 | 1.68 × 10−4 | 1.60 × 10−4 | 1.86 × 10−4 | 1.71 × 10−4 |

| HRI | 2.54 × 10−2 | 2.99 × 10−2 | 3.36 × 10−2 | 3.20 × 10−2 | 3.73 × 10−2 | 3.41 × 10−2 | |

| Zn (RfD 0.3) | EDIBW | 1.47 × 10−3 | 1.52 × 10−3 | 1.43 × 10−3 | 2.53 × 10−3 | 1.68 × 10−3 | 1.83 × 10−3 |

| HRI | 4.90 × 10−3 | 5.08 × 10−3 | 4.77 × 10−3 | 8.44 × 10−3 | 5.60 × 10−3 | 6.08 × 10−3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bini, L.; Baldi, A.; Passaseo, D.; Biricolti, S.; Giordani, E.; Lippi, P.; Zezza Mottola Di Amato, F.; Fibbi, D.; Del Bubba, M.; Lenzi, A. Suitability of Treated Domestic and Urban Wastewaters for the Hydroponic Cultivation of Rocket (Eruca vesicaria [L.] Cav.). Horticulturae 2025, 11, 1115. https://doi.org/10.3390/horticulturae11091115

Bini L, Baldi A, Passaseo D, Biricolti S, Giordani E, Lippi P, Zezza Mottola Di Amato F, Fibbi D, Del Bubba M, Lenzi A. Suitability of Treated Domestic and Urban Wastewaters for the Hydroponic Cultivation of Rocket (Eruca vesicaria [L.] Cav.). Horticulturae. 2025; 11(9):1115. https://doi.org/10.3390/horticulturae11091115

Chicago/Turabian StyleBini, Lorenzo, Ada Baldi, Davide Passaseo, Stefano Biricolti, Edgardo Giordani, Pamela Lippi, Federica Zezza Mottola Di Amato, Donatella Fibbi, Massimo Del Bubba, and Anna Lenzi. 2025. "Suitability of Treated Domestic and Urban Wastewaters for the Hydroponic Cultivation of Rocket (Eruca vesicaria [L.] Cav.)" Horticulturae 11, no. 9: 1115. https://doi.org/10.3390/horticulturae11091115

APA StyleBini, L., Baldi, A., Passaseo, D., Biricolti, S., Giordani, E., Lippi, P., Zezza Mottola Di Amato, F., Fibbi, D., Del Bubba, M., & Lenzi, A. (2025). Suitability of Treated Domestic and Urban Wastewaters for the Hydroponic Cultivation of Rocket (Eruca vesicaria [L.] Cav.). Horticulturae, 11(9), 1115. https://doi.org/10.3390/horticulturae11091115