Soilless Agricultural Systems: Opportunities, Challenges, and Applications for Enhancing Horticultural Resilience to Climate Change and Urbanization

Abstract

1. Introduction

- (1)

- What is climate resilience within the context of global climate change and agricultural adaptation?

- (2)

- How do soilless farming systems improve water-use efficiency and crop productivity in resource-limited environments?

- (3)

- What are SLF systems’ key types and design principles, and how do they differ in nutrient management, crop compatibility, and infrastructure needs?

- (4)

- How can SLF technologies support sustainable horticultural production in urban and peri-urban areas?

- (5)

- What are the current limitations, opportunities, and research gaps for SLF at global and regional levels, particularly in China?

- (6)

- How do digital tools (e.g., AI and IoT) enhance SLF systems’ functionality, scalability, and sustainability?

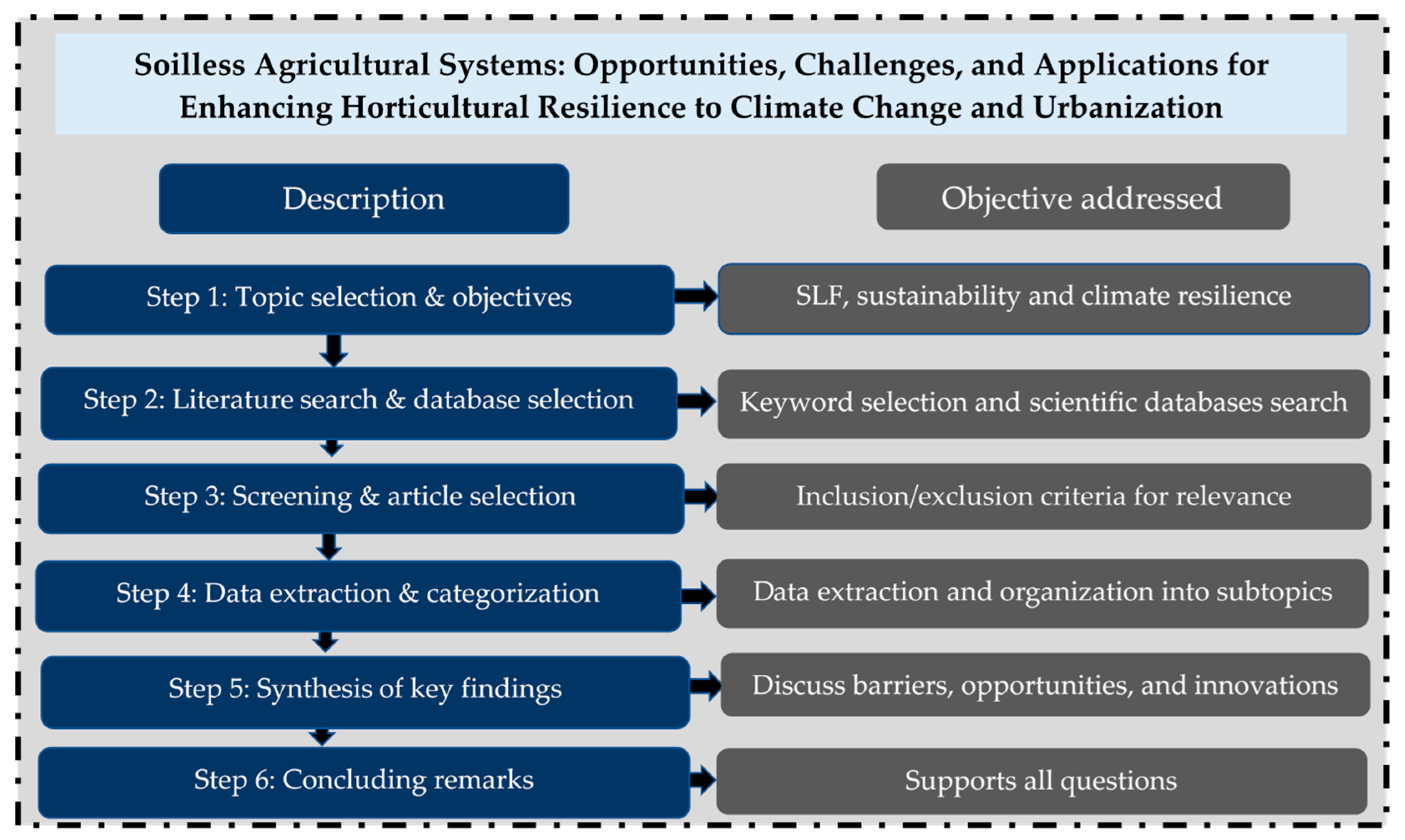

2. Methodology

3. Results and Discussion

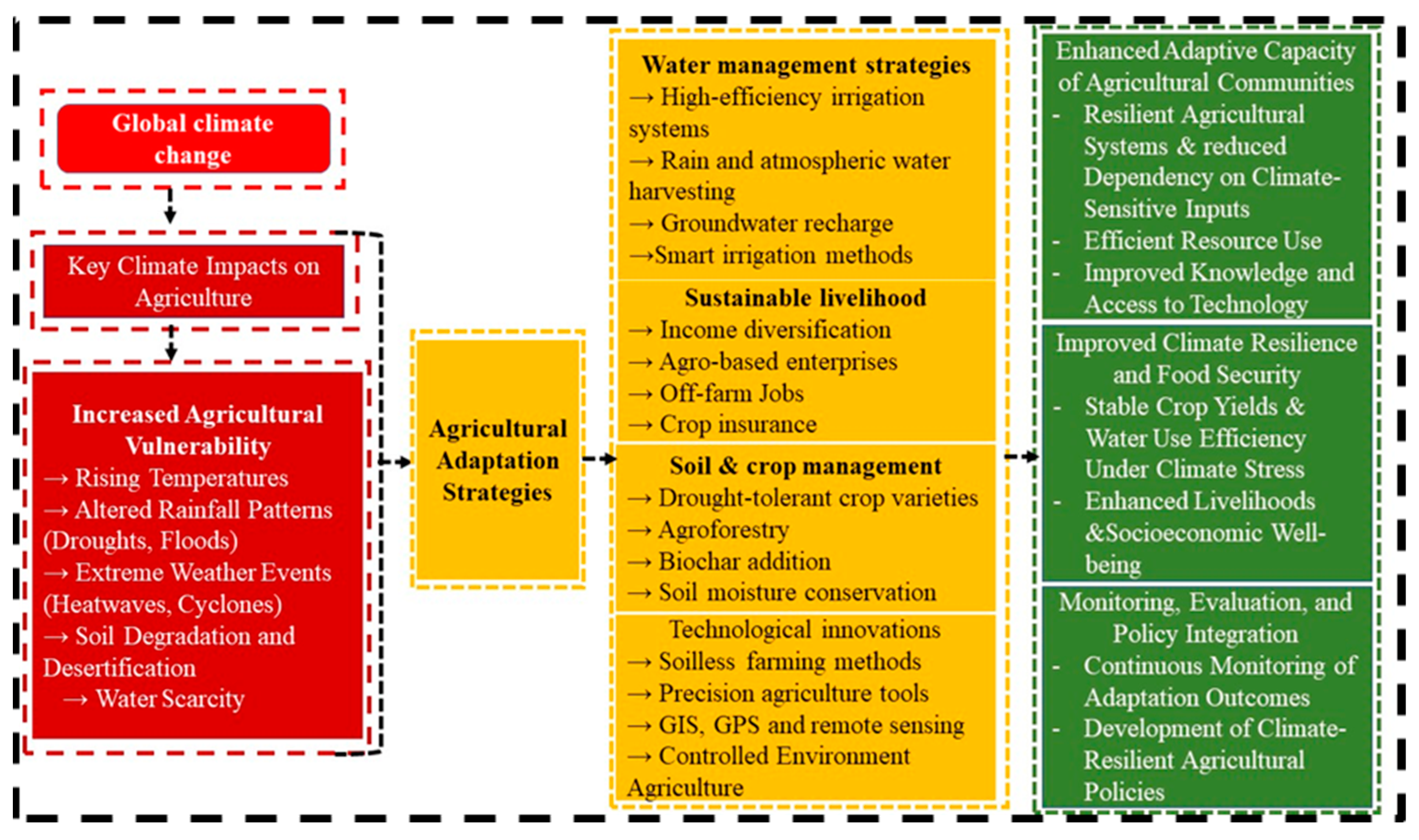

3.1. What Is Climate Resilience Within the Context of Global Climate Change and Agricultural Adaptation?

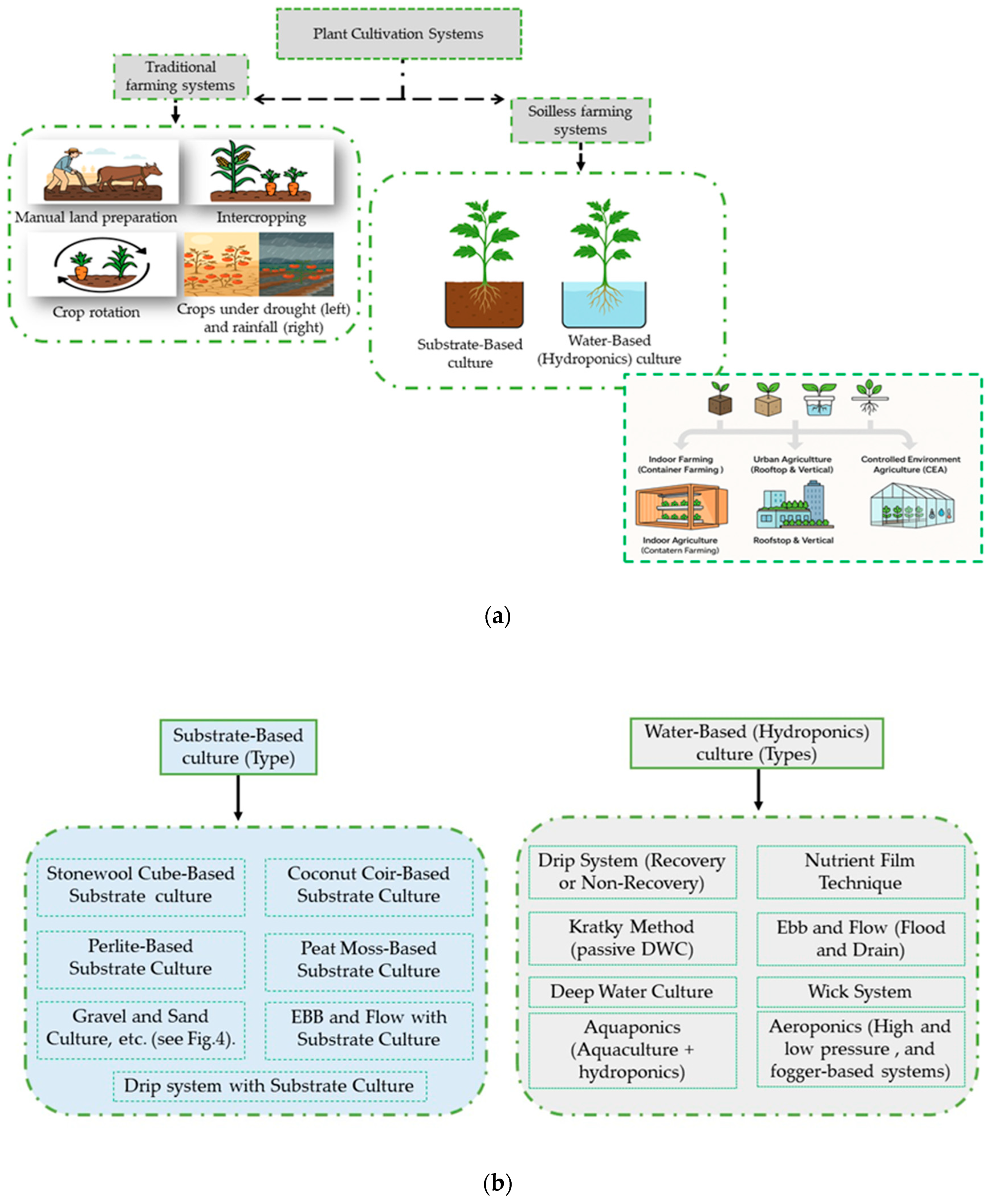

3.2. Traditional Farming and Soilless Farming Systems

3.3. How Does Soilless Farming Improve Water-Use Efficiency and Crop Productivity as a Measure of Climate Resilience?

3.3.1. Water Conservation

3.3.2. Reduced Land Use and Soil Degradation

3.3.3. Minimized Pesticides and Herbicides Use

3.3.4. Higher Crop Yields and Faster Growth

3.3.5. Reduced Environmental Footprint

3.3.6. Waste Minimization and Resource Recycling

3.4. What Are SLF Systems’ Key Types and Design Principles, and How Do They Differ in Nutrient Management, Crop Compatibility, and Infrastructure Needs?

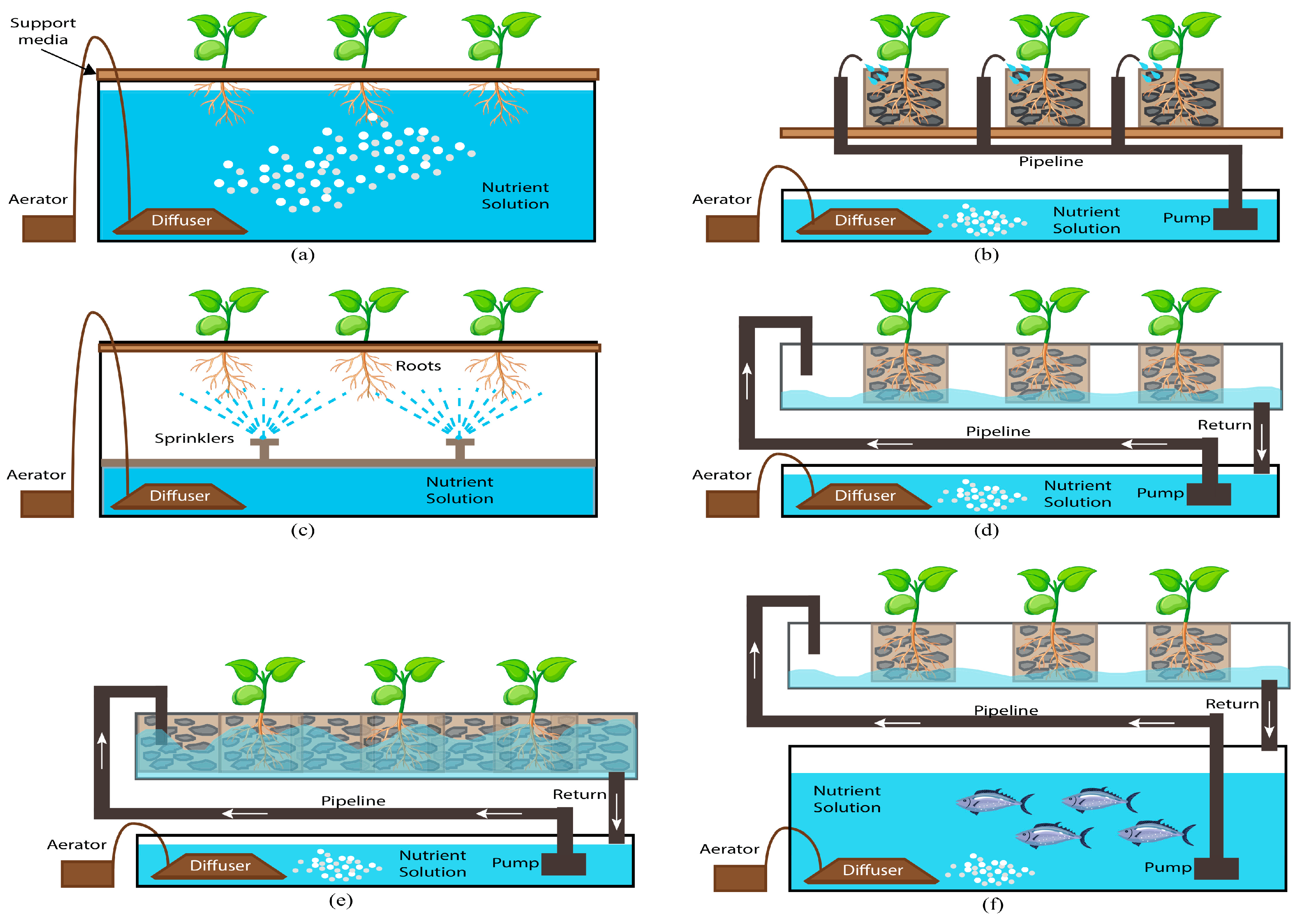

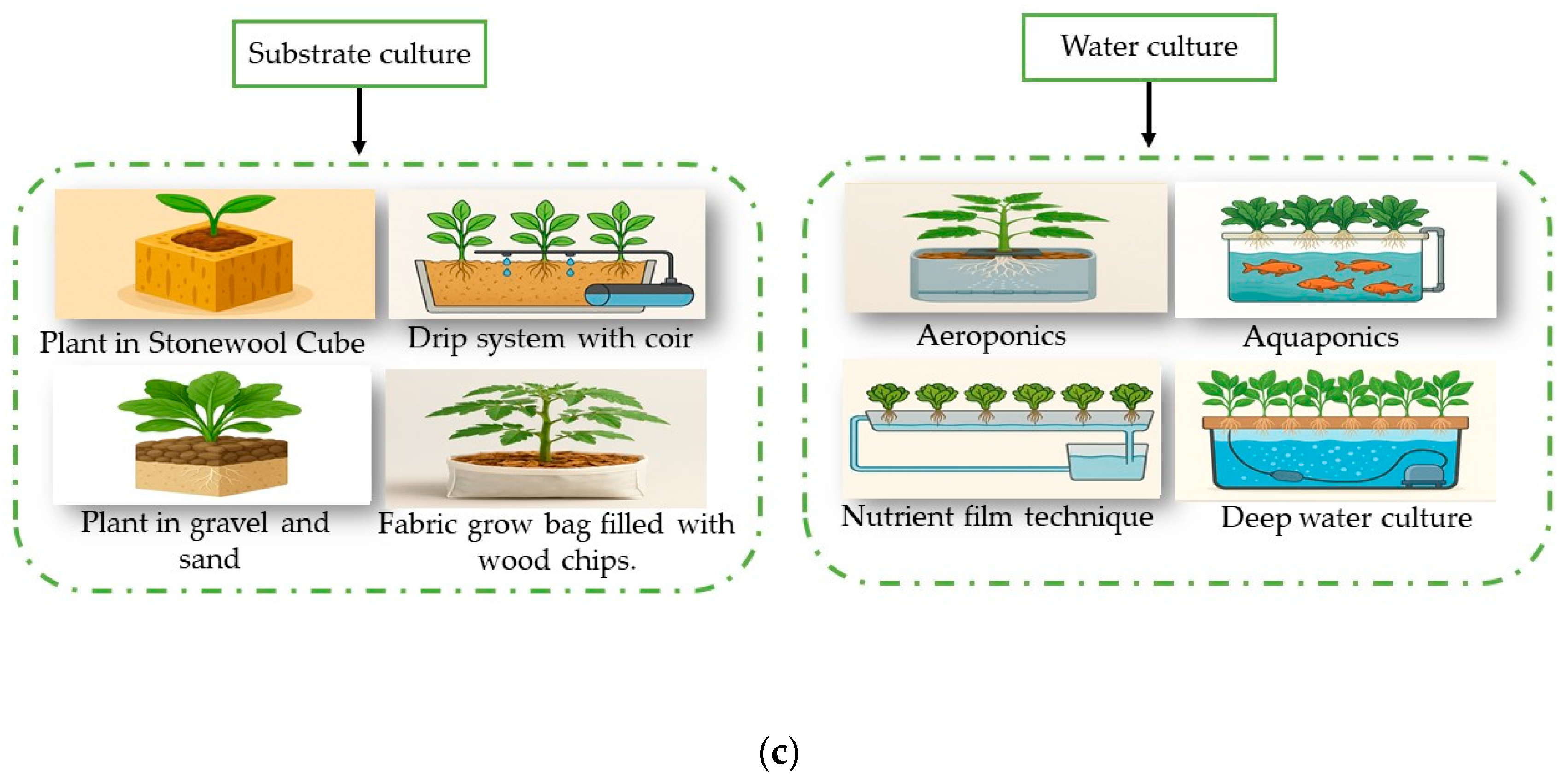

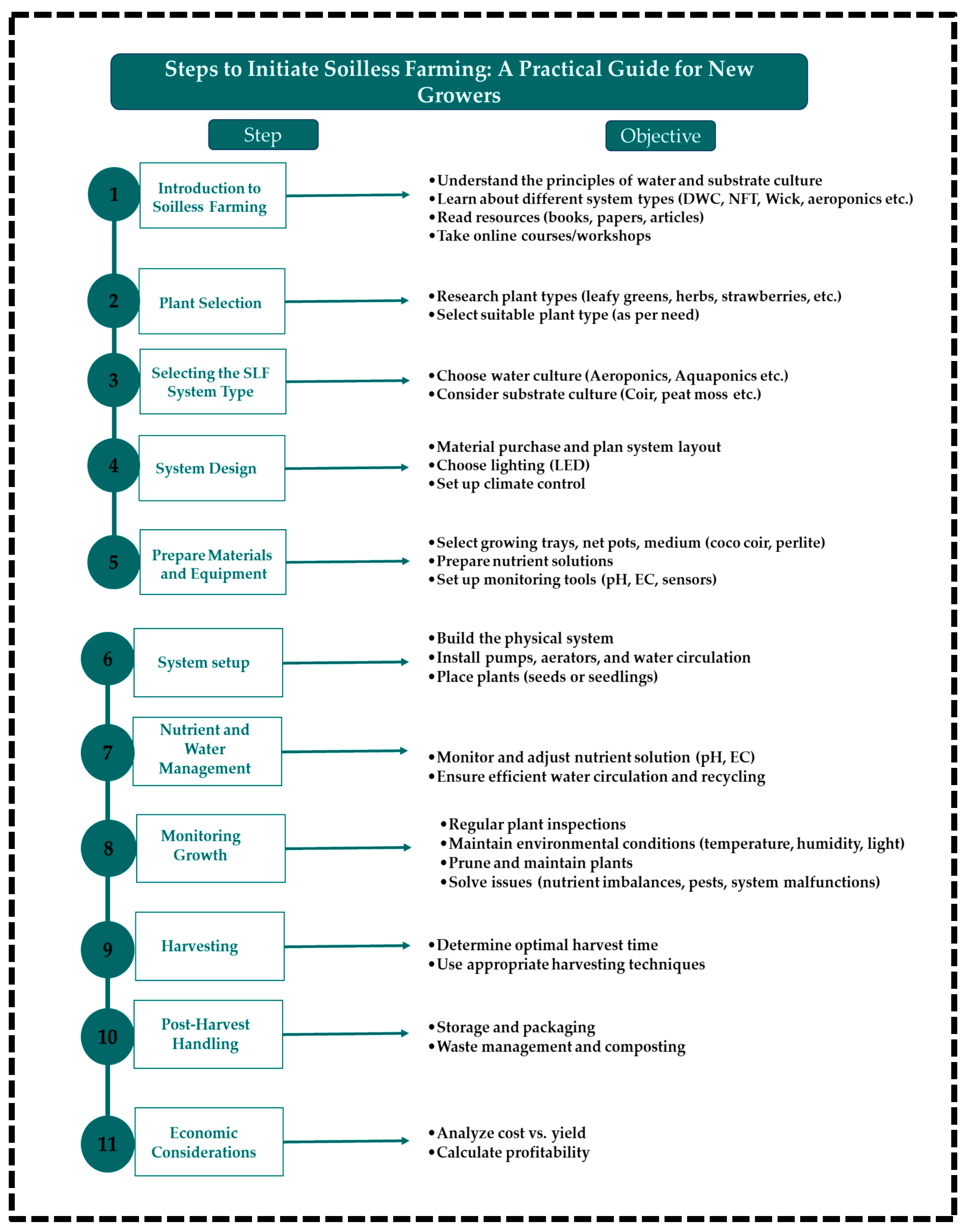

3.4.1. Types of Soilless Farming

Substrate-Based Culture

Water-Based Culture

3.4.2. Selection of Crop-Specific Soilless Cultivation System and Nutrient Solution

| Nutrient | Cooper [120] | Hewitt [125] | Steiner [126] | Hoagland and Arnon [127] |

|---|---|---|---|---|

| N | 200–236 | 168 | 168 | 210 |

| K | 300 | 156 | 273 | 234 |

| Ca | 170–185 | 160 | 180 | 160 |

| P | 60 | 41 | 31 | 31 |

| Mg | 50 | 36 | 48 | 34 |

| S | 68 | 48 | 336 | 64 |

| Fe | 12 | 2.8 | 2–4 | 2.5 |

| B | 0.3 | 0.54 | 0.44 | 0.5 |

| Mo | 0.2 | 0.004 | - | 0.01 |

| Mn | 2.0 | 0.54 | 0.62 | 0.5 |

| Cu | 0.1 | 0.064 | 0.02 | 0.02 |

| Zn | 0.1 | 0.065 | 0.11 | 0.05 |

3.4.3. Optimal Cultivation Conditions Required for Practicing Soilless Farming and Key Factors Influencing Water-Use Efficiency and Crop Productivity

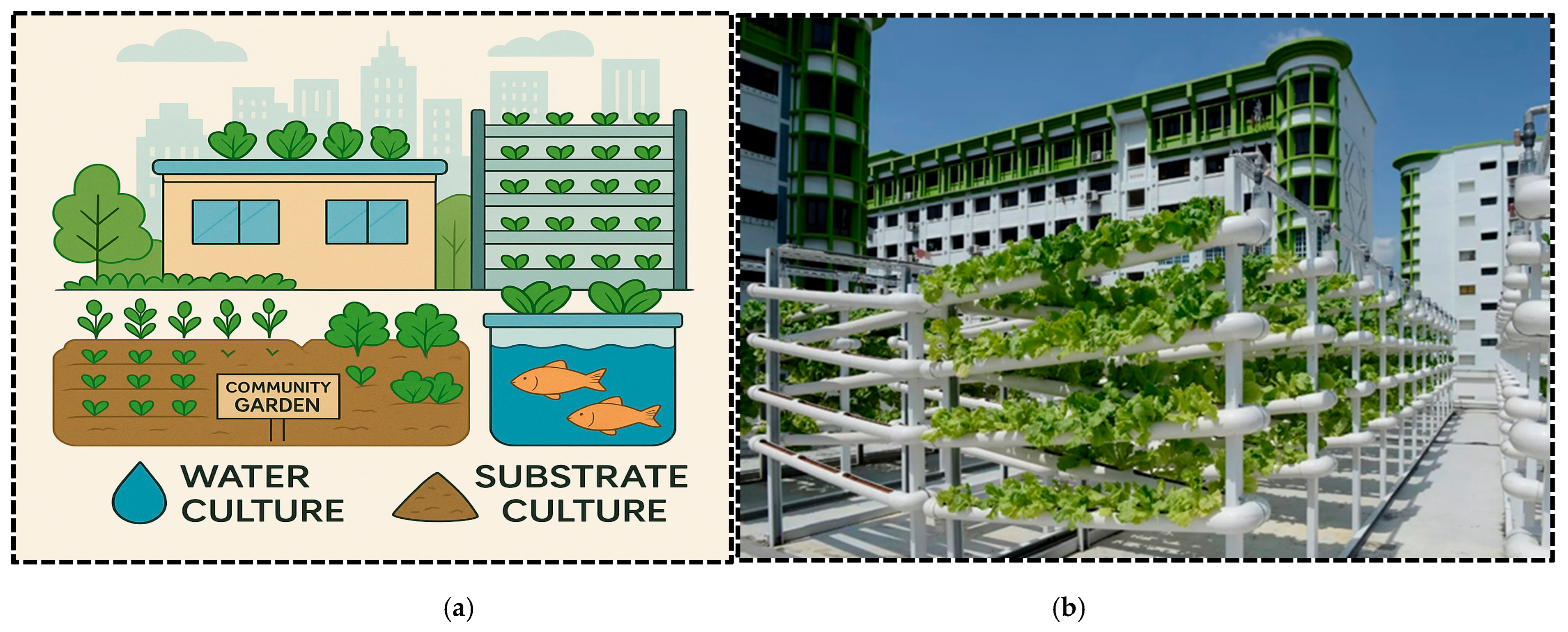

3.4.4. Designing the SLF Systems and Steps to Initiate SLF: A Practical Guide for New Growers

3.4.5. Comparative Analysis of Different Soilless Farming Systems

3.5. Application of SLF in Sustainable Urban Horticulture

3.6. What Are the Current Research, Challenges, Future Opportunities, and Status of Soilless Farming in China and Worldwide?

3.6.1. Global Impact of COVID-19 on Agriculture: Role of Soilless Farming

3.6.2. What Is the Current Status of Soilless Farming in China and Globally?

3.6.3. Future Prospects, Current Challenges, and the State of Research and Innovation in Soilless Farming

3.6.4. Soilless Farming in Developing Regions: Challenges and Opportunities

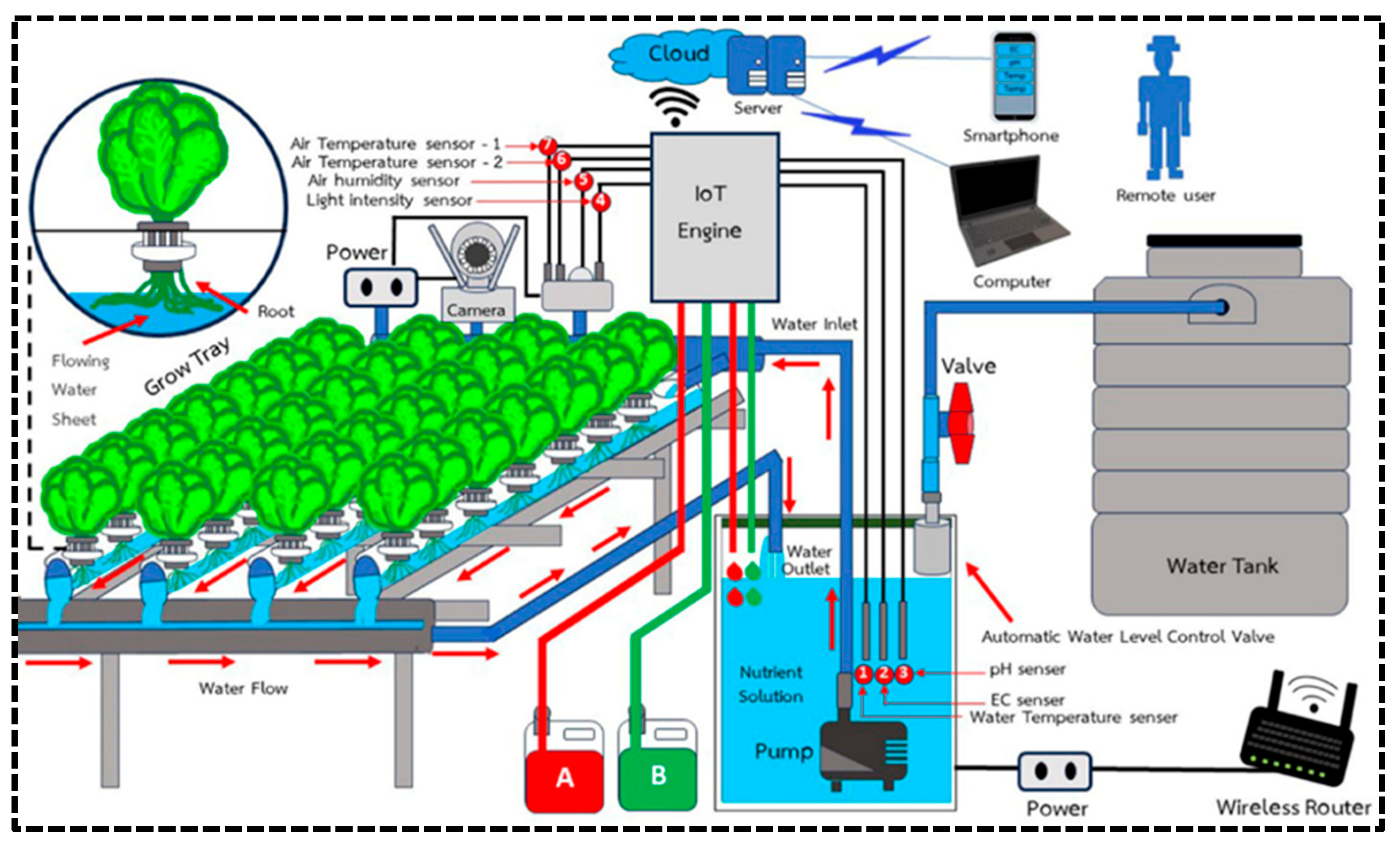

3.7. How Do Artificial Intelligence (AI), Internet of Things (IoT), and Smart Horticulture Tools Enhance the Efficiency, Productivity, and Sustainability of Soilless Farming?

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Guiné, R.P.F. The Challenges and Strategies of Food Security under Global Change. Foods 2024, 13, 2083. [Google Scholar] [CrossRef] [PubMed]

- Disasa, K.N.; Yan, H.; Wang, G.; Zhang, J.; Zhang, C.; Zhu, X. Projection of Future Precipitation, Air Temperature, and Solar Radiation Changes in Southeastern China. Theor. Appl. Climatol. 2024, 155, 4481–4506. [Google Scholar] [CrossRef]

- Li, M.; Yan, H.; Zhang, C.; Zhang, J.; Wang, G.; Acquah, J. Current Deficiencies and Needed Enhancements on Greenhouse Crop Evapotranspiration Models J. Irrig. Drain. Eng. 2024, 42, 57–63. [Google Scholar] [CrossRef]

- Yan, H.; Acquah, S.J.; Zhang, J.Y.; Wang, G.Q.; Zhang, C.; Darko, R.O. Overview of Modelling Techniques for Greenhouse Microclimate Environment and Evapotranspiration. Int. J. Agric. Biol. Eng. 2021, 14, 1–8. [Google Scholar] [CrossRef]

- Zhai, L.; Lee, J.-E. Investigating Vulnerability, Adaptation, and Resilience: A Comprehensive Review within the Context of Climate Change. Atmosphere 2024, 15, 474. [Google Scholar] [CrossRef]

- Abu Shoaib, S.; Rahman, M.M.; Shalabi, F.I.; Alshayeb, A.F.; Shatnawi, Z.N. Climate Resilience and Environmental Sustainability: How to Integrate Dynamic Dimensions of Water Security Modeling. Agriculture 2022, 12, 303. [Google Scholar] [CrossRef]

- Yan, H.; Deng, S.; Zhang, C.; Wang, G.; Zhao, S.; Li, M.; Liang, S.; Jiang, J.; Zhou, Y. Determination of Energy Partition of a Cucumber-Grown Venlo-Type Greenhouse in Southeast China. Agric. Water Manag. 2023, 276, 108047. [Google Scholar] [CrossRef]

- Huang, S.; Yan, H.; Zhang, C.; Wang, G.; Acquah, S.J.; Yu, J.; Li, L.; Ma, J.; Darko, R.O. Modeling Evapotranspiration for Cucumber Plants Based on the Shuttleworth-Wallace Model in a Venlo-Type Greenhouse. Agric. Water Manag. 2020, 228, 105861. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Yan, H.; Zhang, C.; Zhang, J.; Wang, G.; Deng, S.; Syed, T.N.; Wang, B.; Zhou, R. A Review of Evapotranspiration Estimation Methods for Climate-Smart Agriculture Tools under a Changing Climate: Vulnerabilities, Consequences, and Implications. J. Water Clim. Change 2024, 16, 249–288. [Google Scholar] [CrossRef]

- United Nations, Department of Economic and Social Affairs, Population Division. The 2018 Revision of World Urbanization Prospects; United Nations: New York, NY, USA, 2018; Available online: https://www.un.org/en/desa/2018-revision-world-urbanization-prospects (accessed on 26 March 2025).

- National Bureau of Statistics of China. China Sees Rising Urbanization Rate over Past 75 Years. State Council of the People’s Republic of China. 2024. Available online: https://english.www.gov.cn/archive/statistics/202409/23/content_WS66f14531c6d0868f4e8eb2c0.html (accessed on 26 March 2025).

- Xiao, Y.; Song, Y.; Wu, X. How Far Has China’s Urbanization Gone? Sustainability 2018, 10, 2953. [Google Scholar] [CrossRef]

- Lam, H.-M.; Remais, J.; Fung, M.-C.; Xu, L.; Sun, S.S.-M. Food Supply and Food Safety Issues in China. Lancet 2013, 381, 2044–2053. [Google Scholar] [CrossRef] [PubMed]

- Luo, B.; Dou, X. Climate Change, Agricultural Transformation and Climate Smart Agriculture Development in China. Heliyon 2024, 10, e40008. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Buttar, N.A. Modern Plant Cultivation Technologies in Agriculture under Controlled Environment: A Review on Aeroponics. J. Plant Interact. 2018, 13, 338–352. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Jianmin, G.; Syed, T.N.; Chandio, F.A.; Buttar, N.A.; Qureshi, W.A. Monitoring and Control Systems in Agriculture Using Intelligent Sensor Techniques: A Review of the Aeroponic System. J. Sens. 2018, 2018, 8672769. [Google Scholar] [CrossRef]

- Lakhiar, M.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Tunio, M.H.; Ahmad, F.; Solangi, K.A. Overview of the Aeroponic Agriculture —An Emerging Technology for Global Food Security. Int. J. Agric. Biol. Eng. 2020, 13, 1–10. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Yan, H.; Zhang, C.; Wang, G.; He, B.; Hao, B.; Han, Y.; Wang, B.; Bao, R.; Syed, T.N.; et al. A Review of Precision Irrigation Water-Saving Technology under Changing Climate for Enhancing Water Use Efficiency, Crop Yield, and Environmental Footprints. Agriculture 2024, 14, 1141. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Yan, H.; Zhang, J.; Wang, G.; Deng, S.; Bao, R.; Zhang, C.; Syed, T.N.; Wang, B.; Zhou, R.; et al. Plastic Pollution in Agriculture as a Threat to Food Security, the Ecosystem, and the Environment: An Overview. Agronomy 2024, 14, 548. [Google Scholar] [CrossRef]

- Mohamed, T.M.K.; Gao, J.; Abuarab, M.E.; Kassem, M.; Wasef, E.; El-Ssawy, W. Applying Different Magnetic Water Densities as Irrigation for Aeroponically and Hydroponically Grown Strawberries. Agriculture 2022, 12, 819. [Google Scholar] [CrossRef]

- Mohamed, T.M.K.; Gao, J.M.; Tunio, M. Development and experiment of the intelligent control system for rhizosphere temperature of aeroponic lettuce via the Internet of Things. Int. J. Agric. Biol. Eng. 2022, 15, 225–233. [Google Scholar]

- Chopra, A.; Rao, P.; Prakash, O. Biochar-Enhanced Soilless Farming: A Sustainable Solution for Modern Agriculture. Mitig. Adapt. Strateg. Glob. Change 2024, 29, 72. [Google Scholar] [CrossRef]

- Gruda, N.S.; Machado, R.M.A.; van Os, E.A. Is Soilless Culture a Sustainable Form of Agriculture? Horticulturae 2023, 9, 1190. [Google Scholar] [CrossRef]

- Martinez-Mate, M.A.; Martin-Gorriz, B.; Martínez-Alvarez, V.; Soto-García, M.; Maestre-Valero, J.F. Hydroponic System and Desalinated Seawater as an Alternative Farm-Productive Proposal in Water Scarcity Areas: Energy and Greenhouse Gas Emissions Analysis of Lettuce Production in Southeast Spain. J. Clean. Prod. 2018, 172, 1298–1310. [Google Scholar] [CrossRef]

- NASA Spinoff. Progressive plant growing has business blooming. In Environmental and Agricultural Resources; NASASpinoff: New York, NY, USA, 2006; pp. 64–77. [Google Scholar]

- Pomoni, D.I.; Koukou, M.K.; Vrachopoulos, M.G.; Vasiliadis, L. A Review of Hydroponics and Conventional Agriculture Based on Energy and Water Consumption, Environmental Impact, and Land Use. Energies 2023, 16, 1690. [Google Scholar] [CrossRef]

- Tunio, M.H.; Gao, J.; Lakhiar, I.A.; Solangi, K.A.; Qureshi, W.A.; Shaikh, S.A.; Chen, J. Influence of Atomization Nozzles and Spraying Intervals on Growth, Biomass Yield, and Nutrient Uptake of Butter-Head Lettuce under Aeroponics System. Agronomy 2021, 11, 97. [Google Scholar] [CrossRef]

- Tunio, M.H.; Gao, J.; Shaikh, S.A.; Lakhiar, I.A.; Qureshi, W.A.; Solangi, K.A.; Chandio, F.A. Potato Production in Aeroponics: An Emerging Food Growing System in Sustainable Agriculture for Food Security. Chil. J. Agric. Res. 2020, 80, 118–132. [Google Scholar] [CrossRef]

- Elsherbiny, O.; Gao, J.; Ma, M.; Guo, Y.; Tunio, M.H.; Mosha, A.H. Advancing Lettuce Physiological State Recognition in IoT Aeroponic Systems: A Meta-Learning-Driven Data Fusion Approach. Eur. J. Agron. 2024, 161, 127387. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, J.; Tunio, M.H.; Wang, L. Study on the Identification of Mildew Disease of Cuttings at the Base of Mulberry Cuttings by Aeroponics Rapid Propagation Based on a BP Neural Network. Agronomy 2023, 13, 106. [Google Scholar] [CrossRef]

- Iqbal, B.; Alabbosh, K.F.; Jalal, A.; Suboktagin, S.; Elboughdiri, N. Sustainable Food Systems Transformation in the Face of Climate Change: Strategies, Challenges, and Policy Implications. Food Sci. Biotechnol. 2025, 34, 871–883. [Google Scholar] [CrossRef]

- Nazir, M.J.; Li, G.; Nazir, M.M.; Zulfiqar, F.; Siddique, K.H.M.; Iqbal, B.; Du, D. Harnessing Soil Carbon Sequestration to Address Climate Change Challenges in Agriculture. Soil Tillage Res. 2024, 237, 105959. [Google Scholar] [CrossRef]

- FAO. Increased Resilience of Agriculture Sector through Promotion of Climate Smart Agriculture Practices; TCP/MCD/3705; FAO: Rome, Italy, 2022; Available online: https://openknowledge.fao.org/server/api/core/bitstreams/d0124ae2-5f78-471f-abdf-4a0b2d0247b1/content (accessed on 1 April 2025).

- FAO. FAO Strategy on Climate Change 2022–2031; FAO: Rome, Italy, 2022; Available online: https://openknowledge.fao.org/handle/20.500.14283/cc2274en (accessed on 1 April 2025).

- Sanson, A.V.; Masten, A.S. Climate Change and Resilience: Developmental Science Perspectives. Int. J. Behav. Dev. 2024, 48, 93–102. [Google Scholar] [CrossRef]

- Lopez-Muñoz, F.; Soto-Bruna, W.; Baptiste, B.L.G.; Leon-Pulido, J. Evaluating Food Resilience Initiatives Through Urban Agriculture Models: A Critical Review. Sustainability 2025, 17, 2994. [Google Scholar] [CrossRef]

- Benitez-Alfonso, Y.; Soanes, B.K.; Zimba, S.; Sinanaj, B.; German, L.; Sharma, V.; Foyer, C.H. Enhancing Climate Change Resilience in Agricultural Crops. Curr. Biol. 2023, 33, R1246–R1261. [Google Scholar] [CrossRef] [PubMed]

- Reyes, S.R.C.; Miyazaki, A.; Yiu, E.; Saito, O. Enhancing Sustainability in Traditional Agriculture: Indicators for Monitoring the Conservation of Globally Important Agricultural Heritage Systems (GIAHS) in Japan. Sustainability 2020, 12, 5656. [Google Scholar] [CrossRef]

- Wang, B.; Bao, R.; Yan, H.; Zheng, H.; Wu, J.; Zhang, C.; Wang, G. Study of Evapotranspiration and Crop Coefficients for Eggplant in a Venlo-Type Greenhouse in South China. Irrig. Drain. 2024, 74, 556–568. [Google Scholar] [CrossRef]

- Xue, R.; Zhang, C.; Yan, H.; Disasa, K.N.; Lakhiar, I.A.; Akhlaq, M.; Hameed, M.U.; Li, J.; Ren, J.; Deng, S.; et al. Determination of the Optimal Frequency and Duration of Micro-Spray Patterns for High-Temperature Environment Tomatoes Based on the Fuzzy Borda Model. Agric. Wat. Manag. 2024, 307, 109240. [Google Scholar] [CrossRef]

- Wang, S.; Yang, Y.; Yin, H.; Zhao, J.; Wang, T.; Yang, X.; Ren, J.; Yin, C. Towards Digital Transformation of Agriculture for Sustainable Development in China: Experience and Lessons Learned. Sustainability 2025, 17, 3756. [Google Scholar] [CrossRef]

- Othman, Y.; Bataineh, K.; Al-Ajlouni, M.; Alsmairat, N.; Ayad, J.; Shiyab, S.; Al-Qarallah, B.; St Hilaire, R. Soilless Culture: Management of growing substrate, water, nutrient, salinity, microorganism and product quality. Fresenius Environ. Bull. 2019, 28, 3249–3260. [Google Scholar]

- Gebreegziher, W.G. Soilless Culture Technology to Transform Vegetable Farming, Reduce Land Pressure and Degradation in Drylands. Cogent Food Agric. 2023, 9, 2265106. [Google Scholar] [CrossRef]

- Kannan, M.; Elavarasan, G.; Balamurugan, A.; Dhanusiya, B.; Freedon, D. Hydroponic Farming—A State of Art for the Future Agriculture. Mater. Today Proc. 2022, 68, 2163–2166. [Google Scholar] [CrossRef]

- Gruda, N.; Prasad, M.; Maher, M.J. Soilless Culture. In Encyclopedia of Soil Science, Lal, R., Ed.; Taylor & Francis (Marcel Dekker), Inc.: New York, NY, USA, 2004. [Google Scholar]

- Kim, J.; Park, H.; Seo, C.; Kim, H.; Choi, G.; Kim, M.; Kim, B.; Lee, W. Sustainable and Inflatable Aeroponics Smart Farm System for Water Efficiency and High-Value Crop Production. Appl. Sci. 2024, 14, 4931. [Google Scholar] [CrossRef]

- Regmi, A.; Rueda-Kunz, D.; Liu, H.; Trevino, J.; Kathi, S.; Simpson, C.; Regmi, A.; Rueda-Kunz, D.; Liu, H.; Trevino, J.; et al. Comparing Resource Use Efficiencies in Hydroponic and Aeroponic Production Systems. Technol. Hortic. 2024, 4, 1–10. [Google Scholar] [CrossRef]

- Sousa, R.D.; Bragança, L.; da Silva, M.V.; Oliveira, R.S. Challenges and Solutions for Sustainable Food Systems: The Potential of Home Hydroponics. Sustainability 2024, 16, 817. [Google Scholar] [CrossRef]

- Gruda, N. Do soilless culture systems have an influence on product quality of vegetables? J. Appl. Bot. Food Qual. 2009, 82, 141–147. [Google Scholar]

- Fussy, A.; Papenbrock, J. An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability. Plants 2022, 11, 1153. [Google Scholar] [CrossRef]

- Gruda, N.S. Advances in Soilless Culture and Growing Media in Today’s Horticulture—An Editorial. Agronomy 2022, 12, 2773. [Google Scholar] [CrossRef]

- Appicciutoli, D.; Amici, A.S.; Bentivoglio, D.; Chiaraluce, G.; Staffolani, G.; Finco, A. Cultivating the Future: A Bibliometric Review of Emerging Trends in Soilless Farming. Horticulturae 2025, 11, 140. [Google Scholar] [CrossRef]

- Gruda, N.; Tanny, J. Protected crops. In Horticulture: Plants for People and Places, Dixon, G.R., Aldous, D.E., Eds.; Springer: Dordrecht, The Netherlands, 2014; Volume 1, pp. 327–405. [Google Scholar]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under Southern and Central European climatic conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Elsherbiny, O.; Gao, J.M.; Guo, Y.N.; Tunio, M.H.; Mosha, A.H. Fusion of the deep networks for rapid detection of branch-infected aeroponically cultivated mulberries using multimodal traits. Int. J. Agric. Biol. Eng. 2025, 18, 75–88. [Google Scholar]

- Gruda, N.; Gianquinto, G.; Tüzel, Y.; Savvas, D. Soilless Culture. In Encyclopedia of Soil Sciences, 3rd ed.; Lal, R., Ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2016; pp. 533–537. [Google Scholar]

- El-Sayed, S.F.; Hassan, H.A.; Mahmoud, S.O. Effect of some soilless culture techniques on sweet pepper growth, production, leaves chemical contents and water consumption under greenhouse conditions. Middle East J. Agric. Res. 2015, 4, 682–691. [Google Scholar]

- Rouphael, Y.; Colla, G.; Cardarelli, M.; Fanasca, S.; Salerno, A.; Rivera, C.M.; Rea, A.; Karam, F. Water Use Efficiency of Greenhouse Summer Squash in Relation to the Method of Culture: Soil vs. Soilless. Acta Hortic. 2005, 697, 81–86. [Google Scholar] [CrossRef]

- Barbosa, G.L.; Gadelha, F.D.A.; Kublik, N.; Proctor, A.; Reichelm, L.; Weissinger, E.; Wohlleb, G.M.; Halden, R.U. Comparison of Land, Water, and Energy Requirements of Lettuce Grown Using Hydroponic vs. Conventional Agricultural Methods. Int. J. Environ. Res. Public Health 2015, 12, 6879–6891. [Google Scholar] [CrossRef] [PubMed]

- Albadwawi, M.A.O.K.; Ahmed, Z.F.R.; Kurup, S.S.; Alyafei, M.A.; Jaleel, A. A Comparative Evaluation of Aquaponic and Soil Systems on Yield and Antioxidant Levels in Basil, an Important Food Plant in Lamiaceae. Agronomy 2022, 12, 3007. [Google Scholar] [CrossRef]

- Al-Khateeb, S.A.; Zeineldin, F.I.; Elmulthum, N.A.; Al-Barrak, K.M.; Sattar, M.N.; Mohammad, T.A.; Mohmand, A.S. Assessment of Water Productivity and Economic Viability of Greenhouse-Grown Tomatoes under Soilless and Soil-Based Cultivations. Water 2024, 16, 987. [Google Scholar] [CrossRef]

- Shtaya, M.J.Y.; Qubbaj, T. Effect of Different Soilless Agriculture Methods on Irrigation Water Saving and Growth of Lettuce (Lactuca sativa). Res. Crops 2022, 23, 156–162. [Google Scholar]

- Verdoliva, S.G.; Gwyn-Jones, D.; Detheridge, A.; Robson, P. Controlled Comparisons between Soil and Hydroponic Systems Reveal Increased Water Use Efficiency and Higher Lycopene and β-Carotene Contents in Hydroponically Grown Tomatoes. Sci. Hortic. 2021, 279, 109896. [Google Scholar] [CrossRef]

- Shen, P.; Wang, L.; Qureshi, W.A.; Gao, J. Influence of Rhizosphere Temperature and Humidity Regulation on Rooting, Mortality, and Transplant Survival of Aeroponically Rapid Growth Mulberry Cutting. Agronomy 2025, 15, 583. [Google Scholar] [CrossRef]

- Dutta, M.; Gupta, D.; Juneja, S.; Nauman, A.; Muhammad, G. Comparative Growth Analysis of Onion in Deep Water Culture and Soil Based Systems: Enhancing Medicinal Plant Cultivation in Urbanized Environments. IEEE Access 2024, 12, 38202–38218. [Google Scholar] [CrossRef]

- Al Meselmani, M.A. Hydroponics: The Future of Sustainable Farming. In Hydroponics: The Future of Sustainable Farming; Springer US: New York, NY, USA, 2024; pp. 101–122. [Google Scholar]

- Sharma, A.; Hazarika, M.; Heisnam, P.; Pandey, H.; Devadas, V.S.; Wangsu, M. Controlled Environment Ecosystem: A Plant Growth System to Combat Climate Change Through Soilless Culture. Crop Des. 2023, 3, 100044. [Google Scholar] [CrossRef]

- Putra, P.A.; Yuliando, H. Soilless Culture System to Support Water Use Efficiency and Product Quality: A Review. Agric. Agric. Sci. Procedia 2015, 3, 283–288. [Google Scholar] [CrossRef]

- Rajaseger, G.; Chan, K.L.; Tan, K.Y.; Ramasamy, S.; Khin, M.C.; Amaladoss, A.; Haribhai, P.K. Hydroponics: Current Trends in Sustainable Crop Production. Bioinformation 2023, 19, 925. [Google Scholar] [CrossRef]

- Türkten, H.; Ceyhan, V. Environmental Efficiency in Greenhouse Tomato Production Using Soilless Farming Technology. J. Clean. Prod. 2023, 398, 136482. [Google Scholar] [CrossRef]

- Budavári, N.; Pék, Z.; Helyes, L.; Takács, S.; Nemeskéri, E. An Overview on the Use of Artificial Lighting for Sustainable Lettuce and Microgreens Production in an Indoor Vertical Farming System. Horticulturae 2024, 10, 938. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in Greenhouses in the EU: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 5150. [Google Scholar] [CrossRef]

- Chowdhury, H.; Asiabanpour, B. A Circular Economy Integration Approach into Vertical Farming with Computer-Based Simulation Model for Resource Optimization and Waste Reduction. J. Clean. Prod. 2024, 470, 143256. [Google Scholar] [CrossRef]

- Gruda, N. Soilless Culture Systems and Growing Media in Horticulture: An Overview. In Advances in Horticultural Soilless Culture; Gruda, N.S., Ed.; Burleigh Dodds Science: Cambridge, UK, 2021; pp. 1–20. Available online: https://shop.bdspublishing.com/store/bds/detail/workgroup/3-190-89123 (accessed on 1 May 2025)ISBN 9781786762924.

- Massa, D.; Magán, J.J.; Montesano, F.F.; Tzortzakis, N. Minimizing Water and Nutrient Losses from Soilless Cropping in Southern Europe. Agric. Water Manag. 2020, 241, 106395. [Google Scholar] [CrossRef]

- Ehret, D.L.; Helmer, T. A New Wood Fibre Substrate for Hydroponic Tomato and Pepper Crops. Can. J. Plant Sci. 2009, 89, 1127–1132. [Google Scholar] [CrossRef]

- Mahamud, S.; Manisah, M.D. Preliminary Studies on Sago Waste as Growing Medium for Tomato. Acta Hortic. 2007, 742, 163–168. [Google Scholar] [CrossRef]

- Donnan, R. Hydroponics around the World. Pract. Hydroponics Greenh. 1998, 41, 18–25. [Google Scholar]

- Fuentes-Peñailillo, F.; Gutter, K.; Vega, R.; Silva, G.C. New Generation Sustainable Technologies for Soilless Vegetable Production. Horticulturae 2024, 10, 49. [Google Scholar] [CrossRef]

- Gruda, N.S. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy 2019, 9, 298. [Google Scholar] [CrossRef]

- Blok, C.; Urrestarazu, M. Substrate Growing Developments in Europe 2010–2027. Available online: www.horticom.com (accessed on 1 May 2025).

- Nichols, M.A. COIR—A XXI Century Sustainable Growing Medium. Acta Hortic. 2007, 747, 91–95. [Google Scholar] [CrossRef]

- Apodaca, L.E. Peat. In Minerals Yearbook 2016; U.S. Department of the Interior: Washington, DC, USA; U.S. Geological Survey: Reston, VA, USA, 2018. [Google Scholar]

- Gruda, N.; Caron, J.; Prasad, M.; Maher, M.J. Growing media. In Encyclopedia of Soil Sciences, 3rd ed.; Lal, R., Ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2016; pp. 1053–1058. [Google Scholar]

- QUANTIS. Comparative Life Cycle Assessment of Horticultural Growing Media Based on Peat and Other Growing Media Constituents. 2012. Available online: https://erden-substrate.info/wp-content/uploads/2023/02/comparative-life-cycle-assessment-of-horticultural-growing-media-based-on-peat-and-other-growing-media-constituents.pdf (accessed on 1 April 2025).

- Zulfiqar, F.; Allaire, S.E.; Akram, N.A.; Méndez, A.; Younis, A.; Peerzada, A.M.; Shaukat, N.; Wright, S.R. Challenges in organic component selection and biochar as an opportunity in potting substrates: A review. J. Plant Nutr. 2019, 24, 1386–1401. [Google Scholar] [CrossRef]

- Barretta, G.E.; Alexander, P.D.; Robinson, J.S.; Bragg, N.C. Achieving Environmentally Sustainable Growing Media for Soilless Plant Cultivation Systems—A Review. Sci. Hortic. 2016, 212, 220–234. [Google Scholar] [CrossRef]

- Raviv, M. The Future of Composts as Ingredients of Growing Media. Acta Hortic. 2011, 891, 19–32. [Google Scholar] [CrossRef]

- Raviv, M. Suppressing Soil-Borne Disease of Container-Grown Plants Using Composts. Acta Hortic. 2011, 893, 169–181. [Google Scholar] [CrossRef]

- Česonienė, L.; Krikštolaitis, R.; Daubaras, R.; Mažeika, R. Effects of Mixes of Peat with Different Rates of Spruce, Pine Fibers, or Perlite on the Growth of Blueberry Saplings. Horticulturae 2023, 9, 151. [Google Scholar] [CrossRef]

- Bilderback, T.E.; Warren, S.L.; Owen, J.S.; Albano, J.P. Healthy Substrates Need Physicals Too! HortTechnology 2005, 15, 747–751. [Google Scholar] [CrossRef]

- Riggio, G.M.; Jones, S.L.; Gibson, K.E. Risk of Human Pathogen Internalization in Leafy Vegetables During Lab-Scale Hydroponic Cultivation. Horticulturae 2019, 5, 25. [Google Scholar] [CrossRef]

- Nazir, M.; Roy, K.; Saha, A.; Saha, D. A Sustainable Holistic Approach of Hydroponic Farming for Reclaiming and Rehabilitating Wastewater: A Review. Water Air Soil Pollut. 2024, 235, 445. [Google Scholar] [CrossRef]

- Wang, S.; Kleiner, Y.; Clark, S.M.; Raghavan, V.; Tartakovsky, B. Review of Current Hydroponic Food Production Practices and the Potential Role of Bioelectrochemical Systems. Rev. Environ. Sci. Biotechnol. 2024, 23, 897–921. [Google Scholar] [CrossRef]

- Naegel, L.C.A. Combined production of fish and plants in recirculating water. Aquaculture 1977, 10, 17–24. [Google Scholar] [CrossRef]

- Al Tawaha, A.R.; Megat Wahab, P.E.; Jaafar, H.Z. Optimizing Nutrient Availability in Decoupled Recirculating Aquaponic Systems for Enhanced Plant Productivity: A Mini Review. Nitrogen 2025, 6, 3. [Google Scholar] [CrossRef]

- Buzby, K.M.; Lin, L.S. Scaling Aquaponic Systems: Balancing Plant Uptake with Fish Output. Aquac. Eng. 2014, 63, 39–44. [Google Scholar] [CrossRef]

- Ibrahim, L.A.; Shaghaleh, H.; El-Kassar, G.M.; Abu-Hashim, M.; Elsadek, E.A.; Alhaj Hamoud, Y. Aquaponics: A Sustainable Path to Food Sovereignty and Enhanced Water Use Efficiency. Water 2023, 15, 4310. [Google Scholar] [CrossRef]

- Al Tawaha, A.R.; Megat Wahab, P.E.; Binti Jaafar, H.; Kee Zuan, A.T.; Hassan, M.Z.; Al-Tawaha, A.R.M. Yield and nutrients leaf content of butterhead lettuce (Lactuca sativa) in response to fish nutrient solution in a small scale of aquaponic systems. Ecol. Eng. Environ. Technol. 2021, 22, 85–94. [Google Scholar] [CrossRef]

- Junge, R.; König, B.; Villarroel, M.; Komives, T.; Jijakli, M.H. Strategic Points in Aquaponics. Water 2017, 9, 182. [Google Scholar] [CrossRef]

- Yavuzcan Yildiz, H.; Robaina, L.; Pirhonen, J.; Mente, E.; Domínguez, D.; Parisi, G. Fish Welfare in Aquaponic Systems: Its Relation to Water Quality with an Emphasis on Feed and Faeces—A Review. Water 2017, 9, 13. [Google Scholar] [CrossRef]

- Velazquez-Gonzalez, R.S.; Garcia-Garcia, A.L.; Ventura-Zapata, E.; Barceinas-Sanchez, J.D.O.; Sosa-Savedra, J.C. A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations. Agriculture 2022, 12, 646. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Xu, X.; Syed, T.N.; Chandio, F.A.; Jing, Z.; Buttar, N.A. Effects of Various Aeroponic Atomizers (Droplet Sizes) on Growth, Polyphenol Content, and Antioxidant Activity of Leaf Lettuce (Lactuca sativa L.). Trans. ASABE 2019, 62, 1475–1487. [Google Scholar] [CrossRef]

- Tunio, M.H.; Gao, J.; Qureshi, W.A.; Sheikh, S.A.; Chen, J.; Chandio, F.A.; Lakhiar, I.A.; Ali Solangi, K. Effects of Droplet Size and Spray Interval on Root-To-Shoot Ratio, Photosynthesis Efficiency, and Nutritional Quality of Aeroponically Grown Butterhead Lettuce. Int. J. Agric. Biol. Eng. 2021, 14, 79–88. [Google Scholar]

- Broćić, Z.; Oljača, J.; Pantelić, D.; Rudić, J.; Momčilović, I. Potato Aeroponics: Effects of Cultivar and Plant Origin on Minituber Production. Horticulturae 2022, 8, 915. [Google Scholar] [CrossRef]

- Van Kooten, O.; Heuvelink, E.; Stanghellini, C. Nutrient supply in soilless culture: On-demand strategies. Acta Hortic. 2004, 659, 533–540. [Google Scholar] [CrossRef]

- Montesano, F.; Gattullo, C.; Parente, A.; Terzano, R.; Renna, M. Cultivation of potted sea fennel, an emerging mediterranean halophyte, using a renewable seaweed-based material as a peat substitute. Agriculture 2018, 8, 96. [Google Scholar] [CrossRef]

- Gruda, N.; Qaryouti, M.M.; Leonardi, C. Growing media. In Good Agricultural Practices for Greenhouse Vegetable Crops–Principles for Mediterranean Climate Areas; Plant Production and Protection Paper; FAO: Rome, Italy, 2013; pp. 271–302. [Google Scholar]

- Jones, J.B. Hydroponics: A Practical Guide for the Soilless Grower; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Barman, N.C.; Hasan, M.M.; Islam, M.R.; Banu, N.A. A Review on Present Status and Future Prospective of Hydroponics Technique. Plant Environ. Dev. 2016, 5, 1–7. [Google Scholar]

- Korsa, G.; Ayele, A.; Haile, S.; Alemu, D. Hydroponic Farming: Innovative Solutions for Sustainable and Modern Cultivation Technique. In Hydroponic Farming—A Modern Agriculture Technique; Intechopen: London, UK, 2025. [Google Scholar] [CrossRef]

- Majdi, Y.; Ahmandizadeh, M.; Ebrahimi, R. Effect of different substrates on growth indices and yield of green peppers at hydroponic cultivation. Curr. Res. J. Biol. Sci. 2012, 4, 496–499. [Google Scholar]

- Savvas, D.; Gruda, N. Application of soilless culture technologies in the modern greenhouse industry. Eur. J. Hortic. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Walters, K.J.; Currey, C.J. Hydroponic Greenhouse Basil Production: Comparing Systems and Cultivars. HortTechnology 2015, 25, 645–650. [Google Scholar] [CrossRef]

- Resh, H.M. Hydroponic Food Production: A Definitive Guidebook for the Advanced Home Gardener and the Commercial Hydroponic Grower; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Karagöz, F.P.; Dursun, A.; Karaşal, M. A review: Use of soilless culture techniques in ornamental plants. Ornamental Hortic. 2022, 28, 172–180. [Google Scholar] [CrossRef]

- Chandel, A.; Ujala; Thakur, D.; Sharma, D.; Partap, M.; Soni, V.; Bhargava, B. Recent Developments in Soilless Cultivation and Their Implications in Floriculture. In Ornamental Horticulture: Latest Cultivation Practices and Breeding Technologies; Springer Nature: Berlin, Germany, 2024; pp. 85–107. [Google Scholar]

- Olfati, J.-A. Design and Preparation of Nutrient Solution Used for Soilless Culture of Horticultural Crops; Intechopen: London, UK, 2015. [Google Scholar] [CrossRef]

- Steiner, A.A. Soilless culture. In Proceedings of the IPI 1968 6th Colloquium of the International Potash Institute, Florence, Italy, 1968; pp. 324–341. [Google Scholar]

- Cooper, A. The System. In The ABC of NFT; Grower Books: London, UK, 1988; pp. 3–123. ISBN 0901361224. [Google Scholar]

- Lee, G.J.; Kang, B.G.; Kim, T.I.; Kim, T.J.; Kim, J.H. Tomato hydroponics in Korea. Fruit Veg. Cereal Sci. Biotechnol. 2007, 1, 104–109. [Google Scholar]

- Rolot, J.L.; Seutin, H.; Michelante, D. Production de minitubercules de pomme de terre par hydroponie: Évaluation d’un système combinant les techniques “NFT” et “gravel culture” pour deux types de solutions nutritives. Biotec. Agr. Soc. Environ. 2002, 6, 155–161. [Google Scholar]

- Taiz, L.; Zeiger, E. Plant Physiology; Sinauer Associates, Inc. Publishers: Sunderland, MA, USA, 1998; ISBN 0878938311. [Google Scholar]

- Lakhiar, I.A.; Liu, X.; Wang, G.; Gao, J. Experimental study of ultrasonic atomizer effects on values of EC and pH of nutrient solution. Int. J. Agric. Biol. Eng. 2018, 11, 59–64. [Google Scholar] [CrossRef]

- Hewitt, E.J. Sand and Water Culture Methods Used in Study of Plant Nutrition, 2nd ed.; Commonwealth Agricultural Bureaux: Bucks, UK, 1966. [Google Scholar]

- Steiner, A.A. The Universal Nutrient Solution. In Proceedings of the IWOSC 1984 6th International Congress on Soilless Culture, Wageningen, The Netherlands, 29 April–5 May 1984; pp. 633–650, ISSN 9070976048. [Google Scholar]

- Hoagland, D.R.; Arnon, D.I. The Water-Culture Method for Growing Plants Without Soil. Univ. Calif. Agr. Exp. Sta. Circ. 1938, 347, 39. [Google Scholar]

- Al Meselmani, M.A. Nutrient solution for hydroponics. In Recent Research and Advances in Soilless Culture; IntechOpen: London, UK, 2022. [Google Scholar]

- Wada, T. Theory and Technology to Control the Nutrient Solution of Hydroponics. In Plant Factory Using Artificial Light; Elsevier: Amsterdam, The Netherlands, 2019; pp. 5–14. [Google Scholar]

- Sonneveld, C.; Voogt, W. Nutrient Solutions for Soilless Cultures. In Plant Nutrition of Greenhouse Crops; Springer: Berlin, Germany, 2009; pp. 257–275. [Google Scholar]

- Mir, Y.H.; Mir, S.; Ganie, M.A.; Shah, A.M.; Majeed, U.; Chesti, M.H.; Wani, F.J. Soilless farming: An innovative sustainable approach in agriculture. Pharma Innov. J. 2022, 11, 2663–2675. [Google Scholar]

- Kumar, T.V.; Verma, R. A Comprehensive Review on Soilless Cultivation for Sustainable Agriculture. J. Exp. Agric. Int. 2024, 46, 193–207. [Google Scholar] [CrossRef]

- Balliu, A.; Zheng, Y.; Sallaku, G.; Fernández, J.A.; Gruda, N.S.; Tuzel, Y. Environmental and cultivation factors affect the morphology, architecture and performance of root systems in soilless grown plants. Horticulturae 2021, 7, 243. [Google Scholar] [CrossRef]

- Thakulla, D.; Dunn, B.; Hu, B.; Goad, C.; Maness, N. Nutrient Solution Temperature Affects Growth and Brix Parameters of Seventeen Lettuce Cultivars Grown in an NFT Hydroponic System. Horticulturae 2021, 7, 321. [Google Scholar] [CrossRef]

- Beyhan, B.; Paksoy, H.; Daşgan, Y. Root zone temperature control with thermal energy storage in phase change materials for soilless greenhouse applications. Energy Convers. Manag. 2013, 74, 446–453. [Google Scholar] [CrossRef]

- Tang, L.; Syed, A.-U.; Otho, A.R.; Junejo, A.R.; Tunio, M.H.; Hao, L.; Ali, M.N.H.A.; Brohi, S.A.; Otho, S.A.; Channa, J.A. Intelligent Rapid Asexual Propagation Technology—A Novel Aeroponics Propagation Approach. Agronomy 2024, 14, 2289. [Google Scholar] [CrossRef]

- Sena, S.; Kumari, S.; Kumar, V.; Husen, A. Light Emitting Diode (LED) Lights for the Improvement of Plant Performance and Production: A Comprehensive Review. Curr. Res. Biotechnol. 2024, 7, 100184. [Google Scholar] [CrossRef]

- Urrestarazu, M.; Mazuela, P.C.; Boukhalfa, A.; Arán, A.; del Carmen Salas, M. Oxygen content and its diurnal variation in a new recirculating water soilless culture for horticultural crops. HortScience 2005, 40, 1729–1730. [Google Scholar] [CrossRef]

- Signore, A.; Serio, F.; Santamaria, P. A targeted management of the nutrient solution in a soilless tomato crop according to plant needs. Front. Plant Sci. 2016, 7, 391. [Google Scholar] [CrossRef]

- Mielcarek, A.; Kłobukowska, K.; Rodziewicz, J.; Janczukowicz, W.; Bryszewski, K.Ł. Water nutrient management in soilless plant cultivation versus sustainability. Sustainability 2024, 16, 152. [Google Scholar] [CrossRef]

- Nirmal, S.; Ahmad, S. Innovative approaches to sustainable water and nutrient management in soilless crop cultivation. Int. J. Res. Adv. Agri. Sci. 2024, 3, 13–22. [Google Scholar]

- El-Kazzaz, K.A.; El-Kazzaz, A.A. Soilless agriculture: A new and advanced method for agricultural development: An introduction. Agric. Res. Technol. Open Access J. 2017, 3, 63–72. [Google Scholar]

- Shareef, U.; Rehman, A.U.; Ahmad, R. A Systematic Literature Review on Parameters Optimization for Smart Hydroponic Systems. AI 2024, 5, 1517–1533. [Google Scholar] [CrossRef]

- Sulaiman, H.; Yusof, A.A.; Mohamed, N.M.K. Automated Hydroponic Nutrient Dosing System: A Scoping Review of pH and Electrical Conductivity Dosing Frameworks. AgriEngineering 2025, 7, 43. [Google Scholar] [CrossRef]

- Teoh, S.H.; Wong, G.R.; Mazumdar, P. A Review on Urban Farming: Potential, Challenges and Opportunities. Innov. Agric. 2024, 7, 1–11. [Google Scholar] [CrossRef]

- Gumisiriza, M.S.; Ndakidemi, P.; Nalunga, A.; Mbega, E.R. Building Sustainable Societies through Vertical Soilless Farming: A Cost-Effectiveness Analysis on a Small-Scale Non-Greenhouse Hydroponic System. Sustain. Cities Soc. 2022, 83, 103923. [Google Scholar] [CrossRef]

- Blok, C.; De Kreij, C.; Baas, R.O.B.; Wever, G. Analytical methods used in soilless cultivation. In Soilless Culture, Theory and Practice; Elsevier: Amsterdam, The Netherlands, 2008; pp. 245–290. [Google Scholar]

- Bernstein, S. Aquaponic Gardening: A Step-by-Step Guide to Raising Vegetables and Fish Together; New Society Publishers: Gabriola Island, BC, Canada, 2011. [Google Scholar]

- Nambuthiri, S.; Fulcher, A.; Koeser, A.K.; Geneve, R.; Niu, G. Moving toward sustainability with alternative containers for greenhouse and nursery crop production: A review and research update. HortTechnology 2015, 25, 8–16. [Google Scholar] [CrossRef]

- Van Os, E.A.; Gieling, T.H.; Lieth, J.H. Technical equipment in soilless production systems. In Soilless Culture; Elsevier: Amsterdam, The Netherlands, 2019; pp. 587–635. [Google Scholar]

- Tyson, R.V.; Simonne, E.H. A Practical Guide for Aquaponics as an Alternative Enterprise; UF/IFAS Extension Document HS1252; University of Florida Horticultural Science Department: Gainesville, FL, USA, 2014. [Google Scholar]

- Poorter, H.; Fiorani, F.; Stitt, M.; Schurr, U.; Finck, A.; Gibon, Y.; Pons, T.L. The art of growing plants for experimental purposes: A practical guide for the plant biologist. Funct. Plant Biol. 2012, 39, 821–838. [Google Scholar] [CrossRef]

- Mohammed, S. Tomorrow’s Agriculture: "NFT Hydroponics"-Grow Within Your Budget; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; p. 50. [Google Scholar]

- Zheng, Y.; Fields, J.S.; Bragg, N.; Caron, J.; Michel, J.C.; Zaccheo, P.; Kromwijk, A. Advances in Horticultural Soilless Culture; Burleigh Dodds Science Publishing: Cambridge, UK, 2021; Volume 94. [Google Scholar]

- Pramono, S.; Nuruddin, A.; Ibrahim, M.H. Design of a hydroponic monitoring system with deep flow technique (DFT). In AIP Conf. Proc. 2020, 2217, 1–7. [Google Scholar]

- Makhadmeh, I.M.; Al-Tawaha, A.; Edaroyati, P.; Al-Karaki, G.; Tawaha, A.R.A.; Hassan, S.A. Effects of different growth media and planting densities on growth of lettuce grown in a closed soilless system. Res. Crops 2017, 18, 294–298. [Google Scholar] [CrossRef]

- Obaid, A.A.; Khalil, N.H.; Al-Alawy, H.H.; Fahmi, A.H. Effect of planting density, foliar spraying, and overlapping system on the growth and productivity using soilless culture system. J. Saudi Soc. Agric. Sci. 2022, 21, 506–510. [Google Scholar] [CrossRef]

- Baras, T. DIY Hydroponic Gardens: How to Design and Build an Inexpensive System for Growing Plants in Water; Cool Springs Press: Franklin, TN, USA, 2018. [Google Scholar]

- Xydis, G.A.; Liaros, S.; Botsis, K. Energy demand analysis via small scale hydroponic systems in suburban areas—An integrated energy-food nexus solution. Sci. Total Environ. 2017, 593, 610–617. [Google Scholar] [CrossRef][Green Version]

- Grafiadellis, I.; Mattas, K.; Maloupa, E.; Tzouramani, I.; Galanopoulos, K. An economic analysis of soilless culture in gerbera production. HortScience 2000, 35, 300–303. [Google Scholar] [CrossRef]

- Shaheen, W.A.; Saleem, T.; Shafi, N.; Ullah, U. Systematic Literature Review on Capital Budgeting Techniques. UCP J. Bus. Perspect. 2024, 2, 17–29. [Google Scholar] [CrossRef]

- Kalantari, F.; Tahir, O.M.; Joni, R.A.; Fatemi, E. Opportunities and challenges in sustainability of vertical farming: A review. J. Landsc. Ecol. 2018, 11, 35–60. [Google Scholar] [CrossRef]

- Eigenbrod, C.; Gruda, N. Urban vegetable for food security in cities: A review. Agron. Sustain. Dev. 2015, 35, 483–498. [Google Scholar] [CrossRef]

- Mihrete, T.B. Crop Substrates for Sustainable Hydroponic Farming; Intechopen: London, UK, 2025. [Google Scholar]

- Sathyanarayana, S.R.; Gangadhar, W.V.; Badrinath, M.G.; Ravindra, R.M.; Shriramrao, A.U. Hydroponics: An intensified agriculture practice to improve food production. Rev. Agric. Sci. 2022, 10, 101–114. [Google Scholar] [CrossRef]

- Trejo-Téllez, L.I.; Gómez-Merino, F.C. Nutrient solutions for hydroponic systems. In Hydroponics—A Standard Methodology for Plant Biological Researches; InTech: Rijeka, Croatia, 2012; Volume 21, pp. 1–22. [Google Scholar]

- Vafaeian, A.; Fathi, S.; Jaberian, H.; Nazarideljou, M.J. Comparing the Characteristics of Lemongrass Plant in Different Harvesting Time under Soil and Soilless Cultivation Systems. J. Med. Plants By-Prod. 2025, 14, 20–29. [Google Scholar]

- Roosta, H.R.; Azad, H.S.; Mirdehghan, S.H. Comparison of the Growth, Fruit Quality and Physiological Characteristics of Cucumber Fertigated by Three Different Nutrient Solutions in Soil Culture and Soilless Culture Systems. Sci. Rep. 2025, 15, 203. [Google Scholar] [CrossRef] [PubMed]

- Abu-Zahra, T.R.; Alghragher, I.M.; Bani-Issa, R.M.; Bani-Fauaz, M.S.; Alnsour, Z.I.; Abufanar, S.M.; Sawalmeh, M.N. Optimizing Lettuce Yield and Quality: A Comparative Analysis of Hydroponic Cultivation with Different Soilless Amendments. Int. J. Agric. Res. 2025, 20, 1–8. [Google Scholar] [CrossRef]

- Alizaeh, P.; Sodaeizade, H.; Arani, A.M.; Hakimzadeh, M.A. Comparing Yield, Nutrient Uptake, and Water Use Efficiency of Nasturtium officinale Cultivated in Aquaponic, Hydroponic, and Soil Systems. Heliyon 2025, 11, e42339. [Google Scholar] [CrossRef] [PubMed]

- Chamoli, N.; Kumar, M.; Das, S.; Prabha, D.; Chauhan, J.S. Comparative Analysis of Hydroponically and Soil-Grown Lettuce. J. Mt. Res. 2024, 19, 583–591. [Google Scholar] [CrossRef]

- Erdal, İ.; Aktaş, H. Comparison of the Perlite, Leonardite, Vermicompost, and Peat Moss and Their Combinations with Cocopeat as Tomato Growing Media. J. Soil Sci. Plant Nutr. 2025, 1–16. [Google Scholar] [CrossRef]

- Hazrati, S.; Pignata, G.; Casale, M.; Hosseini, S.J.; Nicola, S. Influence of Nutrient Solutions in an NGS® Soilless System on the Yield, Quality, and Shelf Life of Fresh-Cut Commercial Mint at Different Harvest Times. Agronomy 2024, 14, 610. [Google Scholar] [CrossRef]

- Sadek, N.; Shehata, D. Internet of Things-Based Smart Automated Indoor Hydroponics and Aeroponics Greenhouse in Egypt. Ain Shams Eng. J. 2024, 15, 102341. [Google Scholar] [CrossRef]

- Broćić, Z.; Milinković, M.; Momčilović, I.; Oljača, J.; Veljković, B.; Milošević, D.; Poštić, D. Comparison of Aeroponics and Conventional Production System of Virus-Free Potato Mini Tubers in Serbia. Agro-Knowl. J. 2019, 20, 95–105. [Google Scholar] [CrossRef]

- Tican, A.; Chelmea, C.; Cioloca, M.; Popa, M.; Ștefan, M. Preliminary Study about Comparison of Potato Minitubers Production in Conventional Culture and Modern Culture–Aeroponic. J. Agric. Rural Dev. Stud. 2024, 2, 48–54. [Google Scholar] [CrossRef]

- Weingarten, M.; Mattson, N.; Grab, H. Evaluating Propagation Techniques for Cannabis sativa L. Cultivation: A Comparative Analysis of Soilless Methods and Aeroponic Parameters. Plants 2024, 13, 1256. [Google Scholar] [CrossRef]

- El-Helaly, M.A.; Darwish, O.S. Effect of Culture System; Aeroponic, Hydroponic, and Sandy Substrate on Growth, Yield, and Chemical Compositions of Lettuce. Plant Arch. 2019, 19, 2543–2550. [Google Scholar]

- Carroll, P.A.; Griffith, M.A.C.; Buss, G.P.; Yang, X.; Griffis, J.L.; Papkov, G.; Singh, A.K. The Comparative Performance of Soil-Based Systems with Hydroponics. In Proceedings of the 2023 ASABE Annual International Meeting, Wageningen, The Netherlands, 9–12 July 2023; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2023; p. 1. [Google Scholar]

- Wimmerova, L.; Keken, Z.; Solcova, O.; Bartos, L.; Spacilova, M. A Comparative LCA of Aeroponic, Hydroponic, and Soil Cultivations of Bioactive Substance Producing Plants. Sustainability 2022, 14, 2421. [Google Scholar] [CrossRef]

- Bafort, F.; Libault, A.; Maron, E.; Kohnen, S.; Ancion, N.; Jijakli, M.H. Operational Costs and Analysis of Agronomic Characteristics on Cannabidiol and Cannabigerol Hemp (Cannabis sativa L.) in Hydroponic Soilless Greenhouse and Field Cultivation. Horticulturae 2024, 10, 1271. [Google Scholar] [CrossRef]

- Pasch, J.; Appelbaum, S.; Palm, H.W.; Knaus, U. Growth of Basil (Ocimum basilicum) in Aeroponics, DRF, and Raft Systems with Effluents of African Catfish (Clarias gariepinus) in Decoupled Aquaponics (s.s.). AgriEngineering 2021, 3, 559–574. [Google Scholar] [CrossRef]

- Smit, J.; Ratta, A.; Nasr, J. Urban Agriculture: Food, Jobs and Sustainable Cities; The Urban Agriculture Network: New York, NY, USA, 1996; Available online: http://urban.agroeco.org/wp-content/uploads/2015/12/UNDP-Urban-Agriculture-Part-one-1.pdf (accessed on 1 April 2025).

- Mares, T.M.; Peña, D.G. Urban agriculture in the making of insurgent spaces in Los Angeles and Seattle. In Insurgent Public Space: Guerrilla Urbanism and the Remaking of Contemporary Cities; Hou, J., Ed.; Routledge: Abingdon, UK, 2010; pp. 241–254. [Google Scholar]

- Yokohari, M.; Amati, M.; Bolthouse, J.; Kurita, H. Restoring Urban Fringe Landscapes through Urban Agriculture: The Japanese Experience. Disp-Plan. Rev. 2010, 46, 51–59. [Google Scholar] [CrossRef]

- Nicholls, E.; Ely, A.; Birkin, L.; Basu, P.; Goulson, D. The Contribution of Small-Scale Food Production in Urban Areas to the Sustainable Development Goals: A Review and Case Study. Sustain. Sci. 2020, 15, 1585–1599. [Google Scholar] [CrossRef]

- Hernandez, M.; Manu, R. Growing Greener Cities: Urban Agriculture and the Impact on SDG 11; International Institute for Sustainable Development: Winnipeg, MB, Canada, 2018; Available online: https://sdg.iisd.org/commentary/generation-2030/growing-greener-cities-urban-agriculture-and-the-impact-on-sdg-11/ (accessed on 1 April 2025).

- Yuan, G.N.; Marquez, G.P.B.; Deng, H.; Iu, A.; Fabella, M.; Salonga, R.B.; Ashardiono, F.; Cartagena, J.A. A Review on Urban Agriculture: Technology, Socio-Economy, and Policy. Heliyon 2022, 8, e11583. [Google Scholar] [CrossRef]

- Kalantari, F.; Tahir, O.M.; Mahmoudi Lahijani, A.; Kalantari, S. A review of vertical farming technology: A guide for implementation of building integrated agriculture in cities. Adv. Eng. Forum 2017, 24, 76–91. [Google Scholar]

- Yoshida, S.; Yagi, H.; Kiminami, A.; Garrod, G. Farm diversification and sustainability of multifunctional peri-urban agriculture: Entrepreneurial attributes of advanced diversification in Japan. Sustainability 2019, 11, 2887. [Google Scholar] [CrossRef]

- Food and Agriculture Organization (FAO). COVID-19 and Smallholder Producers’Access to Markets; Food and Agriculture Organization: Rome, Italy, 2020. [Google Scholar]

- World Bank. Food Security and COVID-19. 2021. Available online: https://reliefweb.int/report/world/brief-food-security-and-covid-19 (accessed on 1 April 2025).

- Cohen, N.; Reynolds, K. Urban agriculture policy making in New York’s “new political spaces”: Strategizing for a participatory and representative system. J. Plann. Educ. Res. 2014, 34, 221–234. [Google Scholar] [CrossRef]

- Orsini, F.; Pennisi, G.; Michelon, N.; Minelli, A.; Bazzocchi, G.; Sanyé-Mengual, E.; Gianquinto, G. Features and Functions of Multifunctional Urban Agriculture in the Global North: A Review. Front. Sustain. Food Syst. 2020, 4, 562513. [Google Scholar] [CrossRef]

- Marche, G. What Can Urban Gardening Really Do about Gentrification? A Case-Study of Three San Francisco Community Gardens. Eur. J. Am. Stud. 2015, 10. [Google Scholar] [CrossRef]

- McDougall, R.; Kristiansen, P.; Rader, R. Small-Scale Urban Agriculture Results in High Yields but Requires Judicious Management of Inputs to Achieve Sustainability. Proc. Natl. Acad. Sci. USA 2019, 116, 129–134. [Google Scholar] [CrossRef]

- Carolan, M. Urban farming is going high tech: Digital urban agriculture’s links to gentrification and land use. Am. Plan. Assoc. 2020, 86, 47–59. [Google Scholar] [CrossRef]

- Hati, A.J.; Singh, R.R. Smart Indoor Farms: Leveraging Technological Advancements to Power a Sustainable Agricultural Revolution. AgriEngineering 2021, 3, 728–767. [Google Scholar] [CrossRef]

- van Veenhuizen, R.; Danso, G. Profitability and Sustainability of Urban and Peri Urban Agriculture. In Agricultural Management, Marketing and Finance Occasional Paper; Food and Agricultural Organization: Quebec City, QC, Canada, 2007. [Google Scholar]

- Nugent, R. Measuring the sustainability of urban agriculture. In For Hunger-Proof Cities: Sustainable Urban Food Systems; Koc, M., MacRae, R., Mougeot, L.J.A., Welsh, J., Eds.; International Development Research Centre: Ottawa, ON, Canada, 1999; pp. 95–99. [Google Scholar]

- Sridhar, A.; Balakrishnan, A.; Jacob, M.M.; Sillanpää, M.; Dayanandan, N. Global impact of COVID-19 on agriculture: Role of sustainable agriculture and digital farming. Environ. Sci. Pollut. Res. 2023, 30, 42509–42525. [Google Scholar] [CrossRef]

- OECD. Food Supply Chains and COVID-19: Impacts and Policy Lessons. In OECD Policy Responses to Coronavirus (COVID-19); OECD Publishing: Paris, France, 2020. [Google Scholar] [CrossRef]

- Salisu, M.A.; Oyebamiji, Y.O.; Ahmed, O.K.; Shamsudin, N.A.; Fairuz, Y.S.; Yusuff, O.; Arolu, F. A systematic review of emerging trends in crop cultivation using soilless techniques for sustainable agriculture and food security in post-pandemic. AIMS Agric. Food 2024, 9, 666–692. [Google Scholar] [CrossRef]

- Vittuari, M.; Bazzocchi, G.; Blasioli, S.; Cirone, F.; Maggio, A.; Orsini, F.; Penca, J.; Petruzzelli, M.; Specht, K.; Amghar, S.; et al. Envisioning the future of European food systems: Approaches and research priorities after COVID-19. Front. Sustain. Food Syst. 2021, 5, 642787. [Google Scholar] [CrossRef]

- Evans, D.; Davies, J. 4 Reasons Why the World Needs More Urban Farming Post-Pandemic. World Economic Forum Global Agenda. Available online: https://www.weforum.org/stories/2020/09/urban-farming-flourish-post-pandemic/ (accessed on 1 April 2025).

- Molteno, S. How Does Your City Grow? Lockdown Illuminates Urban Farming and Gardening’s Potential. Rapid Transition Alliance Story. Available online: https://rapidtransition.org/stories/how-does-your-city-grow-lockdown-illuminates-urban-farming-and-gardenings-potential/ (accessed on 2 March 2025).

- Gumisiriza, M.S.; Ndakidemi, P.A.; Nampijja, Z.; Mbega, E.R. Soilless urban gardening as a post covid-19 food security salvage technology: A study on the physiognomic response of lettuce to hydroponics in Uganda. Sci. Afr. 2023, 20, e01643. [Google Scholar] [CrossRef]

- Khan, M.M.; Akram, M.T.; Janke, R.; Qadri, R.W.K.; Al-Sadi, A.M.; Farooque, A.A. Urban horticulture for food secure cities through and beyond COVID-19. Sustainability 2020, 12, 9592. [Google Scholar] [CrossRef]

- Pulighe, G.; Lupia, F. Food first: COVID-19 outbreak and cities lockdown a booster for a wider vision on urban agriculture. Sustainability 2020, 12, 5012. [Google Scholar] [CrossRef]

- Cuello, J. Our Fresh-Produce Supply Chain after COVID-19: How vertical farming can play a key role. Resour. Mag. 2020, 27, 10–12. [Google Scholar]

- Sun, J.; Li, Q.-S.; Yue, D.; Gao, H.-B.; Kang, Y.-Y.; Tian, J.; Li, J.; Guo, S. Research status and application prospects of soilless culture technology in the world. J. Nanjing Agric. Univ. 2022, 45, 898–915. [Google Scholar]

- Jia, X.; Ma, P.; Wei, C.I.; Wang, Q. Chitin and chitosan: Pioneering sustainable substrates for next-generation soilless vertical farming. Trends Food Sci. Technol. 2024, 150, 104599. [Google Scholar] [CrossRef]

- Li, Q.; Yu, Z.; Li, M.; Zhang, G.; Lu, T.; Li, Y.; Jiang, W. Urban vegetable production in Beijing, China: Current progress, sustainability, and challenges. Front. Sustain. Food Syst. 2023, 7, 1191561. [Google Scholar] [CrossRef]

- Research and Markets. China Indoor Farming Market Analysis Indicates Surge to $7.5 Billion by 2028: Trends & Shares for Hydroponics, Aeroponics, Aquaponics, Soil-based, and Hybrid Growing Systems Unveiled. Available online: https://www.globenewswire.com/news-release/2024/01/31/2820792/0/en/China-Indoor-Farming-Market-Analysis-Indicates-Surge-to-7-5-Billion-by-2028-Trends-Shares-for-Hydroponics-Aeroponics-Aquaponics-Soil-based-and-Hybrid-Growing-Systems-Unveiled.html (accessed on 31 January 2024).

- Wang, T.; Wu, G.; Chen, J.; Cui, P.; Chen, Z.; Yan, Y.; Chen, H. Integration of solar technology to modern greenhouse in China: Current status, challenges and prospect. Renew. Sustain. Energy Rev. 2017, 70, 1178–1188. [Google Scholar] [CrossRef]

- Wang, J.; Li, W.; Haq, S.U.; Shahbaz, P. Adoption of Renewable Energy Technology on Farms for Sustainable and Efficient Production: Exploring the Role of Entrepreneurial Orientation, Farmer Perception and Government Policies. Sustainability 2023, 15, 5611. [Google Scholar] [CrossRef]

- Guo, B.; Zhou, B.; Zhang, Z.; Li, K.; Wang, J.; Chen, J.; Papadakis, G. A critical review of the status of current greenhouse technology in China and development prospects. Appl. Sci. 2024, 14, 5952. [Google Scholar] [CrossRef]

- Sun, J.; Gao, H.B.; Tian, J.; Wang, J.W.; Du, C.X.; Guo, S.R. Development status and trends in protected horticulture in China. J. Nanjing Agric. Univ. 2019, 42, 594–604. [Google Scholar]

- Qi, F.; Wei, X.; Zhang, Y. Development status and future research emphases on greenhouse horticultural equipment and its relative technology in China. Trans. Chin. Soc. Agric. Eng. 2017, 33, 1–9. [Google Scholar]

- Zhou, X.; Asioli, D.; Jürkenbeck, K. Investigating consumers’ views on foods from soilless farming systems: A review of the literature and discussion of implications and recommendations. Food Qual. Prefer. 2024, 126, 105413. [Google Scholar] [CrossRef]

- Tajudeen, A.L.; Taiwo, O.S. Soilless farming—A key player in the realisation of “zero hunger” of the sustainable development goals in Nigeria. Int. J. Ecol. Sci. Environ. Eng. 2018, 5, 1–7. [Google Scholar]

- Urrestarazu, M. State of the Art and New Trends of Soilless Culture in Spain and in Emerging Countries. In Proceedings of the International Symposium on Growing Media, Composting and Substrate Analysis, Barcelona, Spain, 17 October 2011; Volume 1013, pp. 305–312. [Google Scholar]

- Gonnella, M.; Renna, M. The Evolution of soilless systems towards ecological sustainability in the perspective of a circular economy. Is it really the opposite of organic agriculture? Agronomy 2021, 11, 950. [Google Scholar] [CrossRef]

- Tan, D.M.Y.; Ng, W.J.; Chua, H.S.; Thing, G.; Law, F.L. Exploring the Global Hydroponic Cultivation System: Current and Future Perspectives. In Advances in Material Science and Engineering; Emamian, S.S., Awang, M., Al-Kayiem, H.H., Eds.; Springer: Singapore, 2024; pp. 4–12. [Google Scholar] [CrossRef]

- FAO. The Future of Food and Agriculture—Alternative Pathways to 2050; FAO: Rome, Italy, 2018; p. 224. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/e51e0cf0-4ece-428c-8227-ff6c51b06b16/content (accessed on 1 April 2025).

- Wise Guy Reports. Soilless Culture Market Analysis & Forecast 2032. 2023. Available online: https://www.wiseguyreports.com/reports/soilless-culture-market (accessed on 1 April 2025).

- Research and Markets. Soilless Growing Mediums Market by Product, Farming Type, Distribution Channel, Application-Global Forecast 2025–2030. 2024. Available online: https://www.researchandmarkets.com/reports/6011962/soilless-growing-mediums-market-product-farming (accessed on 5 April 2025).

- PW Consulting. Worldwide Soilless Hydroponic Vegetables Market Research Report 2025, Forecast to 2031. 2024. Available online: https://pmarketresearch.com/product/worldwide-soilless-hydroponic-vegetables-market-research-2024-by-type-application-participants-and-countries-forecast-to-2030 (accessed on 5 April 2025).

- Tatum, M. Inside Singapore’s Huge Bet on Vertical Farming. MIT Technology Review. 2020. Available online: https://www.technologyreview.com/2020/10/13/1009497/singapore-vertical-farming-food-security (accessed on 5 April 2025).

- Incrocci, L.; Thompson, R.B.; Fernandez-Fernandez, M.D.; De Pascale, S.; Pardossi, A.; Stanghellini, C.; Rouphael, Y.; Gallardo, M. Irrigation Management of European Greenhouse Vegetable Crops. Agric. Water Manag. 2020, 242, 106393. [Google Scholar] [CrossRef]

- Satpute, A.N.; Gavhane, K.P.; Kaur, S.; Jha, A.; Pradhan, N.C.; Chowdhury, M. Integration of AI and IoT in Soilless Cultivation to Power Sustainable Agricultural Revolution. In Artificial Intelligence and Smart Agriculture; Pandey, K., Kushwaha, N.L., Pande, C.B., Singh, K.G., Eds.; Springer: Singapore, 2024; pp. 261–280. [Google Scholar] [CrossRef]

- Gao, J.; Al Mamun, A.; Yang, Q.; Rahman, M.K.; Masud, M.M. Environmental and health values, beliefs, norms, and compatibility on intention to adopt hydroponic farming among unemployed youth. Sci. Rep. 2024, 14, 1592. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, A.; Anand, S. Soilless cultivation: A distinct vision for sustainable agriculture. In Artificial Intelligence and Smart Agriculture: Technology and Applications; Springer: Singapore, 2024; pp. 337–368. [Google Scholar]

- Kumar, A.; Mukherjee, G.; Gupta, S. Soilless Cultivation of Plants for Phytoremediation. In Hydroponics and Environmental Bioremediation: Wastewater Treatment; Springer: Cham, Switzerland, 2024; pp. 297–323. [Google Scholar]

- Fathidarehnijeh, E.; Nadeem, M.; Cheema, M.; Thomas, R.; Krishnapillai, M.; Galagedara, L. Current perspective on nutrient solution management strategies to improve the nutrient and water use efficiency in hydroponic systems. Can. J. Plant Sci. 2023, 104, 88–102. [Google Scholar] [CrossRef]

- Elsherbiny, O.; Gao, J.; Ma, M.; Qureshi, W.A.; Mosha, A.H. Developing an IoT-driven delta robot to stimulate the growth of mulberry branch cuttings cultivated aeroponically using machine vision technology. Comput. Electron. Agric. 2025, 232, 110111. [Google Scholar] [CrossRef]

- Qureshi, W.A.; Gao, J.; Elsherbiny, O.; Mosha, A.H.; Tunio, M.H.; Qureshi, J.A. Boosting Aeroponic System Development with Plasma and High-Efficiency Tools: AI and IoT—A Review. Agronomy 2025, 15, 546. [Google Scholar] [CrossRef]

- Sharma, A.; Pandey, H.; Nampoothiri, V.A.S.; Kartha, B.D.; Jha, R. Production of, factors affecting, gene regulations, and challenges in tissue cultured plant through soilless culture. J. Agric. Food Chem. 2023, 71, 5804–5811. [Google Scholar] [CrossRef]

- James, T.P.G.; Bala, K. Utilizing Genomic Prediction Algorithms for Enhancing Resistance to Fungal Root Rot in Vertical Soilless Farming. In Proceedings of the 2024 International Conference on Power, Energy, Control and Transmission Systems (ICPECTS), Chennai, India, 8–9 October 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Sela Saldinger, S.; Rodov, V.; Kenigsbuch, D.; Bar-Tal, A. Hydroponic Agriculture and Microbial Safety of Vegetables: Promises, Challenges, and Solutions. Horticulturae 2023, 9, 51. [Google Scholar] [CrossRef]

- Licastro, A.; Salomone, R.; Mondello, G.; Calabrò, G. Assessing the environmental impacts of soilless systems: A comprehensive literature review of Life Cycle Assessment studies. Int. J. Life Cycle Assess. 2024, 29, 1053–1074. [Google Scholar] [CrossRef]

- Orsini, F.; Pennisi, G.; Zulfiqar, F.; Gianquinto, G. Sustainable use of resources in plant factories with artificial lighting (PFALs). Eur. J. Hortic. Sci. 2020, 85, 297–309. [Google Scholar] [CrossRef]

- Lozano-Castellanos, L.F.; Sánchez-Hernández, E.; Navas-Gracia, L.M.; Martín-Ramos, P.; Correa-Guimaraes, A. Effects of Different Types of Artificial Light on the Phytochemicals of Lactuca sativa L. Variety Great Lakes 118 Cultivated under Aeroponic System. Food Biosci. 2025, 64, 105950. [Google Scholar] [CrossRef]

- Goddek, S.; Delaide, B.; Mankasingh, U.; Ragnarsdottir, K.V.; Jijakli, H.; Thorarinsdottir, R. Challenges of sustainable and commercial aquaponics. Sustainability 2015, 7, 4199–4224. [Google Scholar] [CrossRef]

- Yep, B.; Zheng, Y. Aquaponic trends and challenges–A review. J. Clean. Prod. 2019, 228, 1586–1599. [Google Scholar] [CrossRef]

- Janczukowicz, W.; Rodziewicz, J. Water and wastewater management in agriculture. Appl. Sci. 2024, 14, 2488. [Google Scholar] [CrossRef]

- Fields, J.S.; Owen, J.S., Jr.; Lamm, A.; Altland, J.; Jackson, B.; Oki, L.; Samtani, J.B.; Zheng, Y.; Criscione, K.S. Surveying North American Specialty Crop Growers’ Current Use of Soilless Substrates and Future Research and Education Needs. Agriculture 2023, 13, 1727. [Google Scholar] [CrossRef]

- Rachma, D.F.; Maeda, K.; Yamanouchi, Y.; Ueda, H.; Shinohara, M.; Ahn, D.-H. Tomato Production with Organic Fertilizer from Soluble Bonito Fish Waste in Hydroponic Cultivation Systems. Horticulturae 2025, 11, 381. [Google Scholar] [CrossRef]

- Kaushal, A.; Yadav, R.K.; Singh, N. Biochar application in sustainable production of horticultural crops in the new era of soilless cultivation. In Biochar Production for Green Economy; Academic Press: Cambridge, MA, USA, 2024; pp. 249–267. [Google Scholar]

- Kunnen, K.; Ali, M.M.; Lataf, A.; Van Hees, M.; Nauts, R.; Horemans, N.; Cuypers, A. From crop leftovers to nutrient resource: Growth-stimulating potential of biochar in nutrient solutions for wheat soilless cultivation systems. Front. Plant Sci. 2024, 15, 1414212. [Google Scholar] [CrossRef]

- Qin, C.; Kong, L.; Xu, D.; Qi, Y.; Wu, N.; Xu, W. Application and Development of Hydrogel in Soilless Culture. ChemistrySelect 2024, 9, e202304321. [Google Scholar] [CrossRef]

- Casey, L.; Freeman, B.; Francis, K.; Brychkova, G.; McKeown, P.; Spillane, C.; Styles, D. Comparative environmental footprints of lettuce supplied by hydroponic controlled-environment agriculture and field-based supply chains. J. Clean. Prod. 2022, 369, 133214. [Google Scholar] [CrossRef]

- Casamayor, J.L.; Muñoz, E.; Franchino, M.; Gallego-Schmid, A.; Shin, H.D. Human-powered hydroponic systems: An environmental and economic assessment. Sustain. Prod. Consum. 2024, 46, 268–281. [Google Scholar] [CrossRef]

- Singh, P.; Upadhyay, P.; Singh, S.K. Unlocking the Economic Potential of Potato Cultivars for Mini-tuber Production Under Aeroponic Culture. Potato Res. 2025, 1–24. [Google Scholar] [CrossRef]

- Thomas, B.O.; Lechner, S.L.; Ross, H.C.; Joris, B.R.; Glick, B.R.; Stegelmeier, A.A. Friends and Foes: Bacteria of the Hydroponic Plant Microbiome. Plants 2024, 13, 3069. [Google Scholar] [CrossRef]

- Renganathan, P.; Puente, E.O.R.; Sukhanova, N.V.; Gaysina, L.A. Hydroponics with Microalgae and Cyanobacteria: Emerging Trends and Opportunities in Modern Agriculture. BioTech 2024, 13, 27. [Google Scholar] [CrossRef]

- Hardman, M.; Clark, A.; Sherriff, G. Mainstreaming urban agriculture: Opportunities and barriers to upscaling city farming. Agronomy 2022, 12, 601. [Google Scholar] [CrossRef]

- Mishra, S.J.; Rout, D.; Sahoo, D. Analysing the economic viability of hydroponic farming: A comparative cost-benefit analysis. Int. J. Progress. Res. Eng. Manag. Sci. 2024, 4, 1806–1811. [Google Scholar]

- Zhu, Z.; Chan, F.K.S.; Li, G.; Xu, M.; Feng, M.; Zhu, Y.G. Implementing urban agriculture as nature-based solutions in China: Challenges and global lessons. Soil Environ. Health 2024, 2, 100063. [Google Scholar] [CrossRef]

- Bahri, A.; Ashar, J.R.; Ramly, Z.A.; Al-Ghifari, A.W.F.; Ainun, N.A.; Arisandi, Y.; Hidayat, W. Increasing community food security through aquaponic and aeroponic cultivation. J. Community Serv. Empower. 2022, 3, 122–131. [Google Scholar] [CrossRef]

- Min, A.; Nguyen, N.; Howatt, L.; Tavares, M.; Seo, J. Aeroponic systems design: Considerations and challenges. J. Agric. Eng. 2022, 54, 1–19. [Google Scholar] [CrossRef]

- Miller, J.; Boumtje, P.; Johnson, R. Investment analysis for commercial greenhouse hydroponically produced lettuce and tomato. J. ASFMRA 2017, 1–10. [Google Scholar]

- Sace, C.F.; Natividad, E.P., Jr. Economic analysis of an urban vertical garden for hydroponic production of lettuce (Lactuca sativa). Int. J. Contemp. Appl. Sci. 2015, 2, 42–56. [Google Scholar]

- Zhou, H.; Specht, K.; Kirby, C.K. Consumers’ and Stakeholders’ Acceptance of Indoor Agritecture in Shanghai (China). Sustainability 2022, 14, 2771. [Google Scholar] [CrossRef]

- Fei, S.; Wu, R.; Liu, H.; Yang, F.; Wang, N. Technological innovations in urban and peri-urban agriculture: Pathways to sustainable food systems in metropolises. Horticulturae 2025, 11, 212. [Google Scholar] [CrossRef]

- Nath, S. A vision of precision agriculture: Balance between agricultural sustainability and environmental stewardship. Agron. J. 2024, 116, 1126–1143. [Google Scholar] [CrossRef]

- Amiri, Z.; Heidari, A.; Navimipour, N.J. Comprehensive survey of artificial intelligence techniques and strategies for climate change mitigation. Energy 2024, 308, 132827. [Google Scholar] [CrossRef]

- Syed, T.N.; Zhou, J.; Marinello, F.; Lakhiar, I.A.; Chandio, F.A.; Rottok, L.T.; Gamechu, T.T. Definition of a reference standard for performance evaluation of autonomous vehicles real-time obstacle detection and distance estimation in complex environments. Comput. Electron. Agric. 2025, 232, 110143. [Google Scholar] [CrossRef]

- Syed, T.N.; Jizhan, L.; Xin, Z.; Shengyi, Z.; Yan, Y.; Mohamed, S.H.A.; Lakhiar, I.A. Seedling-lump integrated non-destructive monitoring for automatic transplanting with Intel RealSense depth camera. Artif. Intell. Agric. 2019, 3, 18–32. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Jia, W.; Ou, M.; Dong, X.; Dai, S. A Review of Environmental Sensing Technologies for Targeted Spraying in Orchards. Horticulturae 2025, 11, 551. [Google Scholar] [CrossRef]

- Gómez-Chabla, R.; Real-Avilés, K.; Morán, C.; Grijalva, P.; Recalde, T. IoT applications in agriculture: A systematic literature review. In Proceedings of the 2nd International Conference on ICTs in Agronomy and Environment, Guayaquil, Ecuador, 22–25 January 2019; Springer International Publishing: Cham, Switzerland, 2019; pp. 68–76. [Google Scholar]

- Taha, M.F.; Mao, H.; Wang, Y.; ElManawy, A.I.; Elmasry, G.; Wu, L.; Memon, M.S.; Niu, Z.; Huang, T.; Qiu, Z. High-Throughput Analysis of Leaf Chlorophyll Content in Aquaponically Grown Lettuce Using Hyperspectral Reflectance and RGB Images. Plants 2024, 13, 392. [Google Scholar] [CrossRef]

- Liu, W.; Hu, J.; Zhao, X.; Pan, H.; Lakhiar, I.A.; Wang, W. Development and experimental analysis of an intelligent sensor for monitoring seed flow rate based on a seed flow reconstruction technique. Comput. Electron. Agric. 2019, 164, 104899. [Google Scholar] [CrossRef]

- Solangi, K.A.; Siyal, A.A.; Wu, Y.; Abbasi, B.; Solangi, F.; Lakhiar, I.A.; Zhou, G. An assessment of the spatial and temporal distribution of soil salinity in combination with field and satellite data: A case study in Sujawal District. Agronomy 2019, 9, 869. [Google Scholar] [CrossRef]

- Memon, M.S.; Chen, S.; Shen, B.; Liang, R.; Tang, Z.; Wang, S.; Memon, N. Automatic visual recognition, detection and classification of weeds in cotton fields based on machine vision. Crop Prot. 2025, 187, 106966. [Google Scholar] [CrossRef]

- Chen, S.; Memon, M.S.; Shen, B.; Guo, J.; Du, Z.; Tang, Z.; Memon, H. Identification of weeds in cotton fields at various growth stages using color feature techniques. Ital. J. Agron. 2024, 19, 100021. [Google Scholar] [CrossRef]

- Dutta, M.; Gupta, D.; Tharewal, S.; Goyal, D.; Sandhu, J.K.; Kaur, M.; Alanazi, J.M. Internet of Things-Based Smart Precision Farming in Soilless Agriculture: Opportunities and Challenges for Global Food Security. IEEE Access 2025, 13, 34238–34268. [Google Scholar] [CrossRef]

- Senthil Pandi, S.; Reshmy, A.K.; Elangovan, D.; Vellingiri, J. AI-driven environmental monitoring for hydroponic agriculture: ExCNN-LFCP approach. Earth Sci. Inform. 2025, 18, 73. [Google Scholar] [CrossRef]

- Hanafi, A.M.; Hussien, S.A.; Elnahal, D.H.; Ahmed, S.E.H.; Salem, M.A.; Zainhum, A.R.; Abdel Sattar, Y.S. Revolutionizing Agriculture with IoT, Mobile Apps, and Computer Vision in Automated Hydroponic Greenhouses. Int. J. Eng. Appl. Sci. Oct. 6 Univ. 2025, 2, 1–16. [Google Scholar] [CrossRef]

- Azad, M.O.K.; Gruda, N.S.; Naznin, M.T. Energy Efficiency of Glasshouses and Plant Factories for Sustainable Urban Farming in the Desert Southwest of the United States of America. Horticulturae 2024, 10, 1055. [Google Scholar] [CrossRef]

- Riaz, N.; Sultan, M.; Ashraf, H.; Mahmood, M.H.; Ahmad, F.; Khan, M.U.; Zhang, Z. Study on Evaporative Cooling Assisted Temperature and Humidity Control Systems for Greenhouse Farming in Pakistan. In Air Conditioning Technologies and Applications; IntechOpen: London, UK, 2024. [Google Scholar]

- Ahmed, N.; Assadi, M.; Ahmed, A.A.; Banihabib, R. Optimal design, operational controls, and data-driven machine learning in sustainable borehole heat exchanger coupled heat pumps: Key implementation challenges and advancement opportunities. Energy Sustain. Dev. 2023, 74, 231–257. [Google Scholar] [CrossRef]

- Choi, M.I.; Cho, K.; Hwang, J.Y.; Park, L.W.; Jang, K.H.; Park, S.; Park, S. Design and implementation of IoT-based HVAC system for future zero energy building. In Proceedings of the 2017 IEEE International Conference on Pervasive Computing and Communications Workshops (PerCom Workshops), Kona, HI, USA, 13–17 March 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 605–610. [Google Scholar]

- Chandra, V.S.S.; Hareendran, A.S.; Albaaji, G.F. Precision farming for sustainability: An agricultural intelligence model. Comput. Electron. Agric. 2024, 226, 109386. [Google Scholar] [CrossRef]

- Kabir, M.S.N.; Reza, M.R.; Chowdhury, M.; Ali, M.; Samsuzzaman; Razob Ali, M.; Lee, K.Y.; Chung, S.-O. Technological trends and engineering issues on vertical farms: A review. Horticulturae 2023, 9, 1229. [Google Scholar] [CrossRef]

- Tavan, M.; Wee, B.; Brodie, G.; Fuentes, S.; Pang, A.; Gupta, D. Optimizing sensor-based irrigation management in a soilless vertical farm for growing microgreens. Front. Sustain. Food Syst. 2021, 4, 622720. [Google Scholar] [CrossRef]

- Hosny, K.M.; El-Hady, W.M.; Samy, F.M. Technologies, Protocols, and applications of Internet of Things in greenhouse Farming: A survey of recent advances. Inf. Process. Agric. 2024, 12, 91–111. [Google Scholar] [CrossRef]

- Setiawan, M.H.; Ma’arif, A.; Sharkawy, A.N.; Chotikunnan, P.; Majdoubi, R. Advancing Soilless Agriculture with Sensor and Wireless Technologies: A Comprehensive Review. J. Sci. Agrotechnol. 2024, 2, 1–14. [Google Scholar]

- Taha, M.F.; Mao, H.; Mousa, S.; Zhou, L.; Wang, Y.; Elmasry, G.; Al-Rejaie, S.; Elwakeel, A.E.; Wei, Y.; Qiu, Z. Deep Learning-Enabled Dynamic Model for Nutrient Status Detection of Aquaponically Grown Plants. Agronomy 2024, 14, 2290. [Google Scholar] [CrossRef]

- Taha, M.F.; Mao, H.; Zhang, Z.; Elmasry, G.; Awad, M.A.; Abdalla, A.; Mousa, S.; Elwakeel, A.E.; Elsherbiny, O. Emerging Technologies for Precision Crop Management Towards Agriculture 5.0: A Comprehensive Overview. Agriculture 2025, 15, 582. [Google Scholar] [CrossRef]

- Farhan, S.M.; Yin, J.; Chen, Z.; Memon, M.S. A Comprehensive Review of LiDAR Applications in Crop Management for Precision Agriculture. Sensors 2024, 24, 5409. [Google Scholar] [CrossRef] [PubMed]

- Promwee, A.; Nijibulat, S.; Nguyen, H.H. Enhancing Chinese Cabbage Production and Quality through IoT-Based Smart Farming in NFT-Hydroponics. Agronomy 2024, 14, 579. [Google Scholar] [CrossRef]

- Ming, M.; Elsherbiny, O.; Gao, J. Trinocular Vision-Driven Robotic Fertilization: Enhanced YOLOv8n for Precision Mulberry Growth Synchronization. Sensors 2025, 25, 2691. [Google Scholar] [CrossRef]

- Zhang, R.; Zhu, H.; Chang, Q.; Mao, Q. A Comprehensive Review of Digital Twins Technology in Agriculture. Agriculture 2025, 15, 903. [Google Scholar] [CrossRef]

- Yin, S.; Xi, Y.; Zhang, X.; Sun, C.; Mao, Q. Foundation Models in Agriculture: A Comprehensive Review. Agriculture 2025, 15, 847. [Google Scholar] [CrossRef]

- Shen, Y.; Yang, Z.; Khan, Z.; Liu, H.; Chen, W.; Duan, S. Optimization of Improved YOLOv8 for Precision Tomato Leaf Disease Detection in Sustainable Agriculture. Sensors 2025, 25, 1398. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Li, M.; Fan, W.; Liu, J. State-of-the-Art Techniques for Fruit Maturity Detection. Agronomy 2024, 14, 2783. [Google Scholar] [CrossRef]

- Mahmood ur Rehman, M.; Liu, J.; Nijabat, A.; Faheem, M.; Wang, W.; Zhao, S. Leveraging Convolutional Neural Networks for Disease Detection in Vegetables: A Comprehensive Review. Agronomy 2024, 14, 2231. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, J.; Jin, Y.; Bai, Z.; Liu, J.; Zhou, X. Design and Testing of an Intelligent Multi-Functional Seedling Transplanting System. Agronomy 2022, 12, 2683. [Google Scholar] [CrossRef]

| Feature | Soilless Farming | Traditional Farming |

|---|---|---|

| Growing medium | Nutrient solution and substrate media | Soil |

| Water consumption | 50 to 95% less water usage (if properly managed) and 5–10% wastage of water (due to water quality, salt buildup, and occasional system flushing) | Significantly higher water usage and wastage |

| Space efficacy | Occupied the lower space | Requires more horizontal land space |

| Crop variety selection | Recommended for leafy vegetables | Unlimited access to crop selection and a wide variety of crops suited to the local climate |

| Nutrient control | Precise nutrient control tailored to plant needs | Mainly depends on soil quality |

| Pest and disease | Reduced risk of soilborne pests and diseases | Higher risk of pests, diseases, and weeds |

| Climate impact | Lower overall environmental impacts | Higher environmental impact |

| Setup cost | High initial setup (equipment, infrastructure) | Lower initial cost (depends on land and tools) |

| Labor requirements | Requires specialized knowledge | More manual labor needed for planting, irrigation, and harvesting |

| Climate dependency | Less dependent on external climate conditions | Highly reliant on weather and climate |

| Yield and efficiency | Higher yields per square meter | Depending on climate and soil conditions |

| Crop growth speed | Faster growth | Slower growth |

| Maintenance | Regular monitoring and adjustments to nutrient solutions | Regular tilling, fertilization, irrigation, and pest control |

| Energy use | Requires more energy (60–90% for heating and cooling, 10–30% for lighting, and 5–10% for pumps) and varies depending on type, area, and technologies used | No external energy required for heating, cooling, and lighting |

| Sustainability | Using less land and water is more sustainable, especially in urban areas (spaces like rooftop gardens, indoor farms, green walls, etc.). | Sustainability depends on practices (e.g., crop rotation and conservation) |

| Crop Type | AR | TFS | WU | SLF | WU | YD | Ref. |

|---|---|---|---|---|---|---|---|

| Sweet pepper | Egypt | SS | 312.5 L/m2/s | SC, MP, & PC | 199.6, 269, & 233.2 L/m2/s | SC (12.7%) +, MP (4.6%), & PC (16.2%) − | [57] |

| Zucchini squash | Italy | N/M | 256 L/m2/s | PC, CF, & PM | 200, 221, & 185 L/m2/s | PC (33.5%), CF (20.3%), & PM (32.6%) + | [58] |

| Lettuce | USA | N/M | 250 ± 25 L/kg/y | NFT | 20 ± 3.8 L/kg/y | 11 times + | [59] |

| Basil | UAE | Soil pots | N/M | AQP | N/M | + in AQP | [60] |

| Tomatoes | Saudi Arabia | N/M | HWC | LC | 50% − | − in LC | [61] |

| Lettuce | Palestine | N/M | HWC | VT, PMP, & NFT | SLF systems saved up 94% to 123% | No significant variation observed | [62] |

| Tomatoes | Turkey | N/M | 87.4 (PE) & 102.9 (GE) L plant−1 | DWC & RW | 41.7 (PE), 48.6 (GE), 70.34 (PE), and 92.5 (GE) for DWC & RW | No significant variation observed | [63] |

| Mulberry Cutting | China | N/M | HWC | ARP | Less water | Highest gains in root growth, survival, and biomass with ARP | [64] |

| Onion | India | N/M | More water | DWC | Less water | 2 times + | [65] |

| Crop | pH | EC | Temp | Light | Photoperiod | A. Temp | RH |

|---|---|---|---|---|---|---|---|

| Asparagus | 6–6.8 | 1.4–1.8 | 20–28 | 150–200 | 8/16 | 18–30 | 45–80 |

| Lettuce | 5–7 | 1.5–2.5 | 18–25 | 150–250 | 14–17 | 18–27 | 45–80 |

| Parsley | 6.0–6.5 | 1.8–2.2 | 18–25 | 150–200 | 16/8 or 14/8 | 18–30 | 45–80 |

| Peppers | 5.5–6 | 0.8–1.8 | - | 50–200 | 16/8 | 20–35 | 50–80 |

| Strawberry | 6.0 | 1.8–2.2 | 18–30 | 115–350 | 12–16 | 18–30 | 40–80 |

| Rocket, eruca, or arugula (Eruca sativa) | 5.5–6.0 | 1.5–1.8 | 18–25 | 150–200 | 16/8 | 18–30 | 45–80 |

| Basil | 5.5–6.5 | 1.1–1.6 | 18–24 | 80–250 | 16/8 | 18–30 | 50–85 |

| Celery | 5.5–6.5 | 1.8–3 | 18–25 | 150 | 16/8 | 18–30 | 50–85 |

| Kale | 6–6.5 | 1.2–1.8 | 18–25 | 150–250 | 16/8 | 18–30 | 50–80 |

| Leek | 6.5–7 | 1.4–1.8 | 18–23 | 150–250 | (12–14)/ (12–10) | 18–30 | 60 |

| Tomato | 5.5–6.5 | 2–4 | NM | 50–200 | 15/9 | NM | NM |

| Okra | 5.5–6.5 | 2–2.4 | NM | NM | NM | 20–35 | 50–80 |

| Rhubarb | 5.5–6.0 | 1.6–2.0 | NM | NM | NM | NM | NM |

| Rose | 5.5–6.0 | 1.5–2.5 | NM | NM | NM | NM | NM |

| Sage | 5.5–6.5 | 1.0–1.6 | NM | NM | NM | NM | NM |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lakhiar, I.A.; Yan, H.; Syed, T.N.; Zhang, C.; Shaikh, S.A.; Rakibuzzaman, M.; Vistro, R.B. Soilless Agricultural Systems: Opportunities, Challenges, and Applications for Enhancing Horticultural Resilience to Climate Change and Urbanization. Horticulturae 2025, 11, 568. https://doi.org/10.3390/horticulturae11060568