Abstract

The bruising of fruits occurs at various stages, including picking, transportation, and sale. For fruits with large kernels that occupy a significant portion of their overall volume, considering the impact of the kernel is crucial in elucidating the mechanisms of bruising and controlling bruise formation. This study employs reverse engineering to develop a composite finite element model of loquat peel, flesh, and kernels. Bruise formation during collisions is analyzed from the perspectives of contact force, equivalent stress, energy, bruise volume, and bruise susceptibility, aiming to reveal the significant role of the fruit core in the bruise formation process. In this paper, we propose the use of 3D printing technology to accurately quantify bruise measurement for fruits with large kernels. The results showed that the maximum contact force, equivalent stress, and internal energy between loquat and steel/wood were essentially consistent, but all exceeded those observed when using rubber. Due to the blocking of stress transmission by the kernel, the susceptibility of loquats to bruising increases with height before decreasing. This study elucidates the mechanism of bruise formation in fruits with large kernels and provides methods and ideas for the research and precise measurement of complex fruit bruising characteristics.

1. Introduction

Fruits are the most widely consumed agricultural products in the world and are rich in vitamins, dietary fiber, and other nutrients that are highly favored by consumers [1]. The fruit’s kernel has a direct impact on its cultivation and growth. Loquat is a fruit with a relatively large kernel that is hard and separated from the flesh by a clear boundary, and is widely cultivated in subtropical regions [2].

After fruits have ripened, they are mechanically harvested via methods including mechanical hand picking [3,4], applying vibration to branches [5,6], and contact-based beating [7,8]. Following harvesting, fruits undergo transportation, packaging, and sale, all of which have the potential to cause bruising. Statistics show that over 30% of agricultural products experience bruising issues due to collisions, with falling impacts being the most common and simple path to bruise formation [9]. When the force applied to agricultural products exceeds the biological yield limit, cell rupture occurs, leading to bruising [10,11]. Bruising not only deteriorates sensory quality, but also accelerates the decay of agricultural products, severely impacting food safety.

Currently, research on fruit bruising has mainly focused on bruise detection methods and bruise evaluation [12]. Bruise detection technologies can be roughly categorized into three types as follows: (a) manually measuring key parameters of bruises and applying them to mathematical equations to calculate the bruise area and volume of fruits [13]; (b) imaging bruised tissues and quantifying the extent of damage using image analysis software [14,15,16]; and (c) utilizing non-destructive methods such as optical techniques for in situ detection and analysis [17,18,19]. The mathematical approach simplifies the bruise profile into circles or ellipses and calculates it based on empirical formulas [20]. Using image analysis software and optical instruments for measurement is complex and expensive. Therefore, it is essential to explore an effective and accurate method of measurement for complex bruise characteristics.

In terms of bruise evaluation, several experimental techniques, such as pendulum tests and puncture tests, are commonly used to study the mechanical relationship between the forces involved and the resulting material deformation [21,22]. However, the mechanism of agricultural product bruising cannot be visualized, and can only be analyzed via a large number of experiments that assess the final bruising effect. Fruit kinematics simulation is an emerging technology that effectively explores the bruise formation process and final bruise morphology by determining the physical properties of fruits and simulating them in mechanical models [23,24]. Ji et al. [25] analyzed the dynamic process of gripping apples using the finite element method based on the viscoelastic properties of apples, and proposed a complex model to estimate the stress on apples. Han et al. [26] quantitatively evaluated the internal damage of sweet cherries based on collision type, initial fruit velocity, and ambient temperature using the finite element method, and predicted their susceptibility to bruising. Hou et al. [27] explored the multiscale characteristics of blueberries under different collision angles, falling heights, and contact materials based on the finite element method, assessing the bruising susceptibility of blueberries. Research on agricultural product bruising has also focused on pears [11,28], potatoes [29], radishes [30], kiwifruits [31], and tomatoes [32,33], among others. Fruit peel protects the fruit flesh, and is typically a focal point in simulations. However, kernels are located inside the fruit, vary in sizes among different types of fruits, and are often overlooked in simulation analyses, as smaller kernels occupy a relatively small volume within the fruit, and bruising usually does not penetrate into the kernel region. In recent years, hyperspectral technology has been used in fruit bruise detection, offering the advantage of revealing early-stage bruise features [34,35]. However, the specific impacts suffered by fruits with large kernels (such as loquat, apricot, plum, and cherry) during the bruising process remain unclear. There is a lack of relevant research on the mechanisms underlying bruise formation in these fruits, particularly regarding the role of kernels in bruising.

This study established a three-layer model for loquats, consisting of peel, flesh, and kernel, based on reverse engineering. A method was proposed to quantify bruise volume using 3D printing technology, and indicators such as contact force, equivalent stress, energy, bruise volume, and bruise susceptibility were analyzed. This provides a reference for accurately constructing models and conducting bruise studies on fruits with a large core ratio.

2. Materials and Methods

2.1. Determination of the Physical Properties of Loquats

The “Wuxing” loquat variety extensively cultivated in China was selected as the research subject. The mature fruit is elliptical in shape with a prominent and deep five-pointed-star shape at the apex, along with orange-yellow peel, orange-red flesh, and a hard kernel. According to its anatomical characteristics, the loquat can be divided into three parts: peel, flesh, and kernel. Here, the physical properties of each are measured.

The density of the loquat was determined by measuring its mass (using an electronic analytical balance: JA5003, Shanghai Precision Instrument and Meter Co., Ltd., Shanghai, China) and volume (using a graduated cylinder: 130105004, BKMAM Biotechnology Co., Ltd., Changde, China).

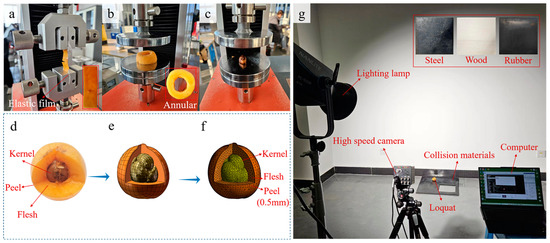

The mechanical properties of the loquat were tested using an agricultural material universal testing machine (model: HT-S50, Beijing Chuangchengzhijia Technology Co., Ltd., Beijing, China) at a test speed of 5 mm min−1. The stress–strain relationship was measured, and the experiment was repeated 10 times, with the results averaged. The fruit peel was subjected to tensile testing with rectangular samples of dimensions 15 45 mm and a thickness of 0.5 mm. To avoid inaccurate measurements due to peel damage by the fixtures, an elastic film was placed on the contact surface between the peel and the fixture. The mechanical properties of the flesh and kernel were tested using uniaxial plane compression, with the fruit flesh samples processed into an annular with an inner diameter of 20 mm, an outer diameter of 40 mm, and a height of 15 mm. Compression tests on loquat flesh and kernels were performed using rigid flat-plate probes. To prevent slippage-induced errors and ensure experimental consistency, the tests were terminated once visible macroscopic damage occurred, which served as the stopping criterion.

We measured the dimensions of the loquat material before and after deformation, and calculated the Poisson’s ratio using Equation (1).

where represents the Poisson’s ratio of the loquat material; denotes the lateral strain; represents the longitudinal strain; stands for the change in width of the material after the experiment, mm; is the height of the material before the experiment, mm; is the width of the material before the experiment, mm; and represents the change in height of the material after the experiment, mm.

The elastic modulus is the ratio of stress to strain in the elastic deformation stage, while the yield strength is the stress value corresponding to a residual deformation of 0.2% (i.e., the conditional yield limit). The tangent modulus is the slope between the yield limit and the ultimate strength.

2.2. Establishment of a Finite Element Model for Loquats

2.2.1. Reverse Engineering Modeling

The typical dimensions of 50 loquats were measured using a vernier caliper, and the average values (length, 40.68 mm; width, 39.46 mm; height, 42.85 mm) were taken (Figure 1d). A three-dimensional laser scanner (MarvelScan, Surui Measurement Technology Co., Ltd., Shenzhen, China) was utilized to capture the external characteristics of loquats and kernels with values close to the average results. A loquat model was established. We merged point clouds and stitched surfaces together using Geomagic Studio software ( version: Geomagic Studio 11, Geomagic Inc., Morrisville, NC, USA). We constructed a three-dimensional solid model of a loquat in SOLIDWORKS (version: 2019, Dassault Systemes, Waltham, MA, USA) software (Figure 1e,f).

Figure 1.

Loquat experiments and related processing. (a). Peel tensile test. (b). Flesh compression test. (c). Kernel compression test. (d). Composition of loquats. (e). Reverse engineering modeling. (f). Mesh division. (g). High-speed camera validation experiment.

2.2.2. Model Processing

Based on the characteristics exhibited by different parts of the loquat during tensile and compressive experiments, in ANSYS Workbench LS-DYNA (version: 2021R1, ANSYS Inc., Canonsburg, PA, USA), the peel and kernel were designated as elastic materials, while the flesh was set as a viscoelastic material. Surface binding contact was employed to connect the peel, flesh, and kernel into a unified whole. The peel was set to a thickness of 0.5 mm.

2.2.3. Mesh Division

In ANSYS Workbench, mesh division was performed using the automatic mode to ensure simulation accuracy and efficiency. The mesh sizes for the peel, flesh, and kernel were defined as 2 mm each. After meshing, the loquat had 91,961 elements and 20,893 nodes (Figure 1f).

2.3. Drop Test Experiment

To quantify the effects of different materials and drop heights on the bruising caused by fruit kernels during impact, three materials commonly used in loquat harvesting and transportation—steel (Q235), wood (oak), and rubber (styrene-butadiene rubber, SBR)—were selected as the contact surfaces. Drop tests were conducted at four heights: 500 mm, 1000 mm, 1500 mm, and 2000 mm. Finite element analysis was conducted to simulate the bruising process, and high-speed camera technology was used to observe the dynamics endured by the loquats during the falling process to ensure consistency with the simulation study.

2.3.1. Finite Element Simulation

An experimental finite element simulation analysis was conducted using ANSYS Workbench LS-DYNA. The contact material dimensions were 200 200 10 mm, with all six degrees of freedom fixed to mimic real-world conditions. The properties of the materials were directly derived from the ANSYS material library. Friction properties were set for the peel and contact materials, and drop heights were set to the four predetermined values. The drop direction was aligned with the standard gravity direction, and the simulation time was set to 0.01 s. Stress cloud maps and simulation data were processed after each simulation run.

2.3.2. Bench Validation Experiment

The contact area and falling state during the actual fruit dropping process can affect the final bruise volume produced. To compare and verify whether the bruise volume in the simulation matches the actual bruise volume generated in fallen loquats, high-speed camera technology was used to track and observe the falling status of the loquats, ensuring consistency in the falling process. The loquats used were approximately the same size as average (Figure 1g). The main instruments included a computer (Lenovo Legion R9000P2023 AMD-R9 7945HX 16 Core, 16GB RAM; Lenovo Group Ltd, Beijing, China), a high-speed camera (Model: SH3-103,Shenshi Intelligent Technology Co., Ltd., Shenzhen, China), and supplementary lighting (Model: Nanlite FC-500B, Guangdong Nanguang Film and Television Equipment Co., Ltd., Shantou, China). A high-speed camera was used to record the actual falling process of the loquats. The frame rate of the high-speed camera was set to 1500 frames/s, with an image resolution of 1280 × 1024 pixels, 8-bit image depth, automatic ISO (International Organization for Standardization) sensitivity, and global shutter mode, and the captured images were stored in .jpg format on the computer.

2.4. Data Processing

After the bench validation experiment, the loquats were left for two hours to allow the bruised flesh to oxidize sufficiently, presenting a clear color difference from the normal flesh. The long and short axes of the elliptical bruised areas formed on the surfaces of the loquats were measured separately, and the bruise depth was measured by longitudinally cutting through the center. The bruise volume can be calculated using Equation (2).

where represents the volume of bruising on the loquat after bench testing, mm3; denotes the depth of the bruise, mm; represents the length of the bruise, mm; and stands for the width of the bruise, mm.

The loquat peel provides protection to the flesh. In the physical property assessment, the peel was found to exhibit characteristics of an elastic material, and no rupture or damage occurred during actual drop tests. Additionally, since the peel was sufficiently thin, the volume of bruising on the surface was neglected during simulation extraction.

Due to the interaction between the kernel and the flesh, the extracted bruising volume was more complex. To precisely quantify the fruit bruise volume, a strategy combining finite element analysis with physical prototyping was adopted. Firstly, based on stress distribution characteristics in bruised regions derived from finite element simulation results, the three-dimensional structure of the bruised area (STL format) was extracted from the complete model through geometric segmentation. Due to the fact that a minimal bruise volume would cause significant measurement errors when using the direct water displacement method, the model underwent proportional scaling; the linear dimensions along each axis were doubled, resulting in an 8-fold volumetric enlargement to ensure an appropriate measurement range for printed prototypes. Scaled models were constructed using a high-precision stereolithography 3D printer (COLIDO SLA-550, Print-rite Printing Consumables Co., Ltd., Zhuhai, China). To achieve volume measurement, we employed the water displacement method, involving the complete immersion of the models in pure water within a high-precision cylindrical container, and recorded volumetric changes before and after submersion. To ensure reliability, each model group underwent 10 repeated measurements and the results were averaged. The final bruise volume was restored to the original scale through reverse scaling (1/8 reduction). The volume was calculated using Equation (3),

where is the bruise volume in the simulation experiment, mm3; is the total volume with water after being placed in the printing model, mm3; is the volume of water without the printing model, mm3; and is the magnification factor of the printing model.

Using the bruise volume in the bench experiment as a reference, the bruising effects were validated. The error is calculated using Equation (4),

where is the error between the bruise volume and the actual bruise volume, %.

Bruising susceptibility is a commonly used indicator for evaluating the bruising characteristics of fruits, calculated using Equation (5).

where BS is the bruising susceptibility of loquat, mm3 J−1; is the bruise volume in the simulation experiment, mm3; and is the energy absorbed (maximum internal energy) during loquat impact, J.

3. Results and Discussion

3.1. Physical Properties of Loquats and Contact Materials

The densities, Poisson ratios, elastic moduli, yield strengths (for flesh), and tangent moduli (for flesh) of the loquat peel, flesh, and kernel were measured and calculated based on their physical characteristics. The parameters of the contact materials (steel, wood, and rubber) were obtained from the ANSYS material library (Table 1).

Table 1.

Physical properties of loquats and contact materials.

The characteristics of loquat bruising during the drop process are analyzed in Section 3.2, Section 3.3 and Section 3.4 from the perspectives of contact force, equivalent stress, and energy. Then, in Section 3.5 and Section 3.6, the impact on the final bruising effect is analyzed in terms of bruise volume and bruise susceptibility.

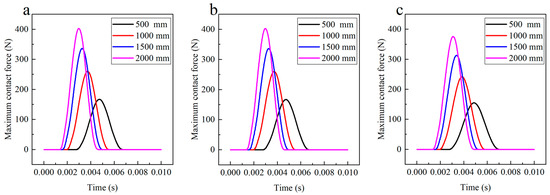

3.2. Contact Force

In this study, we extracted the variations in the maximum contact force over time (Figure 2). When the contact material was steel and the height was 500 mm, the contact force of the loquat gradually increased from 0 at 0.0028 s to a maximum of 167.05 N at 0.0047 s, and it finally decreased to 0 at 0.0067 s. With increasing height, the loquat exhibited an increase in maximum contact force. Specifically, at heights of 1000, 1500, and 2000 mm, the maximum contact forces were 260.27, 336.40, and 403.02 N, respectively. When the contact materials were wood and rubber, the variations in maximum contact force followed similar trends as those observed when using steel as the contact material. When using the same impact height, the maximum contact forces between loquat fruits and both steel and wood were essentially consistent, yet significantly greater than those when using rubber. This phenomenon may be attributed to two factors. First, certain simplifications in the model may introduce deviations from real-world conditions. Second, although steel and oak differ with regard to material properties, the elastic modulus of loquat pulp is substantially lower than that of either material, making it the primary deforming body during collision. The stiffness variations between contact materials might be “masked” by pulp deformation, resulting in contact forces being predominantly determined by the mechanical response of the fruit flesh. A greater contact force results in the more significant deformation of the loquat fruit, making it more susceptible to impact damage.

Figure 2.

The time-dependent variation in the maximum contact force between loquats and three materials: (a) steel; (b) wood; (c) rubber.

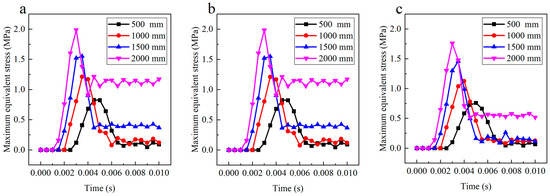

3.3. Equivalent Stress

In finite element simulation, equivalent stress can more intuitively represent the area of bruising, whereby bruising occurs when the equivalent stress exceeds the yield stress range [36]. The variation in maximum equivalent stress over time was extracted (Figure 3). When the contact material was steel and the height was 500 mm, the maximum equivalent stress of the loquat gradually increased to a peak of 0.83 MPa, and then decreased. It is worth noting that, as indicated in Section 3.2, when the maximum contact force was 0, the maximum equivalent stress did not decrease to 0, indicating the presence of residual stress after the impact between the fruit and the contact material, with residual stress fluctuating within a certain range. With increasing height, the loquat showed an increase in maximum equivalent stress. The greater the height, the greater the residual stress and its fluctuation range, with residual stress fluctuating in the range of 1.0–1.15 MPa when the height was 2000 mm. When the contact material was wood or rubber, the variation in maximum equivalent stress followed the same trend as when steel was the contact material. At the same height, the maximum contact forces between loquats and both steel and wood were essentially consistent, yet both were greater than those when using rubber. At heights of 500, 1000, and 1500 mm, when the contact material was rubber, the residual stress was close to 0. When the height was 2000 mm, the residual stress was 0.5 MPa, but this is still lower than when the contact material was steel or wood.

Figure 3.

The time-dependent variation in the maximum equivalent stress between loquats and three materials: (a) steel; (b) wood; (c) rubber.

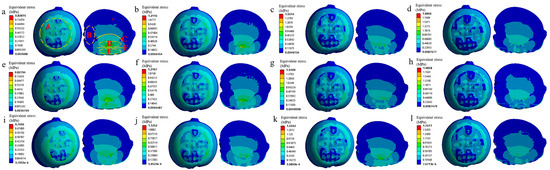

To further analyze the spatial distribution range of maximum equivalent stress, cloud maps of the maximum equivalent stress at the moment of occurrence were extracted (Figure 4). The maximum stress that the loquat surface endured occurred along the contour of region A. After the peel made contact with the impact material, stress was transmitted to the kernel through the flesh, and the interface between the kernel and flesh underwent deformation, preventing stress from spreading more extensively to the surroundings. The maximum stress values appeared in regions D and F, with the kernel dividing the stress propagation range into two parts through line E—one featured the stress between the fruit peel and the contact material, and the other featured the stress between the flesh and the kernel. These two sections of stress were gradually attenuated from the center to both sides, with a significant attenuation of stress after crossing line C, which reduced to 0 at the interface between the kernel and flesh. This phenomenon aligns more closely with real-world bruising scenarios, where impact-induced damage in pitted fruits does not result in structural damage to the kernel itself.

Figure 4.

Maximum equivalent stress cloud maps for drop heights of 500, 1000, 1500, and 2000 mm for different materials: (a–d) steel; (e–h) wood; and (i–l) rubber. Contour A is the boundary with the maximum stress on the peel. Area B is the stress-free region at the end of the loquat. Contour C is the distinct boundary within the kernel where stress attenuation is pronounced, and Areas D–F represent the junction zones and boundaries between the flesh and the kernel.

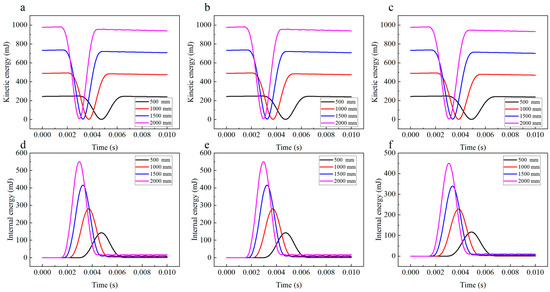

3.4. Energy

The changes in kinetic energy and internal energy over time were analyzed (Figure 5). Regardless of contact material, loquats exhibited consistent trends in kinetic and internal energy variation during collision. When they were dropped from a given height, potential energy was converted to kinetic energy. At the point of material contact, kinetic energy peaked instantaneously before rapidly dissipating to zero, during which internal energy accumulated and reached its maximum value. As the kinetic energy increased from zero to its maximum value, it tended to stabilize, while the internal energy decreased and eventually reached zero. The greater the height, the larger the peaks of maximum kinetic energy and maximum internal energy. When the contact materials were wood and rubber, the changes in kinetic energy and internal energy followed the same trends as those observed when steel was the contact material. At the same height, the maximum kinetic energy of loquats was consistent across all materials, while their maximum internal energies when in contact with steel and wood were essentially consistent, both being greater than with rubber. This indicates that rubber had a good energy absorption effect, which played an important role in reducing loquat bruising. The specific bruising effects are analyzed in Section 3.5 and Section 3.6.

Figure 5.

The variations in kinetic energy and internal energy over time. (a–c) The kinetic energy when the materials were steel, wood, and rubber, respectively. (d–f) The internal energy when the materials were steel, wood, and rubber, respectively.

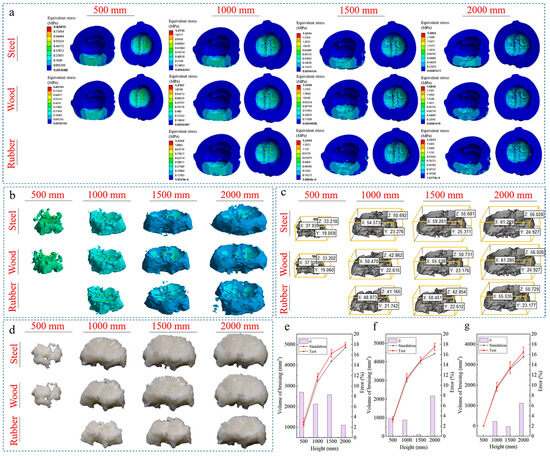

3.5. Bruise Volume

In Section 3.2, Section 3.3 and Section 3.4, the process of bruise formation in loquats was primarily analyzed, which is key to revealing the mechanism behind the bruising effect. To further analyze the effects of different heights and different contact materials on loquat bruising, the results from bench tests were compared with those from simulations. This comparison serves two main purposes. Firstly, it helps to validate the accuracy of the model; secondly, it enables the assessment of the impact of the kernel on bruising effectiveness. When the maximum equivalent stress suffered by loquats during collision exceeds the yield stress, bruising occurs. The bruise volumes of loquats were visually extracted (Figure 6a–d). With the increase in height, the bruise volume showed a distinct kernel contour, and the volume gradually increased. As shown in Section 3.3, when in contact with rubber at a height of 500 mm, the maximum equivalent stress exceeded the yield stress, but no bruise volume was extracted. This was mainly because the maximum equivalent stress occurred at the location of the peel. In the actual experiment and simulation analysis process, the peel did not undergo damage, so the bruising of the peel was neglected in this study. This also proves that the peel has a good protective effect on the flesh. Figure 6c,d show the effects of 3D printing on enlarged bruise volumes in loquats. Although it was concluded in Section 3.3 that the maximum equivalent stresses for contact materials (steel and wood) were essentially consistent, Figure 4 reveals that the regions exceeding the yield stress differed, resulting in different bruise volumes being extracted. This indicates that the maximum equivalent stress is a localized indicator and cannot fully represent bruise severity. However, it may serve as a qualitative metric that can be used to assess the likelihood of bruising.

Figure 6.

The bruise volumes of loquats with different materials and heights. (a,b) Simulation and extraction results. (c) Extracted bruise volume. (d) Three-dimensional printing results. (e–g) Comparison of loquat bruise volumes with materials of steel, wood, and rubber, respectively.

Based on the results of the bench test, further comparative analyses of the extracted bruise volume with the actual bruising effects were conducted (Figure 6e–g). The bruise volumes extracted gradually increased with the increase in height, consistent with the trend seen in the actual experimental results. When the contact materials were steel, wood, and rubber, the maximum errors were 8.78%, 7.9%, and 6.47%, respectively, indicating that the established model was accurate.

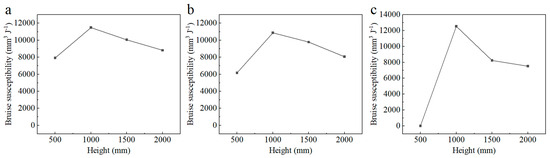

3.6. Bruising Susceptibility

When in contact with steel, wood, and rubber, the susceptibility of loquats to bruising gradually increased at heights between 500 and 1000 mm, whereas it gradually decreased within the 1000–2000 mm height range (Figure 7). This contrasts with the conclusions of Du et al. [31] and Celik et al. [11], whose studies suggest greater bruise susceptibility at greater impact heights. This discrepancy primarily arises from the influence of fruit stone morphology; fruits such as the kiwifruit and pears that were studied in those works have smaller or sometimes no kernels, and their flesh can be modeled as a homogeneous continuum, for which greater drop heights inevitably cause greater flesh damage. Due to the different physical properties of the kernel and flesh, and the relatively high proportion of kernel volume within the entire loquat, at lower heights, stress is mainly transmitted through the flesh, as verified in Figure 4 and Figure 6a–d. When the height exceeds a certain value, the range of stress transmission within the kernel increases. Although it continues to damage the flesh, the kernel blocks the transmission of internal stress within the flesh by absorbing a large amount of internal energy, resulting in a decrease in bruising susceptibility.

Figure 7.

The variation in bruising susceptibility with height. (a) The contact material is steel. (b) The contact material is wood. (c) The contact material is rubber.

In fruits with a relatively large kernel, the flesh absorbs a significant amount of internal energy during collision, leading to bruising, while the kernel prevents stress transmission (Figure 4 and Figure 5). Additionally, different materials exhibit varied effects on the bruising process and its outcomes for loquats. This has led several studies [36,37] to propose that materials with buffering and softening properties should be utilized as contact materials. This is mainly because buffering materials can absorb a portion of the contact energy, reducing the amount of energy absorbed by the loquats during collisions and decreasing the occurrence of bruising. During picking, cushioning materials can be laid on the ground to reduce the impact when fruits fall. During sorting and washing, the presence of rigid conveying surfaces on the conveyor belts should be avoided—the contact areas must be covered with cushioning materials to minimize impact damage to loquats. During transportation, rubber shock-absorbing pads should also be installed to reduce vibration shocks transmitted from road bumps.

This study innovatively combined bruising with 3D printing technology, allowing for the visualization and extraction of bruise volumes. This proffers a new method of measuring bruise volumes, particularly for complex bruise shapes, and is an effective approach. There are various approaches to 3D printing, including stereolithography (SLA), selective laser sintering (SLS), selective laser melting (SLM), laminated object manufacturing (LOM), fused deposition modeling (FDM), and three-dimensional printing (3DP) [38]. It is advisable to avoid the FDM process because it requires the removal of a large number of support structures [39], which can easily damage the fruit and lead to measurement errors.

In later stages, this research can be extended to studies on fruits at different maturity stages. At the experimental level, micro-computed tomography (micro-CT) technology could be introduced to achieve the three-dimensional reconstruction of bruised areas, while simultaneously comparing the sources of measurement errors among traditional methods such as the water displacement method, image threshold segmentation method, and near-infrared spectroscopy. This would facilitate the establishment of volume measurement methods based on fruit maturity parameters, tissue water content, and cell wall structural parameters. Furthermore, the application conditions of bruise volume measurement methods should be thoroughly investigated to effectively improve and supplement the mechanisms and testing methodologies used in fruit bruise research.

4. Conclusions

Based on the established finite element model of loquats with peel–flesh–kernel structures, we investigated the effects of three common contact materials (steel, wood, and rubber) during loquat harvesting and transportation. The results show that the maximum contact force, equivalent stress, and internal energy between loquat and steel/wood were essentially consistent, but all exceeded those observed when using rubber. A novel 3D printing technology-based method was proposed to measure the bruise volume in large-kernel fruits such as loquats. When analyzing indicators including contact force, equivalent stress, energy, bruise volume, and bruise susceptibility during dropping, a notable finding was that bruise susceptibility initially increased and then decreased with increases in drop height, contrasting with small-kernel fruits, for which bruise susceptibility progressively increases with height. This research reveals the bruise formation mechanism in large-kernel fruits, providing methodologies and insights for the precise study and measurement of bruise characteristics in complex-structured fruits. Future studies could establish volume measurement methods incorporating fruit maturity, tissue moisture content, and cell wall structural parameters to further refine bruise research approaches for different fruit types.

Author Contributions

Conceptualization, C.X.; methodology, C.L.; software, B.L.; validation, C.L., and B.L.; resources, C.X.; writing—original draft preparation, C.L. and C.X.; writing—review and editing, C.X. and B.L.; visualization, C.L. and C.X.; funding acquisition, C.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fundamental Research Funds for the Central Universities, [grant numbers: SWU-KQ24038].

Data Availability Statement

All data are presented in the manuscript.

Acknowledgments

We would like to thank the Smart Agriculture Technology and Equipment Team of Southwest University for providing experimental facilities and data support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lin, M.; Fawole, O.A.; Saeys, W.; Wu, D.; Wang, J.; Opara, U.L.; Nicolai, B.; Chen, K. Mechanical damages and packaging methods along the fresh fruit supply chain: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 10283–10302. [Google Scholar] [CrossRef] [PubMed]

- Nkosi, N.; Nkazi, D.; Tumba, K. A review of thermodynamic and kinetic studies relevant to gas hydrate-based fruit juice concentration. J. Food Eng. 2023, 341, 111323. [Google Scholar] [CrossRef]

- Fan, P.; Yan, B.; Wang, M.; Lei, X.; Liu, Z.; Yang, F. Three-finger grasp planning and experimental analysis of picking patterns for robotic apple harvesting. Comput. Electron. Agric. 2021, 188, 106353. [Google Scholar] [CrossRef]

- Shi, Y.; Jin, S.; Zhao, Y.; Huo, Y.; Liu, L.; Cui, Y. Lightweight force-sensing tomato picking robotic arm with a “global-local” visual servo. Comput. Electron. Agric. 2023, 204, 107549. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, L.; Zhang, A.; Hang, X. Finite element explicit dynamics simulation of motion and shedding of jujube fruits under forced vibration. Comput. Electron. Agric. 2022, 198, 107009. [Google Scholar] [CrossRef]

- Hoshyarmanesh, H.; Dastgerdi, H.R.; Ghodsi, M.; Khandan, R.; Zareinia, K. Numerical and experimental vibration analysis of olive tree for optimal mechanized harvesting efficiency and productivity. Comput. Electron. Agric. 2017, 132, 34–48. [Google Scholar] [CrossRef]

- Hu, G.; Zhou, J.; Chen, Q.; Luo, T.; Li, P.; Chen, Y.; Zhang, S.; Chen, J. Effects of different picking patterns and sequences on the vibration of apples on the same branch. Biosyst. Eng. 2024, 237, 26–37. [Google Scholar] [CrossRef]

- Yu, P.; Li, C.; Takeda, F.; Krewer, G.; Rains, G.; Hamrita, T. Quantitative evaluation of a rotary blueberry mechanical harvester using a miniature instrumented sphere. Comput. Electron. Agric. 2012, 88, 25–31. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Bruise damage susceptibility of pomegranates (Punica granatum, L.) and impact on fruit physiological response during short term storage. Sci. Hortic. 2019, 246, 664–674. [Google Scholar] [CrossRef]

- Kafashan, J.; Wiacek, J.; Ramon, H.; Mouazen, A.M. Modelling and simulation of fruit drop tests by discrete element method. Biosyst. Eng. 2021, 212, 228–240. [Google Scholar] [CrossRef]

- Celik, H.K. Determination of bruise susceptibility of pears (Ankara variety) to impact load by means of FEM-based explicit dynamics simulation. Postharvest Biol. Technol. 2017, 128, 83–97. [Google Scholar] [CrossRef]

- Mei, M.; Li, J. An overview on optical non-destructive detection of bruises in fruit: Technology, method, application, challenge and trend. Comput. Electron. Agric. 2023, 213, 108195. [Google Scholar] [CrossRef]

- Zhu, Q.; Guan, J.; Huang, M.; Lu, R.; Mendoza, F. Predicting bruise susceptibility of ‘Golden Delicious’ apples using hyperspectral scattering technique. Postharvest Biol. Technol. 2016, 114, 86–94. [Google Scholar] [CrossRef]

- Mahanti, N.K.; Pandiselvam, R.; Kothakota, A.; Ishwarya, S.P.; Chakraborty, S.K.; Kumar, M.; Cozzolino, D. Emerging non-destructive imaging techniques for fruit damage detection: Image processing and analysis. Trends Food Sci. Technol. 2022, 120, 418–438. [Google Scholar] [CrossRef]

- Stopa, R.; Szyjewicz, D.; Komarnicki, P.; Kuta, Ł. Limit values of impact energy determined from contours and surface pressure distribution of apples under impact loads. Comput. Electron. Agric. 2018, 154, 1–9. [Google Scholar] [CrossRef]

- Lu, Y.; Lu, R.; Zhang, Z. Detection of subsurface bruising in fresh pickling cucumbers using structured-illumination reflectance imaging. Postharvest Biol. Technol. 2021, 180, 111624. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, X.; Zhang, S.; Cheng, Q.; Tan, Z. An effective method to inspect and classify the bruising degree of apples based on the optical properties. Postharvest Biol. Technol. 2017, 127, 44–52. [Google Scholar] [CrossRef]

- Yu, S.; Hu, D.; Qiu, D.; Jia, T.; Zhou, T.; Sun, X.; Sun, Z.; Yan, X. Profile-based diffuse reflectance corrections for improved optical property measurement of spherical fruit with spatial frequency domain imaging. Postharvest Biol. Technol. 2023, 204, 112453. [Google Scholar] [CrossRef]

- Munera, S.; Gómez-Sanchís, J.; Aleixos, N.; Vila-Francés, J.; Colelli, G.; Cubero, S.; Soler, E.; Blasco, J. Discrimination of common defects in loquat fruit cv. ‘Algerie’ using hyperspectral imaging and machine learning techniques. Postharvest Biol. Technol. 2021, 171, 111356. [Google Scholar] [CrossRef]

- Du, Z.; Zeng, X.; Li, X.; Ding, X.; Cao, J.; Jiang, W. Recent advances in imaging techniques for bruise detection in fruits and vegetables. Trends Food Sci. Technol. 2020, 99, 133–141. [Google Scholar] [CrossRef]

- Fu, H.; Du, W.; Yang, J.; Wang, W.; Wu, Z.; Yang, Z. Bruise measurement of fresh market apples caused by repeated impacts using a pendulum method. Postharvest Biol. Technol. 2023, 195, 112143. [Google Scholar] [CrossRef]

- Chavoshi, E.; Ahmadi, E.; Nia, A.A.; Seifi, R. Determination of dynamic deformation behavior of Golden Delicious apple using finite element method and its validation by scanning electron microscopy. Sci. Hortic. 2023, 307, 111531. [Google Scholar] [CrossRef]

- Rashvand, M.; Altieri, G.; Genovese, F.; Li, Z.; Di Renzo, G.C. Numerical simulation as a tool for predicting mechanical damage in fresh fruit. Postharvest Biol. Technol. 2022, 187, 111875. [Google Scholar] [CrossRef]

- Opara, U.L.; Pathare, P.B. Bruise damage measurement and analysis of fresh horticultural produce—A review. Postharvest Biol. Technol. 2014, 91, 9–24. [Google Scholar] [CrossRef]

- Ji, W.; Qian, Z.; Xu, B.; Chen, G.; Zhao, D. Apple viscoelastic complex model for bruise damage analysis in constant velocity grasping by gripper. Comput. Electron. Agric. 2019, 162, 907–920. [Google Scholar] [CrossRef]

- Han, X.; Liu, Y.; Tchuenbou-Magaia, F.; Li, Z.; Khojastehpour, M.; Li, B. Analysis of the collision-damage susceptibility of sweet cherry related to environment temperature: A numerical simulating method. J. Food Eng. 2022, 333, 111140. [Google Scholar] [CrossRef]

- Hou, J.; Park, B.; Li, C.; Wang, X. A multiscale computation study on bruise susceptibility of blueberries from mechanical impact. Postharvest Biol. Technol. 2024, 208, 112660. [Google Scholar] [CrossRef]

- Yousefi, S.; Farsi, H.; Kheiralipour, K. Drop test of pear fruit: Experimental measurement and finite element modelling. Biosyst. Eng. 2016, 147, 17–25. [Google Scholar] [CrossRef]

- Caglayan, N.; Oral, O.; Celik, H.K.; Cinar, R.; Rodrigues, L.C.D.A.; Rennie, A.E.W.; Akinci, I. Determination of time dependent stress distribution on a potato tuber during drop case. J. Food Process. Eng. 2018, 41, e12869. [Google Scholar] [CrossRef]

- Xu, C.; Wang, D.; Xu, F.; Tang, H.; Zhao, J.; Wang, J. Prediction of bruising susceptibility in white radish (Raphanus sativus L.) using FEA-RSM technique. Postharvest Biol. Technol. 2023, 206, 112565. [Google Scholar] [CrossRef]

- Du, D.; Wang, B.; Wang, J.; Yao, F.; Hong, X. Prediction of bruise susceptibility of harvested kiwifruit (Actinidia chinensis) using finite element method. Postharvest Biol. Technol. 2019, 152, 36–44. [Google Scholar] [CrossRef]

- Li, Z.; Andrews, J.; Wang, Y. Mathematical modelling of mechanical damage to tomato fruits. Postharvest Biol. Technol. 2017, 126, 50–56. [Google Scholar] [CrossRef]

- Li, Z.; Li, P.; Yang, H.; Liu, J. Internal mechanical damage prediction in tomato compression using multiscale finite element models. J. Food Eng. 2013, 116, 639–647. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Yan, Y.; Wang, G. Detection of Early Bruises in Honey Peaches Using Shortwave Infrared Hyperspectral Imaging. Spectroscopy 2022, 37, 33–41, 48. [Google Scholar] [CrossRef]

- Huang, X.; Meng, Q.; Wu, Z.; He, F.; Tian, P.; Lin, J.; Zhu, H.; Zhou, X.; Huang, Y. Detection of early bruises in Gongcheng persimmon using hyperspectral imaging. Infrared Phys. Technol. 2022, 125, 104316. [Google Scholar] [CrossRef]

- Guan, X.; Li, T.; Zhou, F. Determination of bruise susceptibility of fresh corn to impact load by means of finite element method simulation. Postharvest Biol. Technol. 2023, 198, 112227. [Google Scholar] [CrossRef]

- Sun, H.; Wan, F.; Huang, Y.; Xu, Z.; Huang, X. Evaluation of a new method to assess blueberry bruising based on intracellular and extracellular water ratios. Sci. Hortic. 2024, 328, 112896. [Google Scholar] [CrossRef]

- Yu, J.; Zhu, J.; Chen, L.; Chao, Y.; Zhu, W.; Liu, Z. A review of adsorption materials and their application of 3D printing technology in the separation process. Chem. Eng. J. 2023, 475, 146247. [Google Scholar] [CrossRef]

- Yadav, A.; Prakash, B.P.; Dileep, K.S.; Rao, S.A.; Kumar, G.V. An experimental examination on surface finish of FDM 3D printed parts. Mater. Today Proc. 2023, 115, 148–155. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).