Abstract

Finding appropriate shaking parameters is crucial in designing effective mechanical harvesters. The maximum fruit removal can be achieved when the machine operator properly adjusts the amplitude and frequency for shaking each tree. This review covers the progress in research and development over the past decades on using mechanical harvesters for nut trees, such as almonds, pistachios, walnuts, and hickories, with a specific focus on the natural frequency of individual trees. Furthermore, the reported values of shaking frequency and amplitude from previous studies were discussed and compared, along with frequency calculation approaches based on various shaking mechanisms. Additionally, other parameters, such as clamping force, height, and shaking amplitude, were investigated to determine optimal values for minimizing tree damage. This review emphasizes that the tree’s diameter, height, and canopy morphology should be the primary factors considered when estimating the optimal shaking frequency for nut trees. It also highlights that, to date, the shaking amplitude, frequency, and duration set by field managers or machine operators tend to remain consistent for all trees, which can limit harvesting efficiency. The findings suggest that selecting these parameters uniformly across all trees may not result in efficient fruit removal for individual trees. However, with the assistance of modern computing technology and its adaptation for in-field applications, it is feasible to determine the optimal shaking frequency for each tree mathematically. This approach can maximize fruit removal rates while minimizing tree damage. Finally, the review suggests that improving existing harvesting machines by incorporating better vibratory patterns could offer benefits such as enhanced productivity, reduced labor costs, and decreased permanent tree damage.

1. Introduction

In recent decades, California has become one of the largest producers of nuts on Earth.The state generates approximately USD 50 billion in annual revenue by accounting for 66% of all fruits and nuts grown in the United States [1]. This includes products like almonds, pistachios, walnuts, and more [2,3,4]. California’s success in nut production is due to various reasons, including appropriate climate conditions, soil fertility, modern field management procedures, and the extensive usage of mechanized harvesters [5,6,7,8]. These elements help to develop large-scale and efficient nut cultivation in the region. As a result, mechanical harvesters are becoming increasingly important instruments in today’s modern agricultural industry [9]. They can significantly reduce labor costs and harvest time, besides increasing the speed and productivity scale. However, the efficiency of this practice is a subject that needs to be investigated and improved.

Many studies have been conducted on evaluating the performance and efficiency of mechanical harvesting machines used in tree crops. There are also multiple patents and publications available on the mechanisms of various parts of these machines. As a brief overview, Ferguson et al. [10] evaluated the California pistachio trunk-shaking harvesters. They recommended that the pistachio industry evaluate improved trunk-shaking technology and tree pruning to enhance the efficiency of trunk shakers. Liu et al. [11] developed a tractor-mounted canopy shaker to shake the tree canopy at shaking frequencies between 2.5 and 5 Hz. Pu et al. [12] highlighted that low harvesting efficiency and tree damage are growers’ top concerns when choosing existing harvesting machines on a large scale. Liu et al. [13] evaluated the tree injuries caused by different materials contacting the tree’s branches during the tree shaking. The study found that tree injuries were significantly less when straight nylon tines were used than with other tines. In another study, Liu et al. [14] examined how the shaking frequency of tines and penetrating depth can affect fruit detachment based on simulation and relevant field experiments. Pu et al. [12] discovered that the combined shaking frequency of 4.7 and 4.1 Hz of the canopy shaker can produce less tree damage. Homayouni et al. [15] found that on a harvester with a computer-controlled shaking system, the actual shaking duration was, on average, 30% longer than the set shaking pattern duration, indicating a significant difference between the planned and actual shaking times. Recently, Manzo et al. [16] found that canopy management and orchard design are two important topics that need to be modified to ensure fruit accessibility and improve harvester efficiency. Furthermore, besides managing the shape of orchards, shaking parameters such as frequency and utilized materials are important for designing efficient nut tree harvesters.

Manufacturers have invented and built several mechanical harvesting tools that, in general, can be categorized into two categories: trunk shakers and canopy shakers [17,18,19,20,21,22]. Some parameters, such as shaking amplitude, frequency, and duration, as well as tree morphology, are critical for achieving the maximum fruit detachment rate [8,11]. This confirms [23]’s belief that shaking frequency is one of the most important aspects in achieving high fruit removal efficiency. However, we must also consider reducing tree damage and keeping trees productive in subsequent years [12,14]. According to García et al. [24], extending the shaking period must be avoided to reduce bark damage in trunk shakers. It appears that to achieve optimal shaking performance, several fundamental vibration physics theories, such as natural frequency and damping ratio, must be considered [15,25,26,27,28]. Whitney et al. [29] measured the dynamic properties of a wooden post, including mass, stiffness, and viscous damping. They combined them with corresponding shaker characteristics, such as unbalanced mass, total mass, eccentricity, and frequency of rotation, to create a mathematical model for predicting applied shaker force and motion. Later, Láng [30] analytically defined the power consumption, produced amplitude, and specific power for each trunk cross-section to design more precise shaker harvesters. Savary et al. [31] stated that a deeper knowledge of the interaction between the shaker and the tree is required to improve the effectiveness of canopy shaker harvesters. As a result, they conducted simulation research for a whole tree subsystem that was suitable for use with a canopy shaker. Hoshyarmanesh et al. [32] used finite element analysis to explore the harvesting productivity of an actual 3D structure involving the moisture and temperature-dependent behavior of elastic variables, load direction, and height. Sanchez-Cachinero et al. [33] proposed a computational model for simulating a trunk shaker working on a test bench and to characterize the dynamic behavior of trunk shakers. Their suggested method maintains repeatable conditions for testing the mechanical trunk shaker. Zhang et al. [34] established a finite element model based on cluster fruit under extrusion and analyzed the vibration harmonic response characteristics. Understanding the fundamental vibration dynamics of the harvesting system such as working frequency [15,35,36,37,38,39,40,41], amplitude [12,42], duration of shaking, and shaking pattern [8,38,43,44] are essential for designing an effective shaking mechanism [23,45] for nut harvesters. In addition, the size and structural shape of the tree are critical factors for selecting a proper shaking mechanism [8,9,46,47,48].

This review examines advancements in mechanical harvesters for nut trees over recent decades, focusing on shaking methods specifically designed for nut tree harvesting. It compares and discusses the mechanisms of trunk, limb, and canopy shaker systems while covering alternative approaches, such as air shaker systems, alongside relevant simulation studies. Additionally, the review highlights the key shaking parameters essential for designing efficient nut tree harvesters for crops like almonds, pistachios, and walnuts. The findings offer valuable insights for harvest machinery manufacturers and the nut production industry, aiming to enhance efficiency and productivity.

The properties that are related to detachment during harvesting include the fruit detachment force (FDF) to fruit weight (W) ratio, fruit maturity, tree hierarchical design, and vibration properties. One of the most important indicators for fruit harvesting is the FDF/W ratio, which helps researchers and growers determine how easily fruit can be detached from its holding limb. A lower FDF/W ratio indicates that the fruit will be detached with less force. The ratio decreases significantly in the ripening process of fruits due to the activation of the abscission compound. The authors of [49,50] confirmed this relationship through experimental testing on cashews. Using this ratio, we can find valuable information that can lead to the prediction of harvesting yield. It was shown by Farinelli et al. [51], in a study conducted from 2004 to 2007, that the FDF/W ratio was linearly related to the harvesting yield, resulting in easier detachment.

Vibratory harvesting of nuts occurs when induced vibrations are applied to the tree trunk or canopy, propagating through the branches. Nuts detach from the stem as a result of various factors, including inertial forces, vibration frequency, amplitude, and the nut’s physiological maturity. Each tree has a distinctive characteristic, and vibration properties vary among trees depending on factors such as trunk diameter, tree height, and stem water potential (SWP). Additionally, the morphological characteristics of trees, such as branch density, canopy structure, and trunk elasticity, directly impact the transmission of mechanical vibrations during harvesting. Also, each branch’s flexibility can change how vibration energy propagates through the tree branches, directly affecting the harvesting efficiency.

2. Diversity of Nut Species

Nuts are valued for their high economic yield and substantial nutritional benefits, driving a global increase in both their production and consumption. The expansion of nut cultivation is largely attributed to their numerous health benefits when included in a balanced diet [52]. Studies suggest that regular nuts are important sources of energy and essential dietary nutrients, and there is an increasing interest in consuming nuts [53,54,55,56,57]. The term "nuts" generally includes almonds, pistachios, walnuts, pecans, hazelnuts, pine nuts, chestnuts, cashews, Brazil nuts, macadamias, and peanuts. While most of these originate from trees, peanuts, often called groundnuts, belong to the legume family [52,58,59,60,61,62,63]. The primary commercial method for harvesting tree nuts involves mechanical harvesters. This section reviews the vibration properties of tree nuts and the shaking parameters of harvesters, emphasizing their influence on harvesting efficiency.

2.1. Almond

California has historically been the sole producer of almonds in the United States and remains the most prominent global exporter of almonds. Almond production is limited to regions with a Mediterranean climate, such as California’s Central Valley, which serves as the primary almond-producing area globally [64,65,66,67]. Based on data from the United States Department of Agriculture (USDA) in 2004, almonds were ranked as California’s leading agricultural export and the United States’ top horticultural export. The California Almond Objective Measurement Report, published by USDA-NASS in July 2023, projected almond production to reach 1.18 billion kg in 2023, reflecting a 1.5% increase compared to 2022 [68,69].

Currently, over 30 varieties of almond trees are cultivated in California. An almond tree typically has a lifespan of 20 to 25 years and generally does not bear fruit during the first 3 to 4 years after planting [65]. Trunk shakers have become widely used for almond harvesting due to their practicality and cost-effectiveness. However, despite their advantages, current mechanical harvesting systems can cause trunk damage, potentially reducing the tree’s long-term productivity. Most almond trunk shakers operate within a high-frequency range of 12 to 40 Hz, characterized by minimal horizontal movement. Limb shakers can also be employed for almond harvesting, but to avoid damage to the tree, shaking must be carefully calibrated with optimal amplitude and frequency settings [9].

2.2. Pistachio

Research indicates that pistachio kernel development in California typically occurs between May and August [70]. Pistachio harvesting operations in the state are predominantly mechanized, utilizing a shaker and catch frame system that simultaneously shakes the tree and collects nuts from both sides [71]. More specifically, these harvesters incorporate trunk clamping shakers that feature double-sided catch frames and are accompanied by systems that collect and transport the harvested pistachios using either field bins or bank out wagons. When harvesting pistachios, the typical vibration frequency ranges from 20 to 30 Hz, with an amplitude range of 50 to 60 mm. Mechanical harvesting methods for pistachios in California have proven to be both efficient and continually improving. However, a potential issue arises as the size of the tree trunks increases, which can reduce harvesting efficiency [9]. Ferguson et al. [10] carried out an experimental study using two types of trunk shakers, both standard commercial and experimental, to measure the final harvester efficiency in trees with different diameters. In another study, Polat et al. [72] determined the level of rigid body vibration experienced by pistachio tree limbs and trunks, as well as the pistachio holding force during harvesting by mechanical methods.

2.3. Pine

According to H. Zhang & Z. Zhang [73], various species of pine trees have spread across diverse regions worldwide, including northeastern China, Europe, Canada, the United States, and Mexico. Over the past centuries, European colonists introduced the stone pine to other regions with Mediterranean climates, such as Australia, Argentina, Chile, California, and South Africa, where it is now cultivated as a significant nut-producing tree [74,75].

As will be discussed in Section 3, frequency and efficiency values exhibit minimal variation across all three studies. However, the shaking duration values for pine tree shaking differ significantly across the studies. This disparity may be due to the different pine species tested in separate regions. Moreover, the operator’s preferences play a decisive role in selecting tree-shaking parameters. It is notable that amplitude was not mentioned in any of these papers.

2.4. Hickory/Walnut/Pecan

The Juglandaceae family comprises around 60 known species globally, including several commercially significant nut crops, such as the Persian walnut (Juglans regia), pecan (Carya illinoinensis), and Chinese hickory (Carya cathayensis) [76]. The Chinese hickory is a well-known nut that is commercially cultivated in the eastern and southeastern provinces of China and has been widely studied for its nutritional value in recent decades.

Walnut is another crop that is mechanically harvested. A study conducted by Liu et al. [77] developed a theoretical model to understand the vibration response of walnuts during mechanical vibration harvesting. The study explored walnuts’ motion and detachment mechanisms by analyzing the response amplitude, motion trajectory, and detachment force under varying vibration frequencies and amplitudes. A combination of horizontal (pendulum) and vertical linear motion creates an elliptical trajectory for the walnut, with the fruit most likely to detach at the endpoints of this path where maximum force is exerted. Field tests validate the model, showing that detachment force directly influences harvest efficiency and is proportional to vibration amplitude and the square of vibration frequency. In their study, a shaker vibration frequency in the range of 10–30 Hz resulted in a walnut response frequency between 4 and 15 Hz, with an approximately 50% attenuation rate. This study provides guidance for designing efficient vibration harvesting devices that can enhance harvesting rates by balancing vibration parameters while minimizing damage to both trees and equipment.

Pecan is another highly nutritious nut because of its healthy fats, natural compounds with antioxidant properties, and essential minerals, all of which collectively contribute to its dietary enrichment [78]. A study conducted by Sarig et al. [79] describes the development of a mechanical pecan harvester tailored for Israel’s unique agricultural conditions, particularly the heavy, wet soils where pecans are typically grown. Traditional pecan harvesters, optimized for lighter soils, performed poorly in Israel. The combined sweeping and lifting movements of previous commercial pecan harvesters generate an upward lift force that inevitably impacts the soil as well. The harvester design integrates a chain-to-soil relationship that minimizes soil disturbance while maximizing nut dislodging efficiency. Key features include an inclined chain elevator and a rubber-fingered reel, which work together to lift nuts from the soil and transport them to a separation system. This project used an air blower with an 18 m/s air velocity and a vibrating conveyor with a frequency of 10 Hz and an eccentricity of 12 mm. The multistage separation process, including air blowers and vibrating conveyors, effectively separates nuts from debris, achieving up to 98% efficiency under optimal conditions.

In another study, Rains et al. [80] focused on enhancing orchard management in order to remove inefficient trees in the orchard by assessing pecan yield using a mechanical harvesting system with integrated yield monitoring, specifically targeting yield estimation at the individual tree level. Researchers designed a method where the yield from a 4 m section of harvested material, which includes both pecans and foreign matter, is used as a representative measure for estimating the total yield of a tree. This approach proved effective, showing a high correlation (r² = 0.84) between the pecan yield from the sampled section and the gross yield, thus allowing accurate yield prediction with minimal field sampling. This precise yield data helps growers identify unproductive trees for removal and manage resources efficiently.

3. Nut Tree Mechanical Harvesting Methods

In the analysis of vibrations in mechanical systems, it is crucial to first establish key concepts. A mode of vibration refers to a distinct pattern of free motion that oscillates over time before gradually dissipating. It is defined by three fundamental properties: its spatial configuration (modal shape), its oscillation frequency, and the rate of decay (damping). Mode-based vibrations occur when a system is allowed to oscillate freely following an initial disturbance. Elastic systems exhibit a vast number of vibration modes, and depending on the loading conditions, one or multiple modes may be activated simultaneously [81].

Vibration itself is the oscillatory motion of an object around its equilibrium position, governed by two fundamental parameters: frequency and amplitude. Frequency (f), measured in hertz (Hz), represents the number of complete oscillations a system undergoes per unit time, where 1 Hz corresponds to one cycle per second. Mathematically, it is expressed as , where T is the period of one full oscillation. Frequency plays a critical role in the analysis of dynamic systems [82,83]. Amplitude (A) defines the maximum displacement of a vibrating object from its mean position and indicates vibration intensity. It is typically measured in meters for linear motion or degrees/radians for angular motion. A higher amplitude corresponds to greater vibration energy and is influenced by external excitation forces and damping effects [84].

Another key parameter to be defined in this context is the fruit harvest efficiency of trees. Harvest efficiency is quantified as the number or weight of mature fruits successfully harvested, expressed as a percentage of the total number or weight of mature fruits [85]. In a related study, Polat et al. [86] formulated the yield of fruit harvesting from trees using the following equation.

In this equation,

- represents the mass of the product harvested;

- represents the mass of the product that remains on the tree and was not successfully detached.

Following our crop-type analysis, we now classify harvesting techniques based on the methods used, emphasizing how variations in mechanical harvesting machines influence parameter selection and outcomes. The mechanization of harvesting operations has become widely adopted since it has significantly reduced costs, addressed seasonal labor shortages, and enhanced production quality by minimizing fruit exposure to atmospheric elements [87]. In recent decades, extensive research has focused on optimizing mechanical fruit harvesting methods. Among these, tree shaking has been widely applied, particularly in almond and pistachio harvesting, where its effectiveness is closely linked to the vibration frequency and amplitude. When carefully calibrated, the optimal vibration parameters can provide sufficient kinetic energy to detach fruit from the branches effectively. Studies indicate that the key metrics for evaluating vibration-based harvesting mechanisms are fruit removal efficiency and the extent of tree damage. According to Loghavi et al. [88], vibration frequency, amplitude, and duration directly affect both outcomes. Various vibration-based techniques for nut harvesting discussed in the literature can be categorized into trunk shakers, limb shakers, canopy shakers, air shakers, prototype vibrators, and simulation models.

3.1. Trunk Shaker System

Studies show that the canopy shaker generally offers the highest efficiency for large-scale fruit harvesting, particularly suited for processing purposes, while trunk shakers provide effective but slightly less efficient alternatives [18]. Notably, the optimal shaking of nut trees is characterized by maximizing fruit harvest while minimizing tree damage. Therefore, the ideal shaker system for tree harvesting must be capable of preventing damage to the tree trunk. Since the early 1920s, there have been suggestions to use machines designed for the efficient harvesting of tree fruit and nut crops in the U.S. [89]. Subsequently, in the early 1960s, the introduction of trunk shakers sparked significant concerns regarding potential bark damage at the attachment point on fruit and nut trees. A Freddy C-clamp trunk shaker (Freddy Tractor Co., Hartford, MI) was installed on the loader frame of a tractor equipped with three hanger links [90].

As illustrated in Figure 1, during the shaking process, the operator should position the shaker head so that one of the internal pads is placed adjacent to the tree trunk. The tree trunk is then grasped by two pads, which are compressed together by the action of a cylinder. Vibrations within the shaker body are induced by the rotation of two eccentric masses, which spin in opposing directions, powered by hydraulic motors. These eccentric masses consist of semicircular steel shells filled with lead. The shaker generates varying vibration patterns based on the instantaneous velocities of the two eccentric masses during its operational cycle. Four piezoelectric accelerometers were installed within the shaker to facilitate the analysis of planar motion.

Figure 1.

A hydraulic trunk shaker head (clamp) with labeled visible components [91].

To evaluate the frequency response of Pinus pinea L. trees during mechanical harvesting, Castro-García et al. [92] studied various cones under controlled laboratory conditions across a wide range of vibration values. In their study, three piezoelectric triaxial accelerometers were utilized to measure the acceleration of the branches. A dynamic signal analyzer was used to record and analyze the resulting data. Conversely, field experiments involving mechanical harvesting using a tractor-mounted tree trunk shaker were conducted to validate the laboratory test results. In the mentioned tests, a flow regulator was integrated into the hydraulic circuit of the shaker, allowing for adjustments to be made to the acceleration and frequency values applied to the tree. The shaker used in this research made it possible to apply combinations of adjustable vibration frequencies and acceleration levels to the stone pine tree trunk. According to their study, vibration frequency was deemed the primary parameter of interest in evaluating the quality and efficiency of harvesting operations. Their test results showed that the optimal harvesting efficiency, approximately 85%, was attained at a frequency of 18 Hz and an approximate acceleration of 65 m/s2. Notably, under controlled laboratory conditions, the resonance frequency range of the stems of three-year-old cones was determined to be 18.0 ± 5.3 Hz. During field tests, the vibration duration was predominantly 6 s. Based on the provided graphical data, it can be inferred that it was necessary to reduce this time to mitigate potential damage to the trees. Consequently, the initial one to two seconds of vibration can be considered the optimal duration for tree vibration.

In another study, Castro-García et al. [93] conducted research aimed at analyzing the vibration process and optimizing mature pine cone harvesting efficiency. One of their primary objectives was to minimize potential damage to the stone pine trees during harvesting using a trunk shaker. The researchers analyzed several key parameters, including vibration intensity, mature pine cone harvest efficiency, tree damage due to branch loss, immature pine cones, and bark damage. In the field tests, a specially designed tree trunk shaker, typically used for olive harvesting, was attached to a tractor. This study employed methods similar to those described in previous research, utilizing a three-axis accelerometer to measure vibration intensity. The researchers concluded that to achieve maximum pine cone harvesting efficiency (85.7%), it is necessary to set the vibration frequency within the range of 16.1 to 18.9 Hz and the acceleration values at the trunk between 51.2 and 78.4 m/s2. Notably, the maximum removal of mature pine cones occurred within the initial seconds of vibration. Therefore, the optimal vibration time for harvesting was estimated to be less than 4 s. Furthermore, two short-period vibrations were found to impact cone harvesting productivity rates positively. Additionally, factors such as harvest timing and the machine operator’s skill played a crucial role in preventing damage to the tree.

In the Alcacer do Sal region of Portugal, umbrella pine cones are traditionally hand-harvested, but this labor-intensive method has led to increased production costs and a heightened risk of workplace accidents for the workers. Gonçalves et al. [85] investigated the efficiency of mechanical harvesting techniques using a tree trunk shaker mounted on the front loader of a four-wheel drive (4WD) agriculture tractor. The shaker, equipped with two hydraulic piston pumps, allowed the machine to operate both pumps simultaneously, enabling precise control over the frequency as it entered the Pinus pinea trees through a valve. On average, the time required to harvest pine cones for each tree was approximately 12 s, a significant improvement over manual harvesting times, averaging around 180 s (3 min) per tree. The vibration frequency generated by the first hydraulic pump was 17 Hz, whereas the frequency produced during the simultaneous operation of hydraulic pumps was 26 Hz. In the field tests, most of the vibration time (90%) was allocated to the frequency of 17 Hz, which was associated with the operation of the first pump operation. For testing purposes, tree diameters ranging from 10 to 70 cm were classified into six categories, with each diameter class increasing in 10 cm increments. The required vibration time was extended with an increase in the trunk diameter, starting from 9 s for trees in the 10–20 cm diameter class and increasing by approximately 1 s per diameter class increment up to 60–70 cm. This suggests that larger trees require longer vibration times. Interestingly, no significant differences were observed in harvesting efficiency by increasing the vibration time in both tested frequencies (17 and 26 Hz), indicating that a longer vibration time may not necessarily lead to improved yields. The results showed that the harvest efficiency exceeds 86%, with minimal damage to the bark and branches.

Polat et al. [86] developed a cost-effective harvesting system for fruit trees by mounting a trunk shaker on a tractor’s three-point linkage system. The study conducted field tests on pistachio trees with varying frequency and amplitude values, allowing a single operator to control both parameters simultaneously. The goal was to determine the optimal harvesting efficiency of pistachio trees with different frequencies (20, 30, and 40 Hz) and amplitudes (10, 15, and 20 mm). The test results revealed that the optimum pistachio harvesting efficiency (90%) is associated with a frequency of 40 Hz and an amplitude of 20 mm. The tree’s damage increased when higher frequencies or amplitudes were selected.

Several studies on nut tree harvesting have utilized a combination of computer simulations (modal analysis) and field tests. Before conducting experimental tests, Wei et al. [94] conducted a comprehensive study by employing modal analysis to determine the optimal vibration frequency range for pistachio trees. To validate the results, the researchers used computer simulations to optimize the pistachio tree trunk shaker parameters based on their findings. The optimization parameters and actual parameters are presented in Table 1. According to the test results, the optimal duration for the shaking period was found to be approximately 10 s. Notably, exceeding this duration may result in damage to the trees. The modal analysis further indicated that the most effective frequency range for the excitation force was between 10 and 18 Hz (optimal range). Ultimately, the optimal vibration parameters were determined to be a frequency of 18 Hz and a force amplitude of 3000 N, which yielded an exceptionally high harvesting efficiency of over 90%. Finally, the field tests identified 18 Hz as the optimal vibration frequency within the 10–18 Hz range, as it yielded the highest harvesting efficiency.

Table 1.

Optimal and actual parameters of the pistachio harvester [94].

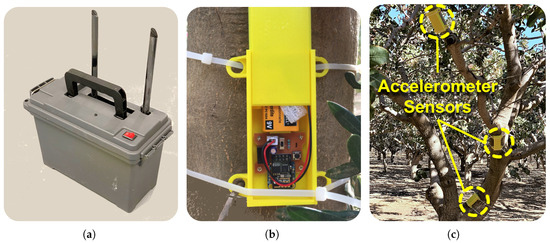

Homayouni et al. [15] investigated the effects of tree morphology and vibration parameters, including tree trunk size and shaking pattern, on energy distribution in pistachio trees. Their study also aimed to optimize the vibration intensity for efficient harvesting. The investigation focused on assessing the impact of each vibration pattern relative to the diameter of the tree trunks. A trunk shaker machine equipped with a central computer control system was utilized to conduct this research. Field tests were designed to determine the optimal frequency for pistachio harvesting using four different shaking patterns. To measure the acceleration transmitted through the tree, a comprehensive wireless 3D sensor system was employed, comprising a control unit, a wireless router, and multiple wireless sensors. During field trials, sensors were integrated into a wireless network hub and remotely activated for data collection at the highest sampling rate. Sensor activation was managed via a web browser on various devices connected to the local network. A Raspberry Pi hosted a local web server to streamline system configuration and communication, ensuring seamless interaction between devices and sensors. Figure 2 illustrates the overall process of the in-field experimental setup for the wireless sensor network. In this experiment, a sensor was affixed to the shaker head, while three additional sensors were installed along a single branch path on each tree. The final sensor was positioned adjacent to fruit clusters at the branch’s tip to capture localized data effectively. In their research, tree trunks were categorized into three distinct groups based on their diameter: small, medium, and large. The effect of all four shaking patterns was analyzed using a continuous wavelet transform, and the optimal shaking intensity was determined for each tree.

Figure 2.

Components of the wireless sensor system used for the field trials: (a) network hub unit comprising a router, Raspberry Pi, converter, and battery pack; (b) wireless accelerometer sensor system; (c) three wireless sensors mounted on the tree to capture vibration data [15].

In another interesting study, Ma et al. [8] investigated the effects of varying tree morphologies on acceleration changes in response to different vibration patterns. The research delved into mathematical modeling acceleration distribution and changes within tree canopies. To perform the field tests, an inertia-type tree trunk shaker mechanical harvester machine was employed, and three pistachio trees of differing sizes and shapes were selected for controlled shaking. It is essential to note that in these tests, the durations of each shaking pattern were all under 3 s. For the mentioned study, a wireless data collection system with substantial storage capacity was required. Consequently, a novel wireless sensor and data logger were specifically designed and constructed for this experiment. By using a third-order equation dependent on the lambda parameter (location index), they were able to compute the acceleration magnitude accurately. The analysis revealed that an increase in distance from the shaking clamps to the fruit zone had a significant damping effect on the vibration force. However, according to the computed results, it can be concluded that a larger pistachio tree requires more energy to harvest using an inertia-type trunk shaker. In the case of large trees, a substantial portion of the force applied to the tree trunk can be absorbed by the primary and secondary branches, with less shaking energy being transferred to the tertiary branch. Nevertheless, it is essential to note that increasing power or energy can cause damage to pistachio trees, and therefore, there will be a limit on the intensity of the applied vibration.

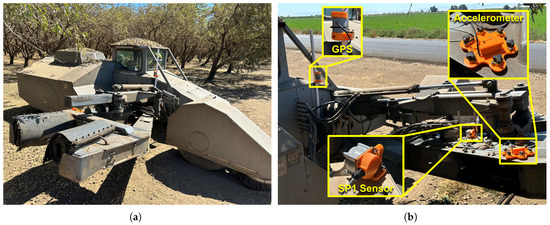

Operators typically rely on their experience to set shaking parameters, such as duration and frequency, during harvest. However, manual adjustments can lead to variability in fruit removal and, in some cases, may cause tree damage. In [91], researchers investigated the development of a data-driven mathematical model crucial for creating an intelligent tree shaker that autonomously optimizes shaking parameters. The Orchard-Rite BULLET trunk shaker machine utilizes a reverse scissor mechanism to securely grasp and shake the tree trunk, enabling stable and powerful vibrations that efficiently transfer kinetic energy from the shaker to both the trunk and the canopy. This design minimizes slippage and promotes a uniform distribution of force throughout the tree structure, which is vital for effective fruit removal. The researchers enhanced the sensor system by incorporating a linear position sensor to develop a robust, data-driven mathematical model. This upgrade enabled the simultaneous collection of GPS coordinates, acceleration data, and tree trunk size measurements. The SP1 linear position sensor used in the study was modified for easy mounting on the shaker head of an almond harvester. The sensor’s output was integrated with the system to record GPS-tagged acceleration data at each time interval. This setup allowed for real-time shaking data collection at a sampling rate of 250 per second. Furthermore, a sensor system was designed to monitor the force distribution throughout the tree canopy. By applying Thales’ theorem, the study developed a mathematical framework that converts measured distance values into accurate trunk diameters, as shown in Figure 3.

Figure 3.

Equipment and sensors utilized for data collection include (a) an Orchard-Rite BULLET shaker machine, (b) the designated sensor installation locations on the shaker [91].

Additionally, a quadratic machine learning regression model was created to estimate the relationships between trunk diameter, acceleration, and shaking duration. The results indicate a positive correlation between trunk diameter, acceleration, and shaking time duration. This research underscores the potential of intelligent harvesting machines that can adjust shaking parameters based on real-time sensor data, enhancing fruit removal efficiency while minimizing the risk of tree damage.

Tree Trunk Shaking Method Analysis

The previous section examined various approaches to mechanically harvesting nut trees through trunk shaking. The discussion centered on the technique of shaking the tree trunk and optimizing it for efficient fruit harvesting while minimizing the damage to the trees. A detailed comparison and an analysis of the methods explored were also presented.

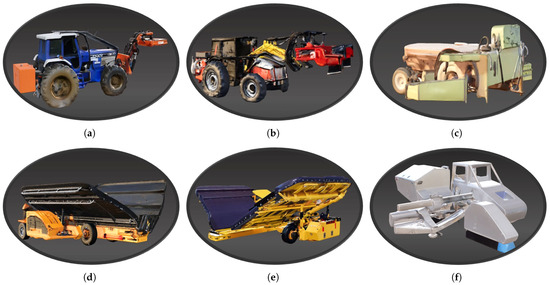

According to the reviewed studies, the method of “shaking” or vibrating the tree trunk appears to have a wide range of advantages and disadvantages compared to traditional manual hand-picking methods. One of the most important advantages is that shaking takes place in all parts of the tree simultaneously and improves the working speed of harvest compared to canopy and limb shaking methods. In this method, the attempt is to achieve maximum fruit harvest with minimal damage to the tree. Typically, the performance of these types of shakers heavily relies on the operator’s skills and efficiency during fruit harvesting [95,96]. However, because the operator must be able to recognize the exact frequency required and the duration of shaking the tree, piezoelectric accelerometers are usually employed to extract data [92,93]. Based on the studies conducted on tree trunk shaker machines, each investigation utilized a specific shaker model characterized by distinct features, as illustrated in Figure 4.

Figure 4.

Schematic of various trunk shaker machines employed in the studies: (a) a trunk shaker mounted on a tractor for stone pine tree harvesting [93]; (b) a trunk shaker mounted on the front loader for Pinus pinea cone harvesting [85]; (c) a body shaker mounted to a tractor’s three-point linkage system for pistachio mechanical harvesting [86]; (d) a hydraulically powered vibration device, driven by the tractor for harvesting pistachio trees [94]; (e) an inertia-type trunk shaker mechanical harvesting machine for pistachio tree shaking [8]; and (f) a trunk shaker machine utilizing a sophisticated reverse scissor mechanism for almond harvesting [91].

In order to maximize fruit harvesting efficiency while minimizing damage to the tree, various studies have calculated optimal values for shaking parameters, including frequency, amplitude, duration, and acceleration. Table 2 presents a summary of findings from various studies, detailing their respective shaking mechanisms and offering insights into the optimal settings for trunk shakers in harvesting operations. The amplitude was only reported in Polat et al. [86], which was 20 mm.

Table 2.

Shaking mechanisms and their key parameters for harvesting nut trees using trunk shakers, as documented in various studies.

As evident from Table 2, the research conducted by [85,92,93] focused on pine cone trees, while the studies by [8,15,86,94] explored the harvesting of pistachio trees. A closer examination reveals that the frequency values associated with harvesting pine cone trees show remarkable consistency across all three studies. This suggests that a frequency range of approximately 18 Hz could be considered optimal for shaking pine cone trees. However, the durations specified for this action vary significantly across the studies. Upon further analysis, this disparity in timing may be attributed to differences in human performance and perception among operators, who play a key role in determining the shaking frequency and duration. Alternatively, the variations could be explained by tree characteristics such as size, age, and species. As previously discussed, operators are entrusted with making critical decisions regarding treatment. Moreover, the varying locations where these studies were conducted may have contributed significantly to the diverse range of tree species encountered.

Regarding the harvesting of pistachio trees, research has yielded varying results concerning the optimal vibration frequency. Specifically, studies suggest that the most effective frequency falls around 18 Hz; however, a value of 40 Hz was reported by Polat et al. [86]. Furthermore, discrepancies exist in the reported shaking durations across different studies: Homayouni et al. [15] and Ma et al. [8] recommended a shaking duration of exactly 3 s, whereas Wei et al. [94] reported an average vibration time of 10 s. These variations could result from differences in operator performance during fruit harvesting or variations in tree age and species. Additionally, differences in the methods employed or variations in the type and size of the machines used for shaking trees are other significant factors influencing the duration and frequency of shaking. As examined in [91], the almond harvesting process employs relatively high acceleration values compared to pistachios and pine cones. Interestingly, the shaking duration is the shortest among the nut types listed in the table, suggesting that almonds may be easier to detach or require less mechanical effort. Finally, Figure 5 illustrates several of the most advanced trunk shaker machines, featuring various mechanisms, which are manufactured and widely used in the United States for harvesting nut trees.

Figure 5.

A selection of the most commonly used trunk shakers in the United States, showcasing a variety of operating mechanisms.

3.2. Canopy Shaker System

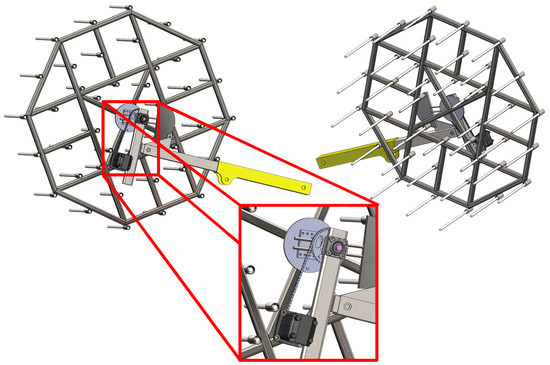

A canopy shaking system typically employs a vibrating device paired with reciprocating shaking rods or utilizing rods connected to an eccentric wheel to harvest the fruit efficiently. Notably, it can be generally stated that the design of various patterns of canopy shakers is directly linked to the characteristics of the fruit and the parameters of the tree crown during harvesting. It should be noted that despite being a highly efficient method for fruit harvesting, excessive shaking of the tree can result in significant leaf fall and damage to the fruits [18]. Research indicates two primary types of canopy shakers: firstly, the continuous canopy shaker with a catching frame, and secondly, the tractor-drawn canopy shaker [9]. Although this method was not reported to be used in the mechanical harvesting of nuts, many studies have used this method to harvest processing citrus, oil, and table olives [20,97]. Considering that nuts have two layers of hard and soft shells that protect the meat or kernel, they are great candidates for mechanical harvesting using canopy shakers. Figure 6 illustrates the canopy shaker designed and constructed by Homayouni et al. [20], which utilizes a crank-slider mechanism to drive the harvesting wheel in a back-and-forth motion for shaking trees.

Figure 6.

The canopy shaker employs a crank-slider mechanism to generate a back-and-forth motion for tree shaking [20].

Research on the canopy shaker began with an example by Sumner [98]. The investigation focused on examining the efficiency of the vertical canopy shaker method for harvesting Valencia oranges, with specific attention to its interaction with frequency, impact, and two shaking systems. The researchers built and tested a canopy shaker prototype test machine that vertically shook the secondary limbs of orange trees. This shaker was equipped with two separate drive systems: a hydraulic cylinder and a hydraulic crank that could adjust its motion over a range of 4–12 inches (10–30 cm) and a frequency of up to 5.833 Hz. The authors opened the mobile tines of the shaker machine to grasp the foliage as part of the harvesting process. They then closed it, allowing for efficient collection of the oranges. Furthermore, the shaker’s extension was made possible by utilizing a pantograph lift that enabled the machine to access higher branches. It is essential to acknowledge that the shaker’s oscillation maintained a consistent vertical direction throughout its operation.

3.3. Limb Shaker System

Manual shaking is the most basic approach for shaking tree limbs during fruit harvesting. This traditional approach can be quite challenging, time-consuming and labor-intensive. Consequently, it was necessary to develop a device that could reduce labor costs and the associated time spent in harvesting by utilizing vibrations to shake tree branches. According to the relevant studies, limb shakers typically employ a crank slider or unbalanced rotating mass mechanism to generate vibrational movements that facilitate efficient fruit collection [9]. When the limb shaker device is activated, it generates vibrations that trigger oscillations in both the primary and secondary branches of the tree. The limb shaking system enables fruit harvesting through individualized vibration stimulation of the branches but with relatively lower harvesting efficiency [18].

Polat et al. [99] used a hydraulic-powered inertial-type limb shaker connected to a tractor for mechanized pistachio harvesting. The mentioned limb shaker was previously designed and constructed by Erdoǧan et al. [100] specifically for harvesting apricot trees, which was mounted on a tractor. The main feature of this shaker device was that the frequency and amplitude range could be configured with the help of the hydraulic system’s flow control valve. Notably, the configuration with the optimal pistachio yield in this study did not inflict any damage on the bark of the trees. Another notable study on the mechanical harvesting of almonds was conducted by Polat, Güner, et al. [101]. This research investigated the effectiveness of a hydraulically powered, tractor-mounted inertia-type limb shaker. In this type of limb shaker, oil is forcibly pumped into the hydraulic motor to initiate the vibration of tree branches, producing a reciprocal motion that effectively dislodges the nuts from their stems.

Loghavi and Rahimi [102] investigated the effects of different shaking intensities and accelerations on pistachio nut and cluster removal using a tractor-mounted limb-shaking machine designed with adjustable vibration settings. They found that specific vibration conditions were highly effective in achieving optimal nut removal rates for pistachio, with high efficiencies observed for both nut and cluster separation under specific settings. Safdari et al. [103] designed, fabricated and evaluated a portable limb shaker for almond harvesting, which Adrian et al. [104] improved to calculate the necessary force, power, and torque. Their portable shaker, equipped with a sliding mechanism and rubber-padded clamps for tree protection, demonstrated high harvesting efficiency under specific vibration conditions while highlighting the risk of tree damage with increased vibration intensity and duration. Loghavi et al. [105] employed a manual limb shaker to explore the effects of adjustable vibration parameters on almond harvesting. Their study demonstrated that both frequency and amplitude significantly influenced yield and identified optimal conditions for efficient harvests within minimal timeframes. Rezaei et al. [106] evaluated a pneumatically actuated limb-shaking device for harvesting wild almonds (Amygdalus scoparia), achieving high fruit removal rates through optimized vibration settings, as confirmed by quantitative analyses using high-speed imaging. The study highlighted the superiority of mechanical methods over manual collection in terms of efficiency. Collectively, these studies underscore the importance of optimizing vibration parameters to maximize mechanical harvesting efficiency while minimizing damage to trees, providing valuable insights into the mechanized harvesting of pistachio and almond trees.

Tree Limb Shaking Method Analysis

In this section, we dig into the mechanical harvesting of nut trees using a limb shaker machine. Listed in Table 3 are approaches used mainly to harvest almond trees. The required shaking frequency for optimum harvesting was reported to be between 15 and 20 Hz with vibration amplitudes of 20 and 50 mm. In the study by Polat, Gezer et al. [99], which focuses on pistachio harvesting, the optimal shaking frequency corresponds to a specific resonance level. This frequency aligns with the range utilized during the gentle shaking of the tree trunk, falling within a narrow band of approximately 18 Hz. The required time is also determined to be 10 s, aligning with the tree trunk shaking technique described by Wei et al. [94].

Table 3.

Shaking mechanisms and their key parameters for harvesting nut trees using limb shakers, as documented in various studies.

According to Table 3, research on almond tree harvesting has primarily taken place in the past two decades. Interestingly, data suggest that trees exhibit optimal vibration at frequencies within a narrow band, specifically a narrow band centered around 16 Hz. Furthermore, it seems that harvesting can take place within a 5 to 10 s window with remarkable efficiency. However, the reported amplitudes are not identical across all studies reviewed. In research by [101,103,105], the shaking amplitude was reported to be 50 mm, while in the research by Loghavi et al. [105], it was reported as equal to 20 mm. The observed discrepancies can be attributed to differences in the mechanisms employed by various devices, as well as variations in trunk size and canopy coverage of almond trees. This table also provides a summary of the limb shaker machine mechanisms used for harvesting pistachio and almond trees, as reported in various studies. Given the variability in experimental conditions and locations, the impact of vibration amplitude and duration on fruit removal efficiency was evident. Increasing the amplitude from 20 mm in trunk shakers (Table 2) to 60 mm in limb shakers (Table 3) resulted in an improvement in harvest efficiency from 90% to 97%. The higher amplitude of the limb shaker is feasible due to the greater flexibility of branches compared to the trunk shaker.

3.4. Air Shaker System

According to recent studies, the method of using air shakers for harvesting has been given relatively less attention compared to other approaches for harvesting nut trees. This approach typically uses a big fan to produce high-speed air that shakes the canopy, facilitating fruit harvest [95]. The vibrational method of shaking the tree canopy to detach fruits by using air blowing was initially explored around the 1970s. In terms of the detailed components of an air vibration system, authors such as Pu et al. [18] have identified key components, including an air blower, vortex chamber, air plenum, air deflector, control panel, air outlet, air regulating valve, and other accessories. According to earlier research conducted by Jutras et al. [107], air shakers were first employed as an innovative method for harvesting oranges. The authors designed and built a specialized air blast shaker machine that utilized a uniaxial fan to release air through a rectangular outlet. The researchers incorporated vertical oscillating vanes within this outlet, whose placement angle could be adjusted according to specific requirements. These systems were successfully integrated into a trailer equipped with a pantograph mechanism, allowing farmers to harvest fruit from trees of varying heights efficiently.

3.5. Prototype Vibrator System

Several researchers utilized controlled laboratory methods to measure the frequency and amplitude of the impact on trees for harvesting fruit. In this approach, a small vibrating device with laboratory dimensions is typically employed, and the entire process of shaking and harvesting occurs in the laboratory rather than the orchard. Consequently, the dimensions of the testing equipment and measuring devices are smaller than their actual size. In this section, we will review the papers in this field related to the simulation of harvesting nut trees in the laboratory.

To investigate the magnitude of frequency and amplitude required to harvest almonds, a vibrating table powered by a variable-speed electric motor was used by Abdel–Fattah et al. [108]. In this study, a laser displacement device was employed to measure the vertical displacement of the vibrating table directly, and a shock recorder was utilized to collect data from accelerometers. More specifically, a three-axis accelerometer system was developed to estimate the frequency and amplitude of vibrations in almond tree trunks. The electric motor and cam were calibrated to achieve a maximum vertical displacement of around 2 mm at about 5 Hz frequency. During their laboratory experiments, they positioned the laser device at a fixed point on the edge of the table. The accelerometer was carefully attached in a vertical position at the same point. Furthermore, a base plate was securely attached to the vibrating clamp arm using epoxy to measure the accelerating forces accurately. They analyzed the results and found that the estimated frequency and amplitude in the horizontal plane were similar to the values previously reported for commercial trunk vibrators. However, they also observed a significant amplitude in the vertical direction, which may cause damage to the bark and roots of almond trees. The results obtained from this experiment revealed that most of the energy is concentrated in the x-direction, yet the dominant frequency of 14.6 Hz is present in all directions.

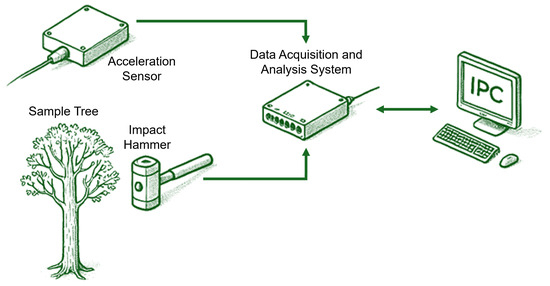

Xiaoqiang et al. [109] presented a new method for evaluating the dynamic characteristics of dwarf Chinese hickory trees and the effect of tree structure on the dynamic response. They analyzed responses at three resonance frequencies of 5, 9, and 12 Hz because the excitation bands were effective for the main part of the tree sample. Their results showed a strong relationship between vibration transmission patterns and the Chinese hickory tree’s structure. The team discovered that branch chain nodes usually hindered acceptable acceleration along the branch chains, which strongly depended on the branch chain configuration but not the crotch. According to the study’s findings, the impact excitations can be applied to nearly straight and uniform branches in the chain to optimize mechanical harvesting efficiency. Figure 7 illustrates a schematic representation of the test setup, encompassing the impact hammer and data acquisition system.

Figure 7.

Schematic representation of the test setup, encompassing the impact hammer and data acquisition system [109].

Du et al. [110] conducted an extensive study on the effective transmission of vibrational energy and enhanced vibrational harvesting efficiency using diverse excitation forces generated by various combinations of eccentric masses for harvesting Chinese hickory nuts. The researchers employed an inertia-type vibrating harvester to perform tests, which vibrated the target tree at a specific frequency and amplitude using the centrifugal force from rotating eccentric masses at high speeds. They developed a finite element model of a Chinese hickory tree using ANSYS to assess the dynamic response under different excitation frequencies. The researchers conducted harmonic response analysis to determine the steady-state responses for the mentioned models, finding that the maximum acceleration response occurred at an excitation frequency of about 22 Hz. They imported the flexible tree model into ADAMS through the data exchange function and applied various load scenarios to simulate responses to different eccentric mass combinations. The results showed that the average acceleration response exceeded 8.64 m/s2, demonstrating that the eccentric masses could uniformly vibrate tree branches in a three-dimensional manner, making them practical for vibrational harvesting.

According to Aragon-Rodriguez et al. [111], the artificial pollination of pistachios requires large amounts of pollen to enhance productivity, making manual labor economically feasible. In their laboratory study, the researchers investigated the dynamic behavior of male branches of “Peter” pistachio trees under controlled conditions. Using an electromagnetic shaker, they applied forced vertical vibrations to the branches and recorded the stem’s response with two piezoelectric accelerometers. The team analyzed various vibration frequencies to stimulate the branch and observed that the stem achieved the maximum transmissible acceleration values within specific frequency ranges: 8–13.5 Hz and 20.5–22 Hz. However, the stem dampened the incoming vibration when the frequency increased to 45 Hz. In contrast, the inflorescence exhibited an intensified response, amplifying its received vibration. Notably, they reported that within a frequency range of 54–59 Hz, the inflorescence amplified the received acceleration by approximately five times.

Cao et al. [112] designed and constructed a laboratory platform to conduct experiments to investigate the static separation force required for walnut harvesting. In these tests, they analyzed the kinetic models of stem–branch and stem–fruit interactions under various vibration modes by developing a vibration model. The vibration response was tested at a frequency of 10 Hz and an amplitude of 80 mm. This setup yielded the maximum separation ratio for inertial tension at the connection points and the maximum separation ratio for the bending moment of inertia. The study found that the harvesting difficulty under inertial bending force was significantly lower than that under inertial tension. To validate the laboratory findings, they conducted field vibration tests on walnut trees using a low-frequency canopy branch shaker on the farm. This shaker operated within a frequency range of 0 to 11 Hz and featured an adjustable amplitude from 20 to 80 mm.

3.6. Simulation

Simulation is the last method of fruit harvesting for nut trees that will be discussed briefly in this review. In this approach, specialized simulation software is typically employed to analyze the laboratory results to obtain the optimal frequency and amplitude of vibrations during harvesting. In another group of studies, by collecting field data and then simulating fruit harvest in the relevant software, a general comparison can be made between the simulation results and the field data to validate the simulation and use the simulation for further nondestructive analysis of fruit harvesting using shakers.

Based on a study by Xu et al. [113], hickory harvesting was improved by investigating the transmission of vibrational energy and simulating the vibration response of different magnitudes of excitation forces on a hickory tree model. They analyzed the results using finite element analysis software such as ANSYS and ADAMS. They selected a 10-year-old hickory tree as a model for analysis to simplify the process. The tree was divided into key points to facilitate the analysis. The harmonic response analysis revealed that applying a sinusoidal load to the hickory tree resulted in the best excitation frequency of 22 Hz, which produced the highest vibration response. In contrast, when the branches vibrated, the main branch showed a strong response, whereas the side branches exhibited small responses. Interestingly, when the tree trunk’s branching was excited, both the main and side branches demonstrated high response levels, with acceleration responses in each branch being remarkably close in value. However, the response in the trunk itself was low.

Prototype Vibrator and Simulation Method Analysis

Table 4 provides a comparative analysis of various parameter values employed in shaking nut trees using prototype vibrators or simulation methods. The data indicate that the preferred vibration frequency in the study by Xiaoqiang et al. [109] differs significantly from those reported in other studies on hickory tree shaking. This discrepancy likely arises from variations in the testing methodologies. Additionally, none of the studies explicitly reported the acceleration values used in their procedures.

Table 4.

Shaking mechanisms and their key parameters for harvesting nut trees using prototype vibrator systems and simulation methods.

4. Discussion

Two mechanical harvesting systems—tree trunk shaking and tree canopy shaking—can increase labor productivity by 5 to 15 times and reduce harvesting costs by 50% or more compared to manual harvesting methods [18,114]. Generally, trunk and canopy shakers are the most common mechanical harvesting systems used in orchards. Meanwhile, the limb-shaking system offers a unique feature for the selective harvesting of fruit products due to the different vibration characteristics of various branches and limbs in the tree canopy based on their age, stem water potential, and elasticity. Another advantage of mechanical harvesting over manual methods is the ability to access high points at the top of the tree canopy, which is difficult or unsafe for laborers to reach without machinery. The morphological characteristics of trees, the diverse structures of fruits, harvesting costs, growth patterns, and cultivation practices in the orchard are key factors in determining the appropriate types of mechanical systems for fruit harvesting. These key characteristics of the trees will help to select the appropriate vibration parameters such as frequency, amplitude, duration, and type of shaking methods for nut trees [96]. Along with tree damage, fruit damage must also be minimized, as mechanical damage to fruits during post-harvest handling significantly affects their quality, usability, and other factors [115].

Based on the research conducted by Sarkar [95], a harvesting machine must satisfy several critical conditions to achieve acceptable performance, including the following:

- It must be accepted by the consumer grower;

- It must meet the necessary safety standards;

- It should be economically viable and affordable for the consumer grower;

- Technically, it should be capable of performing the work efficiently;

- It should comply with the logistics processes of the harvesting operation;

- It should achieve the highest efficiency during operation while causing minimal product damage.

Orchard design is an important factor in utilizing harvesting machines. For maximum efficiency in fruit harvesting operations, nut trees in orchards should be cultivated in a manner that allows the mechanical equipment to cover the maximum area of fruit with minimal forward movement. Since factors such as dust, light conditions, ambient temperature, and other environmental elements significantly affect the performance of shaker machines in agricultural fields, it is crucial to select the most suitable harvesting model after carefully evaluating the environmental conditions and the advantages and disadvantages of various methods [95]. Designing the orchard environment and pruning the trees to suit the desired mechanical harvesting system results in increased productivity rates and improved performance of the harvesting machine [10,96].

Additionally, recent advancements in sensor technology, machine learning methods, and artificial intelligence enable the development of self-learning harvesting systems. By incorporating digital twins and AI-powered control algorithms, shaking parameters can be optimized continuously based on real-time orchard data. Moreover, the integration of IoT-enabled decision-making and autonomous robotic harvesters offers the potential to revolutionize mechanical harvesting, making it more energy-efficient and adaptive. Future research should focus on deploying reinforcement learning models that allow harvesters to refine their strategies with each operation, reducing fruit loss and minimizing damage. These technological innovations will be crucial for ensuring sustainable, high-precision nut harvesting in the coming decades.

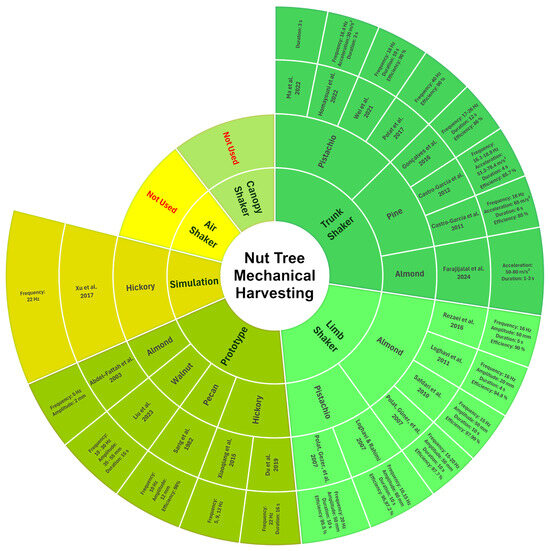

Figure 8 presents a summary of the mechanisms employed in all the studies reviewed in this paper on the mechanical harvesting of nut trees. This chart serves as a valuable resource for orchard managers and machine operators, providing a comprehensive overview of the performance of various harvesting methods. By analyzing key parameters such as shaking frequency, amplitude, duration, and fruit harvesting efficiency, stakeholders can make informed decisions in selecting the most suitable mechanical harvesting method for their operations.

Figure 8.

Infographic summarizing all studies reviewed in this paper on the mechanical harvesting of nut trees [8,15,77,79,85,86,91,92,93,94,99,101,102,103,105,106,108,109,110,113].

Generally, mechanical harvesting can cause injuries such as bark damage in trees at the attachment point, physical damage to the limbs, or root damage due to the vibration of the tree [116]. Fruit injury or bruises during the mechanical harvesting operation may result from detached fruit hitting the limbs inside the canopy while falling, striking the catch frame, or hitting other fruits during detachment, falling, or catching. It is necessary to mention that efficient and cost-effective mechanical harvesting is impossible without modifying the trees’ structure [9]. Table 5 outlines the pros and cons of the four methods discussed in this review, including the trunk shaking system, the limb-shaking system, the canopy-shaking system, and the air-shaking system. These assessments are deduced from various studies and are primarily applicable to the harvesting of nut trees.

Table 5.

A comprehensive analysis of different mechanical harvesting methods employed for nut trees.

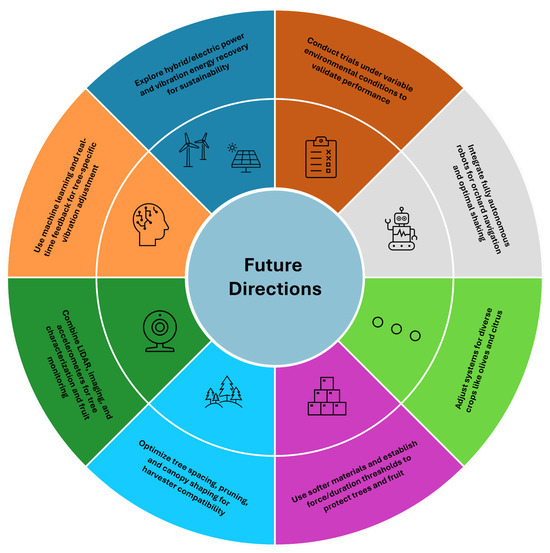

5. Future Research Opportunities and Challenges

While significant advancements have been made in mechanical harvesting systems for nut trees, several areas remain underexplored or require further refinement, as briefly explained in Figure 9.

Figure 9.

Numerous aspects of mechanical harvesting systems for nut trees remain unexplored or require further refinement.

Future research should focus on the following directions to enhance the efficiency, adaptability, and sustainability of these systems:

- Field Testing Under Variable Environmental Conditions: Conduct large-scale, multi-environmental trials to evaluate the performance and reliability of shaker machines under varying temperature, humidity, and dust conditions. These trials will also identify potential limitations and areas for improvement in real-world scenarios.

- Development of Adaptive Shaking Mechanisms: Future shaker designs should incorporate machine learning algorithms and real-time sensor feedback to adjust shaking parameters—frequency, amplitude, and duration—based on the unique physical characteristics of each tree. This can minimize damage while maximizing fruit detachment efficiency.

- Integration of Multimodal Sensing Technologies: Combining LiDAR, visual imaging, and accelerometer data could enable precise tree morphology characterization and real-time fruit detachment monitoring. Research should explore cost-effective implementations of these technologies in field conditions.

- Customizable Orchard Management Practices: Conduct studies on optimizing orchard layouts and tree training techniques (e.g., pruning and canopy shaping) to enhance compatibility with mechanical harvesters. This includes defining ideal tree spacing, growth height, and branch arrangements for various nut species.

- Energy-Efficient Harvesting Solutions: Investigate alternative power sources, such as hybrid or electric systems, to reduce fuel consumption and greenhouse gas emissions. Additionally, research into vibration energy harvesting systems could lead to the development of more eco-friendly technologies.

- Tree and Fruit Damage Mitigation: Develop and test innovative materials for contact surfaces, such as softer polymers or vibration-damping coatings, that reduce bark injury and fruit bruising during harvesting. Future work should also establish guidelines for optimal shaking force thresholds and shaking duration specific to each nut species.

- Expanding Applicability to Diverse Crops: While this paper focuses on nut trees, future studies could explore the adaptability of these mechanical systems for other high-value crops like olives, citrus, and coffee. This would involve adjustments to shaking mechanisms and control algorithms to suit different fruiting characteristics.

- Automation and Robotics Integration: Incorporating fully autonomous robotic systems capable of navigating orchards, identifying target trees, and executing optimal shaking patterns without human intervention represents a transformative goal for future harvesting practices.

To achieve the highest efficiency in the performance of shaker machines for fruit harvesting in the future, researchers should consider some important challenges in their research and development studies [130]:

- Simplifying the functionality and user-friendliness of the machine during fruit harvest operations.

- Overcoming the complexity of the orchard environment that makes it challenging for sensors and algorithms to deploy in real-time, as well as for designing resilient systems to withstand weather conditions and adaptable mechanisms for various cultivars.

- Establishing standardized metrics for measuring harvester performance, such as fruit detachment efficiency (%) and tree damage rates (e.g., % bark injury per harvest cycle), and using these metrics to benchmark current technologies.

- Making a versatile machine or method to harvest across diverse orchard layouts and environmental conditions to ensure broad applicability.

6. Conclusions

In this review, we initially discuss and investigate the characteristics of types of fruit and nut trees. This includes the tree shape, nut shape, and benefits of nuts. These factors are considered in relation to their harvesting by conventional mechanical methods. Subsequently, the history, technical characteristics, and performance of mechanical harvesting systems, which other researchers have investigated in recent decades for shaking nut trees, were reviewed. According to the research conducted, accurately estimating the optimum values of key vibration parameters, such as vibration frequency, amplitude, and duration, can ultimately lead to maximizing fruit harvests, reducing costs, and minimizing damage to the trees. By carefully reviewing past research on the mechanical harvesting of nut trees, the following findings are ultimately obtained:

- Since the accurate estimation of the frequency, amplitude, and duration of tree vibration during mechanical harvesting significantly affects the rate of fruit harvesting, establishing a relationship between these parameters and the morphological characteristics of trees, such as tree diameter, height, and canopy shape, can improve the harvesting operation. The findings indicate that as the tree’s diameter increases, the needed acceleration to shake the tree and the time required for the trees to vibrate increase. Data-driven models are the best approach to finding the optimal shaking parameters.

- Recent advancements in sensor technology, machine learning methods, and artificial intelligence enable us to develop the next generation of intelligent machines. To reduce the costs of fruit harvesting, efforts should be made to minimize the use of human labor as much as possible during the harvesting process. At present, operators’ skills determine the duration of shaking amplitude, frequency, and duration, which remain consistent for all trees. The scarcity of experienced operators who can achieve maximum fruit removal with minimal damage poses a significant challenge for growers. There is a pressing need to make existing machines smarter, allowing them to adjust shaking parameters autonomously. To achieve this, designing and manufacturing an automatic harvesting machine equipped with advanced sensors and image processing capabilities, which can accurately estimate the necessary vibration parameters for each tree, will be crucial. It is possible to mathematically determine a unique optimal shaking frequency for each tree to maximize fruit removal and minimize damage. Theoretically, the maximum displacement of a tree occurs at its natural frequency, using the least amount of energy. However, each tree has a slightly different natural frequency, influenced by its size and branch arrangement, and shaking trees at incorrect frequencies can cause significant damage. The findings of this study, including the optimal parameters, sensors, and control systems, will pave the way for the development of advanced intelligent harvesting machines. Notably, further research is needed to verify the model’s effectiveness across various nut tree varieties. Additionally, modifications to the control units of existing shakers are necessary to enable automatic adjustments of shaking patterns based on trunk size, thus eliminating the need for operator manual programming.

While this review has summarized the key findings and technological advancements in mechanical harvesting, it is crucial to explore the Future Research Opportunities and Challenges section to comprehensively understand the challenges and opportunities that lie ahead. This section outlines innovative research pathways, including integrating artificial intelligence, advanced sensor technologies, and data-driven methods, to enhance the efficiency, adaptability, and sustainability of nut harvesting systems.

Author Contributions

Conceptualization, M.F. and R.E.; Methodology, M.F., C.M. and M.M.; Investigation, M.F., C.M. and A.A.; Writing—original draft preparation, M.F. and C.M.; Writing—review and editing, A.A., M.M., A.T., A.K. and C.M.; Visualization, M.F., A.A., M.M. and A.K.; Supervision, M.M. and A.T.; Project administration, R.E.; funding acquisition, R.E. All authors have read and agreed to the published version of the manuscript.

Funding

This publication was prepared with the support of a financial assistance award approved by the Economic Development Administration Build Back Better Regional Challenge, Farms Food Future (F3) Innovation, and partial support from NSF and AgAID Institute (Agricultural AI for Transforming Workforce and Decision Support) is supported by the USDA-NIFA award No. 2021-67021-35344, under the National AI Research Institutes program.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| 4WD | Four Wheel Drive |

| ADAMS | Automated Dynamic Analysis of Mechanical Systems |

| ANSYS | Analysis System |

| BD | Branch Diameter |

| CD | Crown Diameter |

| CW | Crown Width |

| D | Tree Diameter |

| F3 | Farms Food Future |

| FDF | Fruit Detachment Force |

| GPS | Global Positioning System |

| H | Tree Height |

| Hz | Hertz |

| LiDAR | Light Detection and Ranging |

| NSF | National Sanitation Foundation |

| SWP | Stem Water Potential |

| USDA | United States Department of Agriculture |

References

- Alizadeh, A.; Mortazavi, M.; Farajijalal, M.; Toudeshki, A.; Ehsani, R.; Singhal, M. Enhancing Irrigation Efficiency with a Unified Stochastic Decision Tree Model: Predictive Analysis of Stem Water Potential in Almond and Pistachio Orchards. In Proceedings of the World Congress in Computer Science, Computer Engineering & Applied Computing, Las Vegas, NV, USA, 22–25 July 2024; Springer: Cham, Switzerland, 2024; pp. 499–515. [Google Scholar] [CrossRef]

- Cirhigiri, G.C. Qualitative Assessment of Windfall Almonds (Prunus dulcis) in California; University of California: Davis, CA, USA, 2022. [Google Scholar]

- Goodhue, R.E.; Martin, P.; Simon, L.K. California’s Fruits and Tree Nuts. In California Agriculture: Dimensions and Issues; University of California Giannini Foundation of Agricultural Economics Information Series; Giannini Foundation of Agricultural Economics: Davis, CA, USA, 2018. [Google Scholar]

- Perez, A.; Plattner, K. Fruit and Tree Nuts Outlook: Economic Insight 2012 Census of Agriculture: Overview of Fruit and Tree Nut Sector; USDA/ERS Publication FTS-359SA; U.S. Department of Agriculture: Albany, CA, USA, 2015. [Google Scholar]

- Baur, P.; Iles, A. Replacing humans with machines: A historical look at technology politics in California agriculture. Agric. Hum. Values 2023, 40, 113–140. [Google Scholar]

- Kelly, C.F. Mechanical harvesting. Sci. Am. 1967, 217, 50–59. [Google Scholar] [CrossRef]

- Luedeling, E.; Zhang, M.; Girvetz, E.H. Climatic changes lead to declining winter chill for fruit and nut trees in California during 1950–2099. PLoS ONE 2009, 4, e6166. [Google Scholar]

- Ma, R.; Homayouni, T.; Toudeshki, A.; Ehsani, R.; Zhang, X. An Experimental Study and Mathematical Modeling of Vibration Transfer in Pistachio Trees Using an Inertia-Type Trunk Shaker and Field-Adapted Wireless Sensors. Shock Vib. 2022, 2022, 9966848. [Google Scholar] [CrossRef]

- Afsah-Hejri, L.; Homayouni, T.; Toudeshki, A.; Ehsani, R.; Ferguson, L.; Castro-García, S. Mechanical harvesting of selected temperate and tropical fruit and nut trees. Hortic. Rev. 2022, 49, 171–242. [Google Scholar]

- Ferguson, L.; Glozer, K.; Reyes, H.; Rosa, U.; Castro-Garcia, S. Evaluating California pistachio trunk shaking harvesters. Acta Hort. (ISHS) 2014, 1028, 377–380. [Google Scholar] [CrossRef]

- Liu, T.H.; Ehsani, R.; Toudeshki, A.; Zou, X.J.; Wang, H.J. Experimental study of vibrational acceleration spread and comparison using three citrus canopy shaker shaking tines. Shock Vib. 2017, 2017, 9827926. [Google Scholar] [CrossRef]

- Pu, Y.; Toudeshki, A.; Ehsani, R.; Yang, F. Design and evaluation of a two-section canopy shaker with variable frequency for mechanical harvesting of citrus. Int. J. Agric. Biol. Eng. 2018, 11, 77–87. [Google Scholar] [CrossRef]

- Liu, T.H.; Ehsani, R.; Toudeshki, A.; Abbas, M.; Zou, X.J. Shaking functionality evaluation of four different types of citrus canopy-shaker tines. Appl. Eng. Agric. 2018, 34, 809–817. [Google Scholar]