Evapotranspiration-Based Irrigation Management Effects on Yield and Water Productivity of Summer Cauliflower on the California Central Coast

Abstract

1. Introduction

2. Materials and Methods

2.1. Field Experiment

2.2. Irrigation Treatments

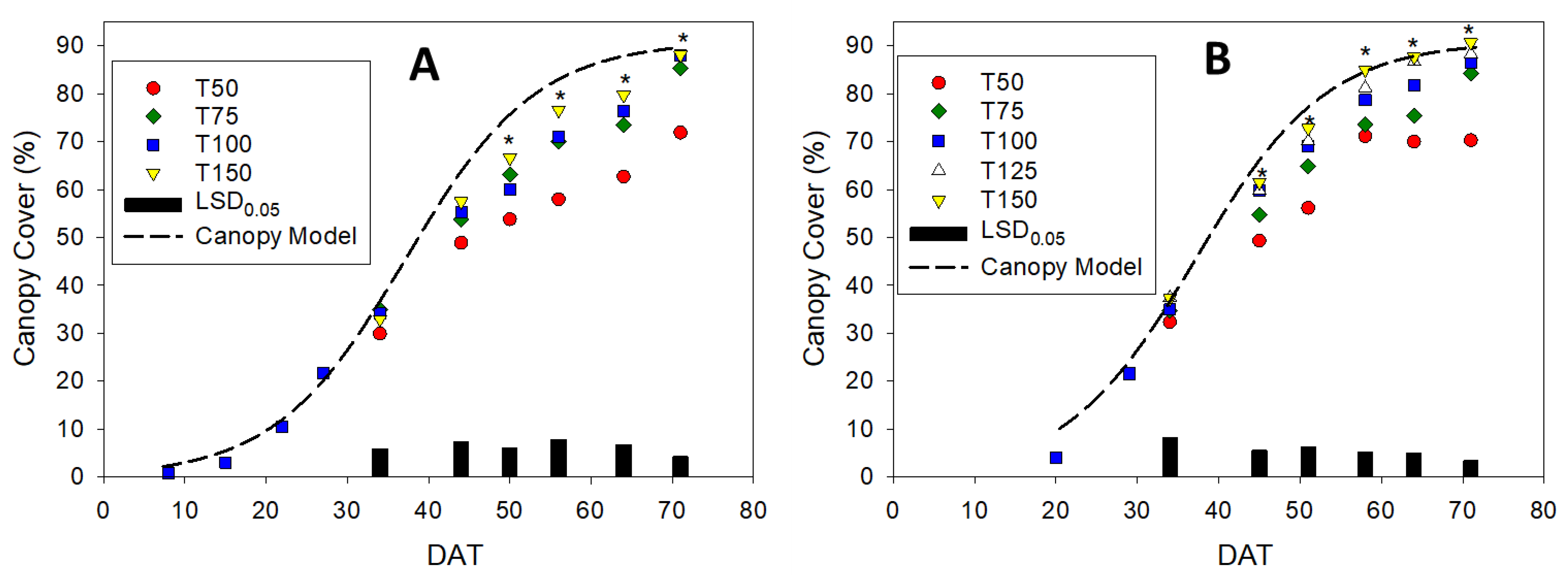

2.3. ETc Model

2.4. Field Measurements

2.5. Water Productivity, N Uptake, and Statistical Analysis

3. Results

3.1. Applied Water Volumes and Soil Moisture Tension

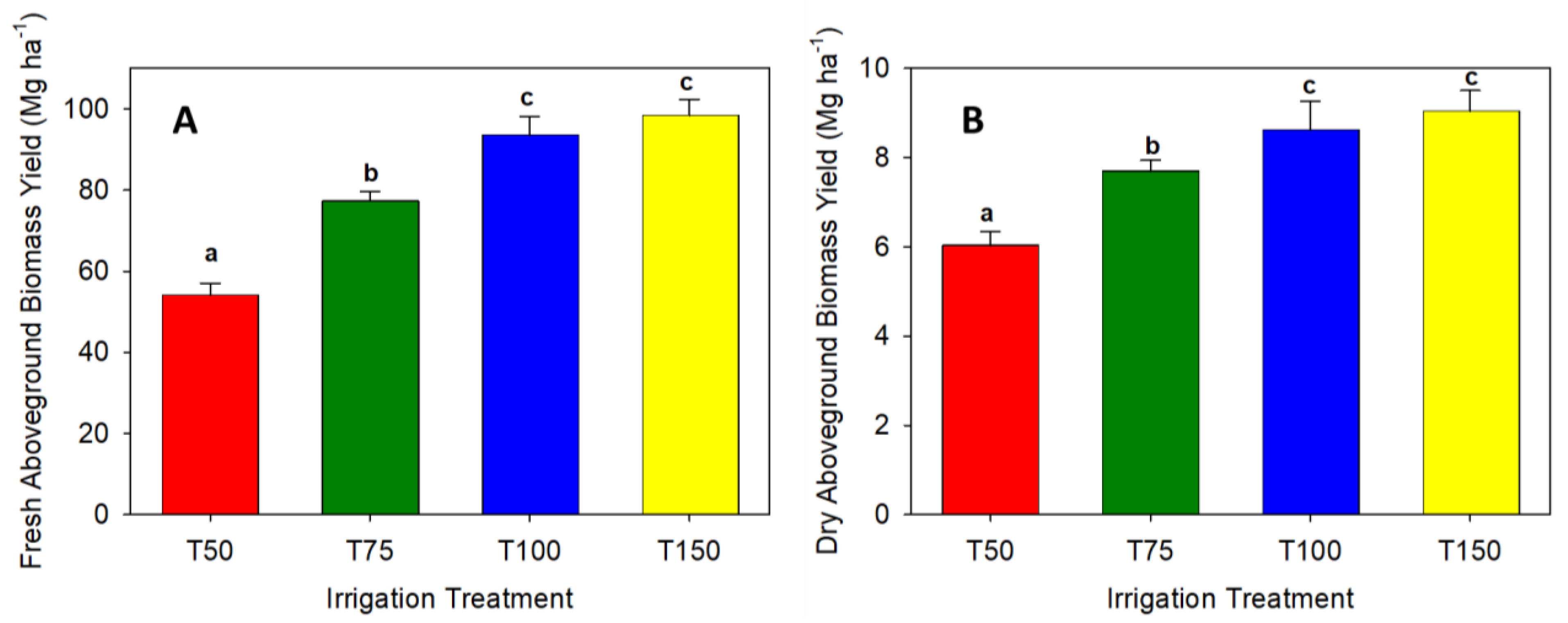

3.2. Treatment Effects on Crop Development and Yield

3.3. Irrigation Water Productivity

3.4. Nitrogen Uptake and Fertilizer N Recovery

4. Discussion

4.1. Crop Response to Irrigation Treatments

4.2. Potential Water Reduction Following ET-Based Irrigation Scheduling Guidance

4.3. Soil Moisture Monitoring

4.4. Adoption of ET-Based Irrigation Scheduling

4.5. Quality Considerations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Harter, T.; Lund, J. Addressing Nitrate in California’s Drinking Water with a Focus on Tulare Lake Basin and Salinas Valley Groundwater; Groundwater Nitrate Project, Implementation of Senate Bill X2 1; Center for Watershed Sciences, University of California: Davis, CA, USA, 2012; p. 92. Available online: https://ucanr.edu/sites/groundwaternitrate/files/138956.pdf (accessed on 21 February 2025).

- CCRWQCB (Central Coast Regional Water Quality Control Board). General Waste Discharge Requirements for Discharges from Irrigated Lands. 2021. Available online: https://www.waterboards.ca.gov/centralcoast/board_decisions/adopted_orders/2021/ao4_order.pdf (accessed on 21 February 2025).

- MCWRA (Monterey County Water Resources Agency). Recommendations to Address the Expansion of Seawater Intrusion in the Salinas Valley Groundwater Basin. 2020. Available online: https://svbgsa.org/wp-content/uploads/2020/08/2020_MCWRA_RecommendationsRpt2020Update.pdf (accessed on 21 February 2025).

- Fulton, A.; Munk, D. Irrigation and Nitrogen Management. University of California, Division of Agriculture and Natural Resources, 2019. Available online: http://ciwr.ucanr.edu/files/300671.pdf (accessed on 21 February 2025).

- Hussain, M.; Abd-Elhamid, H.; Javadi, A.; Sherif, M. Management of seawater intrusion into coastal aquifers: A review. Water 2019, 11, 2467. [Google Scholar] [CrossRef]

- Koike, S.; Cahn, M.; Cantwell, M.; Fennimore, S.; LeStrange, M.; Natwick, E.; Smith, R.; Takele, E. Cauliflower Production in California. UCANR Publication 7219. Regents of the University of California, 2009. Available online: https://anrcatalog.ucanr.edu/pdf/7219.pdf (accessed on 21 February 2025).

- MCACO (Monterey County Agricultural Commissioner’s Office). 2019 Monterey County Crop Report. 2019. Available online: https://www.co.monterey.ca.us/home/showdocument?id=92362 (accessed on 21 February 2025).

- USDA (United States Department of Agriculture) National Agricultural Statistics Service. Vegetables 2019 Summary. 2020. Available online: https://www.nass.usda.gov/Publications/Todays_Reports/reports/vegean20.pdf (accessed on 21 February 2025).

- Allen, R.; Pereira, L.; Raes, D.; Smith, M. Crop Evapotranspiration: Guidelines for Computing Crop Water Requirements; FAO Irrigation and Drainage Paper #56; U.N. Food & Agriculture Organization: Rome, Italy, 1998; Available online: https://www.fao.org/3/X0490E/X0490E00.htm (accessed on 21 February 2025).

- Pereira, L.; Paredes, P.; Lopez-Urrea, R.; Hunsaker, D.; Mota, M.; Shad, Z. Standard single and basal crop coefficients for vegetable crops, an update of FAO56 crop water requirements approach. Agric. Water Manag. 2021, 243, 106196. [Google Scholar] [CrossRef]

- Trout, T.; Gartung, G. Use of crop canopy size to estimate crop coefficients for vegetable crops. In Proceedings of the ASCE World Environmental & Water Resource Congress, Omaha, NE, USA, 21–25 May 2006; Volume 200, pp. 297–303. [Google Scholar] [CrossRef]

- Sahin, U.; Kuslu, Y.; Tunc, T.; Kiziloglu, F. Determining crop and pan coefficients for cauliflower and red cabbage crops under cool season semiarid climatic conditions. Agric. Sci. China 2009, 8, 167–171. [Google Scholar] [CrossRef]

- Andrean, A.; Rezende, R.; Vila, V.; Silva, L.; Wenneck, G. Determination of evapotranspiration and crop coefficient for cauliflower at Paraná northwest region. Colloq. Agrar. 2021, 17, 79–86. [Google Scholar] [CrossRef]

- Okasha, A.; Deraz, N.; Elmetwalli, A.; Elsayed, S.; Falah, M.; Farooque, A.; Yaseen, Z. Effects of irrigation method and water flow rate on irrigation performance, soil salinity, yield, and water productivity of cauliflower. Agriculture 2022, 12, 1164. [Google Scholar] [CrossRef]

- Sengupta, S.; Patra, S.; Laha, A.; Poddar, R.; Bhattacharyya, K.; Dey, P.; Mandal, J. Replacing conventional surface irrigation with micro-irrigation in vegetables can alleviate arsenic toxicity and improve water productivity. Groundw. Sustain. Dev. 2023, 23, 101012. [Google Scholar] [CrossRef]

- Sarkar, S.; Biswas, M.; Goswami, S.; Bandyopadhyay, P. Yield and water use efficiency of cauliflower under varying irrigation frequencies and water application methods in Lower Gangetic Plain of India. Agric. Water Manag. 2010, 97, 1655–1662. [Google Scholar] [CrossRef]

- Abdelkhalik, A.; Pascual, B.; Nájera, I.; Baixauli, C.; Pascual-Seva, N. Deficit irrigation as a sustainable practice in improving irrigation water use efficiency in cauliflower under Mediterranean conditions. Agronomy 2019, 9, 732. [Google Scholar] [CrossRef]

- Silva, M.; Costa, L.; Soares, T.; Gheyi, H. Growth and yield of cauliflower with brackish waters under hydroponic conditions. Rev. Bras. Eng. Agric. Ambient. 2023, 27, 663–672. [Google Scholar] [CrossRef]

- Sanchez, C.; Roth, R.; Gardner, B.; Ayer, H. Economic responses of broccoli and cauliflower to water and nitrogen in the desert. HortScience 1996, 31, 201–205. [Google Scholar] [CrossRef]

- Thompson, T.; Doerge, T.; Godin, K. Nitrogen and water interactions in subsurface drip-irrigated cauliflower: I. Plant Response. Soil Sci. Soc. Am. J. 2000, 64, 406–411. [Google Scholar] [CrossRef]

- Kapoor, R.; Sandal, S.; Sharma, S.; Kumar, A.; Saroch, K. Effect of varying drip irrigation levels and NPK fertigation on soil water dynamics, productivity and water use efficiency of cauliflower (Brassica oleracea var. botrytis) in wet temperate zone of Himachal Pradesh. Indian J. Soil Cons. 2014, 42, 249–254. [Google Scholar]

- Oliveira, R.; Oliveira, R.; Vidigal, S.; Oliveira, E.; Guimarães, L.; Cecon, P. Production and water yield of cauliflower under irrigation depths and nitrogen doses. Rev. Bras. Eng. Agríc. Ambient. 2019, 23, 561–565. [Google Scholar] [CrossRef]

- Smith, R.; Cahn, M.; Hartz, T.; Love, P.; Farrara, B. Nitrogen dynamics of cole crop production: Implications for fertility management and environmental protection. HortScience 2016, 51, 1586–1591. [Google Scholar] [CrossRef]

- Locascio, S. Management of irrigation for vegetables: Past, present, and future. HortTechnology 2005, 15, 482–485. [Google Scholar] [CrossRef]

- Cahn, M.; Johnson, L. New approaches to irrigation scheduling of vegetables. Special issue: Refining irrigation strategies in horticultural production. Horticulturae 2017, 3, 28. [Google Scholar] [CrossRef]

- Cahn, M.; Smith, R.; Hartz, T.; Farrara, B.; Johnson, L.; Melton, F. Irrigation and nitrogen management decision support tool for cool season vegetables and berries. In Proceedings of the USCID Water Management Semi-Annual Conference, Sacramento, CA, USA, 4–7 March 2014; U.S. Committee on Irrigation and Drainage: Denver, CO, USA, 2014; pp. 53–64. Available online: https://www.uscid.org/_files/ugd/43071b_a49bf4c836a44403a8d30cd8c6b0882c.pdf (accessed on 21 February 2025).

- Johnson, L.; Cahn, M.; Martin, F.; Melton, F.; Benzen, S.; Farrara, B.; Post, K. Evapotranspiration-based irrigation scheduling of head lettuce and broccoli. Hortscience 2016, 51, 935–940. [Google Scholar] [CrossRef]

- Johnson, L.; Cahn, M.; Benzen, S.; Zaragoza, I.; Murphy, L.; Lockhart, T.; Melton, F. ET-based Irrigation Management in Leaf Lettuce and Cabbage: Results from 2015 Trials. In Proceedings of the USCID Water Management Conference, U.S. Committee on Irrigation & Drainage, San Diego, CA, USA, 17–20 May 2016; pp. 81–86. Available online: https://www.uscid.org/_files/ugd/43071b_d8aed129c4224ee09471291096695bb5.pdf (accessed on 27 January 2025).

- Cahn, M.; Johnson, L.; Benzen, S.; Qin, Z.; Chambers, D. Optimizing water management in celery using weather-based scheduling. In Proceedings of the American Society for Horticultural Science Annual Conference, Las Vegas, NV, USA, 21–25 July 2019; Available online: https://ashs.confex.com/ashs/2019/meetingapp.cgi/Paper/30407 (accessed on 21 February 2025).

- University of California Cooperative Extension, Division of Agriculture and Natural Resources. CropManage. Available online: https://cropmanage.ucanr.edu (accessed on 2 February 2025).

- Snyder, R.; Lanini, B.; Shaw, D.; Pruitt, W. Using Reference Evapotranspiration and Crop Coefficients to Estimate Crop Evapotranspiration for Agronomic Crops, Grasses, and Vegetable Crops. UCANR Publication 21427; Regents of the University of California, 1994. Available online: https://cimis.water.ca.gov/Content/PDF/21427-KcAgronomicGrassandVeg.pdf (accessed on 27 January 2025).

- Allen, R.; Pereira, L. Estimating crop coefficients from fraction of ground cover and height. Irrig. Sci. 2009, 28, 17–34. [Google Scholar] [CrossRef]

- Bryla, D.; Trout, T.; Ayars, J. Weighing lysimeters for developing crop coefficients and efficient irrigation practices for vegetable crops. HortScience 2010, 45, 1597–1604. [Google Scholar] [CrossRef]

- Pereira, L.; Paredes, P.; Melton, F.; Johnson, L.; Wang, T.; Lopez-Urrea, R.; Cancela, J.; Allen, R. Prediction of crop coefficients from fraction of ground cover and height: Background and validation using ground and remote sensing data. Agric. Water Manag. 2020, 241, 106197. [Google Scholar] [CrossRef]

- Melton, F.; Johnson, L.; Lund, C.; Pierce, L.; Michaelis, A.; Hiatt, S.; Guzman, A.; Adhikari, D.; Purdy, A.; Rosevelt, C.; et al. Satellite Irrigation Management Support with the Terrestrial Observation and Prediction System. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2012, 5, 1709–1721. [Google Scholar] [CrossRef]

- Gallardo, M.; Snyder, R.; Schulbach, K.; Jackson, L. Crop growth and water use model for lettuce. J. Irrig. Drain. Eng. 1996, 6, 354–359. [Google Scholar] [CrossRef]

- Temesgen, B.; Eching, S.; Davidoff, B.; Frame, K. Comparison of some reference evapotranspiration equations for California. J. Irrig. Drain. Eng. 2005, 131, 73–84. [Google Scholar] [CrossRef]

- Hart, Q.; Brugnach, M.; Temesgen, B.; Rueda, C.; Ustin, S.; Frame, K. Daily reference evapotranspiration for California using satellite imagery and weather station measurement interpolation. Civ. Eng. Environ. Syst. 2009, 26, 19–33. [Google Scholar] [CrossRef]

- Gallardo, M.; Jackson, L.; Schulbach, K.; Snyder, R.; Thompson, R.; Wyland, L. Production and water use in lettuce under variable water. Irrig. Sci. 1996, 16, 125–137. [Google Scholar] [CrossRef]

- Cahn, M.; Johnson, L.; Benzen, S. Evapotranspiration based irrigation trials examine water requirement, nitrogen use, and yield of romaine lettuce in the Salinas Valley. Horticulturae 2022, 8, 857. [Google Scholar] [CrossRef]

- Cahn, M.; Melton, F.; Smith, R. Field evaluations of the CropManage decision support tool for improving irrigation and nutrient use of cool season vegetables in California. Agric. Water Manag. 2023, 287, 108401. [Google Scholar] [CrossRef]

- Breschini, S.; Hartz, T. Presidedress soil nitrate testing reduces nitrogen fertilizer use and nitrate leaching hazard in lettuce production. HortScience 2002, 37, 1061–1064. [Google Scholar] [CrossRef]

- USDA (United States Department of Agriculture). United States Standards for Grades of Cauliflower, Issue 82-FR-24095. USDA Agricultural Marketing Service, 2017. Available online: https://www.ams.usda.gov/sites/default/files/media/CauliflowerStandard.pdf (accessed on 27 January 2025).

- AOAC Official Method 972.43. Microchemical Determination of Carbon, Hydrogen, and Nitrogen, Automated Method. In Official Methods of Analysis of AOAC International, 18th ed.; Revision 1, Chapter 12; AOAC International: Gaithersburg, MD, USA, 2006; pp. 5–6. Available online: http://www.aoacofficialmethod.org/index.php?main_page=product_info&cPath=1&products_id=1492 (accessed on 21 February 2025).

- MCACO (Monterey County Agricultural Commissioner’s Office). 2018 Monterey County Crop Report. 2018. Available online: https://www.co.monterey.ca.us/home/showpublisheddocument/78579 (accessed on 21 February 2025).

- Thompson, T.; Doerge, T.; Godin, K. Nitrogen and water interactions in subsurface drip-irrigated cauliflower: II. Agronomic, economic, and environmental outcomes. Soil Sci. Soc. Am. J. 2000, 64, 412–418. [Google Scholar] [CrossRef]

- Bozkurt, S.; Uygur, V.; Agca, N.; Yalcin, M. Yield responses of cauliflower (Brassica oleracea L. var. Botrytis) to different water and nitrogen levels in a Mediterranean coastal area. Acta Agric. Scand. Sect. B—Soil Plant Sci. 2011, 61, 183–194. [Google Scholar] [CrossRef]

- Yanglem, S.D.; Tumbare, A.D. Influence of irrigation regimes and fertigation levels on yield and physiological parameters in cauliflower. Bioscan 2014, 9, 589–594. Available online: https://thebioscan.com/index.php/pub/article/view/694/661 (accessed on 8 February 2025).

- Kumari, P.; Bara, A.D.; Kumar, M.; Job, M.; Rai, P. Crop water requirement and water use efficiency of cauliflower under mulching and drip irrigation in eastern plateau hills region of Jharkhand. Progress. Hortic. 2020, 52, 81–87. [Google Scholar] [CrossRef]

- Subhan, F.; Malik, A.; Haq, Z.U.; Khalil, T.M. Effect of deficit irrigation under different furrow irrigation techniques on cauliflower yield and water productivity in Mardan, Pakistan. Sarhad J. Agric. 2021, 37, 868–876. [Google Scholar] [CrossRef]

- Kaniszewski, S.; Rumpel, J. Effects of irrigation nitrogen fertilization and soil type on yield quality of cauliflower. J. Veg. Crop Prod. 1998, 4, 67–75. [Google Scholar] [CrossRef]

- Zavadil, J. Optimisation of irrigation regime for early potatoes, late cauliflower, early cabbage and celery. Soil Water Res. 2006, 1, 139–152. Available online: http://swr.agriculturejournals.cz/pdfs/swr/2006/04/03.pdf (accessed on 21 February 2025). [CrossRef]

- USDA (United States Department of Agriculture) National Agriculture Statistics Service. Census of Agriculture: 2023 Irrigation and Water Management Survey. Table 25. Methods Used in Deciding When to Irrigate; 2023. Available online: https://www.nass.usda.gov/Publications/AgCensus/2022/Online_Resources/Farm_and_Ranch_Irrigation_Survey/fris_1_025_025.pdf (accessed on 21 February 2025).

- Gallardo, M.; Antonio, E.; Thompson, R.B. Decision support systems and models for aiding irrigation and nutrient management of vegetable crops. Agric. Water Manag. 2020, 240, 106209. [Google Scholar] [CrossRef]

- Gallardo, M.; Fernández, M.D.; Giménez, C.; Padilla, F.M.; Thompson, R.B. Revised VegSyst model to calculate dry matter production, critical N uptake and ETc of several vegetable species grown in Mediterranean greenhouses. Agric. Syst. 2016, 146, 30–43. [Google Scholar] [CrossRef]

- Mannini, P.; Genovesi, R.; Letterio, T. IRRINET: Large scale DSS application for on farm irrigation scheduling. Procedia Environ. Sci. 2013, 19, 823–829. [Google Scholar] [CrossRef]

- Olberz, M.; Kahlen, K.; Zinkernage, J. Assessing the impact of reference evapotranspiration models on decision support systems for irrigation. Horticulturae 2018, 4, 49. [Google Scholar] [CrossRef]

- Washington State University Irrigation Scheduler Mobile. Available online: http://weather.wsu.edu/ism/ (accessed on 23 February 2025).

- Leib, B.G.; Elliott, T.V. Washington Irrigation Scheduling Expert (WISE) Software. In National Irrigation Symposium, Proceedings of the 4th Decennial Symposium, Phoenix, AZ, USA, 14–16 November 2000; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2000; pp. 540–548. [Google Scholar]

- Bartlett, A.C.; Andales, A.A.; Arabi, M.; Bauder, T.A. A smartphone app to extend use of a cloud-based irrigation scheduling tool. Comput. Electron. Agric. 2015, 111, 127–130. [Google Scholar] [CrossRef]

- Migliaccio, K.W.; Morgan, K.T.; Vellidis, G.; Zotarelli, L.; Fraisse, C.; Zurweller, B.A.; Andreis, J.H.; Crane, J.H.; Rowland, D.L. Smartphone apps for irrigation scheduling. Trans. ASABE 2016, 59, 291–301. [Google Scholar] [CrossRef]

| Irrigation Treatment | Applied Water (mm) | ||

|---|---|---|---|

| Establishment | Drip | Total | |

| -----------------2018-------------- | |||

| T50 | 71 | 128 | 199 |

| T75 | 71 | 185 | 256 |

| T100 | 71 | 230 | 301 |

| T150 | 71 | 339 | 410 |

| -----------------2019-------------- | |||

| T50 | 60 | 119 | 179 |

| T75 | 60 | 165 | 225 |

| T100 | 60 | 213 | 273 |

| T125 | 60 | 261 | 321 |

| T150 | 60 | 309 | 369 |

| Harvested Heads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Irrigation Treatment | Total | Marketable | Culled | ||||||

| ----------------------------2018------------------------- | |||||||||

| T50 | 23,299 | (1970) | a | 2370 | (3345) | a | 20,929 | (1463) | a |

| T75 | 26,182 | (729) | ab | 9589 | (1887) | b | 16,593 | (1262) | a |

| T100 | 28,094 | (1026) | b | 19,690 | (997) | c | 8404 | (408) | b |

| T150 | 27,906 | (964) | b | 21,495 | (1018) | c | 6411 | (854) | b |

| -----------------------------2019------------------------- | |||||||||

| T50 | 16,521 | (1300) | a | 1473 | (1430) | a | 15,048 | (307) | ab |

| T75 | 26,792 | (929) | b | 8404 | (2178) | b | 18,388 | (2039) | a |

| T100 | 30,384 | (1293) | c | 15,731 | (941) | c | 14,653 | (1799) | b |

| T125 | 30,204 | (837) | c | 15,228 | (1442) | c | 14,976 | (1558) | ab |

| T150 | 27,368 | (519) | b | 16,629 | (707) | c | 10,739 | (940) | c |

| Irrigation Treatment | Small | Medium | Large | Oversize | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T50 | 63.3 | (8.0) | a | 35.7 | (7.0) | a | 1.0 | (1.2) | a | 0.0 | (0) | a |

| T75 | 32.9 | (12.5) | b | 54.3 | (10.4) | b | 12.8 | (7.3) | b | 0.0 | (0) | a |

| T100 | 22.5 | (9.0) | bc | 50.5 | (3.2) | b | 24.1 | (8.2) | c | 0.6 | (1.3) | a |

| T125 | 16.7 | (8.8) | c | 55.7 | (11.9) | b | 25.7 | (13.3) | c | 0.0 | (0) | a |

| T150 | 26.4 | (3.0) | bc | 56.4 | (2.0) | b | 16.6 | (4.0) | bc | 0.0 | (0) | a |

| Irrigation Treatment | Total Head Yield | Marketable Head Yield | Culled Heads | ||||||

|---|---|---|---|---|---|---|---|---|---|

| ---------------Mg ha−1--------------- | % | ||||||||

| ----------------------2018--------------------- | |||||||||

| T50 | 21.1 | (1.7) | a | 2.8 | (1.6) | a | 82.8 | (11.3) | a |

| T75 | 28.3 | (1.1) | b | 10.9 | (1.5) | b | 61.3 | (5.4) | b |

| T100 | 32.2 | (1.3) | c | 22.7 | (0.9) | c | 29.5 | (2.2) | c |

| T150 | 35.2 | (1.6) | c | 27.0 | (1.0) | d | 22.7 | (3.3) | c |

| -----------------------2019--------------------- | |||||||||

| T50 | 15.5 | (1.2) | a | 1.3 | (0.3) | a | 90.9 | (2.8) | a |

| T75 | 29.1 | (1.2) | b | 7.4 | (2.4) | b | 73.8 | (8.7) | b |

| T100 | 36.1 | (0.9) | c | 16.8 | (1.7) | c | 53.8 | (4.0) | c |

| T125 | 35.5 | (1.0) | c | 16.6 | (1.6) | c | 53.0 | (4.9) | c |

| T150 | 31.4 | (0.6) | b | 17.7 | (1.0) | c | 43.8 | (2.6) | c |

| Irrigation Treatment | WPi Total Head Yield | WPi Fresh Biomass | WPi Dry Biomass | ||||||

|---|---|---|---|---|---|---|---|---|---|

| -------------------kg m−3------------------- | |||||||||

| -----------------------------2018------------------------- | |||||||||

| T50 | 10.6 | (0.9) | a | 31.4 | (0.8) | a | 3.5 | (0.07) | a |

| T75 | 11.1 | (0.4) | a | 32.3 | (0.8) | a | 3.3 | (0.02) | a |

| T100 | 10.7 | (0.4) | a | 35.0 | (0.6) | b | 3.4 | (0.26) | a |

| T150 | 8.6 | (0.4) | b | 26.9 | (0.7) | c | 2.5 | (0.14) | b |

| -----------------------------2019------------------------- | |||||||||

| T50 | 8.7 | (0.7) | a | 25.6 | (1.5) | a | 2.9 | (0.17) | ab |

| T75 | 12.9 | (0.5) | b | 32.1 | (1.2) | b | 3.1 | (0.09) | b |

| T100 | 13.2 | (0.3) | b | 29.9 | (2.1) | b | 2.6 | (0.13) | ac |

| T125 | 11.1 | (0.3) | c | 25.2 | (1.5) | a | 2.3 | (0.15) | cd |

| T150 | 8.5 | (0.2) | a | 23.5 | (0.6) | a | 2.1 | (0.04) | d |

| N Uptake | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Irrigation Treatment | Head | Vegetation | Total | N Fertilizer Recovery | ||||||||

| -------------------kg ha−1------------------- | % | |||||||||||

| ----------------------------2018------------------------- | ||||||||||||

| T50 | 97 | (3.3) | a | 174 | (3.3) | a | 271 | (3.3) | a | 75 | (2.9) | a |

| T75 | 101 | (2.3) | a | 199 | (2.3) | a | 300 | (2.3) | a | 83 | (2.1) | ac |

| T100 | 103 | (8.8) | a | 261 | (8.8) | b | 364 | (8.8) | b | 101 | (7.8) | b |

| T150 | 95 | (6.1) | a | 228 | (6.1) | ab | 323 | (6.1) | ab | 90 | (5.5) | bc |

| -----------------------------2019------------------------- | ||||||||||||

| T50 | 59 | (5.8) | a | 93 | (7.8) | a | 152 | (12.5) | a | 43 | (3.5) | a |

| T75 | 76 | (1.6) | a | 106 | (5.1) | a | 182 | (4.1) | a | 51 | (1.2) | a |

| T100 | 69 | (4.8) | a | 99 | (6.8) | a | 167 | (11.6) | a | 47 | (3.2) | a |

| T125 | 67 | (4.8) | a | 112 | (10.8) | a | 179 | (14.3) | a | 50 | (4.0) | a |

| T150 | 72 | (3.2) | a | 113 | (3.6) | a | 186 | (6.2) | a | 52 | (1.7) | a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cahn, M.; Johnson, L.; Benzen, S. Evapotranspiration-Based Irrigation Management Effects on Yield and Water Productivity of Summer Cauliflower on the California Central Coast. Horticulturae 2025, 11, 322. https://doi.org/10.3390/horticulturae11030322

Cahn M, Johnson L, Benzen S. Evapotranspiration-Based Irrigation Management Effects on Yield and Water Productivity of Summer Cauliflower on the California Central Coast. Horticulturae. 2025; 11(3):322. https://doi.org/10.3390/horticulturae11030322

Chicago/Turabian StyleCahn, Michael, Lee Johnson, and Sharon Benzen. 2025. "Evapotranspiration-Based Irrigation Management Effects on Yield and Water Productivity of Summer Cauliflower on the California Central Coast" Horticulturae 11, no. 3: 322. https://doi.org/10.3390/horticulturae11030322

APA StyleCahn, M., Johnson, L., & Benzen, S. (2025). Evapotranspiration-Based Irrigation Management Effects on Yield and Water Productivity of Summer Cauliflower on the California Central Coast. Horticulturae, 11(3), 322. https://doi.org/10.3390/horticulturae11030322