Abstract

In recent years, Italy’s craft beer industry has seen remarkable growth, fostering the local production of key ingredients, notably hops. However, a research gap exists in exploring open-field hop productivity in typical Mediterranean climates using low-trellis systems. This study addressed this gap by evaluating the productive performances of “Cascade” and “Chinook” hop varieties on “V” trellis systems at different heights (2.60, 3.60, and 4.60 m above ground) in inner Sicily’s Mediterranean climate and soil conditions. The results highlighted the significant impact of trellis height on various parameters, with Cascade displaying exceptional adaptability to low-trellis farming. Key factors like stem and leaf weight emerged as crucial drivers of cone yield, emphasizing their significance in hop cultivation. The distinct responses of Cascade and Chinook varieties to varying trellis heights underscored the need for tailored approaches, offering valuable insights for optimizing hop cultivation practices in semi-arid climates.

1. Introduction

Hop cones are the female inflorescences of the hop plant (Humulus lupulus L.) and represent a key component of the brewing process [1]. Hops are responsible for the distinctive bitterness and aroma, as well as giving antimicrobial properties to the finished product [2].

For several years in Italy, the entire craft beer industry has been growing, which has led to the enhancement of local raw ingredient production, including hops [3,4]. This movement has triggered intensive research focusing on the adaptability of hops species to different cultivation environments in the peninsula [5,6,7,8,9,10,11]. Indeed, several studies conducted in Mediterranean climate environments have highlighted the excellent adaptability of various American varieties, both in terms of production [12,13,14] and quality (i.e., content in alpha acids and aromatic oils) [15,16,17]. This suggests that the Italian hop industry would have nothing to envy about other production markets abroad.

However, in terms of farming management, there are still relevant knowledge gaps, as hops are a new crop for Mediterranean agroecosystems. To our knowledge, no research has investigated, so far, the open-field productivity of hops under typical Mediterranean climates when employing low-trellis systems. Several studies have demonstrated that low-height systems offer benefits in terms of sustainability and environmental protection [12,18]. Besides requiring lower technical inputs (such as water and fertilizers), they are also less demanding in terms of crop management and initial expenses. Furthermore, in low-trellis systems, plant protection treatments can be carried out more efficiently and with less dispersion due to increased plant wall density and reduced vertical development [18,19,20]. This allows for more effective biological control of key insects and phytophagous mites [21].

Thus, utilizing the most suitable hop varieties in “low-trellis” systems could present a highly advantageous opportunity to embrace organic farming practices in Mediterranean environments, enabling local farmers to harmonize both productive and economic objectives. The objective of this work was to assess the performance of two American hop varieties, namely “Cascade” and “Chinook”, in combination with “V” trellis systems at three different heights within the typical Mediterranean climate and soil conditions of inner Sicily.

2. Materials and Methods

2.1. Experimental Site and Design

The trial took place at the “Sparacia” experimental farm, belonging to the Department of Agricultural, Food, and Forestry Sciences of the University of Palermo, in two growing seasons, namely 2022 and 2023 (Figure 1). The farm, located in the territory of Cammarata (Agrigento, AG, Sicily, Italy; (37°63′ N, 13°76′ E; 600 m asl), is predominantly hilly and is characterized by a semi-arid climate [22], with warm, mainly dry summers and mild, rainy winters.

Figure 1.

Satellite image via Google Earth (accessed on 5 February 2024), showing the location of the experimental hopyard in the “Sparacia” farm.

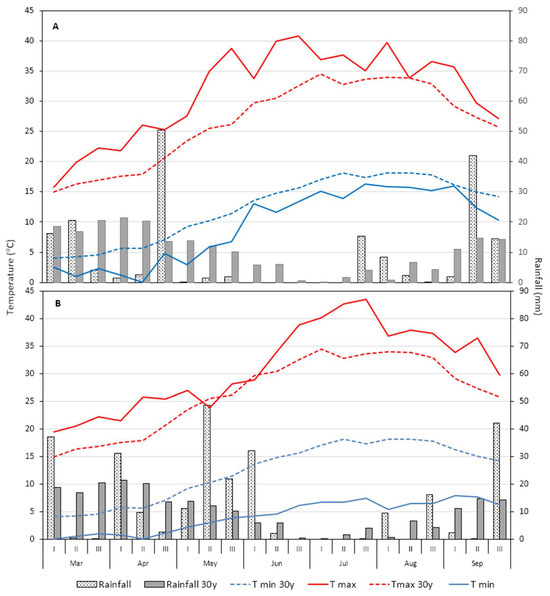

Throughout the trial, climatic conditions were marked by scarce rain events and high summer temperatures, with maximum values exceeding 30 °C (Figure 2).

Figure 2.

Ten-day values of temperatures and rainfall recorded at the “Sparacia” farm (Cammarata, AG, Sicily, Italy) throughout the 2022 (A) and 2023 (B) hop growing seasons, compared with the 30-year (1992–2021) mean values.

The soil was a sub-alkaline Eutric Vertisol [23]; representative soil samples collected before the hop implant exhibited a clayey texture, richness in limestone, and a good mineral endowment (Table 1).

Table 1.

Main chemical and physical characters of the soil used for hop cultivation at the “Sparacia” farm (Cammarata, AG, Italy) in the 2022 and 2023 growing seasons.

For the experiment, two American hop varieties that had already proven good adaptability to Mediterranean environments with semi-arid climates [9,12], i.e., Cascade and Chinook, were selected. The variety Cascade, developed in the USDA breeding program at Oregon State University and released in 1972, is characterized by a dark green elongated cone with a medium-strength aroma, often described as a distinctive floral, grapefruit-like character [24]. The variety Chinook was developed by the USDA breeding program in Washington State and released in 1985 as a high alpha-acid variety, also having a robust spicy, citrus aroma [25]. The trial involved micropropagated plants obtained from the company MrHops® (San Martino di Lupari, PD, Italy), which at transplant time were about 10 cm high (4–6 true leaves). On 5 March 2022, 108 plantlets were transferred into a properly designed planting with “V” trellis systems set up at different heights (2.60, 3.60, and 4.60 m above ground). Plant distances of 3.0 m between rows and 0.7 m in the row were adopted. A “split-plot” experimental layout was arranged, with the “trellis height” as the main experimental factor (I order) and the “variety” (II order) randomized within this. Each treatment was replicated three times, with blocks consisting of six plants each.

2.2. Soil and Plant Management

A double-layer pre-planting tillage (30 cm plowing and 50 cm subsoiling) was carried out, followed by subsequent tillering to break down large clumps. Mechanical weeding was performed during the summer in both years (two operations in 2022 and three in 2023, respectively). After the transplant, an irrigation system and plastic mulch (PE film) were positioned. Fertilization was made using the following commercial products:

- -

- Kelpstar® (Mugavero fertilizers, Palermo, Italy), a liquid extract of Ecklonia maxima, containing organic nitrogen (1%), organic carbon (10%), phytohormones, mainly auxin (11 mg L−1) and cytokinin (0.03 mg L−1), and organic substances with nominal molecular weights < 50 kDa (30%).

- -

- Siapton® (Isagro spa, Milano, Italy), a liquid formulation containing organic matter (567–720 g L−1), composed of organic nitrogen (8.7–9.1%), organic carbon (26%) and free amino acids (7.9–10%).

- -

- YaraTera Deltaspray 20-20-20 +ME (Yara Italia, Milano, Italy), a highly soluble compound fertilizer (N:P2O5:K2O = 20:20:20), also containing microelements (Mo, B, Fe, Zn, Cu, Mn).

All three fertilizers and biostimulants were dosed and supplied in a single foliar treatment (Table 2) both in 2022 (5 July) and 2023 (13 July), i.e., when all plants had fully emitted the secondary shoots (stage 2.9 of the BBCH scale) [25]. The operation was performed using a shoulder sprayer pump with a capacity of 20 L (Record®, Volpi Originale, Casalromano, Italy).

Table 2.

Doses of fertilizers and biostimulants applied on hop in 2022 and 2023 at the “Sparacia” experimental farm.

The localized irrigation system included two dripping lines for each row, with in-line and self-compensating dispensers (2 L h−1). Each block was equipped with a closing valve and a pressure gauge to control the working pressure. Irrigation was administered with frequent shifts and reduced delivery intensities in order to maintain a satisfactory available water content without limiting the growth of the species. Water supply per intervention was kept equal for all treatments, totaling a seasonal amount of about 2000 m3 ha−1 (202 mm and 189 mm for 2022 and 2023, respectively). The trial did not require control interventions for parasites and pathogens in both years.

2.3. Field Measurements

In both growing seasons, field measurements encompassed phenological phases, crop growth rates, and biomass yields. Phenological measurements were carried out weekly following the BBCH model with a centesimal scale [26]. Crop growth rates (GR) were determined according to the following formula:

where Ht is the height value reached on the wire by the plants, represents the corresponding time interval between measurements, and i and k represent the starting and ending dates of each vertical growth interval.

Vertical development and increase in the number of nodes of the plants were monitored weekly by graphic processing of the photographic material collected using the ImageJ software (US National Institutes of Health, Bethesda, MD, USA), version 1.52 t.01.30.2020. Likewise, relative chlorophyll content was estimated weekly by recording the SPAD (Soil Plant Analysis Development) values using a SPAD-502 device (Minolta Camera Co., Osaka, Japan).

Harvest time was identified by evaluating cone dry matter content, with collection occurring once a 20% dry matter value was reached [27]. Representative cone samples were taken from each plot and oven-dried at 104 °C for 24 h, to determine their final dry matter weight (DM). Total biomass yields, sorted by stems and leaves, were recorded at the end of each growing season as fresh matter (FM).

2.4. Statistical Analysis

Statistical analysis was performed using the GLM procedure in Minitab® (Minitab LLC, State College, PA, USA), version 19.2.0.0; and Systat® (Systat Software Inc., San Jose, CA, USA), version 13.2. To ensure compliance with the ANOVA assumptions, all data were tested for normality and variance homogeneity through the Ryan–Joiner test (α = 0.05) and the Levene’s test (α = 0.05), respectively [28]. When the ANOVA yielded significant results, the differences between mean values were appreciated through Tukey’s test (p ≤ 0.05) [28].

A stepwise regression analysis (backward elimination procedure) between cone yield (g DM plant−1; dependent variable) and all the other recorded plant traits (independent variables) was carried out to cope with multicollinearity and to reduce the number of parameters associated to all observations. Eventually, linear regression models were employed to establish associations between cone yield (g DM plant−1; dependent variable) and weight of stems and leaves (g FM plant−1; independent variable).

Repeated-measures ANOVA was applied to analyze separately over time the effect of variety, trellis height, and their interaction on plant heights, SPAD values, and vertical growth rates (GR). Time (expressed as DOY, day of the year), treatments, and their interactions were also used as explanatory variables in the analyses. In all cases, model assumptions, i.e., normality and homoscedasticity of residuals, were checked, and Tukey’s HSD test was used for comparisons of means, unless stated otherwise. The trend over time of the aforementioned variables (plant height, SPAD values, and GRs) was graphically assessed by means of linear and nonlinear regression models, according to the best fitting of each dataset (Table S1, Supplementary Materials).

3. Results and Discussion

3.1. Biomass Yields

The results of the ANOVA on the yield data collected in 2022 and 2023 are shown in Table 3.

Table 3.

Mean values of total biomass, weight of stems and leaves, and cone yield obtained in 2022 and 2023.

For total biomass production, the interaction between “Variety” and “Trellis height” proved significant in both growing seasons (p < 0.05; Table 3). Specifically, Cascade plants in the L-Trellis system exhibited a significantly higher biomass yield, producing, on average, 44% and 40% more than all other treatments in 2022 and 2023, respectively. However, in 2023, yield responses were more heterogeneous, with a general leveling of biomass yields for the Cascade variety, which remained significantly higher than that of Chinook. A slight difference emerged among Chinook plants in the three trellis systems, although statistically not appreciable, given their belonging to the same grouping “b”. The yield in stems and leaves in 2022 was influenced by the “Trellis height” factor, with L-Trellis recording, contrary to expectations, a production almost double that of the M and H-trellis systems (p < 0.01). In 2023, the significant interaction between “Variety” and “Trellis height” confirmed what was observed for total biomass, with a clearly distinct response between the two varieties. According to the results, Cascade plants, regardless of the trellis height adopted, produced more leaves and stems than Chinook. For the latter, the treatments at different heights responded with productions of leaves and stems statistically indistinguishable from each other (same grouping “b”). The cone yield in 2022 varied according to the interaction of both “Variety” and “Trellis height” factors, with highest yields obtained from L-Trellis treatments of 0.29 and 0.21 t ha−1 for Cascade and Chinook, respectively. In 2023, however, yields between all treatments seemed to level, while the difference at the varietal level was statistically significant (p < 0.05), indicating the clear production superiority of Cascade in the semi-arid environment, with cone yield on average 14% higher than Chinook in the same field conditions.

These initial outcomes, derived from this 2-year trial, affirm the suitability of Cascade for cultivation in semi-arid environments. Additionally, hop appears well-suited for low-trellis farming in Mediterranean climates, and this is consistent with the findings of several recent studies [12,13,15]. It is not in doubt that further investigations into other varieties or management systems could significantly contribute to improving our understanding of hop species behavior in new cultural areas, such as the regions of southern Italy.

The productive performance of hop plants was further investigated through stepwise regression analysis, allowing the determination of the most significant predictors of cone yields for each growing season. As shown in Table 4, already since step 1, all the traits included (i.e., stems and leaves, vegetative stages’ length, Spadharv, and Heightmax) explained about 68.4% and 34.2% of the total regression effect for 2022 and 2023, respectively.

Table 4.

Stepwise regression (backward elimination procedure; α to remove = 0.01) between hops cone yields (g DM plant−1; dependent variable) and selected plant traits (independent variables) in 2022 and 2023.

The backward elimination of regressors, conducted in the following steps, revealed that the regression coefficients for stems and leaves remained significant, leading to minor changes in the R2 value. Remarkably, even after removing all other regressors from the regression models for both 2022 and 2023, “stems and leaves” emerged as the most significant trait, underscoring its crucial importance in determining hop cone yields in a Mediterranean semi-arid environment.

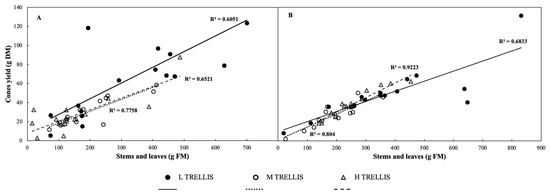

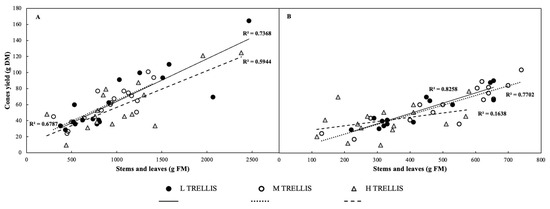

Subsequent linear regression analysis, carried out between cone yield (g DM plant−1; dependent variable) and the weight of stems and leaves (g FM plant-1; independent variable), confirmed that positive correlations occurred for both 2022 (Figure 3) and 2023 (Figure 4) growing seasons.

Figure 3.

Regression lines, according to trellis height (low, medium, and high) between cone yield (g DM plant−1; dependent variable) and weight of stems and leaves (g FM plant−1; independent variable) in ‘Cascade’ (A) and ‘Chinook’ (B) hops in 2022.

Figure 4.

Regression lines, according to trellis height (low, medium, and high) between cone yield (g DM plant−1; dependent variable) and weight of stems and leaves (g FM plant−1; independent variable) in ‘Cascade’ (A) and ‘Chinook’ (B) hops in 2023.

In 2022, the response of Cascade plants was notably uniform, given the general orientation of the regression lines and the significance (p < 0.001) of the R2 values (0.605, 0.776, and 0.652 for L, M, and H-trellis, respectively) (Figure 3). The R2 value of Chinook plants in L-Trellis (0.683), although statistically significant (p < 0.001), in 2022 was lower than the M and H-Trellis treatments, which showed values of 0.804 and 0.922, respectively. In 2023, the R2 values were significant for all varieties and treatments, except for Chinook plants in the H-Trellis system. For Cascade plants, those cultivated at reduced height showed the highest value (0.737), followed by M (0.679) and H-Trellis treatments (0.594) (Figure 4). This further confirms the excellent attitude of this variety to a low-trellis system. In H-trellis, Chinook exhibited a statistically non-significant determination coefficient, notably lower (0.164) than the other treatments (i.e., 0.826 and 0.770 for L and M-Trellis, respectively) (Figure 4). The M-trellis is confirmed as a preferable system for this variety, given its greater propensity for production in terms of canopy and cone yield between years (Table 3). In contrast, the L-trellis appeared to have a dampening effect on the yield potential of Chinook plants in cultivation in a Mediterranean environment.

3.2. Plant Height, SPAD Values, and Growth Trend

In 2022, the mean plant height was significantly influenced by all explanatory variables, including the interaction Time × V × TH (Table 5).

Table 5.

F-values (within subjects) for treatments (variety and trellis height) and interactions from repeated-measures analysis of variance over time for plant height, SPAD values, and growth rates in 2022 and 2023.

Otherwise, in 2023, plant height exhibited variations based on the interactions Time × V (p < 0.001) and Time × TH (p < 0.001). Cascade plants, under L-trellis systems, displayed accelerated growth, swiftly reaching the top of the wire, and differentiating secondary shoots before the other treatments in both growing seasons (Figure S1, Supplementary Material).

Chinook plants exhibited a later but more vigorous growth compared to Cascade, irrespective of the trellis height adopted in both years.

An analysis of the mean SPAD values indicated significant time-dependent differences in 2022 (p < 0.05), reasonably attributable to the typical physiological responses of plants cultivated in open fields. No other influences were identified from the remaining explanatory variables (Table 5). In 2023, the interaction time × V × TH significantly affected SPAD values, except for Chinook plants in the M and H-Trellis systems (Figure S2, Supplementary Material). Nevertheless, the Chinook variety consistently achieved the highest average SPAD values per plant, specifically in the H-Trellis system in 2022 (58.9) and the L-trellis in 2023 (49.3).

Hop growth rates (GR) were ultimately significantly influenced by the interaction T × V × TH in both 2022 (p < 0.001) and 2023 (p < 0.05) (Table 5). Specifically, in 2022, Cascade plants in M-Trellis exhibited the highest GR value (11.32 cm dd−1) around the 203rd day of the year (DOY). The mean GR values of plants on H-Trellis also demonstrated a good fit with a Gaussian distribution pattern, reaching growth rates consistently higher than other treatments, beginning from the 196th DOY (10.85 cm dd−1) and gradually decreasing to zero around the 224th DOY (Figure S3, Supplementary Material).

Chinook plants exhibited in 2022 markedly different responses in growth rates to varying trellis heights. Plants in H-Trellis displayed the highest GR value (11.52 cm dd−1) around the 196th DOY, following a trend similar to that of plants in M-Trellis. The averages of GRs for the L-Trellis treatment were considerably smaller, as depicted by the Gaussian curve in Figure S3 (Supplementary Material). Likewise, in 2022, Cascade plants on M-Trellis showed the highest GR value (11.44 cm dd−1) around the 181st DOY, with a slightly forward translation of the curve, possibly indicating a later growth compared to L and H-Trellis treatments. In 2023, Chinook plants on M and H-Trellis exhibited the highest GR values, recording 13.02 cm dd−1 on the 153rd DOY and 13.24 cm dd−1 on the 160th DOY, respectively. Conversely, the response of the L-Trellis treatment was modest, as evident from the specific trend of the regression.

4. Conclusions

The results underscored the substantial influence of trellis height on multiple parameters, particularly with Cascade exhibiting exceptional adaptability to low-trellis farming. The pivotal role of stem and leaf weight in determining cone yield highlighted its significance in hop cultivation.

Plant height, SPAD values, and growth rates further emphasized the distinct reactions of Cascade and Chinook to different trellis heights. These findings provide valuable insights for optimizing hop cultivation practices in semi-arid climates, underscoring the need for tailored approaches based on specific hop varieties and trellis systems. Exploring additional varieties and management strategies will be our future pursuits to enhance our comprehension of hop species behavior in diverse cropping environments. Furthermore, the study of biochemical attributes, like enzymatic activity or hormonal interaction, will represent a crucial tool for confirming the adaptation mechanisms of the species.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/horticulturae10020181/s1.

Author Contributions

Conceptualization, R.M. and A.C.; methodology, V.A., A.C. and M.S.; software, R.M. and A.A.; validation, A.C. and M.S.; formal analysis, R.M. and A.C.; investigation, R.M. and A.A.; data curation, A.C.; writing—original draft preparation, R.M., A.A. and A.C; writing—review and editing, R.M., V.A., M.S. and A.C.; visualization, R.M.; supervision, A.C.; project administration, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All data underlying the results are available within the article and its Supplementary Material. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gresser, A. Il Manuale del Birraio Pratico. Teoria e Pratica della Preparazione del Malto e della Fabbricazione della Birra; Fachverlag Hans Carl GmbH: Nürnberg, Germany, 2010. [Google Scholar]

- Neve, R.A. Hops; Springer-Science & Business Media, B.V.: Southport, UK, 1991. [Google Scholar]

- Assobirra Annual Report 2022. Available online: https://www.assobirra.it/annual-report-assobirra/ (accessed on 20 September 2023).

- Carbone, K.; Cherubini, D. Il Luppolo fresco “made in Italy”: Qualità e competitività per l’industria brassicola. In Proceedings of the Criticità e Opportunità per lo Sviluppo Sostenibile della Filiera Brassicola, Roma, Italy, 26 October 2016. [Google Scholar]

- Santagostini, L.; Caporali, E.; Giuliani, C.; Bottoni, M.; Ascrizzi, R.; Araneo, S.R.; Papini, A.; Flamini, G.; Fico, G. Humulus lupulus L. cv. Cascade grown in Northern Italy: Morphological and phytochemical characterization. Plant Biosyst. Int. J. Deal. Asp. Plant Biosyst. 2020, 154, 316–325. [Google Scholar] [CrossRef]

- Mongelli, A.; Rodolfi, M.; Ganino, T.; Marieschi, M.; Dall’Asta, C.; Bruni, R. Italian hop germplasm: Characterization of wild Humulus lupulus L. genotypes from Northern Italy by means of phytochemical, morphological traits and multivariate data analysis. Ind. Crops Prod. 2015, 70, 16–27. [Google Scholar] [CrossRef]

- Ruggeri, R.; Loreti, P.; Rossini, F. Exploring the potential of hop as a dual purpose crop in the Mediterranean environment: Shoot and cone yield from nine commercial cultivars. Eur. J. Agron. 2018, 93, 11–17. [Google Scholar] [CrossRef]

- Marceddu, R.; Carrubba, A.; Sarno, M. Cultivation trials of hop (Humulus lupulus L.) in semi-arid environments. Heliyon 2020, 6, e05114. [Google Scholar] [CrossRef] [PubMed]

- Marceddu, R.; Carrubba, A.; Sarno, M. Resilience of hop (Humulus lupulus L.) to salinity, heat and drought stresses: A mini-review. Front. Plant Sci. 2022, 13, 4941. [Google Scholar] [CrossRef] [PubMed]

- Rossini, F.; Loreti, P.; Provenzano, M.E.; De Santis, D.; Ruggeri, R. Agronomic performance and beer quality assessment of twenty hop cultivars grown in Central Italy. Ital. J. Agron. 2016, 11, 180–187. [Google Scholar] [CrossRef]

- Rossini, F.; Virga, G.; Loreti, P.; Iacuzzi, N.; Ruggeri, R.; Provenzano, M.E. Hops (Humulus lupulus L.) as a novel multipurpose crop for the Mediterranean region of Europe: Challenges and opportunities of their cultivation. Agriculture 2021, 11, 484. [Google Scholar] [CrossRef]

- Carrubba, A.; Marceddu, R.; Sarno, M. Hop (Humulus lupulus L.): Suitability of Traditional Cultivars to a Low-Trellis Farming System in a Semiarid Environment. HortScience 2022, 57, 1409–1415. [Google Scholar] [CrossRef]

- Gresta, F.; Calvi, A.; Santonoceto, C.; Strano, T.; Ruberto, G. Agronomic traits and essential oil profiles of Humulus lupulus L. cultivated in southern Italy. J. Essent. Oil Res. 2023, 35, 60–70. [Google Scholar] [CrossRef]

- Marceddu, R.; Carrubba, A.; Sarno, M. Cultivation trials of hop (Humulus lupulus L.) in a Mediterranean environment. In Proceedings of the International Symposium on Innovative Perennial Crops Management, XXXI International Horticultural Congress (IHC2022), Angers, France, 14 August 2022; Volume 1366, pp. 147–154. [Google Scholar] [CrossRef]

- Forteschi, M.; Porcu, M.C.; Fanari, M.; Zinellu, M.; Secchi, N.; Buiatti, S.; Passaghe, P.; Bertoli, S.; Pretti, L. Quality assessment of Cascade Hop (Humulus lupulus L.) grown in Sardinia. Eur. Food Res. Technol. 2019, 245, 863–871. [Google Scholar] [CrossRef]

- Ghiselli, L.; Marini, L.; Taiti, C.; Calamai, L.; Paffetti, D.; Masi, E. Hops Germplasm: Phytochemical Characterization of Wild Humulus lupulus of Central and Northern Italy. Plants 2022, 11, 1564. [Google Scholar] [CrossRef] [PubMed]

- Mongelli, A.; Rodolfi, M.; Ganino, T.; Marieschi, M.; Caligiani, A.; Dall’Asta, C.; Bruni, R. Are Humulus lupulus L. ecotypes and cultivars suitable for the cultivation of aromatic hop in Italy? A phytochemical approach. Ind. Crops Prod. 2016, 83, 693–700. [Google Scholar] [CrossRef]

- Darby, P. The History of Hop Breeding and Development. In Brewery History. Available online: http://www.breweryhistory.com/journal/archive/121/bh-121-094.htm (accessed on 18 September 2023).

- Beatson, R.; Kenny, S.; Pethybridge, S.; Gent, D. Hop Production. In Compendium of Hop Diseases and Pests; Mahaffee, W., Pethybridge, S., Gent, D., Eds.; The American Phytopathological Society: St. Paul, MN, USA, 2009; pp. 5–8. [Google Scholar]

- Biendl, M.; Engelhard, B.; Forster, A.; Gahr, A.; Lutz, A.; Mitter, W.; Schmidt, R.; Schönberger, C. Hops: Their Cultivation, Composition and Usage; Fachverlag Hans Carl: Nuremberg, Germany, 2014. [Google Scholar]

- Darby, P. Hop growing in England in the twenty first century. J. Roy. Agric. Soc. 2004, 165, 84–90. [Google Scholar]

- Rivas-Martínez, S.; Sánchez-Mata, D. Boreal vegetation series of North America. Plant Biosyst. Int. J. Dealing Aspects Plant Biosyst. 2011, 145, 208–219. [Google Scholar] [CrossRef]

- Soil Survey Staff. Keys to Soil Taxonomy, 12th ed.; United States Department of Agriculture—Natural Resources Conservation Service: Washington, DC, USA, 2014. [Google Scholar]

- Yakima Valley Hops. Cascade Hops. Available online: https://yakimavalleyhops.com/products/cascade-hop-pellet (accessed on 5 February 2024).

- Yakima Valley Hops. Chinook Hops. Available online: https://yakimavalleyhops.com/products/chinook-hop-pellets (accessed on 5 February 2024).

- Rossbauer, G.; Buhr, L.; Hack, H.; Hauptmann, S.; Klose, R.; Meier, U.; Stauss, R.; Weber, E. Phanologische Entwicklungsstadien von Kultur-Hopfen (Humulus lupulus L.). Nachrbl. Dtsch. Pflanzenschutzd. 1995, 47, 249–253. [Google Scholar]

- Calderwood, L.; Post, J. Hop Harvest Timing in the Northeast University of Vermont Extension Northwest Crops and Soils Program, Burlington, VT, USA. 2015. Available online: https://www.uvm.edu/sites/default/files/media/Hop_Harvest_Determination_factsheet.pdf (accessed on 18 September 2023).

- Gomez, K.A.; Gomez, A.A. Statistical Procedures for Agricultural Research; John Wiley & Sons: New York, NY, USA, 1984. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).