Influence of Hydroponics Nutrient Solution on Quality of Selected Varieties of Potato Minitubers

Abstract

1. Introduction

2. Material and Methods

2.1. Experimental Location and Layout

2.2. Data Collection

2.3. Composition Analysis

2.4. Statistical Analysis

3. Results and Discussion

3.1. Influence of Nutrient Stock Solution Concentrations on Minitubers Dry Matter, Specific Gravity and Starch Content

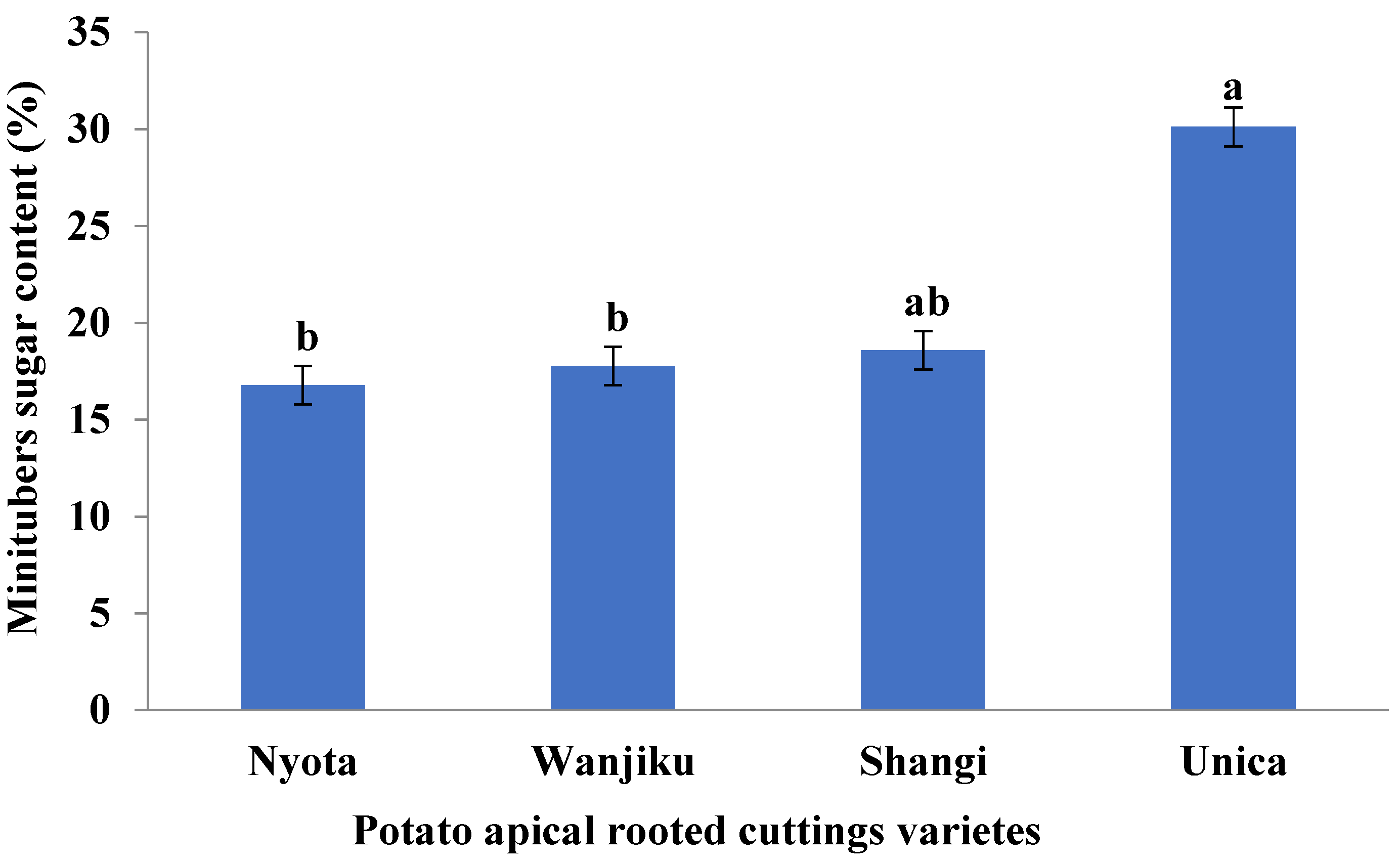

3.2. Influence of Nutrient Stock Solution Concentrations on Ash, Crude Protein, Total Sugars and Phosphorus Contents of Minitubers

3.3. Correlation Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gikundi, E.N.; Sila, D.N.; Orina, I.N.; Buzera, A.K. Physico-chemical properties of selected irish potato varieties grown in Kenya. Afr. J. Food Sci. 2021, 15, 10–19. [Google Scholar] [CrossRef]

- Wambugu, W.; Opiyo, O.; Githengu, S. Rapid multiplication techniques in seed potato production in Kenya: Prospects, opportunities and challenges. In Proceedings of the Egerton University 14th Biennial International Conference, Nakuru, Kenya, 23–25 March 2022. [Google Scholar]

- Amare, T.; Bazie, Z.; Alemu, E.; Alemayehu, B.; Tenage, A.; Kerebh, B.; Taye, Y.; Awoke, A.; Feyisa, T.; Kidanu, S. Yield of potato (Solanum tuberosum L.) increased by more than two-folds through nitrogen and phosphorus fertilizers in the highlands of North-Western Ethiopia. Heliyon 2022, 8, e11111. [Google Scholar] [CrossRef] [PubMed]

- Mystkowska, I.; Zarzecka, K.; Ginter, A.; Gugała, M.; Sikorska, A. Total and protein nitrogen content in potato tubers under the influence of various care and nutrition methods with the use of biostimulants. J. Ecol. Eng. 2023, 24, 247–255. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.; Naznin, S.; Naznin, A.; Uddin, N.; Amin, N.; Rahman, M.; Monirul, M.; Tipu, H.; Alsuhaibani, A.M. Dry matter, starch content, reducing sugar, color and crispiness are key prameters of potatoes required for chip processing. Horticulturae 2022, 8, 362. [Google Scholar] [CrossRef]

- Das, S.; Mitra, B.; Saha, A.; Mandal, S.; Paul, P.K.; El-Sharnouby, M.; Hassan, M.M.; Maitra, S.; Hossain, A. Evaluation of quality parameters of seven processing type potato (Solanum tuberosum L.) cultivars in the Eastern Sub-Himalayan Plains. Foods 2021, 10, 1138. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.R.; Nahar, B.S. Effect of organic farming on nutrient uptake and quality of potato. J. Environ. Sci. Nat. Resour. 2012, 5, 219–224. [Google Scholar] [CrossRef]

- Wadas, W. Nutritional value and sensory quality of new potatoes in response to silicon application. Agriculture 2023, 13, 542. [Google Scholar] [CrossRef]

- Akoto, E.M.; Othieno, C.O.; Ochuodho, J.O. Influence of phosphorus fertilizer on potato seed production in acid soils in Kenya. Sustain. Agric. Res. 2020, 9, 101–117. [Google Scholar] [CrossRef]

- Ministry of Agriculture, Livestock and Fisheries (MoALF). The National Potato Strategy 2016–2020; Ministry of Agriculture, Livestock and Fisheries (MoALF): Nairobi, Kenya, 2016; pp. 1–64. [Google Scholar]

- Kaguongo, W.; Maingi, G.; Barker, I.; Nganga, N.; Guenthner, J. The value of seed potatoes from four systems in Kenya. Am. J. Potato Res. 2013, 91, 109–118. [Google Scholar] [CrossRef]

- Kingori, G.G.; Nyamori, A.J.; Khasungu, I.D. Optimization of seed potato specific density, starch and dry matter contents and tuberization capacity of resultant plants through integrated irrigation, nitrogen and phosphorus management. J. Plant Sci. 2015, 3, 225–233. [Google Scholar]

- Mbiyu, M.W.; Muthoni, J.; Kabira, J.; Elmar, G.; Muchira, C.; Pwaipwai, P.; Ngaruiya, J.; Otieno, S.; Onditi, J. Use of aeroponics technique for potato (Solanum tuberosum) minitubers production in Kenya. Int. J. Hortic. For. 2012, 1, 16–20. [Google Scholar]

- Janssens, S.R.M.; Wiersema, S.G.; Goos, H.; Wiersma, W. The Value Chain for Seed and Ware Potatoes in Kenya: Opportunities for Development; Wageningen University & Research: Wageningen, The Netherlands, 2013; pp. 13–80. [Google Scholar]

- Lemma, T.; Chindi, A.; Wgiorgis, G.; Solomon, A.; Shunka, E.; Seid, E. Accelerating seed potato production by using rapid multiplication systems in Ethiopia. Open Sci. J. 2018, 3, 1–9. [Google Scholar] [CrossRef]

- Byarugaba, A.A.; John, K.; Aheisibwe, R.A.; Barekye, A. Bridging the gap in quality and quantity of seed potatoes through farmer managed screen houses in Uganda. Afr. J. Plant Sci. 2017, 11, 30–37. [Google Scholar] [CrossRef]

- Tessema, L.; Chindi, A.; Giorgis, G.W.; Solomon, A.; Shunka, E.; Seid, E. Determination of nutrient solutions for potato (Solanum tuberosum L.) seed production under aeroponics production system. Open Agric. 2017, 12, 155–159. [Google Scholar] [CrossRef]

- Ebúrneo, J.M.; Garcia, E.L.; Paes, T.; De Freitas, E.; Soratto, R.P.; Fernandes, A.M.; Leonel, M. Influence of nitrogen fertilization on the characteristics of potato starch. J. Crop Sci. 2018, 12, 365–373. [Google Scholar] [CrossRef]

- Petropoulos, S.A.; Fernandes, Â.; Polyzos, N.; Antoniadis, V.; Barros, L.; Ferreira, I.R. The impact of fertilization regime on the crop performance and chemical composition of potato. Agronomy 2020, 10, 474. [Google Scholar] [CrossRef]

- Kamrani, M.H.; Chegeni, A.R.; Hosseinniya, H.; Kamrani, M.H. Effects of different growing media on yield and growth parameters of potato minitubers (Solanum tuberosum L.). Commun. Soil Sci. Plant Anal. 2019, 50, 1838–1853. [Google Scholar] [CrossRef]

- Filho, J.S.; Cezar, P.; Fontes, R.; Ferreira, J.F.S.; Cecon, P.R.; Crutchfield, E. Optimal Nutrient Solution and Dose for the Yield of Nuclear Seed Potatoes under Aeroponics. Agronomy 2022, 12, 2820. [Google Scholar] [CrossRef]

- Liang, Z.H.; Mu, T.H.; Zhang, R.F.; Sun, Q.H.; Xu, Y.W. Nutritional evaluation of different cultivars of potatoes (Solanum tuberosum L.) from China by grey relational analysis (GRA) and its application in potato steamed bread making. J. Integr. Agric. 2019, 18, 231–245. [Google Scholar] [CrossRef]

- Muthoni, J. Soil fertility situation in potato producing Kenyan highlands case of KALRO-Tigoni. Int. J. Hortic. 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Koch, M.; Naumann, M.; Thiel, H.; Gransee, A.; Pawelzik, E. The importance of nutrient management for potato production part I: Plant nutrition and tuber quality. Potato Res. 2020, 63, 121–137. [Google Scholar] [CrossRef]

- Zewide, I.; Mohammed, A.; Tadesse, S.T. Potato (Solanum tuberosum L.) growth and tuber quality, soil nitrogen and phosphorus content as affected by different rates of nitrogen and phosphorus at Masha district in southwestern Ethiopia. Int. J. Agric. Res. 2016, 11, 95–104. [Google Scholar] [CrossRef]

- Öztürk, E.; Kavurmac, Z.; Kara, K.; Polat, T. The effects of different nitrogen and Phosphorus rates on some quality traits of potato. Potato Res. 2010, 53, 309–312. [Google Scholar] [CrossRef]

- Mohammed, W. Specific gravity, dry matter content, and starch content of potato (Solanum tuberosum L.) varieties cultivated in Eastern Ethiopia. East Afr. J. Sci. 2016, 10, 87–102. [Google Scholar]

- Zainaldeen, M.A.; Abdul Rasool, I.J. Response of growth and yield of true potato seed plants to foliar application with organic nutrients. In Proceedings of the Fifth International Conference of Agricultural and Environmental Sciences, Al-Qaim, Iraq, 23 November 2023. [Google Scholar]

- National Potato Council of Kenya (NPCK). Potato Variety Catalogue 2019; National Potato Council of Kenya (NPCK): Nairobi, Kenya, 2019; pp. 1–80. Available online: http://varieties.potato.org.uk/varieties/view/Accord (accessed on 15 April 2020).

- Gbollie, S.N.; Mwonga, S.M.; Kibe, A.M. Effects of calcium nitrate levels and soaking durations on cocopeat nutrient content. J. Agric. Chem. Environ. 2021, 10, 372–388. [Google Scholar] [CrossRef]

- Agle, W.M.; Woodbury, G.W. Specific gravity-dry matter relationship and reducing sugar changes affected by potato variety, production area and storage. Am. Potato J. 1968, 45, 119–131. [Google Scholar] [CrossRef]

- Naz, F.; Ali, A.; Iqbal, Z.; Akhtar, N.; Multan, T. Effect of different levels of NPK fertilizers on the proximate compositon of potato crop at Abbottabad. J. Agric. 2011, 27, 353–356. [Google Scholar]

- AOAC. Official Methods of Analysis in Association of Official Agricultural Chemists; AOAC: Washington, DC, USA, 1995. [Google Scholar]

- Okalebo, J.R.; Gathua, K.W.; Paul, L.W. Laboratory Methods of Soil and Plant Analysis: A Working Manual, 2nd ed.; Sacred Africa: Nairobi, Kenya, 2002; Volume 21, pp. 25–26. [Google Scholar]

- Fernandes, A.M.; Soratto, R.P.; Moreno, L.D.; Evangelista, R.M. Effect of phosphorus nutrition on quality of fresh tuber of potato cultivars. Soil Plant Nutr. 2015, 74, 102–109. [Google Scholar] [CrossRef]

- Hasnat, A.; Solaiman, M.; Nishizawa, T.; Suvra, T. Yield, dry matter, specific gravity and color of three Bangladeshi local potato cultivars as influenced by stage of maturity. J. Plant Sci. 2015, 5, 124–132. [Google Scholar]

- Bekele, D.; Abera, G.; Gobena, A. Effects of chemical fertilizer types and rates on tuber yield and quality of potato (Solanum tuberosum L.) at Assosa, Western Ethiopia. Afr. J. Plant Sci. 2020, 14, 155–164. [Google Scholar]

- Duan, W.; Zhang, H.; Xie, B.; Wang, B.; Zhang, L. Impacts of nitrogen fertilization rate on the root yield, starch yield and starch physicochemical properties of the sweet potato cultivar Jishu 25. PLoS ONE 2019, 14, e221351. [Google Scholar] [CrossRef] [PubMed]

- El-Hadidi, E.; Ewais, M.; Shehata, A. Fertilization effects on potato yield and quality. J. Soil Sci. Agric. Eng. 2017, 8, 769–778. [Google Scholar] [CrossRef]

- Gichuhi, P.N.; Kpomblekou-a, K.; Bovell-benjamin, A.C. Nutritional and physical properties of organic Beauregard sweet potato [Ipomoea batatas (L.)] as influenced by broiler litter application rate. Food Sci. Nutr. 2014, 2, 332–340. [Google Scholar] [CrossRef] [PubMed]

- Nwite, J.C. Enhancing soil fertility status, sweet potato yield and tuber nutrient composition through different manure sources in SouthEastern Nigeria. Arch. Curr. Res. Int. 2016, 4, 1–11. [Google Scholar] [CrossRef]

- Adamovičs, A.; Poiša, L.; Antypova, L. The efficiency of using alternative fertilizers in potato plantations. In Proceedings of the 14th International Scientific and Practical Conference, Tarnovo, Bulgaria, 16 June 2023. [Google Scholar]

- Fernandes, A.M.; Soratto, R.P. Nutrition, dry matter accumulation and partitioning and phosphorus use efficiency of potato grown at different phosphorus levels in nutrient solution. Rev. Bras. Cienc. Solo 2012, 36, 1528–1537. [Google Scholar] [CrossRef]

- Misgina, N.A. Effect of phosphorus and potassium fertilizer rates on yield and yield component of potato (Solanum tubersum L,) at K/Awlaelo, Tigray, Ethiopia. Food Sci. Qual. Manag. 2016, 48, 60–69. [Google Scholar]

- Xing, Y.; Niu, X.; Wang, N.; Jiang, W.; Gao, Y.; Wang, X. The correlation between soil nutrient and potato quality in loess plateau of China based on PLSR. Sustainability 2020, 12, 1588. [Google Scholar] [CrossRef]

| Nutrient Compositions | KH2PO4 | MgSO4 | Microsol-B | Iron (Fe-EDTA) | KNO3 | Ca(NO3)2 |

|---|---|---|---|---|---|---|

| 75% | 25.500 g | 45.750 g | 2.250 g | 3.375 g | 8.625 g | 22.125 g |

| 100% | 34.000 g | 61.000 g | 3.000 g | 4.500 g | 11.500 g | 29.500 g |

| 125% | 42.500 g | 76.250 g | 3.750 g | 5.625 g | 14.375 g | 36.875 g |

| Variety | Days to Maturity | Yield (t ha−1) | Flesh Color | Dry Matter | Use | Dormancy (Months) |

|---|---|---|---|---|---|---|

| Shangi | ≤90 | 30–40 t | Cream skin | 21.4% | Chips, table | <1 |

| Nyota | 90–120 | >40 t | White-cream skin | 20% | Table, crisp, chips | 2–3 |

| Wanjiku | 90–120 | >40 t | White-cream skin | 21% | Table, crisp | >3 |

| Unica | 75–100 | >45 t | Red skin | 21% | Chips, table | 2.5–3.5 |

| Treatments | Starch Content (%) | Specific Gravity | Tuber Dry Matter (%) |

|---|---|---|---|

| NSSC | |||

| 75 (%) | 11.69 b | 1.06 b | 17.89 b |

| 100 (%) | 12.57 b | 1.09 b | 20.98 ab |

| 125 (%) | 15.59 a | 1.18 a | 24.90 a |

| MSD | 1.15 | 0.06 | 5.91 |

| Variety | |||

| Shangi | 13.48 a | 1.10 a | 21.19 a |

| Nyota | 13.03 a | 1.11 a | 20.79 a |

| Wanjiku | 13.19 a | 1.11 a | 20.83 a |

| Unica | 13.44 a | 1.13 a | 21.13 a |

| MSD | 0.81 | 0.06 | 2.34 |

| N × V | NS | NS | NS |

| NSSC | P Content (%) | Ash (%) | Crude Protein (%) |

|---|---|---|---|

| 75 (%) | 0.58 a | 5.83 b | 6.94 a |

| 100 (%) | 0.64 a | 5.92 b | 7.29 a |

| 125 (%) | 0.66 a | 7.12 a | 8.08 a |

| MSD | 0.14 | 0.75 | 3.29 |

| Variety | |||

| Shangi | 0.64 a | 6.89 a | 8.17 a |

| Nyota | 0.63 a | 6.33 a | 8.13 a |

| Wanjiku | 0.62 a | 6.14 a | 7.31 a |

| Unica | 0.62 a | 5.77 a | 7.15 a |

| MSD | 0.15 | 1.38 | 2.60 |

| N × V | NS | NS | NS |

| Parameters | Dry Matter | Specific Gravity | Starch Content | P Content | Ash Content | Crude Protein | Total Sugars |

|---|---|---|---|---|---|---|---|

| Dry Matter | 1 | ||||||

| Specific Gravity | 0.67 *** | 1 | |||||

| Starch Content | 0.82 *** | 0.77 *** | 1 | ||||

| Phosphorus | 0.042 NS | 0.259 ** | 0.185 NS | 1 | |||

| Ash Content | 0.43 ** | 0.414 ** | 0.504 ** | 0.085 *** | 1 | ||

| Crude Protein | −0.026 NS | −0.236 NS | −0.219 NS | 0.109 NS | −0.050 NS | 1 | |

| Total Sugars | 0.52 ** | 0.59 ** | 0.71 *** | 0.185 NS | 0.41 * | −0.134 NS | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wambugu, W.C.; Kibe, A.M.; Opiyo, A.M.; Githeng’u, S.; Odong, T. Influence of Hydroponics Nutrient Solution on Quality of Selected Varieties of Potato Minitubers. Horticulturae 2024, 10, 126. https://doi.org/10.3390/horticulturae10020126

Wambugu WC, Kibe AM, Opiyo AM, Githeng’u S, Odong T. Influence of Hydroponics Nutrient Solution on Quality of Selected Varieties of Potato Minitubers. Horticulturae. 2024; 10(2):126. https://doi.org/10.3390/horticulturae10020126

Chicago/Turabian StyleWambugu, Winnie Chebet, Anthony M. Kibe, Arnold M. Opiyo, Stephen Githeng’u, and Thomas Odong. 2024. "Influence of Hydroponics Nutrient Solution on Quality of Selected Varieties of Potato Minitubers" Horticulturae 10, no. 2: 126. https://doi.org/10.3390/horticulturae10020126

APA StyleWambugu, W. C., Kibe, A. M., Opiyo, A. M., Githeng’u, S., & Odong, T. (2024). Influence of Hydroponics Nutrient Solution on Quality of Selected Varieties of Potato Minitubers. Horticulturae, 10(2), 126. https://doi.org/10.3390/horticulturae10020126