Microbial Composition, Bioactive Compounds, Potential Benefits and Risks Associated with Kombucha: A Concise Review

Abstract

1. Introduction

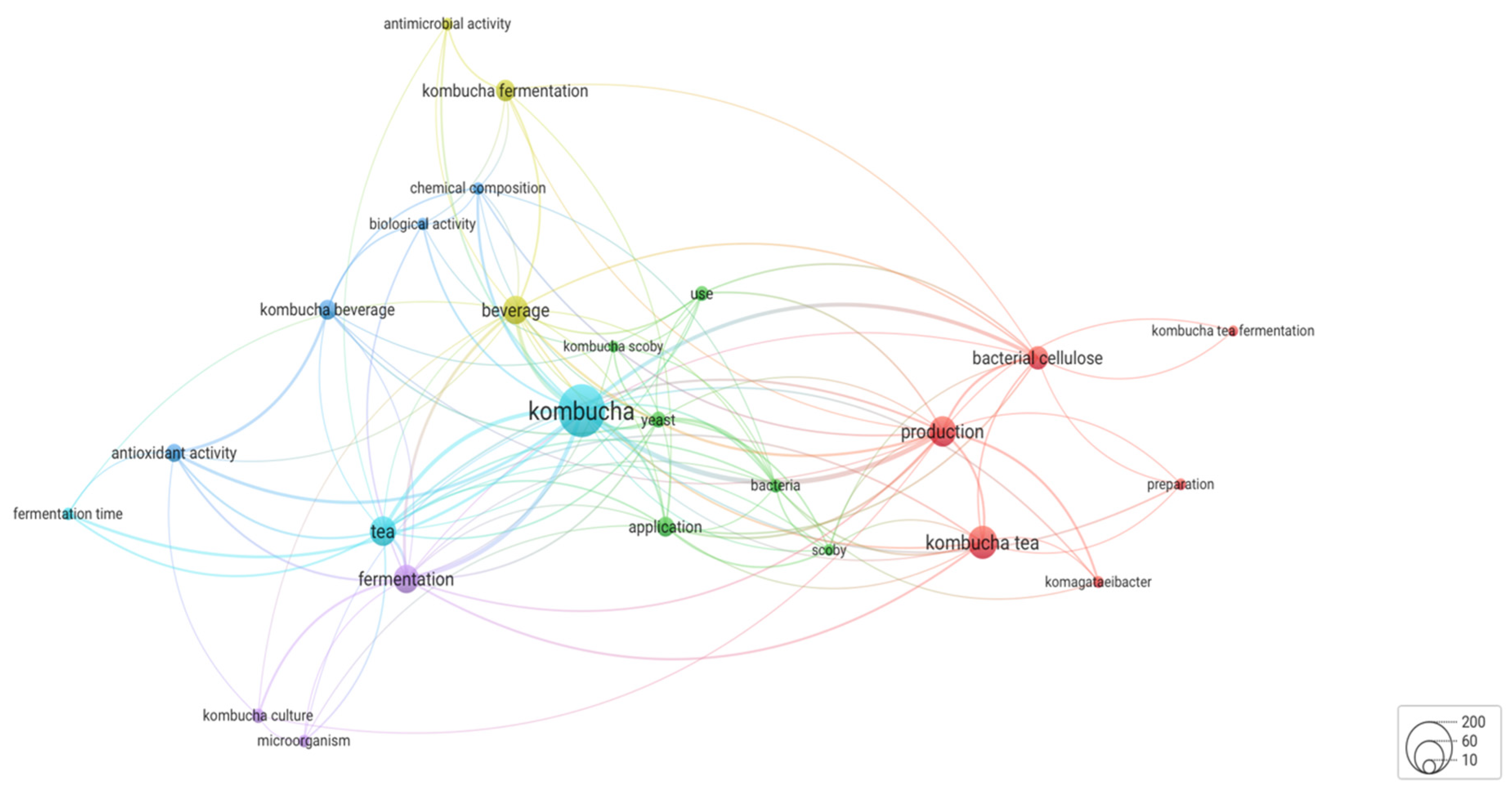

1.1. Developments in Kombucha

1.2. Microbial Compositions of Kombucha

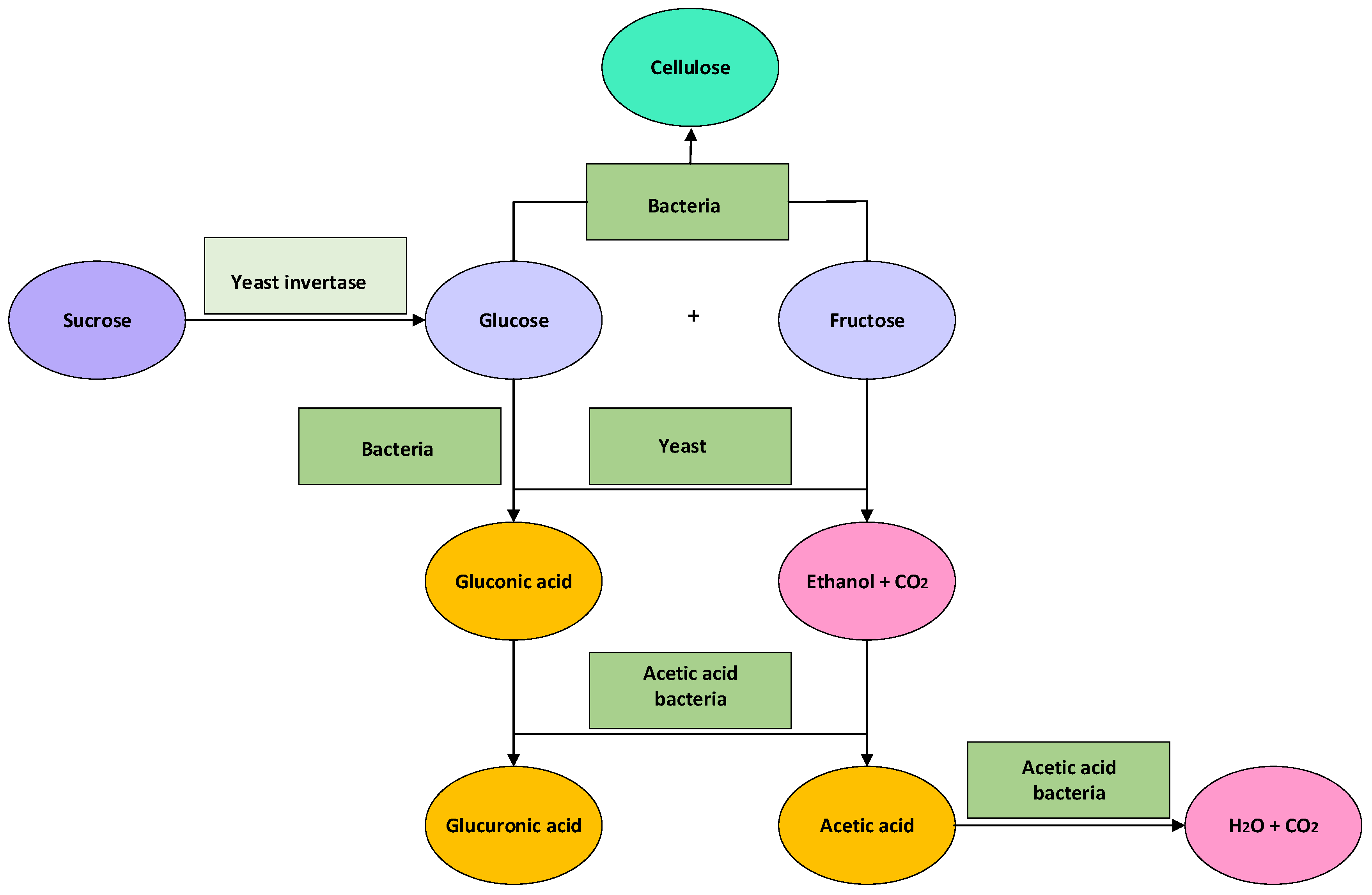

1.3. Kombucha Microbial Interactions

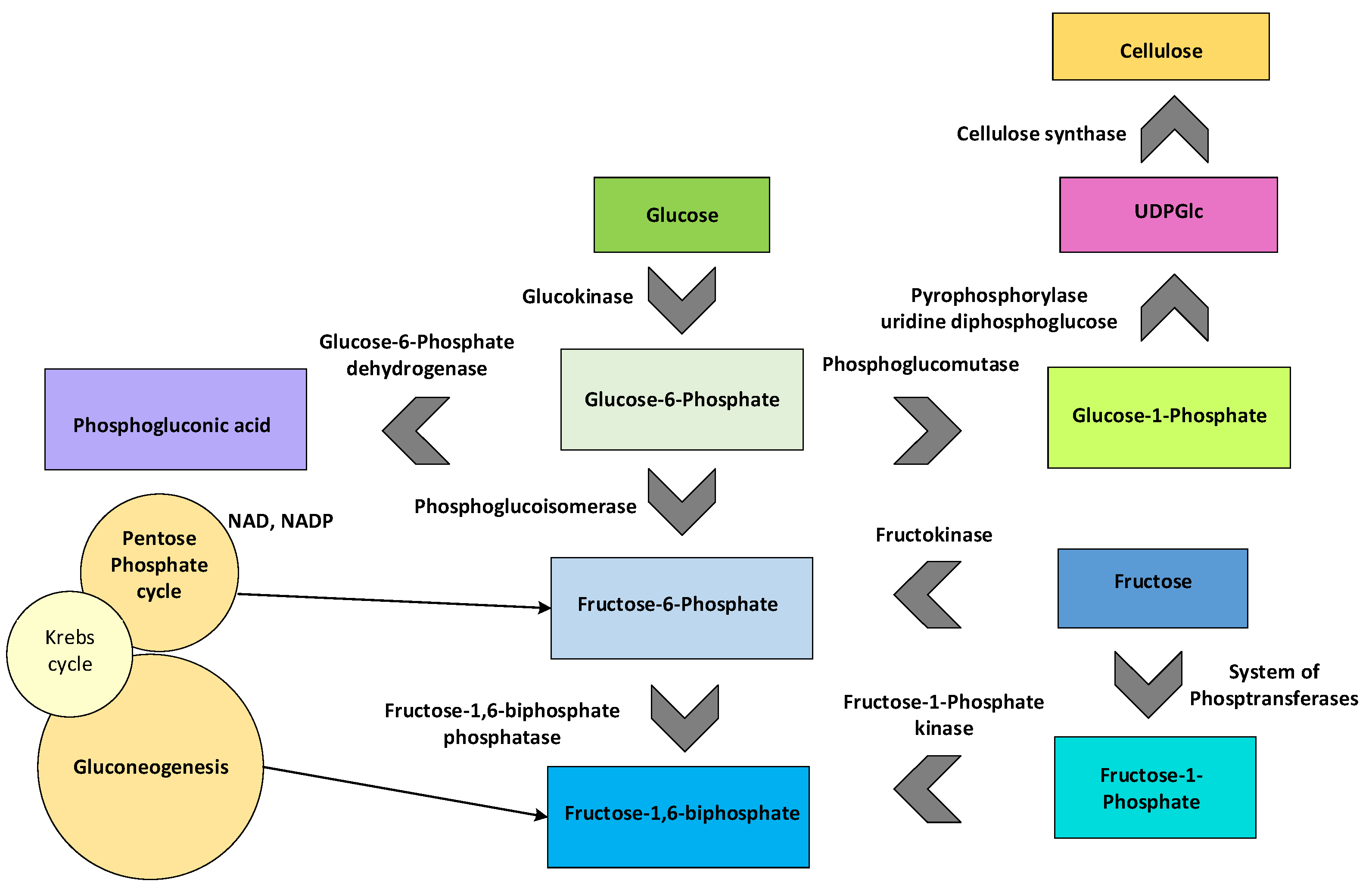

1.4. Microbial Production of Kombucha Cellulose

1.5. Factors Influencing Microbial Compositions of Kombucha

1.6. Tea Types and Bioactive Compounds in Kombucha

1.7. Kombucha Health Benefits

1.8. Potential Risk Factors of Kombucha Consumption

1.9. Toxicity of Kombucha due to Human Error

1.10. Possible Toxicity due to Product Quality

1.11. Alleviating Some Potential Risk Factors

1.12. Current Gaps, Recommendations, and Prospects

1.13. Rooibos Tea for Kombucha Production

1.14. Upcycling Kombucha Waste Products

2. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Laureys, D.; Britton, S.J.; De Clippeleer, J. Kombucha Tea Fermentation: A Review. J. Am. Soc. Brew. Chem. 2020, 78, 165–174. [Google Scholar] [CrossRef]

- De Filippis, F.; Troise, A.D.; Vitaglione, P.; Ercolini, D. Different Temperatures Select Distinctive Acetic Acid Bacteria Species and Promotes Organic Acids Production during Kombucha Tea Fermentation. Food Microbiol. 2018, 73, 11–16. [Google Scholar] [CrossRef] [PubMed]

- Arıkan, M.; Mitchell, A.L.; Finn, R.D.; Gürel, F. Microbial Composition of Kombucha Determined Using Amplicon Sequencing and Shotgun Metagenomics. J. Food Sci. 2020, 85, 455–464. [Google Scholar] [CrossRef] [PubMed]

- Dufresne, C.; Farnworth, E. Tea, Kombucha, and Health: A Review. Food Res. Int. 2000, 33, 409–421. [Google Scholar] [CrossRef]

- Sreeramulu, G.; Zhu, Y.; Knol, W. Kombucha Fermentation and Its Antimicrobial Activity. J. Agric. Food Chem. 2000, 48, 2589–2594. [Google Scholar] [CrossRef]

- Jayabalan, R.; Malbaša, R.V.; Lončar, E.S.; Vitas, J.S.; Sathishkumar, M. A Review on Kombucha Tea-Microbiology, Composition, Fermentation, Beneficial Effects, Toxicity, and Tea Fungus. Compr. Rev. Food Sci. Food Saf. 2014, 13, 538–550. [Google Scholar] [CrossRef]

- Roche, J.; Philosopher, T. The History and Spread of Kombucha. Available online: http://users.bestweb.net/~om/~kombu/roche.html (accessed on 4 April 2023).

- Jayabalan, R.; Malbaša, R.V.; Sathishkumar, M. Kombucha. Ref. Modul. Food Sci. 2016, 1–8. [Google Scholar] [CrossRef]

- Machado, G.; Leon, S.; Santos, F.; Lourega, R.; Dullius, J.; Mollmann, M.E.; Eichler, P. Literature Review on Furfural Production from Lignocellulosic Biomass. Nat. Resour. 2016, 7, 115–129. [Google Scholar] [CrossRef]

- Kim, J.; Adhikari, K. Current Trends in Kombucha: Marketing Perspectives and the Need for Improved Sensory Research. Beverages 2020, 6, 15. [Google Scholar] [CrossRef]

- Bishop, P.; Pitts, E.R.; Budner, D.; Thompson-Witrick, K.A. Kombucha: Biochemical and Microbiological Impacts on the Chemical and Flavor Profile. Food Chem. Adv. 2022, 1, 100025. [Google Scholar] [CrossRef]

- Leal, J.M.; Suárez, L.V.; Jayabalan, R.; Oros, J.H.; Escalante-Aburto, A. A Review on Health Benefits of Kombucha Nutritional Compounds and Metabolites. CYTA-J. Food 2018, 16, 390–399. [Google Scholar] [CrossRef]

- Jakubczyk, K.J.; Piotrowska, G.; Janda, K. Characteristics and Biochemical Composition of Kombucha—Fermented Tea. Med. Ogólna Nauk. Zdrowiu 2020, 26, 94–96. [Google Scholar] [CrossRef]

- May, A.; Narayanan, S.; Alcock, J.; Varsani, A.; Maley, C.; Aktipis, A. Kombucha: A Novel Model System for Cooperation and Conflict in a Complex Multi-Species Microbial Ecosystem. PeerJ 2019, 1, e7565. [Google Scholar] [CrossRef] [PubMed]

- Chakravorty, S.; Bhattacharya, S.; Chatzinotas, A.; Chakraborty, W.; Bhattacharya, D.; Gachhui, R. Kombucha Tea Fermentation: Microbial and Biochemical Dynamics. Int. J. Food Microbiol. 2016, 220, 63–72. [Google Scholar] [CrossRef]

- Wang, B.; Rutherfurd-Markwick, K.; Zhang, X.X.; Mutukumira, A.N. Kombucha: Production and Microbiological Research. Foods 2022, 11, 3456. [Google Scholar] [CrossRef]

- Antolak, H.; Piechota, D.; Kucharska, A. Kombucha Tea—A Double Power of Bioactive Compounds from Tea and Symbiotic Culture of Bacteria and Yeasts (SCOBY). Antioxidants 2021, 10, 1541. [Google Scholar] [CrossRef]

- Villarreal-Soto, S.A.; Beaufort, S.; Bouajila, J.; Souchard, J.P.; Taillandier, P. Understanding Kombucha Tea Fermentation: A Review. J. Food Sci. 2018, 83, 580–588. [Google Scholar] [CrossRef]

- Moreno, J.; Peinado, R. Sugars in Must. In Enological Chemistry; Elsevier: Amsterdam, The Netherlands, 2012; pp. 95–107. [Google Scholar] [CrossRef]

- Markov, S.; Jerinic, V.; Cvetkovic, D.; Loncar, E.; Malbasa, R. Kombucha—Functional Beverage: Composition, Characteristics and Process of Biotransformation. Hem. Ind. 2003, 57, 456–462. [Google Scholar] [CrossRef]

- Marsh, A.J.; O’Sullivan, O.; Hill, C.; Ross, R.P.; Cotter, P.D. Sequence-Based Analysis of the Bacterial and Fungal Compositions of Multiple Kombucha (Tea Fungus) Samples. Food Microbiol. 2014, 38, 171–178. [Google Scholar] [CrossRef]

- Gaggìa, F.; Baffoni, L.; Galiano, M.; Nielsen, D.S.; Jakobsen, R.R.; Castro-Mejía, J.L.; Bosi, S.; Truzzi, F.; Musumeci, F.; Dinelli, G.; et al. Kombucha Beverage from Green, Black and Rooibos Teas: A Comparative Study Looking at Microbiology, Chemistry and Antioxidant Activity. Nutrients 2019, 11, 1. [Google Scholar] [CrossRef]

- Villarreal-Soto, S.A.; Bouajila, J.; Pace, M.; Leech, J.; Cotter, P.D.; Souchard, J.P.; Taillandier, P.; Beaufort, S. Metabolome-Microbiome Signatures in the Fermented Beverage, Kombucha. Int. J. Food Microbiol. 2020, 333, 108778. [Google Scholar] [CrossRef] [PubMed]

- Coton, M.; Pawtowski, A.; Taminiau, B.; Burgaud, G.; Coulloume-Labarthe, L.; Daube, G.; Coton, E. Unravelling Microbial Ecology of Industrial-Scale Kombucha Fermentations by Metabarcoding and Culture Based Methods. FEMS Microbiol. Ecol. 2017, 93, fix048. [Google Scholar] [CrossRef]

- Teoh, A.L.; Heard, G.; Cox, J. Yeast Ecology of Kombucha Fermentation. Int. J. Food Microbiol. 2004, 95, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Watawana, M.I.; Jayawardena, N.; Gunawardhana, C.B.; Waisundara, V.Y. Health, Wellness, and Safety Aspects of the Consumption of Kombucha. J. Chem. 2015, 2015, 591869. [Google Scholar] [CrossRef]

- Mayser, P.; Fromme, S.; Leitzmann, C.; Grunder, K. The Yeast Spectrum of the ‘tea Fungus Kornbucha’. Mycoses 1995, 38, 289–295. [Google Scholar] [CrossRef]

- Herrera, T.; Calderon Villagomez, A. Species of Yeasts Isolated in Mexico from the Tea Fungus. Rev. Mex. Micol. 1989, 5, 205–210. [Google Scholar]

- Yamada, Y.; Yukphan, P.; Thi, H.; Vu, L.; Muramatsu, Y.; Ochaikul, D.; Tanasupawat, S.; Nakagawa, Y. Short Communication Description of Komagataeibacter Gen. Nov., with Proposals of New Combinations (Acetobacteraceae). J. Gen. Appl. Microbiol 2012, 58, 397–404. [Google Scholar] [CrossRef]

- Greenwalt, C.J.; Steinkraus, K.H.; Ledford, R.A. Kombucha, the Fermented Tea: Microbiology, Composition, and Claimed Health Effects. J. Food Prot. 2000, 63, 976–981. Available online: http://meridian.allenpress.com/jfp/article-pdf/63/7/976/1671742/0362-028x-63_7_976.pdf (accessed on 3 April 2023). [CrossRef]

- Dutta, D.; Gachhui, R. Novel Nitrogen-Fixing Acetobacter Nitrogenifigens Sp. Nov., Isolated from Kombucha Tea. Int. J. Syst. Evol. Microbiol. 2006, 56, 1899–1903. [Google Scholar] [CrossRef]

- Dutta, D.; Gachhui, R. Nitrogen-Fixing and Cellulose-Producing Gluconacetobacter kombuchae Sp. Nov., Isolated from Kombucha Tea. Int. J. Syst. Evol. Microbiol. 2007, 57, 353–357. [Google Scholar] [CrossRef]

- Watawana, M.I.; Jayawardena, N.; Gunawardhana, C.B.; Waisundara, V.Y. Enhancement of the Antioxidant and Starch Hydrolase Inhibitory Activities of King Coconut Water (Cocos Nucifera Var. Aurantiaca) by Fermentation with Kombucha “Tea Fungus”. Int. J. Food Sci. Technol. 2016, 51, 490–498. [Google Scholar] [CrossRef]

- Kluz, M.I.; Pietrzyk, K.; Pastuszczak, M.; Kacaniova, M.; Kita, A.; Kapusta, I.; Zaguła, G.; Zagrobelna, E.; Struś, K.; Marciniak-Lukasiak, K.; et al. Microbiological and Physicochemical Composition of Various Types of Homemade Kombucha Beverages Using Alternative Kinds of Sugars. Foods 2022, 11, 1523. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Lagishetty, V.; Kurnia, P.; Henning, S.M.; Ahdoot, A.I.; Jacobs, J.P. Microbial and Chemical Profiles of Commercial Kombucha Products. Nutrients 2022, 14, 670. [Google Scholar] [CrossRef]

- Nyhan, L.M.; Lynch, K.M.; Sahin, A.W.; Arendt, E.K. Advances in Kombucha Tea Fermentation: A Review. Appl. Microbiol. 2022, 2, 73–101. [Google Scholar] [CrossRef]

- Liu, C.; Hsu, W.; Lee, F.; Liao, C. The Isolation and Identification of Microbes from a Fermented Tea Beverage, Haipao, and Their Interactions during Haipao Fermentation. Food Microbiol. 1996, 13, 407–415. [Google Scholar] [CrossRef]

- Mohite, B.V.; Patil, S.V. A Novel Biomaterial: Bacterial Cellulose and Its New Era Applications. Biotechnol. Appl. Biochem. 2014, 61, 101–110. [Google Scholar] [CrossRef] [PubMed]

- Lahiri, D.; Nag, M.; Dutta, B.; Dey, A.; Sarkar, T.; Pati, S.; Edinur, H.A.; Kari, Z.A.; Noor, N.H.M.; Ray, R.R. Bacterial Cellulose: Production, Characterization and Application as Antimicrobial Agent. Int. J. Mol. Sci. 2021, 22, 12984. [Google Scholar] [CrossRef]

- Shoda, M.; Sugano, Y. Recent Advances in Bacterial Cellulose Production. Biotechnol. Bioprocess Eng. 2005, 10, 1–8. [Google Scholar] [CrossRef]

- Tan, L.; Ren, L.; Cao, Y.; Chen, X.; Tang, X. Bacterial Cellulose Synthesis in Kombucha by Gluconacetobacter Sp and Saccharomyces Sp. Adv. Mater. Res. 2012, 554–556, 1000–1003. [Google Scholar] [CrossRef]

- Chawla, P.R.; Bajaj, I.B.; Survase, S.A.; Singhal, R.S. Microbial Cellulose: Fermentative Production and Applications. Food Technol. Biotechnol. 2009, 42, 107–124. [Google Scholar]

- Yu, X.; Atalla, R.H. Production of Cellulose II by Acetobacter Xylinum in the Presence of 2,6-Dichlorobenzonitrile. Int. J. Biol. Macromol. 1996, 19, 145–146. [Google Scholar] [CrossRef] [PubMed]

- Jones, D.; Ormondroyd, G.O.; Curling, S.F.; Popescu, C.-M.; Popescu, M.-C. Chemical Compositions of Natural Fibres. In Advanced High Strength Natural Fibre Composites in Construction; Fan, M., Fu, F., Eds.; Matthew Deans: Oxford, UK, 2017; pp. 23–58. [Google Scholar] [CrossRef]

- Overbeek, R.; Olson, R.; Pusch, G.D.; Olsen, G.J.; Davis, J.J.; Disz, T.; Edwards, R.A.; Gerdes, S.; Parrello, B.; Shukla, M.; et al. The SEED and the Rapid Annotation of Microbial Genomes Using Subsystems Technology (RAST). Nucleic Acids Res. 2014, 42, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Ross, P.; Mayer, R.; Benziman, M. Cellulose Biosynthesis and Function in Bacteria. Microbiol. Rev. 1991, 55, 35–58. [Google Scholar] [CrossRef] [PubMed]

- Goh, W.; Rosma, A.; Kaur, B.; Fazilah, A.; Karim, A.A.; Bhat, R. Fermentation of Black Tea Broth (Kombucha): I. Effects of Sucrose Concentration and Fermentation Time on the Yield of Microbial Cellulose. Int. Food Res. J. 2012, 19, 109–117. [Google Scholar]

- Yim, S.M.; Song, J.E.; Kim, H.R. Production and Characterization of Bacterial Cellulose Fabrics by Nitrogen Sources of Tea and Carbon Sources of Sugar. Process Biochem. 2017, 59, 26–36. [Google Scholar] [CrossRef]

- Gargey, I.A.; Indira, D.; Jayabalan, R.; Balasubramanian, P. Optimization of Etherification Reactions for Recycling of Tea Fungal Biomass Waste into Carboxymethylcellulose. In Green Buildings and Sustainable Engineering; Springer Transactions in Civil and Environmental, Engineering; Drück, H., Pillai, R., Tharian, M., Majeed, A., Eds.; Springer: Singapore, 2019; pp. 337–346. [Google Scholar] [CrossRef]

- Kurtzman, C.P.; Robnett, C.J.; Basehoar-Powers, E. Zygosaccharomyces Kombuchaensis, a New Ascosporogenous Yeast from “Kombucha Tea”. FEMS Yeast Res. 2001, 1, 133–138. [Google Scholar] [CrossRef]

- Amarasekara, A.S.; Wang, D.; Grady, T.L. A Comparison of Kombucha SCOBY Bacterial Cellulose Purification Methods. SN Appl. Sci. 2020, 2, 7. [Google Scholar] [CrossRef]

- Dima, S.O.; Panaitescu, D.M.; Orban, C.; Ghiurea, M.; Doncea, S.M.; Fierascu, R.C.; Nistor, C.L.; Alexandrescu, E.; Nicolae, C.A.; Trica, B.; et al. Bacterial Nanocellulose from Side-Streams of Kombucha Beverages Production: Preparation and Physical-Chemical Properties. Polymers 2017, 9, 374. [Google Scholar] [CrossRef]

- Ramírez Tapias, Y.A.; Peltzer, M.A.; Delgado, J.F.; Salvay, A.G. Kombucha Tea By-Product as Source of Novel Materials: Formulation and Characterization of Films. Food Bioprocess Technol. 2020, 13, 1166–1180. [Google Scholar] [CrossRef]

- Muhialdin, B.J.; Voon, W.; Shobirin, A.; Hussin, M. Effects of Sugar Sources and Fermentation Time on the Properties of Tea Fungus (Kombucha) Beverage. Artic. Int. Food Res. J. 2019, 26, 481–487. [Google Scholar]

- Mizzi, L.; Maniscalco, D.; Gaspari, S.; Chatzitzika, C.; Gatt, R.; Valdramidis, V.P. Assessing the Individual Microbial Inhibitory Capacity of Different Sugars against Pathogens Commonly Found in Food Systems. Lett. Appl. Microbiol. 2020, 71, 251–258. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Liu, B.Y. Changes in Major Components of Tea Fungus Metabolites during Prolonged Fermentation. J. Appl. Microbiol. 2000, 89, 834–839. [Google Scholar] [CrossRef] [PubMed]

- Pou, K.R.J. Fermentation: The Key Step in the Processing of Black Tea. J. Biosyst. Eng. 2016, 41, 85–92. [Google Scholar] [CrossRef]

- Chacko, S.M.; Thambi, P.T.; Kuttan, R.; Nishigaki, I. Beneficial Effects of Green Tea: A Literature Review. Chin. Med. 2010, 5, 13. [Google Scholar] [CrossRef]

- Joubert, E.; Schulz, H. Production and Quality Aspects of Rooibos Tea and Related Products. A Review. J. Appl. Bot. Food Qual. 2006, 80, 138–144. [Google Scholar]

- Butt, M.S.; Imran, A.; Sharif, M.K.; Ahmad, R.S.; Xiao, H.; Imran, M.; Rsool, H.A. Black Tea Polyphenols: A Mechanistic Treatise. Crit. Rev. Food Sci. Nutr. 2014, 54, 1002–1011. [Google Scholar] [CrossRef]

- Wang, K.; Gan, X.; Tang, X.; Wang, S.; Tan, H. Determination of D-Saccharic Acid-1,4-Lactone from Brewed Kombucha Broth by High-Performance Capillary Electrophoresis. J. Chromatogr. B 2010, 878, 371–374. [Google Scholar] [CrossRef]

- Wei, W.; Bao-Chuan, G.; Bao-Ping, J. D-Glucaric Acid and Other Metabolites in Kombucha. Food Sci. 2004, 25, 147–151. [Google Scholar]

- Bauer-Petrovska, B.; Petrushevska-Tozi, L. Mineral and Water Soluble Vitamin Content in the Kombucha Drink. Int. J. Food Sci. Technol. 2000, 35, 201–205. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Gachhui, R.; Sil, P.C. The Prophylactic Role of D-Saccharic Acid-1,4-Lactone against Hyperglycemia-Induced Hepatic Apoptosis via Inhibition of Both Extrinsic and Intrinsic Pathways in Diabetic Rats. Food Funct. 2013, 4, 283–296. [Google Scholar] [CrossRef]

- Martínez-Leal, J.; Ponce-García, N.; Escalante-Aburto, A. Recent Evidence of the Beneficial Effects Associated with Glucuronic Acid Contained in Kombucha Beverages. Curr. Nutr. Rep. 2020, 9, 163–170. [Google Scholar] [CrossRef] [PubMed]

- Vīna, I.; Linde, R.; Patetko, A.; Semjonovs, P. Glucuronic Acid from Fermented Beverages: Biochemical Functions in Humans and Its Role in Health Protection. IJRRAS 2013, 14, 217–230. [Google Scholar]

- Murugesan, G.S.; Sathishkumar, M.; Jayabalan, R.; Binupriya, A.R.; Swaminathan, K.; Yun, S.E. Hepatoprotective and Curative Properties of Kombucha Tea against Carbon Tetrachloride-Induced Toxicity. J. Microbiol. Biotechnol. 2009, 19, 397–402. [Google Scholar] [CrossRef] [PubMed]

- Abshenas, J.; Derakhshanfar, A.; Ferdosi, M.H.; Hasanzadeh, S. Protective Effect of Kombucha Tea against Acetaminophen-Induced Hepatotoxicity in Mice: A Biochemical and Histopathological Study. Comp. Clin. Path. 2012, 21, 1243–1248. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Gachhui, R.; Sil, P.C. Hepatoprotective Properties of Kombucha Tea against TBHP-Induced Oxidative Stress via Suppression of Mitochondria Dependent Apoptosis. Pathophysiology 2011, 18, 221–234. [Google Scholar] [CrossRef]

- Rasouli, L.; Aryaeian, N.; Gorjian, M.; Nourbakhsh, M.; Amiri, F. Evaluation of Cytotoxicity and Anticancer Activity of Kombucha and Doxorubicin Combination Therapy on Colorectal Cancer Cell Line HCT-116. J. Educ. Health Promot. 2021, 10, 376. [Google Scholar] [CrossRef]

- Aloulou, A.; Hamden, K.; Elloumi, D.; Ali, M.B.; Hargafi, K.; Jaouadi, B.; Ayadi, F.; Elfeki, A.; Ammar, E. Hypoglycemic and Antilipidemic Properties of Kombucha Tea in Alloxan-Induced Diabetic Rats. BMC Complement. Altern. Med. 2012, 12, 63. [Google Scholar] [CrossRef]

- Kapp, J.M.; Sumner, W. Kombucha: A Systematic Review of the Empirical Evidence of Human Health Benefit. Ann. Epidemiol. 2019, 30, 66–70. [Google Scholar] [CrossRef]

- Murphy, T.E.; Walia, K.; Farber, J.M. Safety Aspects and Guidance for Consumers on the Safe Preparation, Handling and Storage of Kombucha—A Fermented Tea Beverage. Food Prot. Trends 2018, 38, 329–337. [Google Scholar]

- Bintsis, T. Foodborne Pathogens. AIMS Microbiol. 2017, 3, 529–563. [Google Scholar] [CrossRef]

- Marroquín-Cardona, A.G.; Johnson, N.M.; Phillips, T.D.; Hayes, A.W. Mycotoxins in a Changing Global Environment—A Review. Food Chem. Toxicol. 2014, 69, 220–230. [Google Scholar] [CrossRef] [PubMed]

- Lokunarangodage, C.; Wickramasinghe, I.; Ranaweera, K.K.D.S. Impact of HACCP Based Food Safety Management Systems in Improving Food Safety of Sri Lankan Tea Industry. J. Tea Sci. Res. 2016, 6, 1–16. [Google Scholar] [CrossRef]

- Phan, T.G.; Estell, J.; Duggin, G.; Beer, I.; Smith, D.; Ferson, M.J. Lead Poisoning from Drinking Kombucha Tea Brewed in a Ceramic Pot. Med. J. Aust. 1998, 169, 644–646. [Google Scholar] [CrossRef]

- Tejedor-Calvo, E.; Morales, D. Chemical and Aromatic Changes during Fermentation of Kombucha Beverages Produced Using Strawberry Tree (Arbutus Unedo) Fruits. Fermentation 2023, 9, 326. [Google Scholar] [CrossRef]

- Greenwalt, C.J.; Ledford, R.A.; Steinkraus, K.H. Determination and Characterization of the Antimicrobial Activity of the Fermented Tea Kombucha. LWT-Food Sci. Technol. 1998, 31, 291–296. [Google Scholar] [CrossRef]

- WEBMD. Webmd.Com_BLACK TEA: Overview, Uses, Side Effects, Precautions, Interactions, Dosing and Reviews. Available online: https://www.webmd.com›vitamins›ingredientmono-997 (accessed on 4 April 2023).

- Morton, J.F. Rooibos Tea, Aspalathus linearis, a Caffeineless, Low-Tannin Beverage 1 The Plant Is of Very Limited Distribution, Occurring Naturally Only in the Western Districts of Cape Province, Particularly the Cedarberg Mountains and Higher Areas. Econ. Bot. 1983, 37, 164–173. [Google Scholar] [CrossRef]

- Joubert, E.; Gelderblom, W.C.A.; De Beer, D. Phenolic Contribution of South African Herbal Teas to a Healthy Diet. Nat. Prod. Commun. 2009, 4, 701–718. [Google Scholar] [CrossRef]

- Joubert, E.; de Beer, D. Rooibos (Aspalathus linearis) beyond the Farm Gate: From Herbal Tea to Potential Phytopharmaceutical. S. Afr. J. Bot. 2011, 77, 869–886. [Google Scholar] [CrossRef]

- Hillis, W.E.; Inoue, T. The Polyphenols of Nothofagus Species-II. The Heartwood of Nothofagus Fusca. Phytochemistry 1967, 6, 59–67. [Google Scholar] [CrossRef]

- Huang, C.F.; Gan, X.W.; Bai, H.Y.; Ma, L.; Hu, L.H. Schoepfin A, B, C: Three New Chalcone C-Glycosides from Schoepfia Chinensis. Nat. Prod. Res. 2008, 22, 623–627. [Google Scholar] [CrossRef]

- Krafczyk, N.; Glomb, M.A. Characterization of Phenolic Compounds in Rooibos Tea. J. Agric. Food Chem. 2008, 56, 3368–3376. [Google Scholar] [CrossRef] [PubMed]

- Bramati, L.; Minoggio, M.; Gardana, C.; Simonetti, P.; Mauri, P.; Pietta, P. Quantitative Characterization of Flavonoid Compounds in Rooibos Tea (Aspalathus linearis) by LC-UV/DAD. J. Agric. Food Chem. 2002, 50, 5513–5519. [Google Scholar] [CrossRef] [PubMed]

- CARMIEN. Rooibos and Your Mental Health; CARMIEN: Citrusdal, South Africa, 2023; pp. 1–5. Available online: https://carmientea.co.za/rooibos-tea-and-your-mental-health-stress-anxiety (accessed on 4 April 2023).

- Marnewick, J.L.; Rautenbach, F.; Venter, I.; Neethling, H.; Blackhurst, D.M.; Wolmarans, P.; MacHaria, M. Effects of Rooibos (Aspalathus linearis) on Oxidative Stress and Biochemical Parameters in Adults at Risk for Cardiovascular Disease. J. Ethnopharmacol. 2011, 133, 46–52. [Google Scholar] [CrossRef] [PubMed]

- Marnewick, J.L.; Gelderblom, W.C.A.; Joubert, E. An Investigation on the Antimutagenic Properties of South African Herbal Teas. Mutat. Res.-Genet. Toxicol. Environ. Mutagen. 2000, 471, 157–166. [Google Scholar] [CrossRef] [PubMed]

- Ulicna, O.; Vancova, O.; Waczulikova, I.; Bozek, P.; Janega, P.; Babal, P.; Liskova, S.; Greksak, M. Does Rooibos Tea (Aspalathus linearis) Support Regeneration of Rat Liver after Intoxication by Carbon Tetrachloride? Gen. Physiol. Biophys. 2008, 27, 179–186. [Google Scholar] [PubMed]

- Ajuwon, O.R.; Katengua-Thamahane, E.; Van Rooyen, J.; Oguntibeju, O.O.; Marnewick, J.L. Protective Effects of Rooibos (Aspalathus linearis) and/or Red Palm Oil (Elaeis guineensis) Supplementation on Tert -Butyl Hydroperoxide-Induced Oxidative Hepatotoxicity in Wistar Rats. Evid.-Based Complement. Altern. Med. 2013, 2013, 19. [Google Scholar] [CrossRef]

- Uličná, O.; Vančová, O.; Božek, P.; Čársky, J.; Šebeková, K.; Boor, P.; Nakano, M.; Greksák, M. Rooibos Tea (Aspalathus linearis) Partially Prevents Oxidative Stress in Streptozotocin-Induced Diabetic Rats. Physiol. Res. 2006, 55, 157–164. [Google Scholar] [CrossRef]

- Sasaki, Y.F.; Yamada, H.; Shimoi, K.; Kator, K.; Kinae, N. The Clastogen-Suppressing Effects of Green Tea, Po-Lei Tea and Rooibos Tea in CHO Cells and Mice. Mutat. Res. 1993, 286, 221–232. [Google Scholar] [CrossRef]

- Ajuwon, O.R.; Oguntibeju, O.O.; Marnewick, J.L. Amelioration of Lipopolysaccharide-Induced Liver Injury by Aqueous Rooibos (Aspalathus linearis) Extract via Inhibition of pro-Inflammatory Cytokines and Oxidative Stress. BMC Complement. Altern. Med. 2014, 14, 392. [Google Scholar] [CrossRef]

- Hopfe, S.; Flemming, K.; Lehmann, F.; Möckel, R.; Kutschke, S.; Pollmann, K. Leaching of Rare Earth Elements from Fluorescent Powder Using the Tea Fungus Kombucha. Waste Manag. 2017, 62, 211–221. [Google Scholar] [CrossRef]

- Aduri, P.; Ankita Rao, K.; Fatima, A.; Kaul, P.; Shalini, A. Study of Biodegradable Packaging Material Produced from SCOBY. Life Sci. Inform. Publ. 2019, 5, 389–404. [Google Scholar] [CrossRef]

- Kamiński, K.; Jarosz, M.; Grudzień, J.; Pawlik, J.; Zastawnik, F.; Pandyra, P.; Kołodziejczyk, A.M. Hydrogel Bacterial Cellulose: A Path to Improved Materials for New Eco-Friendly Textiles. Cellulose 2020, 27, 5353–5365. [Google Scholar] [CrossRef]

- Najafpour, A.; Rajabi Khorrami, A.; Aberoomand Azar, P.; Saber Tehrani, M. Study of Heavy Metals Biosorption by Tea Fungus in Kombucha Drink Using Central Composite Design. J. Food Compos. Anal. 2020, 86, 103359. [Google Scholar] [CrossRef]

- Murugesan, G.S.; Sathishkumar, M.; Swaminathan, K. Supplementation of Waste Tea Fungal Biomass as a Dietary Ingredient for Broiler Chicks. Bioresour. Technol. 2005, 96, 1743–1748. [Google Scholar] [CrossRef] [PubMed]

- Kruk, M.; Trząskowska, M.; Ścibisz, I.; Pokorski, P. Application of the “Scoby” and Kombucha Tea for the Production of Fermented Milk Drinks. Microorganisms 2021, 9, 123. [Google Scholar] [CrossRef]

- Zhu, C.; Li, F.; Zhou, X.; Lin, L.; Zhang, T. Kombucha-Synthesized Bacterial Cellulose: Preparation, Characterization, and Biocompatibility Evaluation. J. Biomed. Mater. Res. 2014, 102, 1548–1557. [Google Scholar] [CrossRef]

- Shanmugavel, M.; Nandhini, N.; Supriya, B.; Vasantharaj, S.; Inbasekaran, S.; Gnanamani, A. Kombucha Fungus Mediated Silver Nanoparticles and Their Biological Activities. Int. J. Appl. Bioeng. 2017, 11, 22–26. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ojo, A.O.; de Smidt, O. Microbial Composition, Bioactive Compounds, Potential Benefits and Risks Associated with Kombucha: A Concise Review. Fermentation 2023, 9, 472. https://doi.org/10.3390/fermentation9050472

Ojo AO, de Smidt O. Microbial Composition, Bioactive Compounds, Potential Benefits and Risks Associated with Kombucha: A Concise Review. Fermentation. 2023; 9(5):472. https://doi.org/10.3390/fermentation9050472

Chicago/Turabian StyleOjo, Abidemi Oluranti, and Olga de Smidt. 2023. "Microbial Composition, Bioactive Compounds, Potential Benefits and Risks Associated with Kombucha: A Concise Review" Fermentation 9, no. 5: 472. https://doi.org/10.3390/fermentation9050472

APA StyleOjo, A. O., & de Smidt, O. (2023). Microbial Composition, Bioactive Compounds, Potential Benefits and Risks Associated with Kombucha: A Concise Review. Fermentation, 9(5), 472. https://doi.org/10.3390/fermentation9050472