Development of Novel Textile Bioreactor for Anaerobic Utilization of Flocculating Yeast for Ethanol Production

Abstract

:1. Introduction

2. Methods

2.1. Microorganism

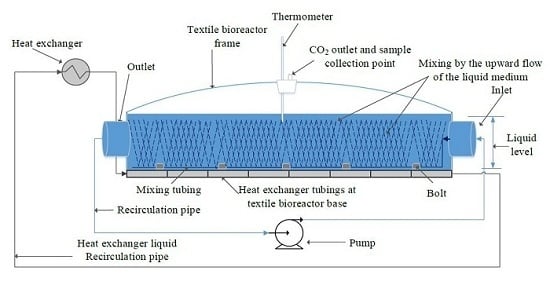

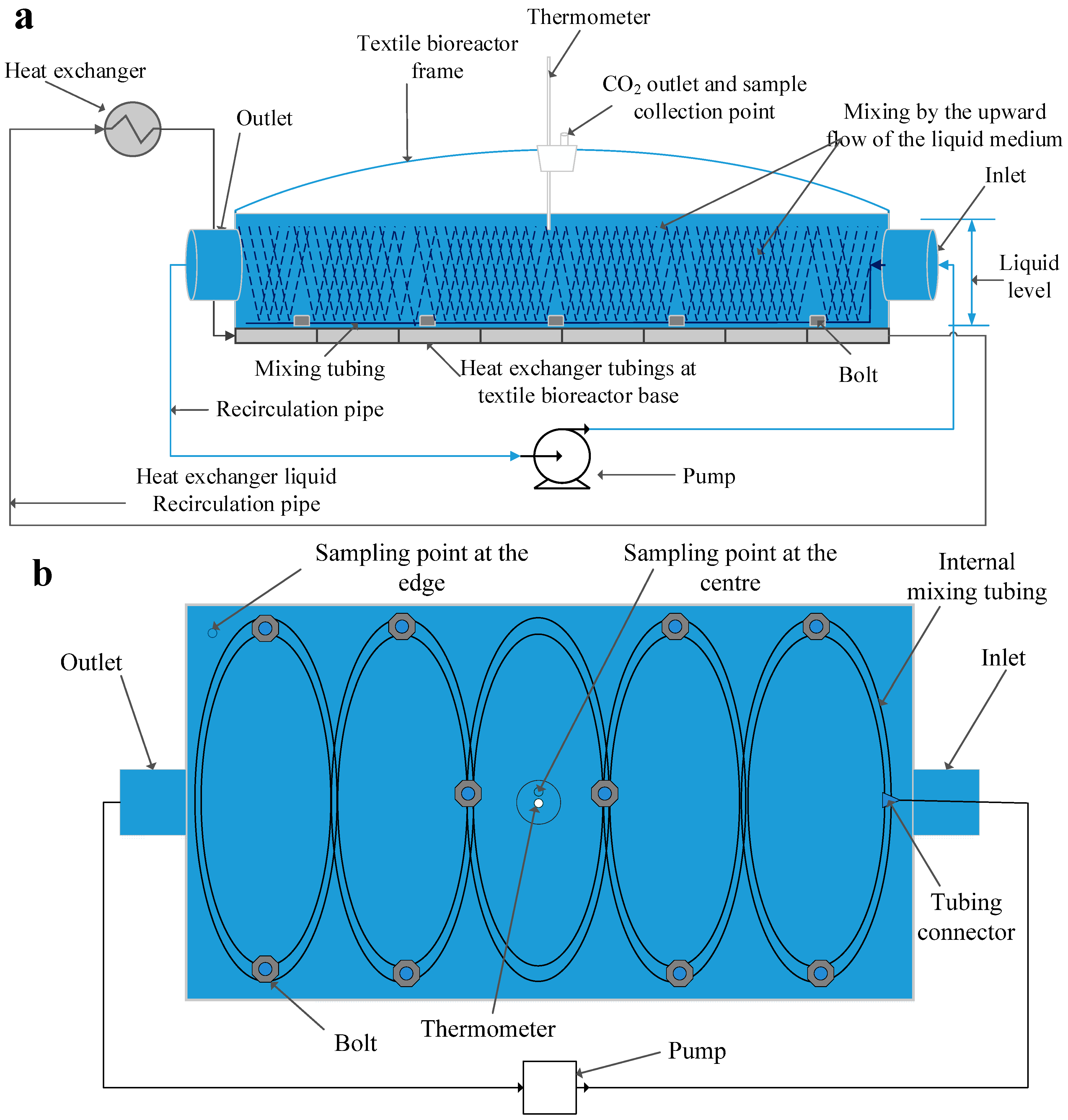

2.2. Textile Bioreactor and Its Development

2.3. Mixing in the Bioreactor

2.4. Analytical Methods

2.5. Experimental Setup for Fermentation

2.6. Fluidization of the Flocs in the Bioreactor

2.7. Statistical Analysis

3. Results and Discussion

3.1. Maintaining Optimal Flocs Contact in the Textile Bioreactor

| Q (VVM) | V0 (m/s) × 106 | Vi (m/s) | Vh at Different Hole Spacing (m/s) | Vs (m/s) | ||

|---|---|---|---|---|---|---|

| 1 cm Spacing | 5 mm Spacing | 2 mm Spacing | ||||

| 0.0016 | 1.78 | 0.03 | 0.004 | 0.002 | 0.001 | 0.01 |

| 0.0120 | 13.37 | 0.25 | 0.030 | 0.015 | 0.006 | 0.01 |

| 0.0160 | 17.83 | 0.34 | 0.040 | 0.020 | 0.008 | 0.01 |

| 0.0320 | 35.64 | 0.68 | 0.080 | 0.040 | 0.016 | 0.01 |

| 0.0600 | 66.84 | 1.27 | 0.151 | 0.075 | 0.030 | 0.01 |

3.2. Mixing as a Means of Reducing Mass Transfer Limitations

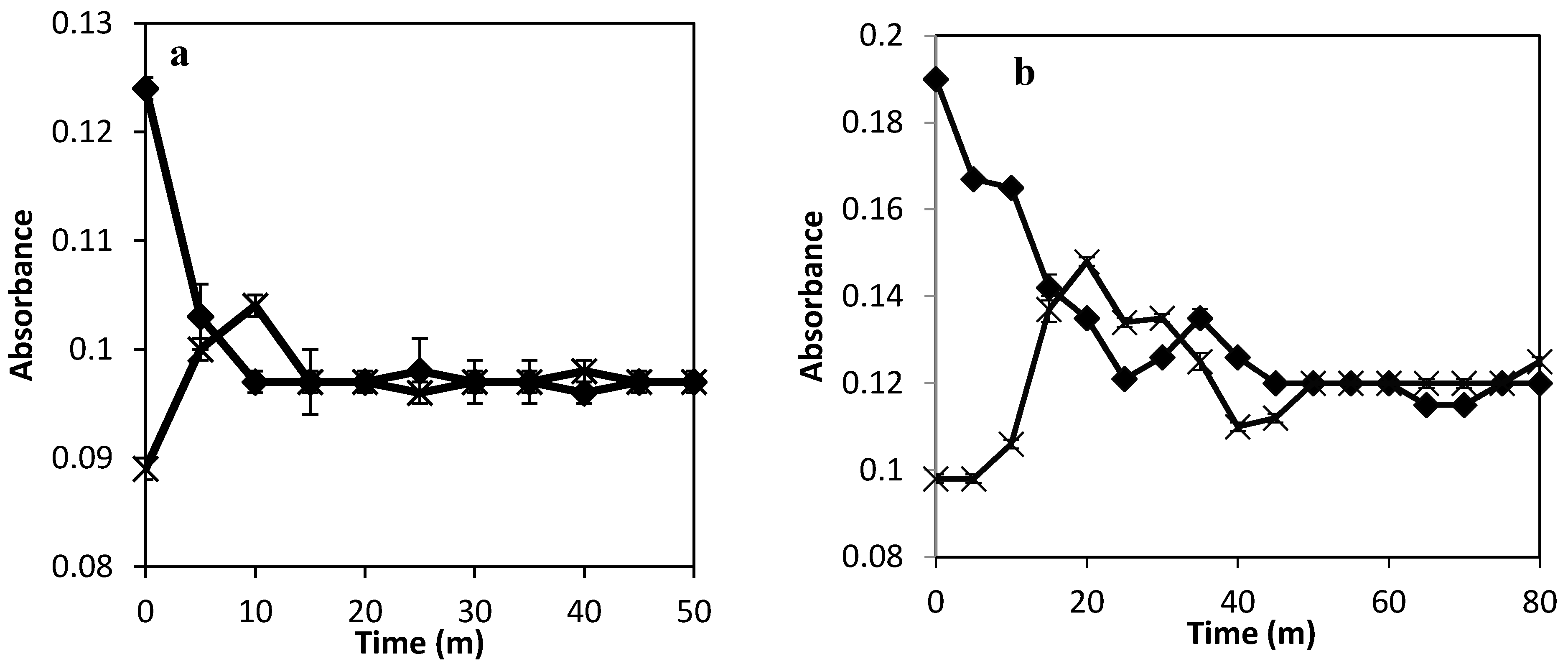

3.2.1. Mass Transfer Enhancement by Internal Mixing Tubing in the Textile Bioreactor

3.2.2. Higher Flow Rate with and without Internal Tubing

3.3. Mixing along the Edges of the Textile Bioreactor

| Time (h) | Run | Ethanol Concentration (g/L) | Sucrose Concentration (g/L) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Edge 8 cm Deep | Edge Surface | Centre 8 cm Deep | Centre Surface | Edge 8 cm Deep | Edge Surface | Centre 8 cm Deep | Centre Surface | ||

| 0 | 1 | 0.00 | 0.00 | 0.00 | 0.00 | 48.96 | 48.46 | 48.75 | 48.75 |

| 4 | 1 | 0.86 | 0.45 | 0.51 | 0.47 | 46.22 | 44.97 | 44.84 | 44.84 |

| 8 | 1 | 2.39 | 2.30 | 2.15 | 2.38 | 43.61 | 41.91 | 40.97 | 40.97 |

| 12 | 1 | 5.14 | 5.41 | 5.23 | 5.44 | 36.16 | 38.04 | 36.01 | 33.70 |

| 24 | 1 | 17.91 | 18.24 | 18.87 | 18.85 | 11.61 | 5.52 | 12.11 | 9.34 |

| 28 | 1 | 20.46 | 19.95 | 20.60 | 20.44 | 3.21 | 2.13 | 3.14 | 5.50 |

| 32 | 1 | 21.20 | 21.25 | 21.68 | 21.04 | 1.35 | 1.35 | 1.38 | 1.39 |

| 0 | 2 | 0.00 | 0.00 | 0.00 | 0.00 | 48.19 | 50.40 | 50.68 | 50.68 |

| 4 | 2 | 1.18 | 1.18 | 1.27 | 1.21 | 46.86 | 46.86 | 47.72 | 47.72 |

| 8 | 2 | 4.56 | 4.41 | 4.41 | 4.44 | 40.87 | 39.94 | 40.10 | 40.10 |

| 12 | 2 | 8.60 | 8.27 | 8.23 | 8.53 | 32.41 | 30.77 | 31.84 | 32.98 |

| 24 | 2 | 20.03 | 19.94 | 20.01 | 19.98 | 10.00 | 10.14 | 10.03 | 10.16 |

| 28 | 2 | 21.93 | 21.65 | 21.88 | 21.52 | 4.34 | 4.16 | 4.31 | 4.22 |

| 32 | 2 | 22.60 | 22.05 | 22.65 | 22.59 | 2.30 | 2.82 | 2.87 | 2.55 |

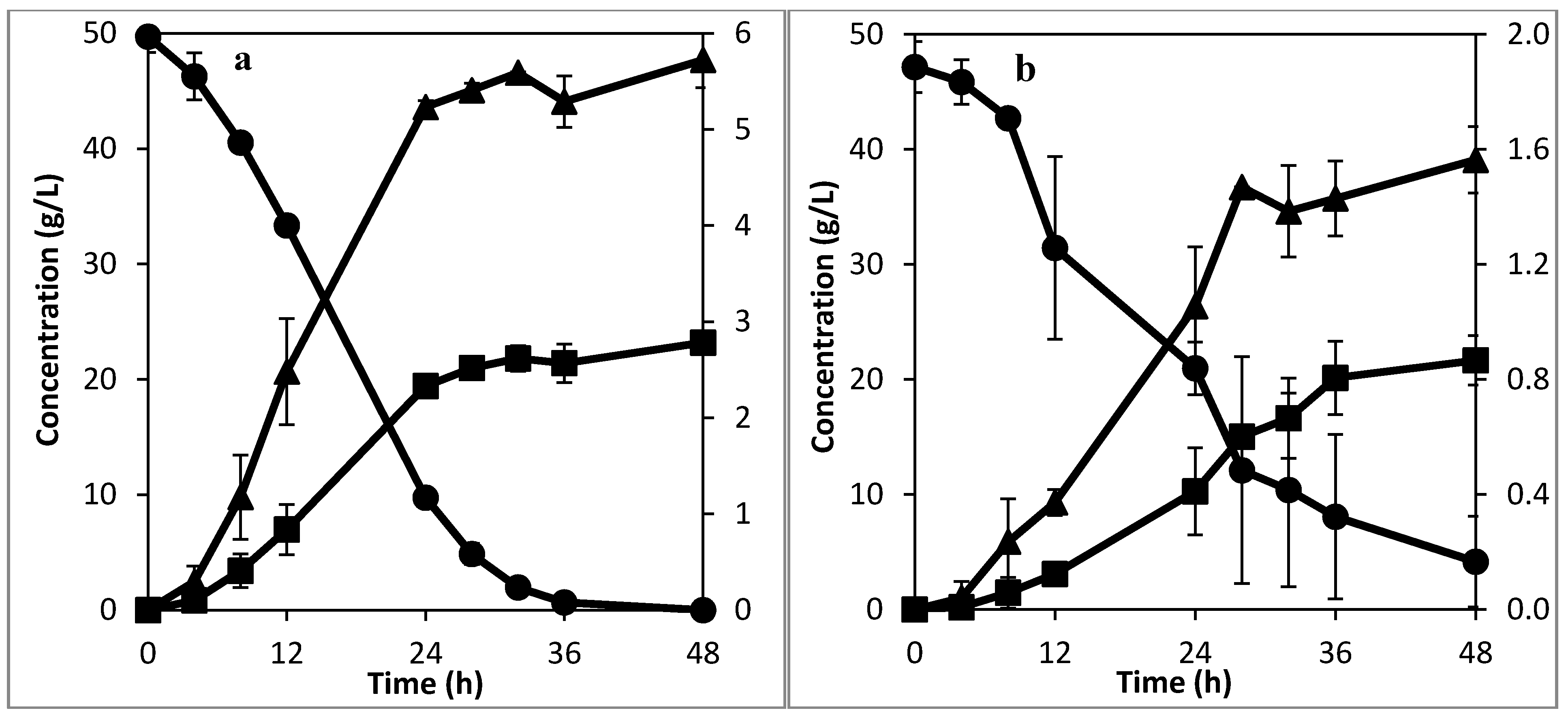

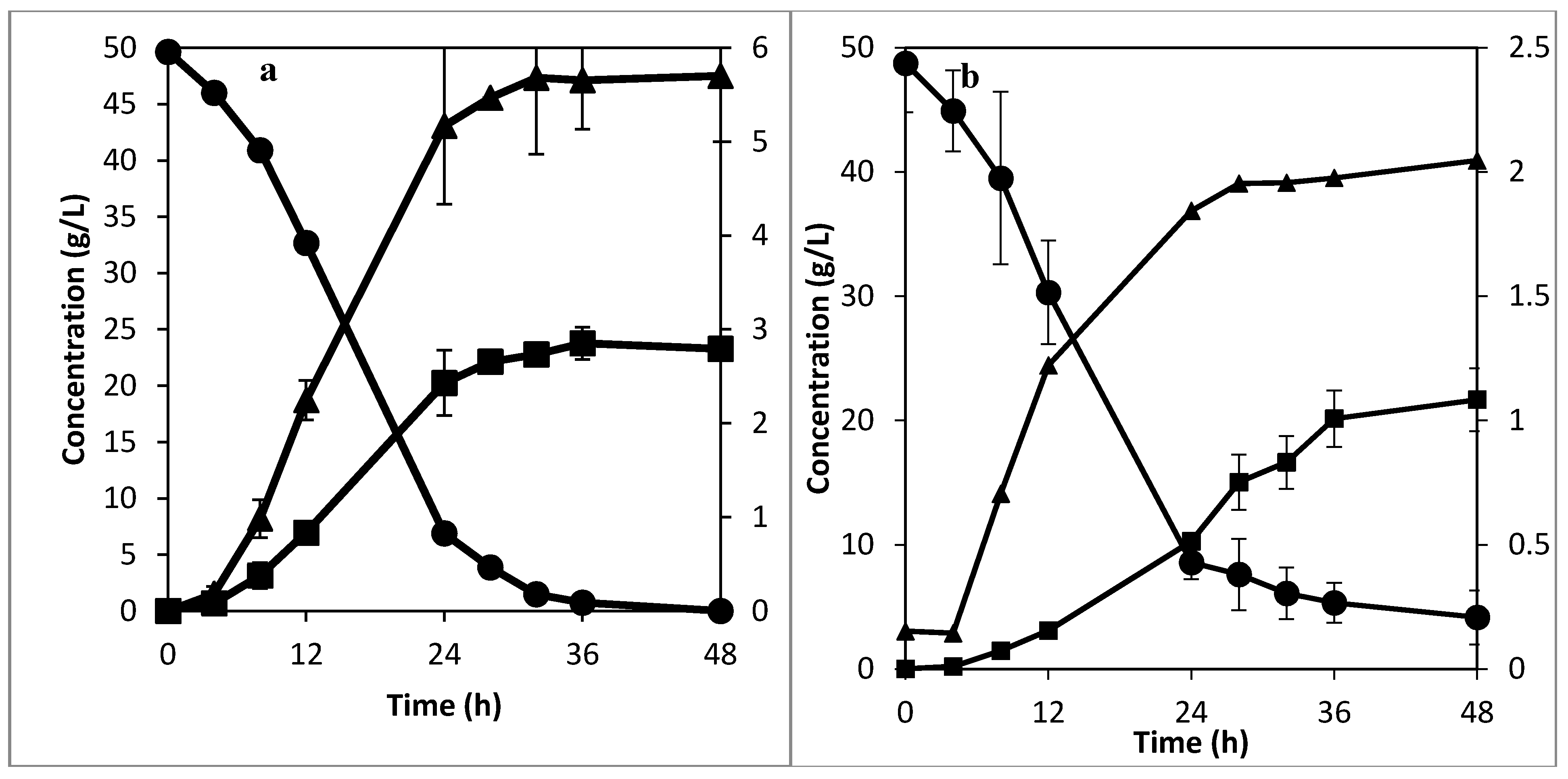

3.4. Ethanol Production Process Development and Cost Reduction

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Balat, M.; Balat, H. Recent trends in global production and utilization of bio-ethanol fuel. Appl. Energ. 2009, 86, 2273–2282. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Dragone, G.; Guimarães, P.M.R.; Silva, J.P.A.; Carneiro, L.M.; Roberto, I.C.; Vicente, A.; Domingues, L.; Teixeira, J.A. Technological trends, global market, and challenges of bio-ethanol production. Biotechnol. Adv. 2010, 28, 817–830. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Domingues, L.; Vicente, A.A.; Lima, N.; Teixeira, J.A. Applications of yeast flocculation in biotechnological processes. Biotechnol. Bioprocess. Eng. 2000, 5, 288–305. [Google Scholar] [CrossRef] [Green Version]

- Verstrepen, K.J.; Klis, F.M. Flocculation, adhesion and biofilm formation in yeasts. Mol. Microbiol. 2006, 60, 5–15. [Google Scholar] [CrossRef] [PubMed]

- Ergun, S.; Orning, A.A. Fluid flow through randomly packed columns and fluidized beds. J. Ind. Eng. Chem. 1949, 41, 1179–1184. [Google Scholar] [CrossRef]

- Muroyama, K.; Fan, L.S. Fundamentals of gas-liquid-solid fluidization. AIChE. J. 1985, 31, 1–34. [Google Scholar] [CrossRef]

- Blakebrough, N. Fundamentals of fermenter design. Pure Appl. Chem. 1973, 36, 305–316. [Google Scholar] [CrossRef]

- Mark, R.; Wilkins, A.H.A. Fermentation. In Food and Industrial Bioproducts and Bioprocessing; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Maiorella, B.L.; Blanch, H.W.; Wilke, C.R.; Wyman, C.E. Economic evaluation of alternative ethanol fermentation processes. Biotechnol. Bioeng. 2009, 104, 419–443. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Wang, J.; Jia, X.; Yeh, J.-M.; Spellane, P. Polyaniline as corrosion protection coatings on cold rolled steel. Polymer 1995, 36, 4535–4537. [Google Scholar] [CrossRef]

- Osadolor, O.A.; Lennartsson, P.R.; Taherzadeh, M.J. Introducing textiles as material of construction of ethanol bioreactors. Energies 2014, 7, 7555–7567. [Google Scholar] [CrossRef]

- Van Hamersveld, E.H.; van der Lans, R.; Luyben, K. Quantification of brewers’ yeast flocculation in a stirred tank: Effect of physical parameters on flocculation. Biotechnol. Bioeng. 1997, 56, 190–200. [Google Scholar] [CrossRef]

- Nagai, Y.; Unsworth, L.D.; Koutsopoulos, S.; Zhang, S. Slow release of molecules in self-assembling peptide nanofiber scaffold. J. Control. Release 2006, 115, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Kunii, D.; Levenspiel, O. Fluidization Engineering; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- McCabe, W.L.; Smith, J.C.; Harriott, P. Unit Operations of Chemical Engineering; McGraw-Hill: New York, NY, USA, 1993; Volume 5. [Google Scholar]

- Benitez, J. Principles and Modern Applications of Mass Transfer Operations; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Bergman, T.L.; Incropera, F.P.; Lavine, A.S. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- West, J.; Gleeson, J.P.; Alderman, J.; Collins, J.K.; Berney, H. Structuring laminar flows using annular magnetohydrodynamic actuation. Sensor Actuator B 2003, 96, 190–199. [Google Scholar] [CrossRef]

- Hayduk, W.; Laudie, H. Prediction of diffusion coefficients for nonelectrolytes in dilute aqueous solutions. AIChE. J. 1974, 20, 611–615. [Google Scholar] [CrossRef]

- Bosma, T.N.P.; Middeldorp, P.J.M.; Schraa, G.; Zehnder, A.J.B. Mass transfer limitation of biotransformation: Quantifying bioavailability. Environ. Sci. Technol. 1996, 31, 248–252. [Google Scholar] [CrossRef]

- Elander, R.T.; Putsche, V.L. Ethanol from Corn: Technology and Economics; Taylor and Francis: Washington, DC, USA, 1996; pp. 329–349. [Google Scholar]

- Fontana, A.; Ghommidh, C.; Guiraud, J.P.; Navarro, J.M. Continuous alcoholic fermentation of sucrose using flocculating yeast. The limits of invertase activity. Biotechnol. Lett. 1992, 14, 505–510. [Google Scholar] [CrossRef]

- Sousa, M.L.; Teixeira, J.A.; Mota, M. Comparative analysis of ethanolic fermentation in two continuous flocculation bioreactors and effect of flocculation additive. Bioprocess. Eng. 1994, 11, 83–90. [Google Scholar] [CrossRef]

- Echegaray, O.F.; Carvalho, J.C.M.; Fernandes, A.N.R.; Sato, S.; Aquarone, E.; Vitolo, M. Fed-batch culture of sacchoromyces cerevisiae in sugar-cane blackstrap molasses: Invertase activity of intact cells in ethanol fermentation. Biomass Bioenergy 2000, 19, 39–50. [Google Scholar] [CrossRef]

- Oca, J.; Masaló, I. Design criteria for rotating flow cells in rectangular aquaculture tanks. Aquacult. Eng. 2007, 36, 36–44. [Google Scholar] [CrossRef]

- Basso, L.C.; Rocha, S.N.; Basso, T.O. Ethanol Production in Brazil: The Industrial Process and its Impact on Yeast Fermentation; Intech: Rijeka, Croatia, 2011. [Google Scholar]

- Verduyn, C.; Zomerdijk, T.P.L.; van Dijken, J.P.; Scheffers, W.A. Continuous measurement of ethanol production by aerobic yeast suspensions with an enzyme electrode. Appl. Microbiol. Biotechnol. 1984, 19, 181–185. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Lennartsson, P.R.; Teichert, O.; Nordholm, H. Bioethanol production processes. Biofuels Prod. 2013, 211–253. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osadolor, O.A.; Lennartsson, P.R.; Taherzadeh, M.J. Development of Novel Textile Bioreactor for Anaerobic Utilization of Flocculating Yeast for Ethanol Production. Fermentation 2015, 1, 98-112. https://doi.org/10.3390/fermentation1010098

Osadolor OA, Lennartsson PR, Taherzadeh MJ. Development of Novel Textile Bioreactor for Anaerobic Utilization of Flocculating Yeast for Ethanol Production. Fermentation. 2015; 1(1):98-112. https://doi.org/10.3390/fermentation1010098

Chicago/Turabian StyleOsadolor, Osagie A., Patrik R. Lennartsson, and Mohammad J. Taherzadeh. 2015. "Development of Novel Textile Bioreactor for Anaerobic Utilization of Flocculating Yeast for Ethanol Production" Fermentation 1, no. 1: 98-112. https://doi.org/10.3390/fermentation1010098

APA StyleOsadolor, O. A., Lennartsson, P. R., & Taherzadeh, M. J. (2015). Development of Novel Textile Bioreactor for Anaerobic Utilization of Flocculating Yeast for Ethanol Production. Fermentation, 1(1), 98-112. https://doi.org/10.3390/fermentation1010098