Analysis of Biochar–Cement Composites by SEM/EDS: Interfacial Interactions and Effects on Mechanical Strength

Abstract

1. Introduction

2. Materials and Methods

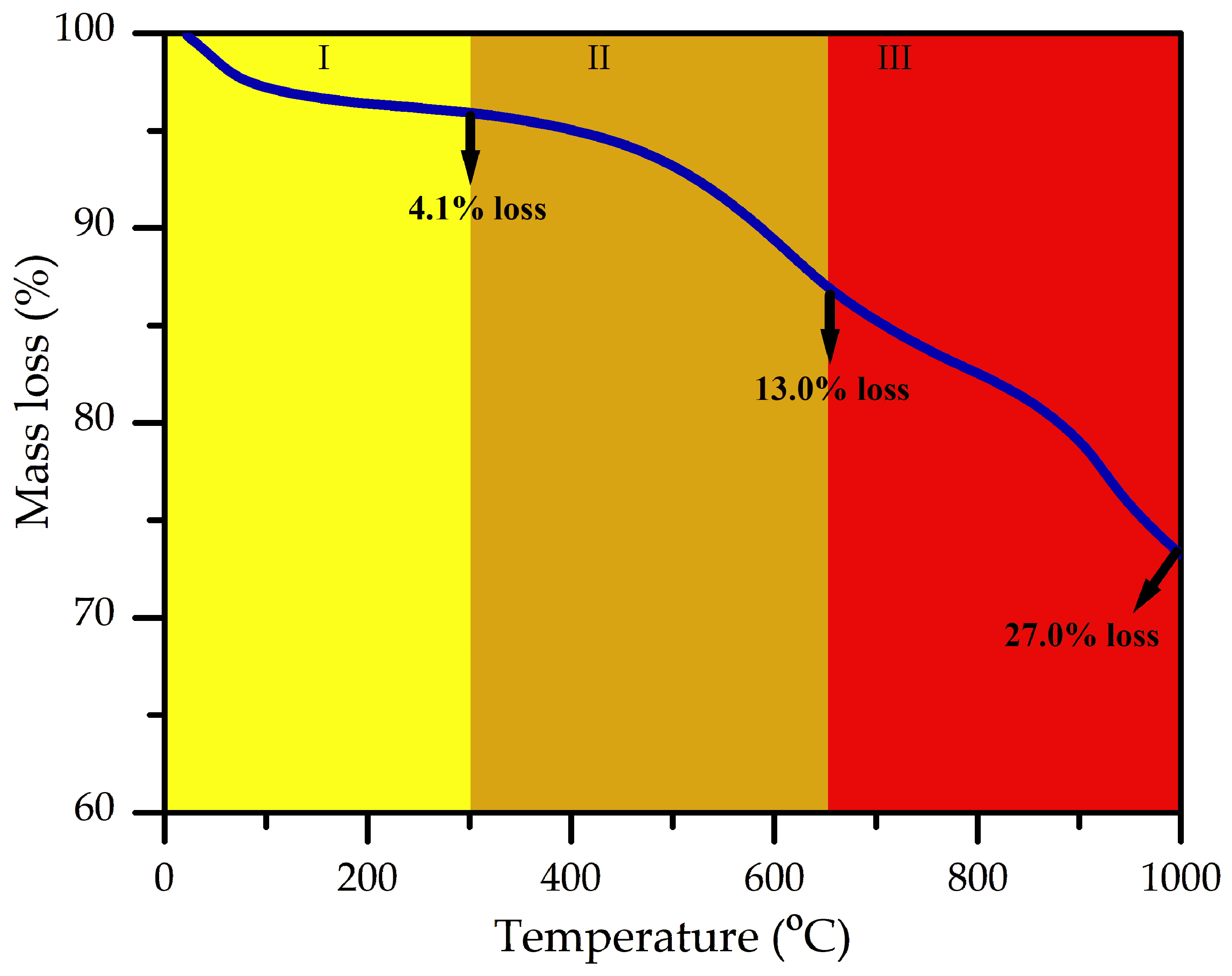

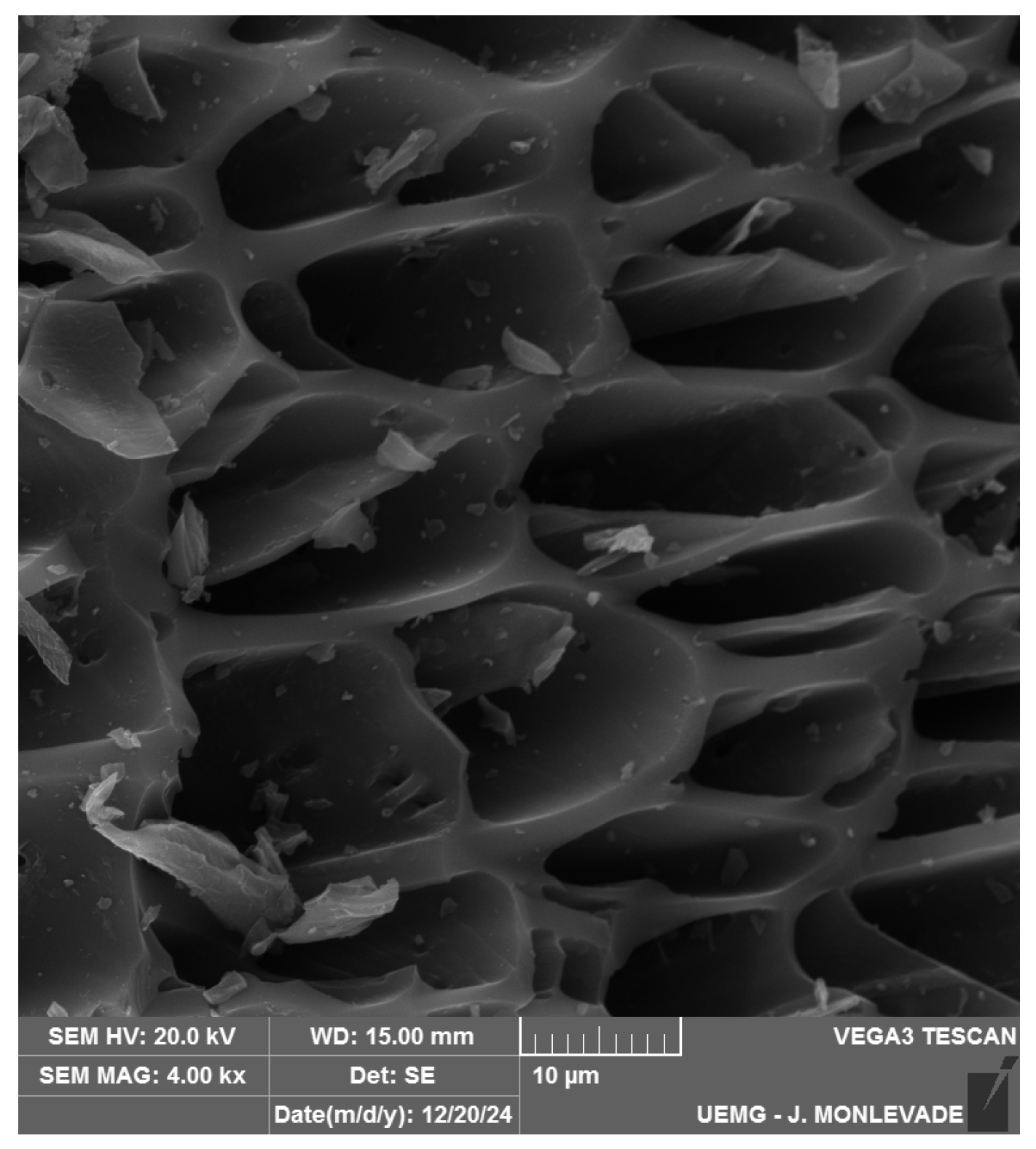

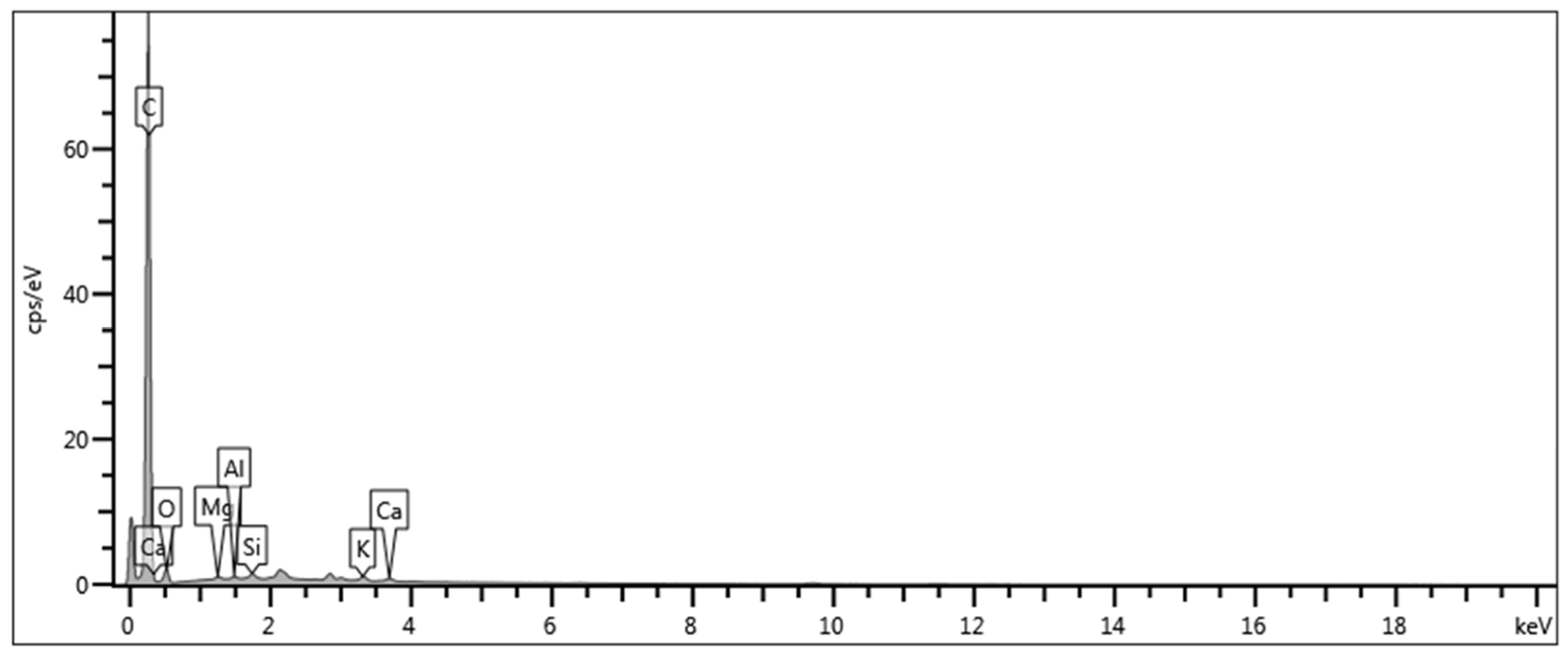

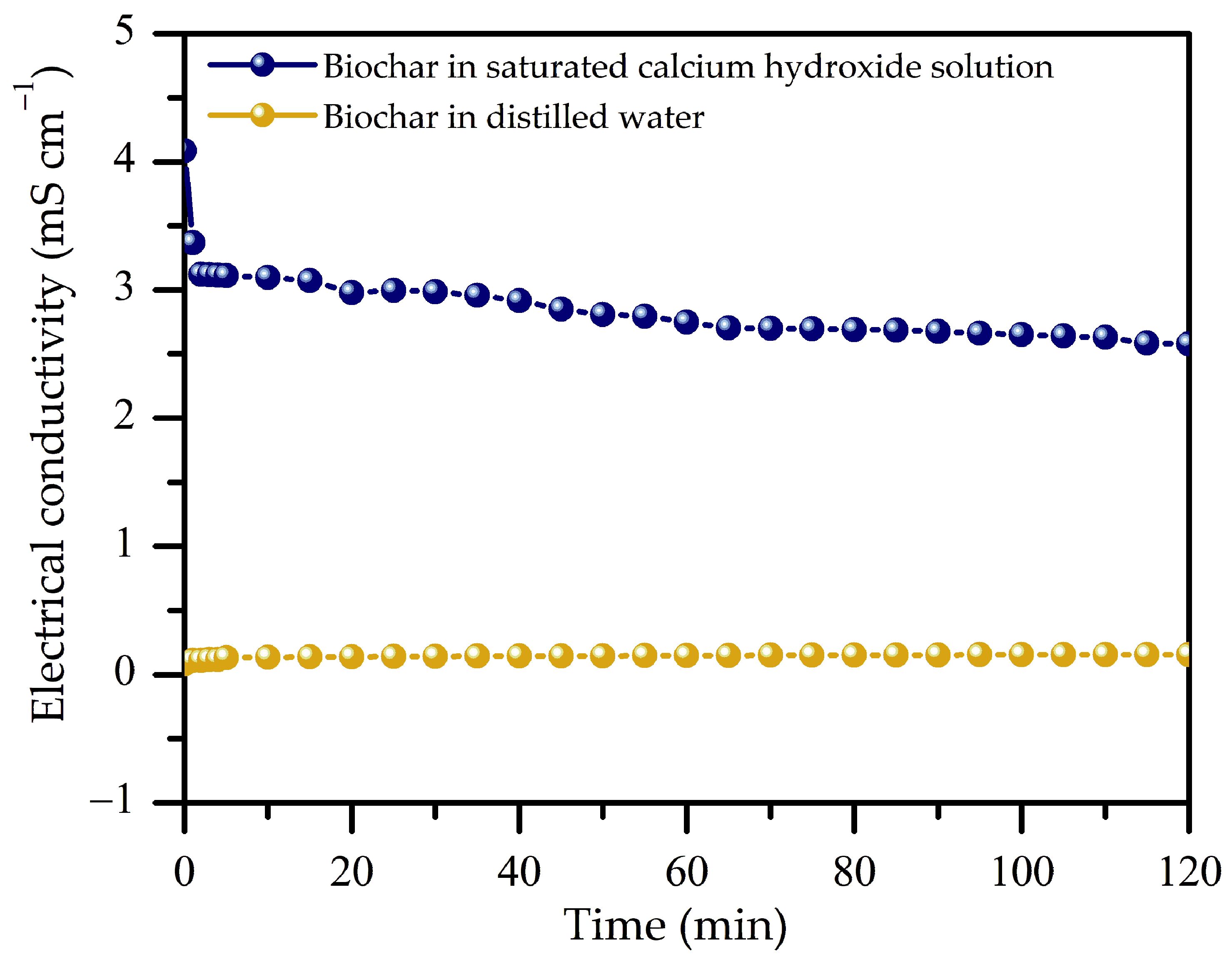

2.1. Production and Characterization of Sugarcane Bagasse Biochar

2.2. Preparation of Biochar–Cement Composites

2.3. Characterization of Biochar–Cement Composites

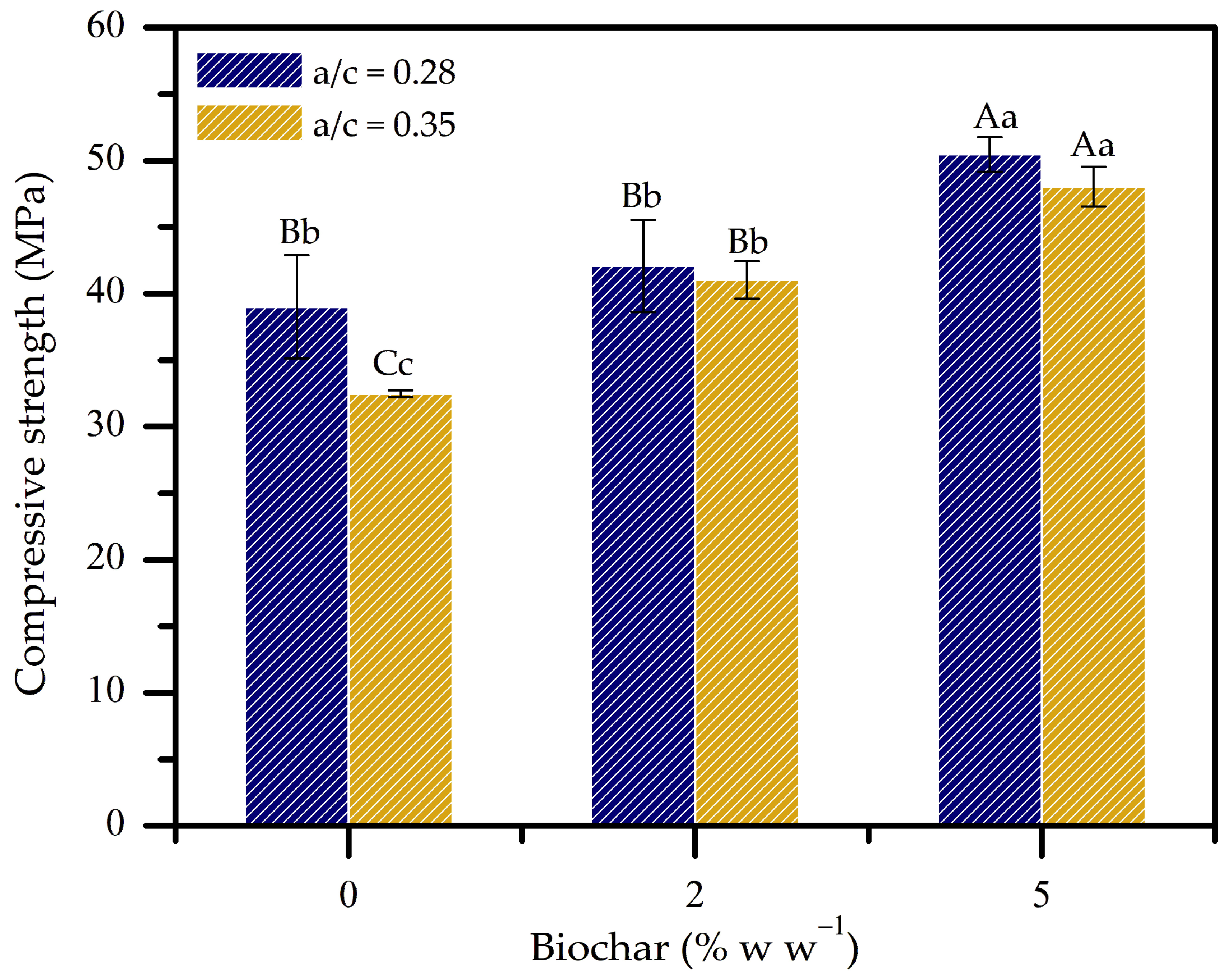

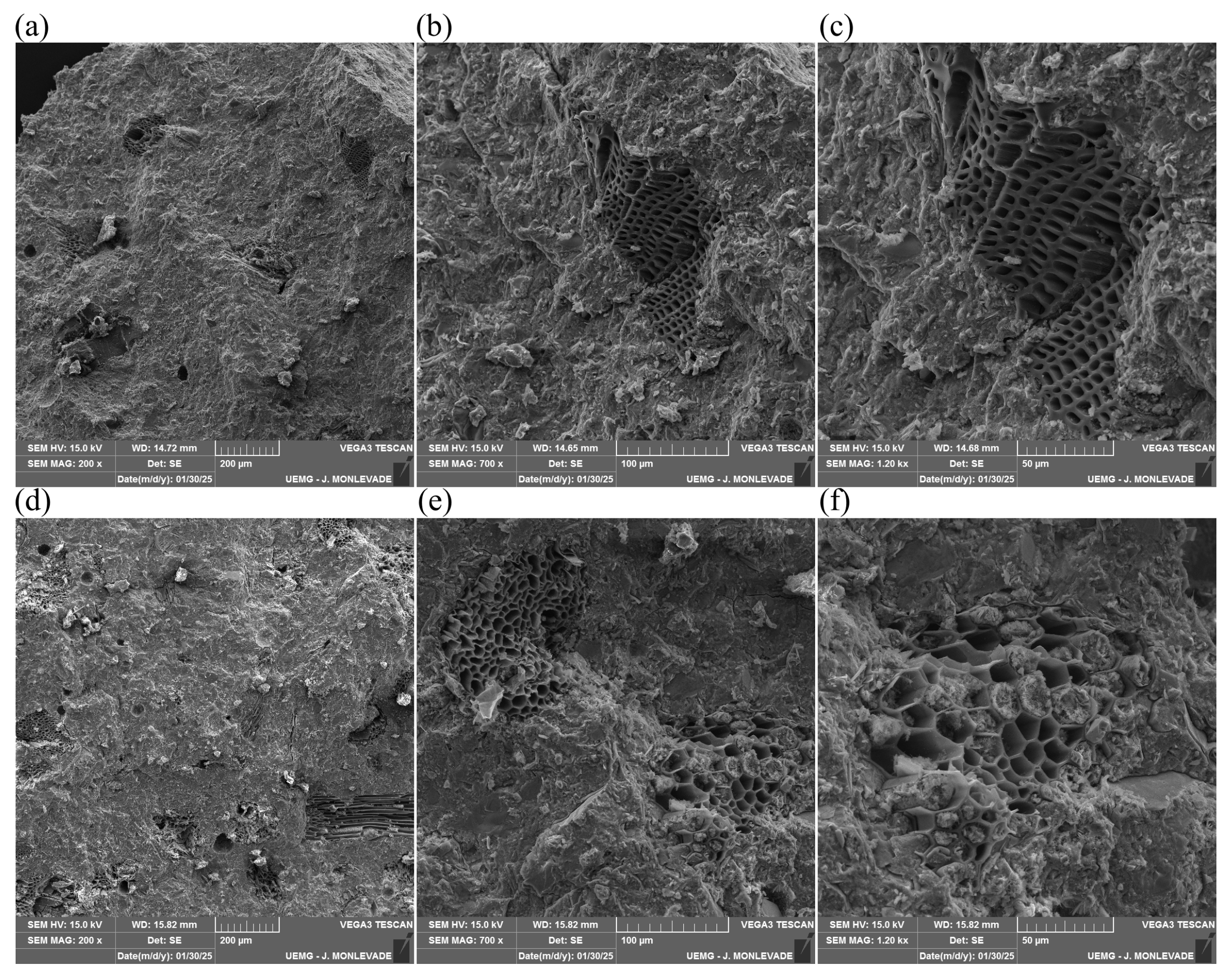

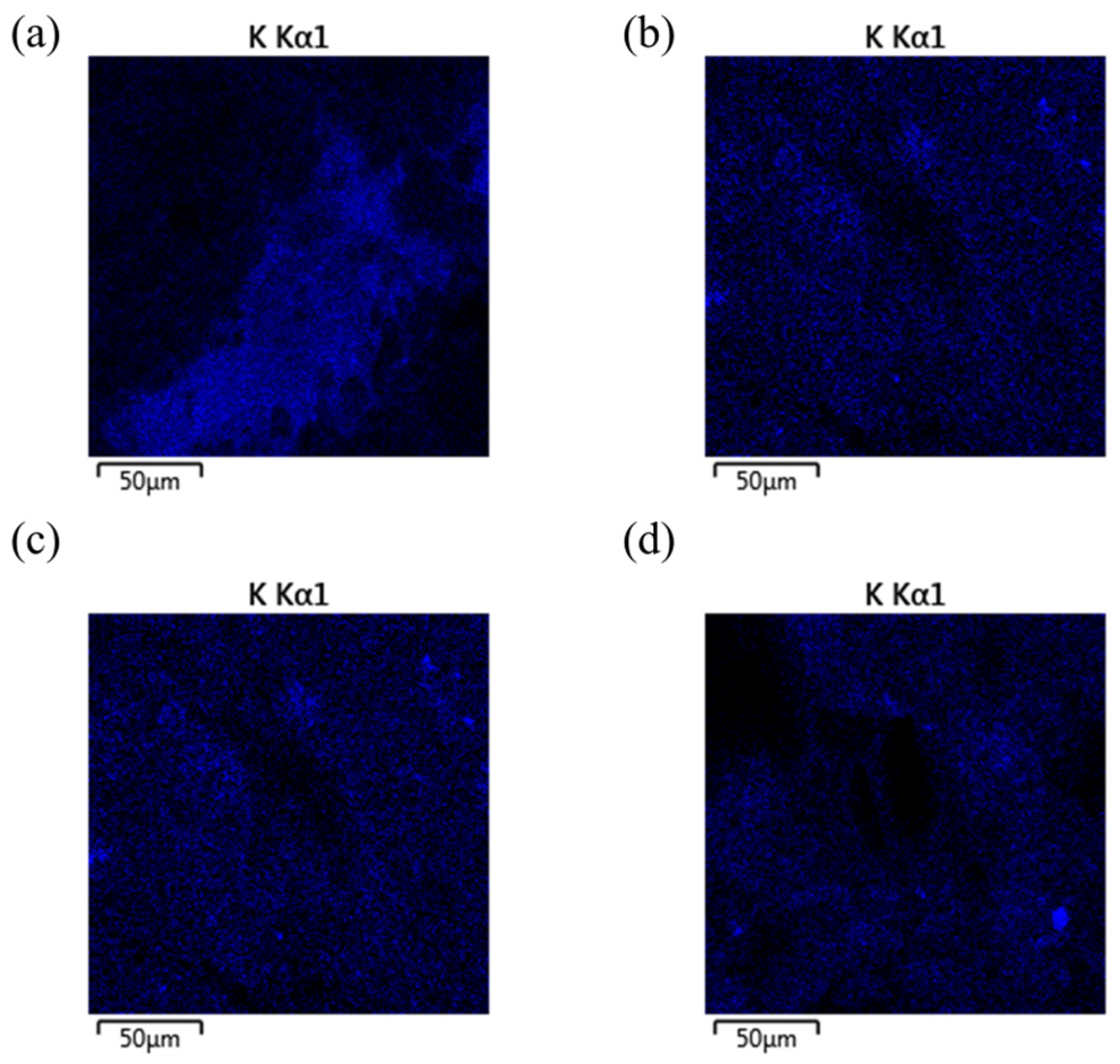

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fan, J.-L.; Mao, Y.; Li, K.; Zhang, X. Early opportunities for onshore and offshore CCUS deployment in the Chinese cement industry. Engineering 2024, 46, 348–362. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2014, 56, 59–72. [Google Scholar] [CrossRef]

- Ozansoy, A.İ.; Özen, S. Effects of colemanite and fiber types on strength and water absorption of mortar mixtures containing Air-Entraining admixture. Buildings 2025, 15, 893. [Google Scholar] [CrossRef]

- Abiodun, Y.O.; Olanrewaju, O.A.; Gbenebor, O.P.; Ochulor, E.F.; Obasa, D.V.; Adeosun, S.O. Cutting Cement Industry CO2 Emissions through Metakaolin Use in Construction. Atmosphere 2022, 13, 1494. [Google Scholar] [CrossRef]

- Bolan, S.; Padhye, L.P.; Jasemizad, T.; Govarthanan, M.; Karmegam, N.; Wijesekara, H.; Amarasiri, D.; Hou, D.; Zhou, P.; Biswal, B.K.; et al. Impacts of climate change on the fate of contaminants through extreme weather events. Sci. Total Environ. 2023, 909, 168388. [Google Scholar] [CrossRef] [PubMed]

- Kushwah, S.; Singh, S.; Agarwal, R.; Nighot, N.S.; Kumar, R.; Athar, H.; Naik B, S. Mixture of biochar as a green additive in cement-based materials for carbon dioxide sequestration. J. Mater. Sci. Mater. Eng. 2024, 19, 27. [Google Scholar] [CrossRef]

- Khan, S.; Al-Deen, S.; Lee, C.K. Development of low carbon concrete with high cement replacement ratio by multi-response optimization. Clean. Mater. 2025, 16, 100304. [Google Scholar] [CrossRef]

- Mrad, R.; Chehab, G. Mechanical and microstructure properties of Biochar-Based mortar: An internal curing agent for PCC. Sustainability 2019, 11, 2491. [Google Scholar] [CrossRef]

- Aneja, A.; Sharma, R.L.; Singh, H. Mechanical and durability properties of biochar concrete. Mater. Today Proc. 2022, 65, 3724–3730. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Koh, H.J. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total Environ. 2018, 619–620, 419–435. [Google Scholar] [CrossRef]

- Gupta, S.; Muthukrishnan, S.; Kua, H.W. Comparing influence of inert biochar and silica rich biochar on cement mortar—Hydration kinetics and durability under chloride and sulfate environment. Constr. Build. Mater. 2021, 268, 121142. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, G.; Yang, D.; Yang, S.; Wang, X.; Li, J.; Yang, J.; Song, M.; Liu, Z.; Wang, W.; et al. Investigation of sludge-based iron-biochar material derived for cement: Composites performance, hydration mechanism, and sustainability. Constr. Build. Mater. 2025, 474, 141099. [Google Scholar] [CrossRef]

- Lorenzoni, R.; Cunningham, P.; Fritsch, T.; Schmidt, W.; Kruschwitz, S.; Bruno, G. Microstructure analysis of cement-biochar composites. Mater. Struct. 2024, 57, 1–16. [Google Scholar] [CrossRef]

- EBC. European Biochar Certificate—Guidelines for a Sustainable Production of Biochar; Version 10.4E from 20 December 2024; Carbon Standards International (CSI): Frick, Switzerland, 2024. [Google Scholar]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Bagasse electricity potential of conventional sugarcane factories. J. Energy 2023, 2023, 1–25. [Google Scholar] [CrossRef]

- Latorre, F.L.; Zica, P.V.C.E. A tecnologia do reator horizontal contínuo de pirólise LZTM. ABM Proc. 2023, 51, 308–319. [Google Scholar] [CrossRef]

- Luxán, M.P.; Madruga, F.; Saavedra, J. Rapid evaluation of pozzolanic activity of natural products by conductivity measurement. Cem. Concr. Res. 1989, 19, 63–68. [Google Scholar] [CrossRef]

- NBR7215; Cimento Portland: Determinação da Resistência à Compressão de Corpos de Prova Cilíndricos. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2019.

- NBR 16697; Cimento Portland: Requisitos. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018.

- NBR 16697; Cimento Portland—Determinação da Pasta de Consistência Normal. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018.

- Mensah, R.; Shanmugam, V.; Narayanan, S.; Razavi, N.; Ulfberg, A.; Blanksvärd, T.; Sayahi, F.; Simonsson, P.; Reinke, B.; Försth, M.; et al. Biochar-Added Cementitious Materials—A review on mechanical, thermal, and environmental properties. Sustainability 2021, 13, 9336. [Google Scholar] [CrossRef]

- Ma, Z.; Zheng, D.; Liang, B.; Li, H. Effect of vermiculite-modified biochar on carbon sequestration potential, mercury adsorption stability, and economics. Biomass Convers. Biorefinery 2024, 15, 9513–9529. [Google Scholar] [CrossRef]

- Gwon, S.; Seifu, M.N.; Shin, M.; Park, S. Water migration mechanism during internal curing of cement composites with cellulose microfibers. Constr. Build. Mater. 2023, 411, 134173. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, P. Effects of different composite mineral admixtures on the early hydration and long-term properties of cement-based materials: A comparative study. Constr. Build. Mater. 2021, 294, 123547. [Google Scholar] [CrossRef]

- Restuccia, L.; Ferro, G.A. Promising low cost carbon-based materials to improve strength and toughness in cement composites. Constr. Build. Mater. 2016, 126, 1034–1043. [Google Scholar] [CrossRef]

- Charitha, V.; Athira, V.S.; Jittin, V.; Bahurudeen, A.; Nanthagopalan, P. Use of different agro-waste ashes in concrete for effective upcycling of locally available resources. Constr. Build. Mater. 2021, 285, 122851. [Google Scholar] [CrossRef]

- Zhang, Q.; Dong, S.; Wu, F.; Cai, Y.; Xie, L.; Huang, C.; Zhao, J.; Yang, S.; Xu, F.; Zhu, Z.; et al. Investigation of the macro performance and mechanism of biochar modified ultra-high performance concrete. Case Stud. Constr. Mater. 2024, 21, e03595. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Poon, C.S.; Wang, C.-H.; Ok, Y.S.; Mechtcherine, V.; Tsang, D.C.W. Roles of biochar and CO2 curing in sustainable Magnesia Cement-Based Composites. ACS Sustain. Chem. Eng. 2021, 9, 8603–8610. [Google Scholar] [CrossRef]

- Liu, W.; Tan, S.; Qing, L.; Li, Y. Pozzolanic activity of biochar with high carbon content and its influence on comprehensive strength-emission performance of biochar-cement composite paste. Constr. Build. Mater. 2025, 478, 141427. [Google Scholar] [CrossRef]

- Kumar, R.; Whelan, A.; Cannon, P.; Reeves, L.; Antunes, E. Transforming contaminated biosolids into biochar for a sustainable cement replacement material. Biomass Convers. Biorefinery 2025. [Google Scholar] [CrossRef]

- Li, L.; Chen, M.; Guo, X.; Lu, L.; Wang, S.; Cheng, X.; Wang, K. Early-age hydration characteristics and kinetics of Portland cement pastes with super low w/c ratios using ice particles as mixing water. J. Mater. Res. Technol. 2020, 9, 8407–8428. [Google Scholar] [CrossRef]

| Analysis | Unit | Result |

|---|---|---|

| Bulk density < 3 mm | kg m−3 | 120.4 |

| pH in CaCl2 | - | 7.20 |

| Electrical conductivity (E.C.) | mS cm−1 | 337.9 |

| Salt content | mg KCl L−1 | 17.8 |

| Water holding capacity (WHC) | % w w−1 | 17.4 |

| Moisture | % w w−1 | 6.51 |

| Volatile matter | % w w−1 | 21.24 |

| Ash | % w w−1 | 10.56 |

| Fixed carbon | % w w−1 | 68.21 |

| Carbon (C) | % w w−1 | 70.81 |

| Hydrogen (H) | % w w−1 | 2.28 |

| Nitrogen (N) | % w w−1 | Nd |

| Oxygen (O) | % w w−1 | 16.35 |

| H/C | - | 0.38 |

| O/C | - | 0.17 |

| Total phosphorus | g t−1 | 54.2 |

| Iron | g kg−1 | 3.603 |

| Potassium | g kg−1 | 2.153 |

| Magnesium | g kg−1 | 0.421 |

| Calcium | g kg−1 | 1.724 |

| Boron | g t−1 | 118.8 |

| Lead | g t−1 | <1.0 |

| Cadmium | g t−1 | <1.0 |

| Copper | g t−1 | 5.1 |

| Nickel | g t−1 | <1.0 |

| Mercury | g t−1 | <10.0 |

| Zinc | g t−1 | 36.8 |

| Chromium | g t−1 | 6.8 |

| Arsenic | g t−1 | <10.0 |

| Silver | g t−1 | <1.0 |

| Manganese | g t−1 | 56.6 |

| Acenaphthene | g t−1 | <0.02 |

| Acenaphthylene | g t−1 | <0.02 |

| Anthracene | g t−1 | <0.01 |

| Benzo(a)anthracene | g t−1 | <0.02 |

| Benzo(a)pyrene | g t−1 | <0.02 |

| Benzo(b)fluoranthene | g t−1 | <0.02 |

| Benzo(g,h,i)perylene | g t−1 | <0.02 |

| Benzo(k)fluoranthene | g t−1 | <0.02 |

| Chrysene | g t−1 | <0.05 |

| Dibenzo(a,h)anthracene | g t−1 | <0.01 |

| Phenanthrene | g t−1 | <0.02 |

| Fluoranthene | g t−1 | <0.01 |

| Fluorene | g t−1 | <0.03 |

| Indeno(1,2,3-c,d)pyrene | g t−1 | <0.01 |

| Naphthalene | g t−1 | <0.01 |

| Pyrene | g t−1 | <0.03 |

| Dioxins and furans | g t−1 | <0.01 |

| Polychlorinated biphenyls (PCBs) | g t−1 | <0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paula, R.; Carvalho, J.; Júnior, A.; Fagundes, F.; de Lima, R.; Lima, E.; Oliveira, C.; de Oliveira, M.; Bezerra, A.; Ferreira, O.; et al. Analysis of Biochar–Cement Composites by SEM/EDS: Interfacial Interactions and Effects on Mechanical Strength. C 2025, 11, 45. https://doi.org/10.3390/c11030045

Paula R, Carvalho J, Júnior A, Fagundes F, de Lima R, Lima E, Oliveira C, de Oliveira M, Bezerra A, Ferreira O, et al. Analysis of Biochar–Cement Composites by SEM/EDS: Interfacial Interactions and Effects on Mechanical Strength. C. 2025; 11(3):45. https://doi.org/10.3390/c11030045

Chicago/Turabian StylePaula, Rafaela, Jaqueline Carvalho, Antônio Júnior, Filipe Fagundes, Robson de Lima, Evaneide Lima, Carlos Oliveira, Magno de Oliveira, Augusto Bezerra, Osania Ferreira, and et al. 2025. "Analysis of Biochar–Cement Composites by SEM/EDS: Interfacial Interactions and Effects on Mechanical Strength" C 11, no. 3: 45. https://doi.org/10.3390/c11030045

APA StylePaula, R., Carvalho, J., Júnior, A., Fagundes, F., de Lima, R., Lima, E., Oliveira, C., de Oliveira, M., Bezerra, A., Ferreira, O., & Machado, A. (2025). Analysis of Biochar–Cement Composites by SEM/EDS: Interfacial Interactions and Effects on Mechanical Strength. C, 11(3), 45. https://doi.org/10.3390/c11030045