Preparation and Performance of Resin-Gel–Rubber Expandable Lost Circulation Material Blend

Abstract

:1. Introduction

2. Results and Discussion

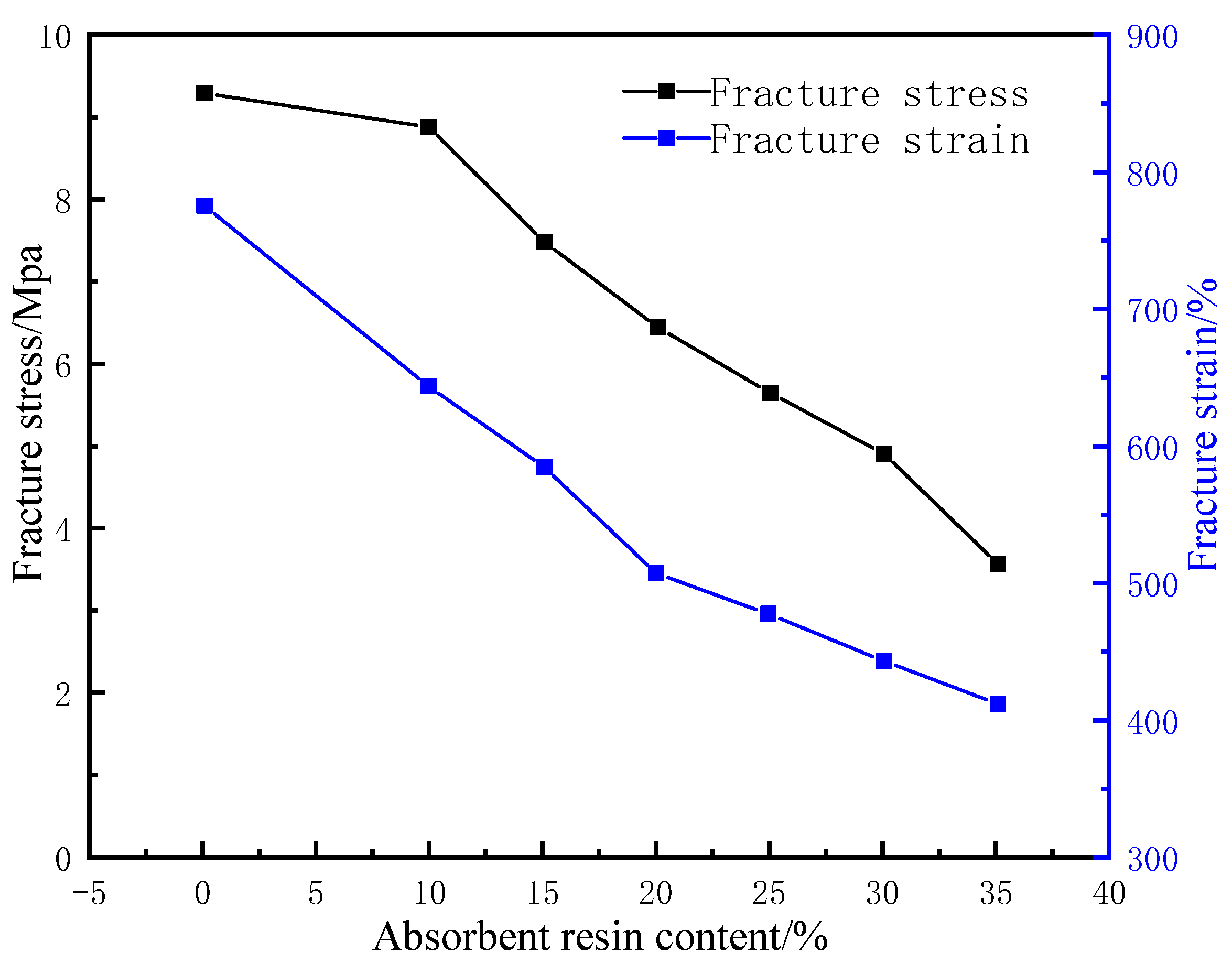

2.1. Preparation of Expandable LCM Blend

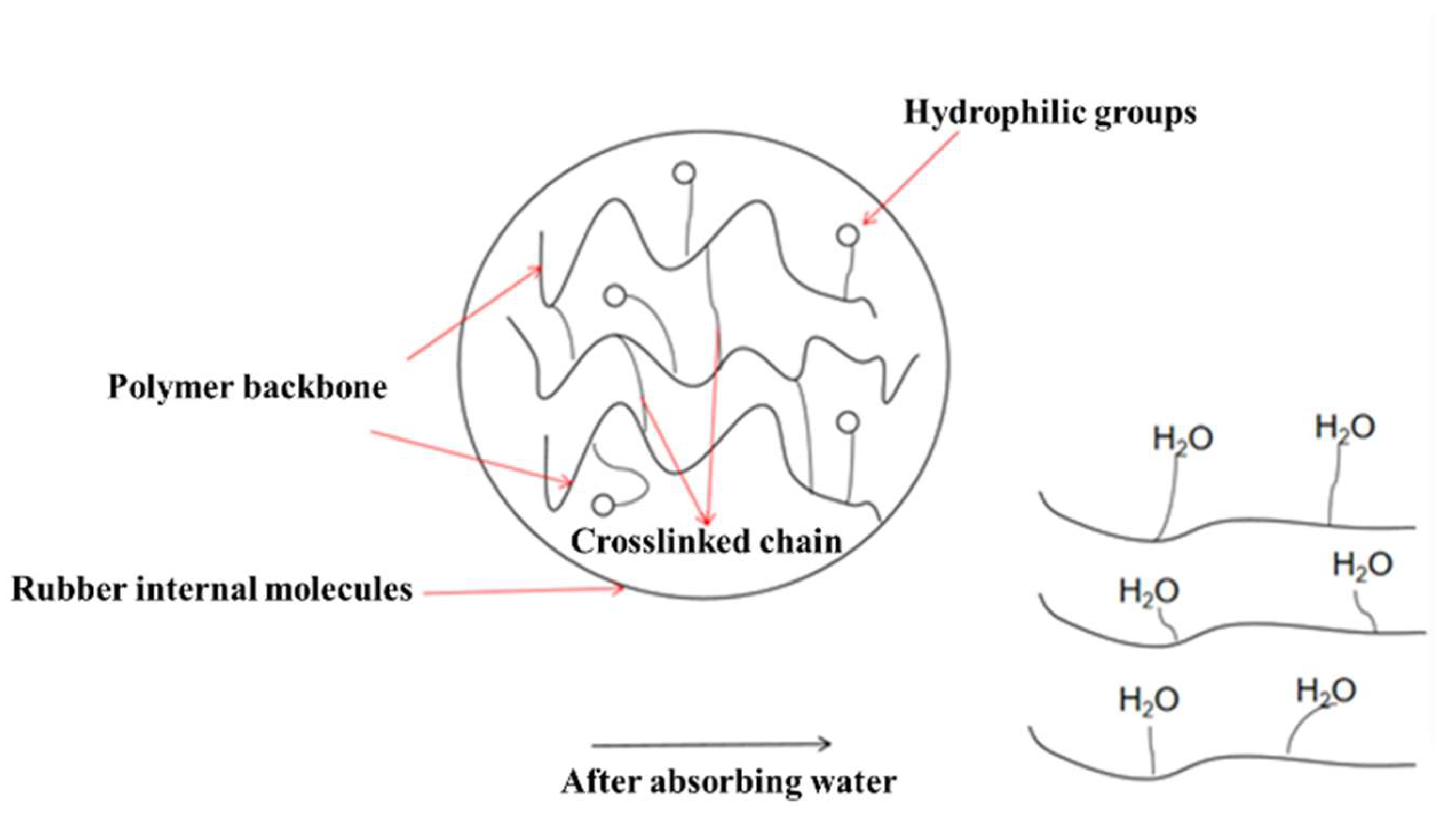

2.1.1. Preparation Principle

2.1.2. Preparation of Expandable LCM Blend

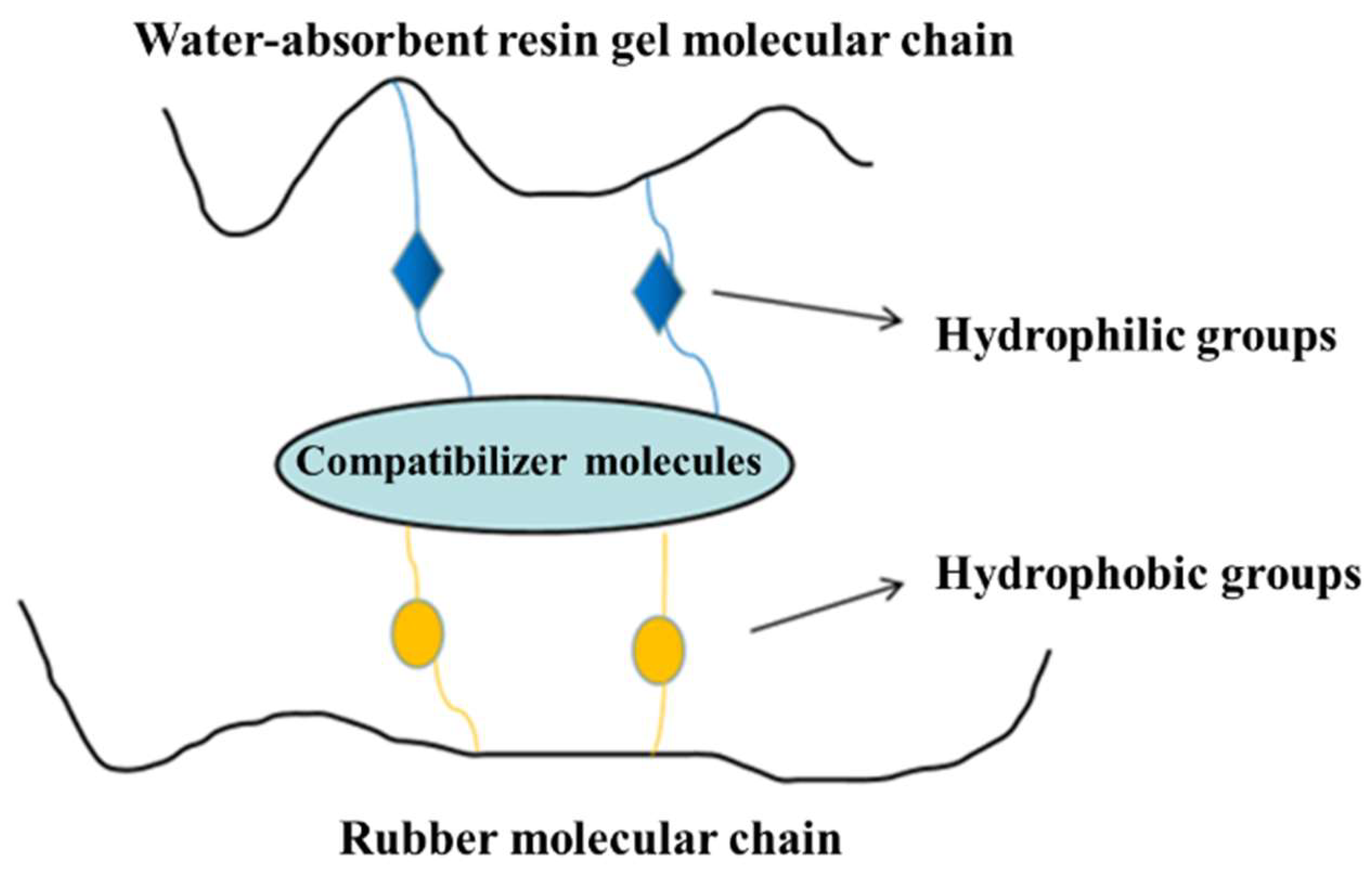

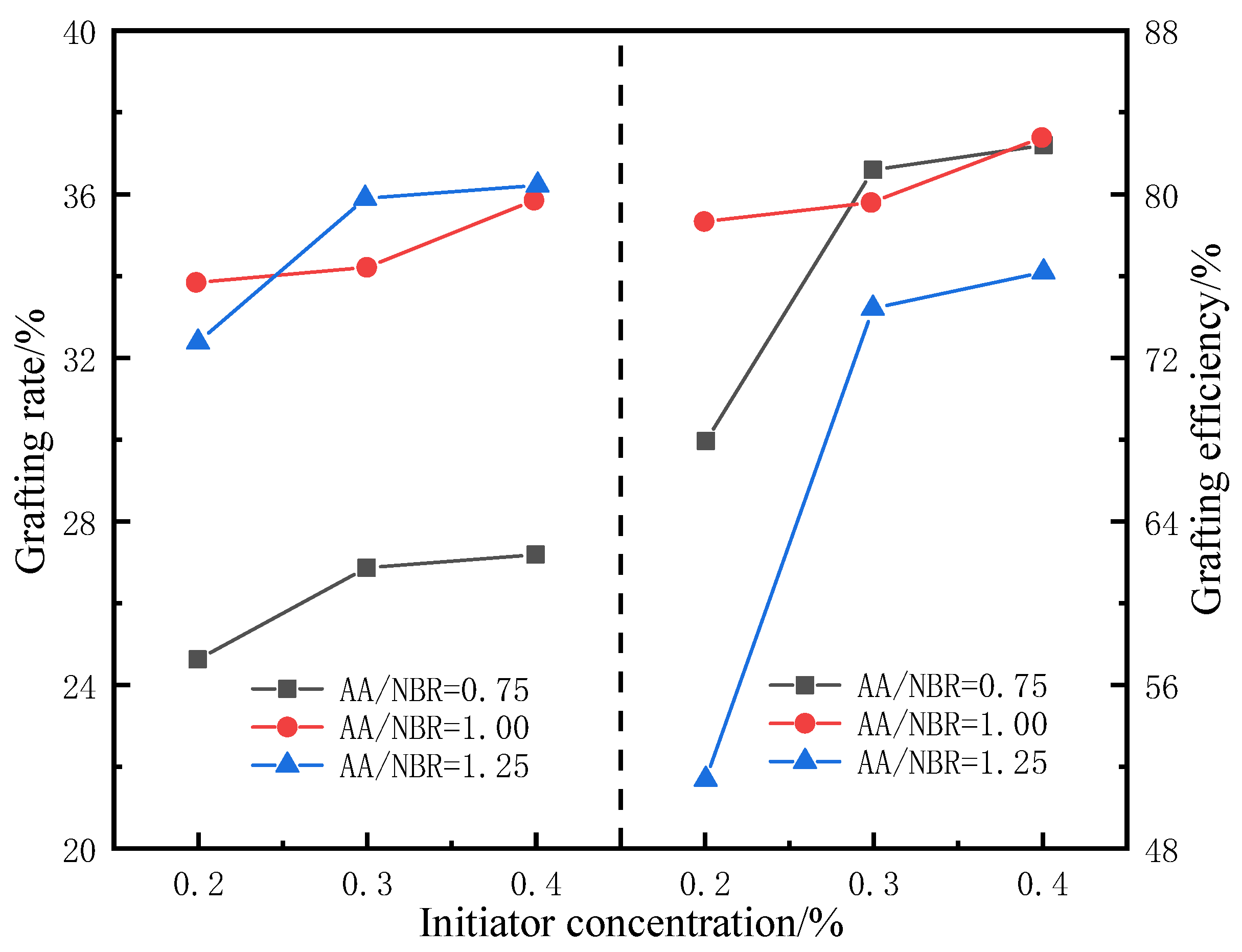

2.1.3. Compatibilizer Synthesis

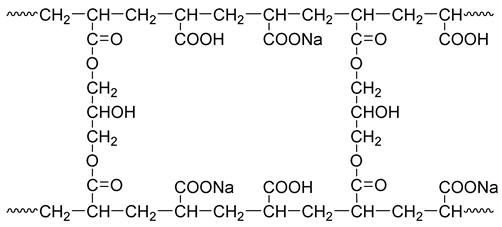

2.1.4. Synthesis of Sodium Polyacrylate Water-Absorbent Resin Gels

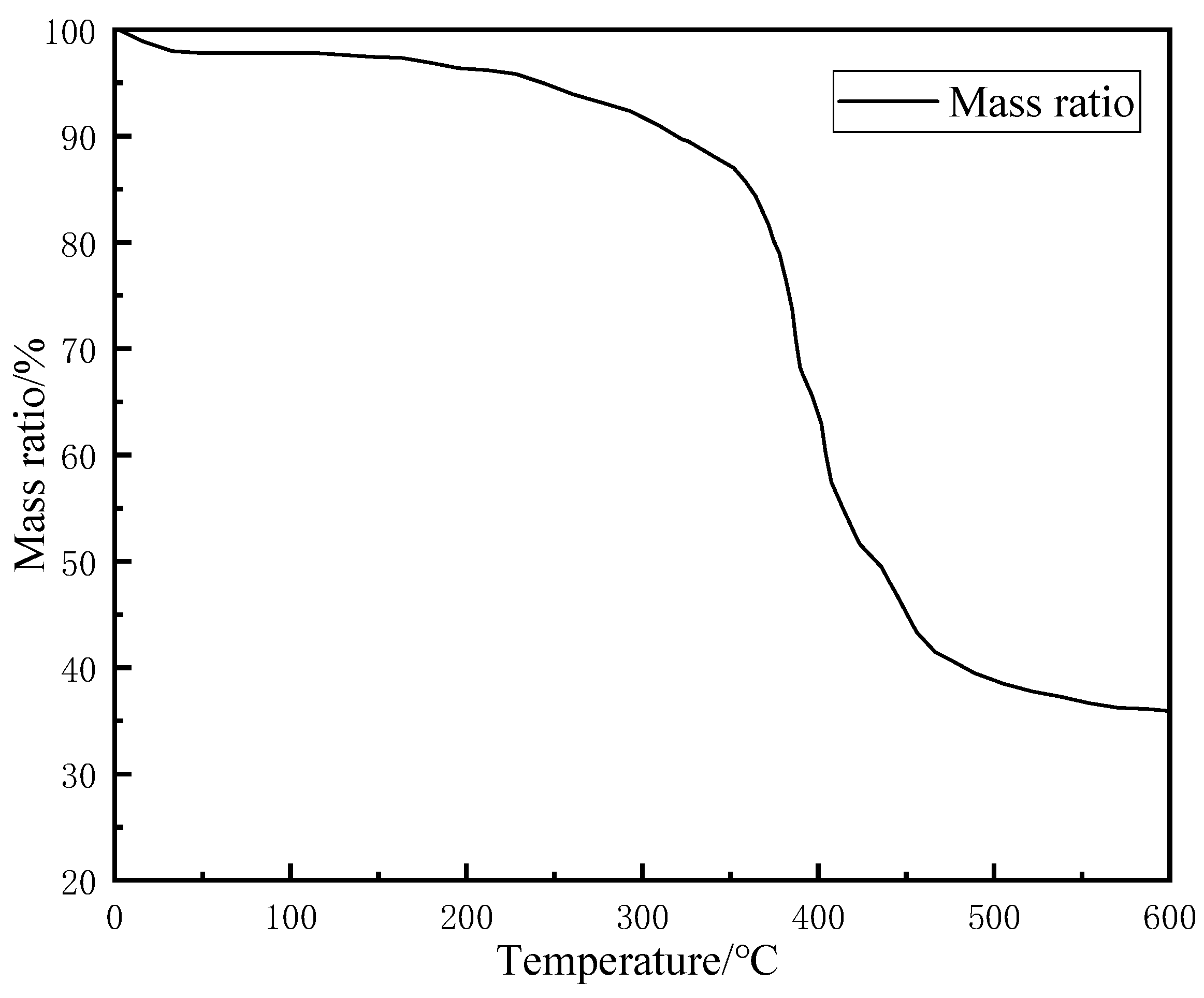

2.1.5. Thermal Stability Analysis

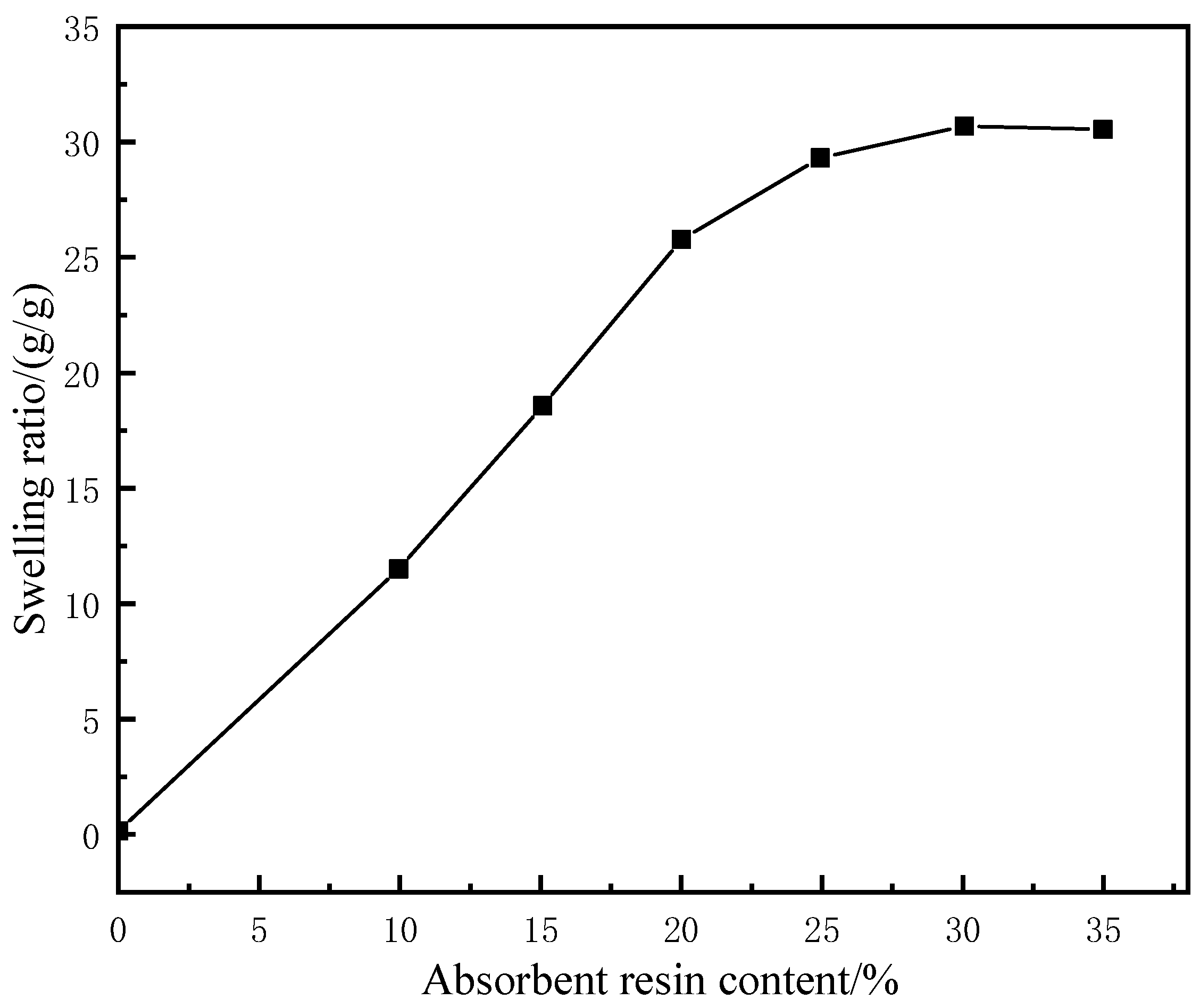

2.2. Factors Influencing Water Absorption Capacity of Expandable LCM Blend

2.2.1. Effect of Particle Size on Water Absorption Rate

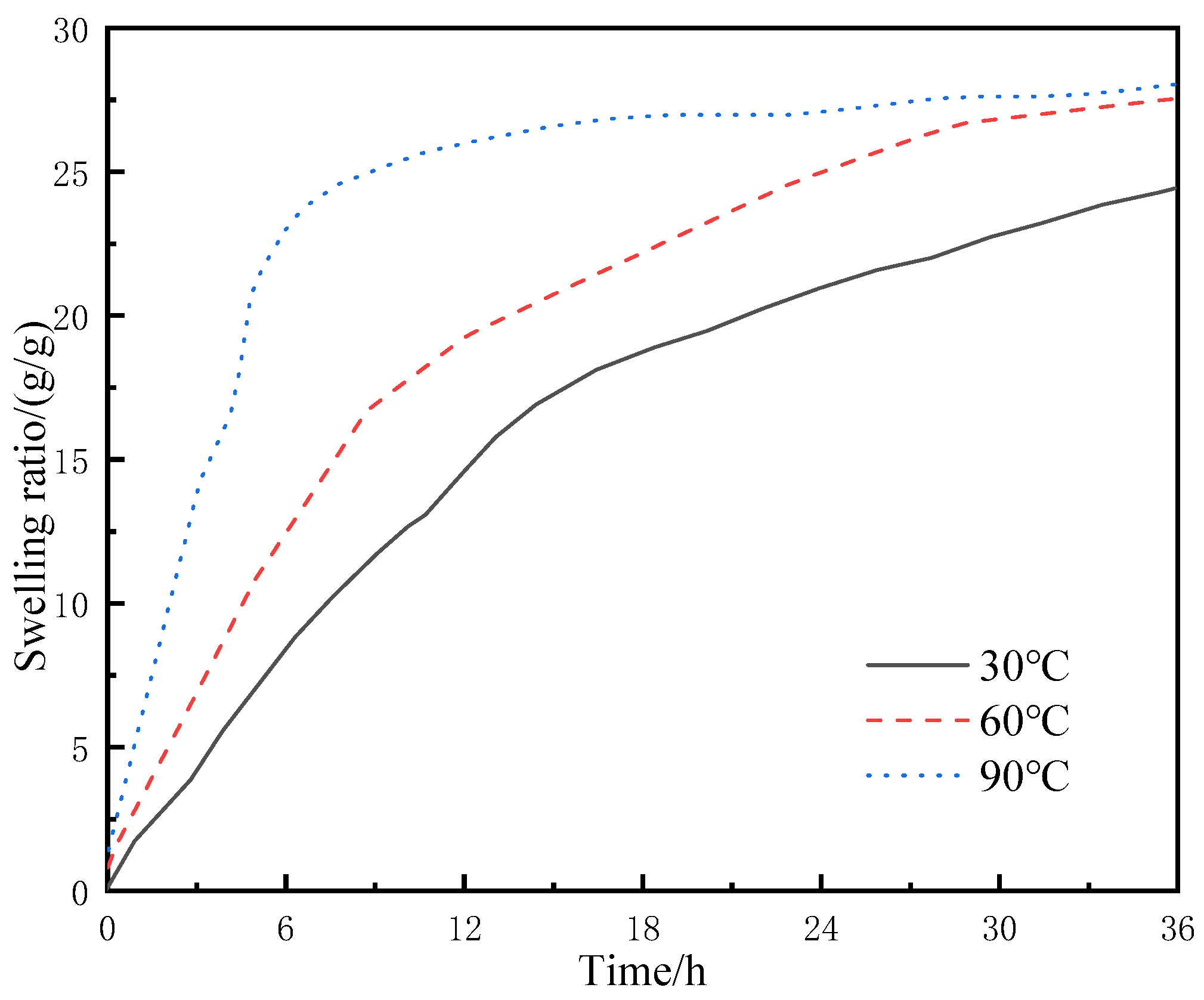

2.2.2. Effect of Temperature on Water Absorption Rate

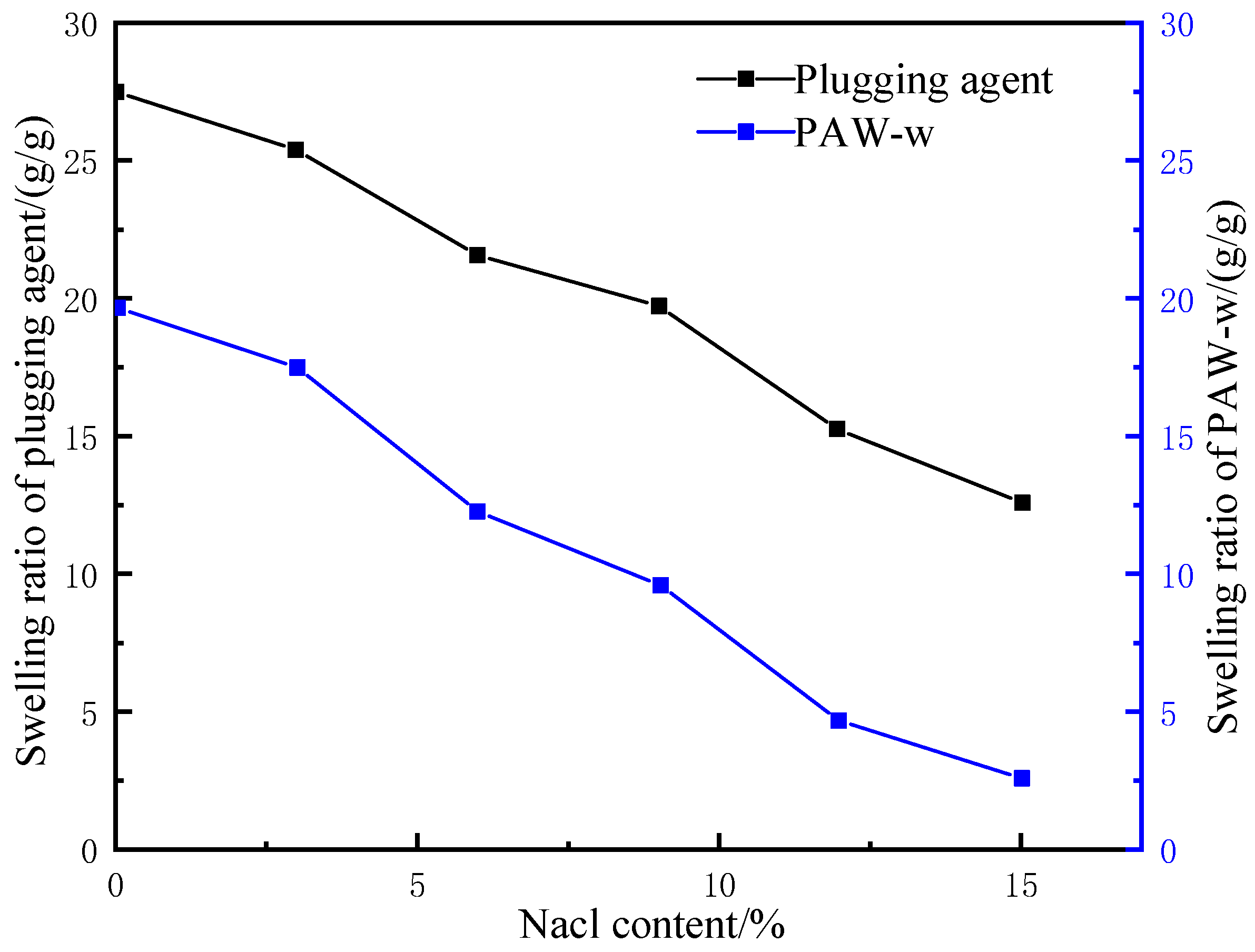

2.2.3. Effect of Salinity on Swelling Ratio

2.3. Lost Circulation Control Performance of Expandable LCM Blend

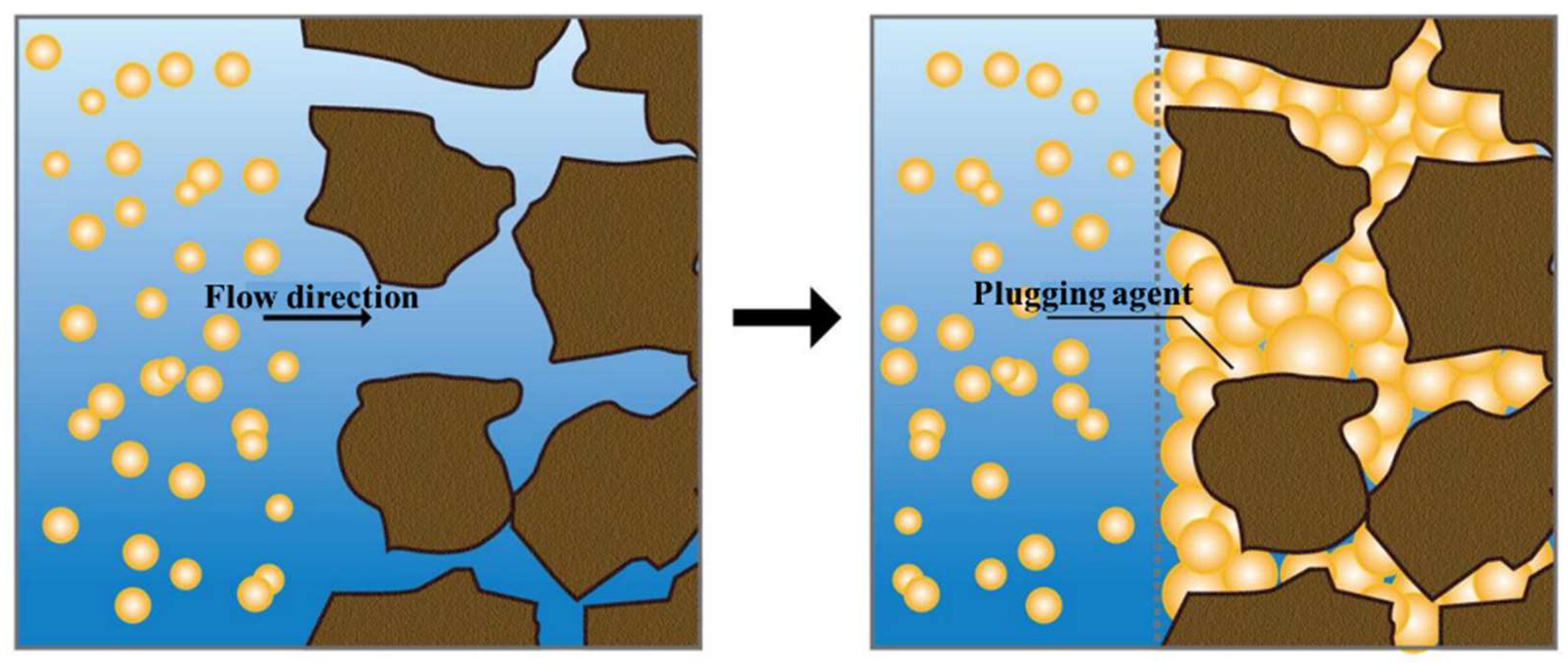

2.4. Fracture Lost Circulation Control Mechanism of Expandable LCM Blend

3. Conclusions

- The developed resin-gel–rubber expandable LCM blend was mainly composed of sodium polyacrylate resin gel and NBR. On the basis of mechanical blending, the use of the homemade amphiphilic compatibilizer reduced the interfacial tension between the two phases, which greatly improved the compatibility of the resin gel in the rubber matrix. The ratio of the resin gel, rubber, and compatibilizer was 0.25:1:0.2.

- The resin-gel–rubber expandable LCM blend absorbed water and swelled under the action of the water-absorbent resin gel. Under certain conditions, smaller particle size and higher temperature were associated with faster water absorption and swelling rates of the LCM particles. Meanwhile, the salinity degree affected the mesh size in the network structure of the resin gel and, thus, influenced the swelling ratio of the LCM particles.

- The resin-gel–rubber expandable LCM blend particles had excellent toughness and elastic deformation ability after absorbing water. They could swell, squeeze, deform, and fill the fractures, achieving a bearing resistance capacity of 7 MPa for 2-mm fractures and displaying superior lost circulation control performance for fractures.

4. Materials and Methods

4.1. Materials

4.2. Equipment

4.3. Evaluation Methods

4.3.1. Water Swelling Ratio

4.3.2. Tensile Strength Test

4.3.3. Lost Circulation Control Performance

4.3.4. TG Test

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- de Andrade, A.R.; Borges, R.A.; Guilherme, H.C.M.; Pinto, J.C.; Nele, M. A New Loss Circulation Control Strategy Combining a Cross-Linkable Polymer and Magnetic Fluid. J. Pet. Sci. Eng. 2019, 180, 958–966. [Google Scholar] [CrossRef]

- Magzoub, M.I.; Salehi, S.; Hussein, I.A.; Nasser, M.S. Loss Circulation in Drilling and Well Construction: The Significance of Applications of Crosslinked Polymers in Wellbore Strengthening: A Review. J. Pet. Sci. Eng. 2020, 185, 106653. [Google Scholar] [CrossRef]

- Pu, L.; Xu, P.; Xu, M.; Song, J.; He, M. Lost Circulation Materials for Deep and Ultra-Deep Wells: A Review. J. Pet. Sci. Eng. 2022, 214, 110404. [Google Scholar] [CrossRef]

- Magzoub, M.; Salehi, S.; Li, G.; Fan, J.; Teodoriu, C. Loss Circulation Prevention in Geothermal Drilling by Shape Memory Polymer. Geothermics 2021, 89, 101943. [Google Scholar] [CrossRef]

- Mansour, A.K.; Taleghani, A.D. Smart Loss Circulation Materials for Drilling Highly Fractured Zones. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Abu Dhabi, United Arab Emirates, 29–31 January 2018; Volume 2018-Janua, pp. 29–31. [Google Scholar]

- Yao, C.; Lei, G.; Cathles, L.M.; Steenhuis, T.S. Pore-Scale Investigation of Micron-Size Polyacrylamide Elastic Microspheres (MPEMs) Transport and Retention in Saturated Porous Media. Environ. Sci. Technol. 2014, 48, 5329–5335. [Google Scholar] [CrossRef] [PubMed]

- Alsabagh, A.M.; Abd elsalam Khalil, A.; Abdou, M.I.; Ahmed, H.E.; Aboulrous, A.A. Investigation of Some Copolymers Based on Acrylic Salts as Circulation Loss Control Agents. Egypt J. Pet. 2013, 22, 481–491. [Google Scholar] [CrossRef]

- Wang, W.; Xu, Y.; Ge, J.; Guo, H.; Wu, Q.; Mao, Y. Phenolic Resin Gel Suitable for Medium-Temperature and High-Salinity Reservoirs. J. Mol. Liq. 2022, 364, 119887. [Google Scholar] [CrossRef]

- Alshubbar, G.; Nygaard, R.; Jeennakorn, M. The Effect of Wellbore Circulation on Building an LCM Bridge at the Fracture Aperture. J. Pet. Sci. Eng. 2018, 165, 550–556. [Google Scholar] [CrossRef]

- Nasiri, A.; Ghaffarkhah, A.; Dijvejin, Z.A.; Mostofi, M.; Moraveji, M.K. Bridging Performance of New Eco-Friendly Lost Circulation Materials. Pet. Explor. Dev. 2018, 45, 1154–1165. [Google Scholar] [CrossRef]

- Sanders, M.W.; Scorsone, J.T.; Friedheim, J.E. High-Fluid-Loss, High-Strength Lost Circulation Treatments. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Galveston, TX, USA, 5–6 October 2010; pp. 93–98. [Google Scholar]

- Sun, X.; Zhang, Y.; Chen, G.; Gai, Z. Application of Nanoparticles in Enhanced Oil Recovery: A Critical Review of Recent Progress. Energies 2017, 10, 345. [Google Scholar] [CrossRef]

- Amanullah, M. Characteristics, Behavior and Performance of ARC Plug- A Date Seed-Based Sized Particulate LCM. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 25–28 April 2016. [Google Scholar]

- Guo, P.; Zhang, S.; Jin, R.; Teng, Z.; Heng, L.; Wang, B.; Jiang, L. A Super Absorbent Resin-Based Solar Evaporator for High-Efficient Various Water Treatment. Colloids Surf. A Physicochem. Eng. Asp. 2022, 648, 129405. [Google Scholar] [CrossRef]

- Li, B.; Chen, Y.; Chen, X.; Liu, D.; Niu, H.; Xiong, J.; Wu, J.; Xie, J.; Bai, J.; Ying, H. A Novel Immobilization Method for Nuclease P 1 on Macroporous Absorbent Resin with Glutaraldehyde Cross-Linking and Determination of Its Properties. Process Biochem. 2012, 47, 665–670. [Google Scholar] [CrossRef]

- Zhu, D.; Bai, B.; Hou, J. Polymer Gel Systems for Water Management in High-Temperature Petroleum Reservoirs: A Chemical Review. Energy Fuels 2017, 31, 13063–13087. [Google Scholar] [CrossRef]

- Huang, X.; Sun, J.; Lv, K.; Liu, J.; Shen, H.; Zhang, F. Application of Core-Shell Structural Acrylic Resin/Nano-SiO2 Composite in Water Based Drilling Fluid to Plug Shale Pores. J. Nat. Gas Sci. Eng. 2018, 55, 418–425. [Google Scholar] [CrossRef]

- Wang, S.; Wu, L.; Jiang, G.; Jian, L.; Zhang, T.; Chen, S.; Chen, L. A High Temperature Composite Cement for Geothermal Application. J. Pet. Sci. Eng. 2020, 195, 107909. [Google Scholar] [CrossRef]

- Hao, W.; Zeng, H.; Chen, X.; He, W.; Zhou, R.; Li, J.; Zhang, H. Insights into the reinforcement and mechanism of silicone mold rubber co-modified with WCB and MMQ resin. Mater. Res. Express 2021, 8, 035201. [Google Scholar] [CrossRef]

- Bai, Y.; Dai, L.; Sun, J.; Lv, K.; Zhang, Q.; Shang, X.; Zhu, Y.; Liu, C. Experimental Study on an Oil-Absorbing Resin Used for Lost Circulation Control during Drilling. J. Pet. Sci. Eng. 2022, 214, 110557. [Google Scholar] [CrossRef]

- El Karsani, K.S.M.; Al-Muntasheri, G.A.; Sultan, A.S.; Hussein, I.A. Impact of Salts on Polyacrylamide Hydrolysis and Gelation: New Insights. J. Appl. Polym. Sci. 2014, 131, 41185. [Google Scholar] [CrossRef]

- Omidian, H.; Hashemi, S.A.; Sammes, P.G.; Meldrum, I. A Model for the Swelling of Superabsorbent Polymers. Polymer 1998, 39, 6697–6704. [Google Scholar] [CrossRef]

- Wang, Z.; Ning, A.; Xie, P.; Gao, G.; Xie, L.; Li, X.; Song, A. Synthesis and Swelling Behaviors of Carboxymethyl Cellulose-Based Superabsorbent Resin Hybridized with Graphene Oxide. Carbohydr. Polym. 2017, 157, 48–56. [Google Scholar] [CrossRef]

- Zhang, J.P.; Zhang, F.S. A New Approach for Blending Waste Plastics Processing: Superabsorbent Resin Synthesis. J. Clean. Prod. 2018, 197, 501–510. [Google Scholar] [CrossRef]

| Level | AA Concentration/% | Glycerol Concentration/% | AIBI Concentration/% | ADSP/HPDSP |

|---|---|---|---|---|

| 1 | 15 | 2 | 0.3 | 1:1 |

| 2 | 20 | 3 | 0.5 | 1:2 |

| 3 | 25 | 4 | 0.7 | 2:1 |

| Experiment No. | Factor Level | Swelling Ratio | |||

|---|---|---|---|---|---|

| AA Concentration/% | Glycerol Concentration/% | AIBI Concentration/% | ADSP/ HPDSP | ||

| 1 | 1 | 1 | 1 | 1 | 36.83 |

| 1 | 1 | 2 | 2 | 2 | 46.32 |

| 1 | 1 | 3 | 3 | 3 | 47.62 |

| 2 | 2 | 1 | 2 | 3 | 62.30 |

| 2 | 2 | 2 | 3 | 1 | 37.69 |

| 2 | 2 | 3 | 1 | 2 | 59.26 |

| 3 | 3 | 1 | 3 | 2 | 42.65 |

| 3 | 3 | 2 | 1 | 3 | 26.48 |

| 3 | 3 | 3 | 2 | 1 | 27.66 |

| K1 | 130.77 | 141.78 | 122.57 | 102.18 | - |

| K2 | 159.25 | 110.49 | 136.28 | 148.23 | - |

| K3 | 96.79 | 134.54 | 127.96 | 136.40 | - |

| k1 | 43.59 | 47.26 | 40.86 | 34.06 | - |

| k2 | 53.08 | 36.83 | 45.43 | 49.41 | - |

| k3 | 32.26 | 43.85 | 42.65 | 45.47 | - |

| R | 20.82 | 10.43 | 4.57 | 15.35 | - |

| Optimal Conditions | 20 | 2 | 0.5 | 2:1 | - |

| Formulation No. | Formulation |

|---|---|

| 1 | 4% bentonite + 2% SQD-98 (fine) + 2% limestone (40–80 mesh) + 6% FDL-1 (80–120 mesh) |

| 2 | 4% bentonite + 2% SQD-98 (medium) + 2% limestone (20–40 mesh) + 6% FDL-1 (40–80 mesh) |

| 3 | 4% bentonite + 2% SQD-98 (fine) + 2% limestone (40–80 mesh) + 6% resin-gel–rubber expandable LCM blend (80–120 mesh) |

| 4 | 4% bentonite + 2% SQD-98 (medium) + 2% limestone (20–40 mesh) + 6% resin-gel–rubber expandable LCM blend (40–80 mesh) |

| Pressure /MPa | Cumulative Fluid Loss Volume/mL | |||

|---|---|---|---|---|

| Formulation 1 | Formulation 2 | Formulation 3 | Formulation 4 | |

| 1.0 | 224 | 337 | 65 | 154 |

| 2.5 | 427 | 458 | 125 | 234 |

| 4.0 | 689 | 796 | 363 | 406 |

| 5.5 | 1064 | Total loss | 365 | 406 |

| 7.0 | Total loss | Total loss | 365 | 406 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Lou, E.; Zhang, S.; Lu, H.; Wang, Z. Preparation and Performance of Resin-Gel–Rubber Expandable Lost Circulation Material Blend. Gels 2023, 9, 862. https://doi.org/10.3390/gels9110862

Zhu J, Lou E, Zhang S, Lu H, Wang Z. Preparation and Performance of Resin-Gel–Rubber Expandable Lost Circulation Material Blend. Gels. 2023; 9(11):862. https://doi.org/10.3390/gels9110862

Chicago/Turabian StyleZhu, Jinzhi, Erbiao Lou, Shaojun Zhang, Haiying Lu, and Ziwu Wang. 2023. "Preparation and Performance of Resin-Gel–Rubber Expandable Lost Circulation Material Blend" Gels 9, no. 11: 862. https://doi.org/10.3390/gels9110862

APA StyleZhu, J., Lou, E., Zhang, S., Lu, H., & Wang, Z. (2023). Preparation and Performance of Resin-Gel–Rubber Expandable Lost Circulation Material Blend. Gels, 9(11), 862. https://doi.org/10.3390/gels9110862