Hydrogels for Climate Change Mitigation: Applications in Water Harvesting, Passive Cooling, and Environmental Solutions

Abstract

1. Introduction

| Application | Representative System | Performance Metrics | Standard Test Conditions | Cycle Protocol | References |

|---|---|---|---|---|---|

| Atmospheric water harvesting (AWH) | PNIPAm- or alginate-based sorbent hydrogels; MOF-hydrogel hybrids; salt-polymer composites | Typical water yield: 2–5 L m−2 day−1; Max reported: 14.9 L m−2 day−1 (60–80% RH, 20–35 °C) | RH 30–90%; ambient 25–40 °C; desorption 40–70 °C (solar) | ≈3 h adsorption + ≈3 h desorption; up to 8 cycles day−1 | [26,27,28,29] |

| Passive cooling—evaporative | Hydrogel evaporators/roof coatings | ΔT 5–15 °C (surface-to-ambient); Cooling power 50–150 W m−2; Duration 3–8 h continuous (day), overnight rehydration | RH 40–80%; ambient 20–45 °C; daytime solar load; moderate wind | Continuous daytime; overnight water recharge; multi-day repeatable | [30,31,32,33,34] |

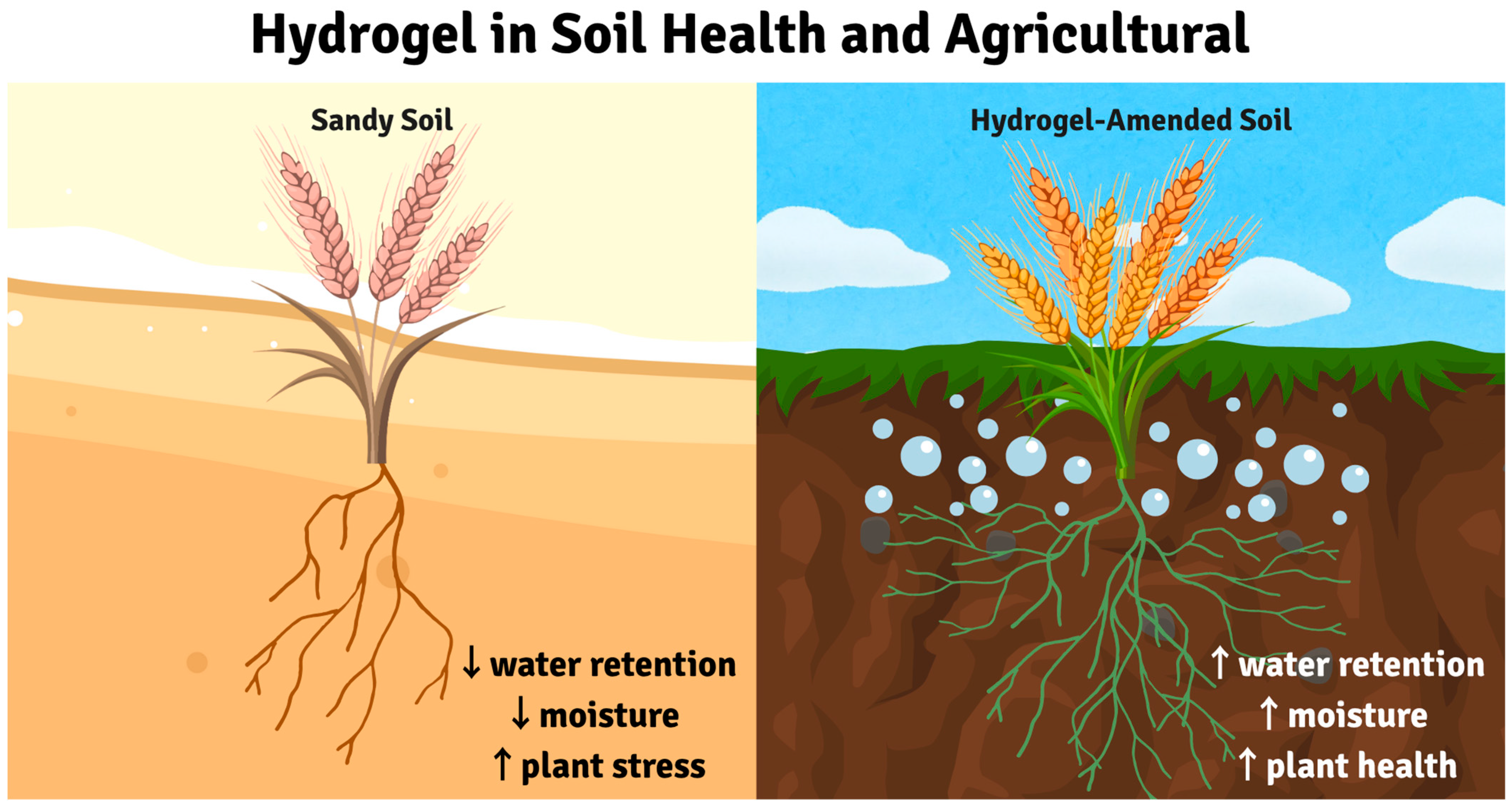

| Soil water retention and yield | Superabsorbent hydrogels in soil (e.g., PAM, natural-polymer blends) | Irrigation reduction 30–50%; Yield increase 11–51%; Absorption 100–1000 g g−1; Application 0.2–0.4 g per 100 g soil; Durability 100–500 hydration cycles | Field/greenhouse; crop-dependent; ambient 15–35 °C; irrigation per protocol | Per-crop growing season; rewet/dry cycles per irrigation schedule | [35,36,37,38,39,40,41,42] |

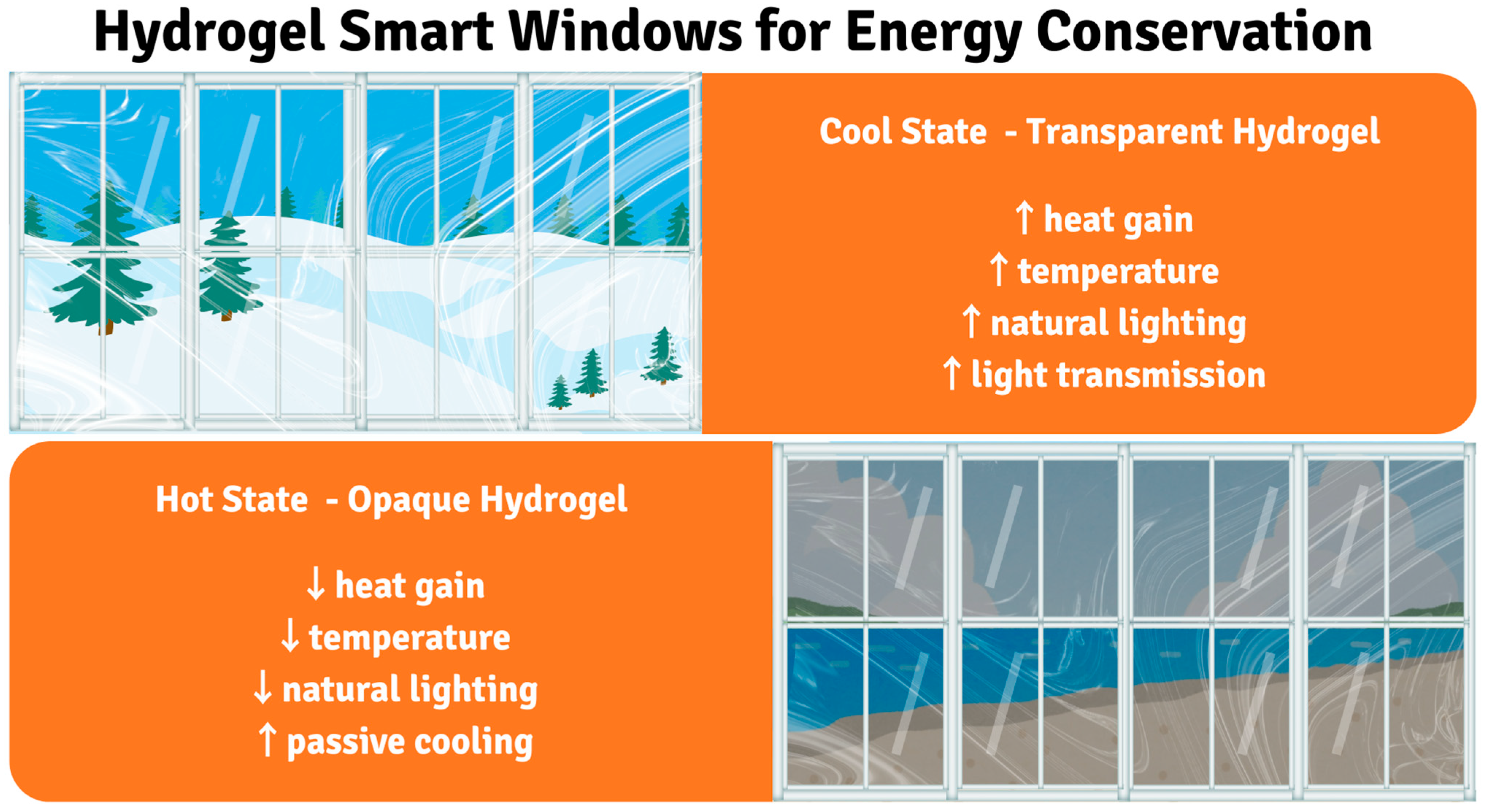

| Energy conservation—smart windows | Thermoresponsive (e.g., PNIPAm/HPC) hydrogel glazing | Solar modulation ΔTsolar up to ≈33%; Visible transmittance Tlum ≈ 95%; Energy reduction up to 45% (model/prototype) | LCST window 20–50 °C; indoor 20–26 °C; outdoor 10–35 °C; standard solar spectra | Reversible LCST cycling >100 cycles without degradation. | [43,44,45,46,47,48] |

| CO2 capture | Amine-functionalized hydrogel sorbents (e.g., PEI-hydrogel) | 6.5 mol kg−1 (pure CO2); 0.7 mol kg−1 (air); 25 °C; 40% RH; ~30 min adsorption; ~60 °C desorption; ~4 h cycle | 400 ppm CO2 (air tests) or pure CO2; ambient pressure; 25 °C; controlled RH (40%) | Batch adsorption/desorption; repeated cycling | [7,13] |

2. Hydrogel Type, Manufacturing and Features

2.1. Classification of Hydrogels

2.1.1. Hydrogels Classification by Polymer Source

| Hydrogel Type and Polymer Source | Climate Applications | Relative-Humidity (RH) Uptake | Regeneration | Outdoor Durability | Soil Cycling | Emissivity | References |

|---|---|---|---|---|---|---|---|

| Natural Polymer: Chitosan, alginate, collagen, gelatin | Soil amendment, water harvesting, passive cooling | 0.1–0.3 g g−1 at <30% RH (limited) | 60–80 °C, 180–250 kJ/mol (moderate efficiency) | 2–12 months (enzymatic degradation, microbial attack) | 6–18 months (full mineralization, enriches soil) | 0.65–0.75 (transparent matrix, poor radiative cooling) | [16,35,54,57] |

| Synthetic Polymer: Polyacrylamide, polyethylene glycol | Atmospheric water generation, CO2 capture, energy storage | 0.8–1.5 g g−1 at 30–50% RH (moderate) | 40–60 °C, 200–350 kJ/mol (higher efficiency) | 5–10 years (UV-resistant but persistent microplastics) | Non-applicable (non-biodegradable persistence) | 0.45–0.60 (absorbed solar radiation, poor radiative window) | [53,54,58,59] |

| Composite/Hybrid: Natural + synthetic combinations, nanoparticle incorporation | Advanced cooling systems, smart windows, precision agriculture | 2.8–3.5 g g−1 at 15–25% RH (excellent) | 55–70 °C, 320–450 kJ/mol (highest efficiency) | 6 months-2 years (salt crystallization stress + UV degradation) | Variable (depends on polymer component ratio) | 0.70–0.85 (enhanced by salt crystalline structure) | [20,21,56,60,61] |

| Interpenetrating Networks (IPNs): Two or more polymer networks | Building materials, thermal regulation, water purification | 0.5–1.2 g g−1 at 25–40% RH (moderate-good) | 45–65 °C, 280–400 kJ/mol (balanced) | 1–3 years (superior UV resistance vs. single polymers) | 8–24 months (controlled mineralization) | 0.55–0.75 (depends on composition) | [58,59] |

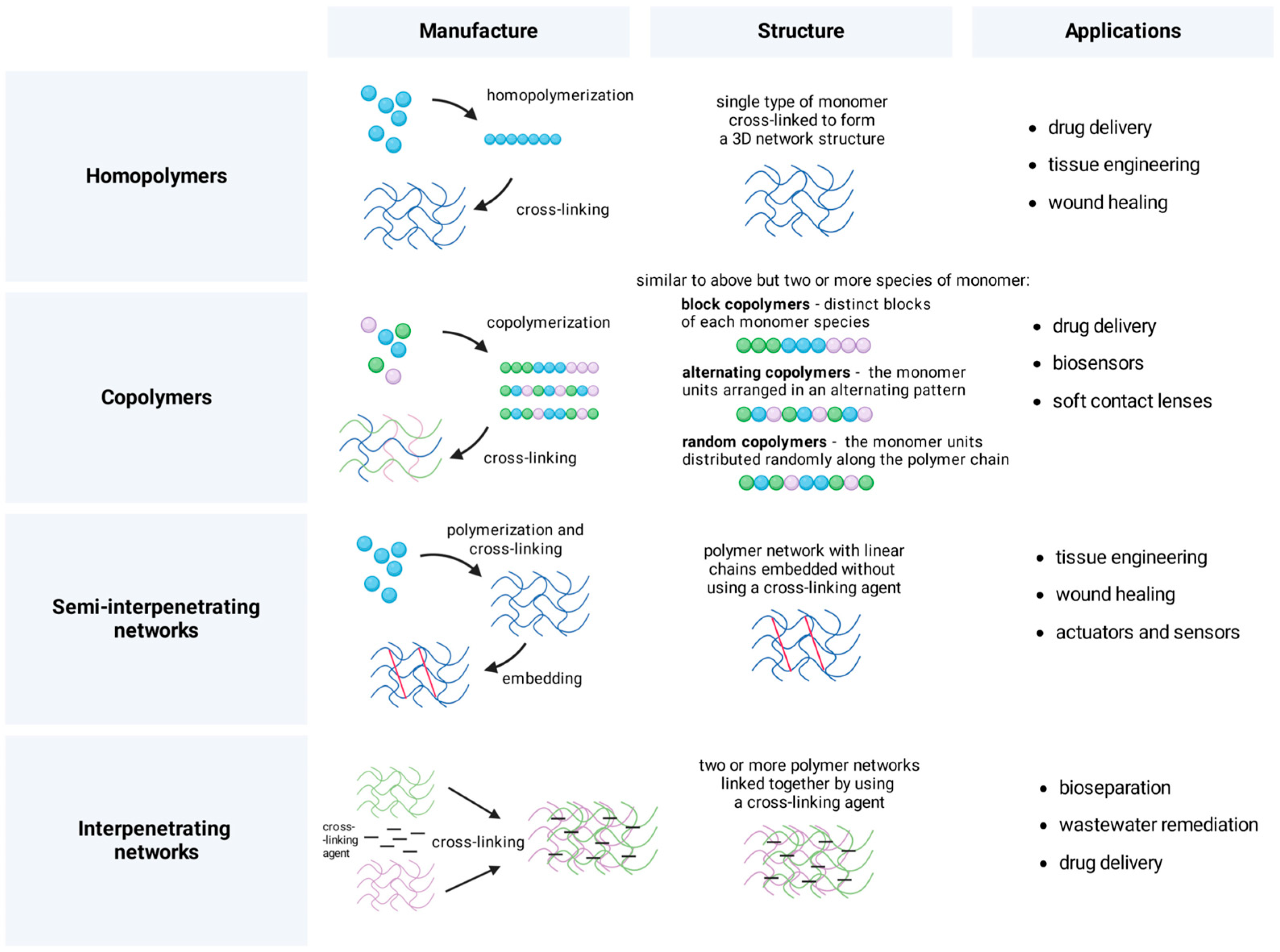

2.1.2. Hydrogels Classification by Manufacturing Approaches

2.1.3. Advanced Synthesis and Comparative Analysis of Fabrication Methods

2.2. Unique Features and Property Characterization of Hydrogels

2.2.1. Biocompatibility and Biodegradability

2.2.2. Stimuli-Responsive Behavior

2.2.3. Swelling Behavior and Kinetics

2.2.4. Water Retention and Release Mechanisms

2.2.5. Thermal Conductivity and Thermal Stability

2.2.6. Mechanical Properties and Stability

2.2.7. Photothermal Properties and Solar Responsiveness

2.3. Sustainability and Current Challenges in Hydrogel Technology

3. Climate Solutions Powered by Hydrogels

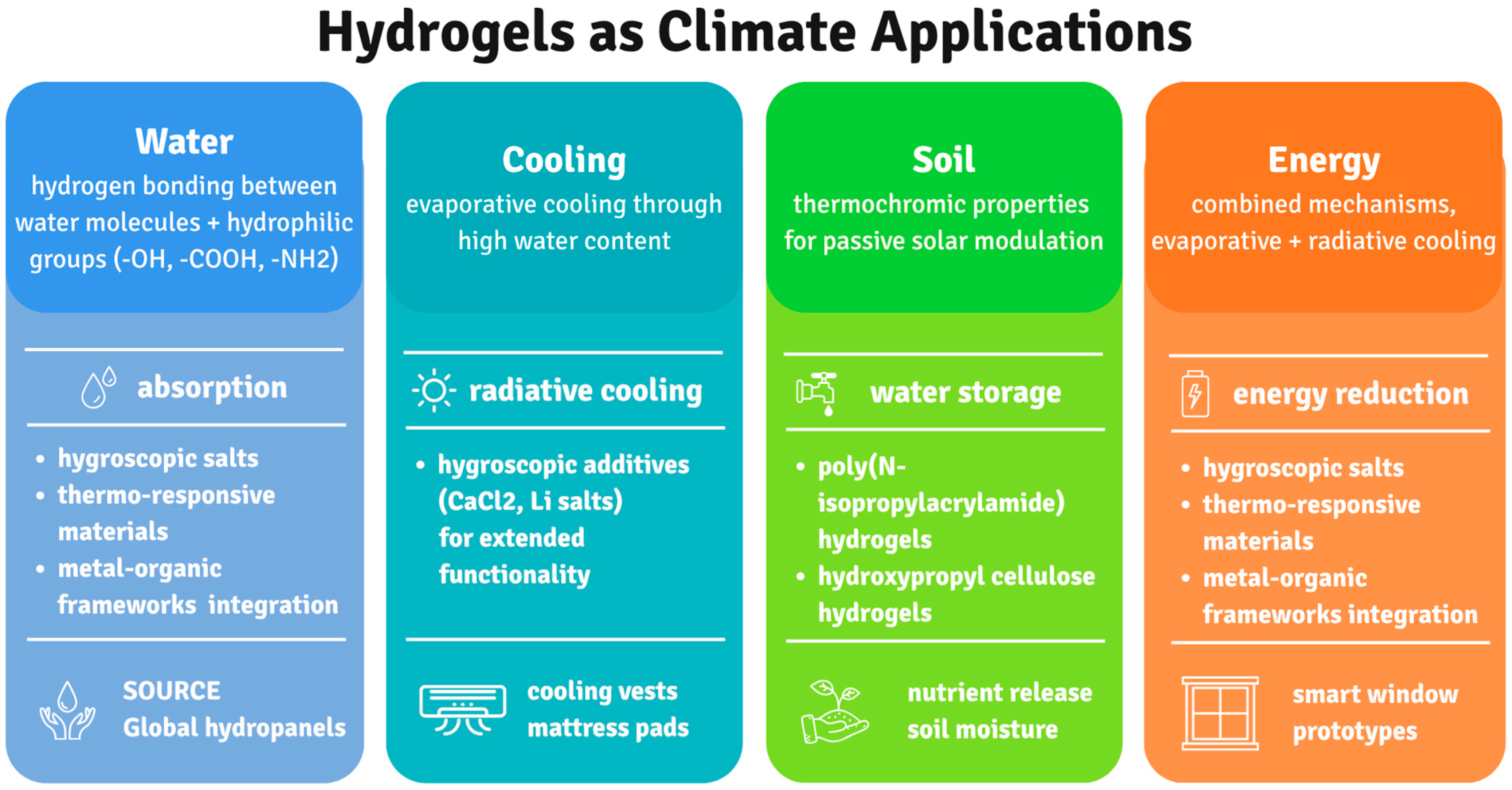

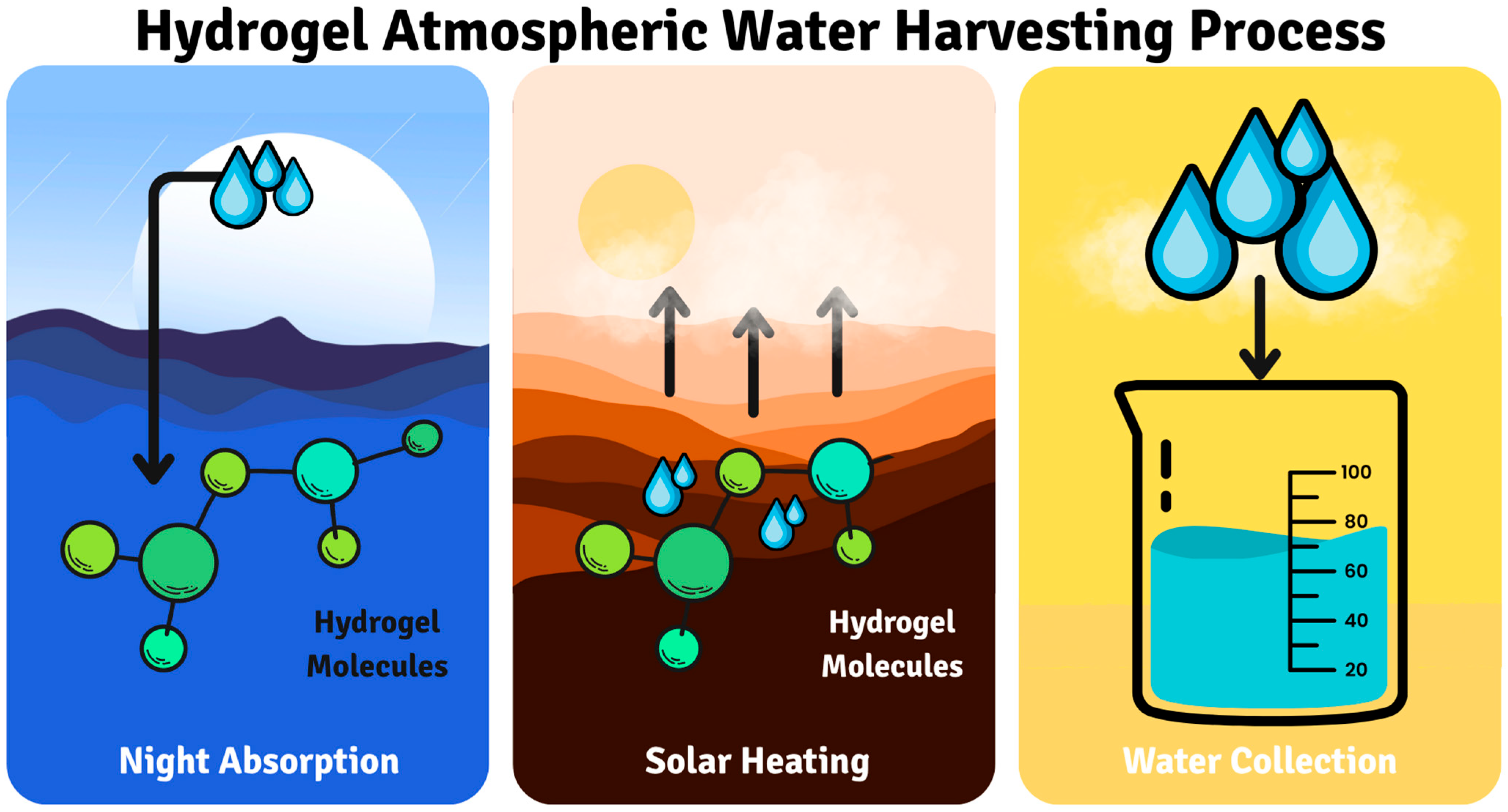

3.1. Hydrogels in Water Harvesting

3.1.1. Advanced Hydrogel Formulations for Water Harvesting

3.1.2. Thermo-Responsive Systems

3.1.3. Performance Analysis and Commercial Viability

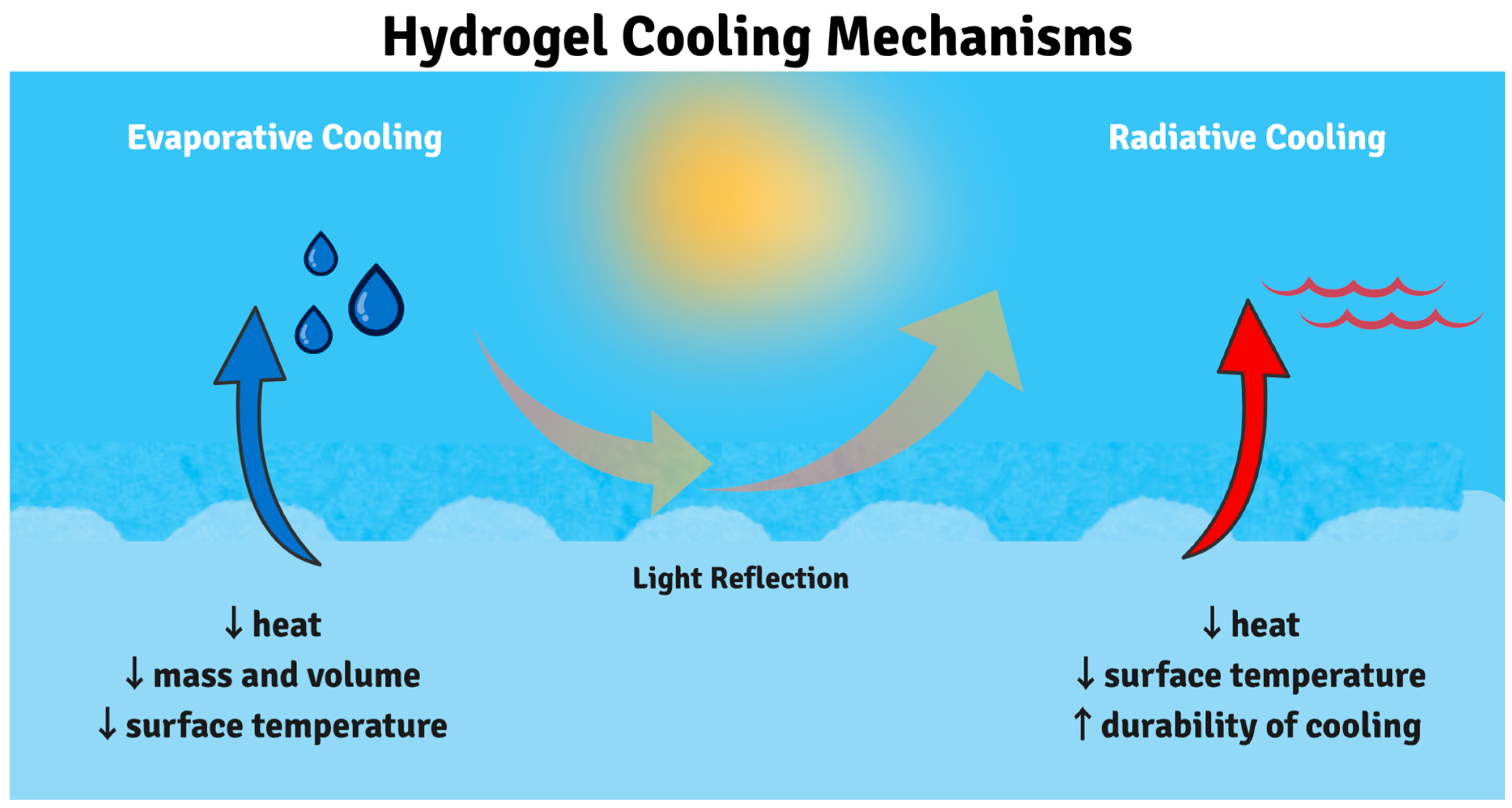

3.2. Hydrogels as Cooling Agents

3.2.1. Cooling Mechanisms and Performance

3.2.2. Comparative Analysis with Conventional Cooling

3.2.3. Commercial Applications and Market Position

3.3. Hydrogels for Soil Health

3.3.1. Performance Metrics and Mechanisms

3.3.2. Multifunctional Soil Improvement

3.3.3. Environmental Considerations and Challenges

3.4. Hydrogels as Energy Saving Particles

3.4.1. Operating Principles and Performance

3.4.2. Alternative Materials and Enhanced Systems

3.4.3. Market Potential and Implementation Challenges

3.5. Comparative Evaluation of Hydrogel Technologies

| Application Domain | Hydrogel System | Key Performance Metrics | Operating Conditions | Advantages | Current Limitations | References |

|---|---|---|---|---|---|---|

| Water Harvesting | Polyelectrolyte hydrogels with hygroscopic salts | 2.4–5.0 L/kg·day water output, 85% release efficiency | 20–90% humidity, 20–60 °C | Energy-free operation, works in arid climates | High cost, salt leaching, limited scalability | [15,27,28,154] |

| Passive Cooling | PVA/hygroscopic salt composites | 5–15 °C temperature reduction, 3–8 h cooling duration | 40–80% humidity, 25–45 °C | No electricity required, reusable, portable | Limited cooling duration, bacterial growth risk | [30,32,136,178] |

| Soil Health | Superabsorbent agricultural hydrogels | 30–50% irrigation reduction, 130–1000 g g−1 absorption | pH 6–8, 15–35 °C soil temperature | Drought resistance, nutrient retention, yield increase | Cost-effectiveness, long-term soil effects | [19,36,215,225] |

| Energy Saving | Thermochromic PNIPAM/HPC systems | 45% energy reduction, 32 °C transition temperature | Building integration −10 to 50 °C; passive operation without external control | Autonomous operation, high transparency, durability | Narrow response range, UV degradation | [44,47] |

| Carbon Capture | PEI hydrogel particles | 6.5 mol CO2/kg (pure), 0.7 mol CO2/kg (air) | 25 °C; 400–100,000 ppm CO2 range | High selectivity, regenerable, scalable | Regeneration energy, humidity sensitivity | [13,157] |

| Environmental Remediation | Polyelectrolyte hydrogels with hygroscopic salts | 90–99% heavy metal removal, pH 4–9 operation | Various contaminated environments | Selective adsorption, eco-friendly, solar-powered | Treatment capacity, fouling resistance | [158,159,213,214] |

4. Overcoming Climate Challenges

4.1. Eco-Friendly Hydrogel Innovations

4.2. Synergistic Approaches

4.3. Integration and Feasability

4.4. Economic Feasibility and Sustainability Assessment

5. Current Limitations and Future Prospects

5.1. Key Issues

- −

- Performance Limitations: Water harvesting efficiency decreases 70–80% below 40% relative humidity [259]. Cooling systems require frequent rehydration and face bacterial growth risks in water-rich environments.

- −

- −

- Environmental Impact: Non-biodegradable synthetic hydrogels persist in soil for years and may release toxic monomers. Manufacturing processes involve potentially harmful chemicals requiring careful handling [260].

- −

5.2. Comparative Performance Analysis and Research Gaps

5.3. Future Research Directions

- −

- Smart Materials: Development of multi-responsive hydrogels with AI integration for predictive behavior and self-healing capabilities;

- −

- Sustainable Manufacturing: Large-scale production using bio-manufacturing and agricultural waste feedstocks;

- −

- Integrated Systems: Internet of Things-enabled smart networks for real-time climate monitoring and automated optimization;

- −

- Environmental Solutions: Complete biodegradability with carbon-negative manufacturing processes.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-dimensional |

| 4D | Four-dimensional |

| AA | Acrylic acid |

| AC | Air conditioning |

| AI | Artificial intelligence |

| AM | Acrylamide |

| ATRP | Atom transfer radical polymerization |

| AWH | Atmospheric water harvesting |

| BNNS | Boron nitride nanosheets |

| CaCl2 | Calcium chloride |

| CH4 | Methane |

| CO2 | Carbon dioxide |

| -COOH | Carboxyl (group) |

| CuAAC | Copper-catalyzed azide-alkyne cycloaddition |

| DMPAP | 2,2-Dimethoxy-2-phenylacetophenone |

| ESR | Equilibrium swelling ratio |

| GHGs | Greenhouse gases |

| HEMA | Hydroxyethyl methacrylate |

| HPC | Hydroxypropyl cellulose |

| HPMC | Hydroxypropylmethyl cellulose |

| HVAC | Heating, ventilation, and air conditioning |

| IPNs | Interpenetrating polymer networks |

| LCST | Lower critical solution temperature |

| LiCl | Lithium chloride |

| MBA | Methylene bisacrylamide |

| ML | Machine learning |

| MOFs | Metal–organic frameworks |

| N2O | Nitrous oxide |

| NBW | Non-bound water |

| -NH2 | Amine (group) |

| -OH | Hydroxyl (group) |

| PAAm | Polyacrylamide |

| PAAS-PNIPAAm | Polyacrylic acid sodium salt-Poly(N-isopropylacrylamide) |

| PAM | Polyacrylamide |

| PEG | Polyethylene glycol |

| PEG-DA/PEO | Poly(ethylene glycol) diacrylate/poly(ethylene oxide) |

| PEI | Polyethylenimine |

| PNIPAM | Poly(N-isopropyl methacrylamide) |

| PNIPAm | Poly(N-isopropylacrylamide) |

| PVA | Poly(vinyl alcohol) |

| PVA/PPy | Polyvinyl alcohol/Polypyrrole |

| RAFT | Reversible addition-fragmentation chain transfer |

| RH | Relative humidity |

| RO | Reverse osmosis |

| SAHs | Superabsorbent hydrogels |

| SAPs | Superabsorbent polymers |

| SBW | Strongly bound water |

| SDGs | Sustainable Development Goals |

| Tlum | Luminous transmittance |

| TEGDMA | Triethylene glycol dimethacrylate |

| TiO2 | Titanium dioxide |

| UV | Ultraviolet |

| VO2 | Vanadium dioxide |

| VPT | Volume phase transition |

| WBW | Weakly bound water |

| ΔTsolar | Solar modulation ability |

References

- Abbass, K.; Qasim, M.Z.; Song, H.; Murshed, M.; Mahmood, H.; Younis, I. A Review of the Global Climate Change Impacts, Adaptation, and Sustainable Mitigation Measures. Environ. Sci. Pollut. Res. Int. 2022, 29, 42539–42559. [Google Scholar] [CrossRef]

- Climate Change: Global Temperature|NOAA Climate.Gov. Available online: https://www.climate.gov/news-features/understanding-climate/climate-change-global-temperature (accessed on 20 May 2025).

- WMO Confirms 2024 as Warmest Year on Record at About 1.55 °C Above Pre-Industrial Level. Available online: https://wmo.int/news/media-centre/wmo-confirms-2024-warmest-year-record-about-155degc-above-pre-industrial-level (accessed on 11 July 2025).

- Global Climate Highlights 2024. Copernicus Climate Change Service (C3S). Global Climate Highlights 2024. Available online: https://climate.copernicus.eu/global-climate-highlights-2024 (accessed on 11 July 2025).

- Lan, X.; Tans, P.; Thoning, K.; NOAA Global Monitoring Laboratory. Trends in Globally-Averaged CO2 Determined from NOAA Global Monitoring Laboratory Measurements; NOAA GML: Boulder, CO, USA, 2023. [Google Scholar]

- Greenhouse Gas Concentrations Surge Again to New Record in 2023. Available online: https://wmo.int/news/media-centre/greenhouse-gas-concentrations-surge-again-new-record-2023 (accessed on 11 July 2025).

- Guo, Y.; Bae, J.; Fang, Z.; Li, P.; Zhao, F.; Yu, G. Hydrogels and Hydrogel-Derived Materials for Energy and Water Sustainability. Chem. Rev. 2020, 120, 7642–7707. [Google Scholar] [CrossRef]

- Agbna, G.H.D.; Zaidi, S.J. Hydrogel Performance in Boosting Plant Resilience to Water Stress—A Review. Gels 2025, 11, 276. [Google Scholar] [CrossRef]

- Elimelech, M.; Phillip, W.A. The Future of Seawater Desalination: Energy, Technology, and the Environment. Science 2011, 333, 712–717. [Google Scholar] [CrossRef]

- Romischke, J.; Scherkus, A.; Saemann, M.; Krueger, S.; Bader, R.; Kragl, U.; Meyer, J. Swelling and Mechanical Characterization of Polyelectrolyte Hydrogels as Potential Synthetic Cartilage Substitute Materials. Gels 2022, 8, 296. [Google Scholar] [CrossRef] [PubMed]

- Bashir, S.; Hina, M.; Iqbal, J.; Rajpar, A.H.; Mujtaba, M.A.; Alghamdi, N.A.; Wageh, S.; Ramesh, K.; Ramesh, S. Fundamental Concepts of Hydrogels: Synthesis, Properties, and Their Applications. Polymers 2020, 12, 2702. [Google Scholar] [CrossRef] [PubMed]

- Hoekstra, A.Y.; Mekonnen, M.M. The Water Footprint of Humanity. Proc. Natl. Acad. Sci. USA 2012, 109, 3232–3237. [Google Scholar] [CrossRef]

- Jiang, J.; Van Daatselaar, E.; Wijnja, H.; De Koning Gans, T.; Schellevis, M.; Venner, C.H.; Brilman, D.W.F.; Visser, C.W. Scalable Jet-Based Fabrication of PEI-Hydrogel Particles for CO2 Capture. Energy Environ. Mater. 2024, 7, e12748. [Google Scholar] [CrossRef]

- Ning, X.; Huang, J.; Yimuhan, A.; Yuan, N.; Chen, C.; Lin, D. Research Advances in Mechanical Properties and Applications of Dual Network Hydrogels. Int. J. Mol. Sci. 2022, 23, 15757. [Google Scholar] [CrossRef]

- Shan, H.; Poredoš, P.; Ye, Z.; Qu, H.; Zhang, Y.; Zhou, M.; Wang, R.; Tan, S.C. All-Day Multicyclic Atmospheric Water Harvesting Enabled by Polyelectrolyte Hydrogel with Hybrid Desorption Mode. Adv. Mater. 2023, 35, e2302038. [Google Scholar] [CrossRef]

- El Sayed, M.M. Production of Polymer Hydrogel Composites and Their Applications. J. Polym. Environ. 2023, 31, 2855–2879. [Google Scholar] [CrossRef]

- Zhao, R.; Zhao, Z.; Song, S.; Wang, Y. Multifunctional Conductive Double-Network Hydrogel Sensors for Multiscale Motion Detection and Temperature Monitoring. ACS Appl. Mater. Interfaces 2023, 15, 59854–59865. [Google Scholar] [CrossRef] [PubMed]

- Koupai, J.A.; Eslamian, S.S.; Kazemi, J.A. Enhancing the Available Water Content in Unsaturated Soil Zone Using Hydrogel, to Improve Plant Growth Indices. Ecohydrol. Hydrobiol. 2008, 8, 67–75. [Google Scholar] [CrossRef]

- Albalasmeh, A.A.; Mohawesh, O.; Gharaibeh, M.A.; Alghamdi, A.G.; Alajlouni, M.A.; Alqudah, A.M. Effect of Hydrogel on Corn Growth, Water Use Efficiency, and Soil Properties in a Semi-Arid Region. J. Saudi Soc. Agric. Sci. 2022, 21, 518–524. [Google Scholar] [CrossRef]

- Biondi, M.; Borzacchiello, A.; Mayol, L.; Ambrosio, L. Nanoparticle-Integrated Hydrogels as Multifunctional Composite Materials for Biomedical Applications. Gels 2015, 1, 162–178. [Google Scholar] [CrossRef]

- Memic, A.; Alhadrami, H.A.; Hussain, M.A.; Aldhahri, M.; Al Nowaiser, F.; Al-Hazmi, F.; Oklu, R.; Khademhosseini, A. Hydrogels 2.0: Improved Properties with Nanomaterial Composites for Biomedical Applications. Biomed. Mater. 2015, 11, 014104. [Google Scholar] [CrossRef]

- Feng, A.; Shi, Y.; Onggowarsito, C.; Zhang, X.S.; Mao, S.; Johir, M.A.H.; Fu, Q.; Nghiem, L.D. Structure-Property Relationships of Hydrogel-Based Atmospheric Water Harvesting Systems. ChemSusChem 2024, 17, e202301905. [Google Scholar] [CrossRef]

- Bharti, R.; Pal, S.; Prasad, N.; Kumar, Y.; Joseph, B.; Sharma, H.; Sahu, G.K. A Comprehensive Review on Hydrogel. Acta Sci. Pharm. Sci. 2024, 8, 64–75. [Google Scholar] [CrossRef]

- Zhan, D.; Fu, C.; Yu, Z.; Tian, G.; He, Y.; Chen, X.; Guo, Z. In-Situ Loaded PPy Hydrogel for Efficient Atmospheric Water Harvesting without Any Energy Consumption. Mater. Today Phys. 2025, 51, 101658. [Google Scholar] [CrossRef]

- Guo, Y.; Yu, G. Engineering Hydrogels for Efficient Solar Desalination and Water Purification. Acc. Mater. Res. 2021, 2, 374–384. [Google Scholar] [CrossRef]

- Yang, X.; Chen, Z.; Xiang, C.; Shan, H.; Wang, R. Enhanced Continuous Atmospheric Water Harvesting with Scalable Hygroscopic Gel Driven by Natural Sunlight and Wind. Nat. Commun. 2024, 15, 7678. [Google Scholar] [CrossRef]

- Feng, A.; Akther, N.; Duan, X.; Peng, S.; Onggowarsito, C.; Mao, S.; Fu, Q.; Kolev, S.D. Recent Development of Atmospheric Water Harvesting Materials: A Review. ACS Mater. Au 2022, 2, 576–595. [Google Scholar] [CrossRef]

- Gao, Y.; Eason, A.; Ricoy, S.; Cobb, A.; Phung, R.; Kashani, A.; Mata, M.R.; Sahm, A.; Ortiz, N.; Rao, S.; et al. High-Yield Atmospheric Water Capture via Bioinspired Material Segregation. Proc. Natl. Acad. Sci. USA 2024, 121, e2321429121. [Google Scholar] [CrossRef]

- Wilson, C.T.; Díaz-Marín, C.D.; Colque, J.P.; Mooney, J.P.; El Fil, B. Solar-Driven Atmospheric Water Harvesting in the Atacama Desert through Physics-Based Optimization of a Hygroscopic Hydrogel Device. Device 2025, 3, 100798. [Google Scholar] [CrossRef]

- Dong, X.; Chan, K.-Y.; Yin, X.; Zhang, Y.; Zhao, X.; Yang, Y.; Wang, Z.; Shen, X. Anisotropic Hygroscopic Hydrogels with Synergistic Insulation-Radiation-Evaporation for High-Power and Self-Sustained Passive Daytime Cooling. Nano-Micro Lett. 2025, 17, 240. [Google Scholar] [CrossRef]

- Galib, R.H.; Tian, Y.; Lei, Y.; Dang, S.; Li, X.; Yudhanto, A.; Lubineau, G.; Gan, Q. Atmospheric-Moisture-Induced Polyacrylate Hydrogels for Hybrid Passive Cooling. Nat. Commun. 2023, 14, 6707. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Guo, C.; Xu, Q.; Zhao, D. Boosting Evaporative Cooling Performance with Microporous Aerogel. Micromachines 2023, 14, 219. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wang, X.; Liang, D.; Xu, N.; Zhu, B.; Li, W.; Yao, P.; Jiang, Y.; Min, X.; Huang, Z.; et al. A Tandem Radiative/Evaporative Cooler for Weather-Insensitive and High-Performance Daytime Passive Cooling. Sci. Adv. 2022, 8, eabq0411. [Google Scholar] [CrossRef] [PubMed]

- Lai, C.; Lu, L. Hydrogel-Based Thermal Regulation Strategies for Passive Cooling: A Review. Energy Built Environ. 2024, 5, S2666123324001016. [Google Scholar] [CrossRef]

- Adjuik, T.A.; Nokes, S.E.; Montross, M.D.; Wendroth, O. The Impacts of Bio-Based and Synthetic Hydrogels on Soil Hydraulic Properties: A Review. Polymers 2022, 14, 4721. [Google Scholar] [CrossRef]

- Ali, K.; Asad, Z.; Agbna, G.H.D.; Saud, A.; Khan, A.; Zaidi, S.J. Progress and Innovations in Hydrogels for Sustainable Agriculture. Agronomy 2024, 14, 2815. [Google Scholar] [CrossRef]

- Piccoli, I.; Camarotto, C.; Squartini, A.; Longo, M.; Gross, S.; Maggini, M.; Cabrera, M.L.; Morari, F. Hydrogels for Agronomical Application: From Soil Characteristics to Crop Growth: A Review. Agron. Sustain. Dev. 2024, 44, 22. [Google Scholar] [CrossRef]

- Cheng, Y.-C.; Wang, C.-P.; Liu, K.-Y.; Pan, S.-Y. Towards Sustainable Management of Polyacrylamide in Soil-Water Environment: Occurrence, Degradation, and Risk. Sci. Total Environ. 2024, 926, 171587. [Google Scholar] [CrossRef]

- Omar, H.; Alsharaeh, E. Improving Water Retention in Sandy Soils with High-Performance Superabsorbents Hydrogel Polymer. ACS Omega 2024, 9, 23531–23541. [Google Scholar] [CrossRef] [PubMed]

- Heise, K.; Kirsten, M.; Schneider, Y.; Jaros, D.; Keller, H.; Rohm, H.; Kalbitz, K.; Fischer, S. From Agricultural Byproducts to Value-Added Materials: Wheat Straw-Based Hydrogels as Soil Conditioners? ACS Sustain. Chem. Eng. 2019, 7, 8604–8612. [Google Scholar] [CrossRef]

- Rashad, M.; Kenawy, E.-R.; Hosny, A.; Hafez, M.; Elbana, M. An Environmental Friendly Superabsorbent Composite Based on Rice Husk as Soil Amendment to Improve Plant Growth and Water Productivity under Deficit Irrigation Conditions. J. Plant Nutr. 2021, 44, 1010–1022. [Google Scholar] [CrossRef]

- Chen, X.; Yang, T.; Cai, X.; Liu, Y.; Huang, C.; He, J.; Tian, D.; Yang, G.; Shen, F.; Zhang, Y. Eco-Friendly Hydrogel Based on Locust Bean Gum for Water Retaining in Sandy Soil. Int. J. Biol. Macromol. 2024, 275, 133490. [Google Scholar] [CrossRef]

- Xu, G.; Lu, Y.; Zhou, X.; Moloto, N.; Liu, J.; Kure-Chu, S.-Z.; Hihara, T.; Zhang, W.; Sun, Z. Thermochromic Hydrogel-Based Energy Efficient Smart Windows: Fabrication, Mechanisms, and Advancements. Mater. Horiz. 2024, 11, 4867–4884. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Sun, H.; Wei, R.; Li, W.; Lai, J.; Tian, Y.; Li, M. Energy-Efficient Smart Window Based on a Thermochromic Hydrogel with Adjustable Critical Response Temperature and High Solar Modulation Ability. Gels 2024, 10, 494. [Google Scholar] [CrossRef]

- Wang, K.; Chen, G.; Weng, S.; Hou, L.; Ye, D.; Jiang, X. Thermo-Responsive Poly(N-Isopropylacrylamide)/Hydroxypropylmethyl Cellulose Hydrogel with High Luminous Transmittance and Solar Modulation for Smart Windows. ACS Appl. Mater. Interfaces 2023, 15, 4385–4397. [Google Scholar] [CrossRef]

- Feng, Y.-Q.; Lv, M.-L.; Yang, M.; Ma, W.-X.; Zhang, G.; Yu, Y.-Z.; Wu, Y.-Q.; Li, H.-B.; Liu, D.-Z.; Yang, Y.-S. Application of New Energy Thermochromic Composite Thermosensitive Materials of Smart Windows in Recent Years. Molecules 2022, 27, 1638. [Google Scholar] [CrossRef]

- Tian, J.; Peng, H.; Du, X.; Wang, H.; Cheng, X.; Du, Z. Durable, Broadband-Light-Manageable Thermochromic Hydrogel with Adjustable LCST for Smart Windows Application. Prog. Org. Coat. 2021, 157, 106287. [Google Scholar] [CrossRef]

- Zhang, L.; Xia, H.; Xia, F.; Du, Y.; Wu, Y.; Gao, Y. Energy-Saving Smart Windows with HPC/PAA Hybrid Hydrogels as Thermochromic Materials. ACS Appl. Energy Mater. 2021, 4, 9783–9791. [Google Scholar] [CrossRef]

- Cuéllar Gaona, C.G.; Ibarra Alonso, M.C.; Narro Céspedes, R.I.; Téllez Rosas, M.M.; Reyna Martínez, R.; Luévanos Escareño, M.P. Novel Studies in the Designs of Natural, Synthetic, and Compound Hydrogels with Biomedical Applications. Rev. Mex. Ing. Bioméd. 2023, 44, 74–96. [Google Scholar] [CrossRef]

- Grabowska-Polanowska, B.; Garbowski, T.; Bar-Michalczyk, D.; Kowalczyk, A. The benefits of synthetic or natural hydrogels application in agriculture: An overview article. J. Water Land Dev. 2022, 51, 208–224. [Google Scholar] [CrossRef]

- Kruczkowska, W.; Gałęziewska, J.; Grabowska, K.; Liese, G.; Buczek, P.; Kłosiński, K.K.; Kciuk, M.; Pasieka, Z.; Kałuzińska-Kołat, Ż.; Kołat, D. Biomedical Trends in Stimuli-Responsive Hydrogels with Emphasis on Chitosan-Based Formulations. Gels 2024, 10, 295. [Google Scholar] [CrossRef]

- Zhang, S.; Shen, J.; Zhang, P.; Schroeder, T.B.H.; Chen, J.; Carnevale, C.; Salmon, S.; Fang, X. 3D-Printed Hydrogel Filter for Biocatalytic CO2 Capture. Adv. Mater. Technol. 2024, 9, 2400025. [Google Scholar] [CrossRef]

- Zhao, F.; Zhou, X.; Liu, Y.; Shi, Y.; Dai, Y.; Yu, G. Super Moisture-Absorbent Gels for All-Weather Atmospheric Water Harvesting. Adv. Mater. 2019, 31, 1806446. [Google Scholar] [CrossRef]

- Gaharwar, A.K.; Peppas, N.A.; Khademhosseini, A. Nanocomposite Hydrogels for Biomedical Applications. Biotechnol. Bioeng. 2014, 111, 441–453. [Google Scholar] [CrossRef]

- Hameed, H.; Faheem, S.; Paiva-Santos, A.C.; Sarwar, H.S.; Jamshaid, M. A Comprehensive Review of Hydrogel-Based Drug Delivery Systems: Classification, Properties, Recent Trends, and Applications. AAPS PharmSciTech 2024, 25, 64. [Google Scholar] [CrossRef]

- Azady, M.A.R.; Ahmed, S.; Islam, M.S. A Review on Polymer Nanocomposite Hydrogel Preparation, Characterization, and Applications. Eur. J. Chem. 2021, 12, 329–339. [Google Scholar] [CrossRef]

- Gun’ko, V.M.; Savina, I.N.; Mikhalovsky, S.V. Properties of Water Bound in Hydrogels. Gels 2017, 3, 37. [Google Scholar] [CrossRef]

- White, C.; Adam, E.; Sabri, Y.; Myers, M.B.; Pejcic, B.; Wood, C.D. Amine-Infused Hydrogels with Nonaqueous Solvents: Facile Platforms to Control CO2 Capture Performance. Ind. Eng. Chem. Res. 2021, 60, 14758–14767. [Google Scholar] [CrossRef]

- White, E.M.; Yatvin, J.; Grubbs, J.B.; Bilbrey, J.A.; Locklin, J. Advances in Smart Materials: Stimuli-responsive Hydrogel Thin Films. J. Polym. Sci. Part B Polym. Phys. 2013, 51, 1084–1099. [Google Scholar] [CrossRef]

- Lei, C.; Guo, Y.; Guan, W.; Lu, H.; Shi, W.; Yu, G. Polyzwitterionic Hydrogels for Efficient Atmospheric Water Harvesting. Angew. Chem. Int. Ed. 2022, 61, e202200271. [Google Scholar] [CrossRef] [PubMed]

- Lyu, T.; Han, Y.; Chen, Z.; Fan, X.; Tian, Y. Hydrogels and Hydrogel Derivatives for Atmospheric Water Harvesting. Mater. Today Sustain. 2024, 25, 100693. [Google Scholar] [CrossRef]

- Siqueira, E.C.D.; França, J.A.A.D.; Souza, R.F.M.D.; Leoterio, D.M.D.S.; Cordeiro, J.N.; Doboszewski, B. Recent Advances in the Development of the Physically Crosslinked Hydrogels and Their Biomedical Applications. Res. Soc. Dev. 2023, 12, e18212843073. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Y.; Zhao, L.; Zhang, J.; Luo, H. Constructions and Properties of Physically Cross-Linked Hydrogels Based on Natural Polymers. Polym. Rev. 2023, 63, 574–612. [Google Scholar] [CrossRef]

- Bustamante-Torres, M.; Romero-Fierro, D.; Arcentales-Vera, B.; Palomino, K.; Magaña, H.; Bucio, E. Hydrogels Classification According to the Physical or Chemical Interactions and as Stimuli-Sensitive Materials. Gels 2021, 7, 182. [Google Scholar] [CrossRef]

- Okay, O. How to Design Both Mechanically Strong and Self-Healable Hydrogels? In Self-Healing and Self-Recovering Hydrogels; Creton, C., Okay, O., Eds.; Advances in Polymer Science; Springer International Publishing: Cham, Switzerland, 2020; Volume 285, pp. 21–62. ISBN 978-3-030-54555-0. [Google Scholar]

- Strandman, S.; Zhu, X.X. Self-Healing Supramolecular Hydrogels Based on Reversible Physical Interactions. Gels 2016, 2, 16. [Google Scholar] [CrossRef]

- Masuda, T.; Saegusa, Y.; Tsuji, T.; Takai, M. Development of Deformable and Adhesive Biocompatible Polymer Hydrogels by a Simple One-Pot Method Using ADIP as a Cationic Radical Initiator. Polym. J. 2025, 57, 1257–1268. [Google Scholar] [CrossRef]

- Lu, K.; Lan, X.; Folkersma, R.; Voet, V.S.D.; Loos, K. Borax Cross-Linked Acrylamide-Grafted Starch Self-Healing Hydrogels. Biomacromolecules 2024, 25, 8026–8037. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Islam, M.; Hasan, M.K.; Nam, K.-W. A Comprehensive Review of Radiation-Induced Hydrogels: Synthesis, Properties, and Multidimensional Applications. Gels 2024, 10, 381. [Google Scholar] [CrossRef]

- Haque, S.N.; Bhuyan, M.M.; Jeong, J.-H. Radiation-Induced Hydrogel for Water Treatment. Gels 2024, 10, 375. [Google Scholar] [CrossRef] [PubMed]

- Mondal, M.I.H.; Haque, M.O.; Ahmed, F.; Pervez, M.N.; Naddeo, V.; Ahmed, M.B. Super-Adsorptive Biodegradable Hydrogel from Simply Treated Sugarcane Bagasse. Gels 2022, 8, 177. [Google Scholar] [CrossRef]

- Lee, J.W.; Song, K.H. Fibrous Hydrogels by Electrospinning: Novel Platforms for Biomedical Applications. J. Tissue Eng. 2023, 14, 20417314231191881. [Google Scholar] [CrossRef] [PubMed]

- Basu, T.; Goswami, D.; Majumdar, S. Fabrication of Crosslinker Free Hydrogels with Diverse Properties: An Interplay of Multiscale Physical Forces within Polymer Matrix. iScience 2024, 27, 111227. [Google Scholar] [CrossRef]

- Sousa, A.C.; Mcdermott, G.; Shields, F.; Alvites, R.; Lopes, B.; Sousa, P.; Moreira, A.; Coelho, A.; Santos, J.D.; Atayde, L.; et al. Innovative Ink-Based 3D Hydrogel Bioprinted Formulations for Tissue Engineering Applications. Gels 2024, 10, 831. [Google Scholar] [CrossRef] [PubMed]

- Mai, N.X.D.; Park, D.; Yoon, J.; Hur, J. Comparative Study of Hydrogel-Based Recyclable Photocatalysts. J. Nanosci. Nanotechnol. 2018, 18, 1361–1364. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, J.; Guo, Z. TiO2 Deposited Dual Functional Hydrogel Coatings with Superhydrophilic and Photocatalytic Properties for Efficient Oil/Water Separation and Dye Photodegradation. J. Environ. Chem. Eng. 2024, 12, 113133. [Google Scholar] [CrossRef]

- Lu, T.; Solis-Ramos, E.; Yi, Y.; Kumosa, M. UV Degradation Model for Polymers and Polymer Matrix Composites. Polym. Degrad. Stab. 2018, 154, 203–210. [Google Scholar] [CrossRef]

- Flores-Rojas, G.G.; Gómez-Lazaro, B.; López-Saucedo, F.; Vera-Graziano, R.; Bucio, E.; Mendizábal, E. Electrospun Scaffolds for Tissue Engineering: A Review. Macromol 2023, 3, 524–553. [Google Scholar] [CrossRef]

- Grewal, M.G.; Highley, C.B. Electrospun Hydrogels for Dynamic Culture Systems: Advantages, Progress, and Opportunities. Biomater. Sci. 2021, 9, 4228–4245. [Google Scholar] [CrossRef]

- Abdullah, T.; Altınkok, C.; Okay, O. Melt-Processable and Electrospinnable Shape-Memory Hydrogels. Macromol. Mater. Eng. 2024, 309, 2400166. [Google Scholar] [CrossRef]

- Haider, A.; Haider, S.; Kang, I.-K. A Comprehensive Review Summarizing the Effect of Electrospinning Parameters and Potential Applications of Nanofibers in Biomedical and Biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- O’Brien, F.J.; Harley, B.A.; Yannas, I.V.; Gibson, L. Influence of Freezing Rate on Pore Structure in Freeze-Dried Collagen-GAG Scaffolds. Biomaterials 2004, 25, 1077–1086. [Google Scholar] [CrossRef] [PubMed]

- Xing, Y.; Wang, X. Precise Application of Water and Fertilizer to Crops: Challenges and Opportunities. Front. Plant Sci. 2024, 15, 1444560. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Y.; Li, Z.; Fu, H.; Huang, J.; Xu, Z.; Lai, Y.; Qian, X.; Zhang, S. Sustainable Hierarchical-Pored PAAS-PNIPAAm Hydrogel with Core-Shell Structure Tailored for Highly Efficient Atmospheric Water Harvesting. ACS Appl. Mater. Interfaces 2022, 14, 55295–55306. [Google Scholar] [CrossRef] [PubMed]

- Entezari, A.; Ejeian, M.; Wang, R. Super Atmospheric Water Harvesting Hydrogel with Alginate Chains Modified with Binary Salts. ACS Mater. Lett. 2020, 2, 471–477. [Google Scholar] [CrossRef]

- Zhu, G.; Xu, G.; Zhang, Y.; Lu, G.; Cai, X.; Zhang, W.; She, W.; Miao, C. Thermochromic Smart Windows with Ultra-High Solar Modulation and Ultra-Fast Responsive Speed Based on Solid–Liquid Switchable Hydrogels. Research 2024, 7, 0462. [Google Scholar] [CrossRef]

- Rajanna, G.A.; Manna, S.; Singh, A.; Babu, S.; Singh, V.K.; Dass, A.; Chakraborty, D.; Patanjali, N.; Chopra, I.; Banerjee, T.; et al. Biopolymeric Superabsorbent Hydrogels Enhance Crop and Water Productivity of Soybean-Wheat System in Indo-Gangetic Plains of India. Sci. Rep. 2022, 12, 11955. [Google Scholar] [CrossRef] [PubMed]

- Stetsyshyn, Y.; Ohar, H.; Budkowski, A.; Lazzara, G. Molecular Design and Role of the Dynamic Hydrogen Bonds and Hydrophobic Interactions in Temperature-Switchable Polymers: From Understanding to Applications. Polymers 2025, 17, 1580. [Google Scholar] [CrossRef] [PubMed]

- Mamidi, N.; De Silva, F.F.; Vacas, A.B.; Gutiérrez Gómez, J.A.; Montes Goo, N.Y.; Mendoza, D.R.; Reis, R.L.; Kundu, S.C. Multifaceted Hydrogel Scaffolds: Bridging the Gap between Biomedical Needs and Environmental Sustainability. Adv. Healthc. Mater. 2024, 13, e2401195. [Google Scholar] [CrossRef]

- Montesano, F.F.; Parente, A.; Santamaria, P.; Sannino, A.; Serio, F. Biodegradable Superabsorbent Hydrogel IncreasesWater Retention Properties of Growing Media and Plant Growth. Agric. Agric. Sci. Procedia 2015, 4, 451–458. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, B.M. Current Advances in Stimuli-Responsive Hydrogels as Smart Drug Delivery Carriers. Gels 2023, 9, 838. [Google Scholar] [CrossRef]

- Yoon, J. Customizing Volume Phase Transition of Thermo-Responsive Hydrogels. Macromol. Symp. 2019, 385, 1800179. [Google Scholar] [CrossRef]

- Mah, E.; Ghosh, R. Thermo-Responsive Hydrogels for Stimuli-Responsive Membranes. Processes 2013, 1, 238–262. [Google Scholar] [CrossRef]

- Cherukupally, P.; Hao, B.; Zhang, Z.; Williams, D.R. Thermoresponsive Hydrogels for Atmospheric Water Vapor Harvesting. ChemRxiv 2021. [Google Scholar] [CrossRef]

- Wang, R.; Cheng, C.; Wang, H.; Wang, D. Swollen Hydrogel Nanotechnology: Advanced Applications of the Rudimentary Swelling Properties of Hydrogels. ChemPhysMater 2024, 3, 357–375. [Google Scholar] [CrossRef]

- He, X.; Zhu, J.; Yang, C. Harnessing Osmotic Swelling Stress for Robust Hydrogel Actuators. Soft Matter 2022, 18, 5177–5184. [Google Scholar] [CrossRef]

- Martwong, E.; Tran, Y. Lower Critical Solution Temperature Phase Transition of Poly(PEGMA) Hydrogel Thin Films. Langmuir 2021, 37, 8585–8593. [Google Scholar] [CrossRef]

- Kaczmarek, B.; Nadolna, K.; Owczarek, A. The Physical and Chemical Properties of Hydrogels Based on Natural Polymers. In Hydrogels Based on Natural Polymers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 151–172. ISBN 978-0-12-816421-1. [Google Scholar]

- Naohara, R.; Namai, S.; Kamiyama, J.; Ikeda-Fukazawa, T. Structure and Diffusive Properties of Water in Polymer Hydrogels. J. Phys. Chem. B 2022, 126, 7992–7998. [Google Scholar] [CrossRef]

- Li, J.; Mooney, D.J. Designing Hydrogels for Controlled Drug Delivery. Nat. Rev. Mater. 2016, 1, 16071. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Shen, S.; Duan, Z.; Deng, J.; Fan, D. Hydrogels for Long-Term Moisture Retention under Ambient Conditions: Inhibiting the Evaporation of Free Water from Macroscopic to Molecular Scales. Adv. Funct. Mater. 2025, 35, 2504356. [Google Scholar] [CrossRef]

- Wanniarachchi, P.C.; Paranagama, I.T.; Idangodage, P.A.; Nallaperuma, B.; Samarasinghe, T.T.; Jayathilake, C. Natural Polymer-based Hydrogels: Types, Functionality, Food Applications, Environmental Significance and Future Perspectives: An Updated Review. Food Biomacromol. 2025, 2, 84–105. [Google Scholar] [CrossRef]

- Liu, Z.; Ma, X.; Liu, J.; Zhang, H.; Fu, D. Advances in the Application of Natural/Synthetic Hybrid Hydrogels in Tissue Engineering and Delivery Systems: A Comprehensive Review. Int. J. Pharm. 2025, 672, 125323. [Google Scholar] [CrossRef]

- Gong, J.P.; Katsuyama, Y.; Kurokawa, T.; Osada, Y. Double-Network Hydrogels with Extremely High Mechanical Strength. Adv. Mater. 2003, 15, 1155–1158. [Google Scholar] [CrossRef]

- Luo, W.; Xuan, X.; Shen, J.; Cheng, P.; Wang, D.; Schaaf, P.; Zhang, Z.; Liu, J. High Performance Photothermal Carbon Nanotubes/Nanostructured Hydrogel for Solar Electricity Production and Solar Water Sterilization. Appl. Surf. Sci. 2024, 643, 158680. [Google Scholar] [CrossRef]

- Wang, D.; Lin, X.; Wu, Y.; Li, L.; Feng, W.; Huang, Y.; Yang, Y. Hanging Photothermal Fabric Based on Polyaniline/Carbon Nanotubes for Efficient Solar Water Evaporation. ACS Omega 2023, 8, 44659–44666. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, Z.; Wang, J.; Zhou, Y.; Cao, P.; Zhang, J.; Yuan, P.; Zhang, Y.; Li, Q. Boosting Solar-Powered Interfacial Water Evaporation by Architecting 3D Interconnected Polymetric Network in CNT Cellular Structure. Chem. Eng. J. 2023, 451, 138676. [Google Scholar] [CrossRef]

- Ge, Y.; Wang, L.; Su, Z.; Ivan, M.N.A.S.; Wang, C.; Han, K.; Tsang, Y.H.; Xu, S.; Bai, G. Efficient Solar-Driven Interfacial Water Evaporator Using Hydrogel Modified Carbon-Based Biomass with Abundant Microchannels. Small 2024, 20, 2309780. [Google Scholar] [CrossRef]

- Scheiger, J.M.; Levkin, P.A. Hydrogels with Preprogrammable Lifetime via UV-Induced Polymerization and Degradation. Adv. Funct. Mater. 2020, 30, 1909800. [Google Scholar] [CrossRef]

- Zhao, L.; Zhou, Y.; Zhang, J.; Liang, H.; Chen, X.; Tan, H. Natural Polymer-Based Hydrogels: From Polymer to Biomedical Applications. Pharmaceutics 2023, 15, 2514. [Google Scholar] [CrossRef]

- Koetting, M.C.; Peters, J.T.; Steichen, S.D.; Peppas, N.A. Stimulus-Responsive Hydrogels: Theory, Modern Advances, and Applications. Mater. Sci. Eng. R Rep. Rev. J. 2015, 93, 1–49. [Google Scholar] [CrossRef]

- Shi, Q.; Liu, H.; Tang, D.; Li, Y.; Li, X.; Xu, F. Bioactuators Based on Stimulus-Responsive Hydrogels and Their Emerging Biomedical Applications. NPG Asia Mater. 2019, 11, 64. [Google Scholar] [CrossRef]

- Sánchez-Cid, P.; Jiménez-Rosado, M.; Romero, A.; Pérez-Puyana, V. Novel Trends in Hydrogel Development for Biomedical Applications: A Review. Polymers 2022, 14, 3023. [Google Scholar] [CrossRef]

- Richbourg, N.R.; Wancura, M.; Gilchrist, A.E.; Toubbeh, S.; Harley, B.A.C.; Cosgriff-Hernandez, E.; Peppas, N.A. Precise Control of Synthetic Hydrogel Network Structure via Linear, Independent Synthesis-Swelling Relationships. Sci. Adv. 2021, 7, eabe3245. [Google Scholar] [CrossRef]

- Mashabela, L.T.; Maboa, M.M.; Miya, N.F.; Ajayi, T.O.; Chasara, R.S.; Milne, M.; Mokhele, S.; Demana, P.H.; Witika, B.A.; Siwe-Noundou, X.; et al. A Comprehensive Review of Cross-Linked Gels as Vehicles for Drug Delivery to Treat Central Nervous System Disorders. Gels 2022, 8, 563. [Google Scholar] [CrossRef]

- Omidian, H.; Dey Chowdhury, S. Multifunctional Hydrogel Microneedles (HMNs) in Drug Delivery and Diagnostics. Gels 2025, 11, 206. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, J.; Hu, H.; Ma, J.; Yang, H.; Chen, J.; Xu, H.; Hu, H.; Luo, H.; Chen, G. Recent Applications of Stimulus-Responsive Smart Hydrogels for Osteoarthritis Therapy. Front. Bioeng. Biotechnol. 2025, 13, 1539566. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, S.; Huang, Y.; Tang, Q.; Fu, T.; Su, R.; Fan, C.; Xia, S.; Lee, P.S.; Lin, Y. Bioinspired Structural Hydrogels with Highly Ordered Hierarchical Orientations by Flow-Induced Alignment of Nanofibrils. Nat. Commun. 2024, 15, 118. [Google Scholar] [CrossRef]

- El-Husseiny, H.M.; Mady, E.A.; Hamabe, L.; Abugomaa, A.; Shimada, K.; Yoshida, T.; Tanaka, T.; Yokoi, A.; Elbadawy, M.; Tanaka, R. Smart/Stimuli-Responsive Hydrogels: Cutting-Edge Platforms for Tissue Engineering and Other Biomedical Applications. Mater. Today Bio 2022, 13, 100186. [Google Scholar] [CrossRef]

- Bediaga-Bañeres, H.; Moreno-Benítez, I.; Arrasate, S.; Pérez-Álvarez, L.; Halder, A.K.; Cordeiro, M.N.D.S.; González-Díaz, H.; Vilas-Vilela, J.L. Artificial Intelligence-Driven Modeling for Hydrogel Three-Dimensional Printing: Computational and Experimental Cases of Study. Polymers 2025, 17, 121. [Google Scholar] [CrossRef]

- Word Meteorological Organization (WMO). State of the Global Climate 2024. Available online: https://library.wmo.int/records/item/69455-state-of-the-global-climate-2024 (accessed on 20 May 2025).

- Maslin, M.; Ramnath, R.D.; Welsh, G.I.; Sisodiya, S.M. Understanding the Health Impacts of the Climate Crisis. Future Healthc. J. 2025, 12, 100240. [Google Scholar] [CrossRef]

- Dong, Y.; Ghasemzadeh, M.; Khorsandi, Z.; Sheibani, R.; Nasrollahzadeh, M. Starch-Based Hydrogels for Environmental Applications: A Review. Int. J. Biol. Macromol. 2024, 269, 131956. [Google Scholar] [CrossRef]

- Song, M.; Wang, J.; He, J.; Kan, D.; Chen, K.; Lu, J. Synthesis of Hydrogels and Their Progress in Environmental Remediation and Antimicrobial Application. Gels 2022, 9, 16. [Google Scholar] [CrossRef]

- Park, J.; Guan, W.; Yu, G. Smart Hydrogels for Sustainable Agriculture. EcoMat 2025, 7, e70011. [Google Scholar] [CrossRef]

- JMP. Water, Sanitation, Hygiene, Environmental Cleaning and Waste Management in Health Care Facilities: 2023 Data Update and Special Focus on Primary Health Care. Available online: https://washdata.org/reports/jmp-2024-wash-hcf (accessed on 20 May 2025).

- Maity, D.; Teixeira, A.P.; Fussenegger, M. Hydratable Core-Shell Polymer Networks for Atmospheric Water Harvesting Powered by Sunlight. Small Weinh. Bergstr. Ger. 2023, 19, e2301427. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Y.; Liu, Y.; Mu, B.; Wang, A. Slow Release and Water Retention Performance of Poly(Acrylic Acid-Co-Acrylamide)/Fulvic Acid/Oil Shale Semicoke Superabsorbent Composites. Polymers 2022, 14, 1719. [Google Scholar] [CrossRef]

- Zhai, N.; Wang, B. Preparation of Fast-Swelling Porous Superabsorbent Hydrogels with High Saline Water Absorbency under Pressure by Foaming and Post Surface Crosslinking. Sci. Rep. 2023, 13, 13815. [Google Scholar] [CrossRef]

- Vo, T.S.; Vo, T.T.B.C.; Tran, T.T.; Pham, N.D. Enhancement of Water Absorption Capacity and Compressibility of Hydrogel Sponges Prepared from Gelatin/Chitosan Matrix with Different Polyols. Prog. Nat. Sci. Mater. Int. 2022, 32, 54–62. [Google Scholar] [CrossRef]

- Chin, C.-L.; Huang, L.-J.; Lu, Z.-X.; Weng, W.-C.; Chao, L. Using the Water Absorption Ability of Dried Hydrogels to Form Hydrogel-Supported Lipid Bilayers. Gels 2023, 9, 751. [Google Scholar] [CrossRef]

- Graeber, G.; Díaz-Marín, C.D.; Gaugler, L.C.; El Fil, B. Intrinsic Water Transport in Moisture-Capturing Hydrogels. Nano Lett. 2024, 24, 3858–3865. [Google Scholar] [CrossRef]

- Yan, J.; Li, W.; Yu, Y.; Huang, G.; Peng, J.; Lv, D.; Chen, X.; Wang, X.; Liu, Z. A Polyzwitterionic@MOF Hydrogel with Exceptionally High Water Vapor Uptake for Efficient Atmospheric Water Harvesting. Molecules 2024, 29, 1851. [Google Scholar] [CrossRef]

- Du, X.; Xie, Z.; Zhang, H.; Jiang, S.; Su, X.; Fan, J. Robust Mix-Charged Polyzwitterionic Hydrogels for Ultra-Efficient Atmospheric Water Harvesting and Evaporative Cooling. Adv. Mater. 2025, 37, e2505279. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Li, H.; Liu, G.; Zhao, K.; Wang, Y.; Li, Z.; Huang, J.; Xu, Z.; Lai, Y.; et al. A Humidity/Thermal Dual Response 3D-Fabric with Porous Poly(N-Isopropyl Acrylamide) Hydrogel towards Efficient Atmospheric Water Harvesting. J. Colloid. Interface Sci. 2024, 653, 1040–1051. [Google Scholar] [CrossRef]

- Shi, Y.; Ilic, O.; Atwater, H.A.; Greer, J.R. All-Day Fresh Water Harvesting by Microstructured Hydrogel Membranes. Nat. Commun. 2021, 12, 2797. [Google Scholar] [CrossRef]

- Hendrickson, W.A.; Ward, K.B. Atomic Models for the Polypeptide Backbones of Myohemerythrin and Hemerythrin. Biochem. Biophys. Res. Commun. 1975, 66, 1349–1356. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, F.; Yu, Y.; Wu, J.; Cai, Y.; Shi, J.; Morikawa, H.; Zhu, C. Multi-Bioinspired Hierarchical Integrated Hydrogel for Passive Fog Harvesting and Solar-Driven Seawater Desalination. Chem. Eng. J. Lausanne Switz. 1996 2023, 466, 143330. [Google Scholar] [CrossRef]

- Guo, Y.; Lu, H.; Zhao, F.; Zhou, X.; Shi, W.; Yu, G. Biomass-Derived Hybrid Hydrogel Evaporators for Cost-Effective Solar Water Purification. Adv. Mater. 2020, 32, e1907061. [Google Scholar] [CrossRef]

- Song, M.; Cheng, T.; Li, Y.; Huang, D.; Huang, X.; Xie, H.; Wang, L.; Yue, Y.; Yu, W. Spongy Hygroscopic Hydrogels for Efficient Atmospheric Water Harvesting over a Wide Humidity Range. J. Clean. Prod. 2024, 461, 142661. [Google Scholar] [CrossRef]

- Guan, W.; Lei, C.; Guo, Y.; Shi, W.; Yu, G. Hygroscopic-Microgels-Enabled Rapid Water Extraction from Arid Air. Adv. Mater. 2024, 36, 2207786. [Google Scholar] [CrossRef]

- Zhang, L.; Li, R.; Zheng, S.; Zhu, H.; Cao, M.; Li, M.; Hu, Y.; Long, L.; Feng, H.; Tang, C.Y. Hydrogel-Embedded Vertically Aligned Metal-Organic Framework Nanosheet Membrane for Efficient Water Harvesting. Nat. Commun. 2024, 15, 9738. [Google Scholar] [CrossRef]

- Combita, D.; Ahmed, M. Thermoresponsive and Antifouling Hydrogels as a Radiative Energy Driven Water Harvesting System. Mater. Chem. Front. 2021, 5, 917–928. [Google Scholar] [CrossRef]

- Matsumoto, K.; Sakikawa, N.; Miyata, T. Thermo-Responsive Gels That Absorb Moisture and Ooze Water. Nat. Commun. 2018, 9, 2315. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Tripathi, B.P. Amino Acid-Based Thermoresponsive Hydrogel/MOF Composite for Enhanced Atmospheric Water Harvesting and Solar Desalination. ACS EST Eng. 2024, 4, 1644–1656. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, W.; Zhou, X.; Perwez, A.; Qin, G.; Zheng, X. Biomimetic Thermo-Responsive Hydrogel Coating for Passive Photovoltaic Cooling via Self-Adaptive Water Management. Small Weinh. Bergstr. Ger. 2025, 21, e2502386. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Tripathi, B.P. Synergistic Super-Hygroscopic Composite Gel for Enhanced Atmospheric Water Harvesting and Desalination Applications. Small 2025, 21, 2501809. [Google Scholar] [CrossRef]

- Pei, W.; Xie, Z.; Pei, X.; Wang, J. Intelligent Solar-Driven “Switch” Photothermal Hydrogel for Clean Water Harvesting. Chem. Eng. J. 2024, 495, 153420. [Google Scholar] [CrossRef]

- Wang, J.; Ying, W.; Lin, B.; Li, C.; Deng, C.; Zhang, H.; Wang, S.; Wang, R. Tillandsia-Inspired Ultra-Efficient Thermo-Responsive Hygroscopic Nanofibers for Solar-Driven Atmospheric Water Harvesting. Adv. Mater. 2025, 37, e2408977. [Google Scholar] [CrossRef]

- Guo, H.; Luo, Q.; Liu, D.; Li, X.; Zhang, C.; He, X.; Miao, C.; Zhang, X.; Qin, X. Super Moisture-Sorbent Sponge for Sustainable Atmospheric Water Harvesting and Power Generation. Adv. Mater. 2024, 36, e2414285. [Google Scholar] [CrossRef]

- Guan, W.; Zhao, Y.; Lei, C.; Wang, Y.; Wu, K.; Yu, G. Molecularly Functionalized Biomass Hydrogels for Sustainable Atmospheric Water Harvesting. Adv. Mater. 2025, 37, e2420319. [Google Scholar] [CrossRef] [PubMed]

- Thanusing, M.K.; Pollard, B.L.; Connal, L.A. Arginine-Functionalised Hydrogels as a Novel Atmospheric Water-Harvesting Material. RSC Appl. Polym. 2025, 3, 480–487. [Google Scholar] [CrossRef]

- Park, H. Hydrogel-Based Materials for Atmospheric Water Harvesting and Surface Antifogging; ETH: Zurich, Switzerland, 2023; p. 133. [Google Scholar]

- Graeber, G.; Díaz-Marín, C.D.; Gaugler, L.C.; Zhong, Y.; El Fil, B.; Liu, X.; Wang, E.N. Extreme Water Uptake of Hygroscopic Hydrogels through Maximized Swelling-Induced Salt Loading. Adv. Mater. 2024, 36, e2211783. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, T.; Ju, A.; Xu, Z.; Zhao, Y. Macroporous, Highly Hygroscopic, and Leakage-Free Composites for Efficient Atmospheric Water Harvesting. ACS Appl. Mater. Interfaces 2024, 16, 16893–16902. [Google Scholar] [CrossRef]

- He, P.; Park, J.H.; Jiao, Y.; Ganguli, R.; Huang, Y.; Lee, A.; Ahn, C.H.; Wang, M.; Peng, Y.; Long, Y.; et al. High-Voltage Water-Scarce Hydrogel Electrolytes Enable Mechanically Safe Stretchable Li-Ion Batteries. Sci. Adv. 2025, 11, eadu3711. [Google Scholar] [CrossRef]

- Guo, Y.; Bolongaro, V.; Hatton, T.A. Scalable Biomass-Derived Hydrogels for Sustainable Carbon Dioxide Capture. Nano Lett. 2023, 23, 9697–9703. [Google Scholar] [CrossRef]

- Jiang, Y.; An, N.; Sun, Q.; Guo, B.; Wang, Z.; Zhou, W.; Gao, B.; Li, Q. Biomass Hydrogels Combined with Carbon Nanotubes for Water Purification via Efficient and Continuous Solar-Driven Steam Generation. Sci. Total Environ. 2022, 837, 155757. [Google Scholar] [CrossRef]

- Alsubaie, F.S.; Srdar, M.; Fayraa, O.; Alsulami, F.M.; Omran, F.; Alamry, K.A. Development of Eco-Friendly Date Palm Biomass-Based Hydrogels for Enhanced Water Retention in Soil. Gels 2025, 11, 349. [Google Scholar] [CrossRef] [PubMed]

- Lv, B.; Song, C.; Liu, Y.; Xu, Y.; Fan, X. A Novel, Flexible Porous Nanofibrous Hydrogel Interfacial Solar Evaporator for Highly Efficient Seawater and Wastewater Purification. Chemosphere 2022, 309, 136818. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Xiong, Y.; Yu, D.; Yang, P.; Shi, H.; Huang, L.; Wu, Y.; Xi, M.; Xiao, P.; Yang, L. Fe–Co Controlled Super-Hygroscopic Hydrogels toward Efficient Atmospheric Water Harvesting. Nanoscale 2022, 14, 18022–18032. [Google Scholar] [CrossRef]

- Li, H.; Yang, H.; Lv, W.; Liu, X.; Bai, S.; Li, L.; Zhao, S.; Wang, Y.; Guo, X. Hygroscopic Hydrogels for Removal of Trace Water from Liquid Fuels. Ind. Eng. Chem. Res. 2021, 60, 17065–17071. [Google Scholar] [CrossRef]

- Anjali, J.; Jose, V.K.; Lee, J.-M. Carbon-Based Hydrogels: Synthesis and Their Recent Energy Applications. J. Mater. Chem. A 2019, 7, 15491–15518. [Google Scholar] [CrossRef]

- Achazhiyath Edathil, A.; Rezaei, B.; Almdal, K.; Keller, S.S. In Situ Mineralization of Biomass-Derived Hydrogels Boosts Capacitive Electrochemical Energy Storage in Free-Standing 3D Carbon Aerogels. Energy Environ. Mater. 2024, 7, e12591. [Google Scholar] [CrossRef]

- An, N.; Jiang, Y.; Wang, Z.; Sun, Q.; Guo, B.; Gao, B.; Zhou, W.; Li, Q. Efficient Water Purification and Desalination Using Hydrogel and Aerogel Solar Evaporators Based on Different Carbon Materials. Sep. Purif. Technol. 2022, 301, 122003. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Alsaedi, M.; Wu, M.; Shi, L.; Wang, P. Hybrid Hydrogel with High Water Vapor Harvesting Capacity for Deployable Solar-Driven Atmospheric Water Generator. Environ. Sci. Technol. 2018, 52, 11367–11377. [Google Scholar] [CrossRef] [PubMed]

- Thavalengal, M.S.; Jamil, M.A.; Mehroz, M.; Xu, B.B.; Yaqoob, H.; Sultan, M.; Imtiaz, N.; Shahzad, M.W. Progress and Prospects of Air Water Harvesting System for Remote Areas: A Comprehensive Review. Energies 2023, 16, 2686. [Google Scholar] [CrossRef]

- Yavari, N.; Azizian, S. Mixed Diffusion and Relaxation Kinetics Model for Hydrogels Swelling. J. Mol. Liq. 2022, 363, 119861. [Google Scholar] [CrossRef]

- Szekalska, M.; Sosnowska, K.; Czajkowska-Kośnik, A.; Winnicka, K. Calcium Chloride Modified Alginate Microparticles Formulated by the Spray Drying Process: A Strategy to Prolong the Release of Freely Soluble Drugs. Materials 2018, 11, 1522. [Google Scholar] [CrossRef]

- Shahidul Islam, S.; Dode, T.; Kawashima, S.; Fukuoka, M.; Tsuruoka, T.; Nagahama, K. Metal–Organic Framework–Injectable Hydrogel Hybrid Scaffolds Promote Accelerated Angiogenesis for in Vivo Tissue Engineering. RSC Adv. 2025, 15, 32143–32154. [Google Scholar] [CrossRef]

- Xie, S.-P.; Miyamoto, A.; Zhang, P.; Kosaka, Y.; Liang, Y.; Lutsko, N.J. What Made 2023 and 2024 the Hottest Years in a Row? Npj Clim. Atmos. Sci. 2025, 8, 117. [Google Scholar] [CrossRef]

- Khourchid, A.M.; Ajjur, S.B.; Al-Ghamdi, S.G. Building Cooling Requirements under Climate Change Scenarios: Impact, Mitigation Strategies, and Future Directions. Buildings 2022, 12, 1519. [Google Scholar] [CrossRef]

- Li, J.; Zhai, Z.; Li, H.; Ding, Y.; Chen, S. Climate Change’s Effects on the Amount of Energy Used for Cooling in Hot, Humid Office Buildings and the Solutions. J. Clean. Prod. 2024, 442, 140967. [Google Scholar] [CrossRef]

- Bruhwiler, L.; Basu, S.; Butler, J.H.; Chatterjee, A.; Dlugokencky, E.; Kenney, M.A.; McComiskey, A.; Montzka, S.A.; Stanitski, D. Observations of Greenhouse Gases as Climate Indicators. Clim. Chang. 2021, 165, 12. [Google Scholar] [CrossRef] [PubMed]

- O’Callaghan, J. Controversial Geoengineering Projects to Test Earth-Cooling Tech Funded by UK Agency. Nature 2025, 641, 567–568. [Google Scholar] [CrossRef] [PubMed]

- Elnagar, E.; Gendebien, S.; Georges, E.; Berardi, U.; Doutreloup, S.; Lemort, V. Framework to Assess Climate Change Impact on Heating and Cooling Energy Demands in Building Stock: A Case Study of Belgium in 2050 and 2100. Energy Build. 2023, 298, 113547. [Google Scholar] [CrossRef]

- Baiman, R.; Clarke, S.; Elsworth, C.; Field, L.; MacCracken, M.; Macdonald, J.; Mitchell, D.; Oeste, F.D.; Reed, S.; Salter, S.; et al. Addressing the Urgent Need for Direct Climate Cooling: Rationale and Options. Oxf. Open Clim. Change 2024, 4, kgae014. [Google Scholar] [CrossRef]

- Zou, J.; Ling, H.; Zheng, Y.; Bacilio Contreras, B.; Narvaez, E.J.; Liu, G.; Wang, L.; Sun, G. Pioneering Hydrogel Cooling Technologies: A Comprehensive Approach to Theoretical Modeling and One-Step Fabrication Strategy. Mater. Today 2025, 83, 132–144. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive Radiative Cooling below Ambient Air Temperature under Direct Sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef]

- Mehryan, S.A.M.; Jannesari, H. Improving Li-Ion Battery Thermal Management via Hydrogel Evaporative Cooling. Appl. Therm. Eng. 2024, 248, 123173. [Google Scholar] [CrossRef]

- Yahaya, N.A.; Abdul Rahman, M.A.S.; Mohd Sumari, H.S.; Amir, A.; Jerai, F.; Ab. Ghani, A.R. Experimental Investigation of Hydrogel-Based Passive Cooling for Battery Thermal Management in EV Applications. J. Appl. Eng. Des. Simul. 2025, 5, 1–11. [Google Scholar] [CrossRef]

- Li, M.-D.; Shen, X.-Q.; Chen, X.; Gan, J.-M.; Wang, F.; Li, J.; Wang, X.-L.; Shen, Q.-D. Thermal Management of Chips by a Device Prototype Using Synergistic Effects of 3-D Heat-Conductive Network and Electrocaloric Refrigeration. Nat. Commun. 2022, 13, 5849. [Google Scholar] [CrossRef]

- Xu, L.; Sun, D.-W.; Tian, Y.; Sun, L.; Fan, T.; Zhu, Z. Combined Effects of Radiative and Evaporative Cooling on Fruit Preservation under Solar Radiation: Sunburn Resistance and Temperature Stabilization. ACS Appl. Mater. Interfaces 2022, 14, 45788–45799. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Strobach, E.; Chen, N.; Ferralis, N.; Grossman, J.C. Passive Sub-Ambient Cooling from a Transparent Evaporation-Insulation Bilayer. Joule 2020, 4, 2693–2701. [Google Scholar] [CrossRef]

- Mu, X.; Shi, X.-L.; Zhou, J.; Chen, H.; Yang, T.; Wang, Y.; Miao, L.; Chen, Z.-G. Self-Hygroscopic and Smart Color-Changing Hydrogels as Coolers for Improving Energy Conversion Efficiency of Electronics. Nano Energy 2023, 108, 108177. [Google Scholar] [CrossRef]

- Tang, N.; Peng, Z.; Guo, R.; An, M.; Chen, X.; Li, X.; Yang, N.; Zang, J. Thermal Transport in Soft PAAm Hydrogels. Polymers 2017, 9, 688. [Google Scholar] [CrossRef]

- Zhao, D.; Aili, A.; Zhai, Y.; Xu, S.; Tan, G.; Yin, X.; Yang, R. Radiative Sky Cooling: Fundamental Principles, Materials, and Applications. Appl. Phys. Rev. 2019, 6, 021306. [Google Scholar] [CrossRef]

- Li, S.; Zhu, P.; Xue, Y.; Wang, L.; Wong, T.-W.; Yang, X.; Zhou, H.; Li, T.; Yang, W. Inhibition of Heterogeneous Nucleation in Water by Hydrogel Coating. Research 2023, 6, 0190. [Google Scholar] [CrossRef] [PubMed]

- Ishugah, T.F.; Kiplagat, J.; Madete, J.; Musango, J. Current Status, Challenges, and Opportunities of Evaporative Cooling for Building Indoor Thermal Comfort Using Water as a Refrigerant: A Review. Int. J. Energy Res. 2024, 2024, 2376927. [Google Scholar] [CrossRef]

- Kumar, S.; Hariharan, G.; Ganesha, A.; Gowri Shankar, M.C.; Suranjan Salins, S.; Kumar, N. A Comparative Study of Performance and Energy Efficiency in Evaporative Cooling: Assessing Different Configurations of Organic Packings. Cogent Eng. 2024, 11, 2376927. [Google Scholar] [CrossRef]

- Arunkumar, H.S.; Madhwesh, N.; Shenoy, S.; Kumar, S. Performance Evaluation of an Indirect-Direct Evaporative Cooler Using Biomass-Based Packing Material. Int. J. Sustain. Eng. 2024, 17, 469–480. [Google Scholar] [CrossRef]

- Kapilan, N.; Isloor, A.M.; Karinka, S. A Comprehensive Review on Evaporative Cooling Systems. Results Eng. 2023, 18, 101059. [Google Scholar] [CrossRef]

- Zeljko, M.; Ocelić Bulatović, V.; Špada, V.; Blagojević, S.L. Environmentally Friendly UV-Protective Polyacrylate/TiO2 Nanocoatings. Polymers 2021, 13, 2609. [Google Scholar] [CrossRef] [PubMed]

- Jung, Y.S.; Kim, K.S.; Suh, G.J.; Cho, J.-H. Comparison between Gel Pad Cooling Device and Water Blanket during Target Temperature Management in Cardiac Arrest Patients. Acute Crit. Care 2018, 33, 246–251. [Google Scholar] [CrossRef]

- Keum, K.T.; Kim, Y.H.; Lee, J.H.; Ahn, S.J.; Hwang, S.Y.; Oh, J.S.; Kim, S.J.; Kim, S.H.; Jeung, K.W.; KORHN Investigators. Comparison of Hydrogel Pad and Water-Circulating Blanket Cooling Methods for Targeted Temperature Management: A Propensity Score-Matched Analysis from a Prospective Multicentre Registry. Resuscitation 2021, 169, 78–85. [Google Scholar] [CrossRef]

- Stott, R. IaaC Students Develop a Passive Cooling System from Hydrogel and Ceramic. Available online: https://www.archdaily.com/590348/iaac-students-develop-a-passive-cooling-system-from-hydrogel-and-ceramic (accessed on 12 July 2025).

- Zhou, Y.; Wang, S.; Peng, J.; Tan, Y.; Li, C.; Boey, F.Y.C.; Long, Y. Liquid Thermo-Responsive Smart Window Derived from Hydrogel. Joule 2020, 4, 2458–2474. [Google Scholar] [CrossRef]

- Peng, Y.; Li, W.; Liu, B.; Jin, W.; Schaadt, J.; Tang, J.; Zhou, G.; Wang, G.; Zhou, J.; Zhang, C.; et al. Integrated Cooling (i-Cool) Textile of Heat Conduction and Sweat Transportation for Personal Perspiration Management. Nat. Commun. 2021, 12, 6122. [Google Scholar] [CrossRef]

- Li, Z.; Guo, N.; Zhu, Y.; Feng, W.; Wang, H.; Zhang, P.; Zhao, F. Hygroscopic Cooling (h-Cool) Fabric with Highly Efficient Sweat Evaporation and Heat Dissipation for Personal Thermo-Moisture Management. Int. J. Biol. Macromol. 2024, 267, 131658. [Google Scholar] [CrossRef]

- Fei, J.; Han, D.; Zhang, X.; Li, K.; Lavielle, N.; Zhou, K.; Wang, X.; Tan, J.Y.; Zhong, J.; Wan, M.P.; et al. Ultrahigh Passive Cooling Power in Hydrogel with Rationally Designed Optofluidic Properties. Nano Lett. 2024, 24, 623–631. [Google Scholar] [CrossRef]

- Yang, M.; Zou, W.; Luo, H.; Liu, Y.; Zhao, N.; Xu, J. Bright-White Hydrogels for on-Demand Passive Cooling. Sci. China Chem. 2023, 66, 1511–1519. [Google Scholar] [CrossRef]

- Farahpour, M.; Azizian, S. Basil Seed Hydrogel Incorporated Activated Carbon as a Capable, Bio-Based, and Cost-Effective Interfacial Solar Steam Generator. J. Ind. Eng. Chem. 2025, 141, 285–296. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Du, Z.; Cheng, X.; Wang, H.; Du, X. Highly Flexible and Self-Healing Phase Change Hydrogel with Superior Solar-Thermal Storage and Sensitive Motion Detection for Wearable Thermal Management. Compos. Part A Appl. Sci. Manuf. 2025, 197, 109038. [Google Scholar] [CrossRef]

- Wang, Z.; Li, N.; Yang, X.; Zhang, Z.; Zhang, H.; Cui, X. Thermogalvanic Hydrogel-Based e-Skin for Self-Powered on-Body Dual-Modal Temperature and Strain Sensing. Microsyst. Nanoeng. 2024, 10, 55. [Google Scholar] [CrossRef]

- Ye, Q.; Chen, D.; Zhao, Z.; Yan, H.; Chen, M. Adhesive Hydrogel Paint for Passive Heat Dissipation via Radiative Coupled Evaporation Cooling. Small Weinh. Bergstr. Ger. 2025, 21, e2412221. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Z.; Wen, Y.; Song, X.; Tan, W.K.; Ong, C.N.; Li, J. Recent Advances in Superabsorbent Hydrogels Derived from Agro Waste Materials for Sustainable Agriculture: A Review. J. Agric. Food Chem. 2024, 72, 22399–22419. [Google Scholar] [CrossRef]

- Abdelghafar, R.; Abdelfattah, A.; Mostafa, H. Effect of Super Absorbent Hydrogel on Hydro-Physical Properties of Soil under Deficit Irrigation. Sci. Rep. 2024, 14, 7655. [Google Scholar] [CrossRef]

- Abdelgelil, A.A.; Omer, A.M.; Hassan, A.F.; Moustafa, A.A.; Mohy Eldin, M.S. Enhancement of Sandy Soil Water Retention Using Superabsorbent Carboxymethyl Cellulose Grafted with Polyacrylamide and Polyacrylamidomethyl Propanesulfonic Acid Copolymer. Sci. Rep. 2025, 15, 16604. [Google Scholar] [CrossRef]

- Zowada, R.; Foudazi, R. Macroporous Hydrogels for Soil Water Retention in Arid and Semi-Arid Regions. RSC Appl. Polym. 2023, 1, 243–253. [Google Scholar] [CrossRef]

- Ganji, F.; Vasheghani-Farahani, S.; Vasheghani-Farahani, E. Theoretical Description of Hydrogel Swelling: A Review. Iran. Polym. J. 2010, 19, 375–398. [Google Scholar]

- Frioni, T.; Bonicelli, P.G.; Ripa, C.; Poni, S. Soil Incorporation of Superabsorbent Hydrogels to Counteract Water Scarcity: Modelling Tree Physiological and Biochemical Response. Plant Physiol. Biochem. 2025, 223, 109775. [Google Scholar] [CrossRef] [PubMed]

- Malik, S.; Chaudhary, K.; Malik, A.; Punia, H.; Sewhag, M.; Berkesia, N.; Nagora, M.; Kalia, S.; Malik, K.; Kumar, D.; et al. Superabsorbent Polymers as a Soil Amendment for Increasing Agriculture Production with Reducing Water Losses under Water Stress Condition. Polymers 2022, 15, 161. [Google Scholar] [CrossRef]

- Anae, J.; Ahmad, N.; Kumar, V.; Thakur, V.K.; Gutierrez, T.; Yang, X.J.; Cai, C.; Yang, Z.; Coulon, F. Recent Advances in Biochar Engineering for Soil Contaminated with Complex Chemical Mixtures: Remediation Strategies and Future Perspectives. Sci. Total Environ. 2021, 767, 144351. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Gotoh, T.; Nakai, S.; Ueda, A. Functional Hydrogels Promote Vegetable Growth in Cadmium-Contaminated Soil. Gels 2024, 10, 348. [Google Scholar] [CrossRef] [PubMed]

- Patra, S.K.; Poddar, R.; Brestic, M.; Acharjee, P.U.; Bhattacharya, P.; Sengupta, S.; Pal, P.; Bam, N.; Biswas, B.; Barek, V.; et al. Prospects of Hydrogels in Agriculture for Enhancing Crop and Water Productivity under Water Deficit Condition. Int. J. Polym. Sci. 2022, 2022, 4914836. [Google Scholar] [CrossRef]

- El-Aziz, M.A.A.; Elbagory, M.; Arafat, A.A.; Aboelsoud, H.M.; El-Nahrawy, S.; Khalifa, T.H.; Omara, A.E.-D. Evaluating the Impact of Nano-Silica and Silica Hydrogel Amendments on Soil Water Retention and Crop Yield in Rice and Clover Under Variable Irrigation Conditions. Agronomy 2025, 15, 652. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Tso, C.Y.; Wong, Y.M.; Chao, C.Y.H.; Huang, B. Daytime Passive Radiative Cooling by Ultra Emissive Bio-Inspired Polymeric Surface. Sol. Energy Mater. Sol. Cells 2020, 206, 110296. [Google Scholar] [CrossRef]

- Simonne, E.; Hochmuth, R.; Breman, J.; Lamont, W.; Treadwell, D.; Gazula, A. Drip-Irrigation Systems for Small Conventional Vegetable Farms and Organic Vegetable Farms: HS 1144/HS388, 6/2008. EDIS 2008, 2008, 1–28. [Google Scholar] [CrossRef]

- Shang, J.; Zhang, J.; Zhang, Y.; Zhang, X.; An, Q. Highly Potent Transparent Passive Cooling Coating via Microphase-Separated Hydrogel Combining Radiative and Evaporative Cooling. Nano Lett. 2024, 24, 7055–7062. [Google Scholar] [CrossRef]

- Xu, G.; Xia, H.; Chen, P.; She, W.; Zhang, H.; Ma, J.; Ruan, Q.; Zhang, W.; Sun, Z. Thermochromic Hydrogels with Dynamic Solar Modulation and Regulatable Critical Response Temperature for Energy-Saving Smart Windows. Adv. Funct. Mater. 2022, 32, 2109597. [Google Scholar] [CrossRef]

- Roy, A.; Mallick, T.K.; Tahir, A.A. An Optimal Climate-Adaptable Hydrogel-Filled Smart Window for the Energy-Saving Built Environment. J. Mater. Chem. C 2022, 10, 15474–15482. [Google Scholar] [CrossRef]

- Wolde-Kidan, A.; Herrmann, A.; Prause, A.; Gradzielski, M.; Haag, R.; Block, S.; Netz, R.R. Particle Diffusivity and Free-Energy Profiles in Hydrogels from Time-Resolved Penetration Data. Biophys. J. 2021, 120, 463–475. [Google Scholar] [CrossRef]

- Zhang, G.; Wu, H.; Li, N.; Ji, J.; Yu, B. The Performance Analysis on a Thermochromic Hydrogel Double Window: Material Design and Thermal Performnace. SSRN 2025, 1–28. [Google Scholar]

- Chen, G. Thermodynamics of Hydrogels for Applications in Atmospheric Water Harvesting, Evaporation, and Desalination. Phys. Chem. Chem. Phys. 2022, 24, 12329–12345. [Google Scholar] [CrossRef]

- García-Mollá, M.; Medina, R.P.; Vega-Carrero, V.; Sanchis-Ibor, C. Economic Efficiency of Drip and Flood Irrigation. Comparative Analysis at Farm Scale Using DEA. Agric. Water Manag. 2025, 309, 109314. [Google Scholar] [CrossRef]

- Liu, C.; Yan, X.-Y.; Li, S.; Zhang, H.; Deng, B.; Fang, N.X.; Habibi, Y.; Chen, S.-C.; Zhao, X. A Metre-Scale Vertical Origami Hydrogel Panel for Atmospheric Water Harvesting in Death Valley. Nat. Water 2025, 3, 714–722. [Google Scholar] [CrossRef]

- Zhang, Z.; Fu, H.; Li, Z.; Huang, J.; Xu, Z.; Lai, Y.; Qian, X.; Zhang, S. Hydrogel Materials for Sustainable Water Resources Harvesting & Treatment: Synthesis, Mechanism and Applications. Chem. Eng. J. 2022, 439, 135756. [Google Scholar] [CrossRef]

- Bai, M.; Hou, Y.; Li, G.; Fang, J.; Wu, X.; Zhou, Y.; Qi, J.; Yang, Z.; Li, H. Sustainable Agricultural Water Supply: Atmospheric Water Harvesting with Degradable and Biosafe Hydrogel. Chem. Eng. J. 2024, 503, 158156. [Google Scholar] [CrossRef]

- Rodrigo, L.; Munaweera, I. Employing Sustainable Agriculture Practices Using Eco-Friendly and Advanced Hydrogels. RSC Adv. 2025, 15, 21212–21228. [Google Scholar] [CrossRef]

- Tariq, Z.; Iqbal, D.N.; Rizwan, M.; Ahmad, M.; Faheem, M.; Ahmed, M. Significance of Biopolymer-Based Hydrogels and Their Applications in Agriculture: A Review in Perspective of Synthesis and Their Degree of Swelling for Water Holding. RSC Adv. 2023, 13, 24731–24754. [Google Scholar] [CrossRef]

- Amboka, A.A.; Gachene, C.; Olaka, L. Evaluation of Hydrogels in Improving Soil-Water Retention, Plant Survival and Climate Adaptation Strategies in Kitui County, Kenya. J. Appl. Sci. Environ. Manag. 2025, 29, 425–435. [Google Scholar] [CrossRef]

- Lindsay, S.; Hsu, S.; Ragunathan, S.; Lindsay, J. The Impact of Climate Change Related Extreme Weather Events on People with Pre-Existing Disabilities and Chronic Conditions: A Scoping Review. Disabil. Rehabil. 2023, 45, 4338–4358. [Google Scholar] [CrossRef]

- Rawat, A.; Kumar, D.; Khati, B.S. A Review on Climate Change Impacts, Models, and Its Consequences on Different Sectors: A Systematic Approach. J. Water Clim. Change 2024, 15, 104–126. [Google Scholar] [CrossRef]

- Allan, R.P.; Arias, P.A.; Berger, S.; Canadell, J.G.; Cassou, C.; Chen, D.; Cherchi, A.; Connors, S.L.; Coppola, E.; Cruz, F.A.; et al. Intergovernmental Panel on Climate Change (Ipcc) Climate Change 2021—The Physical Science Basis: Working Group I Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change, 1st ed.; Cambridge University Press: Cambridge, UK, 2023; ISBN 978-1-009-15789-6. [Google Scholar]

- Pu, S.; Fu, J.; Liao, Y.; Ge, L.; Zhou, Y.; Zhang, S.; Zhao, S.; Liu, X.; Hu, X.; Liu, K.; et al. Promoting Energy Efficiency via a Self-Adaptive Evaporative Cooling Hydrogel. Adv. Mater. 2020, 32, e1907307. [Google Scholar] [CrossRef]

- Guan, H.; Lu, Y.; You, Y.; Gao, S.; Liu, L.; Wu, G. Toughness and Thermoresponsive Hydrogel for Sandwich Smart Window with Adaptive Solar Modulation and Energy Saving. ACS Appl. Mater. Interfaces 2024, 16, 52997–53006. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, F.; Guo, Y.; Zhang, Y.; Yu, G. A Hydrogel-Based Antifouling Solar Evaporator for Highly Efficient Water Desalination. Energy Environ. Sci. 2018, 11, 1985–1992. [Google Scholar] [CrossRef]

- Jiao, W.; Li, X.; Shan, J.; Wang, X. Study of Several Alginate-Based Hydrogels for In Vitro 3D Cell Cultures. Gels 2022, 8, 147. [Google Scholar] [CrossRef] [PubMed]

- Kabir, M.M.; Sabur, G.M.; Mamun, M.F.K.; Arman; Tijing, L.; Choden, Y.; Phuntsho, S.; Shon, H.K. Hydrogels in Next-Generation Energy Solutions. Desalination 2025, 603, 118639. [Google Scholar] [CrossRef]

- Bercea, M. Bioinspired Hydrogels as Platforms for Life-Science Applications: Challenges and Opportunities. Polymers 2022, 14, 2365. [Google Scholar] [CrossRef] [PubMed]

- Xiang, C.; Yang, X.; Deng, F.; Chen, Z.; Wang, R. Daytime Air–Water Harvesting Based on Super Hygroscopic Porous Gels with Simultaneous Adsorption–Desorption. Appl. Phys. Rev. 2023, 10, 041413. [Google Scholar] [CrossRef]

- Nandakumar, D.K.; Zhang, Y.; Ravi, S.K.; Guo, N.; Zhang, C.; Tan, S.C. Solar Energy Triggered Clean Water Harvesting from Humid Air Existing above Sea Surface Enabled by a Hydrogel with Ultrahigh Hygroscopicity. Adv. Mater. 2019, 31, e1806730. [Google Scholar] [CrossRef]

- Ashraf, A.M.; Ragavan, T.; Begam, S.N. Superabsorbent Polymers (SAPs) Hydrogel: Water Saving Technology for Increasing Agriculture Productivity in Drought Prone Areas: A Review. Agric. Rev. 2021, 42, 183. [Google Scholar] [CrossRef]

- Mariem, D.; Mohamed, H. Effect of Salinity on the Hydro-Structural Properties of a Sandy Soil Amended by the Conditioner Stockosorb. Commun. Soil Sci. Plant Anal. 2022, 53, 2982–2995. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, X. Energy Consumption and Heat Island Effect Mitigation Analysis of Different Roofs Considering Superposition Coupling. Front. Energy Res. 2023, 10, 1047614. [Google Scholar] [CrossRef]

- Tsimpoukis, D.; Syngounas, E.; Petsanas, D.; Mitsopoulos, G.; Anagnostatos, S.; Bellos, E.; Tzivanidis, C.; Vrachopoulos, M.G. Energy and Environmental Investigation of R744 All-in-One Configurations for Refrigeration and Heating/Air Conditioning Needs of a Supermarket. J. Clean. Prod. 2021, 279, 123234. [Google Scholar] [CrossRef]

- Elavarasan, R.M.; Pugazhendhi, R.; Shafiullah, G.M.; Irfan, M.; Anvari-Moghaddam, A. A Hover View over Effectual Approaches on Pandemic Management for Sustainable Cities—The Endowment of Prospective Technologies with Revitalization Strategies. Sustain. Cities Soc. 2021, 68, 102789. [Google Scholar] [CrossRef]

- Garcia-Garcia, A.; Muñana-González, S.; Lanceros-Mendez, S.; Ruiz-Rubio, L.; Alvarez, L.P.; Vilas-Vilela, J.L. Biodegradable Natural Hydrogels for Tissue Engineering, Controlled Release, and Soil Remediation. Polymers 2024, 16, 2599. [Google Scholar] [CrossRef]

- El-Aziz, G.H.A.; Ibrahim, A.S.; Fahmy, A.H. Using Environmentally Friendly Hydrogels to Alleviate the Negative Impact of Drought on Plant. Open J. Appl. Sci. 2022, 12, 111–133. [Google Scholar] [CrossRef]

- Thakur, S.; Sharma, B.; Verma, A.; Chaudhary, J.; Tamulevicius, S.; Thakur, V.K. Recent Progress in Sodium Alginate Based Sustainable Hydrogels for Environmental Applications. J. Clean. Prod. 2018, 198, 143–159. [Google Scholar] [CrossRef]

- García-Gómez, C.; Uysal, Y.; Doğaroğlu, Z.G.; Kalderis, D.; Gasparatos, D.; Fernández, M.D. Influence of Biochar-Reinforced Hydrogel Composites on Growth and Biochemical Parameters of Bean Plants and Soil Microbial Activities under Different Moisture Conditions. Agriculture 2024, 14, 1405. [Google Scholar] [CrossRef]

- Tewari, M.; Yang, J.; Kusaka, H.; Salamanca, F.; Watson, C.; Treinish, L. Interaction of Urban Heat Islands and Heat Waves under Current and Future Climate Conditions and Their Mitigation Using Green and Cool Roofs in New York City and Phoenix, Arizona. Environ. Res. Lett. 2019, 14, 034002. [Google Scholar] [CrossRef]

- Biutty, M.N.; Koo, J.-M.; Kim, J.H.; Kim, S.; Choi, U.H.; Imani, K.B.C.; Yoon, J.; Chang, B.-Y.; Yoo, S.I. Ion Transport through Layered Hydrogels for Low-Frequency Energy Harvesting toward Self-Powered Chemical Systems. J. Mater. Chem. A 2022, 10, 11881–11892. [Google Scholar] [CrossRef]

- Hagiwara, R.; Yoshida, R.; Okeyoshi, K. Bioinspired Hydrogels: Polymeric Designs towards Artificial Photosynthesis. Chem. Commun. 2024, 60, 13314–13324. [Google Scholar] [CrossRef]

- Chang, X.; Li, S.; Li, N.; Wang, S.; Li, J.; Guo, C.; Yu, L.; Murto, P.; Xu, X. Marine Biomass-Derived, Hygroscopic and Temperature-Responsive Hydrogel Beads for Atmospheric Water Harvesting and Solar-Powered Irrigation. J. Mater. Chem. A 2022, 10, 18170–18184. [Google Scholar] [CrossRef]

- Wang, W.; Wang, X.; Zhang, A.; Liu, H.; Huang, Y. Targeted Strategy of Straw Derived Hydrogels for Sustainable Water and Fertilizer. Sci. Total Environ. 2025, 959, 178153. [Google Scholar] [CrossRef]

- Amnuaylojaroen, T.; Parasin, N. Human Health Adaptation Strategies to Climate-Induced Extreme Weather Events: A Systematic Review. Earth 2024, 5, 724–742. [Google Scholar] [CrossRef]

- Skrzypczak, D.; Mikula, K.; Kossińska, N.; Widera, B.; Warchoł, J.; Moustakas, K.; Chojnacka, K.; Witek-Krowiak, A. Biodegradable Hydrogel Materials for Water Storage in Agriculture—Review of Recent Research. Desalination Water Treat. 2020, 194, 324–332. [Google Scholar] [CrossRef]

- Yang, Y.-S.; Zhou, Y.; Yin Chiang, F.B.; Long, Y. Temperature-Responsive Hydroxypropylcellulose Based Thermochromic Material and Its Smart Window Application. RSC Adv. 2016, 6, 61449–61453. [Google Scholar] [CrossRef]

- Dhanapal, V.; Subhapriya, P.; Nithyanandam, K.P.; Kiruthika, M.V.; Keerthana, T.; Dineshkumar, G. Design, Synthesis and Evaluation of N,N1-Methylenebisacrylamide Crosslinked Smart Polymer Hydrogel for the Controlled Release of Water and Plant Nutrients in Agriculture Field. Mater. Today Proc. 2021, 45, 2491–2497. [Google Scholar] [CrossRef]

- Telin, A.; Safarov, F.; Yakubov, R.; Gusarova, E.; Pavlik, A.; Lenchenkova, L.; Dokichev, V. Thermal Degradation Study of Hydrogel Nanocomposites Based on Polyacrylamide and Nanosilica Used for Conformance Control and Water Shutoff. Gels 2024, 10, 846. [Google Scholar] [CrossRef]

- Cai, S.; Suo, Z. Mechanics and Chemical Thermodynamics of Phase Transition in Temperature-Sensitive Hydrogels. J. Mech. Phys. Solids 2011, 59, 2259–2278. [Google Scholar] [CrossRef]

- Lu, W.; Ong, W.L.; Pan, X.; Li, Z.; Tian, G.; Ho, G.W. Design Strategies and Roles of Hydrogels for Sustainable Energy Conversion and Harvesting from Natural and Biological Environments. Adv. Mater. 2025, 37, e10270. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Cheng, Y.; Yang, T.; Chen, H.; Niu, B.; Fang, X.; Wu, W.; Shen, C.; Wang, G.; Liu, B.; et al. State-of-the-Art Insights into Hydrogel Innovations from Structural Engineering to Smart Preservation: Research Trends and Future Directions. Trends Food Sci. Technol. 2026, 167, 105411. [Google Scholar] [CrossRef]

- Ballarano, A.; Trotta, F.; Caldera, F.; Hoti, G.; López-Nicolás, J.M.; Matencio, A. Eco-Hydrogels: The New Frontier of Sustainability: A Review. Sustain. Chem. Pharm. 2025, 48, 102223. [Google Scholar] [CrossRef]

| Hydrogel Type | Application | Performance Metric | Test Conditions | Reference |

|---|---|---|---|---|

| Polyelectrolyte | Atmospheric Water Harvesting | 2410 mL/kg/day | 30% RH, 25 °C, 3 h cycles (8 cycles/day) | [15] |

| Polyacrylamide-based | Atmospheric Water Harvesting | 2.76 g g−1 water uptake | 90% RH, 25 °C, 24 h absorption | [84] |

| Salt-embedded composite | Atmospheric Water Harvesting | 0.8–1.5 g g−1 at low RH | <30% RH, 25 °C, diurnal cycles | [85] |

| PEI hydrogel particles | CO2 Capture (pure) | 6.5 mol/kg | 100% CO2, 25 °C, 1 bar, 30 min cycles | [13] |

| Hygroscopic salt-polymer | Water Harvesting (desert) | ~5.6 g g−1 max capacity | Enhanced with LiCl/CaCl2 | [85] |

| Thermochromic composite | Passive Cooling | 22 °C reduction | Ambient conditions, solar exposure, summer outdoor testing | [86] |

| PAAm-based | Agricultural water retention | 30–50% irrigation reduction | Field studies, maize and soybean-wheat systems | [8,87] |

| Hydrogel System | RH (%) | Temperature (°C) | Water Flux (L/m2/day) | Regeneration Energy Requirements | Key Feature | References |

|---|---|---|---|---|---|---|

| PNIPAm-salt composite | 90 | 25–40 | 5.6–6.7 | 0.3–0.5 | High capacity | [26,29,167] |

| Solar-wind coupled | 60–80 | 20–35 | 14.9 | 0.1–0.2 | Highest yield | [28,29,167] |

| Alginate-CaCl2 | 40–70 | 15–30 | 2.4–3.8 | 0.4–0.6 | Low-RH capable | [169] |

| MOF-hydrogel hybrid | 30–50 | 25–40 | 3.2–5.0 | 0.2–0.4 | Arid climate | [170] |

| Conventional (RO desalination) | N/A | 10–35 | 1000+ | 3.0–4.0 | Energy intensive | [6,7,8,9] |

| Application | Primary Metric | Secondary Metric | Durability | Conditions | References |

|---|---|---|---|---|---|

| Passive Cooling-Evaporative | ΔTnoon = 8–15 °C (temperature reduction at noon) | Cooling power: 50–150 W/m2 | 2–8 h continuous (40% RH) | 20–40% RH, 20–40 °C | [30,31,32] |

| Passive Cooling-Radiative | ΔTnoon = 3–7 °C (temperature reduction at noon) | Cooling power: 40–93 W/m2 | 24 h continuous (no water needed) | Any RH, Clear sky | [217] |

| Soil Amendment-Sandy | Yield per water: 11–51% increase | Leaching reduction: 30–60% | 100–500 cycles (2–3 seasons) | 0.2–0.4 g of hydrogel per 100 g of soil | [36,37,38,209] |

| Soil Amendment-Loam/Clay | Yield per water: 8–25% increase | Leaching reduction: 20–45% | 50–200 cycles (1–2 seasons) | 0.1–0.2 g of hydrogel per 100 g of soil | [35] |

| Conventional Systems | AC: 15–25 °C, Drip irrigation: 85–95% efficiency | AC: 2–3 Kw/ton, Irrigation: high capex | AC: 10–15 years, Irrigation: 20–30 years | Energy intensive | [215,218] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gałęziewska, J.; Kruczkowska, W.; Grabowska, K.H.; Kałuzińska-Kołat, Ż.; Płuciennik, E. Hydrogels for Climate Change Mitigation: Applications in Water Harvesting, Passive Cooling, and Environmental Solutions. Gels 2025, 11, 924. https://doi.org/10.3390/gels11110924

Gałęziewska J, Kruczkowska W, Grabowska KH, Kałuzińska-Kołat Ż, Płuciennik E. Hydrogels for Climate Change Mitigation: Applications in Water Harvesting, Passive Cooling, and Environmental Solutions. Gels. 2025; 11(11):924. https://doi.org/10.3390/gels11110924

Chicago/Turabian StyleGałęziewska, Julia, Weronika Kruczkowska, Katarzyna Helena Grabowska, Żaneta Kałuzińska-Kołat, and Elżbieta Płuciennik. 2025. "Hydrogels for Climate Change Mitigation: Applications in Water Harvesting, Passive Cooling, and Environmental Solutions" Gels 11, no. 11: 924. https://doi.org/10.3390/gels11110924

APA StyleGałęziewska, J., Kruczkowska, W., Grabowska, K. H., Kałuzińska-Kołat, Ż., & Płuciennik, E. (2025). Hydrogels for Climate Change Mitigation: Applications in Water Harvesting, Passive Cooling, and Environmental Solutions. Gels, 11(11), 924. https://doi.org/10.3390/gels11110924