Abstract

Pigments play a major role in many industries. Natural colors are usually much safer when compared to synthetic colors and may even possess some medicinal benefits. Synthetic colors are economical and can easily be produced compared to natural colors. In addition, raw plant materials for natural colors are limited and season dependent. Microorganisms provide an alternative source for natural colors and, among them, fungi provide a wide range of natural colorants that could easily be produced cheaply and with high yield. Along with pigment, some microbial strains are also capable of producing a number of mycotoxins. The commercial use of microbial pigments relies on the safety of colorants. This review provides a toxicity evaluation of pigments from fungal origins for food application.

1. Introduction

Due to the global increase in processed food production, the market for fresh food is predicted to grow more in coming years. Modern consumers have become more nutrition and health conscious and have a growing interest in (i) where their food comes from and (ii) in food additives [1]. Food labeling has increased interest in understanding the physiological needs of the body. Consumers tend to shy away from chemical compounds such as food additives, viz., antioxidants, preservatives and colors. They search for natural additives in natural foods that are safe and good for them. On the other hand, consumers have a growing awareness of natural products where toxicants may also be present [2].

Historically, throughout the world, natural pigments have been used for many purposes. The advent of synthetic dyes reduced the use of natural pigments to a greater extent. Recently, dyes derived from natural sources are gaining importance, since some synthetic dyes have been reported to have carcinogenic effects [3,4]. Natural pigments gained interest due to worldwide concern over the use of eco-friendly and biodegradable materials. Demand for natural colorants, especially yellow and red pigments, israpidly increasing worldwide. Production of safe and natural pigments from natural resources are mainly being focused on in food, textile and pharmaceutical industries, due to the serious environmental and safety problems caused by many artificial synthetic pigments [5].

Many natural pigments are from plant or microorganism-based origins. There are a number of major drawbacks to plant pigments, viz., non-availability throughout the year, pigment stability and solubility. Exploitation of plants on a large scale may lead to a loss of valuable species. For these reasons, the pigments from plant sources are not considered viable. Microorganisms, viz., fungi, bacteria, algae and actinomycetes, are a reliable and readily available alternative source of natural pigments [6,7]. Microorganisms are advantageous over plant for pigments production because of easy and rapid multiplication in a low cost medium, easy processing and growth independent from weather conditions [8].

2. Synthetic Food Colors

Color is an important factor as far as food is concerned, as it plays a major role in the taste and perception of food, along with flavor and texture. It is a known fact that consumers will probably reject food that does not look attractive. To make food more appealing to customers, manufacturers add color to retain the food’s natural look, as far as possible. Natural appearance is always preferable to anything that looks unusually colored. Even though many foods can contain added artificial colors, most consumers believe that the color of the food is its natural color.

The first synthetic organic dye, discovered by William Henry Perkin in 1856, was a purplish lilac color named “mauve”. Similar organic aniline dyes were synthesized, representing every color and tint of the rainbow, and these were used for food coloring with little or few tests regarding their safety. Aniline and coaltar-based colors exhibited significant toxicity, which prompted regulators to examine the exact use of synthetic colors in the food industry [9].

In recent years, an astonishing amount of the food we eat is processed. To increase the shelf life and appearance of food, additives and colors are added, which make them unsafe for consumption. On average, processed food accounts for about 70% of the diet of U.S. residents. This includes soft drinks, confectionery, packaged bread, buns, biscuits, cakes, preserved meat products, instant soups, noodles, packaged pizzas, pies and packaged meals. The U.S. consumption of processed food is about forty times more than the diet of Indian residents [10].

Health Hazards of Synthetic Food Colors

Risk analysis helps to evaluate the adverse effects of synthetic agents in food. In a global context, food colors are of major concern with regard to the possible adverse effects of additives. In the mid-1980s, a possible link between tartrazine and hyperactivity in children was suggested [11].

- The azo-dye group of colorants consists of bright colors and is widely used in the food industry. Increasing attention on these dyes revealed that they were potential carcinogens, occurring in the intestines’ microbiota, after their azo reduction to carcinogenic metabolites [12]. Even at low levels of ingestion, permitted food colors, viz., ponceau, tartrazine and sunset yellow, provoked allergic reactions in many individuals. Common allergic responses were urticaria, dermatitis, angioedema and the exacerbation of asthmatic symptoms [13]. A symptom of glossitis was reported due to the consumption of a very high level of ponceau 4R in a particular brand of aniseed [14]. Hypertensive children aged between 2 and 14 years were diagnosed with irritability, restlessness and sleep disturbance due to high levels of tartrazine. Ever rising demand for the use of natural colorants has replaced the use of synthetic dyes in food [15].

3. Microbial Pigments

Natural pigments obtained from plants, animals and microorganisms are eco-friendly and have usually low or no toxicity [16,17]. The many disadvantages of using plants and animals prevent them from large-scale exploitation [18]. However, advantages of microbial pigments help to utilize their immense potential in various fields [19,20]. Even though the cost of microbial β-carotene production is several times more expensive, it can still compete with synthetic dyes in terms of it being natural and safe [21,22].

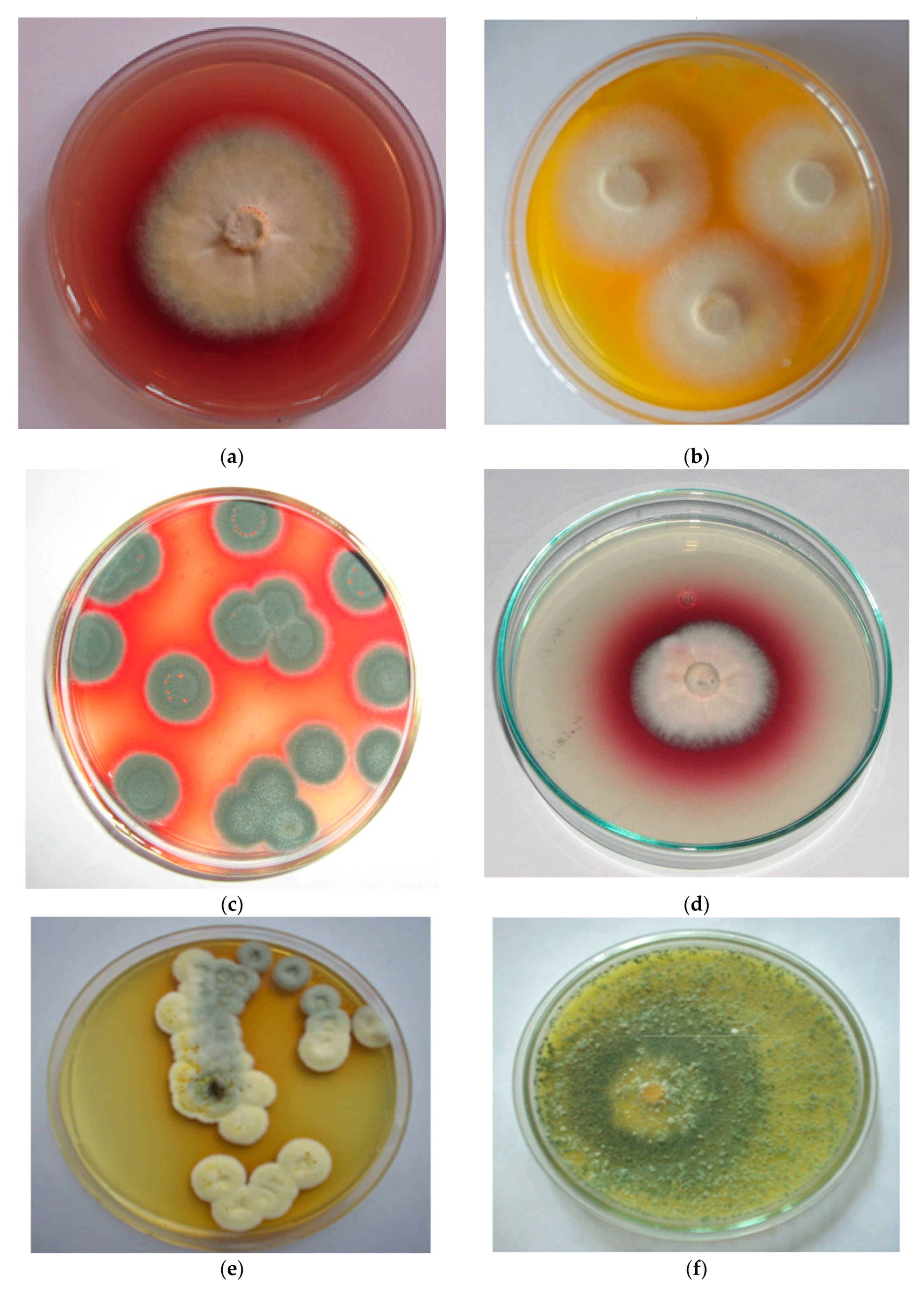

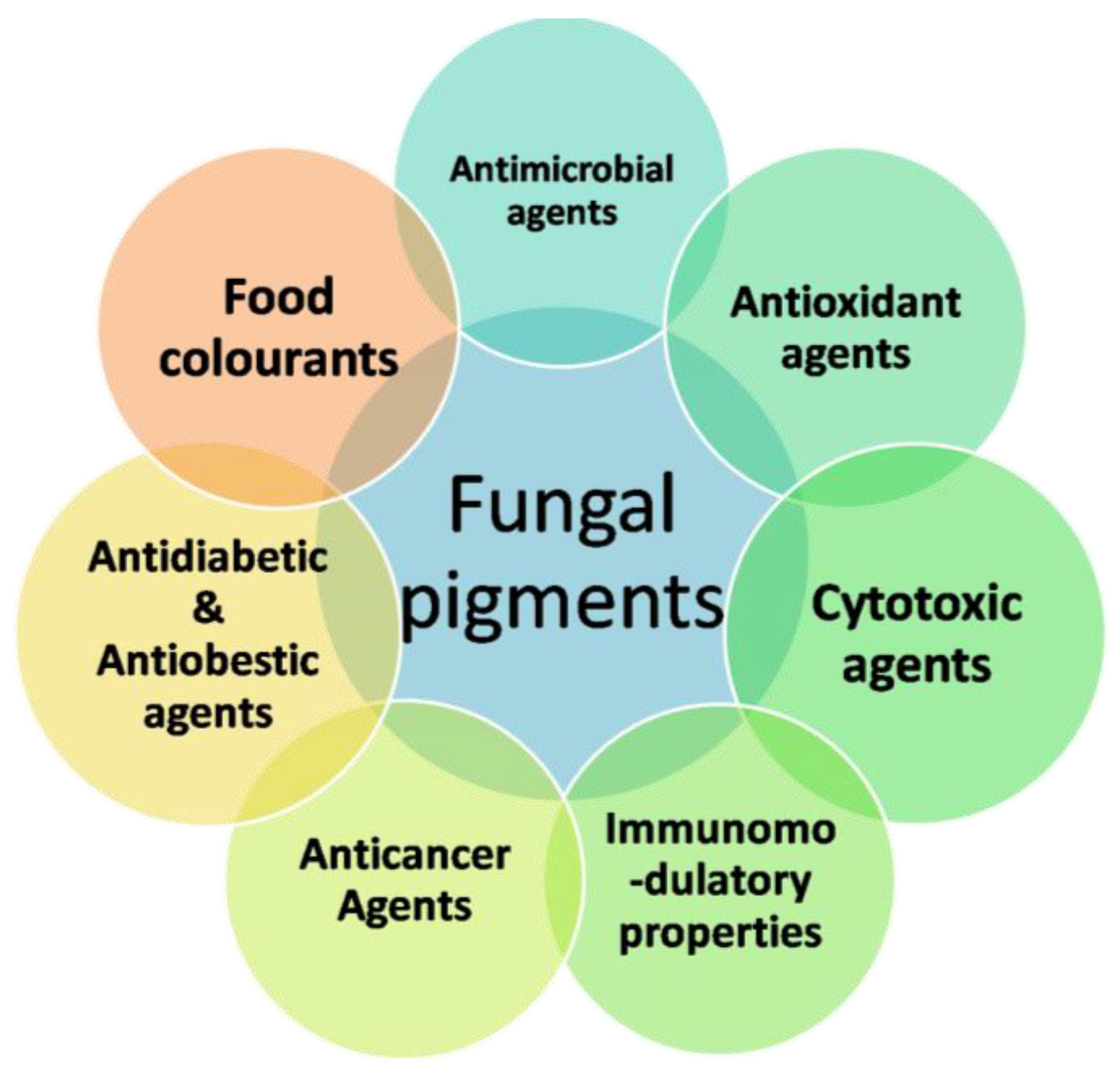

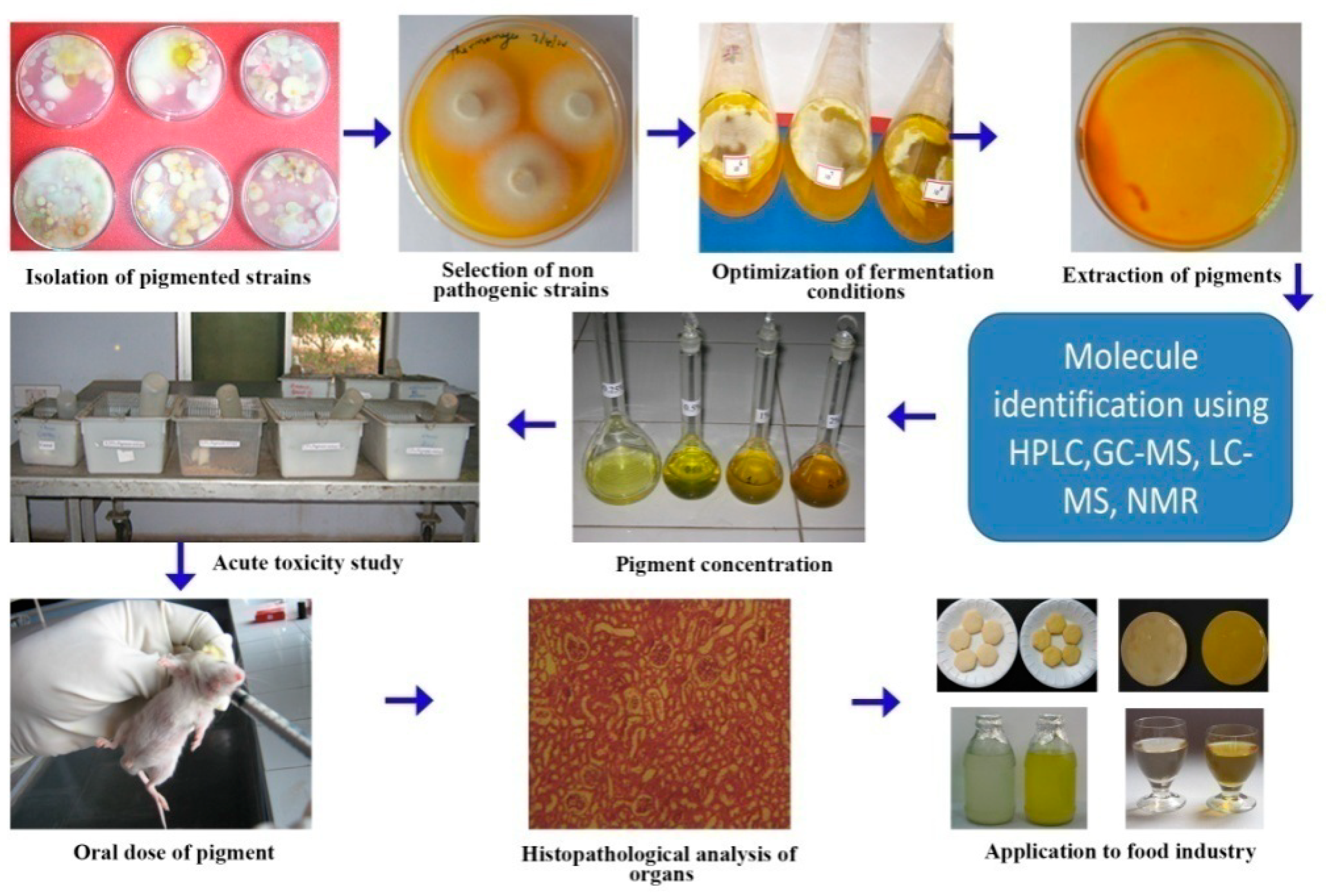

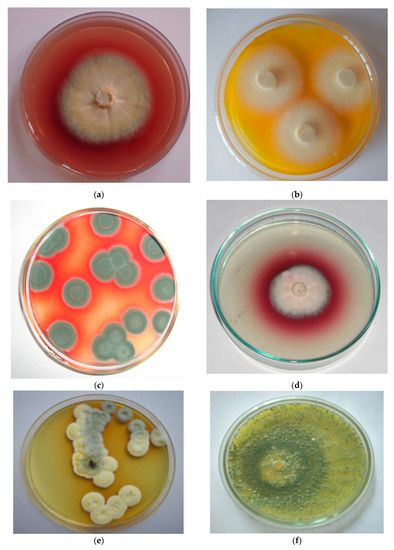

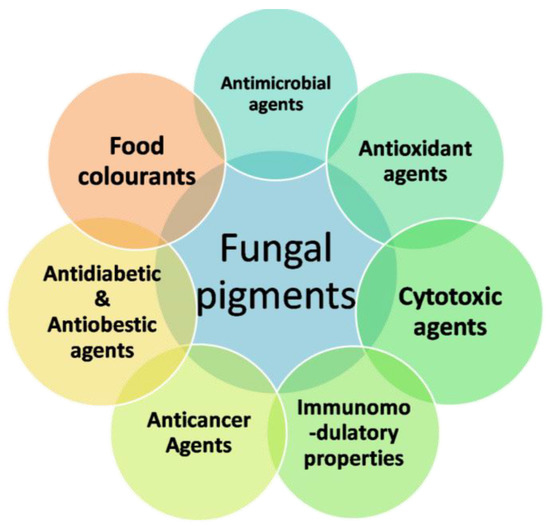

Microbial cells that produce color are referred to as microbial pigments producers [23]. They produce a wide range of colors (Figure 1) and are mostly water-soluble [24,25]. Natural pigments are mainly used as color additives or intensifiers; moreover, they are used as antioxidants and antibiotics (Figure 2). Due to indiscriminate use of synthetic colors and contrary reports on the safety of synthetic dyes, there is an important need to identify safe colorants from natural pigments. Microbial pigments have several advantages, viz., yield, cost efficiency, stability and ease of downstream processing compared to pigments from plant or animal origins [26,27].

Figure 1.

Pigments produced by different fungi: (a) Chaetomium sp. producing red pigment; (b) Thermomyces sp. producing yellow pigment; (c) Penicillium purpurogenum producing red pigment; (d) Fusarium sp. producing red pigment; (e) Penicillium purpurescens producing brown pigment (f) Trichoderma sp. producing yellow pigment.

Figure 2.

Applications of fungal pigments in the food industry.

Among pigment-producing microbes, fungi produce a wide range of water-soluble bio-pigments that have a variety of functions. Pigments extracted from fungi that are isolated from soil have various industrial applications. Filamentous fungi, viz., Monascus, Aspergillus, Penicillium, Neurospora, Eurotium, Drechslera and Trichoderma [28,29,30] are potential producers of bio-pigments. The pigments include carotenoids, melanins, flavins, phenazines, quinones, monacins and indigo [31]. Hence, they are the subject of many studies.

Recently, fungal pigments have been used for textile dyes, food colorants, antimicrobial and anticancer applications. They are also natural without having undesirable effects on the environment. Many scientific researchers have proved that pigments from soil fungi are a safer alternative to synthetic colorants, and there is good scope for industrial application [32,33].

4. Fungal Pigments and Toxicity Evaluation

Most fungi produce pigments along with mycotoxins. The presence of mycotoxins in pigments restricts the application of pigments as an additive in the food industry [16,34]. The European Union and the United States prohibit the consumption of Monascus pigments that are produced along with citrinin toxin, which poses a challenge over its safe use [35]. In short, natural pigments are a potential source of colorants that are eco-friendly, biodegradable, antimicrobial and have antioxidant properties. Apart from food additives, they are also used in cosmetics, pharmaceuticals and drug applications [36] (Table 1).

Table 1.

Important fungal pigments and their safety evaluation.

4.1. Aspergillus carbonarius

Aspergillus carbonarius, an Ascomycota fungus of the family Aspergillaceae, is capable of producing a yellow-colored pigment in its biomass. It does not produce any antinutrients or mycotoxins [60]. It has been exploited for large-scale production of polygalacturonase and is capable of temperature tolerance by UV irradiation when grown in shake-flask cultures. During the growth phase, a yellow colored pigment is accumulated in its biomass and has the potential to be used as a food colorant [61].

Toxicity studies in both sexes of albino rats at acute and subacute doses of the pigment revealed that feeding of fungal biomass did not show any mortality in rats and there are no significant differences in food intake or organ and body weight. When comparing treated and untreated rats, hematological parameters, serum enzymes lactate dehydrogenase (LDH), alkaline phosphatase (ALP), alanine aminotransferase (ALT or ALAT) and cholesterol assay also remain normal [62].

4.2. Blackslea trispora

Blakesleatrispora is a Zygomycetes fungus of the order Mucorales, family Choanephoraceae. It is capable of undergoing both sexual and asexual reproduction through the production of zygospores and sporangiospores. The fungus does not produce any toxic compounds; hence, it is of industrial interest as a source of β-carotene for commercial exploitation [63,64]. β-carotene from B. trispora was the first authorized microbial food colorant in the European Union. It is efficient and can achieve the highest yield of all trans β-carotene at the expense of other structurally related carotenoids [33]. The process production was improved over a number of years, producing carotenoid contents of up to 20% dry weight [65,66].

The safety assessment of β-carotene, derived from B. trispora, has revealed no genotoxicity or subacute toxicity for 4weeks [38,67]. A subchronic toxicity study of 90 days was performed with oral administration of F344.Rats of both sexes showed no adverse effects on their biological systems [39]. β-carotene derived from the B. trispora at a 5.0% dietary level, equivalent to 3127 mg/kg/day and 3362 mg/kg/day for male and female rats, caused no adverse effects. The findings revealed that the daily intake of synthetic β-carotene from B. trispora by human beings is a negligible toxicological hazard [68].

4.3. Fusarium sp.

Fusarium are Ascomycota fungi that belong to the order Hypocreales, family Nectriaceae. They produce a wide range of fungal pigments that are structurally and functionally diverse. However, among the Fusarium sp., Fusarium graminearum (red naphthoquinone pigment, rubrofusarin) [40], Fusarium fujikuroi (orange carotenoids pigment, fusarubin) [43,69] and Fusarium oxysporum (red naphthoquinone pigment, bikaverin) [44] are the major pigment-producing fungi. Secondary metabolites from these fungi contain numerous toxic compounds, viz., fumonisins, zearalenone, fusaric acid, fusarins and beauvericins [70].

Toxicity analysis revealed that the red dimeric naphthoquinone pigment from F. oxysporum-contaminated products affects human health. Recently, red naphthoquinone pigment has often been reported as a mycotoxin. However, naphthoquinone pigment was not genotoxic according to a DNA synthesis assay. Biotechnological approaches and intelligent screening of the toxic metabolite pathway of the pigment from Fusarium sp. will be helpful in producing the pigment for food coloring [41,42].

4.4. Monascus sp.

Monascus sp. are fungi placed under order Eurotiales, family Monascaceae. There are many species in this genus, among which M. purpureus (monascorubramine and rubropunctamine) [45], M. anka (ankaflavin and monascin) [46] and M. ruber (monascorubrinandrubropunctatin) [47] are of greatest significance to the food industry. Traditionally, Monascus pigments were produced on rice using solid-state microbial fermentation. Synonyms for this food product include, Hon-Chi, Hong Qu, Dan Qu, Anka, Ankak rice, Beni-Koji, red koji, red Chinese rice, red yeast rice and red mold rice (RMR). RMR was utilized as a food colorant in traditional Chinese medicine for more than 1000 years [71].

Chinese, as well as other East Asian people, have confirmed the safety of red yeast rice. The European Food Safety Authority (EFSA) and the United States excluded red yeast rice on the list of permissible food additives, due to complex secondary metabolites [72,73]. The toxigenic strain of Monascus purpureus is capable of producing nephrotoxic and hepatotoxic mycotoxin citrinin, which limits the wide application of the pigment [74].

For more than a thousand years, pigments produced by Monascus sp. were legally used as food colorants in South East Asia, even though they were demonstrated to have physiological effects. There are numerous toxicological data available on this Monascus red pigment.

A genetically modified industrial strain, M. purpureus SM001 isolated in China, is capable of producing pigment without citrinin, which is the best Monascus pigment producer.This results in the prolonged safety of Monascus-related products and their application [75].

4.5. Penicillium sp.

Penicillium are Ascomycota fungi belonging to the order Eurotiales, family Trichocomaceae. They are capable of producing many pigments. Penicillium are ubiquitous saprophytic soil fungi, present wherever organic material is available. Several species are capable of producing highly toxic mycotoxins. Some species of the genus Penicillium are capable of producing antibiotics, while some other species are used in cheese making; however, pigment production by these fungi is less well known [48,76]. Patents contain information about acute oral toxicity in mice. A 90-day subchronic toxicological study found acute dermal irritation, acute eye irritation, antitumor activity, micronucleus test in mice, AMES test (Salmonella typhimurium reverse mutation assay) and an estimation of antibiotic activity, including results of estimation of five mycotoxins [77].

Penicillium purpurogenum is capable of producing an azaphilone-like pigment. It secretes a brick red pigment during growth, which generally diffuses into commonly used media. However, violet pigment (PP-V) and orange pigment (PP-O) were also reported by altering culture conditions [78]. The production of pigment from Penicillium is more efficient and profitable than any other microorganism. It secretes enzymes and pigments out of the cell and the secreted pigment is water-soluble and relatively stable; thus, it is easily purified [79].

Toxicity studies of P. purpurogenum DPUA 1275 on brine shrimp, Artemia salina, showed antimicrobial effects and absence of toxicity to go along with pigment production. It also does not produce any known mycotoxins and is nonpathogenic to humans. It is a potential strain for the production of food pigments [80]. Although many species of Penicillium are found to produce pigments, only a few toxicological studies have been conducted.

Penicillium europium, isolated from forest soil, is capable of producing a pinkish pigment by using longifolene as a sole carbon source. A toxicity study on albino rats revealed that the pigment had no toxic effect on rats. Synthesized pigments from P. europium could be used in food, feed and pharmaceutical industries. Apart from the food industry, it could be used for various industrial applications, viz., dyes for textile and non-textile substrates such as paper, leather, paints and cosmetics. Moreover, as it is non cytotoxic, the pigment could be a potential replacement for hazardous synthetic dyes [50,81].

Penicillium resticulosum is capable of producing red pigments. An evaluation of the subacute toxicity of oral exposure on the synthesized pigment on adult male and female mice for 28 days, using a pigment dose of up to 500 mg kg−1 body weight daily, had no effect on body weight, organ weight, or the activity of lactate dehydrogenase (LDH), alkaline phosphatase (ALP), alanine aminotransferase (ALT or ALAT) enzymes or blood urea nitrogen (BUN) levels. However, mice taking the pigment over 500 mg·kg−1 body weight daily showed fatty degeneration and mild necrosis of liver cells, indicating that doses under 500 mg·kg−1 body weight were safe for daily consumption [51,82].

Penicillium aculeatum produces a yellow (ankaflavin) pigment under submerged fermentation. Cytotoxicity studies of the pigment interacting with human colon carcinoma cell lines (HCT116) and human prostatic carcinoma cell lines (PC3) exhibited apoptosis and cell cycle inhibition at lower concentrations. An assay of human erythrocytes and human embryonic kidney (HEK-293) cell lines showed the least cytotoxicity atfor highest concentrations tested. Displaying selective cytotoxicity is an important property for an ideal anticancer drug [52].

4.6. Talaromyces purpureogenus

Talaromyces purpureogenus (basionym: Penicillium purpureogenum), is capable of producing yellow and red pigments under submerged fermentation. Pigments from T. purpureogenus CFRM02 are non toxic to Artemia franciscana (brine shrimp). In a single-dose acute toxicity study, (50, 300, 1000 and 2000 mg/kg body weight) conducted on female Wistar rats, there was no evidence of adverse effects on body weight and mortality after 14 days. Subacute studies (250–1000 mg/kg body weight) showed no significant changes in food intake, body weight gain and relative weight of vital organs after 28 days. Furthermore, a histopathological examination of the liver and kidney was normal. There were no significant changes in serum enzyme activities in the treated and control groups (acute and subacute). Safety efficacy of the pigment from T. purpureogenus CFRM02 is suggested for application in food and nutraceuticals [53]. This potential strain has resulted in in-depth studies of some strains of Talaromyces species, viz., Talaromyces aculeatus, T. funiculosum, T. pinophilus and T. purpurogenum. They are capable of producing Monascus-like polyketide azaphilone pigments, with or without coproducing citrinin or any other known mycotoxins [83].

4.7. Thermomyces sp.

Thermomyces are Ascomycota fungi ofthe order Eurotiales, family Trichocomaceae, and they are capable of producing a yellow pigment. They are thermophilic and hemicellulose degraders. One strain was isolated from soil in Kodaikanal, Dindugul District, Tamil Nadu, India. The yellow pigment can scavenge reactive oxygen species (ROS) induced by chemicals and UV rays and reduce the DNA damage by their antioxidant capabilities [84]. The bright pigmentation varies from yellow to red, depending on the growth, temperature, age and substrate [85].Food and beverages fortified by the yellow pigment recorded high antioxidant properties, antimicrobial properties and color stability [86].

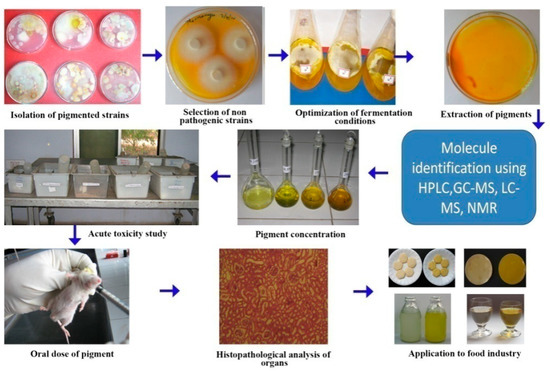

Toxicological studies on the Thermomyces pigment using albino mice that orally ingested Thermomyces sp. pigment for 28 days showed no alterations in red blood cells, white blood cells, haemoglobin, organ weight orhistopathology of the liver or kidneys [54] (Figure 3). Apart from pigmentation, in vivo antioxidant activity was also observed [87,88]. Therefore, pigments from Thermomyces sp. could be safe for the food industry.

Figure 3.

Toxicity evaluation of Thermomyces sp. pigment using an animal model.

4.8. Trichoderma viride

Trichoderma viride is an Ascomycota fungus belonging to the order Hypocreales, family Hypocreaceae. It is capable of producing a brown colored pigment, identified as furfural (only one study and this should be confirmed) [89]. It is mostly used as a biological control agent against soil-borne plant pathogenic fungi. It is also capable of synthesizing emodin, a yellow pigment. T. polysporum is the only fungi capable of producing emodin in culture media. A phytotoxicity assay proved the nontoxic nature of T. viride on the germination of Phaseolus aureus Roxb. The pigment, i.e., furfural, produced by Trichoderma viride, has possible wide applications in various industries [89].

4.9. Scytalidium cuboideum

Scytalidium cuboideum, an Ascomycota fungus belonging to the order Helotiales, family Chaetomiaceae, is isolated from wood and is capable of coloring wood. It produces a red pigment, identified as xylindein.

Toxicity studies of the red pigment in zebrafish revealed a relatively high LD50 value, making it unlikely to affect humans. Pure solidified pigments from S. cuboideum did not demonstrate toxicity. However, significant mortality was associated with impure fungal metabolites containing pigments. Hence, xylindein is considered as an environmentally safe pigmentation for future applications [55,90].

4.10. Neurospora crassa

Neurospora crassa is a type of red bread mold of the phylum Ascomycota in the order Sordariales, family Sordariaceae. It is a genetically and biochemically well-studied eukaryotic microorganism [91,92]. It is capable of producing polyketide and carotenoid fungal pigments that are yellow to orange-red pigments widely used as food colorants. Research on Neurospora sp. has generally recognized it as safe after more than two centuries, with no record of mycotoxin production. For the production of ethanol, biomass and pigments, it can be grown rapidly on industrial residuals and lignocelluloses.

4.11. Other Fungal Pigments

The Cordycipitaceae family have promising pigment-producing genera such as Torrubiella, Cordyceps, Beauveria, Hyperdermium and Lecanicillium. Beauveria bassiana produces tenellin and Beauveria brongniartii produces bassianin. Beauveria bassiana produces pyridovericin, blood-red dibenzoquinone and pyridomacrolidin, along with mycotoxin. Torubiella produces torrubiellones and Lecanicillium aphanocladii produces a pigment, along with oosporein [93]. This molecule has a wide range of bioactivities from antifungal, antimicrobial and phytotoxic effects to growth inhibition in plants. Additionally, kidney damage and even death were noticed in poultry exposed to oosporein.

5. Yeast

Yeast synthesizes a variety of commercially important carotenoids, viz., carotene, torulene, torularhodin and astaxanthin. Genera Rhodotorula, Sporobolomyces and Phaffia are potential sources of pigments. Carotenoids from yeast are used in pharmaceutical, chemical, food and feed industries. They are also an important precursor for vitamin A synthesis. Apart from coloring, it also has antioxidant and possible tumor-inhibiting properties [94,95].

5.1. Rhodotorula sp.

Rhodotorula a pigment-producing yeasts from division Basidiomycota are capable of synthesizing carotenoid pigments. Other species such as R. gracilis, R. rubra and R. graminis are also capable of producing pigments. The main compounds produced by Rhodotorula glutinis (red yeasts) are torulene and torularhodin, with a minute quantity of β-carotene [96,97].

A toxicological evaluation of R. gracilis CFR-1, using acute doses in freeze-dried form at 0.5–6.0 g/kg of body weight (w/w), did not show any toxic symptoms or mortality in adult rats. Dietary intake at low concentrations of 0.1–2.0% level (w/w) for 14 weeks did not induce any significant change in food intake and body weight gain in experimental rats compared to control animals [56,57].

Toxicity studies of β-carotene, torulene and torularhodin produced by R. glutinis conducted on rats demonstrated that they can be used as safe food additives. Dry powdered R. glutinis NCIM 3353 yeast biomass was added to the fodder of rats. The rats had protective effects against precancerous lesions of the liver induced by N-nitrosodimethylamine [98].

5.2. Yarrowia lipolytica

Yarrowia lipolytica is an Ascomycetous yeast and the only described species of the genus Yarrowia. It is widespread in nature, has many industrial uses and is important in the food industry and medical field. It is used as an alternative source of β-carotene. The major constituents of the carotenoids include all-trans-β-carotene with small amounts of 9-cis β-carotene, 15-cis β-carotene, 13-cis β- carotene and others [99].

Toxicity studies of β-carotene from Y. lipolytica in genotoxicity models and a standard subchronic rat study revealed no significant difference, compared with commercial products. An extracellular nontoxic pyomelanin pigment from Y. lipolytica was found to have antioxidant and noncytotoxic properties for two mammalian cell lines, viz., mouse fibroblast (NIH3T3) and human keratinocytes (HaCaT). Purified pyomelanin has a significant sun protection factor (SPF) value, highlighting its potential as a UVfilter in cosmetic preparations. Biomass of this yeast was defined as a safe novel food by the European Food Safety Authority [100].

6. Conclusions

In recent decades, natural pigments have been extensively used as colorants in food, pharmaceutical, cosmetic and textile industries. Several fungal strains are known for pigment production, while many fungi have not been systematically explored for their pigment-producing capability. Therefore, there is a need to explore novel and safe pigments using appropriate tools and techniques. Many pigments, including those with antibiotic-like properties, need to be studied for selective toxicity so that they can be produced commercially for human use. Fungal pigments open many new avenues in the production of textiles for medical use. This provides an extensive area of exploration to identify natural, eco-friendly pigments for diverse applications to satisfy public demand. In addition, biotechnological approaches help to produce pigments on a large scale with low cost, high yield and easy extraction without mycotoxins. The manufacture of fungal pigments has taken a big step to promote eco-friendly pigments. A literature search reveals the application of fungal pigments in the food and health care industries. These fungal pigments need to pass toxicity tests, quality tests and regulatory approval before their final entry into the market as food colorants or as drugs. Moreover, toxicology testing for most of the fungal pigments was not available. Another major impediment is that the funding required to carry out the necessary safety studies on such food additives is not available. For the above pigments to be feasible, testing is imperative. Fungal pigments could be a boon to the food industry.

Author Contributions

Writing—original draft, conceptualization (R.P.); writing—review and editing, supervision, resources (S.P.); supervision, conceptualization, writing—review and editing, validation (L.D.); visualization, supervision, conceptualization, resources (J.K.). All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Kalra, R.; Conlan, X.A.; Goel, M. Fungi as a Potential Source of Pigments: Harnessing Filamentous Fungi. Front. Chem. 2020, 8, 369. [Google Scholar] [CrossRef] [PubMed]

- Yusuf, M.; Shabbir, M.; Mohammad, F. Natural Colorants: Historical, Processing and Sustainable Prospects. Nat. Prod. Bioprospecting 2017, 7, 123–145. [Google Scholar] [CrossRef]

- Martins, N.; Roriz, C.L.; Morales, P.; Barros, L.; Ferreira, I.C.F.R. Food colorants: Challenges, opportunities and current desires of agro-industries to ensure consumer expectations and regulatory practices. Trends Food Sci. Technol. 2016, 52, 1–15. [Google Scholar] [CrossRef]

- Ntrallou, K.; Gika, H.; Tsochatzis, E. Analytical and Sample Preparation Techniques for the Determination of Food Colorants in Food Matrices. Foods 2020, 9, 58. [Google Scholar] [CrossRef]

- Sigurdson, G.T.; Tang, P.; Giusti, M.M. Natural Colorants: Food Colorants from Natural Sources. Annu. Rev. Food Sci. Technol. 2017, 8, 261–280. [Google Scholar] [CrossRef]

- Rodriguez-Amaya, D.B. Natural food pigments and colorants. Curr. Opin. Food Sci. 2016, 7, 20–26. [Google Scholar] [CrossRef]

- Gmoser, R.; Ferreira, J.A.; Lennartsson, P.R.; Taherzadeh, M.J. Filamentous ascomycetes fungi as a source of natural pigments. Fungal Biol. Biotechnol. 2017, 4, 4. [Google Scholar] [CrossRef]

- Narsing Rao, M.P.; Xiao, M.; Li, W.-J. Fungal and Bacterial Pigments: Secondary Metabolites with Wide Applications. Front. Microbiol. 2017, 8, 1113. [Google Scholar] [CrossRef] [PubMed]

- Rao, P.; Bhat, R.V. A comparative study on the synthetic food colours usage in foods procured from urban and rural areas of Hyderabad. Nutr. Food Sci. 2003, 33, 230–234. [Google Scholar] [CrossRef]

- Mittal, J. Permissible Synthetic Food Dyes in India. Resonance 2020, 25, 567–577. [Google Scholar] [CrossRef]

- Oplatowska-Stachowiak, M.; Elliott, C.T. Food colors: Existing and emerging food safety concerns. Crit. Rev. Food Sci. Nutr. 2017, 57, 524–548. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Shao, Y.; Chen, F. Monascus pigments. Appl. Microbiol. Biotechnol. 2012, 96, 1421–1440. [Google Scholar] [CrossRef] [PubMed]

- WHO. Toxicological Evaluation of Certain Food Additives and Contaminants; WHO Food Additives Series; World Health Organization: Geneva, Switzerland, 1991; Volume 28. [Google Scholar]

- Rao, P.; Bhat, R.V.; Sudershan, R.V.; Prasanna Krishna, T. Consumption of synthetic food colours during festivals in Hyderabad, India. Br. Food J. 2005, 107, 276–284. [Google Scholar] [CrossRef]

- Rowe, K.S.; Rowe, K.J. Synthetic food coloring and behavior: A dose response effect in a double-blind, placebo-controlled, repeated-measures study. J. Pediatr. 1994, 125, 691–698. [Google Scholar] [CrossRef]

- Dufossé, L.; Fouillaud, M.; Caro, Y.; Mapari, S.A.; Sutthiwong, N. Filamentous fungi are large-scale producers of pigments and colorants for the food industry. Curr. Opin. Biotechnol. 2014, 26, 56–61. [Google Scholar] [CrossRef]

- Gupta, N.; Poddar, K.; Sarkar, D.; Kumari, N.; Padhan, B.; Sarkar, A. Fruit waste management by pigment production and utilization of residual as bioadsorbent. J. Environ. Manag. 2019, 244, 138–143. [Google Scholar] [CrossRef]

- Aruldass, C.A.; Dufossé, L.; Ahmad, W.A. Current perspective of yellowish-orange pigments from microorganisms—A review. J. Clean. Prod. 2018, 180, 168–182. [Google Scholar] [CrossRef]

- Panesar, R.; Kaur, S.; Panesar, P. Production of microbial pigments utilizing agro-industrial waste: A review. Curr. Opin. Food Sci. 2015, 1, 70–76. [Google Scholar] [CrossRef]

- Tirumale, S.; Wani, N.A. Biopigments: Fungal Pigments; Springer: Singapore, 2018. [Google Scholar]

- Nigam, P.S.; Luke, J.S. Food additives: Production of microbial pigments and their antioxidant properties. Curr. Opin. Food Sci. 2016, 7, 93–100. [Google Scholar] [CrossRef]

- Venil, C.K.; Zakaria, Z.A.; Ahmad, W.A. Bacterial pigments and their applications. Process. Biochem. 2013, 48, 1065–1079. [Google Scholar] [CrossRef]

- Joshi, V.A.; Bala, A.; Bhushan, S. Microbial Pigments. Indian J. Biotechnol. 2003, 2, 362–369. [Google Scholar]

- Chattopadhyay, P.; Chatterjee, S.; Sen, S.K. Biotechnological potential of nature food grade biocolourants. Afr. J. Biotechnol. 2008, 7, 2972–2985. [Google Scholar]

- Lin, L.; Xu, J. Fungal Pigments and Their Roles Associated with Human Health. J. Fungi 2020, 6, 280. [Google Scholar] [CrossRef]

- Tuli, H.S.; Chaudhary, P.; Beniwal, V.; Sharma, A.K. Microbial pigments as natural color sources: Current trends and future perspectives. J. Food Sci. Technol. 2015, 52, 4669–4678. [Google Scholar] [CrossRef] [PubMed]

- Velmurugan, P.; Kim, M.-J.; Park, J.-S.; Karthikeyan, K.; Lakshmanaperumalsamy, P.; Lee, K.-J.; Park, Y.-J.; Oh, B.-T. Dyeing of cotton yarn with five water soluble fungal pigments obtained from five fungi. Fibers Polym. 2010, 11, 598–605. [Google Scholar] [CrossRef]

- Nirlane da Costa Souza, P.; Luiza Bim Grigoletto, T.; Alberto Beraldo de Moraes, L.; Abreu, L.M.; Henrique Souza Guimarães, L.; Santos, C.; Ribeiro Galvão, L.; Gomes Cardoso, P. Production and chemical characterization of pigments in filamentous fungi. Microbiology 2016, 162, 12–22. [Google Scholar] [CrossRef]

- Heo, Y.M.; Kim, K.; Kwon, S.; Na, J.; Lee, H.; Jang, S.; Kim, C.-H.; Jung, J.; Kim, J.-J. Investigation of Filamentous Fungi Producing Safe, Functional Water-Soluble Pigments. Mycobiology 2018, 46, 269–277. [Google Scholar] [CrossRef]

- Mostafa, M.; Abbady, M. Secondary Metabolites and Bioactivity of the Monascus Pigments—Review Article. Glob. J. Biotechnol. Biochem. 2014, 9, 1–13. [Google Scholar]

- Saravanan, A.; Jayasree, R.; Kumar, P.S.; Varjani, S.; Hemavathy, R.; Jeevanantham, S.; Yaashikaa, P.R. Production of pigment using Aspergillus tamarii: New potentials for synthesizing natural metabolites. Environ. Technol. Innov. 2020, 19, 100967. [Google Scholar] [CrossRef]

- Kongsak Boonyapranai, R.T. Sorasak Lhieochaiphant and Suree Phutrakul. Optimization of Submerged Culture for the Production of Naphthoquinones Pigment by Fusarium verticillioides. Chiang Mai J. Sci. 2008, 35, 457–466. [Google Scholar]

- Dufossé, L. Microbial Production of Food Grade Pigments. Food Technol. Biotechnol. 2006, 44, 313–321. [Google Scholar]

- Lagashetti, A.C.; Dufossé, L.; Singh, S.K.; Singh, P.N. Fungal Pigments and Their Prospects in Different Industries. Microorganisms 2019, 7, 604. [Google Scholar] [CrossRef]

- Carvalho, J.C.; Oishi, B.O.; Pandey, A.; Soccol, C. Biopigments from Monascus: Strains selection, citrinin production and color stability. Braz. Arch. Biol. Technol. 2005, 48, 885–894. [Google Scholar] [CrossRef]

- Dufossé, L. 16—Current and Potential Natural Pigments From Microorganisms (Bacteria, Yeasts, Fungi, Microalgae). In Handbook on Natural Pigments in Food and Beverages; Carle, R., Schweiggert, R.M., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 337–354. [Google Scholar] [CrossRef]

- Bezirhan Arikan, E.; Canli, O.; Caro, Y.; Dufossé, L.; Dizge, N. Production of Bio-Based Pigments from Food Processing Industry By-Products (Apple, Pomegranate, Black Carrot, Red Beet Pulps) Using Aspergillus carbonarius. J. Fungi 2020, 6, 240. [Google Scholar] [CrossRef]

- The Joint FAO/WHO Expert Committee on Food Additives. Evaluation of Certain Food Additives and Contaminants. FAO/WHO Expert Committee on Food Additive; World Health Organization: Geneva, Switzerland, 1996; pp. 1–100. [Google Scholar]

- Woutersen, R.A.; Wolterbeek, A.P.; Appel, M.J.; van den Berg, H.; Goldbohm, R.A.; Feron, V.J. Safety evaluation of synthetic beta-carotene. Crit. Rev. Toxicol. 1999, 29, 515–542. [Google Scholar] [CrossRef]

- Cambaza, E. Comprehensive Description of Fusarium graminearum Pigments and Related Compounds. Foods 2018, 7, 165. [Google Scholar] [CrossRef] [PubMed]

- Díaz-Sánchez, V.; Avalos, J.; Limón, M.C. Identification and regulation of fusA, the polyketide synthase gene responsible for fusarin production in Fusarium fujikuroi. Appl. Environ. Microbiol. 2012, 78, 7258–7266. [Google Scholar] [CrossRef] [PubMed]

- Soumya, K.; Narasimha Murthy, K.; Sreelatha, G.L.; Tirumale, S. Characterization of a red pigment from Fusarium chlamydosporum exhibiting selective cytotoxicity against human breast cancer MCF-7 cell lines. J. Appl. Microbiol. 2018, 125, 148–158. [Google Scholar] [CrossRef] [PubMed]

- Menezes, B.S.; Solidade, L.S.; Conceição, A.A.; Santos Junior, M.N.; Leal, P.L.; de Brito, E.S.; Canuto, K.M.; Mendonça, S.; de Siqueira, F.G.; Marques, L.M. Pigment production by Fusarium solani BRM054066 and determination of antioxidant and anti-inflammatory properties. AMB Express 2020, 10, 117. [Google Scholar] [CrossRef] [PubMed]

- Santos, M.C.d.; Mendonça, M.d.L.; Bicas, J.L. Modeling bikaverin production by Fusarium oxysporum CCT7620 in shake flask cultures. Bioresour. Bioprocess. 2020, 7, 13. [Google Scholar] [CrossRef]

- Mohankumari, H.P.; Naidu, K.A.; Narasimhamurthy, K.; Vijayalakshmi, G. Bioactive Pigments of Monascus purpureus Attributed to Antioxidant, HMG-CoA Reductase Inhibition and Anti-atherogenic Functions. Front. Sustain. Food Syst. 2021, 5, 590427. [Google Scholar] [CrossRef]

- Shi, K.; Tang, R.; Huang, T.; Wang, L.; Wu, Z. Pigment fingerprint profile during extractive fermentation with Monascus anka GIM 3.592. BMC Biotechnol. 2017, 17, 46. [Google Scholar] [CrossRef] [PubMed]

- Darwesh, O.M.; Matter, I.A.; Almoallim, H.S.; Alharbi, S.A.; Oh, Y.-K. Isolation and Optimization of Monascus ruber OMNRC45 for Red Pigment Production and Evaluation of the Pigment as a Food Colorant. Appl. Sci. 2020, 10, 8867. [Google Scholar] [CrossRef]

- Mapari, S.A.S.; Meyer, A.S.; Thrane, U.; Frisvad, J.C. Identification of potentially safe promising fungal cell factories for the production of polyketide natural food colorants using chemotaxonomic rationale. Microb. Cell Factories 2009, 8, 24. [Google Scholar] [CrossRef] [PubMed]

- Mapari, S.A.S.; Meyer, A.S.; Thrane, U.; Frisvad, J. Production of Monascus-like Pigments. European Patent EP2262862B1, 28 March 2012. [Google Scholar]

- Khan, A.A.; Iqubal, S.S.; Shaikh, I.A.; Niyongabo Niyonzima, F.; More, V.S.; Muddapur, U.M.; Bennur, R.S.; More, S.S. Biotransformation of longifolene by Penicillium europium. Biocatal. Biotransform. 2021, 39, 41–47. [Google Scholar] [CrossRef]

- Sopandi, T.; Wardah, W. Sub-Acute Toxicity of Pigment Derived from Penicillium resticulosum in Mice. Microbiol. Indones. 2012, 6, 6. [Google Scholar] [CrossRef]

- Krishnamurthy, S.; Narasimha Murthy, K.; Thirumale, S. Characterization of ankaflavin from Penicillium aculeatum and its cytotoxic properties. Nat. Prod. Res. 2020, 34, 1630–1635. [Google Scholar] [CrossRef]

- Gopal Pandit, S.; Honganoor Puttananjaiah, M.; Serva Peddha, M.; Appasaheb Dhale, M. Corrigendum to ‘Safety efficacy and chemical profiling of water-soluble Talaromyces purpureogenus CFRM02 pigment’ [Food Chem. 310 (2020) 125869]. Food Chem. 2020, 317, 126403. [Google Scholar] [CrossRef]

- Poorniammal, R.; Gunasekaran, S.; Sriharasivakumar, H. Toxicity evaluation of funfal food colourant from Thermomyces sp in albino mice. J. Sci. Ind. Res. 2011, 70, 773–777. [Google Scholar]

- Almurshidi, B.H.; Van Court, R.C.; Vega Gutierrez, S.M.; Harper, S.; Harper, B.; Robinson, S.C. Preliminary Examination of the Toxicity of Spalting Fungal Pigments: A Comparison between Extraction Methods. J. Fungi 2021, 7, 155. [Google Scholar] [CrossRef] [PubMed]

- Latha, B.V.; Jeevaratanm, K. Thirteen-week oral toxicity study of carotenoid pigment from Rhodotorula glutinis DFR-PDY in rats. Indian J. Exp. Biol. 2012, 50, 645–651. [Google Scholar]

- Naidu, K.A.; Venkateswaran, G.; Vijayalakshmi, G.; Manjula, K.; Viswanatha, S.; Murthy, K.N.; Srinivas, L.; Joseph, R. Toxicological assessment of the yeast Rhodotorula gracilis in experimental animals. Z. Für Lebensm. Und Forsch. A 1999, 208, 444–448. [Google Scholar] [CrossRef]

- Kot, A.M.; Błażejak, S.; Gientka, I.; Kieliszek, M.; Bryś, J. Torulene and torularhodin: “new” fungal carotenoids for industry? Microb. Cell Fact. 2018, 17, 49. [Google Scholar] [CrossRef] [PubMed]

- Groenewald, M.; Boekhout, T.; Neuvéglise, C.; Gaillardin, C.; van Dijck, P.W.; Wyss, M. Yarrowia lipolytica: Safety assessment of an oleaginous yeast with a great industrial potential. Crit. Rev. Microbiol. 2014, 40, 187–206. [Google Scholar] [CrossRef] [PubMed]

- Venkatesh, K.S. Strain and Process Improvement for Polygalacturonase Production by Aspergillus carbonarius. Ph.D. Thesis, University of Mysore, Mysore, India, 2004. [Google Scholar]

- Narendrababu, B.N.; Shishupala, S. Spectrophotometric detection of pigments from Aspergillus and Penicillium isolates. J. Appl. Biol. Biotechnol. 2017, 5, 53–58. [Google Scholar] [CrossRef]

- Sanjay, K.R.; Kumaresan, N.; Akhilender Naidu, K.; Viswanatha, S.; Narasimhamurthy, K.; Umesh Kumar, S.; Vijayalakshmi, G. Safety evaluation of pigment containing Aspergillus carbonarius biomass in albino rats. Food Chem. Toxicol. 2007, 45, 431–439. [Google Scholar] [CrossRef]

- Mantzouridou, F.; Tsimidou, M.Z. On the monitoring of carotenogenesis by Blakeslea trispora using HPLC. Food Chem. 2007, 104, 439–444. [Google Scholar] [CrossRef]

- Sen, T.; Barrow, C.J.; Deshmukh, S.K. Microbial Pigments in the Food Industry-Challenges and the Way Forward. Front. Nutr. 2019, 6, 7. [Google Scholar] [CrossRef]

- Papaioannou, E.H.; Liakopoulou-Kyriakides, M. Substrate contribution on carotenoids production in Blakeslea trispora cultivations. Food Bioprod. Process. 2010, 88, 305–311. [Google Scholar] [CrossRef]

- Papadaki, E.; Mantzouridou, F. Natural ²-Carotene Production by Blakeslea trispora Cultivated in Spanish-Style Green Olive Processing Wastewaters. Foods 2021, 10, 327. [Google Scholar] [CrossRef]

- Finkelstein, M.; Huang, C.C.; Byng, G.S.; Tsau, B.R.; Leach, J. Blakeslea Trispora Mated Culture Capable of Increased Beta-carotene Production. U.S. Patent US5422247A, 6 June 1995. [Google Scholar]

- Nabae, K.; Ichihara, T.; Hagiwara, A.; Hirota, T.; Toda, Y.; Tamano, S.; Nishino, M.; Ogasawara, T.; Sasaki, Y.; Nakamura, M.; et al. A 90-day oral toxicity study of beta-carotene derived from Blakeslea trispora, a natural food colorant, in F344 rats. Food Chem. Toxicol. 2005, 43, 1127–1133. [Google Scholar] [CrossRef] [PubMed]

- Tudzynski, B. Gibberellin biosynthesis in fungi: Genes, enzymes, evolution, and impact on biotechnology. Appl. Microbiol. Biotechnol. 2005, 66, 597–611. [Google Scholar] [CrossRef]

- Avalos, J.; Prado-Cabrero, A.; Estrada, A.F. Neurosporaxanthin production by Neurospora and Fusarium. Methods Mol. Biol. 2012, 898, 263–274. [Google Scholar] [CrossRef]

- Ma, J.; Li, Y.; Ye, Q.; Li, J.; Hua, Y.; Ju, D.; Zhang, D.; Cooper, R.; Chang, M. Constituents of red yeast rice, a traditional Chinese food and medicine. J. Agric. Food Chem. 2000, 48, 5220–5225. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; He, Y.; Zhou, Y.; Shao, Y.; Feng, Y.; Li, M.; Chen, F. Edible Filamentous Fungi from the Species Monascus: Early Traditional Fermentations, Modern Molecular Biology, and Future Genomics. Compr. Rev. Food Sci. Food Saf. 2015, 14, 555–567. [Google Scholar] [CrossRef]

- Kallscheuer, N. Engineered Microorganisms for the Production of Food Additives Approved by the European Union—A Systematic Analysis. Front. Microbiol. 2018, 9, 1746. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Y.; Yi, T.; Zhao, M.; Xie, N.; Lei, M.; Liu, Q.; Shao, Y.; Chen, F. Identification and role analysis of an intermediate produced by a polygenic mutant of Monascus pigments cluster in Monascus ruber M7. Appl. Microbiol. Biotechnol. 2016, 100, 7037–7049. [Google Scholar] [CrossRef]

- Blanc, P.J.; Loret, M.O.; Goma, G. Production of citrinin by various species ofMonascus. Biotechnol. Lett. 1995, 17, 291–294. [Google Scholar] [CrossRef]

- Gunasekaran Sanjeevi, P.R. Optimization of fermentation conditions for red pigment production from Penicillium sp. under submerged cultivation. Afr. J. Biotechnol. 2008, 7, 1894–1898. [Google Scholar] [CrossRef]

- Sardaryan, E.; Zihlova, H.; Strnad, R.; Cermakova, Z. Arpink red—meet a new natural red food colourant of microbial origin. In Pigments in Food, More Than Colours; Elsevier: Amsterdam, TheNetherlands, 2004; pp. 207–208. [Google Scholar]

- Kojima, R.; Arai, T.; Matsufuji, H.; Kasumi, T.; Watanabe, T.; Ogihara, J. The relationship between the violet pigment PP-V production and intracellular ammonium level in Penicillium purpurogenum. AMB Express 2016, 6, 43. [Google Scholar] [CrossRef]

- Corrêia Gomes, D.; Takahashi, J.A. Sequential fungal fermentation-biotransformation process to produce a red pigment from sclerotiorin. Food Chem. 2016, 210, 355–361. [Google Scholar] [CrossRef] [PubMed]

- Visagie, C.M.; Houbraken, J.; Frisvad, J.C.; Hong, S.B.; Klaassen, C.H.W.; Perrone, G.; Seifert, K.A.; Varga, J.; Yaguchi, T.; Samson, R.A. Identification and nomenclature of the genus Penicillium. Stud. Mycol. 2014, 78, 343–371. [Google Scholar] [CrossRef]

- Khan, A.A.; Alshabi, A.M.; Alqahtani, Y.S.; Alqahtani, A.M.; Bennur, R.S.; Shaikh, I.A.; Muddapur, U.M.; Iqubal, S.M.S.; Mohammed, T.; Dawoud, A.; et al. Extraction and identification of fungal pigment from Penicillium europium using different spectral studies. J. King Saud Univ. Sci. 2021, 33, 101437. [Google Scholar] [CrossRef]

- Sethi, B.K.P.; Parida, P.; Sahoo, S.L.; Dikshit, B.; Pradhan, C.; Sena, S.; Behera, B.C. Extracellular production and characterization of red pigment from Penicillium purpurogenum BKS9. Alger. J. Nat. Prod. 2016, 4, 379–392. [Google Scholar]

- Pandit, S.G.; Puttananjaih, M.H.; Harohally, N.V.; Dhale, M.A. Functional attributes of a new molecule-2-hydroxymethyl-benzoic acid 2’-hydroxy-tetradecyl ester isolated from Talaromyces purpureogenus CFRM02. Food Chem. 2018, 255, 89–96. [Google Scholar] [CrossRef]

- Poorniammal, R.; Gunasekaran, S.; Gnanasambandam, A.V.; Murugesan, R. Process of Extracting Yellow Pigment from Thermomyces sp. Indian Patent 304979, 15 December 2018. [Google Scholar]

- Somasundaram, T.; Rao, S.S.R.; Maheswari, R. Pigments in Thermophilic fungi. Curr. Sci. 1986, 55, 957–960. [Google Scholar]

- Poorniammal, R.; Balachandar, D.; Gunasekaran, S. Evaluation of antioxidant property of some fungal pigments by DNA protection assay. Ann. Phytomedicine 2018, 7, 106–111. [Google Scholar] [CrossRef]

- Poorniammal, R.; Gunasekaran, S.; Murugesan, R. In Vivo Antioxidant Activities of Thermomyces sp Pigment in Albino Mice. Int. J. Agric. Environ. Biotechnol. 2014, 7, 355–360. [Google Scholar] [CrossRef]

- Poorniammal, R.; Prabhu, S.; Sakthi, A.R. Evaluation of In Vitro antioxidant activity of fungal pigments. Pharma Innov. 2019, 8, 326–330. [Google Scholar]

- Chitale, A.; Jadhav, D.V.; Waghmare, S.R.; Sahoo, A.K.; Ranveer, R.C. Production and characterization of brown coloured pigment from Trichoderma viride. Electron. J. Environ. Agric. Food Chem. 2012, 11, 529–537. [Google Scholar]

- Vega Gutierrez, S.M.; Stone, D.W.; He, R.; Vega Gutierrez, P.T.; Walsh, Z.M.; Robinson, S.C. Potential Use of the Pigments from Scytalidium cuboideum and Chlorociboria aeruginosa to Prevent ‘Greying’ Decking and Other Outdoor Wood Products. Coatings 2021, 11, 511. [Google Scholar] [CrossRef]

- Perkins, D.D.; Davis, R.H. Evidence for safety of Neurospora species for academic and commercial uses. Appl. Environ. Microbiol. 2000, 66, 5107–5109. [Google Scholar] [CrossRef] [PubMed]

- Priatni, S. Review: Potential production of carotenoids from Neurospora. Nusant. Biosci. 2016, 6, 63–68. [Google Scholar]

- Gaffoor, I.; Brown, D.W.; Plattner, R.; Proctor, R.H.; Qi, W.; Trail, F. Functional analysis of the polyketide synthase genes in the filamentous fungus Gibberella zeae (anamorph Fusarium graminearum). Eukaryot. Cell 2005, 4, 1926–1933. [Google Scholar] [CrossRef] [PubMed]

- Poorniammal, R.; Sarathambal, C.; Sakthi, A.R.; Arun, S. Yeast carotenoids importance in food and feed industries and its health benefits. Agric. Rev. 2013, 34, 307–312. [Google Scholar] [CrossRef]

- Bogacz-Radomska, L.; Harasym, J. β-Carotene—properties and production methods. Food Qual. Saf. 2018, 2, 69–74. [Google Scholar] [CrossRef]

- Bhosale, P.B.; Gadre, R.V. Production of beta-carotene by a mutant of Rhodotorula glutinis. Appl. Microbiol. Biotechnol. 2001, 55, 423–427. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Guo, L.; Xia, Y.; Zhuang, X.; Chu, W. Isolation, Identification of Carotenoid-Producing Rhodotorula sp. from Marine Environment and Optimization for Carotenoid Production. Mar. Drugs 2019, 17, 161. [Google Scholar] [CrossRef] [PubMed]

- Bhosale, P.; Motiwale, L.; Ingle, A.D.; Gadre, R.V.; Rao, K.V.K. Protective effect of Rhodotorulaglutinis NCIM 3353 on the development of hepatic preneoplastic lesions. Curr. Sci. 2002, 83, 303–308. [Google Scholar]

- Ben Tahar, I.; Kus-Liśkiewicz, M.; Lara, Y.; Javaux, E.; Fickers, P. Characterization of a nontoxic pyomelanin pigment produced by the yeast Yarrowia lipolytica. Biotechnol. Prog. 2020, 36, e2912. [Google Scholar] [CrossRef]

- Grenfell-Lee, D.; Zeller, S.; Cardoso, R.; Pucaj, K. The safety of β-carotene from Yarrowia lipolytica. Food Chem. Toxicol. 2014, 65, 1–11. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).