Viscoelastic Characterization of Corn Starch Paste: (I) The First Normal Stress Difference of a Cross-Linked Waxy Corn Starch Paste with Sucrose

Abstract

1. Introduction

2. Materials and Methods

2.1. Corn Starch Paste

2.2. Viscoelastic Model

2.3. Characterization of Viscoelastic Property

3. Results and Discussion

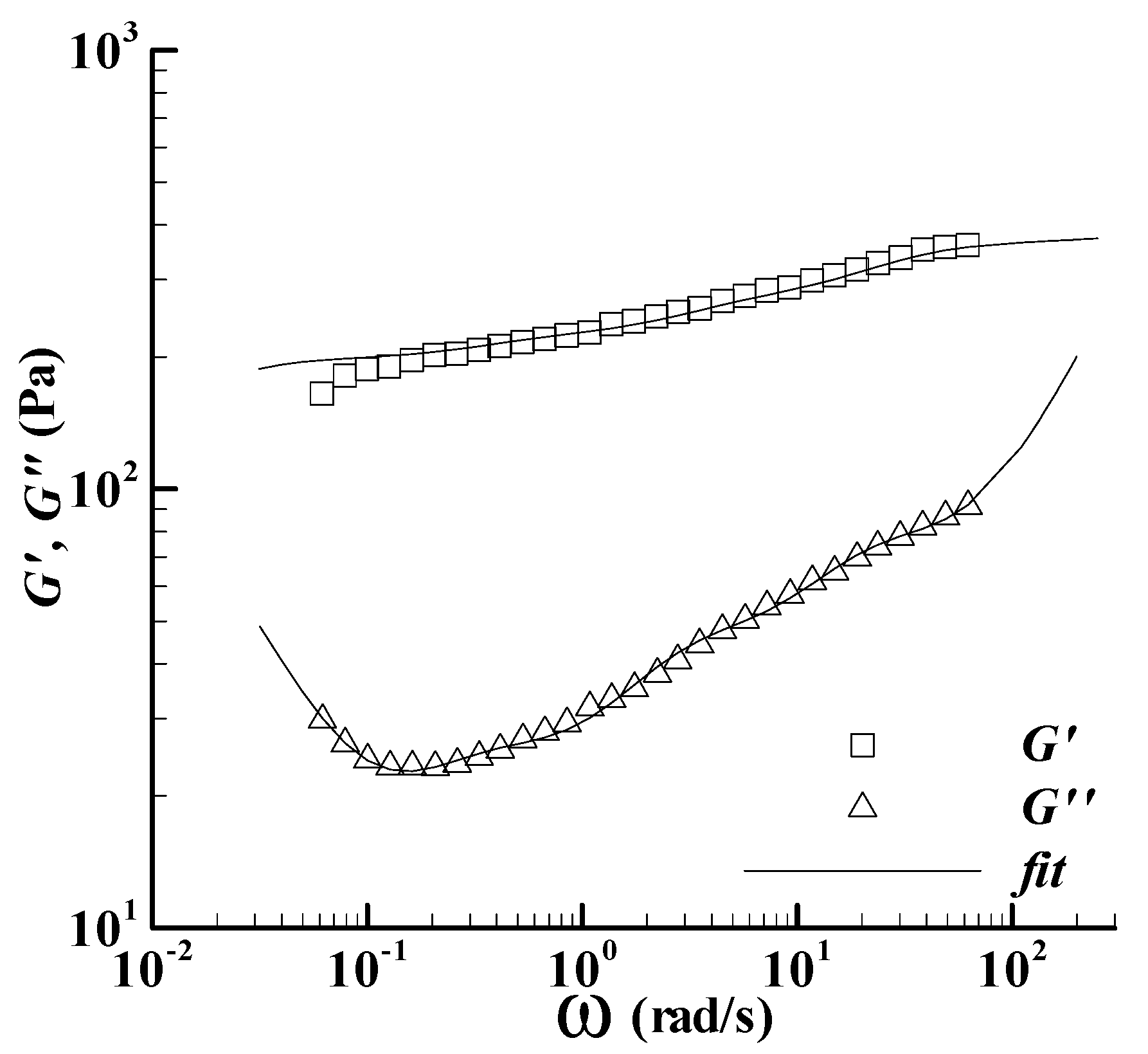

3.1. Linear Viscoelastic Property

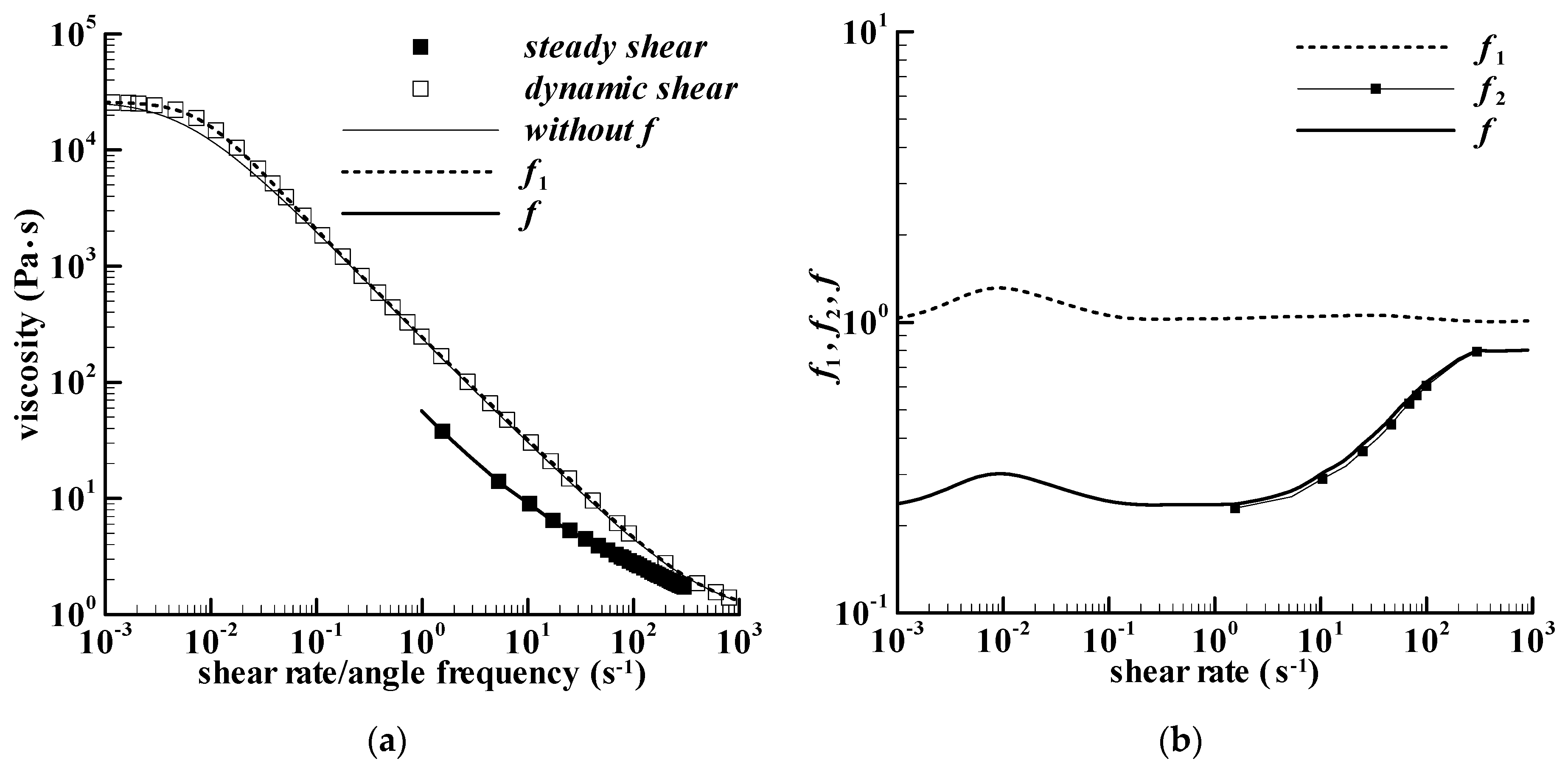

3.2. Viscosity

3.3. First Normal Stress Difference

3.3.1. Prediction

3.3.2. Characterization

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Alloncle, M.; Doublier, J.L. Viscoelastic properties of maize starch/hydrocolloid pastes and gels. Food Hydrocoll. 1991, 5, 455–467. [Google Scholar] [CrossRef]

- Hirashima, M.; Takahashi, R.; Nishinari, K. Changes in the viscoelasticity of maize starch pastes by adding sucrose at different stages. Food Hydrocoll. 2005, 19, 777–784. [Google Scholar] [CrossRef]

- Loisel, C.; Maache-Rezzoug, Z.; Esneault, C.; Doublier, J.L. Effect of hydrothermal treatment on the physical and rheological properties of maize starches. J. Food Eng. 2006, 73, 45–54. [Google Scholar] [CrossRef]

- Ma, S.; Zhu, P.; Wang, M. Effects of konjac glucomannan on pasting and rheological properties of corn starch. Food Hydrocoll. 2019, 89, 234–240. [Google Scholar] [CrossRef]

- Luo, Y.; Shen, M.; Han, X.; Wen, H.; Xie, J. Gelation characteristics of Mesona chinensis polysaccharide-maize starches gels: Influences of KCl and NaCl. J. Cereal Sci. 2020, 96, 103108. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Li, D.; Özkan, N.; Chen, X.; Mao, Z. Effect of flaxseed gum addition on rheological properties of native maize starch. J. Food Eng. 2008, 89, 87–92. [Google Scholar] [CrossRef]

- Tecante, A.; Doublier, J.L. Steady flow and viscoelastic behavior of crosslinked waxy corn starch-k-carrageenan pastes and gels. Carbohydr. Polym. 1999, 40, 221–231. [Google Scholar] [CrossRef]

- Tattiyakul, J.; Rao, M.A. Rheological behavior of cross-linked waxy maize starch dispersions during and after heating. Carbohydr. Polym. 2000, 43, 215–222. [Google Scholar] [CrossRef]

- Luo, Y.; Shen, M.; Li, E.; Xiao, Y.; Wen, H.; Ren, Y.; Xie, J. Effect of Mesona chinensis polysaccharide on pasting, rheological and structural properties of corn starches varying in amylose contents. Carbohydr. Polym. 2020, 230, 115713. [Google Scholar] [CrossRef]

- Rao, M.A.; Okechukwu, P.E.; Da Silva, P.M.S.; Oliveira, J.C. Rheological behavior of heated starch dispersions in excess water: Role of starch granule. Carbohydr. Polym. 1997, 33, 273–283. [Google Scholar] [CrossRef]

- Da Silva, P.M.S.; Oliveira, J.C.; Rao, M.A. The effect of granule size distribution on the rheological behavior of heated modified and unmodified maize starch dispersions. J. Texture Stud. 1997, 28, 123–138. [Google Scholar]

- Li, H.; Zhang, H.; Zhao, C.; Zhang, S.; Guo, H.; Liu, J. Effect of cellulose and polydextrose on gelatinization and rheological properties of corn starch. Food Ind. 2018, 39, 59–64. (In Chinese) [Google Scholar]

- Wang, B.; Li, D.; Wang, L.J.; Özkan, N. Anti-thixotropic properties of waxy maize starch dispersions with different pasting conditions. Carbohydr. Polym. 2010, 79, 1130–1139. [Google Scholar] [CrossRef]

- Ptaszek, P.; Grzesik, M. Viscoelastic properties of maize starch and guar gum gels. J. Food Eng. 2007, 82, 227–237. [Google Scholar] [CrossRef]

- Huang, S. Structural viscoelasticity of a water-soluble polysaccharide extract. Int. J. Biol. Macromol. 2018, 120, 1601–1609. [Google Scholar] [CrossRef]

- Huang, S. Corrigendum to “Structural viscoelasticity of a water-soluble polysaccharide extract” [Int. J. Biol. Macromol. 120 (2018) 1601–1609]. Int. J. Biol. Macromol. 2021, 193, 2389. [Google Scholar] [CrossRef]

- Huang, S. Viscoelastic characterization of the mucus from the skin of loach. Korea-Aust. Rheol. J. 2021, 33, 1–9. [Google Scholar] [CrossRef]

- Acquarone, V.M.; Rao, M.A. Influence of sucrose on the rheology and granule size of cross-linked waxy maize starch dispersions heated at two temperatures. Carbohydr. Polym. 2003, 51, 451–458. [Google Scholar] [CrossRef]

- Achayuthakan, P.; Suphantharika, M. Pasting and rheological properties of waxy corn starch as affected by guar gum and xanthan gum. Carbohydr. Polym. 2008, 71, 9–17. [Google Scholar] [CrossRef]

- Wang, B.; Wang, L.; Li, D.; Özkan, N.; Li, S.J.; Mao, Z.H. Rheological properties of waxy maize starch and xanthan gum mixtures in the presence of sucrose. Carbohydr. Polym. 2009, 77, 472–481. [Google Scholar] [CrossRef]

- Chen, L.; Tian, Y.; Bai, Y.; Wang, J.; Jiao, A.; Jin, Z. Effect of frying on the pasting and rheological properties of normal maize starch. Food Hydrocoll. 2018, 77, 85–95. [Google Scholar] [CrossRef]

- Romero-Bastida, C.A.; Gutiérrez, M.C.; Bello-Pérez, L.A.; Abarca-Ramírez, E.; Velazquez, G.; Mendez-Montealvo, G. Rheological properties of nanocomposite-forming solutions and film based on montmorillonite and corn starch with different amylose content. Carbohydr. Polym. 2018, 188, 121–127. [Google Scholar] [CrossRef] [PubMed]

- Meister, B.J. An integral constitutive equation based on molecular network theory. Trans. Soc. Rheol. 1971, 15, 63–89. [Google Scholar] [CrossRef]

- Rivlin, R.S.; Sawyers, K.N. Nonlinear continuum mechanics of viscoelastic fluids. Annu. Rev. Fluid Mech. 1971, 3, 117–146. [Google Scholar] [CrossRef]

- Bird, R.B.; Armstrong, R.C.; Hassager, O. Dynamics of Polymeric Fluids, Fluid Mechanics, 2nd ed.; Wiley: New York, NY, USA, 1987; Volume 1, pp. 273, 436–437. [Google Scholar]

- Huang, S. Viscoelastic characterization and prediction of a wormlike micellar solution. Acta Mech. Sin. 2021, 37, 1648–1658. [Google Scholar] [CrossRef]

- Xu, S. Fortran Codes for Common Numerical Method, 2nd ed.; Qinghua University Press: Beijing, China, 1995; pp. 236–237. (In Chinese) [Google Scholar]

- Marques, D.M.C.; Silva, J.C.; Serro, A.P.; Cabral, J.M.S.; Sanjuan-Alberte, P.; Ferreira, F.C. 3D bioprinting of novel κ-carrageenan bioinks: An algae-derived polysaccharide. Bioengineering 2022, 9, 109. [Google Scholar] [CrossRef]

- Laun, H.M. Description of the non-linear shear behaviour of a low density polyethylene melt by means of an experimentally determined strain dependent memory function. Rheol. Acta 1978, 17, 1–15. [Google Scholar] [CrossRef]

| No. | Material * | Experiment ** | Theory *** | Ref. |

|---|---|---|---|---|

| 1 | CWCS | G′-ω, G″-ω, η-, η-t | power law, HB | [10] |

| 2 | CWCS | G′-ω, G″-ω, η-, η-t | power law | [9] |

| 3 | CWCS, sucrose | G′-ω, G″-ω, η-, N1- | power law | [18] |

| 4 | WCS, guar, xanthan | G′-ω, G″-ω, η-, multi η-t | power law | [19] |

| 5 | WCS, xanthan, sucrose | G′-ω, G″-ω, η-, η-t, multi η-t | power law | [20] |

| 6 | NCS, WCS | G′-ω, G″-ω, η-, η-t, multi η-t | power law | [13] |

| 7 | NCS, oil, water | G′-ω, G″-ω, η-, J-t | HB, Burgers | [21] |

| 8 | NCS, HACS | G′-ω, G″-ω, η-, r-t | power law | [22] |

| 9 | NCS, cellulose, polydextrose | G′-ω, G″-ω, η-, multi η-t | HB | [12] |

| i | λi (s) | gi (Pa) |

|---|---|---|

| 1 | 9.903 × 10−5 | 9.560 × 103 |

| 2 | 4.146 × 10−2 | 8.914 × 101 |

| 3 | 2.977 × 10−1 | 5.166 × 101 |

| 4 | 2.662 × 100 | 2.782 × 101 |

| 5 | 1.303 × 102 | 1.990 × 102 |

| Sample | Equation (7) | Equation (8) | |

|---|---|---|---|

| k | n | k | |

| 85 °C | 2.074 | 0.945 | 1.733 |

| 110 °C | 1.701 | 1.053 | 2.024 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S. Viscoelastic Characterization of Corn Starch Paste: (I) The First Normal Stress Difference of a Cross-Linked Waxy Corn Starch Paste with Sucrose. Bioengineering 2022, 9, 465. https://doi.org/10.3390/bioengineering9090465

Huang S. Viscoelastic Characterization of Corn Starch Paste: (I) The First Normal Stress Difference of a Cross-Linked Waxy Corn Starch Paste with Sucrose. Bioengineering. 2022; 9(9):465. https://doi.org/10.3390/bioengineering9090465

Chicago/Turabian StyleHuang, Shuxin. 2022. "Viscoelastic Characterization of Corn Starch Paste: (I) The First Normal Stress Difference of a Cross-Linked Waxy Corn Starch Paste with Sucrose" Bioengineering 9, no. 9: 465. https://doi.org/10.3390/bioengineering9090465

APA StyleHuang, S. (2022). Viscoelastic Characterization of Corn Starch Paste: (I) The First Normal Stress Difference of a Cross-Linked Waxy Corn Starch Paste with Sucrose. Bioengineering, 9(9), 465. https://doi.org/10.3390/bioengineering9090465