Experimental Study to Evaluate the Wear Performance of UHMWPE and XLPE Material for Orthopedics Application

Abstract

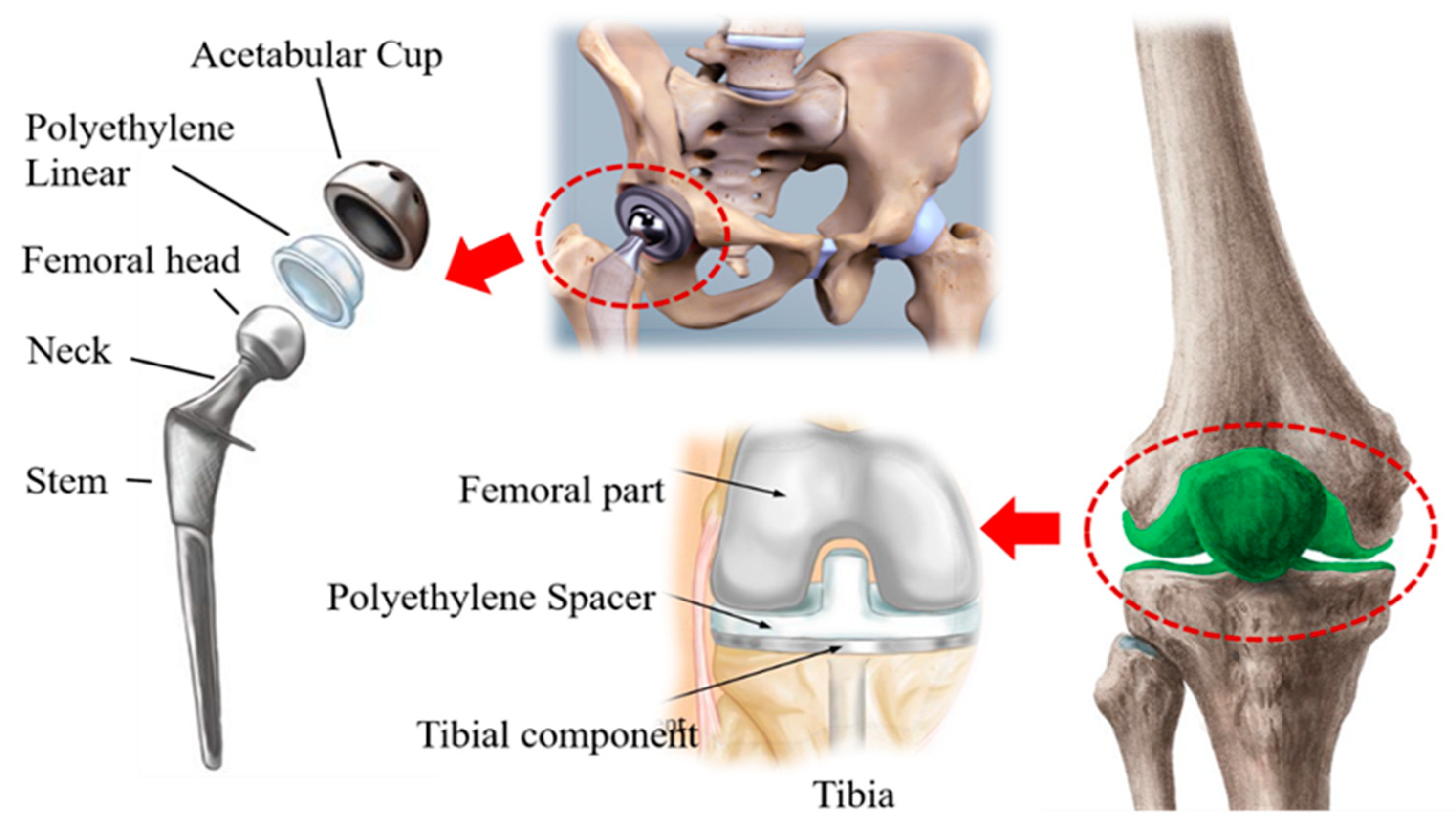

1. Introduction

2. Recent Developments in Biomechanical Tribology

3. Experimental Procedure and Problem Definition

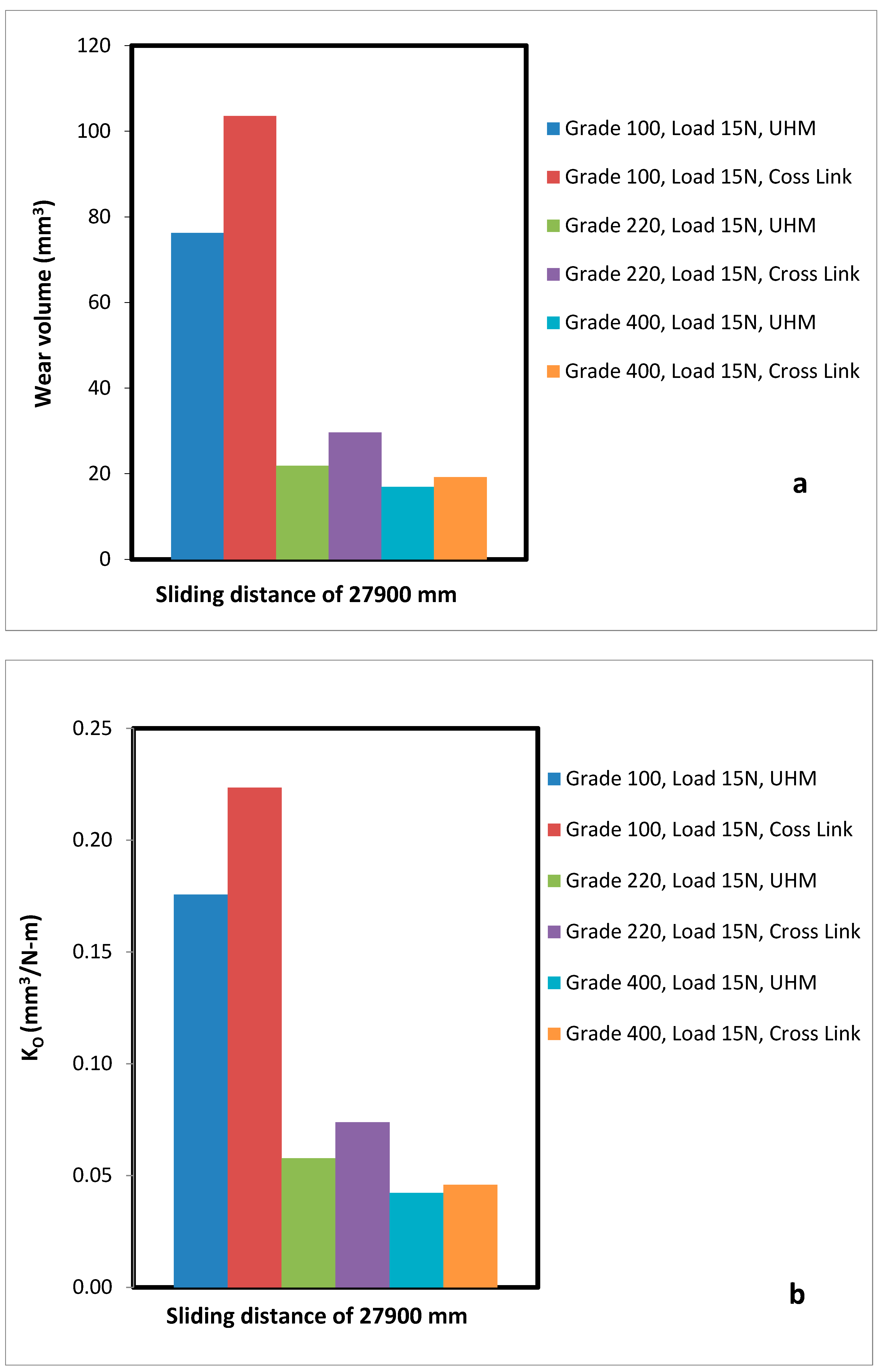

4. Results and Discussions

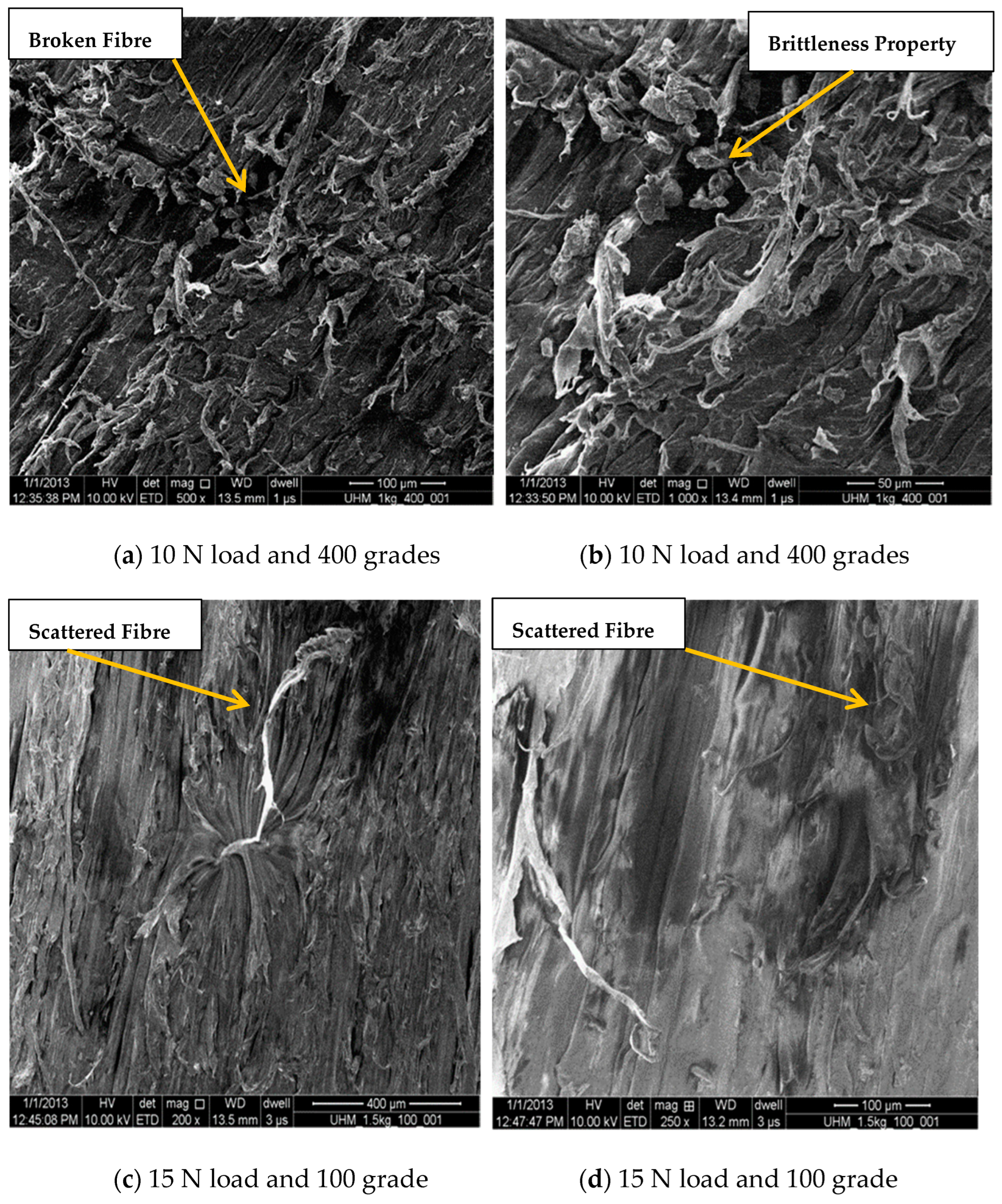

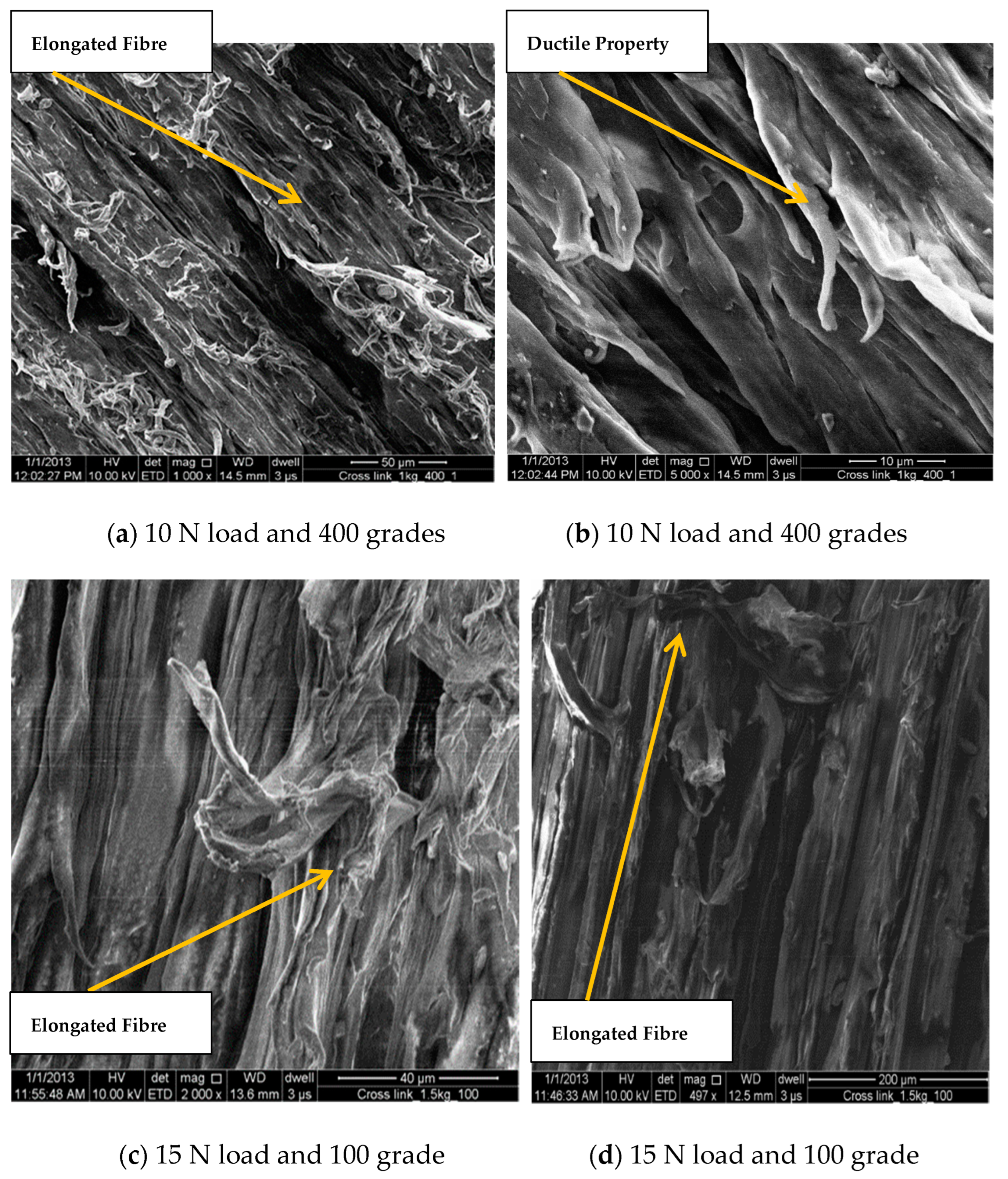

Micrographic Examination (SEM Test)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti-based biomaterials, the ultimate choice for orthopedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Ramakrishna, S.; Mayer, J.; Wintermantel, E.; Leong Kam, W. Biomedical applications of polymer-composite materials: A review. Compos. Sci. Technol. 2001, 61, 224–1189. [Google Scholar] [CrossRef]

- Wise, D.L. Biomaterials Engineering and Devices; Humana Press: Berlin, Germany, 2000; pp. 205–319. [Google Scholar]

- Kumar, A.; Datta, A.; Kumar, A. Recent Advancements and Future Trends in Next-Generation Materials for Biomedical Applications. In Advanced Materials for Biomedical Applications; Kumar, A., Gori, Y., Kumar, A., Meena, C.S., Dutt, N., Eds.; CRC Press: Boca Raton, FL, USA, 2022; Chapter 1; pp. 1–19. [Google Scholar] [CrossRef]

- Prasad, A.; Sankar, M.R.; Katiyar, V. State of Art on Solvent Casting Particulate Leaching Method for Orthopedic Scaffolds Fabrication. Mater. Today Proc. 2017, 4, 898–907. [Google Scholar] [CrossRef]

- Gupta, A.; Prasad, A.; Mulchandani, N.; Shah, M.; Ravi Sankar, M.; Kumar, S.; Katiyar, V. Multifunctional Nanohydroxyapatite-Promoted Toughened High-Molecular-Weight Stereocomplex Poly (lactic acid)-Based Bionanocomposite for Both 3D-Printed Orthopedic Implants and High-Temperature Engineering Applications. ACS Omega 2017, 2, 4039–4052. [Google Scholar] [CrossRef]

- Mulchandani, N.; Prasad, A.; Katiyar, V. Resorbable polymers in bone repair and regeneration. In Materials for Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Prasad, A. Bioabsorbable polymeric materials for biofilms and other biomedical applications: Recent and future trends. Mater. Today Proc. 2021, 44, 2447–2453. [Google Scholar] [CrossRef]

- Prasad, A.; Chakraborty, G.; Kumar, A. Bio-based Environmentally Benign Polymeric Resorbable Materials for Orthopedic Fixation Applications. In Advanced Materials for Biomedical Applications; Kumar, A., Gori, Y., Kumar, A., Meena, C.S., Dutt, N., Eds.; CRC Press: Boca Raton, FL, USA, 2022; Chapter 15; pp. 251–266. [Google Scholar] [CrossRef]

- Prasad, A.; Bhasney, S.; Katiyar, V.; Sankar, M.R. Biowastes Processed Hydroxyapatite filled Poly (Lactic acid) Bio-Composite for Open Reduction Internal Fixation of Small Bones. Mater. Today Proc. 2017, 4, 10153–10157. [Google Scholar] [CrossRef]

- Prasad, A.; Devendar, B.; Sankar, M.R.; Robi, P.S. Micro-Scratch Based Tribological Characterization of Hydroxyapatite (HAp) Fabricated through Fish Scales. Mater. Today Proc. 2015, 2, 1216–1224. [Google Scholar] [CrossRef]

- Patil, P.P.; Sharma, S.C.; Jaiswal, H.; Kumar, A. Modeling Influence of Tube Material on Vibration based EMMFS using ANFIS. Procedia Mater. Sci. 2014, 6, 1097–1103. [Google Scholar] [CrossRef][Green Version]

- Heisel, C.; Silva, M.; dela Rosa, M.; Schmalzried, T. Short-term in vivo wear of cross-linked polyethylene. J. Bone Jt. Surg. 2004, 86, 748–751. [Google Scholar] [CrossRef]

- Bitsch, R.G.; Loidolt, T.; Heisel, C.; Ball, S.; Schmalzried, T.P. Reduction of Osteolysis with Use of Marathon Cross-Linked Polyethylene. J. Bone Jt. Surg. 2008, 90, 1487–1491. [Google Scholar] [CrossRef]

- Kurtz, S.; Ong, K.; Lau, E.; Mowat, F.; Halpern, M. Projections of primary and revision hip and knee arthroplasty in the United States from 2005 to 2030. J. Bone Jt. Surg. 2007, 89, 780–785. [Google Scholar] [CrossRef]

- Datta, A.; Kumar, A.; Kumar, A.; Kumar, A.; Singh, V.P. Advanced Materials in Biological Implants and Surgical Tools. In Advanced Materials for Biomedical Applications; Kumar, A., Gori, Y., Kumar, A., Meena, C.S., Dutt, N., Eds.; CRC Press: Boca Raton, FL, USA, 2022; Chapter 2; pp. 21–43. [Google Scholar] [CrossRef]

- Kumar, A.; Gangwar, A.K.S.; Kumar, A.; Meena, C.S.; Singh, V.P.; Dutt, N.; Prasad, A.; Gori, Y. Biomedical Study of Femur Bone Fracture and healing. In Advanced Materials for Biomedical Applications; Kumar, A., Gori, Y., Kumar, A., Meena, C.S., Dutt, N., Eds.; CRC Press: Boca Raton, FL, USA, 2022; Chapter 14; pp. 235–250. [Google Scholar] [CrossRef]

- Harsha, A.P.; Joyce, T.J. Challenges associated with using bovine serum in wear testing orthopedic biopolymers. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2011, 225, 948–958. [Google Scholar] [CrossRef]

- Kurtz, S.M. The UHMWPE Handbook: Ultra-High Molecular Weight Polyethylene in Total Joint Replacement; Elsevier Academic Press: New York, NY, USA, 2005. [Google Scholar]

- Harris, W.H. Osteolysis and particle disease in hip replacement: A review. Acta Orthop. 1994, 65, 113–123. [Google Scholar] [CrossRef] [PubMed]

- Sochart, D.H. Relationship of acetabular wear to osteolysis and loosening into total hip arthroplasty. Clin. Orthop. 1999, 363, 135–150. [Google Scholar] [CrossRef]

- Bradford, L.; Kurland, M.; Sankaran, H.; Kim, H.; Pruitt, L.; Ries, M. Early failure due to osteolysis in highly crosslinked ultra-high molecular weight polyethylene: A case report. J. Bone Jt. Surg. Am. 2004, 86, 1051–1056. [Google Scholar] [CrossRef]

- Halley, D.; Glassman, A.; Crowninshield, R.D. Recurrent dislocation after revision total hip replacement with a large prosthetic femoral head: A case report. J. Bone Jt. Surg. 2004, 86, 827–830. [Google Scholar] [CrossRef]

- Pruitt, L.A. Deformation, yielding, fracture and fatigue behavior of conventional and highly crosslinked ultra-high molecular weight polyethylene. Biomaterials 2005, 26, 905–915. [Google Scholar] [CrossRef]

- Rimnac, C.M.; Kurtz, S.M. Ionizing radiation and orthopedic prostheses. Nucl. Instrum. Methods Phys. Res. B 2005, 236, 30–37. [Google Scholar] [CrossRef]

- Glyn-Jones, S.; Isaac, S.; Hauptfleisch, J.; McLardy-Smith, P.; Murray, D.W.; Gill, H. Does Highly Cross-Linked Polyethylene Wear Less Than Conventional Polyethylene in Total Hip Arthroplasty? A Double-Blind, Randomized, and Controlled Trial Using Roentgen Stereophotogrammetric Analysis. J. Arthroplast. 2008, 23, 337–343. [Google Scholar] [CrossRef]

- Edidin, A.A.; Jewett, C.W.; Foulds, J.R.; Kurtz, S.M.; Stryker, O.; Allendale, N.J. Exponent Failure Analysis Associates; The University of California: Berkeley, CA, USA.

- Bauer, T.W.; Ming, J.; D'Antonio, J.A.; Morawa, L.G. Abrasive Three-Body Wear of Polyethylene Caused by Broken Multifilament Cables of a Total Hip Prosthesis: A Report of Three Cases. J. Bone Jt. Surg. Am. 1996, 78, 1244–1247. [Google Scholar] [CrossRef]

- Hulbert, S.F.; Megremis, S.J. Effects of UHMWPE Wear Debris Generated from Total Hip and Total Knee Replacements; Rose-Human Institute of Technology: Terre Haute, IN, USA, 1996. [Google Scholar]

- Wang, A.; Essner, A. Three-body wear of UHMWPE acetabular cups by PMMA particles against CoCr, alumina and zirconia heads in a hip joint simulator. Wear 2001, 250, 212–216. [Google Scholar] [CrossRef]

- Bhoi, S.; Singh, R.B.; Harsha, A.P.; Manna, R. Effect of Grain Refinement on Tribological Study of Low Carbon Steel. Trans. Indian Inst. Met. 2021, 74, 1489–1499. [Google Scholar] [CrossRef]

- Patil, P.P.; Gori, Y.; Kumar, A.; Tyagi, M. Experimental analysis of tribological properties of polyisobutylene thickened oil in lubricated contacts. Tribol. Int. 2021, 159, 106983. [Google Scholar] [CrossRef]

- Kumar, A.; Rana, S.; Gori, Y.; Sharma, N.K. Thermal Contact Conductance prediction Using FEM Based computational Techniques. In Advanced Computational Methods in Mechanical and Materials Engineering; CRC Press: Boca Raton, FL, USA, 2021; pp. 183–220. ISBN 9781032052915. [Google Scholar] [CrossRef]

- Gangwar, A.K.S.; Rao, P.S.; Kumar, A. Bio-mechanical design and analysis of femur bone. Mater. Today Proc. 2021, 44, 2179–2187. [Google Scholar] [CrossRef]

- Gangwar, A.K.S.; Rao, P.S.; Kumar, A.; Patil, P.P. Design and Analysis of Femur Bone: BioMechanical Aspects. J. Crit. Rev. 2019, 6, 133–139. [Google Scholar]

- Kumar, A.; Jaiswal, H.; Garg, T.; Patil, P.P. Free Vibration Modes Analysis of Femur Bone Fracture Using Varying Boundary Conditions based on FEA. Procedia Mater. Sci. 2014, 6, 1593–1599. [Google Scholar] [CrossRef]

- Kumar, A.; Behmad, S.I.; Patil, P.P. Vibration Characterization and Static Analysis of Cortical Bone Fracture Based on Finite Element Analysis. Eng. Autom. Probl. 2014, 115–119. [Google Scholar]

- Kumar, A.; Mamgain, D.P.; Jaiswal, H.; Patil, P.P. Modal Analysis of Hand Arm Vibration (Humerus Bone) for Biodynamic Response Using Varying Boundary Conditions Based on FEA; Springer: New York, NY, USA, 2015; Volume 308, pp. 169–176. [Google Scholar] [CrossRef]

- Kumar, A.; Patil, P.P. FEA Simulation and RSM based Parametric Optimization of Vibrating Transmission Gearbox Housing. Perspect. Sci. 2016, 8, 388–391. [Google Scholar] [CrossRef][Green Version]

- John, K.S.; Gupta, M. Evaluation of the wear performance of a polycarbonate-urethane acetabular component in a hip joint simulator and comparison with UHMWPE and cross-linked UHMWPE. J. Biomater. Appl. 2010, 27, 55–65. [Google Scholar] [CrossRef]

- Saravanan, I.; Perumal, A.E.; Issac, R.F. Wear study of cross linked UHMWPE hybrid composite-TiN interface. Surf. Interfaces 2016, 4, 42–50. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Vickers Hardness Number (Hv) |

|---|---|---|

| UHMWPE | 935 | 25.7 |

| Cross-link PE | 934 | 27.8 |

| Grade | Material | Load (N) | Wear Rate (mm3/mm) | Wear Co-Efficient ‘K’ ×10−3 |

|---|---|---|---|---|

| 100 | UHMWPE | 10 | 1.617 × 10−3 | 4.157 |

| 100 | UHMWPE | 15 | 2.733 × 10−3 | 4.682 |

| 220 | UHMWPE | 10 | 4.98 × 10−4 | 1.280 |

| 220 | UHMWPE | 15 | 7.82 × 10−4 | 1.330 |

| 400 | UHMWPE | 10 | 5.44 × 10−4 | 1.390 |

| 400 | UHMWPE | 15 | 6.05 × 10−4 | 1.030 |

| 100 | Cross L PE | 10 | 2.17 × 10−3 | 6.030 |

| 100 | Cross L PE | 15 | 3.71 × 10−3 | 6.870 |

| 220 | Cross L PE | 10 | 7.63 × 10−4 | 2.120 |

| 220 | Cross L PE | 15 | 1.06 × 10−3 | 1.970 |

| 400 | Cross L PE | 10 | 4.95 × 10−4 | 1.370 |

| 400 | Cross L PE | 15 | 6.86 × 10−4 | 1.270 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhoi, S.; Prasad, A.; Kumar, A.; Sarkar, R.B.; Mahto, B.; Meena, C.S.; Pandey, C. Experimental Study to Evaluate the Wear Performance of UHMWPE and XLPE Material for Orthopedics Application. Bioengineering 2022, 9, 676. https://doi.org/10.3390/bioengineering9110676

Bhoi S, Prasad A, Kumar A, Sarkar RB, Mahto B, Meena CS, Pandey C. Experimental Study to Evaluate the Wear Performance of UHMWPE and XLPE Material for Orthopedics Application. Bioengineering. 2022; 9(11):676. https://doi.org/10.3390/bioengineering9110676

Chicago/Turabian StyleBhoi, Sandeep, Arbind Prasad, Ashwani Kumar, Rudra Bubai Sarkar, Bidyanand Mahto, Chandan Swaroop Meena, and Chandan Pandey. 2022. "Experimental Study to Evaluate the Wear Performance of UHMWPE and XLPE Material for Orthopedics Application" Bioengineering 9, no. 11: 676. https://doi.org/10.3390/bioengineering9110676

APA StyleBhoi, S., Prasad, A., Kumar, A., Sarkar, R. B., Mahto, B., Meena, C. S., & Pandey, C. (2022). Experimental Study to Evaluate the Wear Performance of UHMWPE and XLPE Material for Orthopedics Application. Bioengineering, 9(11), 676. https://doi.org/10.3390/bioengineering9110676