The “Federica” Hand

Abstract

:1. Introduction

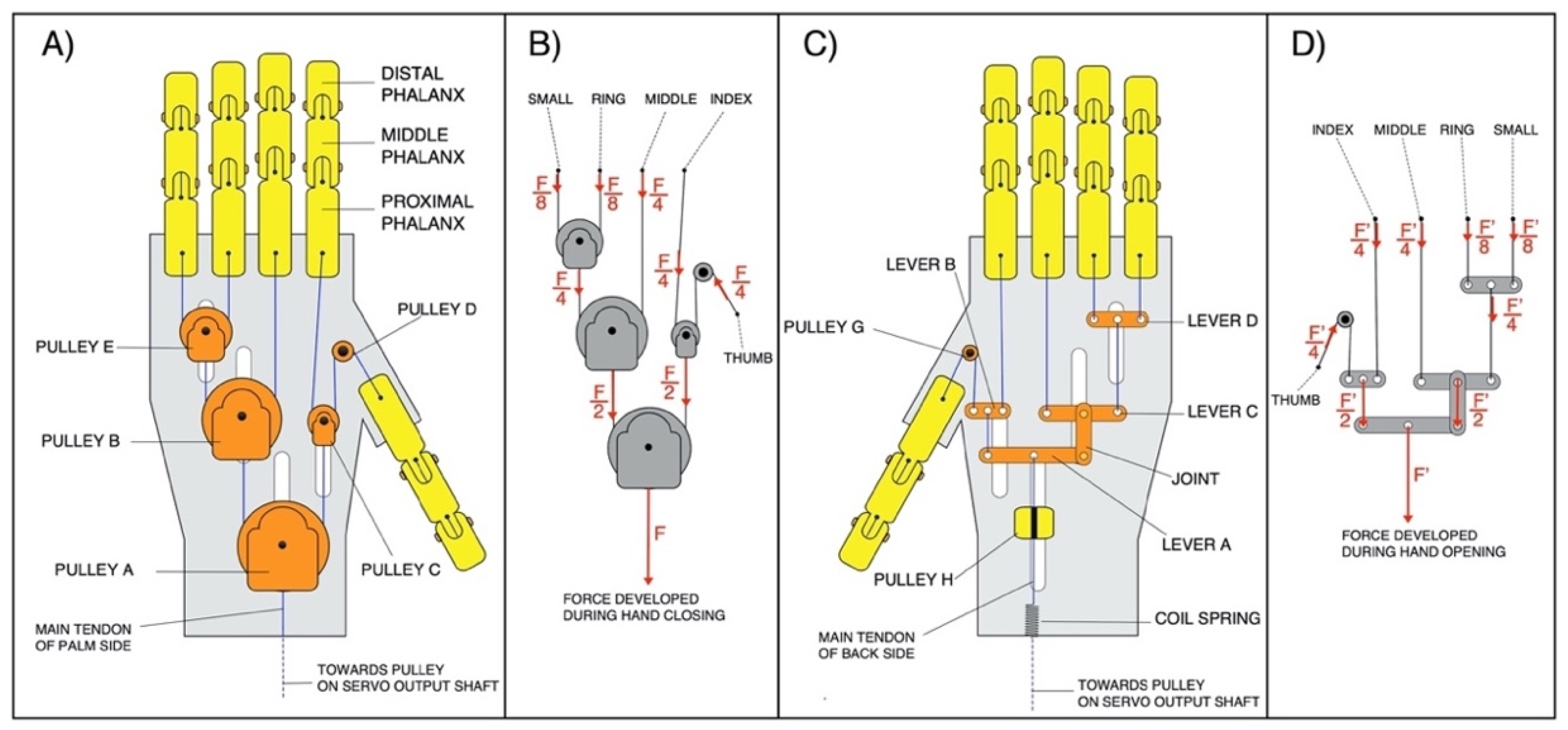

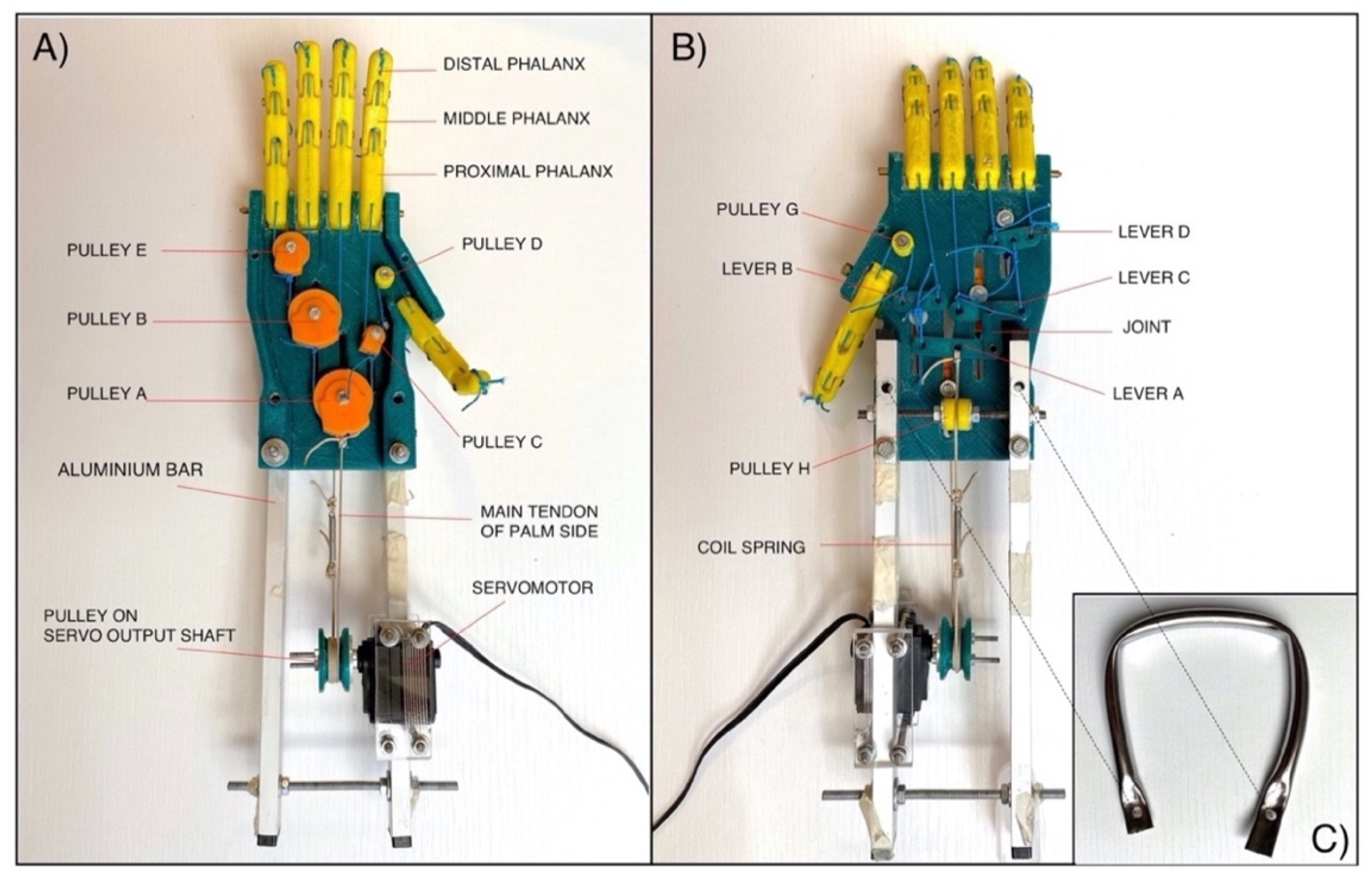

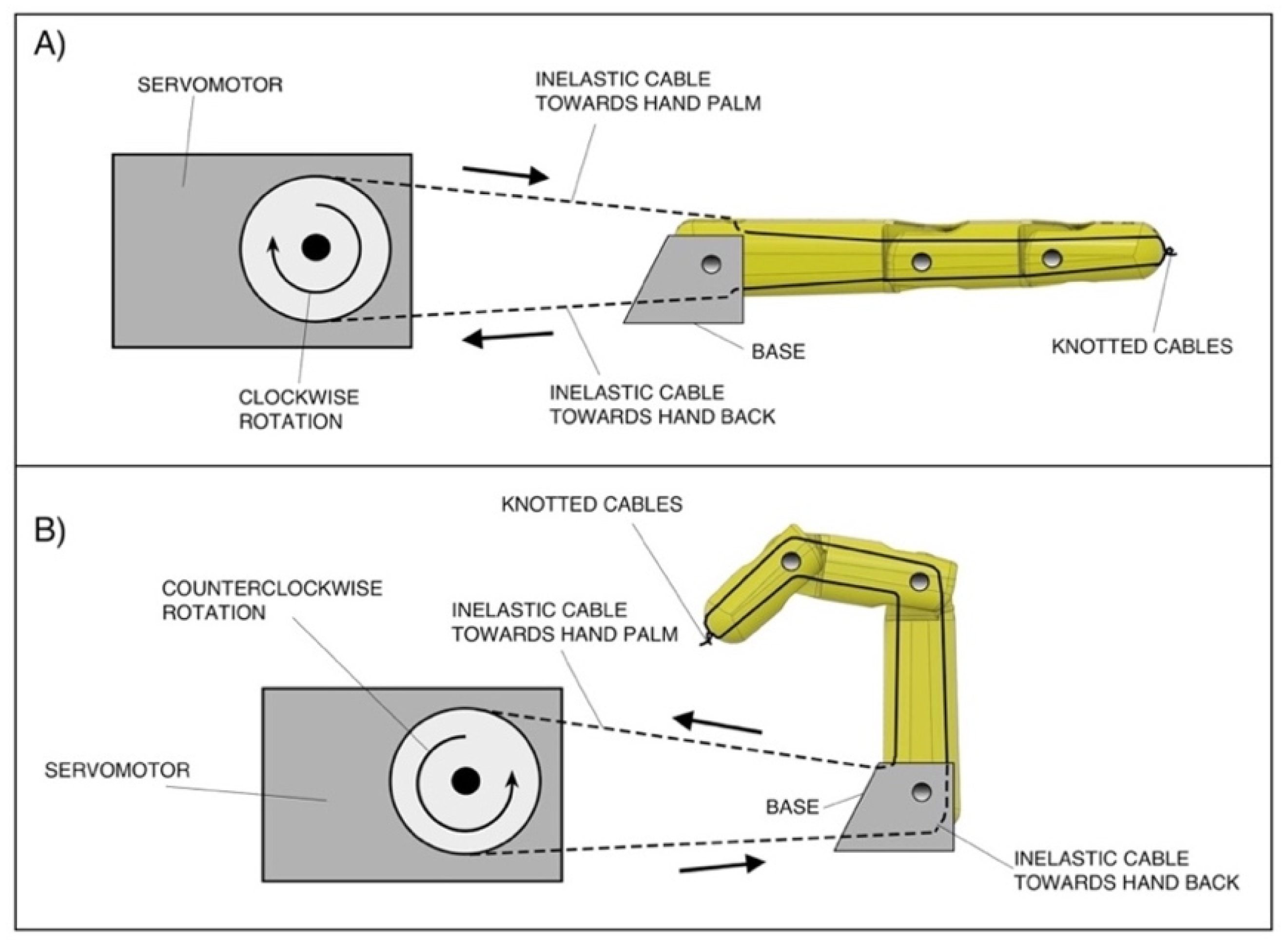

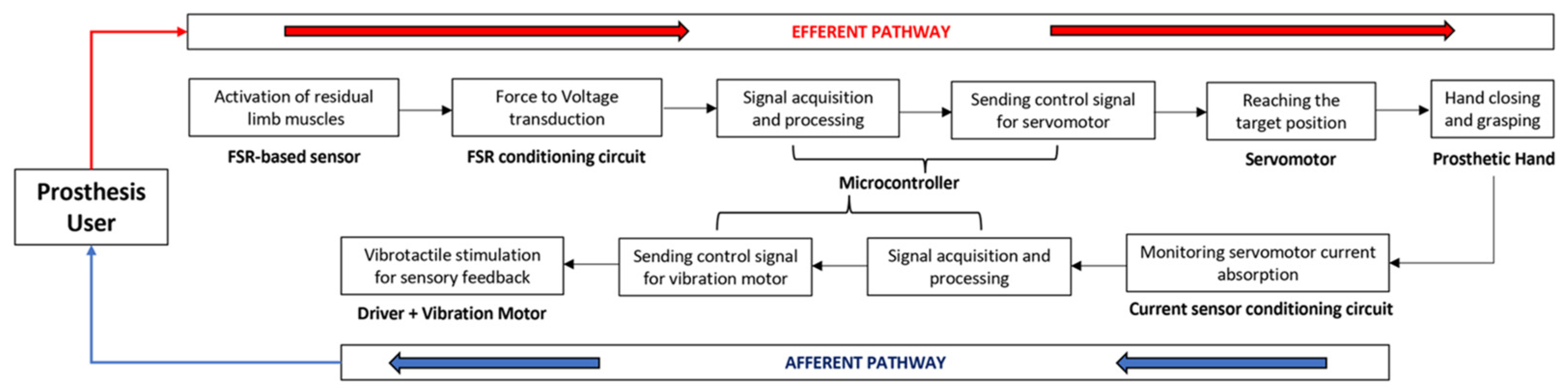

2. Materials and Methods

2.1. Mechanical Design Specifications

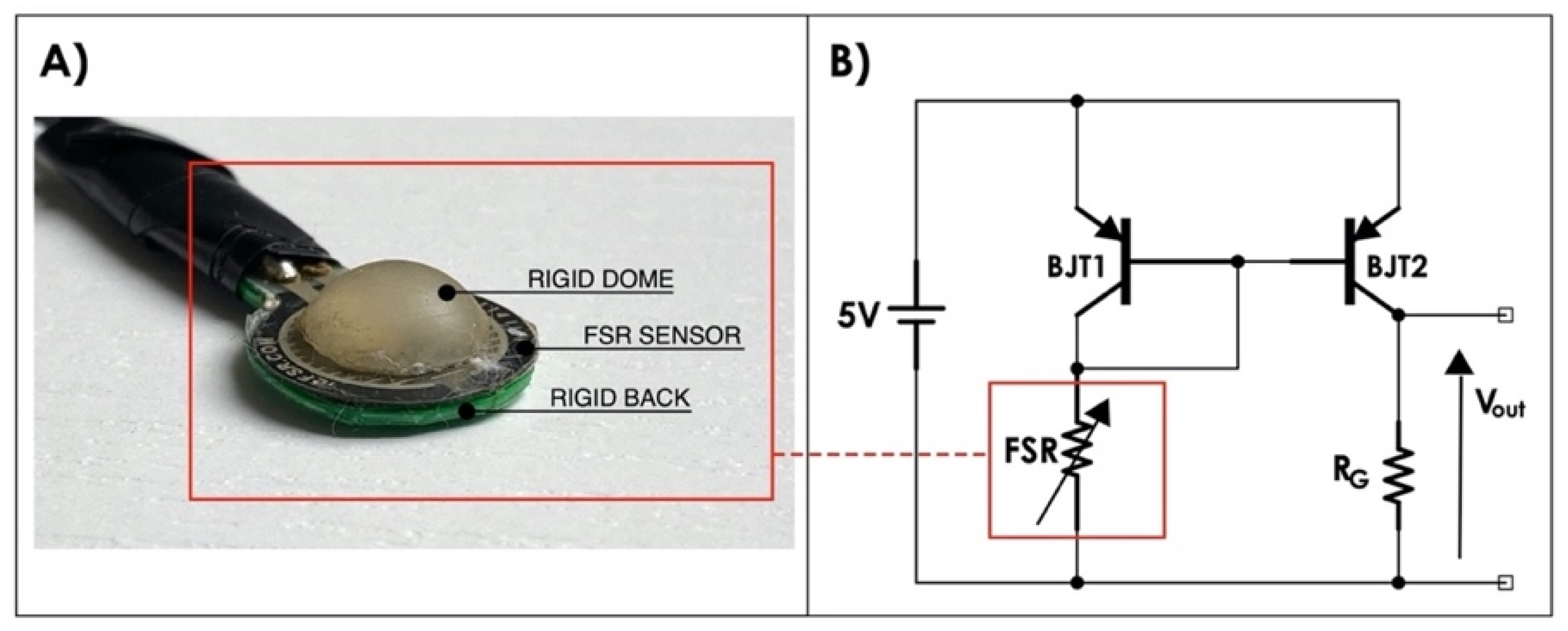

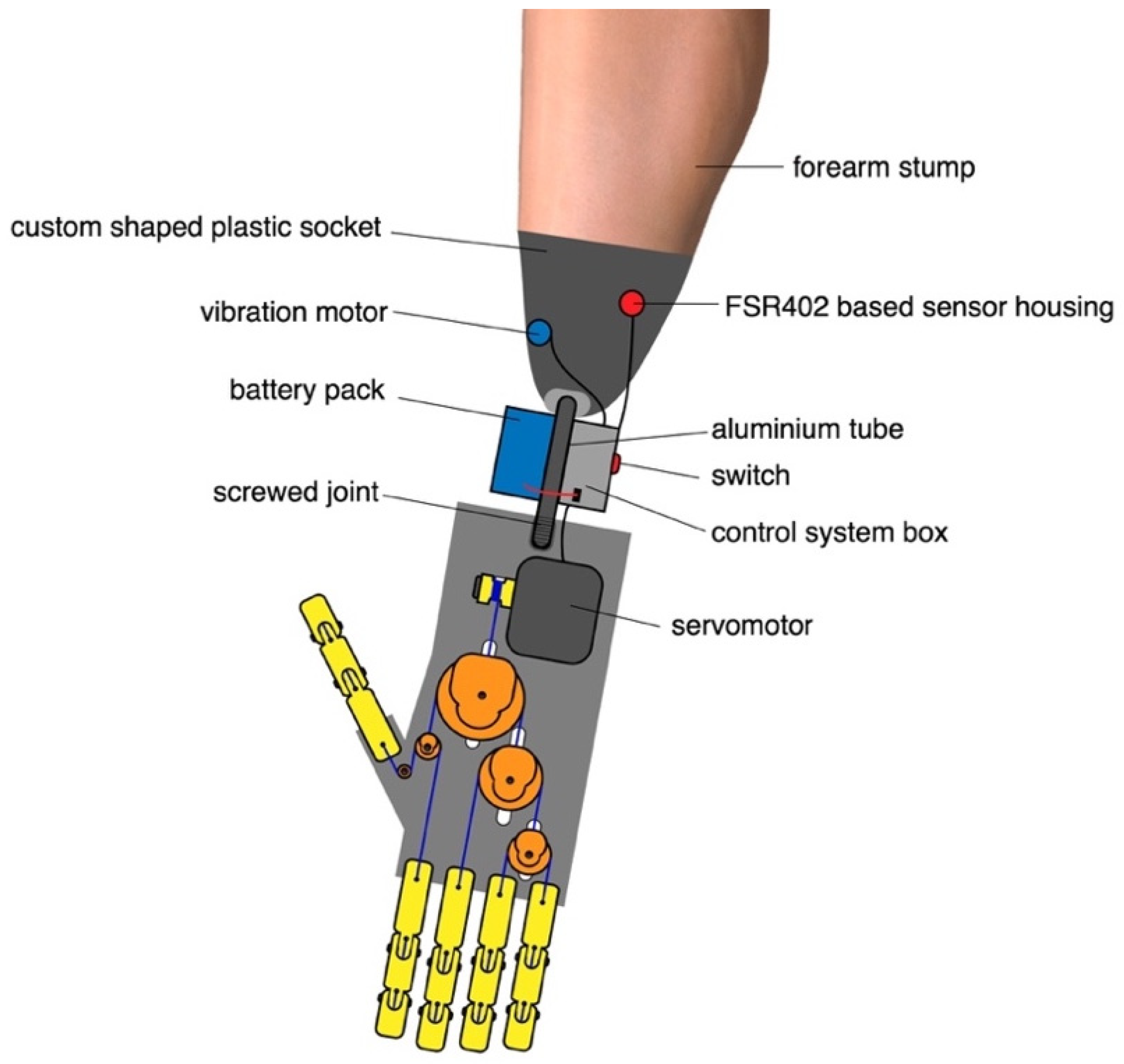

2.2. Force-Myographic Control and Vibrotactile Feedback System

3. Results

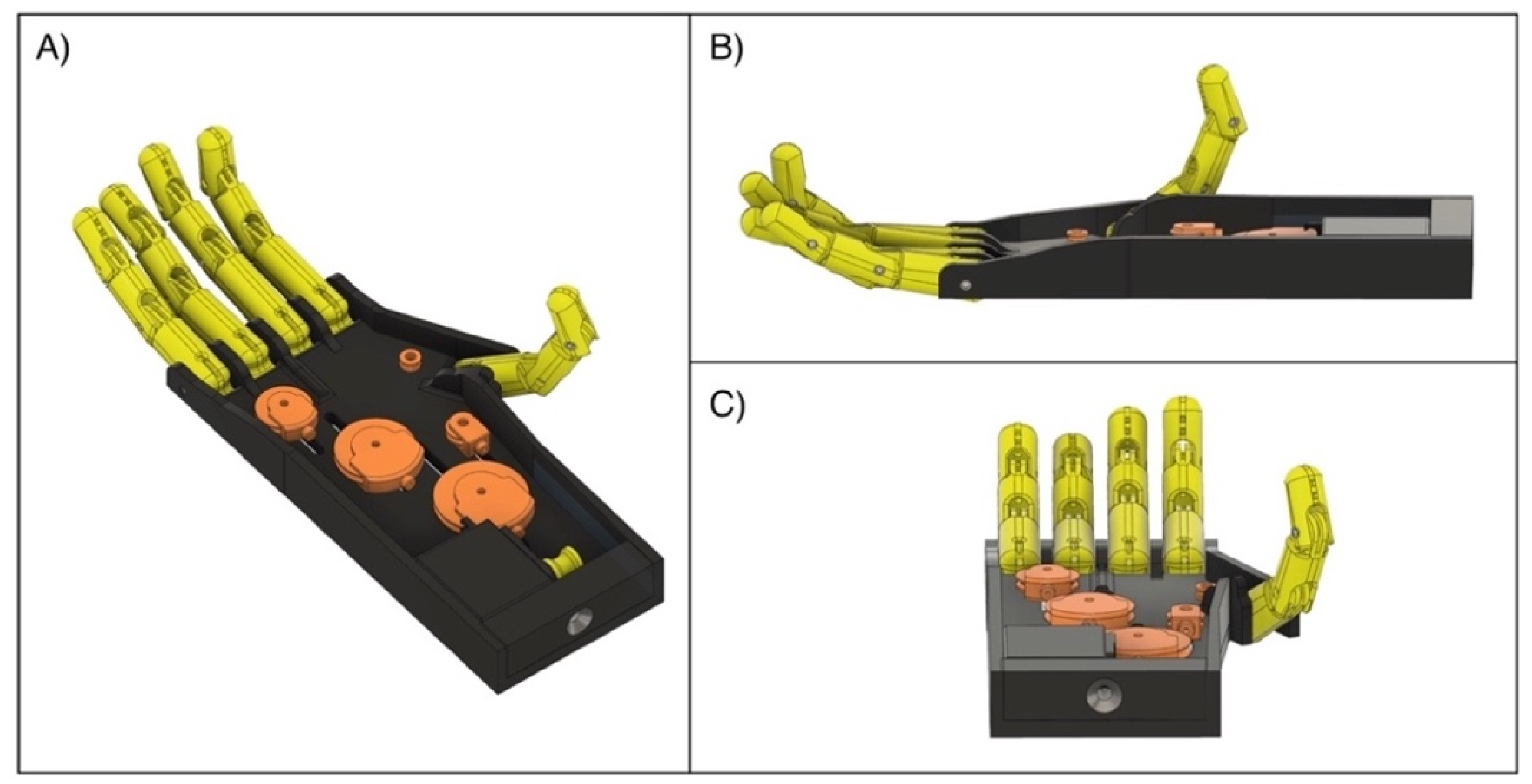

3.1. Current Realization of “Federica” Hand

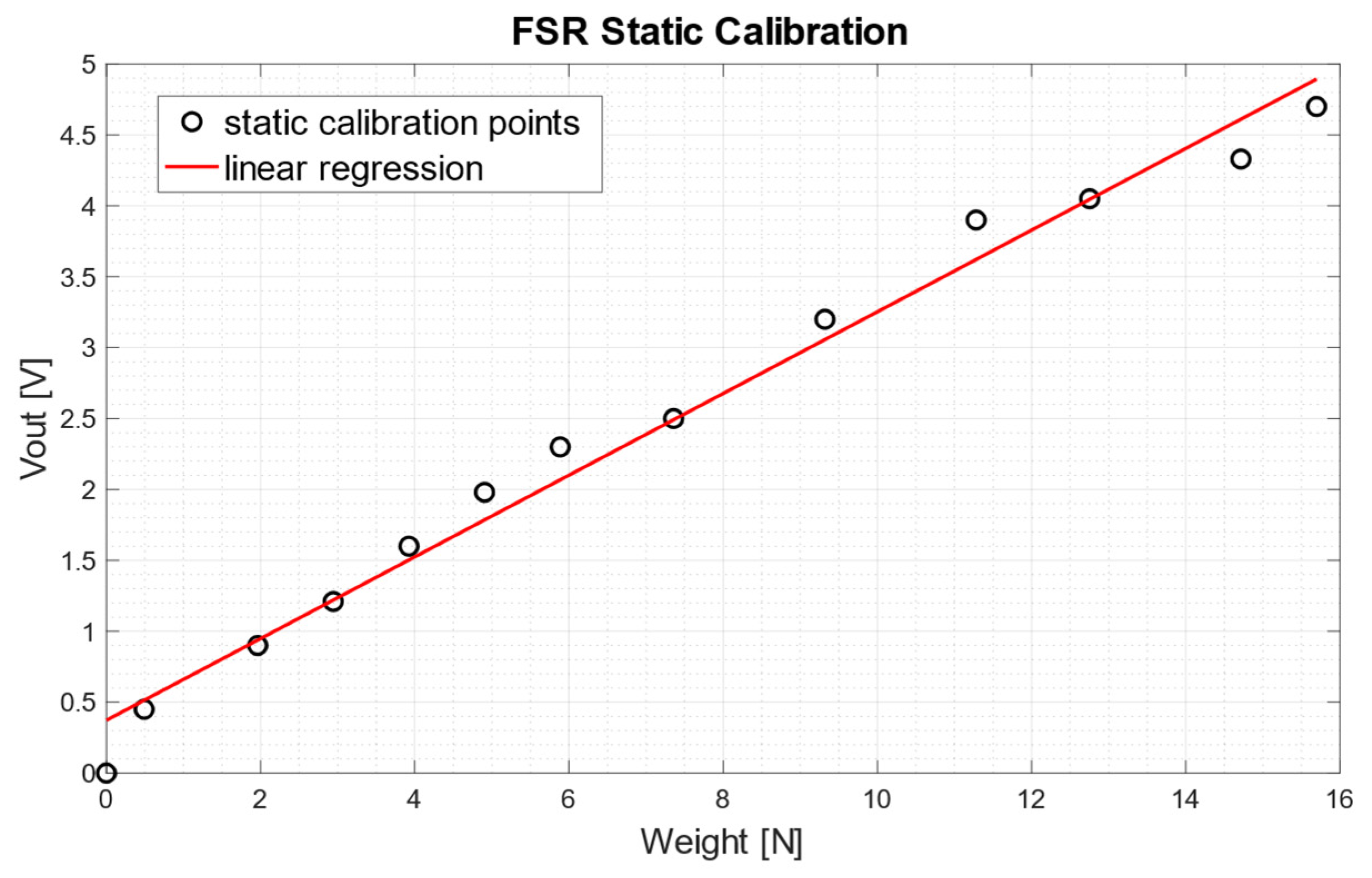

3.2. Static Calibration of the FSR-Based Sensor

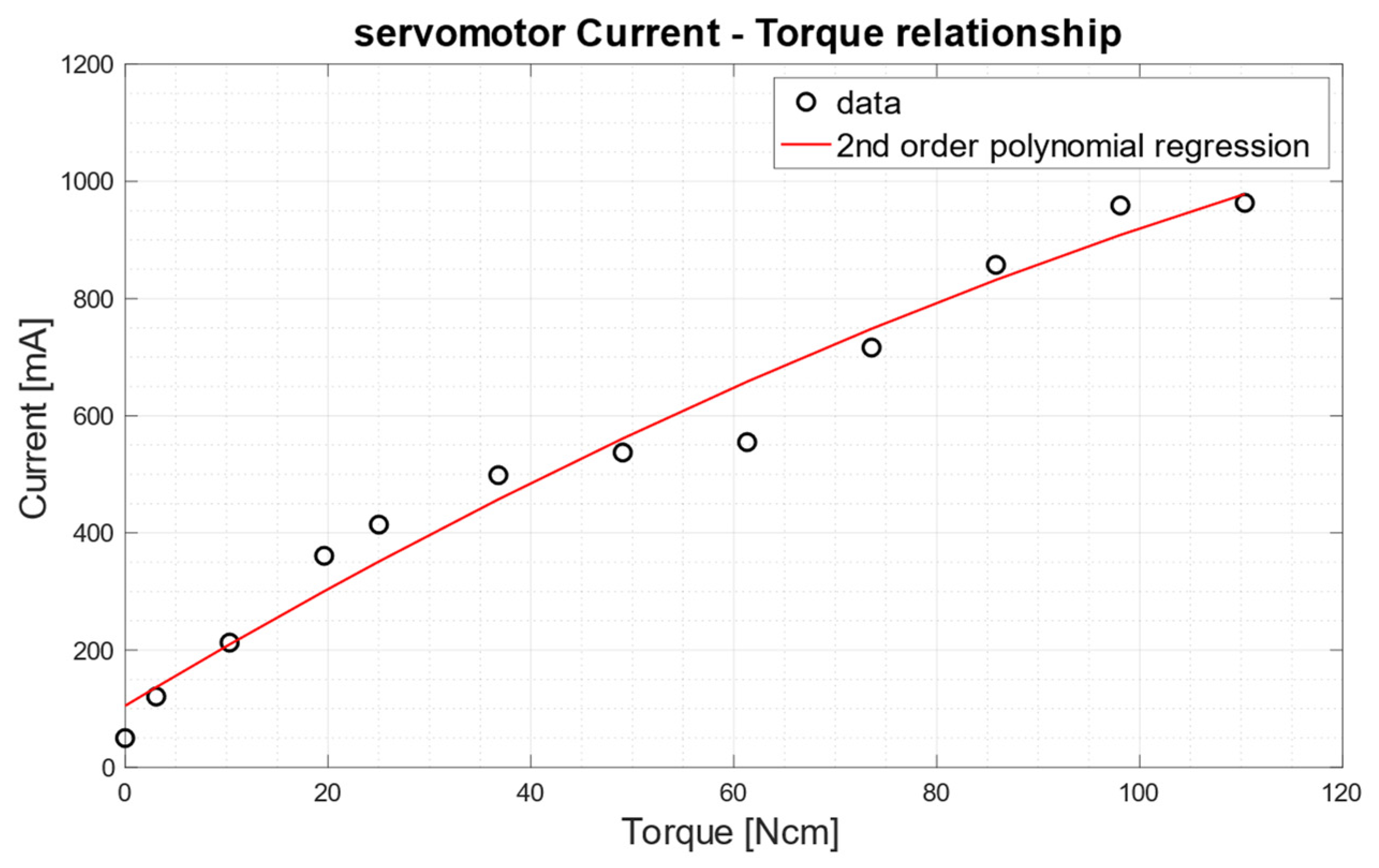

3.3. Servomotor Characterization

3.4. FMG–EMG Comparison

3.5. Grip Force Sensing

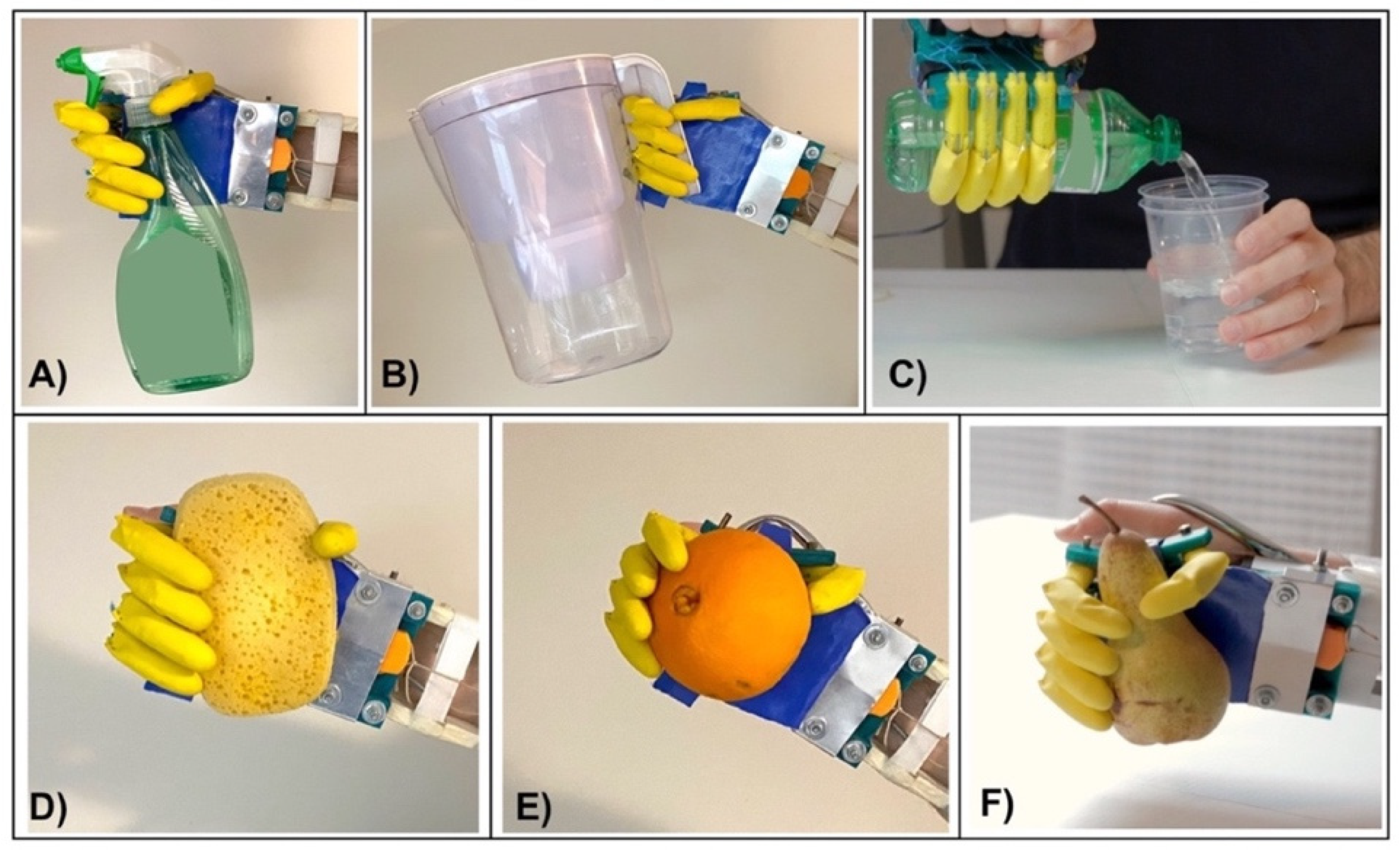

3.6. Test on Healthy Subjects

3.7. Comparison between “Federica” Hand and Other Hand Prostheses

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Polisiero, M.; Bifulco, P.; Liccardo, A.; Cesarelli, M.; Romano, M.; Gargiulo, G.D.; McEwan, A.L.; D’Apuzzo, M. Design and Assessment of a Low-Cost, Electromyographically Controlled, Prosthetic Hand. Med. Devices 2013, 6, 97–104. [Google Scholar] [CrossRef] [Green Version]

- Ulloa, G.D.F.; Sreenivasan, N.; Bifulco, P.; Cesarelli, M.; Gargiulo, G.; Gunawardana, U. Cost Effective Electro—Resistive Band Based Myo Activated Prosthetic Upper Limb for Amputees in the Developing World. In Proceedings of the 2017 IEEE Life Sciences Conference (LSC), Sydney, NSW, Australia, 13–15 December 2017; pp. 250–253. [Google Scholar]

- Sreenivasan, N.; Ulloa Gutierrez, D.F.; Bifulco, P.; Cesarelli, M.; Gunawardana, U.; Gargiulo, G.D. Towards Ultra Low-Cost Myoactivated Prostheses. Available online: https://www.hindawi.com/journals/bmri/2018/9634184/ (accessed on 17 August 2020).

- 3D Printed Hand|Victoria Hand Project. Available online: https://www.victoriahandproject.com (accessed on 17 August 2020).

- Home|The Open Prosthetics Project. Available online: https://openprosthetics.org/ (accessed on 17 August 2020).

- The Open Hand Project—Home. Available online: http://www.openhandproject.org/?LMCL=WO2wve&LMCL=rtU4ls&LMCL=fhyeQY (accessed on 17 August 2020).

- Cosenza, C.; Niola, V.; Savino, S. A Mechanical Hand for Prosthetic Applications: Multibody Model and Contact Simulation. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2018, 232, 819–825. [Google Scholar] [CrossRef] [PubMed]

- Niola, V.; Rossi, C.; Savino, S.; Troncone, S. An Underactuated Mechanical Hand: A First Prototype. In Proceedings of the 2014 23rd International Conference on Robotics in Alpe-Adria-Danube Region (RAAD), Smolenice, Slovakia, 3–5 September 2014; pp. 1–6. [Google Scholar]

- Bifulco, P.; Esposito, D.; Gargiulo, G.D.; Savino, S.; Niola, V.; Iuppariello, L.; Cesarelli, M. A Stretchable, Conductive Rubber Sensor to Detect Muscle Contraction for Prosthetic Hand Control. In Proceedings of the 2017 E-Health and Bioengineering Conference (EHB), Sinaia, Romania, 22–24 June 2017; pp. 173–176. [Google Scholar]

- Esposito, D.; Cosenza, C.; Gargiulo, G.D.; Andreozzi, E.; Niola, V.; Fratini, A.; D’Addio, G.; Bifulco, P. Experimental Study to Improve “Federica” Prosthetic Hand and Its Control System. In Proceedings of the XV Mediterranean Conference on Medical and Biological Engineering and Computing—MEDICON 2019, Coimbra, Portugal, 26–28 September 2019; Henriques, J., Neves, N., de Carvalho, P., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 586–593. [Google Scholar]

- Esposito, D.; Savino, S.; Cosenza, C.; Gargiulo, G.D.; Fratini, A.; Cesarelli, G.; Bifulco, P. Study on the Activation Speed and the Energy Consumption of “Federica” Prosthetic Hand. In Proceedings of the XV Mediterranean Conference on Medical and Biological Engineering and Computing—MEDICON 2019, Coimbra, Portugal, 26–28 September 2019; Henriques, J., Neves, N., de Carvalho, P., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 594–603. [Google Scholar]

- Basmajian, J.V.; de Luca, C.J. Muscles Alive: Their Functions Revealed by Electromyography; Williams & Wilkins: Baltimore, MD, USA, 1985; ISBN 978-0-683-00414-4. [Google Scholar]

- Parajuli, N.; Sreenivasan, N.; Bifulco, P.; Cesarelli, M.; Savino, S.; Niola, V.; Esposito, D.; Hamilton, T.J.; Naik, G.R.; Gunawardana, U.; et al. Real-Time EMG Based Pattern Recognition Control for Hand Prostheses: A Review on Existing Methods, Challenges and Future Implementation. Sensors 2019, 19, 4596. [Google Scholar] [CrossRef] [Green Version]

- Esposito, D.; Gargiulo, G.D.; Parajuli, N.; Cesarelli, G.; Andreozzi, E.; Bifulco, P. Measurement of Muscle Contraction Timing for Prosthesis Control: A Comparison between Electromyography and Force-Myography. In Proceedings of the 2020 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Bari, Italy, 1 June–1 July 2020; pp. 1–6. [Google Scholar]

- Interlink Electronics FSR Sensor, Force Sensing Resistor|Interlink Electronics. Available online: https://www.interlinkelectronics.com/force-sensing-resistor (accessed on 13 November 2020).

- Esposito, D.; Andreozzi, E.; Fratini, A.; Gargiulo, G.D.; Savino, S.; Niola, V.; Bifulco, P. A Piezoresistive Sensor to Measure Muscle Contraction and Mechanomyography. Sensors 2018, 18, 2553. [Google Scholar] [CrossRef] [Green Version]

- Esposito, D.; Andreozzi, E.; Gargiulo, G.D.; Fratini, A.; D’Addio, G.; Naik, G.R.; Bifulco, P. A Piezoresistive Array Armband With Reduced Number of Sensors for Hand Gesture Recognition. Front. Neurorobot. 2020, 13, 114. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carrozza, M.C.; Suppo, C.; Sebastiani, F.; Massa, B.; Vecchi, F.; Lazzarini, R.; Cutkosky, M.R.; Dario, P. The SPRING Hand: Development of a Self-Adaptive Prosthesis for Restoring Natural Grasping. Auton. Robot. 2004, 16, 125–141. [Google Scholar] [CrossRef]

- Belter, J.T.; Dollar, A.M. Novel Differential Mechanism Enabling Two DOF from a Single Actuator: Application to a Prosthetic Hand. In Proceedings of the 2013 IEEE 13th International Conference on Rehabilitation Robotics (ICORR), Seattle, WA, USA, 24–26 June 2013; pp. 1–6. [Google Scholar]

- Kamikawa, Y.; Maeno, T. Underactuated Five-Finger Prosthetic Hand Inspired by Grasping Force Distribution of Humans. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, IROS, Nice, France, 22–26 September 2008; pp. 717–722. [Google Scholar]

- Fukaya, N.; Toyama, S.; Asfour, T.; Dillmann, R. Design of the TUAT/Karlsruhe Humanoid Hand. In Proceedings of the 2000 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2000) (Cat. No.00CH37113), Takamatsu, Japan, 31 October–5 November 2000. [Google Scholar] [CrossRef]

- Fukaya, N.; Asfour, T.; Dillmann, R.; Toyama, S. Development of a Five-Finger Dexterous Hand without Feedback Control: The TUAT/Karlsruhe Humanoid Hand. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013. [Google Scholar] [CrossRef]

- Weiner, P.; Starke, J.; Hundhausen, F.; Beil, J.; Asfour, T. The KIT Prosthetic Hand: Design and Control. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018. [Google Scholar] [CrossRef]

- Esposito, D.; Savino, S.; Cosenza, C.; Andreozzi, E.; Gargiulo, G.D.; Polley, C.; Cesarelli, G.; D’Addio, G.; Bifulco, P. Evaluation of Grip Force and Energy Efficiency of the “Federica” Hand. Machines 2021, 9, 25. [Google Scholar] [CrossRef]

- Mnyusiwalla, H.; Vulliez, P.; Gazeau, J.-P.; Zeghloul, S. A New Dexterous Hand Based on Bio-Inspired Finger Design for Inside-Hand Manipulation. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 809–817. [Google Scholar] [CrossRef]

- Jacobsen, S.C.; Wood, J.E.; Knutti, D.F.; Biggers, K.B. The UTAH/M.I.T. Dextrous Hand: Work in Progress. Int. J. Robot. Res. 2016, 3, 21–50. [Google Scholar] [CrossRef]

- Antfolk, C.; D’Alonzo, M.; Rosén, B.; Lundborg, G.; Sebelius, F.; Cipriani, C. Sensory Feedback in Upper Limb Prosthetics. Expert Rev. Med. Devices 2013, 10, 45–54. [Google Scholar] [CrossRef]

- Brown, J.D.; Paek, A.; Syed, M.; O’Malley, M.K.; Shewokis, P.A.; Contreras-Vidal, J.L.; Davis, A.J.; Gillespie, R.B. An Exploration of Grip Force Regulation with a Low-Impedance Myoelectric Prosthesis Featuring Referred Haptic Feedback. J. Neuroeng. Rehabil. 2015, 12, 104. [Google Scholar] [CrossRef]

- Cloutier, A.; Yang, J. Design, Control, and Sensory Feedback of Externally Powered Hand Prostheses: A Literature Review. Crit. Rev. Biomed. Eng. 2013, 41, 161–181. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Fang, Y.; Zhou, Y.; Liu, H. Non-Invasive Stimulation-Based Tactile Sensation for Upper-Extremity Prosthesis: A Review. IEEE Sens. J. 2017, 17, 2625–2635. [Google Scholar] [CrossRef] [Green Version]

- VINCENTevolution 2. Available online: https://vincentsystems.de/en/prosthetics/vincent-evolution-2/ (accessed on 17 August 2020).

- Fu, Q.; Santello, M. Improving Fine Control of Grasping Force during Hand–Object Interactions for a Soft Synergy-Inspired Myoelectric Prosthetic Hand. Front. Neurorobot. 2018, 11, 71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Drake, R.L.; Vogl, W.; Mitchell, A.W.M.; Gray, H. Gray’s Anatomy for Students; Elsivier: Amsterdam, The Netherlands, 2015; ISBN 978-0-7020-5131-9. [Google Scholar]

- Belter, J.T.; Segil, J.L.; Dollar, A.M.; Weir, R.F. Mechanical Design and Performance Specifications of Anthropomorphic Prosthetic Hands: A Review. J. Rehabil. Res. Dev. 2013, 50, 599–618. [Google Scholar] [CrossRef] [PubMed]

- Vujaklija, I.; Farina, D.; Aszmann, O.C. New Developments in Prosthetic Arm Systems. Orthop. Res. Rev. 2016, 8, 31–39. [Google Scholar] [CrossRef] [Green Version]

- Kamen, G.; Gabriel, D.A. Essentials of Electromyography. Available online: /paper/Essentials-of-Electromyography-Kamen-Gabriel/17a0c87549f413a0cea07cefb086a03baf51d1bb (accessed on 18 August 2020).

- Konrad, P. The ABC of EMG: A Practical Introduction to Kinesiological Electromyography; Version 1.0; Noraxon Inc.: Scottsdale, AZ, USA, 2005. [Google Scholar]

- Dollar, A.M. Classifying Human Hand Use and the Activities of Daily Living. In The Human Hand as an Inspiration for Robot Hand Development; Balasubramanian, R., Santos, V.J., Eds.; Springer Tracts in Advanced Robotics; Springer International Publishing: Cham, Switzerland, 2014; pp. 201–216. ISBN 978-3-319-03017-3. [Google Scholar]

- Cipriani, C.; Controzzi, M.; Carrozza, M.C. The SmartHand Transradial Prosthesis. J. Neuroeng. Rehabil. 2011, 8, 29. [Google Scholar] [CrossRef] [Green Version]

- Light, C.M.; Chappell, P.H. Development of a Lightweight and Adaptable Multiple-Axis Hand Prosthesis. Med. Eng. Phys. 2000, 22, 679–684. [Google Scholar] [CrossRef]

- Melchiorri, C.; Palli, G.; Berselli, G.; Vassura, G. Development of the UB Hand IV: Overview of Design Solutions and Enabling Technologies. IEEE Robot. Autom. Mag. 2013, 20, 72–81. [Google Scholar] [CrossRef]

- Dechev, N.; Cleghorn, W.L.; Naumann, S. Multiple Finger, Passive Adaptive Grasp Prosthetic Hand. Mech. Mach. Theory 2001, 36, 1157–1173. [Google Scholar] [CrossRef]

- Pons, J.L.; Rocon, E.; Ceres, R.; Reynaerts, D.; Saro, B.; Levin, S.; Van Moorleghem, W. The MANUS-HAND Dextrous Robotics Upper Limb Prosthesis: Mechanical and Manipulation Aspects. Auton. Robot. 2004, 16, 143–163. [Google Scholar] [CrossRef]

- Dalley, S.A.; Wiste, T.E.; Withrow, T.J.; Goldfarb, M. Design of a Multifunctional Anthropomorphic Prosthetic Hand With Extrinsic Actuation. IEEE/ASME Trans. Mechatron. 2009, 14, 699–706. [Google Scholar] [CrossRef]

- Xiao, Z.G.; Menon, C. A Review of Force Myography Research and Development. Sensors 2019, 19, 4557. [Google Scholar] [CrossRef] [Green Version]

- Ahmadizadeh, C.; Khoshnam, M.; Menon, C. Human Machine Interfaces in Upper-Limb Prosthesis Control: A Survey of Techniques for Preprocessing and Processing of Biosignals. IEEE Signal Process. Mag. 2021, 38, 12–22. [Google Scholar] [CrossRef]

- Chadwell, A.; Kenney, L.; Thies, S.; Galpin, A.; Head, J. The Reality of Myoelectric Prostheses: Understanding What Makes These Devices Difficult for Some Users to Control. Front. Neurorobot. 2016, 10, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arm Prosthesis|Ottobock UK. Available online: https://www.ottobock.co.uk/prosthetics/upper_limbs_prosthetics/ (accessed on 17 November 2020).

- Steeper Group—Upper Limb. Available online: https://www.steepergroup.com/prosthetics/upper-limb-prosthetics/ (accessed on 21 January 2021).

- Saudabayev, A.; Rysbek, Z.; Khassenova, R.; Varol, H.A. Human Grasping Database for Activities of Daily Living with Depth, Color and Kinematic Data Streams. Sci. Data 2018, 5, 180101. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| ITEM | SPECIFICATION |

|---|---|

| size | suitable for an adult man |

| mass | ≈200 g (the only prosthetic hand) |

| modularity | yes |

| number of actuators | 1 |

| degrees of freedom | 15 |

| sensing of grip force | vibrotactile |

| max tested load | 1 kg |

| activation speed (from trigger to complete closure) | ≈0.5 s |

| energy power | 2 × 3.7 V batteries (3000 mA h) |

| mean grip force | 8.8 N |

| mean hysteresis for a complete cycle of closing–opening | 106.80 Nm |

| force transfer ratio | 12.85% |

| Component | Cost (USD) |

|---|---|

| 3D-printed components (PLA) | 20 |

| other mechanical components (cables, screws…) | 5 |

| servomotor (Hitec HSR-5990TG) or equivalent | 35 |

| Arduino nano (processing unit board) | 10 |

| battery pack (2 × 3.7 V rechargeable battery) | 10 |

| piezoresistive force sensor (FSR 402 short) | 5 |

| electronic components (BJTs, resistors, capacitors, switch) | 5 |

| vibration motor | (5) |

| current sensor (ACS712-5A) | (5) |

| Total | 90 (100) |

| Developer/Manufacturer | Weight | Size (Height) | Grasp Speed | Grip Force | DOF | Kind/Number of Actuators | Power—Intermediate-Precision (Grasp) | Adaptive Grip | Price | Other Characteristics | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Federica Hand | University of Naples “Federico II”, Italy | ≈200 g | 24 cm | ≈0.5 s | ≈9 N | 15 | 1 servo | yes—no—no | yes | 100 $ | - tendon-based actuation - vibrotactile feedback |

| SmartHand [39] | ARTS Laboratory, Pontedera, Italy | 520 g | - | ≈2 s | ≈36 N | 16 | 4 brushed DC motors | yes—yes—yes | yes | - | tendon/spring based actuation |

| Remedi Hand [40] | University of Southampton, UK | 400 | human hand-sized | 0.84 s | ≈38 N | 6 | 6 DC motors | yes—yes—yes | no | - | bar-linkage mechanism |

| UB Hand IV [41] | University of Bologna, Italy | - | human hand-sized | - | - | 20 | 24 twisted-string actuators | yes—yes—yes | yes | - | tendon-based actuation |

| TBM Hand [42] | University of Toronto, CDN | 280 | 14.6 cm | ≈5 s | - | 6 | 1 DC motor | yes—no—no | yes | - | compliant springs |

| MANUS hand [43] | Spain/Belgium/Israel | 1200 g | - | - | - | 3 | 2 brushless DC motors | yes—no—yes | no | - | crossed-tendons transmission |

| Vanderbilt Hand [44] | Vanderbilt University, Tennessee, US | 580 g | 19 cm | ≈200 °/s | ≈ 80 N | 16 | 5 brushed DC servomotors | yes—no—yes | yes | - | tendon-based actuation |

| The SPRING hand [18] | ARTS Laboratory, Pontedera, Italy | - | - | - | <9 N | 8 | 1 DC motor | yes—no—no | yes | - | - tendon-based actuation - 3 fingers prosthesis |

| TUAT/Karlsruhe Humanoid Hand [22] | College of Industrial Technology, Tokyo, Japan | - | 17.5 cm | - | - | 24 | 1 main servo + 6 sub-servos | yes—no—yes | yes | - | 1 sub-servo for each finger and 2 for thumb |

| The KIT prosthetic hand [23] | Institute of Technology, Karlsruhe, Germany | - | - | 1.3 s | ≈24 N | 10 | 2 DC motors | yes—no—no | yes | 1000 € | video camera in the palm |

| ROBIOSS hand [25] | PPRIME, Poitiers University, France | - | - | 70 °/s | - | 16 | 16 DC motors | yes—no—yes | yes | - | - tendon-based actuation - 4 fingers prosthesis |

| Michelangelo | Ottobock | 420 g | human hand-sized | 0.35 s | 70 N | 2 | 2 | yes—yes—no | no | 60,000 $ | cam design |

| Sensor Hand | Ottobock | 500 g | - | 300 mm/s | 100 N | 1 | 1 DC motor | yes—no—no | no | - | fixed pinch |

| Vincent Hand | Vincent Systems | - | - | - | - | 6 | 6 DC motors-worm gear | yes—no—yes | yes | - | bar-linkage mechanism |

| iLimb Pulse | Touch Bionics | 460 g | 18.2 cm | 1.2 s | 136 N | 6 | 5 DC motors-worm gear | yes—no—yes | yes | - | tendon-based actuation |

| Bebionic v2 | RSL Steeper | 540 g | 20 cm | 0.9 s | 75 | 6 | 5 DC motors—lead screw | yes—no—yes | yes | - | bar-linkage mechanism |

| Prosthesis | Work for Hand Closing [Nmm] (Mean Value ± SD) | Work for Hand Opening [Nmm] (Mean Value ± SD) | Hysteresis [Nmm] (Mean Value ± SD) |

|---|---|---|---|

| “Federica” Hand | 302.17 ± 4.42 | 196.84 ± 5.91 | 106.80 ± 3.31 |

| Hosmer APRL VC Hand 52541 | 1058 ± 4 | - | 298 ± 8 |

| Hosmer Soft VC hand 61794 | 2292 ± 12 | - | 1409 ± 37 |

| Otto Bock VC 8K24, frame | 1624 ± 8 | - | 389 ± 19 |

| Hosmer Sierra VO Hand (ungloved) | - | 1152 ± 8 | 637 ± 6 |

| RSL Steeper VO Hand (ungloved) | - | 1758 ± 27 | 855 ± 6 |

| Otto Bock VO Hand (ungloved) | - | 2545 ± 11 | 917 ± 5 |

| Hosmer Becker VO (ungloved) | - | 2748 ± 17 | 1710 ± 9 |

| RSL Steeper Carbon VO | - | 1619 ± 2 | 487 ± 4 |

| Hosmer APRL VC Hook 52601 | 720 ± 6 | - | 138 ± 3 |

| TSR VC Hook-Grip 2SS | 284 ± 3 | - | 52 ± 1 |

| Hosmer Model VO 5XA Hook (1 band) | - | 1128 ± 14 | 290 ± 3 |

| Otto Bock VO 10A60 Hook | - | 1002 ± 3 | 482 ± 5 |

| Hosmer Sierra 2 Load VO Hook | - | 1243 ± 11 | 379 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esposito, D.; Savino, S.; Andreozzi, E.; Cosenza, C.; Niola, V.; Bifulco, P. The “Federica” Hand. Bioengineering 2021, 8, 128. https://doi.org/10.3390/bioengineering8090128

Esposito D, Savino S, Andreozzi E, Cosenza C, Niola V, Bifulco P. The “Federica” Hand. Bioengineering. 2021; 8(9):128. https://doi.org/10.3390/bioengineering8090128

Chicago/Turabian StyleEsposito, Daniele, Sergio Savino, Emilio Andreozzi, Chiara Cosenza, Vincenzo Niola, and Paolo Bifulco. 2021. "The “Federica” Hand" Bioengineering 8, no. 9: 128. https://doi.org/10.3390/bioengineering8090128

APA StyleEsposito, D., Savino, S., Andreozzi, E., Cosenza, C., Niola, V., & Bifulco, P. (2021). The “Federica” Hand. Bioengineering, 8(9), 128. https://doi.org/10.3390/bioengineering8090128