An Update on Nickel-Titanium Rotary Instruments in Endodontics: Mechanical Characteristics, Testing and Future Perspective—An Overview

Abstract

:1. Introduction

1.1. Advantages in Using NiTi Rotary Instruments

- Reduction in time of endodontic treatments

- Simplification of instrumentation procedures

- Increase of predictability and effectiveness of endodontic treatments

1.2. Nickel-Titanium Alloy

1.3. Evaluation of Mechanical Properties of NiTi Endodontic Rotary Instruments

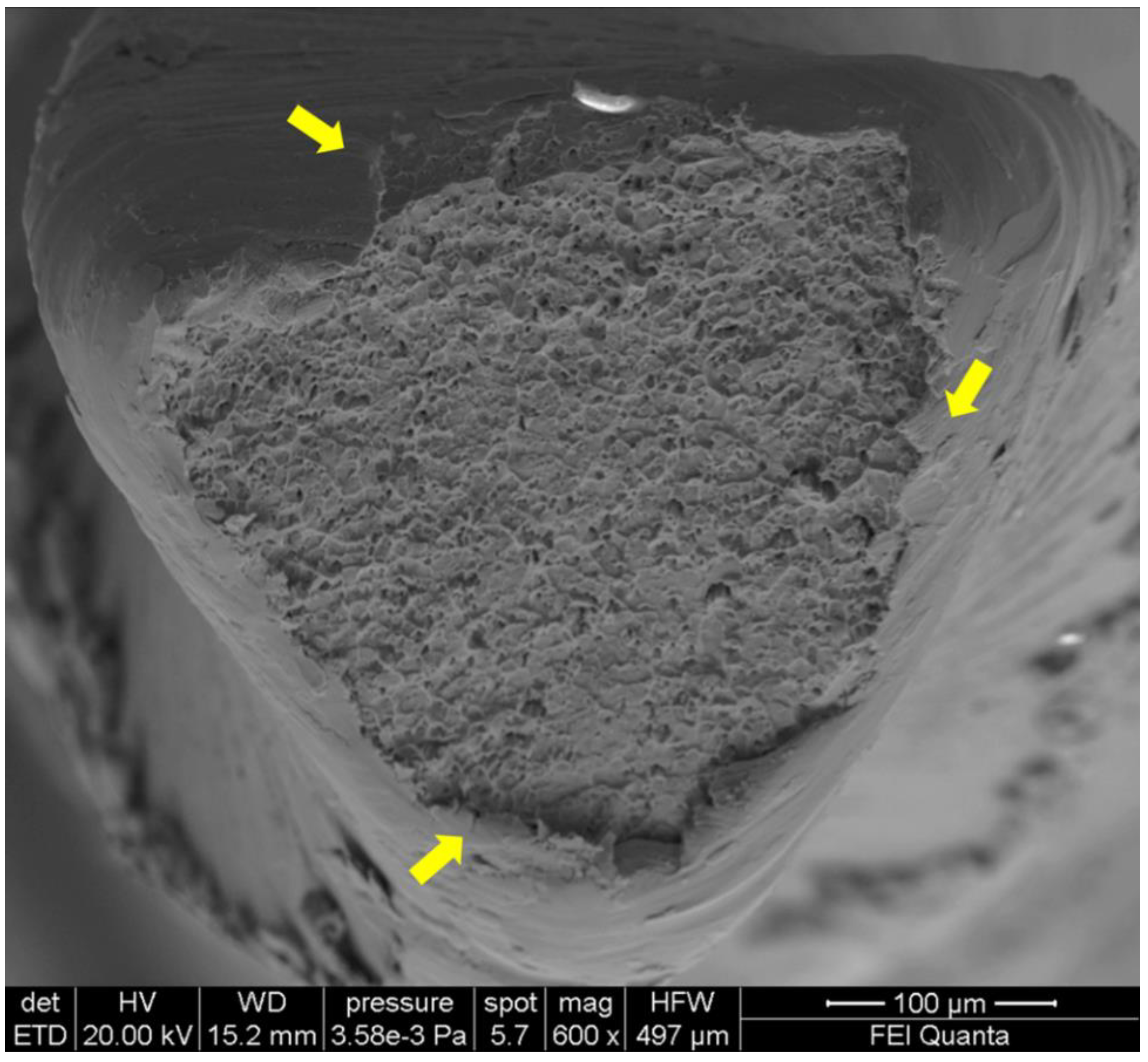

1.3.1. Cyclic Fatigue Resistance

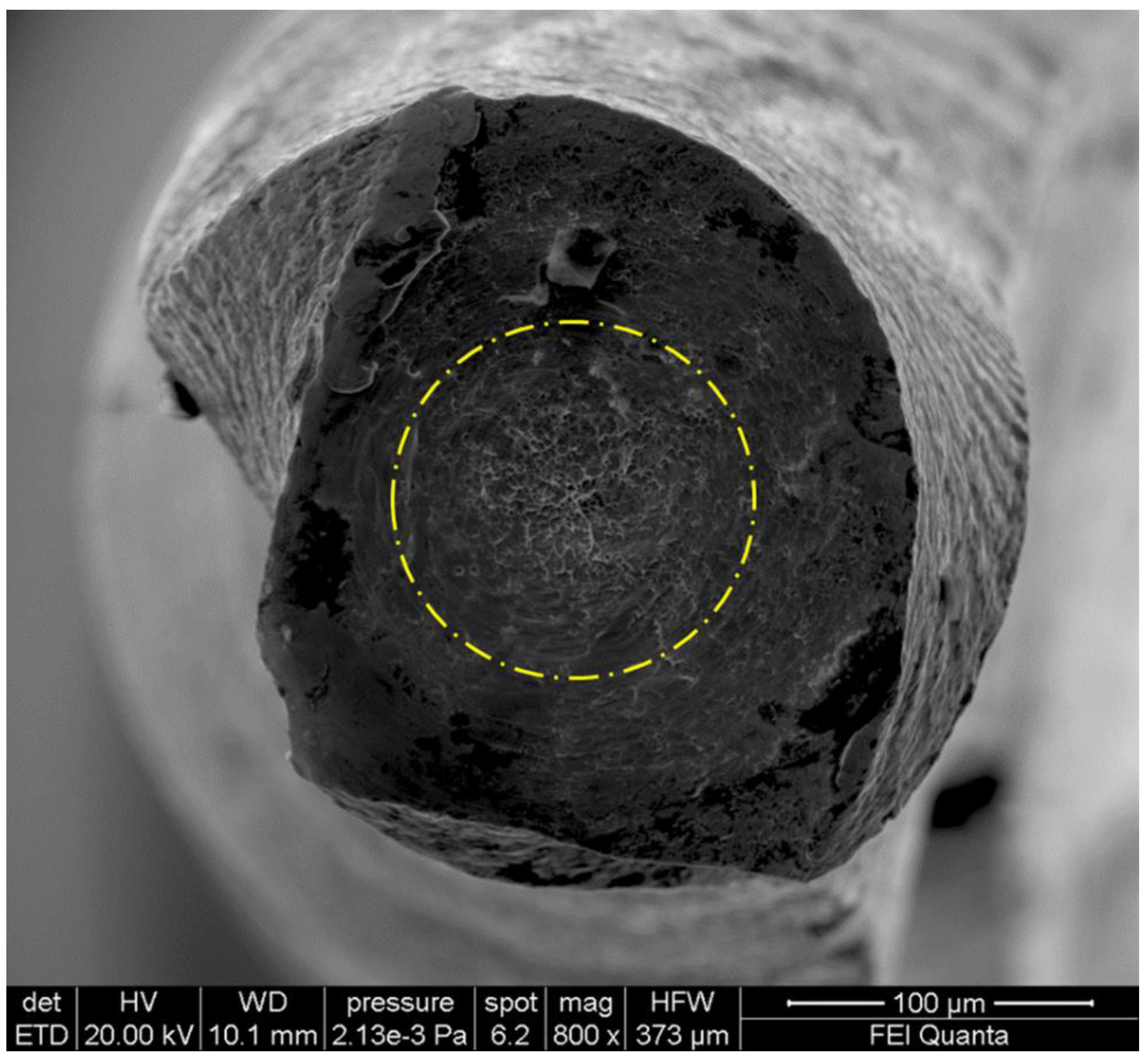

1.3.2. Torsional Resistance

1.3.3. Combined Torsional and Flexural Stresses

1.3.4. Bending Ability

1.4. Centering Ability, Canal Transportation and Shaping Ability

2. Materials and Methods

3. Results

- Reduction in time of endodontic treatments,

- Simplification of instrumentation procedures,

- Increase of predictability and effectiveness of endodontic treatments.

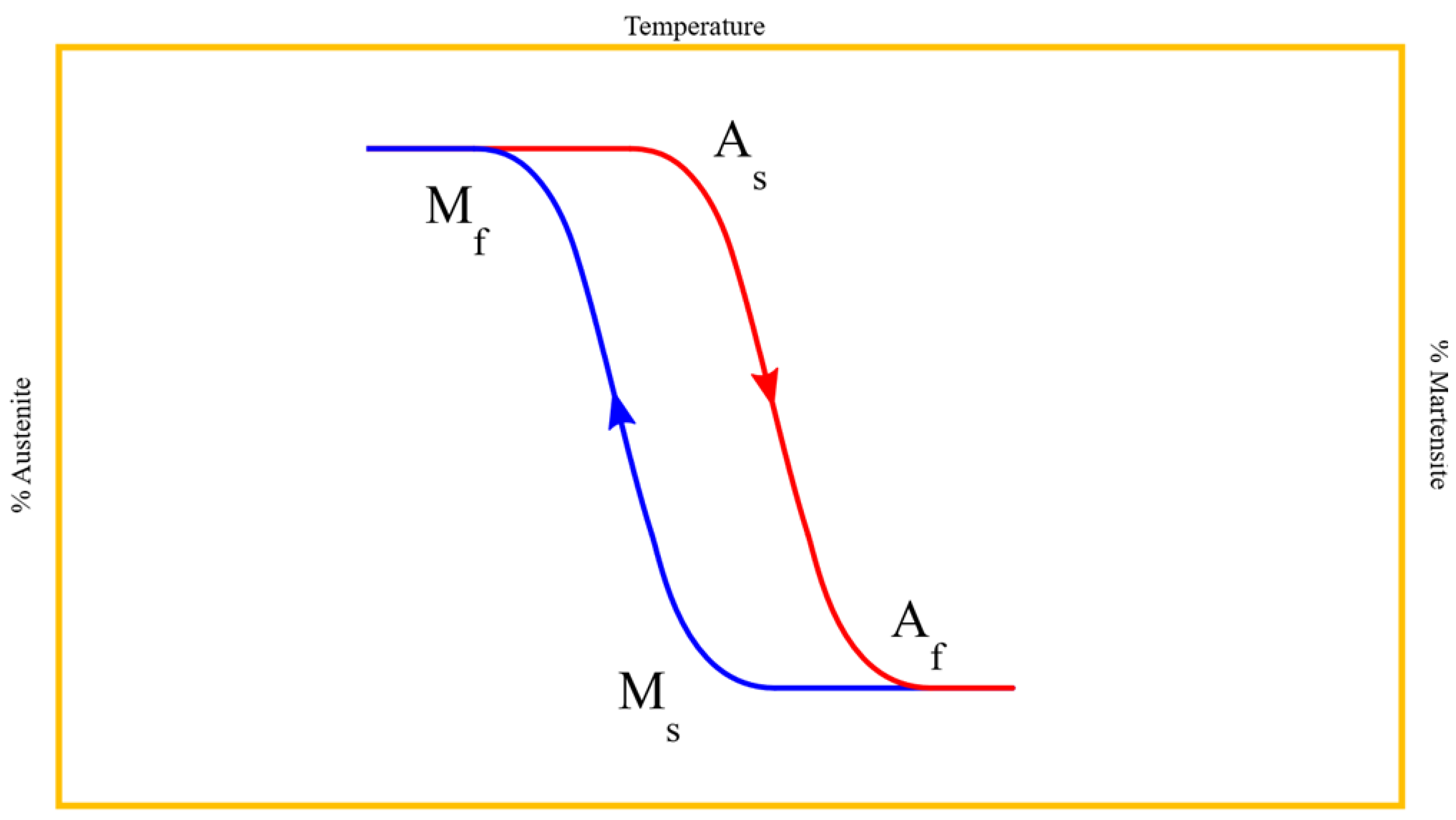

3.1. Thermal Treatments

3.2. Cyclic Fatigue and Torsional Stress Resistance

3.3. Bending Tests

3.4. Centering Ability

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Walia, H.M.; Brantley, W.A.; Gerstein, H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J. Endod. 1988, 14, 346–351. [Google Scholar] [CrossRef]

- Tepel, J.; Schäfer, E.; Hoppe, W. Properties of endodontic hand instruments used in rotary motion. Part 1. Cutting efficiency. J. Endod. 1995, 21, 418–421. [Google Scholar] [CrossRef]

- Schäfer, E.; Tepel, J.; Hoppe, W. Properties of endodontic hand instruments used in rotary motion. Part 2. Instrumentation of curved canals. J. Endod. 1995, 21, 493–497. [Google Scholar] [CrossRef]

- Tepel, J.; Schäfer, E.; Hoppe, W. Properties of endodontic hand instruments used in rotary motion. Part 3. Resistance to bending and fracture. J. Endod. 1997, 23, 141–145. [Google Scholar] [CrossRef]

- Glossen, C.R.; Haller, R.H.; Dove, S.B.; del Rio, C.E. A comparison of root canal preparations using Ni-Ti hand, Ni-Ti engine-driven, and K-Flex endodontic instruments. J. Endod. 1995, 21, 146–151. [Google Scholar] [CrossRef]

- Short, J.A.; Morgan, L.A.; Baumgartner, J.C. A comparison of canal centering ability of four instrumentation techniques. J. Endod. 1997, 23, 503–507. [Google Scholar] [CrossRef]

- Bergmans, L.; Van Cleynenbreugel, J.; Wevers, M.; Lambrechts, P. Mechanical root canal preparation with NiTi rotary instruments: Rationale, performance and safety. Am. J. Dent. 2001, 14, 324–333. [Google Scholar]

- Connert, T.; Truckenmüller, M.; ElAyouti, A.; Eggmann, F.; Krastl, G.; Löst, C.; Weiger, R. Changes in periapical status, quality of root fillings and estimated endodontic treatment need in a similar urban German population 20 years later. Clin. Oral Investig. 2019, 23, 1373–1382. [Google Scholar] [CrossRef]

- Matwychuk, M.J.; Bowles, W.R.; McClanahan, S.B.; Hodges, J.S.; Pesun, I.J. Shaping abilities of two different engine-driven rotary nickel titanium systems or stainless steel balanced-force technique in mandibular molars. J. Endod. 2007, 33, 868–871. [Google Scholar] [CrossRef] [PubMed]

- Weiger, R.; Brückner, M.; ElAyouti, A.; Löst, C. Preparation of curved root canals with rotary FlexMaster instruments compared to Lightspeed instruments and NiTi hand files. Int. Endod. J. 2003, 36, 483–490. [Google Scholar] [CrossRef] [PubMed]

- Vaudt, J.; Bitter, K.; Neumann, K.; Kielbassa, A.M. Ex vivo study on root canal instrumentation of two rotary nickel-titanium systems in comparison to stainless steel hand instruments. Int. Endod. J. 2009, 42, 22–33. [Google Scholar] [CrossRef]

- Govindaraju, L.; Jeevanandan, G.; Subramanian, E. Clinical Evaluation of Quality of Obturation and Instrumentation Time using Two Modified Rotary File Systems with Manual Instrumentation in Primary Teeth. J. Clin. Diagn. Res. 2017, 11, Zc55–Zc58. [Google Scholar] [CrossRef]

- Sadeghi, S. Shaping ability of NiTi rotary versus stainless steel hand instruments in simulated curved canals. Med. Oral Patol. Oral Cir. Bucal. 2011, 16, e454–e458. [Google Scholar] [CrossRef]

- Htun, P.H.; Ebihara, A.; Maki, K.; Kimura, S.; Nishijo, M.; Tokita, D.; Okiji, T. Comparison of torque, force generation and canal shaping ability between manual and nickel-titanium glide path instruments in rotary and optimum glide path motion. Odontology 2020, 108, 188–193. [Google Scholar] [CrossRef]

- Kandaswamy, D.; Venkateshbabu, N.; Porkodi, I.; Pradeep, G. Canal-centering ability: An endodontic challenge. J. Conserv. Dent. 2009, 12, 3–9. [Google Scholar]

- Gergi, R.; Rjeily, J.A.; Sader, J.; Naaman, A. Comparison of canal transportation and centering ability of twisted files, Pathfile-ProTaper system, and stainless steel hand K-files by using computed tomography. J. Endod. 2010, 36, 904–907. [Google Scholar] [CrossRef]

- Donfrancesco, O.; Del Giudice, A.; Zanza, A.; Relucenti, M.; Petracchiola, S.; Gambarini, G.; Testarelli, L.; Seracchiani, M. SEM Evaluation of Endosequence BC Sealer Hiflow in Different Environmental Conditions. J. Compos. Sci. 2021, 5, 99. [Google Scholar] [CrossRef]

- Namazikhah, M.S.; Mokhlis, H.R.; Alasmakh, K. Comparison between a hand stainless-steel K file and a rotary NiTi 0.04 taper. J. Calif Dent. Assoc. 2000, 28, 421–426. [Google Scholar]

- Taşdemir, T.; Aydemir, H.; Inan, U.; Unal, O. Canal preparation with Hero 642 rotary Ni-Ti instruments compared with stainless steel hand K-file assessed using computed tomography. Int. Endod. J. 2005, 38, 402–408. [Google Scholar] [CrossRef]

- Cheung, G.S.; Liu, C.S. A retrospective study of endodontic treatment outcome between nickel-titanium rotary and stainless steel hand filing techniques. J. Endod. 2009, 35, 938–943. [Google Scholar] [CrossRef]

- Del Fabbro, M.; Afrashtehfar, K.I.; Corbella, S.; El-Kabbaney, A.; Perondi, I.; Taschieri, S. In Vivo and In Vitro Effectiveness of Rotary Nickel-Titanium vs Manual Stainless Steel Instruments for Root Canal Therapy: Systematic Review and Meta-analysis. J. Evid. Based Dent. Pract. 2018, 18, 59–69. [Google Scholar] [CrossRef]

- Makanjuola, J.O.; Umesi, D.C.; Oderinu, O.H. Treatment outcome of manual versus rotary techniques in single-visit endodontics for patients in a Nigerian Teaching Hospital: A randomized clinical trial. J. West Afr. Coll. Surg. 2018, 8, 44–75. [Google Scholar]

- Buehler, W.J.; Wang, F.E. A summary of recent research on the nitinol alloys and their potential application in ocean engineering. Ocean. Eng. 1968, 1, 105–120. [Google Scholar] [CrossRef]

- Kauffman, G.B.; Mayo, I. The Story of Nitinol: The Serendipitous Discovery of the Memory Metal and Its Applications. Chem. Educator 1997, 2, 1–21. [Google Scholar] [CrossRef]

- Speck, K.M.; Fraker, A.C. Anodic polarization behavior of Ti-Ni and Ti-6A1-4V in simulated physiological solutions. J. Dent. Res. 1980, 59, 1590–1595. [Google Scholar] [CrossRef]

- Pedullà, E.; Grande, N.M.; Plotino, G.; Palermo, F.; Gambarini, G.; Rapisarda, E. Cyclic fatigue resistance of two reciprocating nickel-titanium instruments after immersion in sodium hypochlorite. Int. Endod. J. 2013, 46, 155–159. [Google Scholar] [CrossRef] [PubMed]

- Thompson, S.A. An overview of nickel-titanium alloys used in dentistry. Int. Endod. J. 2000, 33, 297–310. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ounsi, H.F.; Nassif, W.; Grandini, S.; Salameh, Z.; Neelakantan, P.; Anil, S. Evolution of Nickel-titanium Alloys in Endodontics. J. Contemp. Dent. Pract. 2017, 18, 1090–1096. [Google Scholar]

- Tabassum, S.; Zafar, K.; Umer, F. Nickel-Titanium Rotary File Systems: What’s New? Eur Endod. J. 2019, 4, 111–117. [Google Scholar]

- Zhou, H.; Peng, B.; Zheng, Y.-F. An overview of the mechanical properties of nickel–titanium endodontic instruments. Endodontic Topics. 2013, 29, 42–54. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Sehitoglu, H.; Chumlyakov, Y.; Maier, H.J. Stress dependence of the hysteresis in single crystal NiTi alloys. Acta Materialia 2004, 52, 3383–3402. [Google Scholar] [CrossRef]

- McKelvey, A.L.; Ritchie, R.O. Fatigue-crack growth behavior in the superelastic and shape-memory alloy nitinol. Metall. Mater. Trans. A 2001, 32, 731–743. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, H.M.; Zheng, Y.F.; Peng, B.; Haapasalo, M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J. Endod. 2013, 39, 163–172. [Google Scholar] [CrossRef] [Green Version]

- Alapati, S.B.; Brantley, W.A.; Iijima, M.; Clark, W.A.; Kovarik, L.; Buie, C.; Liu, J.; Ben Johnson, W. Metallurgical characterization of a new nickel-titanium wire for rotary endodontic instruments. J. Endod. 2009, 35, 1589–1593. [Google Scholar] [CrossRef] [PubMed]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New thermomechanically treated NiTi alloys—A review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef] [Green Version]

- Panitvisai, P.; Parunnit, P.; Sathorn, C.; Messer, H.H. Impact of a retained instrument on treatment outcome: A systematic review and meta-analysis. J. Endod. 2010, 36, 775–780. [Google Scholar] [CrossRef]

- Sattapan, B.; Nervo, G.J.; Palamara, J.E.; Messer, H.H. Defects in rotary nickel-titanium files after clinical use. J. Endod. 2000, 26, 161–165. [Google Scholar] [CrossRef] [Green Version]

- Pruett, J.P.; Clement, D.J.; Carnes, D.L. Cyclic fatigue testing of nickel-titanium endodontic instruments. J. Endod. 1997, 23, 77–85. [Google Scholar] [CrossRef]

- Leonardi Dutra, K.; Haas, L.; Porporatti, A.L.; Flores-Mir, C.; Nascimento Santos, J.; Mezzomo, L.A.; Corrêa, M.; Canto, G.D.L. Diagnostic Accuracy of Cone-beam Computed Tomography and Conventional Radiography on Apical Periodontitis: A Systematic Review and Meta-analysis. J. Endod. 2016, 42, 356–364. [Google Scholar] [CrossRef] [PubMed]

- Reda, R.; Zanza, A.; Mazzoni, A.; Cicconetti, A.; Testarelli, L.; Di Nardo, D. An update of the possible applications of magnetic resonance imaging (Mri) in dentistry: A literature review. J. Imaging 2021, 7, 75. [Google Scholar] [CrossRef]

- Di Nardo, D.; Gambarini, G.; Seracchiani, M.; Mazzoni, A.; Zanza, A.; Giudice, A.; D’Angelo, M.; Testarelli, L. Influence of different cross-section on cyclic fatigue resistance of two nickel-titanium rotary instruments with same heat treatment: An in vitro study. Saudi Endod. J. 2020, 10, 221–225. [Google Scholar]

- Seracchiani, M.; Miccoli, G.; Reda, R.; Zanza, A.; Obino, F.V.; Bhandi, S.; Gambarini, G.; Testarelli, L. A comprehensive in vitro comparison of mechanical properties of two rotary endodontic instruments. World J. Dent. 2020, 11, 185–188. [Google Scholar]

- Bhandi, S.; Seracchiani, M.; Donfrancesco, O.; Reda, R.; Mazzoni, A.; Nottola, S.; Familiari, G. Nickel-Titanium Rotary Instruments: An In Vitro Comparison (Torsional Resistance of Two Heat-treated Reciprocating Files). J. Contemp. Dent. Pract. 2021, 22, 361–364. [Google Scholar] [CrossRef] [PubMed]

- Grande, N.M.; Plotino, G.; Pecci, R.; Bedini, R.; Malagnino, V.A.; Somma, F. Cyclic fatigue resistance and three-dimensional analysis of instruments from two nickel-titanium rotary systems. Int. Endod. J. 2006, 39, 755–763. [Google Scholar] [CrossRef]

- Pedullà, E.; La Rosa, G.R.M.; Virgillito, C.; Rapisarda, E.; Kim, H.C.; Generali, L. Cyclic Fatigue Resistance of Nickel-titanium Rotary Instruments according to the Angle of File Access and Radius of Root Canal. J. Endod. 2020, 46, 431–436. [Google Scholar] [CrossRef]

- Kitchens, G.G., Jr.; Liewehr, F.R.; Moon, P.C. The effect of operational speed on the fracture of nickel-titanium rotary instruments. J. Endod. 2007, 33, 52–54. [Google Scholar] [CrossRef]

- Pedullà, E.; Grande, N.M.; Plotino, G.; Gambarini, G.; Rapisarda, E. Influence of continuous or reciprocating motion on cyclic fatigue resistance of 4 different nickel-titanium rotary instruments. J. Endod. 2013, 39, 258–261. [Google Scholar] [CrossRef]

- Pedullà, E.; Corsentino, G.; Ambu, E.; Rovai, F.; Campedelli, F.; Rapisarda, S.; Rapisarda, E.; Grandini, S.; La Rosa, G.R. Influence of continuous rotation or reciprocation of Optimum Torque Reverse motion on cyclic fatigue resistance of nickel-titanium rotary instruments. Int. Endod. J. 2018, 51, 522–528. [Google Scholar] [CrossRef]

- Gambarini, G.; Seracchiani, M.; Zanza, A.; Miccoli, G.; Del Giudice, A.; Testarelli, L. Influence of shaft length on torsional behavior of endodontic nickel–titanium instruments. Odontology 2020, 109, 568–573. [Google Scholar] [CrossRef]

- Peters, O.A.; Peters, C.I.; Schönenberger, K.; Barbakow, F. ProTaper rotary root canal preparation: Assessment of torque and force in relation to canal anatomy. Int. Endod. J. 2003, 36, 93–99. [Google Scholar] [CrossRef] [Green Version]

- Boessler, C.; Peters, O.A.; Zehnder, M. Impact of lubricant parameters on rotary instrument torque and force. J. Endod. 2007, 33, 280–283. [Google Scholar] [CrossRef]

- Gambarini, G.; Seracchiani, M.; Piasecki, L.; Valenti Obino, F.; Galli, M.; Di Nardo, D.; Testarelli, L. Measurement of torque generated during intracanal instrumentation in vivo. Int. Endod. J. 2019, 52, 737–745. [Google Scholar] [CrossRef]

- Roland, D.D.; Andelin, W.E.; Browning, D.F.; Hsu, G.H.; Torabinejad, M. The effect of preflaring on the rates of separation for 0.04 taper nickel titanium rotary instruments. J. Endod. 2002, 28, 543–545. [Google Scholar] [CrossRef]

- Yared, G.; Sleiman, P. Failure of ProFile instruments used with air, high torque control, and low torque control motors. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2002, 93, 92–96. [Google Scholar] [CrossRef] [Green Version]

- Parashos, P.; Messer, H.H. Rotary NiTi instrument fracture and its consequences. J. Endod. 2006, 32, 1031–1043. [Google Scholar] [CrossRef]

- Ha, J.H.; Park, S.S. Influence of glide path on the screw-in effect and torque of nickel-titanium rotary files in simulated resin root canals. Restor. Dent. Endod. 2012, 37, 215–219. [Google Scholar] [CrossRef]

- Tokita, D.; Ebihara, A.; Nishijo, M.; Miyara, K.; Okiji, T. Dynamic Torque and Vertical Force Analysis during Nickel-titanium Rotary Root Canal Preparation with Different Modes of Reciprocal Rotation. J. Endod. 2017, 43, 1706–1710. [Google Scholar] [CrossRef] [PubMed]

- Kwak, S.W.; Ha, J.H.; Cheung, G.S.; Kim, H.C.; Kim, S.K. Effect of the Glide Path Establishment on the Torque Generation to the Files during Instrumentation: An In Vitro Measurement. J. Endod. 2018, 44, 496–500. [Google Scholar] [CrossRef]

- Kimura, S.; Ebihara, A.; Maki, K.; Nishijo, M.; Tokita, D.; Okiji, T. Effect of Optimum Torque Reverse Motion on Torque and Force Generation during Root Canal Instrumentation with Crown-down and Single-length Techniques. J. Endod. 2020, 46, 232–237. [Google Scholar] [CrossRef]

- Di Nardo, D.; Zanza, A.; Seracchiani, M.; Donfrancesco, O.; Gambarini, G.; Testarelli, L. Angle of Insertion and Torsional Resistance of Nickel–Titanium Rotary Instruments. Materials 2021, 14, 3744. [Google Scholar] [CrossRef]

- Seracchiani, M.; Miccoli, G.; Di Nardo, D.; Zanza, A.; Cantore, M.; Gambarini, G.; Testarelli, L. Effect of Flexural Stress on Torsional Resistance of NiTi Instruments. J. Endod. 2021, 47, 472–476. [Google Scholar] [CrossRef]

- Baek, S.H.; Lee, C.J.; Versluis, A.; Kim, B.M.; Lee, W.; Kim, H.C. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J. Endod. 2011, 37, 1283–1286. [Google Scholar] [CrossRef]

- Vivan, R.R.; Alcalde, M.P.; Candeiro, G.; Gavini, G.; Caldeira, C.L.; Duarte, M.A.H. Torsional fatigue strength of reciprocating and rotary pathfinding instruments manufactured from different NiTi alloys. Braz. Oral Res. 2019, 33, e097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gambarini, G.; Cicconetti, A.; Nardo, D.D.; Miccoli, G.; Zanza, A.; Testarelli, L.; Seracchiani, M. Influence of different heat treatments on torsional and cyclic fatigue resistance of nickel-titanium rotary files: A comparative study. Appl. Sci. 2020, 10, 5604. [Google Scholar] [CrossRef]

- Camps, J.J.; Pertot, W.J.; Levallois, B. Relationship between file size and stiffness of nickel titanium instruments. Endod. Dent. Traumatol. 1995, 11, 270–273. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.C.; Kim, H.J.; Lee, C.J.; Kim, B.M.; Park, J.K.; Versluis, A. Mechanical response of nickel-titanium instruments with different cross-sectional designs during shaping of simulated curved canals. Int. Endod. J. 2009, 42, 593–602. [Google Scholar] [CrossRef] [PubMed]

- Berutti, E.; Chiandussi, G.; Gaviglio, I.; Ibba, A. Comparative analysis of torsional and bending stresses in two mathematical models of nickel-titanium rotary instruments: ProTaper versus ProFile. J. Endod. 2003, 29, 15–19. [Google Scholar] [CrossRef]

- Zanza, A.; Seracchiani, M.; Di Nardo, D.; Reda, R.; Gambarini, G.; Testarelli, L. A Paradigm Shift for Torsional Stiffness of Nickel-Titanium Rotary Instruments: A Finite Element Analysis. J. Endod. 2021, 47, 1149–1156. [Google Scholar] [CrossRef]

- Iacono, F.; Pirani, C.; Gatto, M.R.; Prati, C.; Peters, O. Combining apical torsional load and cyclic fatigue resistance of NiTi instruments: New approach to determine the effective lifespan of rotary instruments. Aust. Endod. J. 2021. online ahead of print. [Google Scholar] [CrossRef]

- Santos, C.B.; Simões-Carvalho, M.; Perez, R.; Vieira, V.T.L.; Antunes, H.S.; Cavalcante, D.F.; De-Deus, G.; Silva, E.J.N.L. Torsional fatigue resistance of R-Pilot and WaveOne Gold Glider NiTi glide path reciprocating systems. Int. Endod. J. 2019, 52, 874–879. [Google Scholar] [CrossRef]

- Zanza, A.; Seracchiani, M.; Reda, R.; Di Nardo, D.; Gambarini, G.; Testarelli, L. Role of the Crystallographic Phase of NiTi Rotary Instruments in Determining Their Torsional Resistance during Different Bending Conditions. Materials 2021, 14, 6324. [Google Scholar] [CrossRef]

- Gambarini, G.; Miccoli, G.; D’Angelo, M.; Seracchiani, M.; Obino, F.V.; Reda, R.; Testarelli, L. The relevance of operative torque and torsional resistance of nickel-titanium rotary instruments: A preliminary clinical investigation. Saudi Endod. J. 2020, 10, 260–264. [Google Scholar]

- Viana, A.C.; Chaves Craveiro de Melo, M.; Guiomar de Azevedo Bahia, M.; Lopes Buono, V.T. Relationship between flexibility and physical, chemical, and geometric characteristics of rotary nickel-titanium instruments. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2010, 110, 527–533. [Google Scholar] [CrossRef] [PubMed]

- Bahia, M.G.A.; Martins, R.C.; Gonzalez, B.M.; Buono, V.T.L. Physical and mechanical characterization and the influence of cyclic loading on the behaviour of nickel-titanium wires employed in the manufacture of rotary endodontic instruments. Int. Endod. J. 2005, 38, 795–801. [Google Scholar] [CrossRef]

- Hamdy, T.M.; Galal, M.; Ismail, A.G.; Abdelraouf, R.M. Evaluation of Flexibility, Microstructure and Elemental Analysis of Some Contemporary Nickel-Titanium Rotary Instruments. Open Access Maced J. Med. Sci. 2019, 7, 3647–3654. [Google Scholar] [CrossRef] [Green Version]

- Park, H. A comparison of Greater Taper files, ProFiles, and stainless steel files to shape curved root canals. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2001, 91, 715–718. [Google Scholar] [CrossRef] [PubMed]

- de Arruda Santos, L.; López, J.B.; de Las Casas, E.B.; de Azevedo Bahia, M.G.; Buono, V.T. Mechanical behavior of three nickel-titanium rotary files: A comparison of numerical simulation with bending and torsion tests. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 37, 258–263. [Google Scholar] [CrossRef]

- Razcha, C.; Zacharopoulos, A.; Anestis, D.; Mikrogeorgis, G.; Zacharakis, G.; Lyroudia, K. Micro-Computed Tomographic Evaluation of Canal Transportation and Centering Ability of 4 Heat-Treated Nickel-Titanium Systems. J. Endod. 2020, 46, 675–681. [Google Scholar] [CrossRef]

- Yahata, Y.; Yoneyama, T.; Hayashi, Y.; Ebihara, A.; Doi, H.; Hanawa, T.; Suda, H. Effect of heat treatment on transformation temperatures and bending properties of nickel-titanium endodontic instruments. Int. Endod. J. 2009, 42, 621–626. [Google Scholar] [CrossRef]

- Hou, X.; Yahata, Y.; Hayashi, Y.; Ebihara, A.; Hanawa, T.; Suda, H. Phase transformation behaviour and bending property of twisted nickel-titanium endodontic instruments. Int. Endod. J. 2011, 44, 253–258. [Google Scholar] [CrossRef]

- Testarelli, L.; Plotino, G.; Al-Sudani, D.; Vincenzi, V.; Giansiracusa, A.; Grande, N.M.; Gambarini, G. Bending properties of a new nickel-titanium alloy with a lower percent by weight of nickel. J. Endod. 2011, 37, 1293–1295. [Google Scholar] [CrossRef]

- Miccoli, G.; Cicconetti, A.; Gambarini, G.; Del Giudice, A.; Ripanti, F.; Di Nardo, D.; Testarelli, L.; Seracchiani, M. A New Device to Test the Bending Resistance of Mechanical Endodontic Instruments. Appl. Sci. 2020, 10, 7215. [Google Scholar] [CrossRef]

- Silva, E.; Martins, J.N.R.; Lima, C.O.; Vieira, V.T.L.; Braz Fernandes, F.M.; De-Deus, G.; Versiani, M.A. Mechanical Tests, Metallurgical Characterization, and Shaping Ability of Nickel-Titanium Rotary Instruments: A Multimethod Research. J. Endod. 2020, 46, 1485–1494. [Google Scholar] [CrossRef] [PubMed]

- Chugal, N.; Mallya, S.M.; Kahler, B.; Lin, L.M. Endodontic Treatment Outcomes. Dent. Clin. North Am. 2017, 61, 59–80. [Google Scholar] [CrossRef] [PubMed]

- Ng, Y.L.; Mann, V.; Rahbaran, S.; Lewsey, J.; Gulabivala, K. Outcome of primary root canal treatment: Systematic review of the literature—Part 1. Effects of study characteristics on probability of success. Int. Endod. J. 2007, 40, 921–939. [Google Scholar] [CrossRef] [PubMed]

- Ng, Y.L.; Mann, V.; Rahbaran, S.; Lewsey, J.; Gulabivala, K. Outcome of primary root canal treatment: Systematic review of the literature—Part 2. Influence of clinical factors. Int. Endod. J. 2008, 41, 6–31. [Google Scholar] [CrossRef]

- Gorni, F.G.; Gagliani, M.M. The outcome of endodontic retreatment: A 2-yr follow-up. J. Endod. 2004, 30, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Lin, L.M.; Rosenberg, P.A.; Lin, J. Do procedural errors cause endodontic treatment failure? J. Am. Dent. Assoc. 2005, 136, 187–193. [Google Scholar] [CrossRef]

- Song, M.; Kim, H.C.; Lee, W.; Kim, E. Analysis of the cause of failure in nonsurgical endodontic treatment by microscopic inspection during endodontic microsurgery. J. Endod. 2011, 37, 1516–1519. [Google Scholar] [CrossRef]

- Sousa-Neto, M.D.; Silva-Sousa, Y.C.; Mazzi-Chaves, J.F.; Carvalho, K.K.T.; Barbosa, A.F.S.; Versiani, M.A.; Jacobs, R.; Leoni, G. Root canal preparation using micro-computed tomography analysis: A literature review. Braz. Oral Res. 2018, 32, e66. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Drukteinis, S.; Peciuliene, V.; Dummer, P.M.H.; Hupp, J. Shaping ability of BioRace, ProTaper NEXT and Genius nickel-titanium instruments in curved canals of mandibular molars: A MicroCT study. Int. Endod. J. 2019, 52, 86–93. [Google Scholar] [CrossRef] [PubMed]

- Htun, P.H.; Ebihara, A.; Maki, K.; Kimura, S.; Nishijo, M.; Okiji, T. Cleaning and Shaping Ability of Gentlefile, HyFlex, EDM, and ProTaper Next Instruments: A Combined Micro-computed Tomographic and Scanning Electron Microscopic Study. J. Endod. 2020, 46, 973–979. [Google Scholar] [CrossRef] [PubMed]

- Velozo, C.; Silva, S.; Almeida, A.; Romeiro, K.; Vieira, B.; Dantas, H.; de Sousa, F.B.; De Albuquerque, D.S. Shaping ability of XP-endo Shaper and ProTaper Next in long oval-shaped canals: A micro-computed tomography study. Int. Endod. J. 2020, 53, 998–1006. [Google Scholar] [CrossRef] [PubMed]

- Muruganandhan, J.; Sujatha, G.; Poorni, S.; Srinivasan, M.; Boreak, N.; Al-Kahtani, A.; Mashyakhy, M.; Chohan, H.; Bhandi, S.; Raj, A.; et al. Comparison of Four Dental Pulp-Capping Agents by Cone-Beam Computed Tomography and Histological Techniques—A Split-Mouth Design Ex Vivo Study. Appl. Sci. 2021, 11, 3045. [Google Scholar] [CrossRef]

- Kabil, E.; Katić, M.; Anić, I.; Bago, I. Micro-computed Evaluation of Canal Transportation and Centering Ability of 5 Rotary and Reciprocating Systems with Different Metallurgical Properties and Surface Treatments in Curved Root Canals. J. Endod. 2021, 47, 477–484. [Google Scholar] [CrossRef] [PubMed]

- Hülsmann, M.; Rümmelin, C.; Schäfers, F. Root canal cleanliness after preparation with different endodontic handpieces and hand instruments: A comparative SEM investigation. J. Endod. 1997, 23, 301–306. [Google Scholar] [CrossRef]

- Garip, Y.; Sazak, H.; Gunday, M.; Hatipoglu, S. Evaluation of smear layer removal after use of a canal brush: An SEM study. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2010, 110, e62–e66. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Özyürek, T.; Grande, N.M.; Gündoğar, M. Influence of size and taper of basic root canal preparation on root canal cleanliness: A scanning electron microscopy study. Int. Endod. J. 2019, 52, 343–351. [Google Scholar] [CrossRef]

- Gambill, J.M.; Alder, M.; del Rio, C.E. Comparison of nickel-titanium and stainless steel hand-file instrumentation using computed tomography. J. Endod. 1996, 22, 369–375. [Google Scholar] [CrossRef]

- Poly, A.; AlMalki, F.; Marques, F.; Karabucak, B. Canal transportation and centering ratio after preparation in severely curved canals: Analysis by micro-computed tomography and double-digital radiography. Clin. Oral Investig. 2019, 23, 4255–4262. [Google Scholar] [CrossRef]

- De-Deus, G.; Belladonna, F.G.; Silva, E.J.; Marins, J.R.; Souza, E.M.; Perez, R.; Lopes, R.T.; Versiani, M.; Paciornik, S.; Neves, A.D.A. Micro-CT Evaluation of Non-instrumented Canal Areas with Different Enlargements Performed by NiTi Systems. Braz. Dent. J. 2015, 26, 624–629. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Silva, A.A.; Belladonna, F.G.; Rover, G.; Lopes, R.T.; Moreira, E.J.L.; De-Deus, G.; Silva, E.J.N.L. Does ultraconservative access affect the efficacy of root canal treatment and the fracture resistance of two-rooted maxillary premolars? Int. Endod. J. 2020, 53, 265–275. [Google Scholar] [CrossRef]

- De-Deus, G.; Marins, J.; Silva, E.J.; Souza, E.; Belladonna, F.G.; Reis, C.; Machado, A.S.; Lopes, R.T.; Versiani, M.A.; Paciornik, S.; et al. Accumulated hard tissue debris produced during reciprocating and rotary nickel-titanium canal preparation. J. Endod. 2015, 41, 676–681. [Google Scholar] [CrossRef]

- Paqué, F.; Laib, A.; Gautschi, H.; Zehnder, M. Hard-tissue debris accumulation analysis by high-resolution computed tomography scans. J. Endod. 2009, 35, 1044–1047. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhandi, S.; Mashyakhy, M.; Abumelha, A.S.; Alkahtany, M.F.; Jamal, M.; Chohan, H.; Raj, A.T.; Testarelli, L.; Reda, R.; Patil, S. Complete Obturation-Cold Lateral Condensation vs. Thermoplastic Techniques: A Systematic Review of Micro-CT Studies. Materials 2021, 14, 4013. [Google Scholar] [CrossRef]

- Paqué, F.; Ganahl, D.; Peters, O.A. Effects of root canal preparation on apical geometry assessed by micro-computed tomography. J. Endod. 2009, 35, 1056–1059. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Velozo, C.; Albuquerque, D. Microcomputed Tomography Studies of the Effectiveness of XP-endo Shaper in Root Canal Preparation: A Review of the Literature. Sci. World J. 2019, 2019, 3570870. [Google Scholar] [CrossRef]

- Schneider, S.W. A comparison of canal preparations in straight and curved root canals. Oral Surg. Oral Med. Oral Pathol. 1971, 32, 271–275. [Google Scholar] [CrossRef]

- Setzer, F.C.; Kwon, T.K.; Karabucak, B. Comparison of apical transportation between two rotary file systems and two hybrid rotary instrumentation sequences. J. Endod. 2010, 36, 1226–1229. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Shen, Y.; Peng, B.; Haapasalo, M. Micro-computed tomography evaluation of the preparation of mesiobuccal root canals in maxillary first molars with Hyflex, CM Twisted Files, and K3 instruments. J. Endod. 2013, 39, 385–388. [Google Scholar] [CrossRef]

- Seracchiani, M.; Donfrancesco, O.; Relucenti, M.; Reda, R.; Zanza, A.; Gambarini, G.; Testarelli, L. In vitro evaluation of a recently developed rotary file: AF rotary. Braz. Dent. Sci. 2021, 24. [Google Scholar] [CrossRef]

| Alloy | Crystallographic Phase | NiTi System |

|---|---|---|

| Conventional NiTi alloy | Austenitic | Mtwo OneShape ProFile ProTaper Universal RaCe, BioRaCe, iRace F360, F6 Skytaper EdgeTaper |

| R-phase | Austenitic | Twisted File Twisted File Adaptive K3XF (not twisted) |

| M-Wire | Austenitic with small amounts of R-phase and martensite | ProFile Vortex ProFile GT Series X ProTaper Next Reciproc WaveOne |

| CM Wire | Martensitic with varying amounts of austenite and R-phase | Hyflex CM THYPOON Infinite Flex NiTi Files V-Taper 2H Hyflex EDM |

| Gold heat-treated | Martensitic with varying amounts of austenite and R-phase | ProTaper Gold WaveOne Gold |

| Blue heat-treated | Martensitic with varying amounts of austenite and R-phase | ProFile Vortex Blue Reciproc Blue Rotate |

| MaxWire | Martensitic (20 °C), austenitic (35 °C) | XP-endo Finisher XP-endo Shaper |

| T-Wire | Martensitic with varying amounts of austenite and R-phase | 2Shape |

| C-Wire | Martensitic with varying amounts of austenite and R-phase | OneCurve RECI One |

| FireWire | Martensitic with varying amounts of austenite and R-phase | EdgeOne Fire EdgeSequel Sapphire EdgeTaper Platinum EdgeFile X7 |

| AF-R Wire | Martensitic with varying amounts of austenite and R-phase | AF-One |

| FKG heat treatment | Phase transition ranging from 32 °C to 35 °C (between martensite and austenite) | R-Motion file System Race Evo |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zanza, A.; D’Angelo, M.; Reda, R.; Gambarini, G.; Testarelli, L.; Di Nardo, D. An Update on Nickel-Titanium Rotary Instruments in Endodontics: Mechanical Characteristics, Testing and Future Perspective—An Overview. Bioengineering 2021, 8, 218. https://doi.org/10.3390/bioengineering8120218

Zanza A, D’Angelo M, Reda R, Gambarini G, Testarelli L, Di Nardo D. An Update on Nickel-Titanium Rotary Instruments in Endodontics: Mechanical Characteristics, Testing and Future Perspective—An Overview. Bioengineering. 2021; 8(12):218. https://doi.org/10.3390/bioengineering8120218

Chicago/Turabian StyleZanza, Alessio, Maurilio D’Angelo, Rodolfo Reda, Gianluca Gambarini, Luca Testarelli, and Dario Di Nardo. 2021. "An Update on Nickel-Titanium Rotary Instruments in Endodontics: Mechanical Characteristics, Testing and Future Perspective—An Overview" Bioengineering 8, no. 12: 218. https://doi.org/10.3390/bioengineering8120218

APA StyleZanza, A., D’Angelo, M., Reda, R., Gambarini, G., Testarelli, L., & Di Nardo, D. (2021). An Update on Nickel-Titanium Rotary Instruments in Endodontics: Mechanical Characteristics, Testing and Future Perspective—An Overview. Bioengineering, 8(12), 218. https://doi.org/10.3390/bioengineering8120218