Comminution of Dry Lignocellulosic Biomass, a Review: Part I. From Fundamental Mechanisms to Milling Behaviour

Abstract

1. Introduction

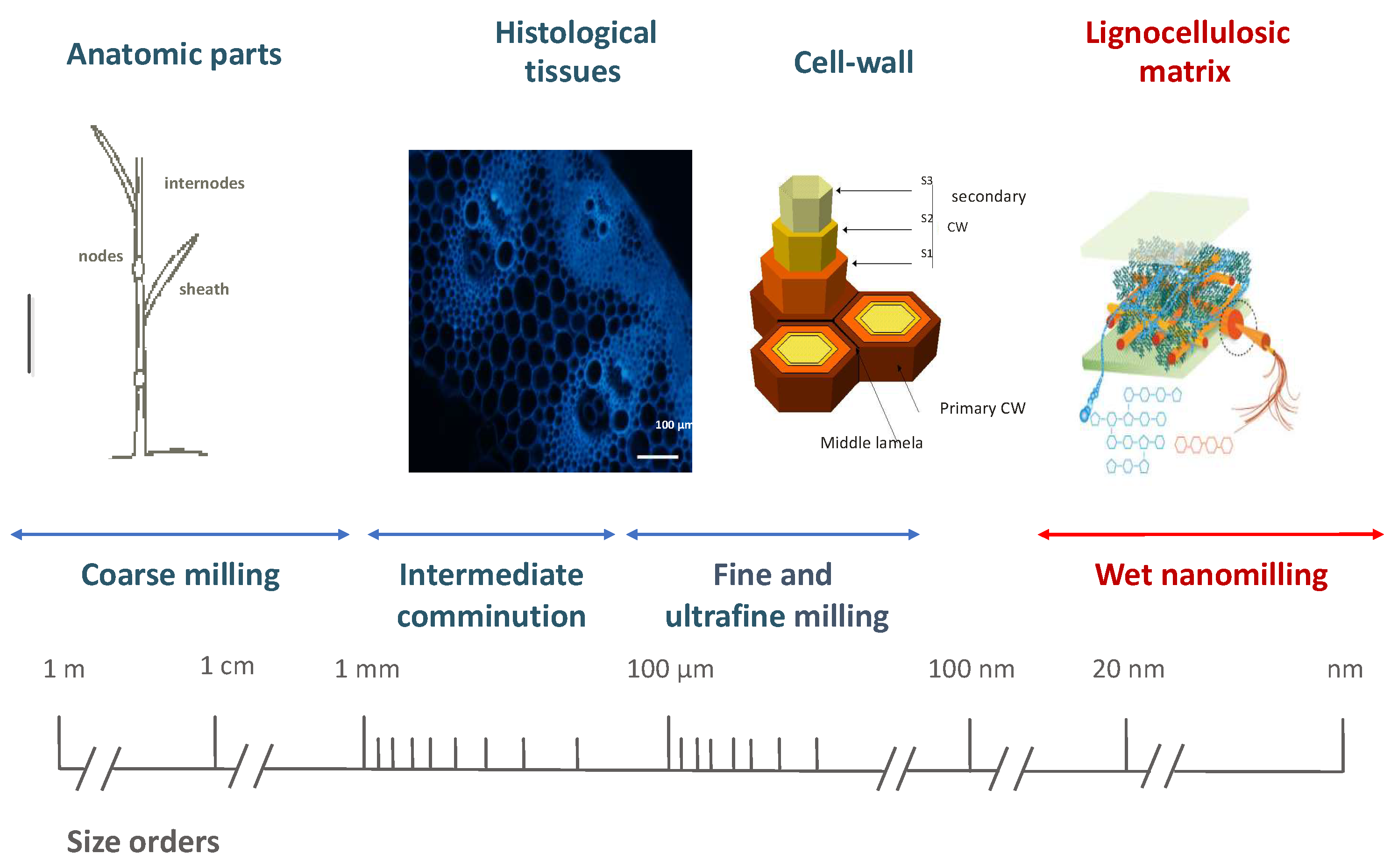

2. Lignocellulosic Biomass Structure and Composition

3. Milling Processes

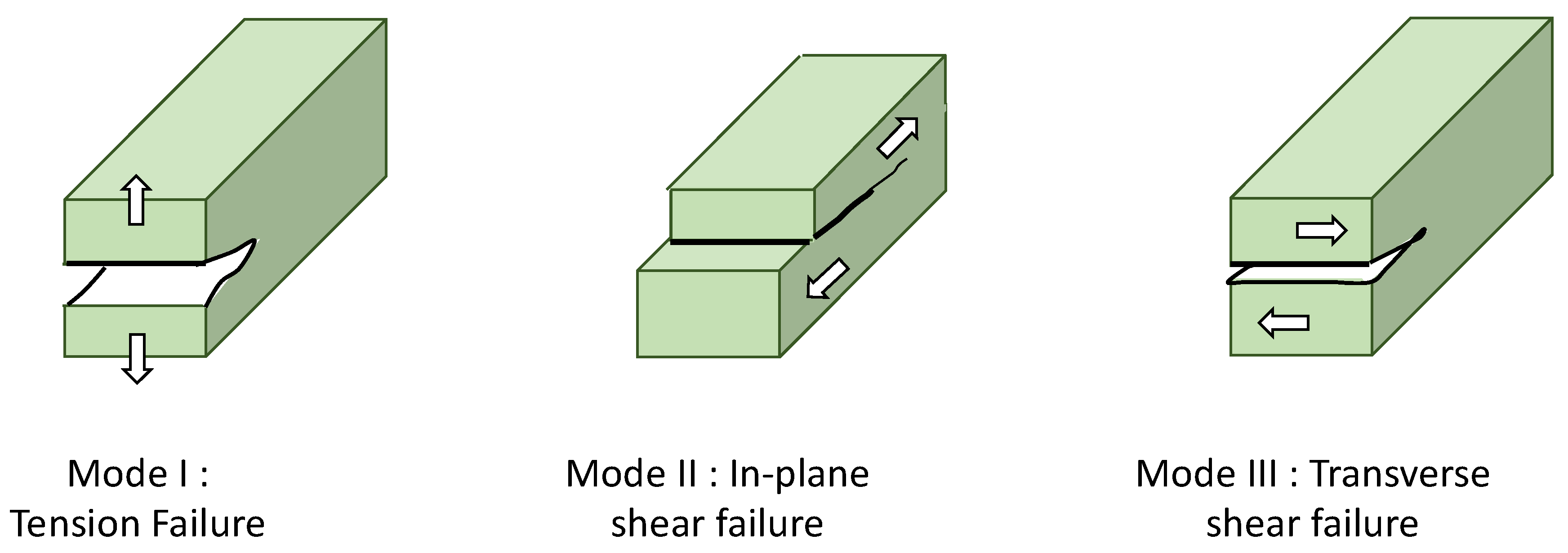

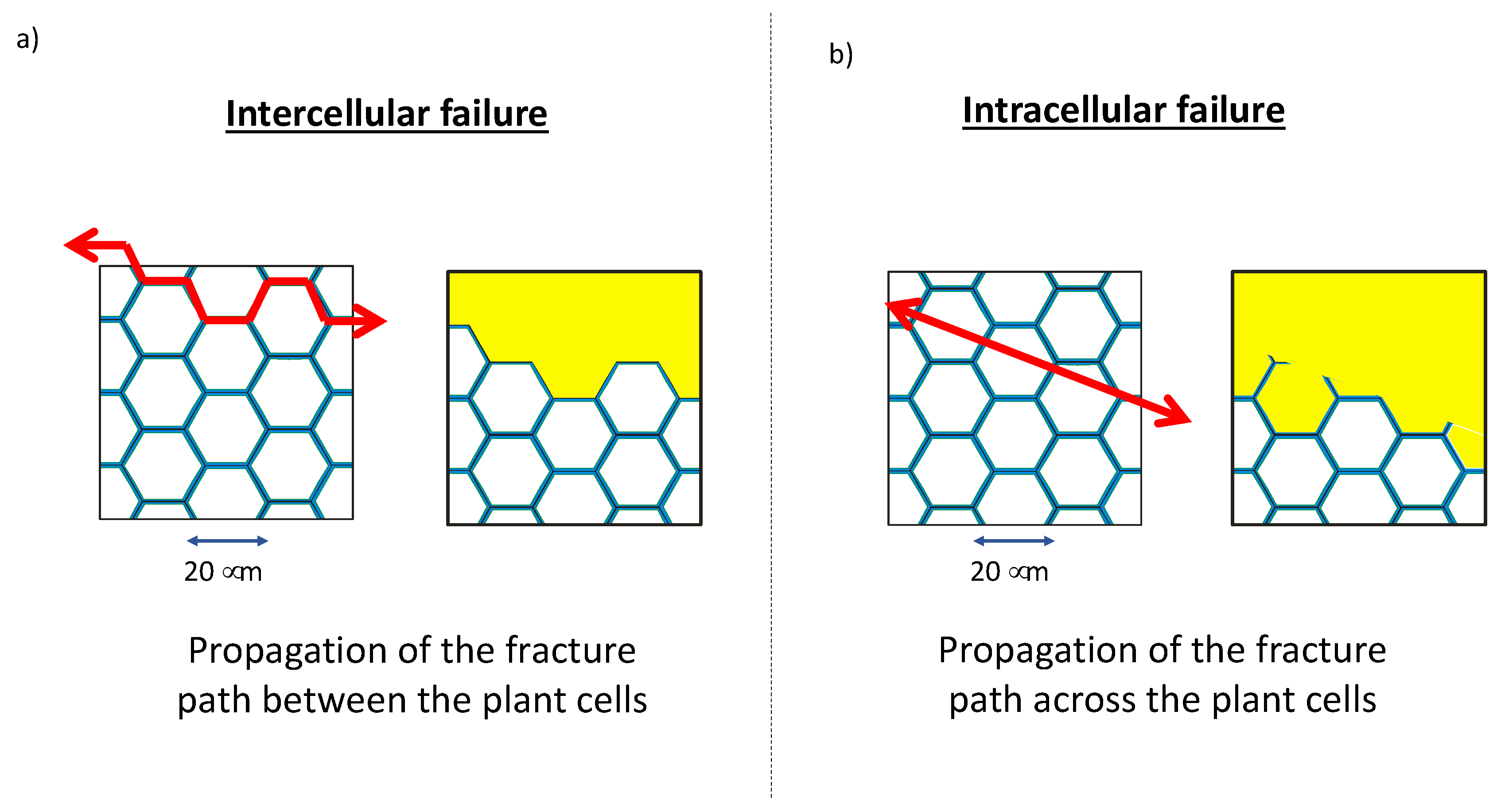

4. Interactions between Plant Material and Mechanical Stress during the Comminution

5. Influence of Milling on the Properties of Particles (Size, Shape, Surface Area)

6. Energy Consumption during Comminution

7. Conclusions

Author Contributions

Conflicts of Interest

References

- IEA. World Energy Outlook 2017; International Energy Agency: Paris, France, November 2017. [Google Scholar]

- Hadar, Y. Sources for lignocellulosic raw materials for the production of ethanol. In Lignocellulose Conversion: Enzymatic and Microbial Tools for Bioethanol Production; Faraco, V., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 21–38. [Google Scholar]

- Motte, J.C.; Escudié, R.; Bernet, N.; Delgenes, J.P.; Steyer, J.P.; Dumas, C. Dynamic effect of total solid content, low substrate/inoculum ratio and particle size on solid-state anaerobic digestion. Bioresour. Technol. 2013, 144, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Silva, G.G.D.; Couturier, M.; Berrin, J.-G.; Buléon, A.; Rouau, X. Effects of grinding processes on enzymatic degradation of wheat straw. Bioresour. Technol. 2012, 103, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Guizani, C.; Escudero Sanz, F.J.; Salvador, S. Influence of temperature and particle size on the single and mixed atmosphere gasification of biomass char with H2O and CO2. Fuel Process. Technol. 2015, 134, 175–188. [Google Scholar] [CrossRef]

- McKnight, J. Powdered Fuels, Dispersions Thereof, and Combustion Devices Related Thereto. WO2008063549A2, 29 May 2008. [Google Scholar]

- Piriou, B.; Vaitilingom, G.; Veyssière, B.; Cuq, B.; Rouau, X. Potential direct use of solid biomass in internal combustion engines. Prog. Energy Combust. Sci. 2013, 39, 169–188. [Google Scholar] [CrossRef]

- Hemery, Y.; Chaurand, M.; Holopainen, U.; Lampi, A.-M.; Lehtinen, P.; Piironen, V.; Sadoudi, A.; Rouau, X. Potential of dry fractionation of wheat bran for the development of food ingredients, part i: Influence of ultra-fine grinding. J. Cereal Sci. 2011, 53, 1–8. [Google Scholar] [CrossRef]

- Trivelato, P.; Mayer, C.; Barakat, A.; Fulcrand, H.; Aouf, C. Douglas bark dry fractionation for polyphenols isolation: From forestry waste to added value products. Ind. Crops Prod. 2016, 86, 12–15. [Google Scholar] [CrossRef]

- Maya, J.J.; Sabu, T. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar]

- Berthet, M.A.; Angellier-Coussy, H.; Chea, V.; Guillard, V.; Gastaldi, E.; Gontard, N. Sustainable food packaging: Valorising wheat straw fibres for tuning phbv-based composites properties. Compos. Part A Appl. Sci. Manuf. 2015, 72, 139–147. [Google Scholar] [CrossRef]

- Womac, R.A.; Igathinathane, C.; Bitra, P.; Miu, P.; Yang, T.; Sokhansanj, S.; Narayan, S. Biomass pre-processing size reduction with instrumented mills. In 2007 ASAE Annual Meeting; ASABE: St. Joseph, MI, USA, 2007. [Google Scholar]

- Buchanan, B.B.; Gruissem, W.; Jones, R.L. Biochemistry and Molecular Biology of Plants, 2nd ed.; Wiley & sons Publisher: Somerset, NJ, USA, 2015. [Google Scholar]

- Jauberthie, R.; Rendell, F.; Tamba, S.; Cisse, I. Origin of the pozzolanic effect of rice husks. Constr. Build. Mater. 2000, 14, 419–423. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions; Fengel, D., Wegener, G., Eds.; Verlag Kessel: Remagen, Germany, 1984; pp. 227–239. [Google Scholar]

- da Silva, G.G.D. Fractionnement par Voie Sèche de la Biomasse ligno-Cellulosique: Broyage Poussé de la Paille de Blé et Effets sur ses Bioconversions. Ph.D. Thesis, Supagro, Montpellier, France, 2011. [Google Scholar]

- Monties, B. Les Polymères Végétaux; Gauthier-Villars: Paris, France, 1980. [Google Scholar]

- Monties, B. Plant Phenolics; Elsevier Publisher: Amsterdam, The Netherlands, 1989; Volume 1. [Google Scholar]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Mallek-Fakhfakh, H.; Fakhfakh, J.; Walha, K.; Hassairi, H.; Gargouri, A.; Belghith, H. Enzymatic hydrolysis of pretreated alfa fibers (Stipa tenacissima) using β-d-glucosidase and xylanase of talaromyces thermophilus from solid-state fermentation. Int. J. Biol. Macromol. 2017, 103, 543–553. [Google Scholar] [CrossRef] [PubMed]

- Trache, D.; Donnot, A.; Khimeche, K.; Benelmir, R.; Brosse, N. Physico-chemical properties and thermal stability of microcrystalline cellulose isolated from alfa fibres. Carbohydr. Polym. 2014, 104, 223–230. [Google Scholar] [CrossRef] [PubMed]

- Pereira, H. Variability in the chemical composition of plantation eucalypts (Eucalyptus globulus labill.). Wood Fiber Sci. 1988, 11, 52–57. [Google Scholar]

- Brosse, N.; Dufour, A.; Meng, X.; Sun, Q.; Ragauskas, A. Miscanthus: A fast-growing crop for biofuels and chemicals production. Biofuels Bioprod. Biorefin. 2012, 6, 580–598. [Google Scholar] [CrossRef]

- Khan, T.; Mubeen, U. Wheat straw: A pragmatic overview. Curr. Res. J. Biol. Sci. 2012, 4, 673–675. [Google Scholar]

- Waliszewska, B.; PrąDzyński, W.; Zborowska, M.; Stachowiak-Wencek, A.; Waliszewska, H.; Spek-Dźwigała, A. The diversification of chemical composition of pine wood depending on the tree age. For. Wood Technol. 2015, 91, 182–187. [Google Scholar]

- Wyman, C. Handbook on Bioethanol: Production and Utilization; Taylor & Francis: Oxford, UK, 1996. [Google Scholar]

- Dorez, G.; Ferry, L.; Sonnier, R.; Taguet, A.; Lopez-Cuesta, J.M. Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. J. Anal. Appl. Pyrolysis 2014, 107, 323–331. [Google Scholar] [CrossRef]

- Sain, M.; Fortier, D. Flax shives refining, chemical modification and hydrophobisation for paper production. Ind. Crops Prod. 2002, 15, 1–13. [Google Scholar] [CrossRef]

- Soulié, F. Cohésion par capillarité et comportement mécanique de milieux granulaires. Ph.D. Thesis, Université de Montpellier II, Montpellier, France, 2005. [Google Scholar]

- Buranov, A.U.; Mazza, G. Extraction and characterization of hemicelluloses from flax shives by different methods. Carbohydr. Polym. 2010, 79, 17–25. [Google Scholar] [CrossRef]

- Kostic, M.; Pejic, B.; Skundric, P. Quality of chemically modified hemp fibers. Bioresour. Technol. 2008, 99, 94–99. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2011, 46, 973–986. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties characterization of chemically modified hemp hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef] [PubMed]

- Gandolfi, S.; Ottolina, G.; Riva, S.; Fantoni, G.P.; Patel, I. Complete chemical analysis of carmagnola hemp hurds and structural features of its components. BioResources 2013, 8, 2641–2656. [Google Scholar] [CrossRef]

- Monteil-Rivera, F.; Phuong, M.; Ye, M.; Halasz, A.; Hawari, J. Isolation and characterization of herbaceous lignins for applications in biomaterials. Ind. Crops Prod. 2013, 41, 356–364. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, X.; Liu, H. Experimental research on shape and size distribution of biomass particle. Fuel 2012, 94, 551–555. [Google Scholar] [CrossRef]

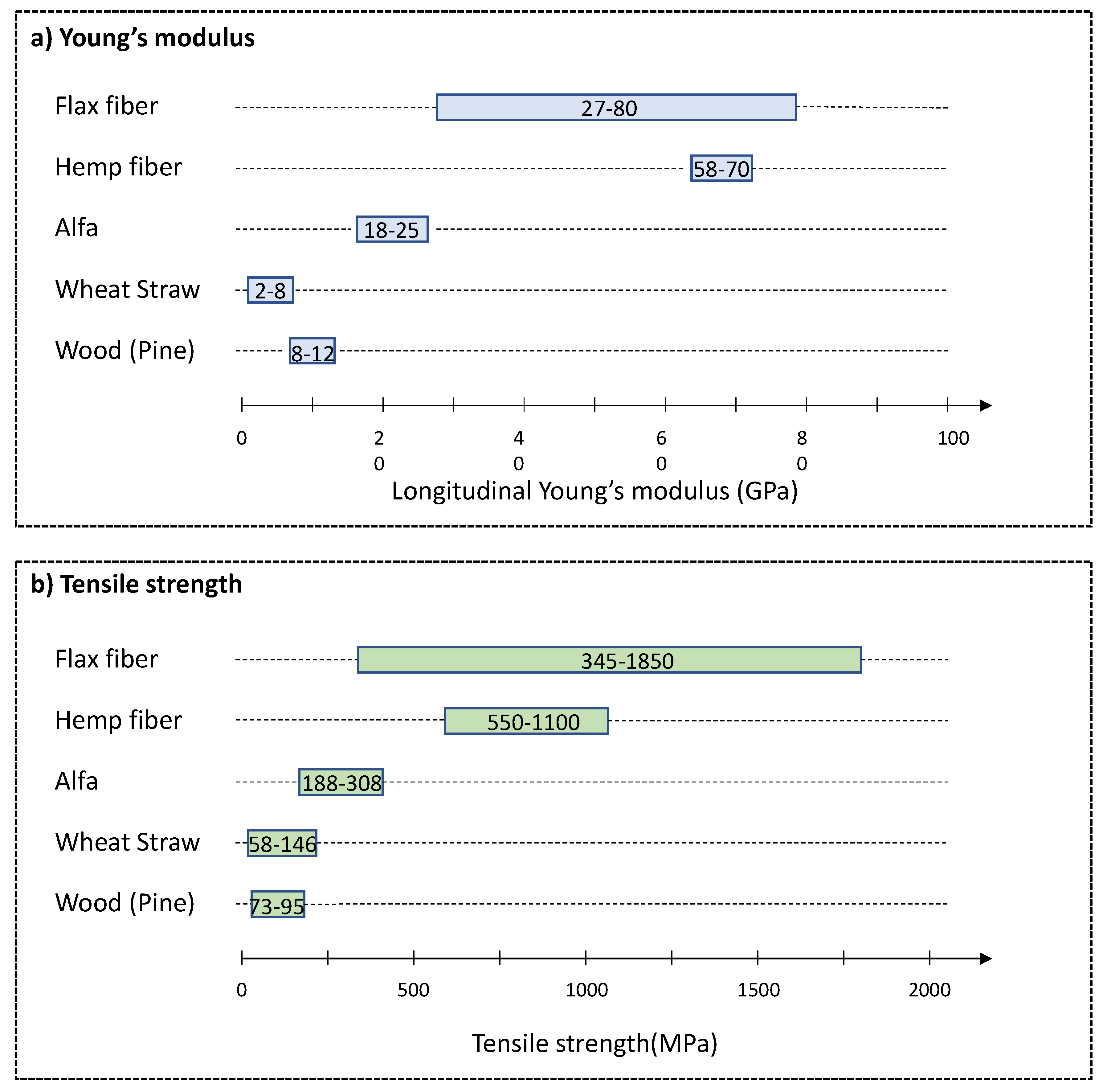

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Zhang, S.-Y.; Fei, B.-H.; Yu, Y.; Cheng, H.-T.; Wang, C.-G. Effect of the amount of lignin on tensile properties of single wood fibers. For. Sci. Pract. 2013, 15, 56–60. [Google Scholar]

- Annoussamy, M.; Richard, G.; Recous, S.; Guérif, J. Change in mechanical properties of wheat straw due to decomposition and moisture. Appl. Eng. Agric. 2000, 16, 657. [Google Scholar] [CrossRef]

- Leblicq, T.; Vanmaercke, S.; Ramon, H.; Saeys, W. Mechanical analysis of the bending behaviour of plant stems. Biosyst. Eng. 2015, 129, 87–99. [Google Scholar] [CrossRef]

- Chen, Z.; Qu, G. Shearing characteristics of corn stalk pith for separation. BioResources 2017, 12, 2296–2309. [Google Scholar] [CrossRef]

- Green, D.W.; Winandy, J.E.; Kretschmann, D.E. Wood Handbook: Wood as an engineering Material; USDA Forest Service: Madison, WI, USA, 1999; pp. 1–45.

- Barakat, A.; Mayer-Laigle, C.; Solhy, A.; Arancon, R.A.D.; de Vries, H.; Luque, R. Mechanical pretreatments of lignocellulosic biomass: Towards facile and environmentally sound technologies for biofuels production. RSC Adv. 2014, 4, 48109–48127. [Google Scholar] [CrossRef]

- Karinkanta, P. Dry Fine Grinding of Norway Spruce (Picea abies) Wood in Impact-Based Fine Grinding Mills; Oulun Yliopiston Tutkijakoulu: Oulu, Finland, 2015. [Google Scholar]

- Kaya, E.; Hogg, R.; Kumar, S. Particle shape modification in comminution. KONA Powder Part. J. 2002, 20, 188–195. [Google Scholar] [CrossRef]

- Motte, J.C.; Delenne, J.Y.; Rouau, X.; Mayer-Laigle, C. Mineral–vegetal co-milling: An effective process to improve lignocellulosic biomass fine milling and to increase interweaving between mixed particles. Bioresour. Technol. 2015, 192, 703–710. [Google Scholar] [CrossRef] [PubMed]

- Mayer-Laigle, C.; Barakat, A.; Barron, C.; Delenne, J.-Y.; Frank, X.; Mabille, F.; Rouau, X.; Sadoudi, A.; Samson, M.F.; Lullien, V. Dry biorefineries: Multiscale modeling studies and innovative processing. Innov. Food Sci. Emerg. Technol. 2017. [Google Scholar] [CrossRef]

- Conrad, M.P.C.; Smith, G.D.; Fernlund, G. Fracture of solid wood: A review of structure and properties at different length scales. Wood Fiber Sci. 2003, 4, 570–584. [Google Scholar]

- Boatright, S.W.J.; Garrett, G.G. The effect of microstructure and stress state on the fracture behaviour of wood. J. Mater. Sci. 1983, 18, 2181–2199. [Google Scholar] [CrossRef]

- Motte, J.-C.; Delenne, J.-Y.; Barron, C.; Dubreucq, E.; Mayer, C. Elastic properties of packing of granulated cork: Effect of particle size. Ind. Crops Prod. 2017, 99, 126–134. [Google Scholar] [CrossRef]

- Lammi, S.; Barakat, A.; Mayer-Laigle, C.; Djenane, D.; Gontard, N.; Angellier-Coussy, H. Dry fractionation of olive pomace as a sustainable process to produce fillers for biocomposites. Powder Technol. 2018, 326, 44–53. [Google Scholar] [CrossRef]

- Karinkanta, P.; Illikainen, M.; Niinimäki, J. Effect of different impact events in fine grinding mills on the development of the physical properties of dried norway spruce (Picea abies) wood in pulverisation. Powder Technol. 2014, 253, 352–359. [Google Scholar] [CrossRef]

- Williams, O.; Newbolt, G.; Eastwick, C.; Kingman, S.; Giddings, D.; Lormor, S.; Lester, E. Influence of mill type on densified biomass comminution. Appl. Energy 2016, 182, 219–231. [Google Scholar] [CrossRef]

- Domokos, G.; Kun, F.; Sipos, A.Á.; Szabó, T. Universality of fragment shapes. Sci. Rep. 2015, 5, 9147. [Google Scholar] [CrossRef] [PubMed]

- Tannous, K.; Lam, P.S.; Sokhansanj, S.; Grace, J.R. Physical properties for flow characterization of ground biomass from douglas fir wood. Part. Sci. Technol. 2013, 31, 291–300. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.; Sokhansanj, S. Mechanical Properties of Corn Stover Grind; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2004; Volume 47, pp. 1983–2013. [Google Scholar]

- Chevanan, N.; Womac, A.R.; Bitra, V.S.; Sokhansanj, S. Effect of particle size distribution on loose-filled and tapped densities of selected biomass after knife mill size reduction. Appl. Eng. Agric. 2011, 27, 631. [Google Scholar] [CrossRef]

- Li, Q.; Rudolph, V.; Weigl, B.; Earl, A. Interparticle van der waals force in powder flowability and compactibility. Int. J. Pharm. 2004, 280, 77–93. [Google Scholar] [CrossRef] [PubMed]

- Tomas, J.; Kleinschmidt, S. Improvement of flowability of fine cohesive powders by flow additives. Chem. Eng. Technol. 2009, 32, 1470–1483. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Z.; Gai, G.; Yang, Y. Effect of superfine grinding on properties of ginger powder. J. Food Eng. 2009, 91, 217–222. [Google Scholar] [CrossRef]

- Chen, M.Q.; Fu, R.M.; Yue, L.F.; Cheng, Y.Y. Effect of superfine grinding on physicochemical properties, antioxidant activity and phenolic content of red rice (Oryza sativa l.). Food Nutr. Sci. 2015, 6, 1277–1284. [Google Scholar]

- Gao, C.; Xiao, W.; Ji, G.; Zhang, Y.; Cao, Y.; Han, L. Regularity and mechanism of wheat straw properties change in ball milling process at cellular scale. Bioresour. Technol. 2017, 241, 214–219. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Wang, J.; Zhang, X.; Wolcott, M. Evaluation of physical structural features on influencing enzymatic hydrolysis efficiency of micronized wood. RSC Adv. 2016, 6, 103026–103034. [Google Scholar] [CrossRef]

- Khan, A.S.; Man, Z.; Bustam, M.A.; Kait, C.F.; Khan, M.I.; Muhammad, N.; Nasrullah, A.; Ullah, Z.; Ahmad, P. Impact of ball-milling pretreatment on pyrolysis behavior and kinetics of crystalline cellulose. Waste Biomass Valorization 2016, 7, 571–581. [Google Scholar] [CrossRef]

- Stubičar, N.; Šmit, I.; Stubičar, M.; Tonejc, A.; Jánosi, A.; Schurz, J.; Zipper, P. An X-ray diffraction study of the crystalline to amorphous phase change in cellulose during high-energy dry ball milling. Int. J. Biol. Chem. Phys. Technol. Wood 1998, 52, 455–458. [Google Scholar] [CrossRef]

- Yu, Y.; Wu, H. Effect of ball milling on the hydrolysis of microcrystalline cellulose in hot-compressed water. AIChE J. 2011, 57, 793–800. [Google Scholar] [CrossRef]

- Avolio, R.; Bonadies, I.; Capitani, D.; Errico, M.E.; Gentile, G.; Avella, M. A multitechnique approach to assess the effect of ball milling on cellulose. Carbohydr. Polym. 2012, 87, 265–273. [Google Scholar] [CrossRef]

- Tarafdar, J.C.; Meena, S.C.; Kathju, S. Influence of straw size on activity and biomass of soil microorganisms during decomposition. Eur. J. Soil Biol. 2001, 37, 157–160. [Google Scholar] [CrossRef]

- Schell, D.J.; Harwood, C. Milling of lignocellulosic biomass. Appl. Biochem. Biotechnol. 1994, 45, 159–168. [Google Scholar] [CrossRef]

- Raghavendra, S.N.; Ramachandra Swamy, S.R.; Rastogi, N.K.; Raghavarao, K.S.M.S.; Kumar, S.; Tharanathan, R.N. Grinding characteristics and hydration properties of coconut residue: A source of dietary fiber. J. Food Eng. 2006, 72, 281–286. [Google Scholar] [CrossRef]

- Kanda, Y.; Kotake, N. Chapter 12 comminution energy and evaluation in fine grinding. In Handbook of Powder Technology; Salman, A.D., Ghadiri, M., Hounslow, M.J., Eds.; Elsevier Science B.V.: Amsterdam, The Netherlands, 2007; Volume 12, pp. 529–550. [Google Scholar]

- Weibull, W. A Statistical Theory of the Strength of Materials; Generalstabens Litografiska Anstalts Förlag: Stockholm, Sweden, 1939. [Google Scholar]

- Epstein, B. Statistical aspects of fracture problems. J. Appl. Phys. 1948, 19, 140–147. [Google Scholar] [CrossRef]

- Tavares, L.M.; King, R.P. Single-particle fracture under impact loading. Int. J. Miner. Process. 1998, 54, 1–28. [Google Scholar] [CrossRef]

- Yashima, S.; Kanda, Y.; Sano, S. Relationships between particle size and fracture energy or impact velocity required to fracture as estimated from single particle crushing. Powder Technol. 1987, 51, 277–282. [Google Scholar] [CrossRef]

- Olsson, A.M.; Salmén, L. Viscoelasticity of In Situ Lignin as Affected by Structure; Swedish Pulp and Paper Research Institute: Stockholm, Sweden, 1992; pp. 133–143. [Google Scholar]

- Sedan, D.; Pagnoux, C.; Smith, A.; Chotard, T. Mechanical properties of hemp fibre reinforced cement: Influence of the fibre/matrix interaction. J. Eur. Ceram. Soc. 2008, 28, 183–192. [Google Scholar] [CrossRef]

- Gutsche, O.; Fuerstenau, D.W. Fracture kinetics of particle bed comminution—Ramifications for fines production and mill optimization. Powder Technol. 1999, 105, 113–118. [Google Scholar] [CrossRef]

- Beke, B. The Process of Fine Grinding; Springer: Dordrecht, The Netherlands, 2012. [Google Scholar]

- Temmerman, M.; Jensen, P.D.; Hébert, J. Von rittinger theory adapted to wood chip and pellet milling, in a laboratory scale hammermill. Biomass Bioenergy 2013, 56, 70–81. [Google Scholar] [CrossRef]

- Miao, Z.; Grift, T.E.; Hansen, A.C.; Ting, K.C. Energy requirement for comminution of biomass in relation to particle physical properties. Ind. Crops Prod. 2011, 33, 504–513. [Google Scholar] [CrossRef]

- Hess, J.; Wright, C.L.; Kenney, K. Cellulosic biomass feedstocks and logistics for ethanol production. Biofuels Bioprod. Biorefin. 2007, 1, 181–190. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding performance and physical properties of wheat and barley straws, corn stover and switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Chand, N.; Hashmi, S.A.R. Mechanical properties of sisal fibre at elevated temperatures. J. Mater. Sci. 1993, 28, 6724–6728. [Google Scholar] [CrossRef]

- Ghorbani, Z.; Masoumi, A.A.; Hemmat, A. Specific energy consumption for reducing the size of alfalfa chops using a hammer mill. Biosyst. Eng. 2010, 105, 34–40. [Google Scholar] [CrossRef]

| Biomass | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Water–Soluble (%) | Ash (%) | References |

|---|---|---|---|---|---|---|

| Alfa | 44–47 | 22–30 | 12–20 | ≈4 | ≈2 | [20,21] |

| Eucalyptus | 53–58 | 17–20 | 19–22 | 1–5 | <1 | [22] |

| Miscanthus | 43–50 | 24–34 | 9–12 | 1–2 | 2–4 | [23] |

| Wheat Straw | 33–40 | 21–26 | 11–23 | 4–10 | 7–10 | [24,25] |

| Wood (Pine) | 45–50 | 20–30 | 25–30 | 2–10 | <1 | [26] |

| Flax fiber | 78–80 | 6–13 | 2–5 | 2–4 | 1–2 | [27,28] |

| Flax shives | 32–53 | 13–21 | 23–25 | 1–2 | 2–3 | [28,29,30] |

| Hemp fiber | 67–76 | 8–12 | 2–5 | 2–16 | <1 | [27,31,32] |

| Hemp Hurds | 39–49 | 16–23 | 16–23 | 0–2 | 2–4 | [33,34,35] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mayer-Laigle, C.; Blanc, N.; Rajaonarivony, R.K.; Rouau, X. Comminution of Dry Lignocellulosic Biomass, a Review: Part I. From Fundamental Mechanisms to Milling Behaviour. Bioengineering 2018, 5, 41. https://doi.org/10.3390/bioengineering5020041

Mayer-Laigle C, Blanc N, Rajaonarivony RK, Rouau X. Comminution of Dry Lignocellulosic Biomass, a Review: Part I. From Fundamental Mechanisms to Milling Behaviour. Bioengineering. 2018; 5(2):41. https://doi.org/10.3390/bioengineering5020041

Chicago/Turabian StyleMayer-Laigle, Claire, Nicolas Blanc, Rova Karine Rajaonarivony, and Xavier Rouau. 2018. "Comminution of Dry Lignocellulosic Biomass, a Review: Part I. From Fundamental Mechanisms to Milling Behaviour" Bioengineering 5, no. 2: 41. https://doi.org/10.3390/bioengineering5020041

APA StyleMayer-Laigle, C., Blanc, N., Rajaonarivony, R. K., & Rouau, X. (2018). Comminution of Dry Lignocellulosic Biomass, a Review: Part I. From Fundamental Mechanisms to Milling Behaviour. Bioengineering, 5(2), 41. https://doi.org/10.3390/bioengineering5020041