Application of Multivariate Regression and Artificial Neural Network Modelling for Prediction of Physicochemical Properties of Grape-Skin Compost

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Biowaste for Composting

2.1.2. Chemicals

2.2. Methods

2.2.1. Grape-Skin Composting Process

2.2.2. Physicochemical Analyses of the Compost Samples

Dry-Matter Content and Moisture Content of the Compost Samples

Extraction Procedure, pH Value, Conductivity and Total Dissolved Solids of Compost Samples

Organic Matter Content and Ash Content of Compost Samples

Carbon and Nitrogen Content of the Compost Samples

Total Colour Change of the Compost Samples and Compost Extract Samples

2.2.3. Statistical Analyses and Mathematical Modelling

Descriptive Statistics

Multiple Linear Regression Modelling, Pricewise Linear Regression Modelling and Artificial Neural Network Modelling

3. Results and Discussion

3.1. Physicochemical Properties of Compost Samples

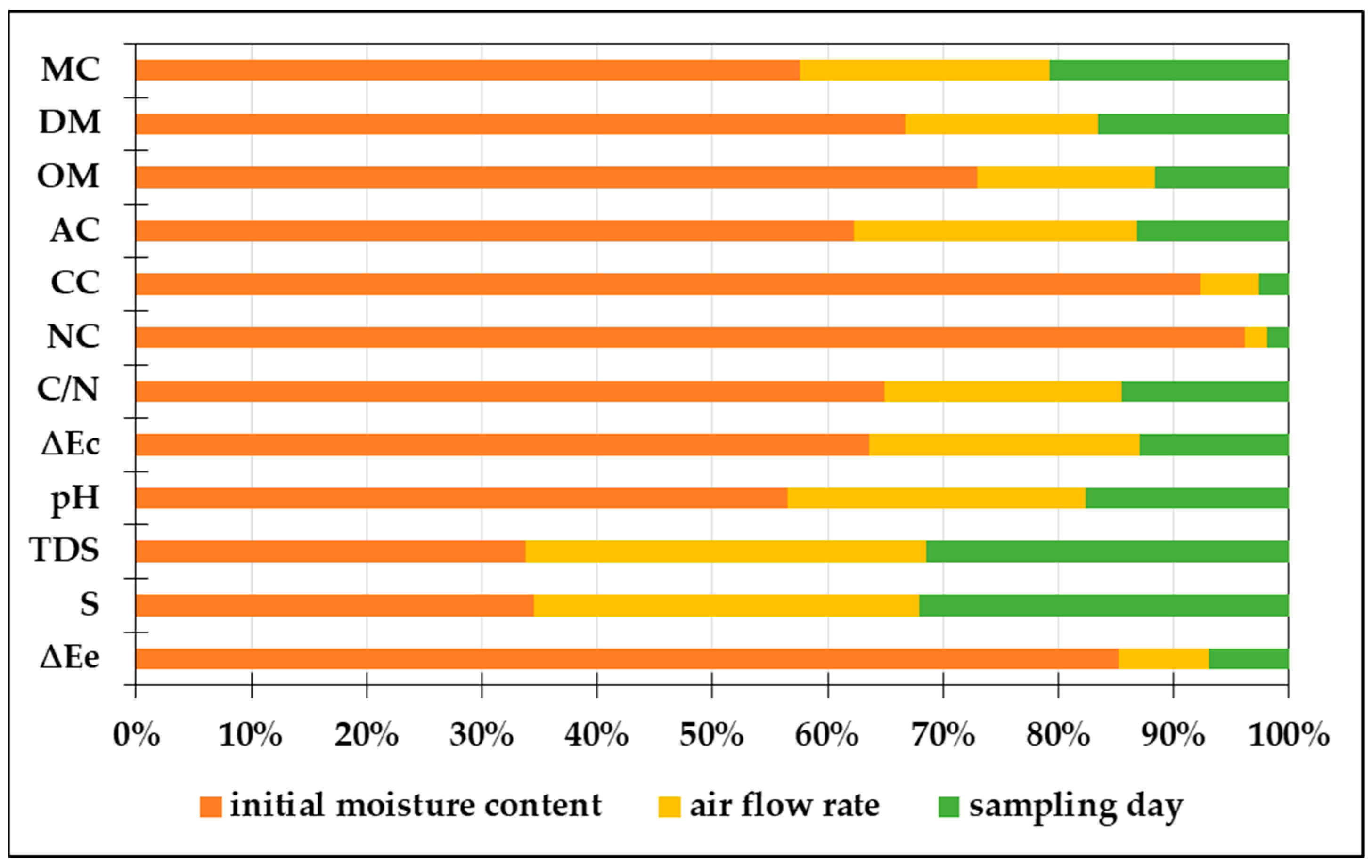

3.2. Multiple Linear Regression, Piecewise Linear Regression and Artificial Neural Network Models for Prediction of Physicochemical Properties of Compost during the Composting Process

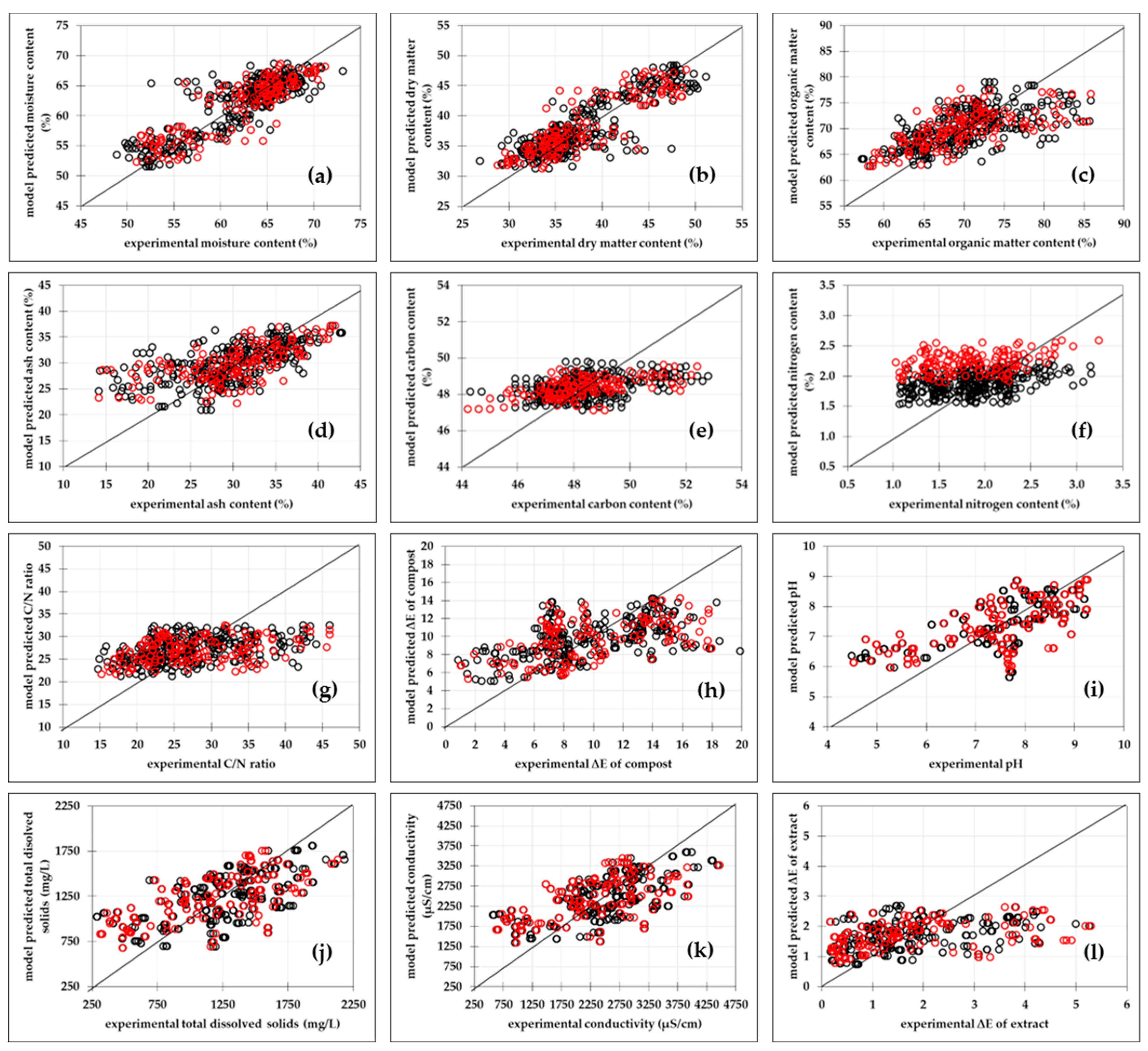

3.2.1. Multiple Linear Regression Models

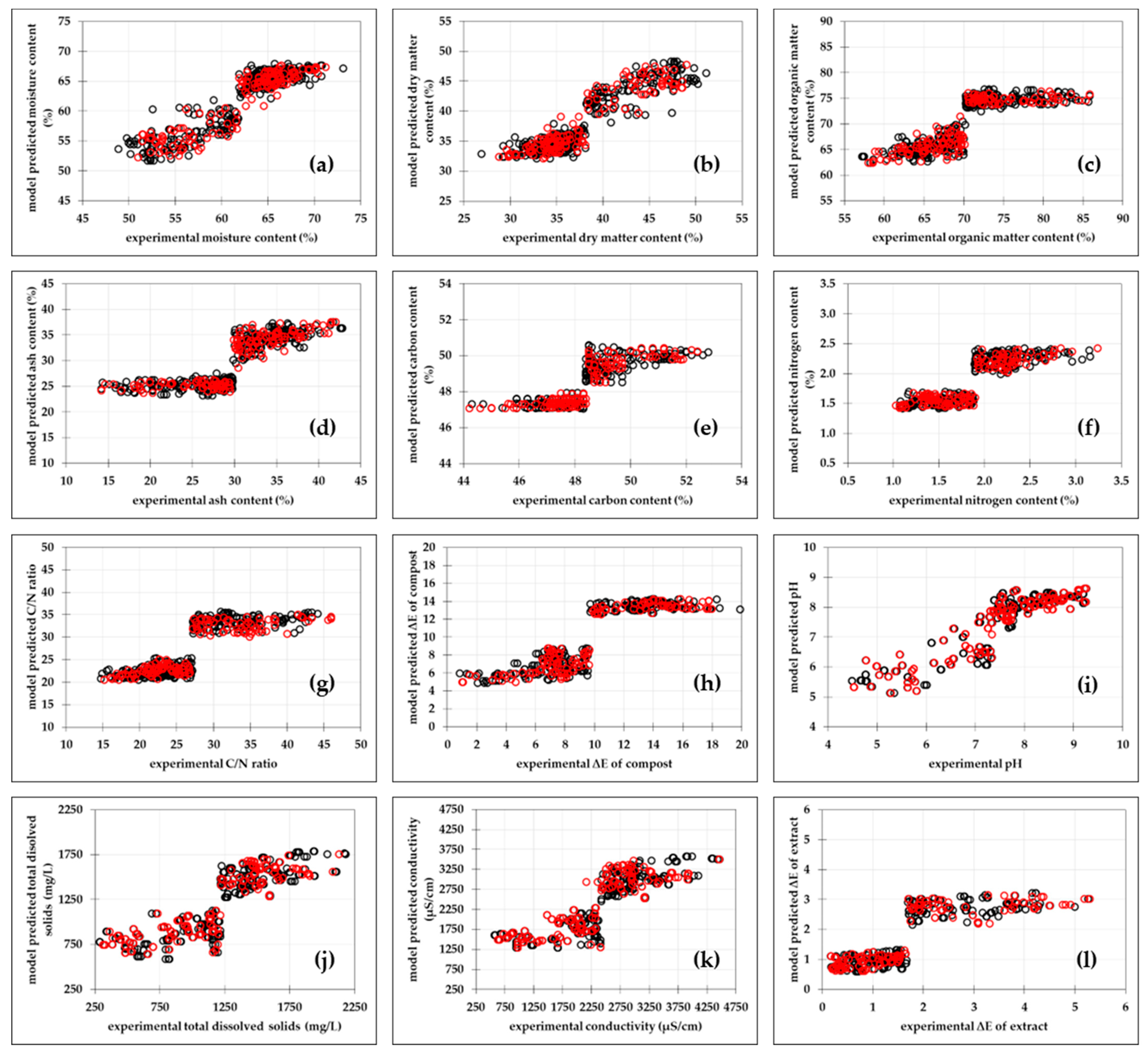

3.2.2. Piecewise Linear Regression Models

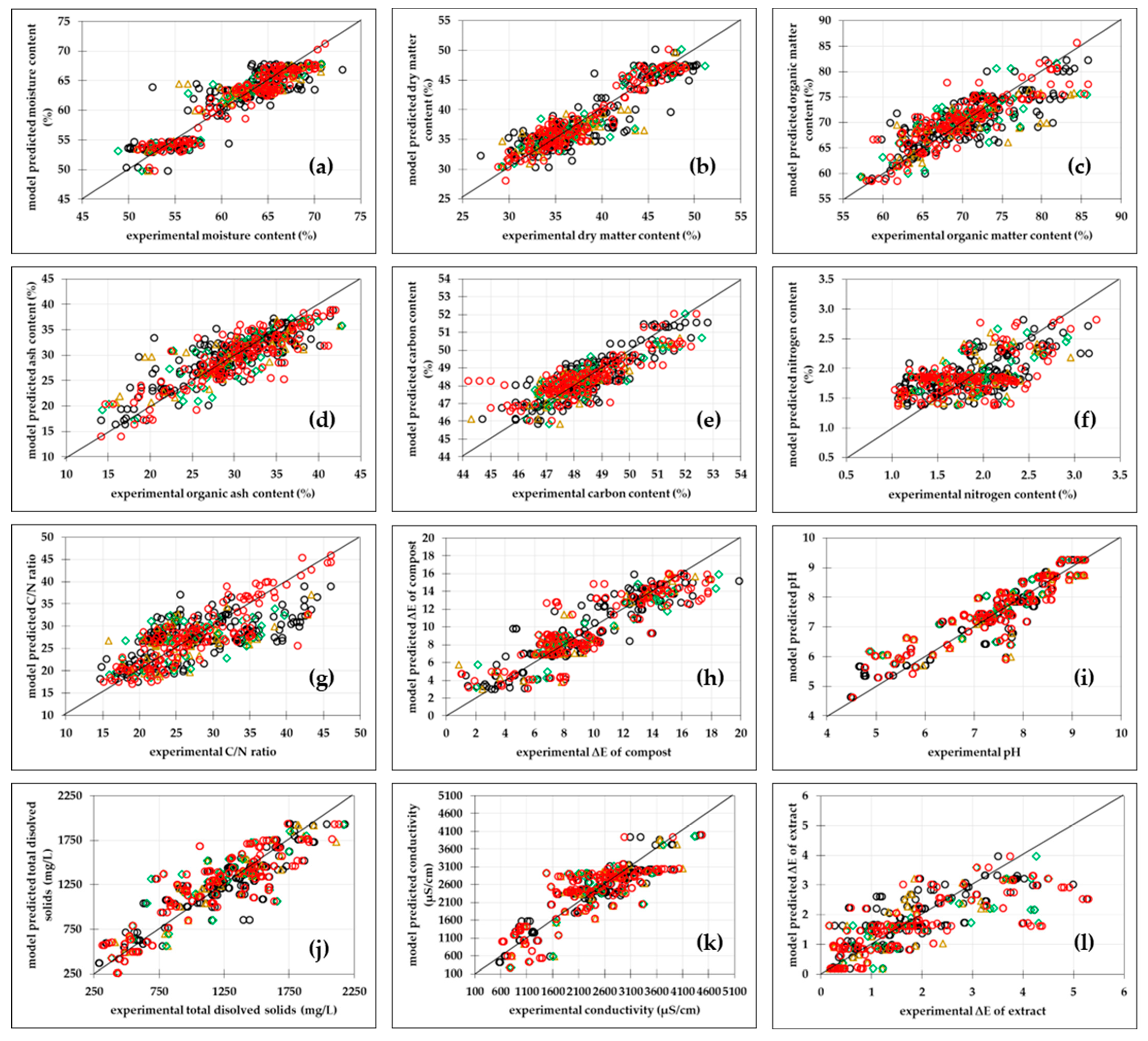

3.2.3. Artificial Neural Network Models

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Waqas, M.; Hashim, S.; Humphries, U.W.; Ahmad, S.; Noor, R.; Shoaib, M.; Naseem, A.; Hlaing, P.T.; Lin, H.A. Composting Processes for Agricultural Waste Management: A Comprehensive Review. Processes 2023, 11, 731. [Google Scholar] [CrossRef]

- Debrah, J.K.; Vidal, D.G.; Dinis, M.A.P. Raising Awareness on Solid Waste Management through Formal Education for Sustainability: A Developing Countries Evidence Review. Recycling 2021, 6, 6. [Google Scholar] [CrossRef]

- Sokač, T.; Valinger, D.; Benković, M.; Jurina, T.; Kljusurić, J.G.; Redovniković, I.R.; Tušek, A.J. Application of Optimization and Modeling for the Enhancement of Composting Processes. Processes 2022, 10, 229. [Google Scholar] [CrossRef]

- Zohoori, M.; Ghani, A. Municipal Solid Waste Management Challenges and Problems for Cities in Low-Income and Developing Countries. Int. J. Sci. Eng. Appl. 2017, 6, 039–048. [Google Scholar] [CrossRef]

- Spoann, V.; Fujiwara, T.; Seng, B.; Lay, C. Municipal Solid Waste Management: Constraints and Opportunities to Improve Capacity of Local Government Authorities of Phnom Penh Capital. Waste Manag. Res. 2018, 36, 985–992. [Google Scholar] [CrossRef] [PubMed]

- Sayara, T.; Basheer-Salimia, R.; Hawamde, F.; Sánchez, A. Recycling of Organic Wastes through Composting: Process Performance and Compost Application in Agriculture. Agronomy 2020, 10, 1838. [Google Scholar] [CrossRef]

- Fan, S.; Li, A.; ter Heijne, A.; Buisman, C.J.N.; Chen, W.S. Heat Potential, Generation, Recovery and Utilization from Composting: A Review. Resour. Conserv. Recycl. 2021, 175, 105850. [Google Scholar] [CrossRef]

- Spinei, M.; Oroian, M. The Potential of Grape Pomace Varieties as a Dietary Source of Pectic Substances. Foods 2021, 10, 867. [Google Scholar] [CrossRef]

- Martínez Salgado, M.M.; Ortega Blu, R.; Janssens, M.; Fincheira, P. Grape Pomace Compost as a Source of Organic Matter: Evolution of Quality Parameters to Evaluate Maturity and Stability. J. Clean. Prod. 2019, 216, 56–63. [Google Scholar] [CrossRef]

- Muhlack, R.A.; Potumarthi, R.; Jeffery, D.W. Sustainable Wineries through Waste Valorisation: A Review of Grape Marc Utilisation for Value-Added Products. Waste Manag. 2018, 72, 99–118. [Google Scholar] [CrossRef] [PubMed]

- Azis, F.A.; Rijal, M.; Suhaimi, H.; Abas, P.E. Patent Landscape of Composting Technology: A Review. Inventions 2022, 7, 38. [Google Scholar] [CrossRef]

- Malakahmad, A.; Idrus, N.B.; Abualqumboz, M.S.; Yavari, S.; Kutty, S.R.M. In-Vessel Co-Composting of Yard Waste and Food Waste: An Approach for Sustainable Waste Management in Cameron Highlands, Malaysia. Int. J. Recycl. Org. Waste Agric. 2017, 6, 149–157. [Google Scholar] [CrossRef]

- Walker, L.; Charles, W.; Cord-Ruwisch, R. Comparison of Static, in-Vessel Composting of MSW with Thermophilic Anaerobic Digestion and Combinations of the Two Processes. Bioresour. Technol. 2009, 100, 3799–3807. [Google Scholar] [CrossRef]

- Papraćanin, E.A.; Petric, I. Mathematical Modeling and Simulation of the Composting Process in a Pilot Reactor. Bull. Chem. Technol. Bosnia Herzeg. 2017, 47, 39–48. [Google Scholar]

- Ajmal, M.; Aiping, S.; Uddin, S.; Awais, M.; Faheem, M.; Ye, L.; Rehman, K.U.; Ullah, M.S.; Shi, Y. A Review on Mathematical Modeling of In-Vessel Composting Process and Energy Balance. Biomass Convers. Biorefinery 2022, 12, 4201–4213. [Google Scholar] [CrossRef]

- He, X.; Han, L.; Ge, J.; Huang, G. Modelling for Reactor-Style Aerobic Composting Based on Coupling Theory of Mass-Heat-Momentum Transport and Contois Equation. Bioresour. Technol. 2018, 253, 165–174. [Google Scholar] [CrossRef] [PubMed]

- Loan, L.T.T.; Takahashi, Y.; Nomura, H.; Yabe, M. Modeling Home Composting Behavior toward Sustainable Municipal Organic Waste Management at the Source in Developing Countries. Resour. Conserv. Recycl. 2019, 140, 65–71. [Google Scholar] [CrossRef]

- Koolivand, A.; Godini, K.; Saeedi, R.; Abtahi, H.; Ghamari, F. Oily Sludge Biodegradation Using a New Two-Phase Composting Method: Kinetics Studies and Effect of Aeration Rate and Mode. Process Biochem. 2019, 79, 127–134. [Google Scholar] [CrossRef]

- Jain, M.S.; Paul, S.; Kalamdhad, A.S. Kinetics and Physics during Composting of Various Organic Wastes: Statistical Approach to Interpret Compost Application Feasibility. J. Clean. Prod. 2020, 255, 120324. [Google Scholar] [CrossRef]

- Zbytniewski, R.; Buszewski, B. Characterization of Natural Organic Matter (NOM) Derived from Sewage Sludge Compost. Part 2: Multivariate Techniques in the Study of Compost Maturation. Bioresour. Technol. 2005, 96, 479–484. [Google Scholar] [CrossRef]

- Karak, T.; Bhattacharyya, P.; Paul, R.K. Assessment of Co-Compost Quality by Physico-Chemical and Exploratory Data Analysis. Clean—Soil Air Water 2014, 42, 836–848. [Google Scholar] [CrossRef]

- Shen, G.; Chen, Y.; Zhang, J.; Wu, Y.; Yi, Y.; Li, S.; Yin, S. Quantitative Analysis of Index Factors in Agricultural Compost by Infrared Spectroscopy. Heliyon 2023, 9, e14010. [Google Scholar] [CrossRef]

- Chikae, M.; Ikeda, R.; Kerman, K.; Morita, Y.; Tamiya, E. Estimation of Maturity of Compost from Food Wastes and Agro-Residues by Multiple Regression Analysis. Bioresour. Technol. 2006, 97, 1979–1985. [Google Scholar] [CrossRef]

- Wan, X.; Li, J.; Xie, L.; Wei, Z.; Wu, J.; Wah Tong, Y.; Wang, X.; He, Y.; Zhang, J. Machine Learning Framework for Intelligent Prediction of Compost Maturity towards Automation of Food Waste Composting System. Bioresour. Technol. 2022, 365, 128107. [Google Scholar] [CrossRef]

- Bertran, E.; Sort, X.; Soliva, M.; Trillas, I. Composting Winery Waste: Sludges and Grape Stalks. Bioresour. Technol. 2004, 95, 203–208. [Google Scholar] [CrossRef]

- Pinto, R.; Correia, C.; Mourão, I.; Moura, L.; Brito, L.M. Composting Waste from the White Wine Industry. Sustainability 2023, 15, 3454. [Google Scholar] [CrossRef]

- Chan, M.T.; Selvam, A.; Wong, J.W.C. Reducing Nitrogen Loss and Salinity during “struvite” Food Waste Composting by Zeolite Amendment. Bioresour. Technol. 2016, 200, 838–844. [Google Scholar] [CrossRef] [PubMed]

- Waqas, M.; Nizami, A.S.; Aburiazaiza, A.S.; Barakat, M.A.; Ismail, I.M.I.; Rashid, M.I. Optimization of Food Waste Compost with the Use of Biochar. J. Environ. Manag. 2018, 216, 70–81. [Google Scholar] [CrossRef] [PubMed]

- Nasreen, Z.; Qazi, J.I. Lab Scale Composting of Fruits and Vegetable Waste at Elevated Temperature and Forced Aeration. Pak. J. Zool. 2012, 44, 1285–1290. [Google Scholar]

- Diaz, M.J.; Madejon, E.; Lopez, F.; Lopez, R.; Cabrera, F. Optimization of the Rate Vinasse / Grape Marc for Co-Composting Process. Process Biochem. 2002, 37, 1143–1150. [Google Scholar] [CrossRef]

- Lovreškov, L.; Radojčić Redovniković, I.; Limić, I.; Potočić, N.; Seletković, I.; Marušić, M.; Butorac, L.; Jurinjak Tušek, A.; Jakovljević, T. Are Foliar Nutrition Status and Indicators of Oxidative Stress Associated with Tree Defoliation of Four Mediterranean. Plants 2022, 11, 3484. [Google Scholar] [CrossRef] [PubMed]

- Jurinjak Tušek, A.; Jurina, T.; Benković, M.; Valinger, D.; Belščak-Cvitanović, A.; Gajdoš Kljusurić, J. Application of Multivariate Regression and Artificial Neural Network Modelling for Prediction of Physical and Chemical Properties of Medicinal Plants Aqueous Extracts. J. Appl. Res. Med. Aromat. Plants 2020, 16, 100229. [Google Scholar] [CrossRef]

- Fearn, T. Assessing Calibrations: SEP, RPD, RER and R2. NIR News 2002, 13, 12. [Google Scholar] [CrossRef]

- Friday Oyewusi, T.; Akinfemi Osunbitan, J.; Abidemi Ogunwande, G.; Akinola Omotosho, O. Investigation into Physico-Chemical Properties of Compost Extract as Affected by Processing Parameters Investigation into Physico-Chemical Properties of Compost Extract as Affected by Processing Parameters. Environ. Chall. 2021, 5, 100370. [Google Scholar] [CrossRef]

- Onwosi, C.O.; Igbokwe, V.C.; Odimba, J.N.; Eke, I.E.; Nwankwoala, M.O.; Iroh, I.N.; Ezeogu, L.I. Composting Technology in Waste Stabilization: On the Methods, Challenges and Future Prospects. J. Environ. Manag. 2017, 190, 140–157. [Google Scholar] [CrossRef]

- Peng, L.; Tang, R.; Wang, G.; Ma, R.; Li, Y.; Li, G.; Yuan, J. Effect of Aeration Rate, Aeration Pattern, and Turning Frequency on Maturity and Gaseous Emissions during Kitchen Waste Composting. Environ. Technol. Innov. 2023, 29, 102997. [Google Scholar] [CrossRef]

- Irvan; Husaini, T.; Trisakti, B.; Batubara, F.; Daimon, H. Composting of Empty Fruit Bunches in the Tower Composter—Effect of Air Intake Holes Composting of Empty Fruit Bunches in the Tower Composter—Effect of Air Intake Holes. IOP Conf. Ser. Mater. Sci. Eng. 2018, 309, 012066. [Google Scholar] [CrossRef]

- Karanja, A.W.; Njeru, E.M.; Maingi, J.M. Assessment of Physicochemical Changes during Composting Rice Straw with Chicken and Donkey Manure. Int. J. Recycl. Org. Waste Agric. 2019, 8, 65–72. [Google Scholar] [CrossRef]

- Makan, A.; Assobhei, O.; Mountadar, M. Effect of Initial Moisture Content on the In-Vessel Composting under Air Pressure of Organic Fraction of Municipal Solid Waste in Morocco. J. Environ. Health Sci. Eng. 2013, 10, 3. [Google Scholar] [CrossRef]

- Yeh, C.K.; Lin, C.; Shen, H.C.; Cheruiyot, N.K.; Camarillo, M.E.; Wang, C.L. Optimizing Food Waste Composting Parameters and Evaluating Heat Generation. Appl. Sci. 2020, 10, 2284. [Google Scholar] [CrossRef]

- Nguyen, T.P.; Koyama, M.; Nakasaki, K. Effects of Oxygen Supply Rate on Organic Matter Decomposition and Microbial Communities during Composting in a Controlled Lab-Scale Composting System. Waste Manag. 2022, 153, 275–282. [Google Scholar] [CrossRef]

- Mejias, L.; Komilis, D.; Gea, T.; Sánchez, A. The Effect of Airflow Rates and Aeration Mode on the Respiration Activity of Four Organic Wastes: Implications on the Composting Process. Waste Manag. 2017, 65, 22–28. [Google Scholar] [CrossRef]

- Topp, R.; Gomez, G. Residual Analysis in Linear Regression Models with an Interval-Censored Covariate. Stat. Med. 2004, 23, 3377–3391. [Google Scholar] [CrossRef] [PubMed]

- Panić, M.; Radović, M.; Cvjetko Bubalo, M.; Radošević, K.; Rogošić, M.; Coutinho, J.A.P.; Radojčić Redovniković, I.; Jurinjak Tušek, A. Prediction of PH Value of Aqueous Acidic and Basic Deep Eutectic Solvent Using COSMO-RS σ Profiles’ Molecular Descriptors. Molecules 2022, 27, 4489. [Google Scholar] [CrossRef] [PubMed]

- Palechor-Tróchez, J.J.; Ordoñez Santos, L.E.; Villada-Castillo, H.S. Relationship between Color CIELab and Total Organic Carbon in Compost. Adv. Mater. Sci. Eng. 2018, 2018, 5474239. [Google Scholar] [CrossRef]

- Zahrim, A.Y.; Leong, P.S.; Ayisah, S.R.; Janaun, J.; Chong, K.P.; Cooke, F.M.; Haywood, S.K. Composting Paper and Grass Clippings with Anaerobically Treated Palm Oil Mill Effluent. Int. J. Recycl. Org. Waste Agric. 2016, 5, 221–230. [Google Scholar] [CrossRef]

- Tredennick, A.T.; Hooker, G.; Ellner, S.P.; Adler, P.B. A Practical Guide to Selecting Models for Exploration, Inference, and Prediction in Ecology. Ecology 2021, 102, e03336. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sinkovics, R.R. The Use of Partial Least Squares Path Modeling in International Marketing. Adv. Int. Mark. 2009, 20, 277–319. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. Partial Least Squares Structural Equation Modeling: Rigorous Applications, Better Results and Higher Acceptance. Long. Range Plann 2013, 46, 1–12. [Google Scholar] [CrossRef]

- Hussain, S.; Fangwei, Z.; Siddiqi, A.F.; Ali, Z.; Shabbir, M.S. Structural Equation Model for Evaluating Factors Affecting Quality of Social Infrastructure Projects. Sustainability 2018, 10, 1415. [Google Scholar] [CrossRef]

- Chang, C.-W.; Laird, D.A.; Mausbach, M.J.; Hurburgh, C.R. Near—Infrared Reflectance Spectroscopy–Principal Components Regression Analyses of Soil Properties. Soil. Sci. Soc. Am. J. 2001, 65, 480–490. [Google Scholar] [CrossRef]

- Sim, J.; McGoverin, C.; Oey, I.; Frew, R.; Kebede, B. Near-Infrared Reflectance Spectroscopy Accurately Predicted Isotope and Elemental Compositions for Origin Traceability of Coffee. Food Chem. 2023, 427, 136695. [Google Scholar] [CrossRef] [PubMed]

- Fouguira, S.; El Haji, M.; Benhra, J.; Ammar, E. Optimization of Olive Oil Extraction Wastes Co Composting Procedure Based on Bioprocessing Parameters. Heliyon 2023, 9, e19645. [Google Scholar] [CrossRef]

- Yang, L.; Liu, S.; Tsoka, S.; Papageorgiou, L.G. Mathematical Programming for Piecewise Linear Regression Analysis. Expert. Syst. Appl. 2016, 44, 156–167. [Google Scholar] [CrossRef]

- Costello, R.C.; Sullivan, D.M.; Bryla, D.R.; Strik, B.C.; Owen, J.S. Compost Feedstock and Compost Acidification Affect Growth and Mineral Nutrition in Northern Highbush Blueberry. HortScience 2019, 54, 1067–1076. [Google Scholar] [CrossRef]

- Abdi, R.; Shahgholi, G.; Sharabiani, V.R.; Fanaei, A.R.; Szymanek, M. Prediction Compost Criteria of Organic Wastes with Biochar Additive in In-Vessel Composting Machine Using ANFIS and ANN Methods. Energy Rep. 2023, 9, 1684–1695. [Google Scholar] [CrossRef]

- Chen, X.; Zheng, H.; Wang, H.; Yan, T. Can Machine Learning Algorithms Perform Better than Multiple Linear Regression in Predicting Nitrogen Excretion from Lactating Dairy Cows. Sci. Rep. 2022, 12, 12478. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Baziar, M.; Alidadi, H.; Zhou, J.L.; Altaee, A.; Asghar, A.; Jafarpour, S. Bioresource Technology Application of Artificial Neural Network and Multiple Linear Regression in Modeling Nutrient Recovery in Vermicompost under Different Conditions. Bioresour. Technol. 2020, 303, 122926. [Google Scholar] [CrossRef]

- Aycan Dümenci, N.; Cagcag Yolcu, O.; Aydin Temel, F.; Turan, N.G. Identifying the Maturity of Co-Compost of Olive Mill Waste and Natural Mineral Materials: Modelling via ANN and Multi-Objective Optimization. Bioresour. Technol. 2021, 338, 125516. [Google Scholar] [CrossRef]

- Singh, T.; Uppaluri, R.V.S. Application of ANN and Traditional ML Algorithms in Modelling Compost Production under Different Climatic Conditions. Neural Comput. Appl. 2023, 35, 13465–13484. [Google Scholar] [CrossRef]

- Shi, C.F.; Yang, H.T.; Chen, T.T.; Guo, L.P.; Leng, X.Y.; Deng, P.B.; Bi, J.; Pan, J.G.; Wang, Y.M. Artificial Neural Network-Genetic Algorithm-Based Optimization of Aerobic Composting Process Parameters of Ganoderma Lucidum Residue. Bioresour. Technol. 2022, 357, 127248. [Google Scholar] [CrossRef]

- Gurusamy, N.N.; Puffer, N.; Jongh, C.D.; Rodriguez, C.; Aspray, T.J. Effect of Initial Moisture Content and Sample Storage Duration on Compost Stability Using the ORG0020 Dynamic Respiration Test. Waste Manag. 2021, 125, 215–219. [Google Scholar] [CrossRef]

- Ghanney, P.; Qiu, H.; Anning, D.K.; Yang, H.; Wang, Y.; Kugbe, J.X. Applied Sciences Moisture-Induced Pattern of Gases and Physicochemical Indices in Corn Straw and Cow Manure Composting. Appl. Sci. 2021, 11, 8493. [Google Scholar] [CrossRef]

- Abdallah, S.E.; Mazrou, Y.S.A.; Elsakhawy, T.; Elgarhy, R.; Elmetwalli, A.H.; Elsayed, S.; Elmessery, W.M. Optimizing the In-Vessel Composting Process of Sugarbeet Dry-Cleaning Residue. Agriculture 2022, 12, 427. [Google Scholar] [CrossRef]

- Antızar-Ladislao, B.; Lopez-Real, J.; Beck, A.J. Investigation of Organic Matter Dynamics during In-Vessel Composting of an Aged Coal—Tar Contaminated Soil Using Fluorescence Excitation—Emission Spectroscopy. Chemosphere 2006, 64, 839–847. [Google Scholar] [CrossRef] [PubMed]

| MC (%) | DM (%) | OM (%) | AC (%) | CC (%) | NC (%) | C/N | ∆Ec | pH | TDS (mg/L) | S (µS/cm) | ∆Ee | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Exp1 | Min | 50.144 | 41.575 | 66.548 | 16.525 | 47.500 | 1.170 | 21.549 | 2.074 | 4.520 | 491.000 | 1002.000 | 0.374 |

| Max | 58.425 | 49.856 | 83.475 | 33.452 | 52.400 | 2.330 | 40.940 | 18.308 | 8.080 | 1551.000 | 3120.000 | 4.994 | |

| St.dev. | 2.143 | 2.143 | 4.670 | 4.670 | 1.304 | 0.345 | 5.637 | 4.645 | 1.064 | 389.335 | 723.974 | 0.875 | |

| Exp2 | Min | 48.855 | 39.187 | 66.787 | 14.181 | 47.300 | 1.160 | 21.120 | 1.019 | 4.490 | 286.000 | 568.000 | 0.242 |

| Max | 60.813 | 51.145 | 85.819 | 33.213 | 52.800 | 2.500 | 41.724 | 19.899 | 7.790 | 1700.000 | 3400.000 | 2.922 | |

| St.dev. | 2.332 | 2.332 | 4.753 | 4.753 | 1.458 | 0.354 | 5.673 | 4.590 | 1.039 | 477.961 | 933.359 | 0.734 | |

| Exp3 | Min | 55.440 | 29.201 | 57.183 | 14.642 | 46.400 | 1.070 | 19.876 | 0.855 | 5.130 | 387.000 | 799.000 | 0.179 |

| Max | 70.799 | 44.560 | 85.358 | 42.817 | 52.600 | 2.460 | 45.981 | 18.518 | 9.250 | 1442.000 | 2940.000 | 4.505 | |

| St.dev. | 3.893 | 3.893 | 8.430 | 8.430 | 1.718 | 0.369 | 6.046 | 4.715 | 1.167 | 375.912 | 757.741 | 1.262 | |

| Exp4 | Min | 56.423 | 30.499 | 63.186 | 14.315 | 47.000 | 1.070 | 20.664 | 1.466 | 4.770 | 337.000 | 674.000 | 0.192 |

| Max | 69.501 | 43.577 | 85.685 | 36.814 | 51.800 | 2.410 | 45.981 | 14.002 | 8.220 | 1752.000 | 3520.000 | 2.378 | |

| St.dev. | 2.591 | 2.591 | 5.694 | 5.480 | 1.090 | 0.361 | 6.253 | 3.396 | 1.058 | 464.734 | 914.862 | 0.710 | |

| Exp5 | Min | 56.423 | 30.192 | 58.806 | 14.315 | 46.700 | 1.070 | 20.377 | 1.466 | 4.660 | 313.000 | 627.000 | 0.192 |

| Max | 69.808 | 41.203 | 82.372 | 41.194 | 51.700 | 2.390 | 45.981 | 15.018 | 8.270 | 1413.000 | 2880.000 | 2.588 | |

| St.dev. | 2.476 | 2.476 | 5.510 | 5.389 | 1.306 | 0.350 | 5.763 | 3.553 | 1.124 | 417.009 | 820.501 | 0.706 | |

| Exp6 | Min | 49.755 | 34.027 | 62.076 | 24.541 | 43.900 | 1.080 | 14.873 | 2.444 | 5.700 | 1044.000 | 1991.000 | 0.554 |

| Max | 65.973 | 50.245 | 75.459 | 37.924 | 48.900 | 3.160 | 44.167 | 9.303 | 8.600 | 2180.000 | 4470.000 | 5.294 | |

| St.dev. | 4.135 | 4.135 | 3.671 | 3.671 | 1.044 | 0.519 | 7.574 | 1.445 | 1.029 | 380.752 | 822.307 | 1.390 | |

| Exp7 | Min | 56.989 | 26.926 | 57.970 | 23.526 | 44.200 | 1.030 | 14.698 | 1.527 | 5.360 | 835.000 | 1666.000 | 0.167 |

| Max | 73.074 | 43.011 | 76.474 | 42.030 | 49.100 | 3.240 | 45.534 | 10.462 | 9.260 | 1867.000 | 3930.000 | 4.373 | |

| St.dev. | 3.655 | 34.027 | 5.251 | 5.251 | 1.103 | 0.584 | 8.108 | 1.967 | 1.382 | 318.789 | 896.393 | 1.405 | |

| Exp8 | Min | 52.566 | 3.655 | 60.912 | 20.479 | 45.900 | 1.080 | 19.350 | 1.920 | 5.620 | 926.000 | 1833.000 | 0.244 |

| Max | 70.058 | 29.942 | 79.521 | 39.088 | 48.900 | 2.470 | 43.364 | 11.418 | 8.520 | 1598.000 | 3180.000 | 4.022 | |

| St.dev. | 3.022 | 36.823 | 3.903 | 3.903 | 0.773 | 0.385 | 6.534 | 1.796 | 0.752 | 208.822 | 424.283 | 1.217 | |

| Exp9 | Min | 58.678 | 3.022 | 61.238 | 24.262 | 45.600 | 1.100 | 15.505 | 1.319 | 5.230 | 802.000 | 1567.000 | 0.379 |

| Max | 70.740 | 29.260 | 75.738 | 38.762 | 49.300 | 3.070 | 43.364 | 9.582 | 8.680 | 2111.000 | 4100.000 | 4.165 | |

| St.dev. | 2.564 | 34.460 | 3.641 | 3.641 | 0.816 | 0.517 | 7.195 | 1.552 | 1.166 | 374.269 | 720.654 | 1.055 | |

| IMC | AFR | SD | MC | DM | OM | AC | CC | NC | C/N | ΔEc | pH | TDS | S | ΔEe | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IMC | 1.000 | ||||||||||||||

| AFR | −0.234 | 1.000 | |||||||||||||

| SD | 0.000 | 0.000 | 1.000 | ||||||||||||

| MC | 0.683 | −0.076 | 0.317 | 1.00 | |||||||||||

| DM | −0.683 | 0.076 | −0.317 | −1.00 | 1.00 | ||||||||||

| OM | −0.220 | −0.130 | −0.537 | −0.66 | 0.66 | 1.000 | |||||||||

| AC | 0.222 | 0.131 | 0.536 | 0.66 | −0.66 | −1.000 | 1.000 | ||||||||

| CC | −0.006 | −0.224 | −0.255 | −0.28 | 0.28 | 0.451 | −0.450 | 1.000 | |||||||

| NC | −0.029 | 0.153 | 0.303 | 0.22 | −0.22 | −0.270 | 0.270 | 0.045 | 1.000 | ||||||

| C/N | 0.023 | −0.173 | −0.353 | −0.25 | 0.25 | 0.331 | −0.331 | 0.071 | −0.990 | 1.000 | |||||

| ΔEc | 0.150 | −0.278 | 0.432 | 0.07 | −0.07 | −0.153 | 0.151 | −0.019 | −0.167 | 0.146 | 1.000 | ||||

| pH | 0.183 | 0.106 | 0.585 | 0.49 | −0.49 | −0.595 | 0.594 | −0.462 | 0.326 | −0.400 | 0.203 | 1.000 | |||

| TDS | −0.167 | 0.284 | 0.550 | 0.14 | −0.14 | −0.446 | 0.445 | −0.359 | 0.217 | −0.275 | 0.146 | 0.512 | 1.000 | ||

| S | −0.151 | 0.253 | 0.554 | 0.15 | −0.15 | −0.438 | 0.437 | −0.342 | 0.194 | −0.252 | 0.179 | 0.503 | 0.985 | 1.000 | |

| ΔEe | −0.059 | 0.213 | 0.402 | 0.23 | −0.23 | −0.407 | 0.405 | −0.407 | 0.024 | −0.079 | 0.058 | 0.337 | 0.409 | 0.415 | 1.000 |

| Calibration | Prediction | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Output | Network | Train. Perf. Train. Error | Test Perf. Test Error | Valid. Perf. Valid. Eror | Hidden Activation | Output Activation | Rpred2 | Rpred2adj | RMSEP | SEP | RPD | RER |

| MC | MLP 3-6-1 | 0.9262 1.1201 | 0.9248 1.1335 | 0.9137 1.5458 | Tanh | Logistic | 0.9050 | 0.9028 | 1.7078 | 0.1504 | 3.1726 | 11.8455 |

| DM | MLP 3-10-1 | 0.9248 1.1222 | 0.9117 1.1258 | 0.9107 1.4933 | Tanh | Logistic | 0.9038 | 0.9015 | 1.7173 | 0.1512 | 3.1550 | 11.7799 |

| OM | MLP 3-9-1 | 0.7978 2.2311 | 0.7677 2.4293 | 0.7594 2.8152 | Tanh | Tanh | 0.7531 | 0.7472 | 3.1022 | 0.2731 | 2.0047 | 8.9766 |

| AC | MLP 3-10-1 | 0.8359 1.6794 | 0.8344 1.8354 | 0.8057 2.0836 | Tanh | Tanh | 0.7233 | 0.7167 | 3.3030 | 0.2908 | 1.8587 | 8.4310 |

| CC | MLP 3-8-1 | 0.8623 0.5664 | 0.8613 0.6265 | 0.8522 0.7596 | Logistic | Identity | 0.6658 | 0.6571 | 0.9770 | 0.0860 | 1.6380 | 8.3933 |

| NC | MLP 3-4-1 | 0.7556 0.0605 | 0.7554 0.0625 | 0.7236 0.0639 | Logistic | Exponential | 0.6516 | 0.6433 | 0.2793 | 0.0246 | 1.6819 | 7.9125 |

| C/N | MLP 3-10-1 | 0.7367 0.2016 | 0.6826 0.2683 | 0.6672 0.3913 | Tanh | Exponential | 0.6542 | 0.6483 | 3.6098 | 0.3178 | 1.9895 | 8.5399 |

| ∆Ec | MLP 3-5-1 | 0.9219 1.3085 | 0.9177 1.3384 | 0.9056 1.3718 | Logistic | Exponential | 0.7344 | 0.7281 | 2.0842 | 0.1835 | 1.9943 | 8.1286 |

| pH | MLP 3-10-1 | 0.9137 0.1148 | 0.8961 0.1569 | 0.8674 0.1640 | Tanh | Identity | 0.8322 | 0.8282 | 0.4896 | 0.0431 | 2.3890 | 9.6603 |

| TDS | MLP 3-8-1 | 0.9231 83.3771 | 0.8961 134.5269 | 0.8334 163.2544 | Tanh | Tanh | 0.7151 | 0.7084 | 236.9514 | 20.8624 | 1.8418 | 7.6682 |

| S | MLP 3-10-1 | 0.8670 87.4412 | 0.8965 151.1360 | 0.8076 182.1221 | Tanh | Logistic | 0.7529 | 0.7447 | 522.9934 | 46.0470 | 1.9763 | 8.5246 |

| ∆Ee | MLP 3-7-1 | 0.8055 0.3691 | 0.7936 0.6189 | 0.7853 0.6371 | Logistic | Logistic | 0.6952 | 0.6856 | 0.8746 | 0.0770 | 1.9531 | 7.8557 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sokač Cvetnić, T.; Krog, K.; Valinger, D.; Gajdoš Kljusurić, J.; Benković, M.; Jurina, T.; Jakovljević, T.; Radojčić Redovniković, I.; Jurinjak Tušek, A. Application of Multivariate Regression and Artificial Neural Network Modelling for Prediction of Physicochemical Properties of Grape-Skin Compost. Bioengineering 2024, 11, 285. https://doi.org/10.3390/bioengineering11030285

Sokač Cvetnić T, Krog K, Valinger D, Gajdoš Kljusurić J, Benković M, Jurina T, Jakovljević T, Radojčić Redovniković I, Jurinjak Tušek A. Application of Multivariate Regression and Artificial Neural Network Modelling for Prediction of Physicochemical Properties of Grape-Skin Compost. Bioengineering. 2024; 11(3):285. https://doi.org/10.3390/bioengineering11030285

Chicago/Turabian StyleSokač Cvetnić, Tea, Korina Krog, Davor Valinger, Jasenka Gajdoš Kljusurić, Maja Benković, Tamara Jurina, Tamara Jakovljević, Ivana Radojčić Redovniković, and Ana Jurinjak Tušek. 2024. "Application of Multivariate Regression and Artificial Neural Network Modelling for Prediction of Physicochemical Properties of Grape-Skin Compost" Bioengineering 11, no. 3: 285. https://doi.org/10.3390/bioengineering11030285

APA StyleSokač Cvetnić, T., Krog, K., Valinger, D., Gajdoš Kljusurić, J., Benković, M., Jurina, T., Jakovljević, T., Radojčić Redovniković, I., & Jurinjak Tušek, A. (2024). Application of Multivariate Regression and Artificial Neural Network Modelling for Prediction of Physicochemical Properties of Grape-Skin Compost. Bioengineering, 11(3), 285. https://doi.org/10.3390/bioengineering11030285