Trueness and Internal Fit of 3D Printed Provisional Veneers: An In Vitro Comparative Study

Abstract

1. Introduction

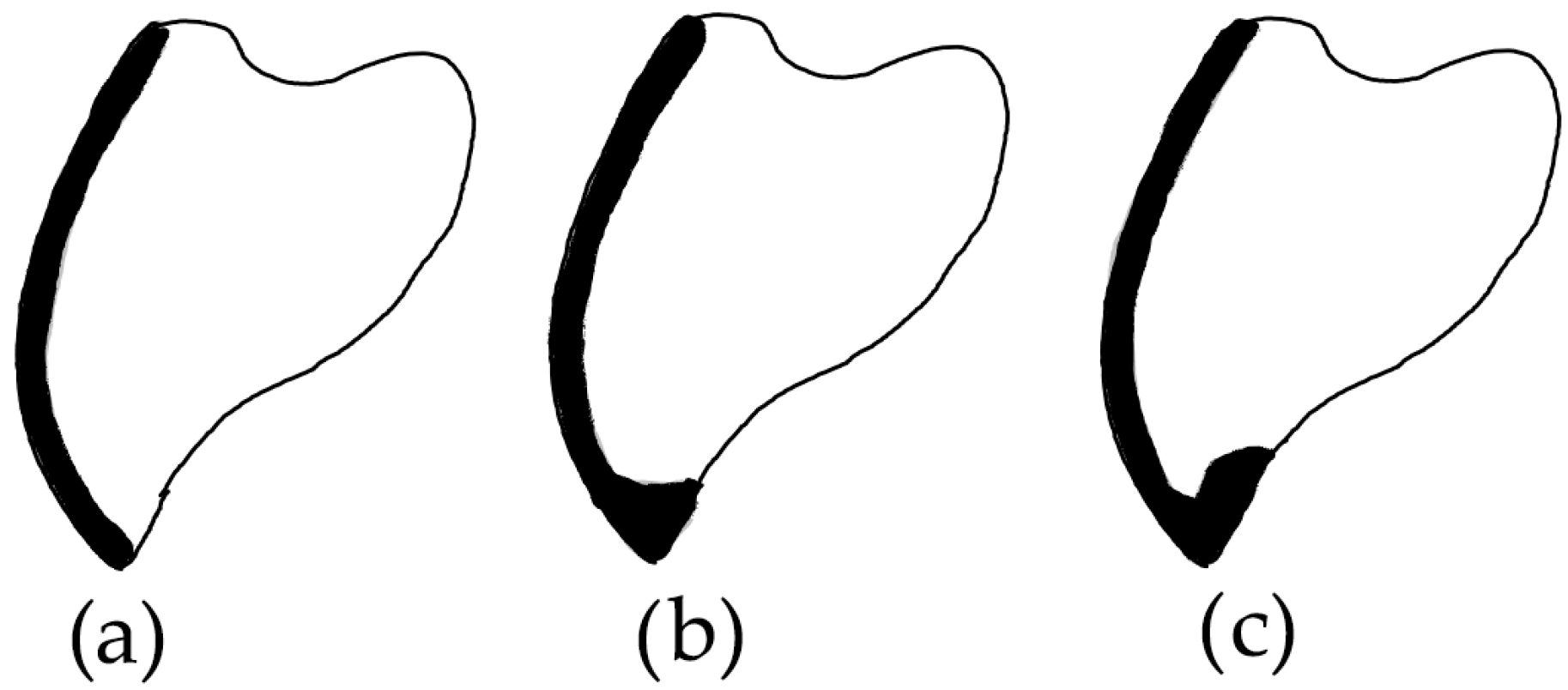

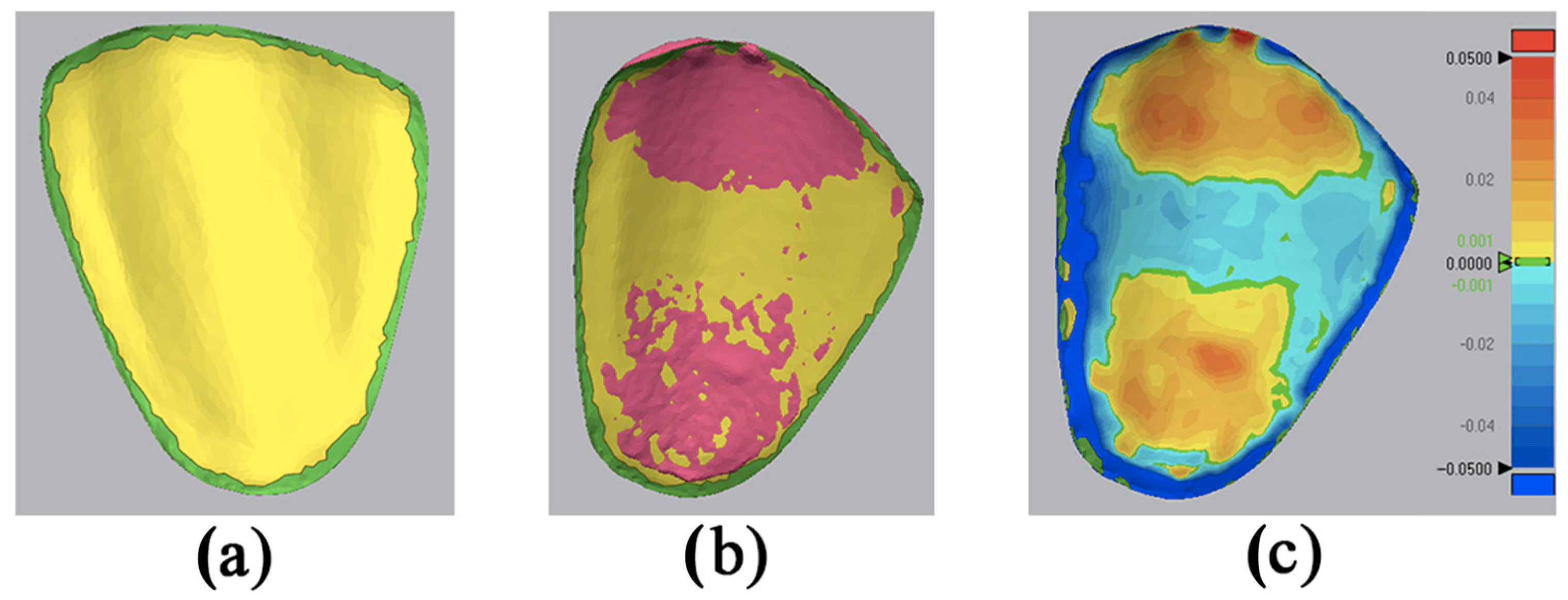

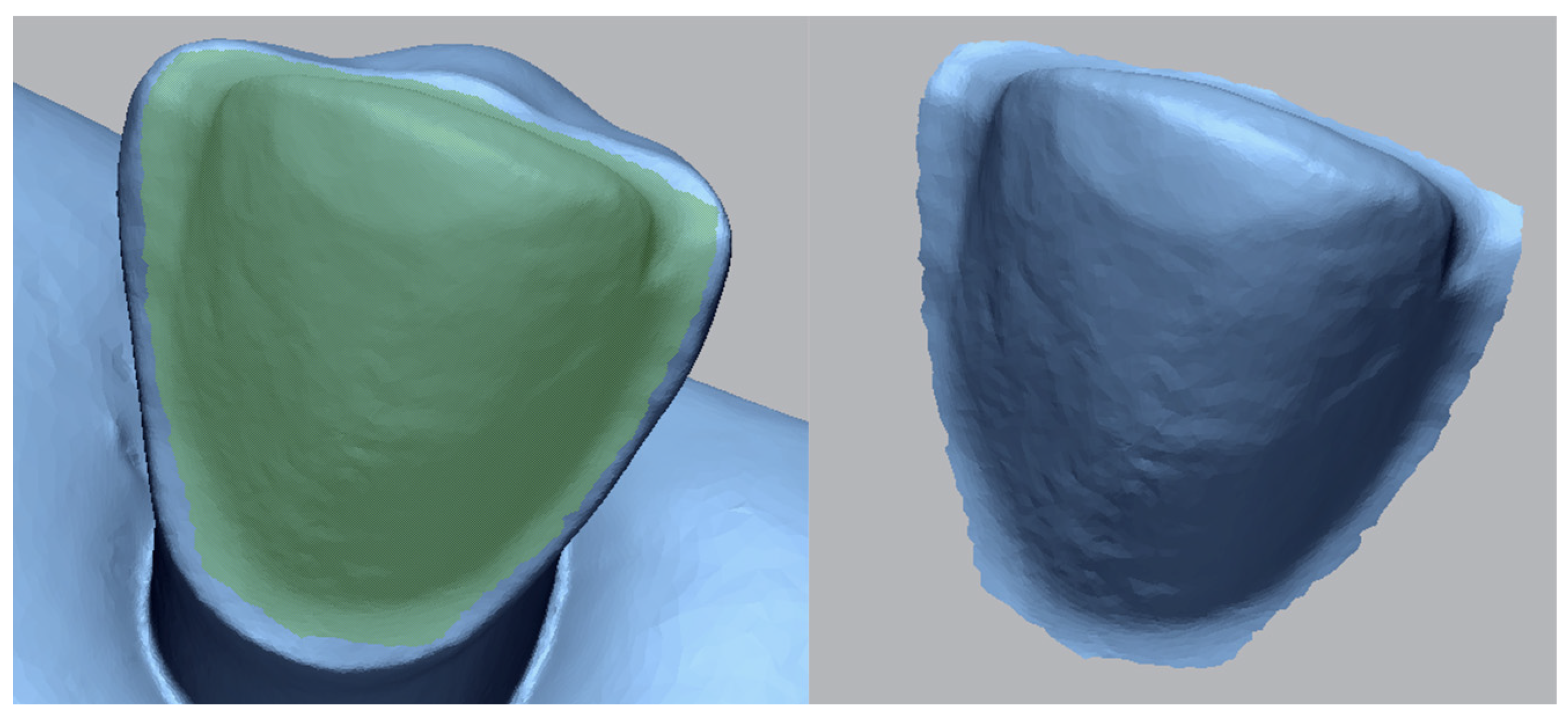

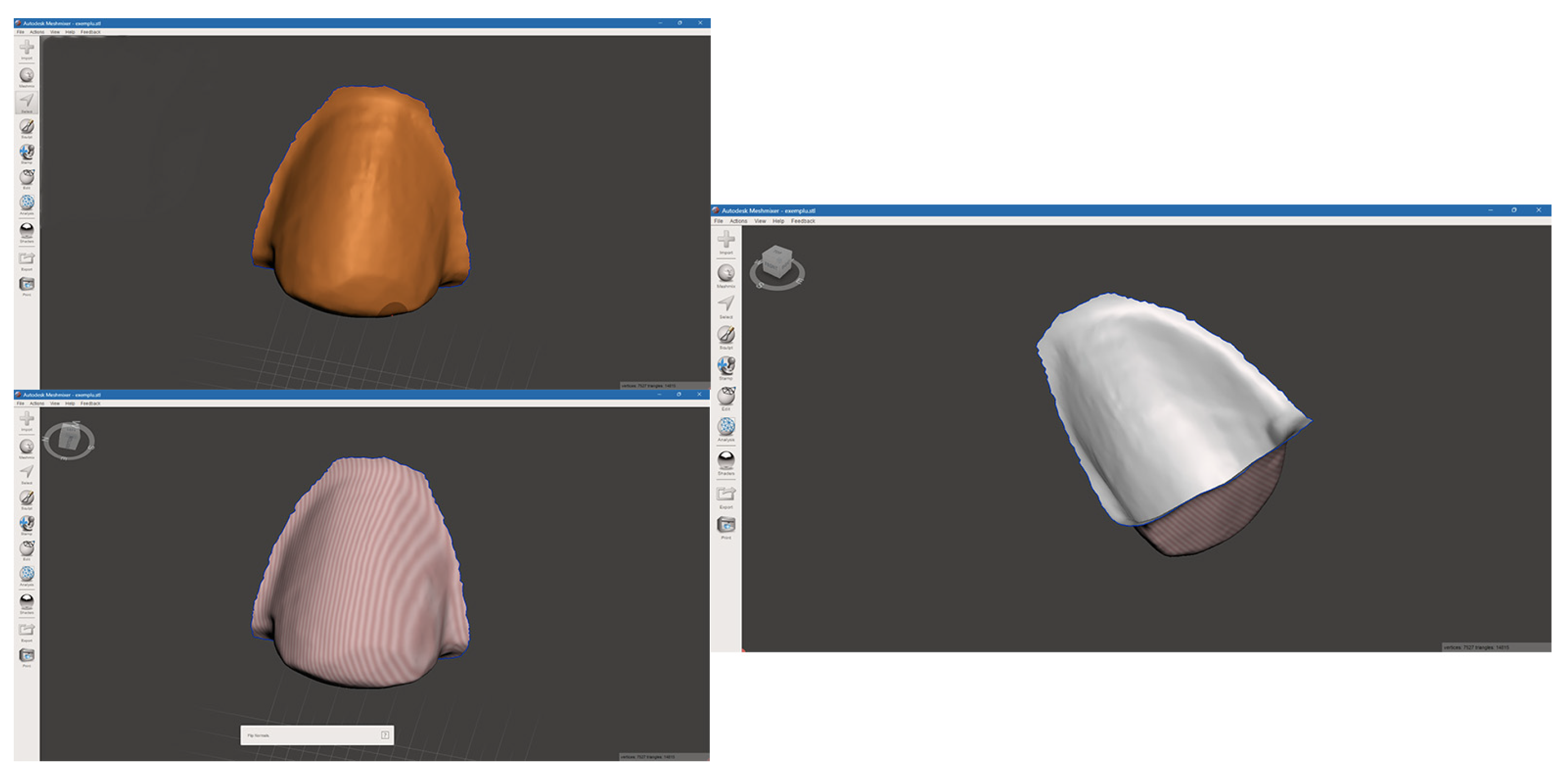

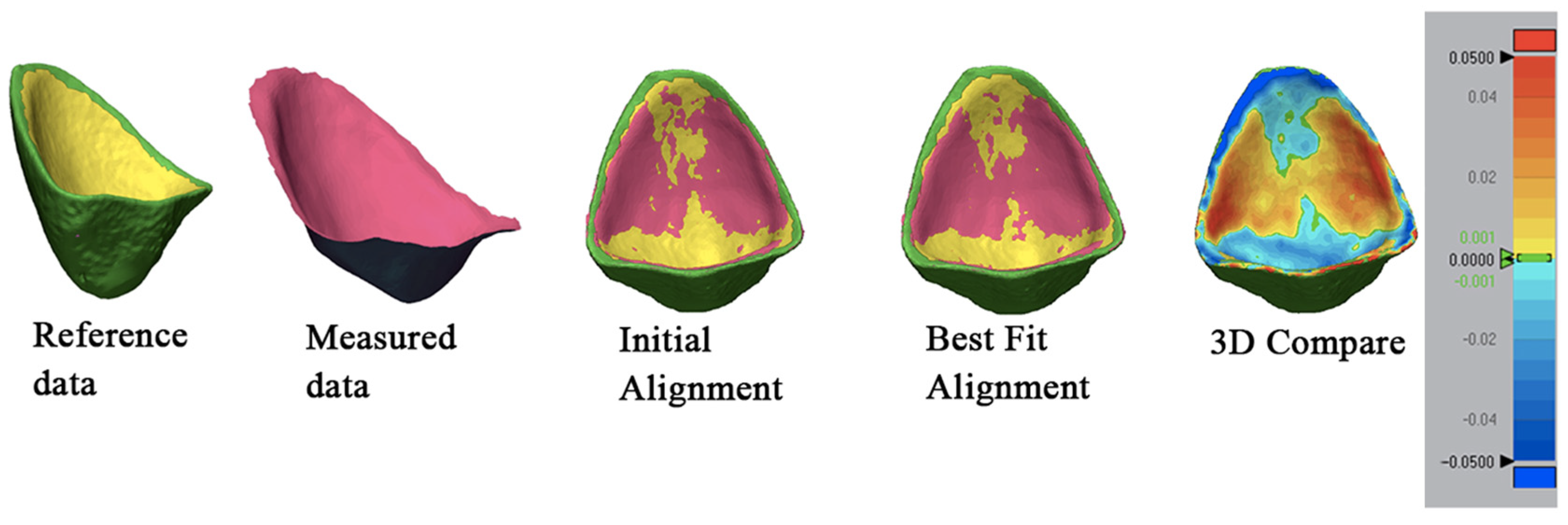

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

- (1)

- Butt joint preparation has the best trueness out of the three groups of preparation and the best trueness out of the two sets of analysis.

- (2)

- There is no statistically significant difference between butt joint and feather edge groups in the CAD design-scanned veneers analysis.

- (3)

- Regarding the scanned veneers-inverted surfaces of the typodont teeth preparations, there is no statistically significant difference between the palatal chamfer and feather edge groups.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bayazıt, E.Ö.; Karabıyık, M. Chairside Restorations of Maxillary Anterior Teeth with CAD/CAM Porcelain Laminate Veneers Produced by Digital Workflow: A Case Report with a Step to Facilitate Restoration Design. Case Rep. Dent. 2019, 2019, 6731905. [Google Scholar] [CrossRef]

- Abdulkarim, L.I.; Alharamlah, F.S.S.; Abubshait, R.M.; Alotaibi, D.A.; Abouonq, A.O. Impact of Digital Workflow Integration on Fixed Prosthodontics: A Review of Advances and Clinical Outcomes. Cureus 2024, 16, e72286. [Google Scholar] [CrossRef] [PubMed]

- Alt, V.; Hannig, M.; Wöstmann, B.; Balkenhol, M. Fracture Strength of Temporary Fixed Partial Dentures: CAD/CAM versus Directly Fabricated Restorations. Dent. Mater. 2011, 27, 339–347. [Google Scholar] [CrossRef] [PubMed]

- Hasanzade, M.; Aminikhah, M.; Afrashtehfar, K.I.; Alikhasi, M. Marginal and Internal Adaptation of Single Crowns and Fixed Dental Prostheses by Using Digital and Conventional Workflows: A Systematic Review and Meta-Analysis. J. Prosthet. Dent. 2021, 126, 360–368. [Google Scholar] [CrossRef]

- Hasanzade, M.; Shirani, M.; Afrashtehfar, K.I.; Naseri, P.; Alikhasi, M. In Vivo and In Vitro Comparison of Internal and Marginal Fit of Digital and Conventional Impressions for Full-Coverage Fixed Restorations: A Systematic Review and Meta-Analysis. J. Evid.-Based Dent. Pract. 2019, 19, 236–254. [Google Scholar] [CrossRef] [PubMed]

- Papadiochou, S.; Pissiotis, A.L. Marginal Adaptation and CAD-CAM Technology: A Systematic Review of Restorative Material and Fabrication Techniques. J. Prosthet. Dent. 2018, 119, 545–551. [Google Scholar] [CrossRef] [PubMed]

- Serdar Çötert, H.; Dündar, M.; Öztürk, B. The Effect of Various Preparation Designs on the Survival of Porcelain Laminate Veneers. J. Adhes. Dent. 2009, 11, 405–411. [Google Scholar]

- Coutinho, M.; Schiaveto De Souza, A. A Meta-Analysis of the Most Indicated Preparation Design for Porcelain Laminate Veneers. Artic. J. Adhes. Dent. 2013, 15, 215–220. [Google Scholar] [CrossRef]

- Jurado, C.A.; Sadid-Zadeh, R.; Watanabe, H.; Robbins, C.E.; Afrashtehfar, K.I.; Fischer, N.G.; Lee, D.J. Effect of Incisal Preparation Design on the Fracture Strength of Monolithic Zirconia-Reinforced Lithium Silicate Laminate Veneers. J. Prosthodont. 2024, 33, 281–287. [Google Scholar] [CrossRef]

- Walls, A.W.G.; Steele, J.G.; Wassell, R.W. Crowns and Other Extra-Coronal Restorations: Porcelain Laminate Veneers. Br. Dent. J. 2002, 193, 73–82. [Google Scholar] [CrossRef][Green Version]

- Mai, H.N.; Lee, K.B.; Lee, D.H. Fit of Interim Crowns Fabricated Using Photopolymer-Jetting 3D Printing. J. Prosthet. Dent. 2017, 118, 208–215. [Google Scholar] [CrossRef] [PubMed]

- Van Noort, R. The Future of Dental Devices Is Digital. Dent. Mater. 2012, 28, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Schweiger, J.; Edelhoff, D.; Güth, J.F. 3d Printing in Digital Prosthetic Dentistry: An Overview of Recent Developments in Additive Manufacturing. J. Clin. Med. 2021, 10, 2010. [Google Scholar] [CrossRef] [PubMed]

- Braian, M.; Jimbo, R.; Wennerberg, A. Production Tolerance of Additive Manufactured Polymeric Objects for Clinical Applications. Dent. Mater. 2016, 32, 853–861. [Google Scholar] [CrossRef]

- Dawood, A.; Marti, B.M.; Sauret-Jackson, V.; Darwood, A. 3D Printing in Dentistry. Br. Dent. J. 2015, 219, 521–529. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D Printing with Polymers: Challenges among Expanding Options and Opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- Gebler, M.; Schoot Uiterkamp, A.J.M.; Visser, C. A Global Sustainability Perspective on 3D Printing Technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Weller, C.; Kleer, R.; Piller, F.T. Economic Implications of 3D Printing: Market Structure Models in Light of Additive Manufacturing Revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- Alghauli, M.A.; Alqutaibi, A.Y. 3D-Printed Intracoronal Restorations, Occlusal and Laminate Veneers: Clinical Relevance, Properties, and Behavior Compared to Milled Restorations; a Systematic Review and Meta-Analysis. J. Esthet. Restor. Dent. 2024, 36, 1153–1170. [Google Scholar] [CrossRef]

- Çakmak, G.; Donmez, M.B.; Yılmaz, D.; Yoon, H.I.; Kahveci, Ç.; Abou-Ayash, S.; Yilmaz, B. Fabrication Trueness and Marginal Quality of Additively Manufactured Resin-Based Definitive Laminate Veneers with Different Restoration Thicknesses. J. Dent. 2024, 144, 104941. [Google Scholar] [CrossRef]

- Kessler, A.; Hickel, R.; Reymus, M. 3D Printing in Dentistry-State of the Art. Oper. Dent. 2020, 45, 30–40. [Google Scholar] [CrossRef]

- Revilla-León, M.; Özcan, M. Additive Manufacturing Technologies Used for Processing Polymers: Current Status and Potential Application in Prosthetic Dentistry. J. Prosthodont. 2019, 28, 146–158. [Google Scholar] [CrossRef]

- Emir, F.; Ayyildiz, S. Accuracy Evaluation of Complete-Arch Models Manufactured by Three Different 3d Printing Technologies: A Three-Dimensional Analysis. J. Prosthodont. Res. 2021, 65, 365–370. [Google Scholar] [CrossRef]

- de Castro, E.F.; Nima, G.; Rueggeberg, F.A.; Giannini, M. Effect of Build Orientation in Accuracy, Flexural Modulus, Flexural Strength, and Microhardness of 3D-Printed Resins for Provisional Restorations. J. Mech. Behav. Biomed. Mater. 2022, 136, 105479. [Google Scholar] [CrossRef]

- Alharbi, N.; Osman, R.; Wismeijer, D. Factors Influencing the Dimensional Accuracy of 3D-Printed Full-Coverage Dental Restorations Using Stereolithography Technology. Int. J. Prosthodont. 2016, 29, 503–510. [Google Scholar] [CrossRef]

- Button, H.; Kois, J.C.; Barmak, A.B.; Zeitler, J.M.; Rutkunas, V.; Revilla-León, M. Scanning Accuracy and Scanning Area Discrepancies of Intraoral Digital Scans Acquired at Varying Scanning Distances and Angulations among 4 Different Intraoral Scanners. J. Prosthet. Dent. 2023, 132, 1044–1060. [Google Scholar] [CrossRef]

- Gavounelis, N.A.; Gogola, C.M.C.; Halazonetis, D.J. The Effect of Scanning Strategy on Intraoral Scanner’s Accuracy. Dent. J. 2022, 10, 123. [Google Scholar] [CrossRef]

- Vafaee, F.; Firouz, F.; Mohajeri, M.; Hashemi, R.; Ghorbani Gholiabad, S.; Author, C. In Vitro Comparison of the Accuracy (Precision and Trueness) of Seven Dental Scanners. J. Dent. Shiraz Univ. Med. Sci. 2021, 22, 8–13. [Google Scholar] [CrossRef]

- Al Wadei, M.H.D.; Sayed, M.E.; Jain, S.; Aggarwal, A.; Alqarni, H.; Gupta, S.G.; Alqahtani, S.M.; Alahmari, N.M.; Alshehri, A.H.; Jain, M.; et al. Marginal Adaptation and Internal Fit of 3D-Printed Provisional Crowns and Fixed Dental Prosthesis Resins Compared to CAD/CAM-Milled and Conventional Provisional Resins: A Systematic Review and Meta-Analysis. Coatings 2022, 14, 2691. [Google Scholar] [CrossRef]

- Hoang, L.N.; Thompson, G.A.; Cho, S.H.; Berzins, D.W.; Ahn, K.W. Die Spacer Thickness Reproduction for Central Incisor Crown Fabrication with Combined Computer-Aided Design and 3D Printing Technology: An in Vitro Study. J. Prosthet. Dent. 2015, 113, 398–404. [Google Scholar] [CrossRef]

- Magne, P.; Hanna, J.; Magne, M. The case for moderate “guided prep” indirect porcelain veneers in the anterior dentition. The pendulum of porcelain veneer preparations: From almost no-prep to over-prep to no-prep. Eur. J. Esthet. Dent. 2013, 8, 376–388. [Google Scholar] [PubMed]

- Nordb, H.; Rygh-Thoresen, N.; Henaug, T. Clinical Performance of Veneers without Inci 3-Year Results. J. Dent. 1994, 22, 342–345. [Google Scholar] [CrossRef] [PubMed]

- Calamia, J.R. Materials and Technique for Etched Porcelain Facial Veneers. Alpha Omegan 1988, 81, 48–51. [Google Scholar] [PubMed]

- Garber, D. Porcelain Laminate Veneers: Ten Years Later. Part I: Tooth Preparation. J. Esthet. Dent. 1993, 5, 56–62. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Alqahtani, N.M.; Addas, M.K.; Alfarsi, M.A. Marginal and Internal Fit of Provisional Crowns Fabricated Using 3D Printing Technology. Technol. Health Care 2020, 28, 635–642. [Google Scholar] [CrossRef]

| Group 1 | Group 2 | |

|---|---|---|

| Measured data | Scanned veneers (feather edge, butt joint, palatal chamfer) vs. CAD designs (feather edge, butt joint, palatal chamfer) | Scanned veneers (feather edge, butt joint, palatal chamfer) vs. Inverted surfaces of the preparations (feather edge, butt joint, palatal chamfer) |

| Reference data |

| Group1 (Scanned Veneers-CAD Designs) | n | Mean | Standard Deviation | Different (p < 0.05) from Factor nr |

|---|---|---|---|---|

| 20 | 62.145 μm | 9.549 | (3) |

| 20 | 63.075 μm | 29.351 | (3) |

| 20 | 86.440 μm | 17.422 | (1), (2) |

| Group2 (Scanned Veneers-Inverted Surfaces of the Preparations) | n | Mean | Standard Deviation | Different (p < 0.05) from Factor nr |

|---|---|---|---|---|

| 20 | 37.745 μm | 8.149 | (2), (3) |

| 20 | 52.730 μm | 17.283 | (1) |

| 20 | 46.075 μm | 10.743 | (1) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anghel-Lorinți, A.-E.; Faur, A.-B.; Rotar, R.N.; Jivănescu, A. Trueness and Internal Fit of 3D Printed Provisional Veneers: An In Vitro Comparative Study. Bioengineering 2024, 11, 1204. https://doi.org/10.3390/bioengineering11121204

Anghel-Lorinți A-E, Faur A-B, Rotar RN, Jivănescu A. Trueness and Internal Fit of 3D Printed Provisional Veneers: An In Vitro Comparative Study. Bioengineering. 2024; 11(12):1204. https://doi.org/10.3390/bioengineering11121204

Chicago/Turabian StyleAnghel-Lorinți, Anca-Elena, Andrei-Bogdan Faur, Raul N. Rotar, and Anca Jivănescu. 2024. "Trueness and Internal Fit of 3D Printed Provisional Veneers: An In Vitro Comparative Study" Bioengineering 11, no. 12: 1204. https://doi.org/10.3390/bioengineering11121204

APA StyleAnghel-Lorinți, A.-E., Faur, A.-B., Rotar, R. N., & Jivănescu, A. (2024). Trueness and Internal Fit of 3D Printed Provisional Veneers: An In Vitro Comparative Study. Bioengineering, 11(12), 1204. https://doi.org/10.3390/bioengineering11121204