Characterization of Poly(3-hydroxybutyrate) (P3HB) from Alternative, Scalable (Waste) Feedstocks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

2.3. Injection Molding Processing

2.4. Characterizations

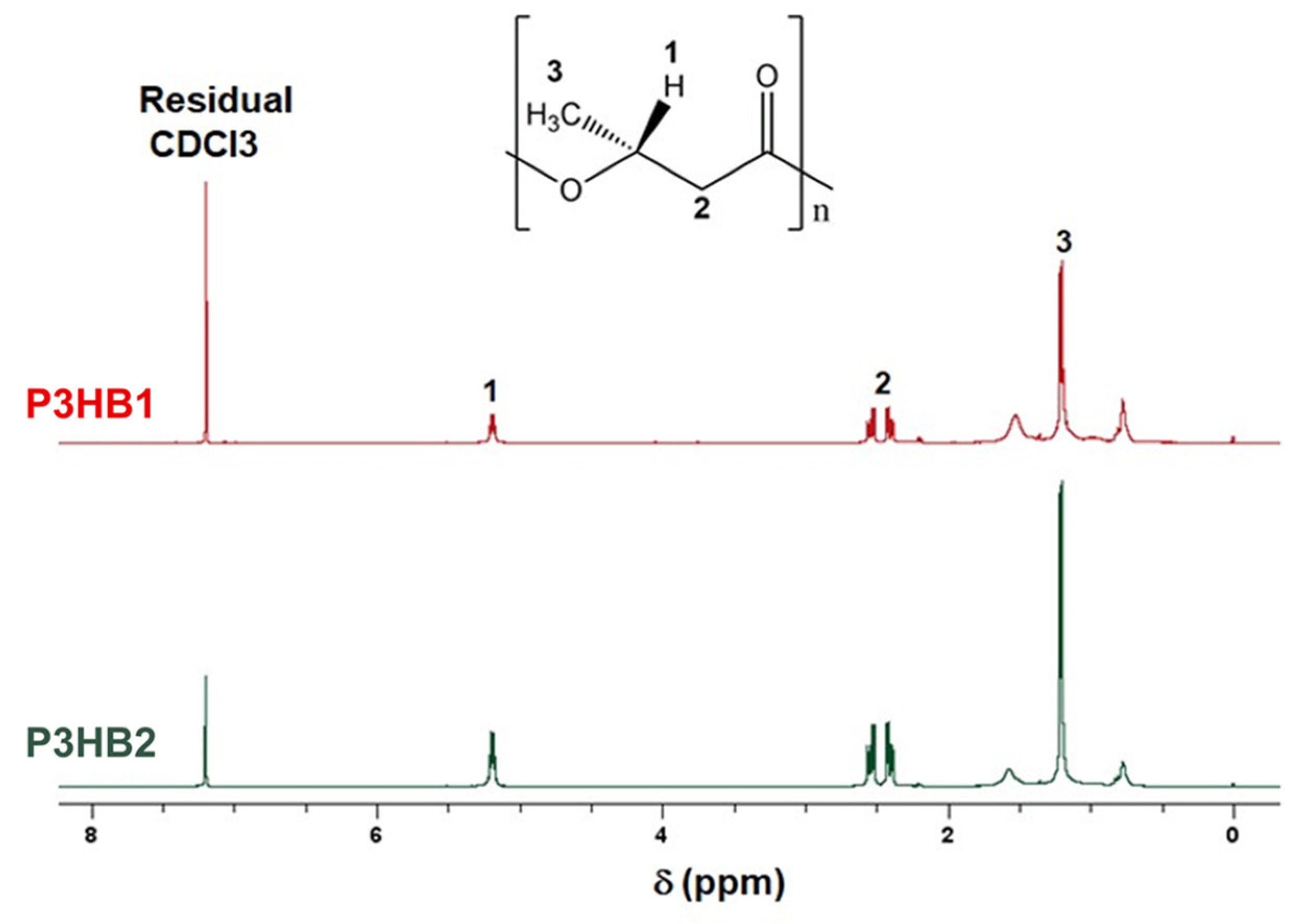

2.4.1. 1H Nuclear Magnetic Resonance

2.4.2. Size Exclusion Chromatography

2.4.3. Differential Scanning Calorimetry

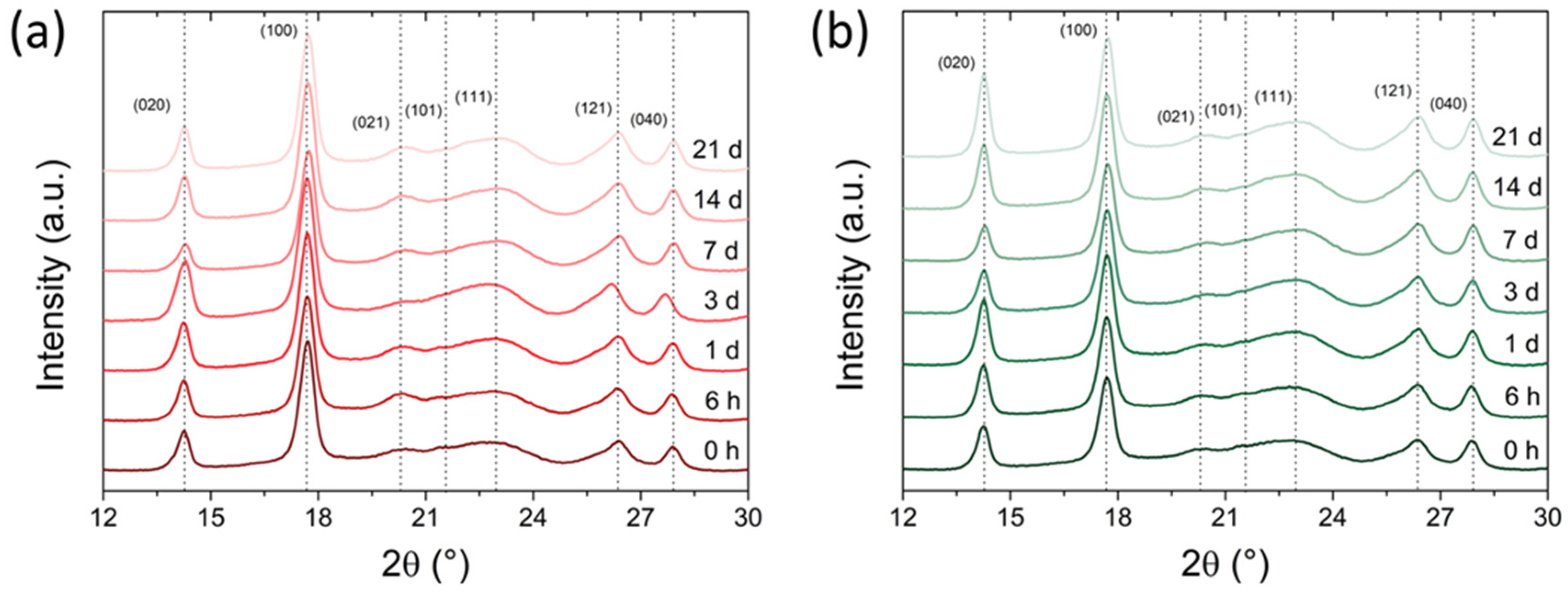

2.4.4. X-ray Diffraction

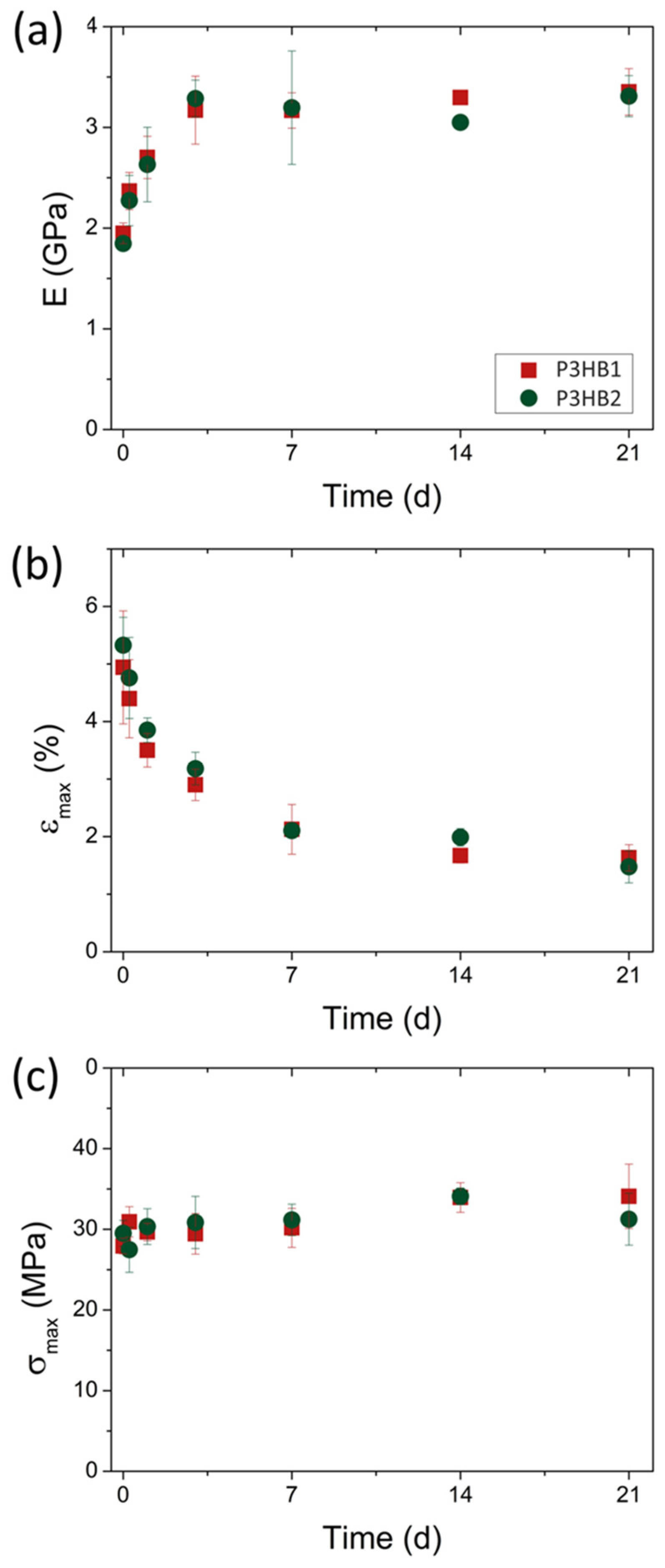

2.4.5. Tensile Test

3. Results and Discussion

3.1. Characterization of P3HB

3.2. Thermal Properties

3.3. Crystalline Structure

3.4. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brahney, J.; Mahowald, N.; Prank, M.; Cornwell, G.; Klimont, Z.; Matsui, H.; Prather, K.A. Constraining the Atmospheric Limb of the Plastic Cycle. Proc. Natl. Acad. Sci. USA 2021, 118, 1–10. [Google Scholar] [CrossRef]

- Pimentel Pincelli, I.; Borges de Castilhos Júnior, A.; Seleme Matias, M.; Wanda Rutkowski, E. Post-Consumer Plastic Packaging Waste Flow Analysis for Brazil: The Challenges Moving towards a Circular Economy. Waste Manag. 2021, 126, 781–790. [Google Scholar] [CrossRef] [PubMed]

- Plastic Pollution Is Growing Relentlessly as Waste Management and Recycling Fall Short, Says OECD. Available online: https://www.oecd.org/environment/plastic-pollution-is-growing-relentlessly-as-waste-management-and-recycling-fall-short.htm (accessed on 12 September 2023).

- Zhao, Y.-B.; Lv, X.-D.; Ni, H.-G. Solvent-Based Separation and Recycling of Waste Plastics: A Review. Chemosphere 2018, 209, 707–720. [Google Scholar] [CrossRef]

- Li, H.; Aguirre-Villegas, H.A.; Allen, R.D.; Bai, X.; Benson, C.H.; Beckham, G.T.; Bradshaw, S.L.; Brown, J.L.; Brown, R.C.; Cecon, V.S.; et al. Expanding Plastics Recycling Technologies: Chemical Aspects, Technology Status and Challenges. Green Chem. 2022, 24, 8899–9002. [Google Scholar] [CrossRef]

- Diversion of Waste from Landfill in Europe. Available online: https://www.eea.europa.eu/en/analysis/indicators/diversion-of-waste-from-landfill (accessed on 21 November 2023).

- Safaeian, P.; Yazdian, F.; Khosravi-Darani, K.; Rashedi, H.; Lackner, M. P3HB from CH4 Using Methanotrophs: Aspects of Bioreactor, Fermentation Process and Modelling for Cost-Effective Biopolymer Production. Front. Bioeng. Biotechnol. 2023, 11, 1137749. [Google Scholar] [CrossRef] [PubMed]

- Tumu, K.; Vorst, K.; Curtzwiler, G. Global Plastic Waste Recycling and Extended Producer Responsibility Laws. J. Environ. Manag. 2023, 348, 119242. [Google Scholar] [CrossRef] [PubMed]

- Muiruri, J.K.; Yeo, J.C.C.; Zhu, Q.; Ye, E.; Loh, X.J.; Li, Z. Poly(Hydroxyalkanoates): Production, Applications and End-of-Life Strategies-Life Cycle Assessment Nexus. ACS Sustain. Chem. Eng. 2022, 10, 3387–3406. [Google Scholar] [CrossRef]

- Madison, L.L.; Huisman, G.W. Metabolic Engineering of Poly(3-Hydroxyalkanoates): From DNA to Plastic. Microbiol. Mol. Biol. Rev. 1999, 63, 21–53. [Google Scholar] [CrossRef] [PubMed]

- Anderson, A.J.; Dawes, E.A. Occurrence, Metabolism, Metabolic Role, and Industrial Uses of Bacterial Polyhydroxyalkanoates. Microbiol. Rev. 1990, 54, 450–472. [Google Scholar] [CrossRef]

- Meereboer, K.W.; Misra, M.; Mohanty, A.K. Review of Recent Advances in the Biodegradability of Polyhydroxyalkanoate (PHA) Bioplastics and Their Composites. Green Chem. 2020, 22, 5519–5558. [Google Scholar] [CrossRef]

- Muthuraj, R.; Valerio, O.; Mekonnen, T.H. Recent Developments in Short- and Medium-Chain- Length Polyhydroxyalkanoates: Production, Properties, and Applications. Int. J. Biol. Macromol. 2021, 187, 422–440. [Google Scholar] [CrossRef]

- Yeo, J.C.C.; Muiruri, J.K.; Thitsartarn, W.; Li, Z.; He, C. Recent Advances in the Development of Biodegradable PHB-Based Toughening Materials: Approaches, Advantages and Applications. Mater. Sci. Eng. C 2018, 92, 1092–1116. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M. Present and Future Development in Plastics from Biomass. Biofuels, Bioprod. Biorefining 2010, 4, 25–40. [Google Scholar] [CrossRef]

- Raza, Z.A.; Khalil, S.; Abid, S. Recent Progress in Development and Chemical Modification of Poly(Hydroxybutyrate)-Based Blends for Potential Medical Applications. Int. J. Biol. Macromol. 2020, 160, 77–100. [Google Scholar] [CrossRef]

- Markl, E.; Grünbichler, H.; Lackner, M. PHB—Bio Based and Biodegradable Replacement for PP: A Review. Nov. Technol. Nutr. Food Sci. 2018, 2, 206–209. [Google Scholar] [CrossRef]

- Abdelwahab, M.A.; El-Barbary, A.A.; El-Said, K.S.; Betiha, M.; Elkholy, H.M.; Chiellini, E.; El-Magd, M.A. Functionalization of Poly(3-hydroxybutyrate) with Different Thiol Compounds Inhibits MDM2–P53 Interactions in MCF7 Cells. J. Appl. Polym. Sci. 2019, 136, 46924. [Google Scholar] [CrossRef]

- Keskin, G.; Kızıl, G.; Bechelany, M.; Pochat-Bohatier, C.; Öner, M. Potential of Polyhydroxyalkanoate (PHA) Polymers Family as Substitutes of Petroleum Based Polymers for Packaging Applications and Solutions Brought by Their Composites to Form Barrier Materials. Pure Appl. Chem. 2017, 89, 1841–1848. [Google Scholar] [CrossRef]

- Popa, M.S.; Frone, A.N.; Panaitescu, D.M. Polyhydroxybutyrate Blends: A Solution for Biodegradable Packaging? Int. J. Biol. Macromol. 2022, 207, 263–277. [Google Scholar] [CrossRef] [PubMed]

- Darie-Niță, R.N.; Râpă, M.; Frąckowiak, S. Special Features of Polyester-Based Materials for Medical Applications. Polymers 2022, 14, 951. [Google Scholar] [CrossRef] [PubMed]

- Basnett, P.; Matharu, R.K.; Taylor, C.S.; Illangakoon, U.; Dawson, J.I.; Kanczler, J.M.; Behbehani, M.; Humphrey, E.; Majid, Q.; Lukasiewicz, B.; et al. Harnessing Polyhydroxyalkanoates and Pressurized Gyration for Hard and Soft Tissue Engineering. ACS Appl. Mater. Interfaces 2021, 13, 32624–32639. [Google Scholar] [CrossRef] [PubMed]

- Mohapatra, S.; Mohanty, D.; Mohapatra, S.; Sharma, S.; Dikshit, S.; Kohli, I.; Samantaray, D.P.; Kathpalia, M. Biomedical Application of Polymeric Biomaterial: Polyhydroxybutyrate. In Bioresource Utilization and Management Applications in Therapeutics, Biofuels, Agriculture, and Environmental Science; Thatoi, H., Das, S.K., Mohapatra, S., Eds.; Apple Academic Press: New York, NY, USA, 2021; pp. 1–14. [Google Scholar]

- Yao, C.-L.; Chen, J.-H.; Lee, C.-H. Effects of Various Monomers and Micro-Structure of Polyhydroxyalkanoates on the Behavior of Endothelial Progenitor Cells and Endothelial Cells for Vascular Tissue Engineering. J. Polym. Res. 2018, 25, 187. [Google Scholar] [CrossRef]

- Degli Esposti, M.; Chiellini, F.; Bondioli, F.; Morselli, D.; Fabbri, P. Highly Porous PHB-Based Bioactive Scaffolds for Bone Tissue Engineering by in Situ Synthesis of Hydroxyapatite. Mater. Sci. Eng. C 2019, 100, 286–296. [Google Scholar] [CrossRef]

- Koller, M.; Salerno, A.; Reiterer, A.; Malli, H.; Malli, K.; Kettl, K.-H.; Narodoslawsky, M.; Schnitzer, H.; Chiellini, E.; Braunegg, G. Sugarcane as Feedstock for Biomediated Polymer Production. In Sugarcane: Production, Cultivation and Uses; Goncalves, J.F., Correia, K.D., Eds.; Nova Science Publisher: New York, NY, USA, 2012; pp. 105–136. [Google Scholar]

- Lackner, K.S. The Thermodynamics of Direct Air Capture of Carbon Dioxide. Energy 2013, 50, 38–46. [Google Scholar] [CrossRef]

- Strong, P.; Laycock, B.; Mahamud, S.; Jensen, P.; Lant, P.; Tyson, G.; Pratt, S. The Opportunity for High-Performance Biomaterials from Methane. Microorganisms 2016, 4, 11. [Google Scholar] [CrossRef]

- McAdam, B.; Brennan Fournet, M.; McDonald, P.; Mojicevic, M. Production of Polyhydroxybutyrate (PHB) and Factors Impacting Its Chemical and Mechanical Characteristics. Polymers 2020, 12, 2908. [Google Scholar] [CrossRef]

- Pradhan, S.; Dikshit, P.K.; Moholkar, V.S. Production, Ultrasonic Extraction, and Characterization of Poly (3-hydroxybutyrate) (PHB) Using Bacillus Megaterium and Cupriavidus Necator. Polym. Adv. Technol. 2018, 29, 2392–2400. [Google Scholar] [CrossRef]

- Domínguez-Díaz, M.; Meneses-Acosta, A.; Romo-Uribe, A.; Peña, C.; Segura, D.; Espin, G. Thermo-Mechanical Properties, Microstructure and Biocompatibility in Poly-β-Hydroxybutyrates (PHB) Produced by OP and OPN Strains of Azotobacter Vinelandii. Eur. Polym. J. 2015, 63, 101–112. [Google Scholar] [CrossRef]

- Crétois, R.; Chenal, J.-M.; Sheibat-Othman, N.; Monnier, A.; Martin, C.; Astruz, O.; Kurusu, R.; Demarquette, N.R. Physical Explanations about the Improvement of PolyHydroxyButyrate Ductility: Hidden Effect of Plasticizer on Physical Ageing. Polymer 2016, 102, 176–182. [Google Scholar] [CrossRef]

- Barham, P.J.; Keller, A.; Otun, E.L.; Holmes, P.A. Crystallization and Morphology of a Bacterial Thermoplastic: Poly-3-Hydroxybutyrate. J. Mater. Sci. 1984, 19, 2781–2794. [Google Scholar] [CrossRef]

- ISO 527-2; Determination of Tensile Properties. Part 2: Test Conditions for Moulding and Extrusion Plastics. Technical Report; International Standardization Organization: Geneva, Switzerland, 2012.

- Chaber, P.; Kwiecień, M.; Zięba, M.; Sobota, M.; Adamus, G. The Heterogeneous Selective Reduction of PHB as a Useful Method for Preparation of Oligodiols and Surface Modification. RSC Adv. 2017, 7, 35096–35104. [Google Scholar] [CrossRef]

- Li, R.; Jiang, Y.; Wang, X.; Yang, J.; Gao, Y.; Zi, X.; Zhang, X.; Gao, H.; Hu, N. Psychrotrophic Pseudomonas Mandelii CBS-1 Produces High Levels of Poly-β-Hydroxybutyrate. Springerplus 2013, 2, 335. [Google Scholar] [CrossRef] [PubMed]

- Van-Thuoc, D.; Huu-Phong, T.; Thi-Binh, N.; Thi-Tho, N.; Minh-Lam, D.; Quillaguamán, J. Polyester Production by Halophilic and Halotolerant Bacterial Strains Obtained from Mangrove Soil Samples Located in Northern Vietnam. Microbiologyopen 2012, 1, 395–406. [Google Scholar] [CrossRef] [PubMed]

- Laycock, B.; Halley, P.; Pratt, S.; Werker, A.; Lant, P. The Chemomechanical Properties of Microbial Polyhydroxyalkanoates. Prog. Polym. Sci. 2014, 39, 397–442. [Google Scholar] [CrossRef]

- Wellen, R.M.R.; Rabello, M.S.; Fechine, G.J.M.; Canedo, E.L. The Melting Behaviour of Poly(3-Hydroxybutyrate) by DSC. Reproducibility Study. Polym. Test. 2013, 32, 215–220. [Google Scholar] [CrossRef]

- De Sousa Junior, R.R.; dos Santos, C.A.S.; Ito, N.M.; Suqueira, A.N.; Lackner, M.; dos Santos, D.J. PHB Processability and Property Improvement with Linear-Chain Polyester Oligomers Used as Plasticizers. Polymers 2022, 14, 4197. [Google Scholar] [CrossRef] [PubMed]

- Di Lorenzo, M.L.; Gazzano, M.; Righetti, M.C. The Role of the Rigid Amorphous Fraction on Cold Crystallization of Poly(3-Hydroxybutyrate). Macromolecules 2012, 45, 5684–5691. [Google Scholar] [CrossRef]

- Mousavioun, P.; Halley, P.J.; Doherty, W.O.S. Thermophysical Properties and Rheology of PHB/Lignin Blends. Ind. Crop. Prod. 2013, 50, 270–275. [Google Scholar] [CrossRef]

- Abdelwahab, M.A.; Flynn, A.; Chiou, B.-S.; Imam, S.; Orts, W.; Chiellini, E. Thermal, Mechanical and Morphological Characterization of Plasticized PLA–PHB Blends. Polym. Degrad. Stab. 2012, 97, 1822–1828. [Google Scholar] [CrossRef]

- Mahmood, N.; Kolesov, I.; Glüge, R.; Altenbach, H.; Androsch, R.; Beiner, M. Influence of Structure Gradients in Injection Moldings of Isotactic Polypropylene on Their Mechanical Properties. Polymer 2020, 200, 122556. [Google Scholar] [CrossRef]

- Kurusu, R.S.; Demarquette, N.R.; Gauthier, C.; Chenal, J.-M. Effect of Ageing and Annealing on the Mechanical Behaviour and Biodegradability of a Poly(3-Hydroxybutyrate) and Poly(Ethylene-Co-Methyl-Acrylate-Co-Glycidyl-Methacrylate)Blend. Polym. Int. 2014, 63, 1085–1093. [Google Scholar] [CrossRef]

- De Koning, G.J.M.; Lemstra, P.J. Crystallization Phenomena in Bacterial Poly[(R)-3-Hydroxybutyrate]: 2. Embrittlement and Rejuvenation. Polymer 1993, 34, 4089–4094. [Google Scholar] [CrossRef]

- Srubar, W.V.; Wright, Z.C.; Tsui, A.; Michel, A.T.; Billington, S.L.; Frank, C.W. Characterizing the Effects of Ambient Aging on the Mechanical and Physical Properties of Two Commercially Available Bacterial Thermoplastics. Polym. Degrad. Stab. 2012, 97, 1922–1929. [Google Scholar] [CrossRef]

| P3HB1 | P3HB2 | |

|---|---|---|

| Host | Cyanobacteria (pure culture) | Aerobic methanotrophs (pure culture) |

| Strain | Synechocystis sp. PCC 6714 | Methylocystis sp. GB 25 |

| Carbon source | CO2 | CH4 |

| Appearance | White powder | White powder |

| P3HB1 | P3HB2 | |

|---|---|---|

| Mn (Da) | 696,394 | 207,475 |

| Mw (Da) | 1,073,000 | 1,084,000 |

| Mw/Mn | 1.54 | 5.23 |

| Thermal Properties | P3HB1 | P3HB2 |

|---|---|---|

| Tg (°C) | 4.02 | 4.43 |

| Tc (°C) | 79.56 | 70.29 |

| Tm (°C) | 174.32 | 175.10 |

| XDSC (%) | 64.49 | 63.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Sousa Junior, R.R.; Cezario, F.E.M.; Antonino, L.D.; dos Santos, D.J.; Lackner, M. Characterization of Poly(3-hydroxybutyrate) (P3HB) from Alternative, Scalable (Waste) Feedstocks. Bioengineering 2023, 10, 1382. https://doi.org/10.3390/bioengineering10121382

de Sousa Junior RR, Cezario FEM, Antonino LD, dos Santos DJ, Lackner M. Characterization of Poly(3-hydroxybutyrate) (P3HB) from Alternative, Scalable (Waste) Feedstocks. Bioengineering. 2023; 10(12):1382. https://doi.org/10.3390/bioengineering10121382

Chicago/Turabian Stylede Sousa Junior, Rogerio Ramos, Fabiano Eduardo Marques Cezario, Leonardo Dalseno Antonino, Demetrio Jackson dos Santos, and Maximilian Lackner. 2023. "Characterization of Poly(3-hydroxybutyrate) (P3HB) from Alternative, Scalable (Waste) Feedstocks" Bioengineering 10, no. 12: 1382. https://doi.org/10.3390/bioengineering10121382

APA Stylede Sousa Junior, R. R., Cezario, F. E. M., Antonino, L. D., dos Santos, D. J., & Lackner, M. (2023). Characterization of Poly(3-hydroxybutyrate) (P3HB) from Alternative, Scalable (Waste) Feedstocks. Bioengineering, 10(12), 1382. https://doi.org/10.3390/bioengineering10121382