Effect of Rotation Speed and Powder Bed Volume on Powder Flowability Measured by a Powder Rheometer: Evaluation of the Humidity Effect on Lactose Powder Flowability

Abstract

1. Introduction

2. Experiment

2.1. Materials

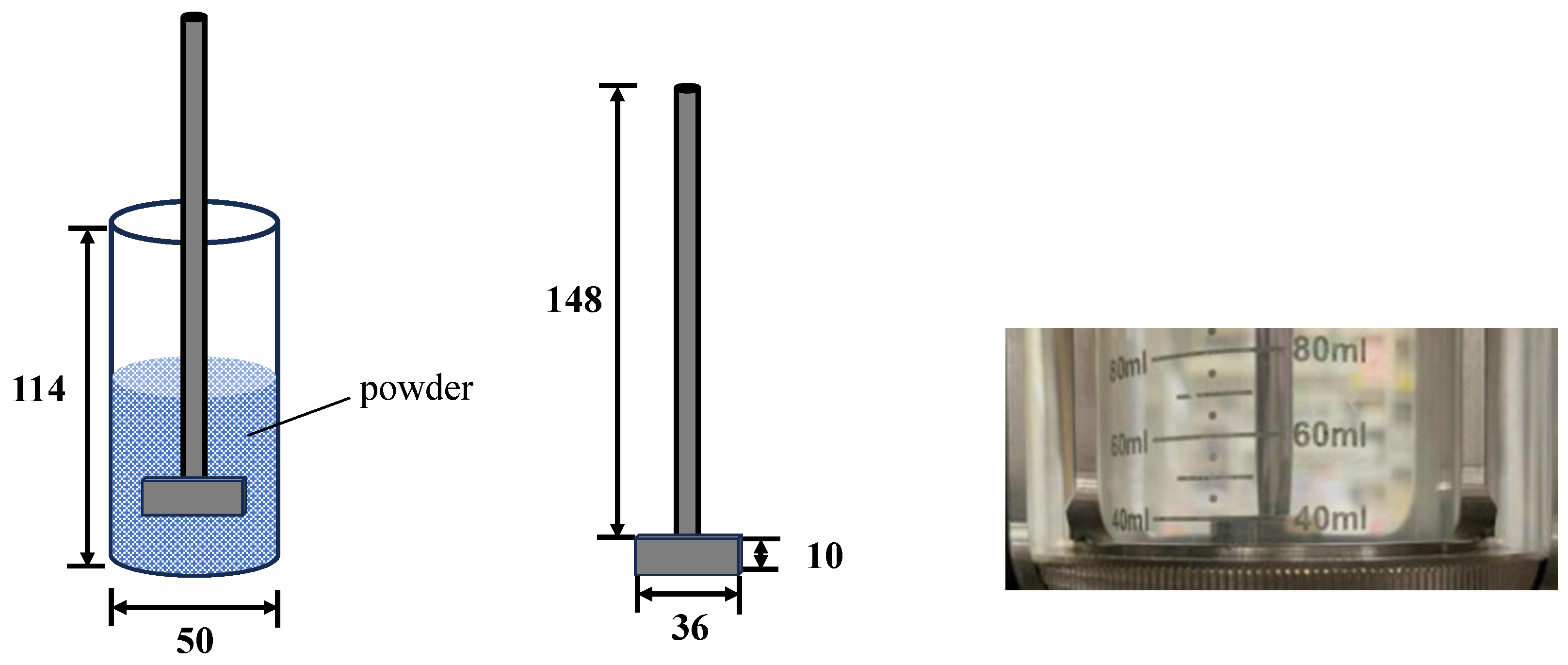

2.2. Powder Flowability Evaluation of the Powder Flow Cell

2.3. Measurements of the Angle of Repose and Bulk Density

3. Results and Discussion

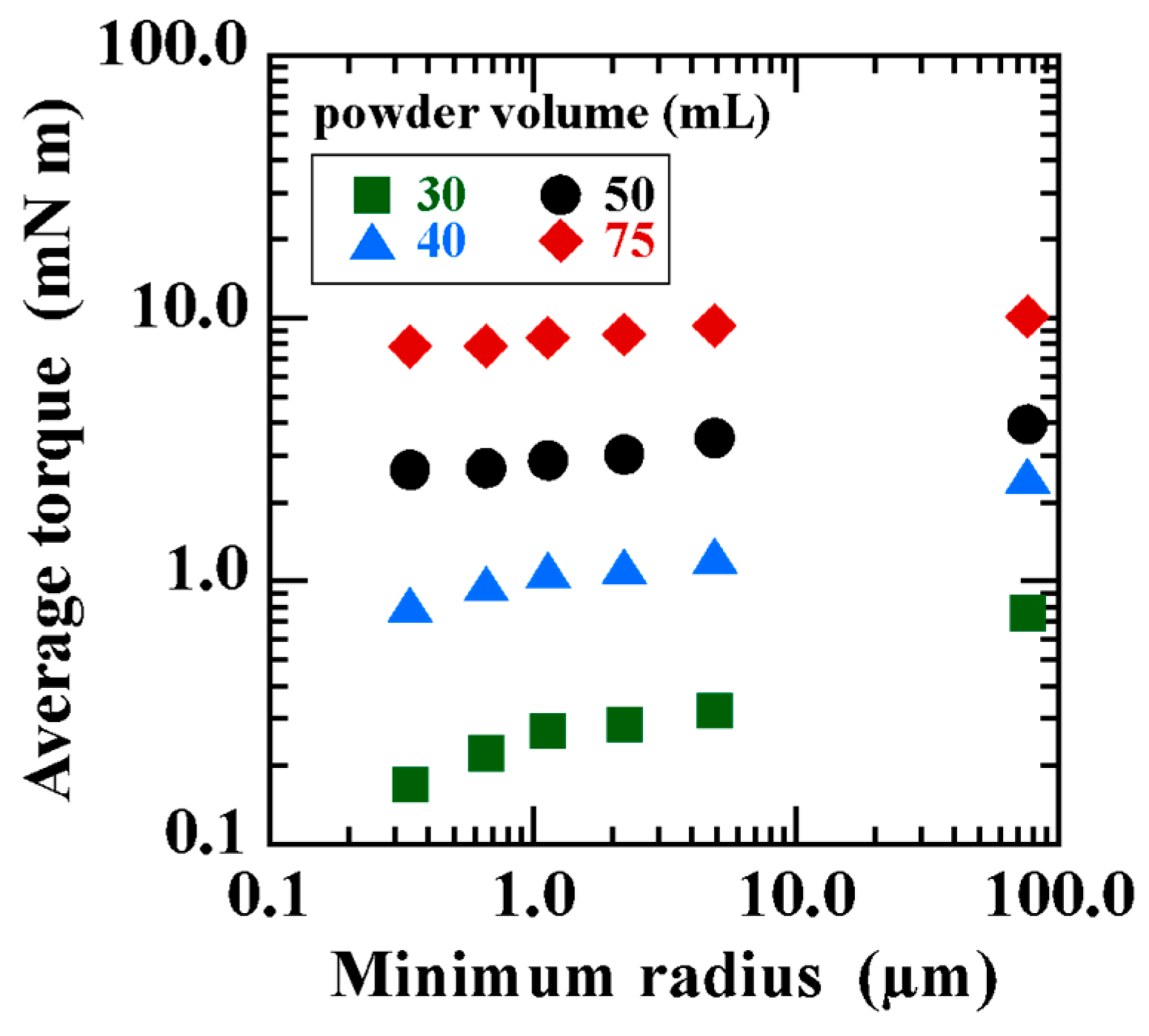

3.1. Evaluation via the Powder Flow Cell

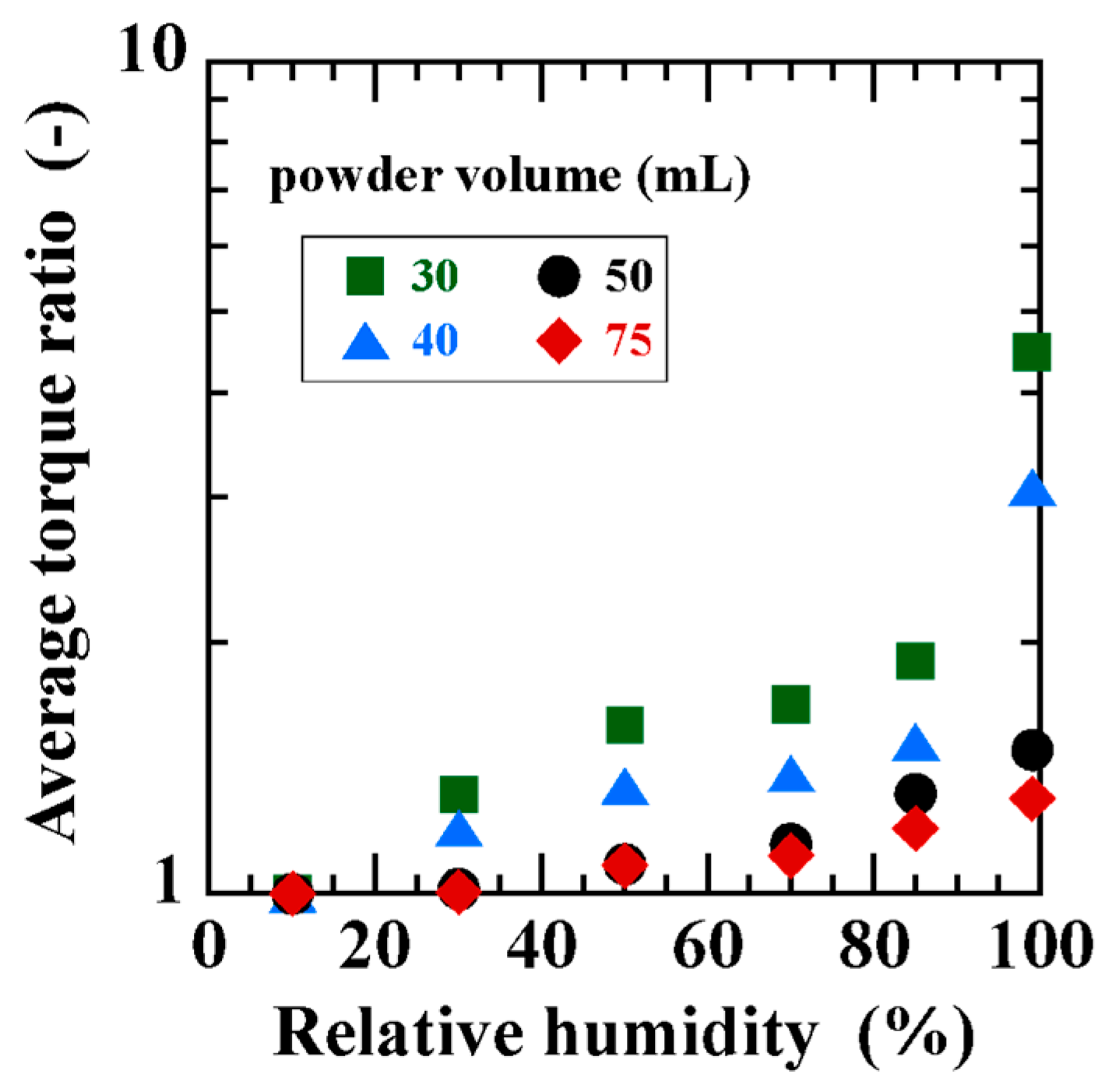

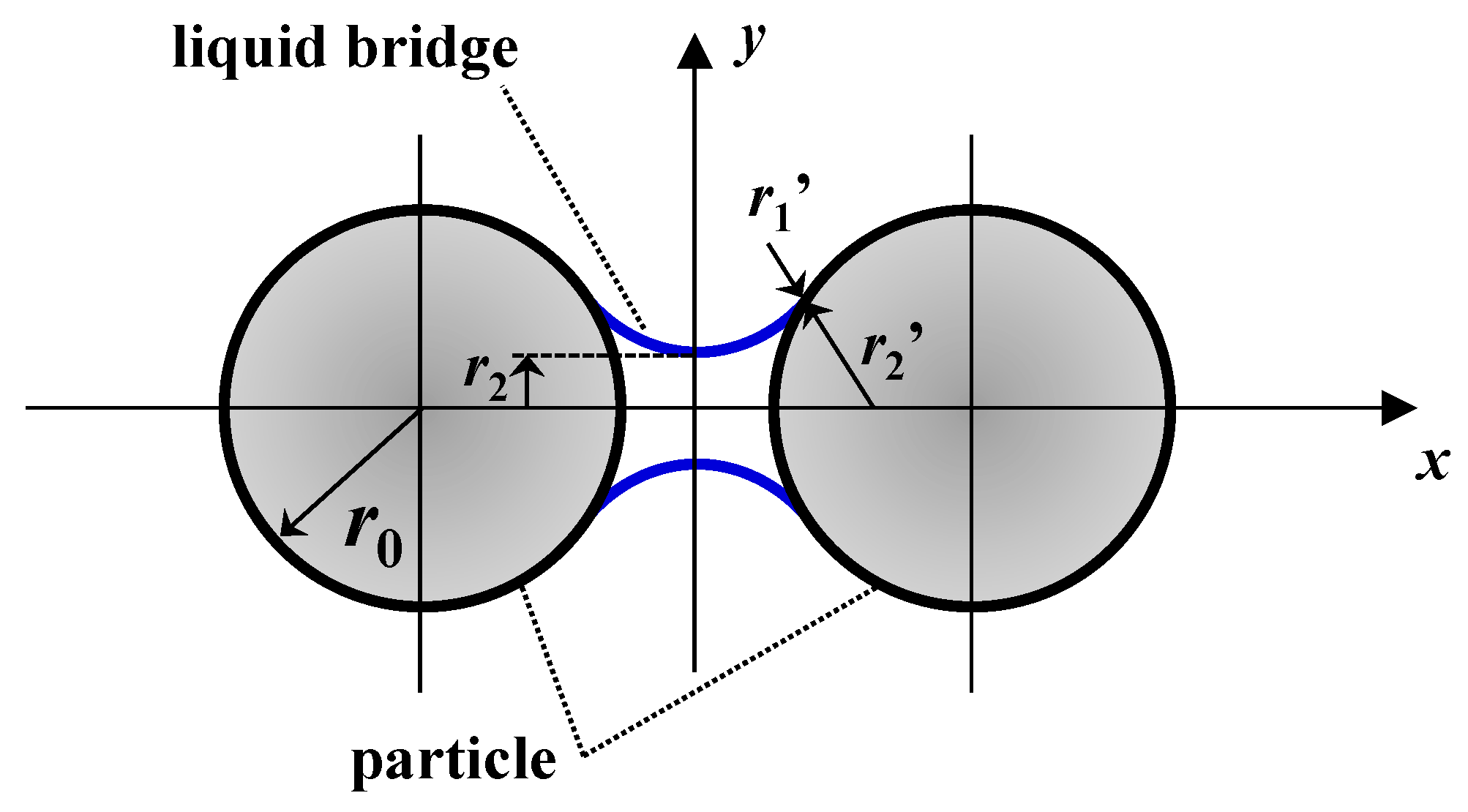

3.2. Effect of Relative Humidity on Powder Flowability During Storage

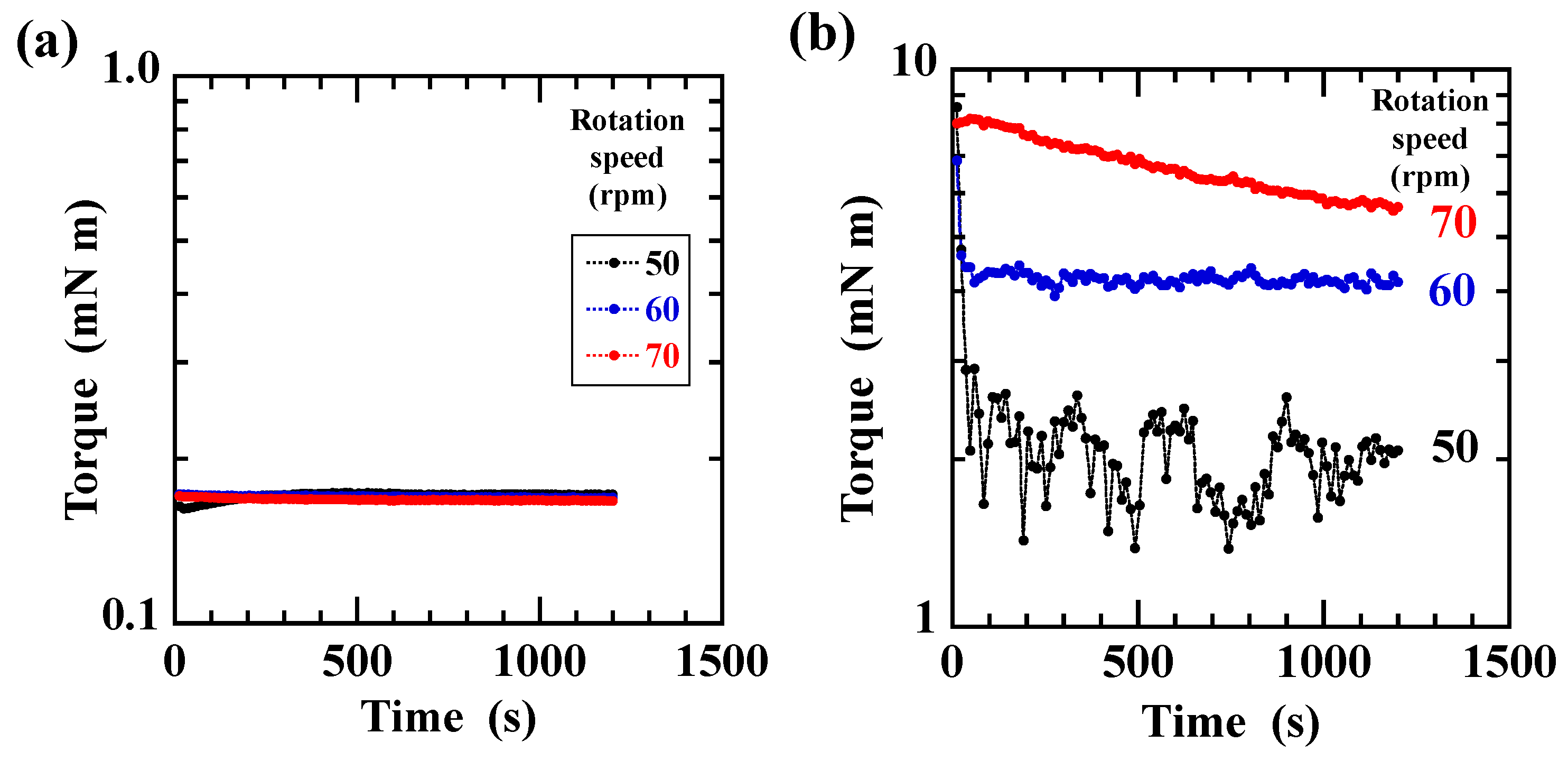

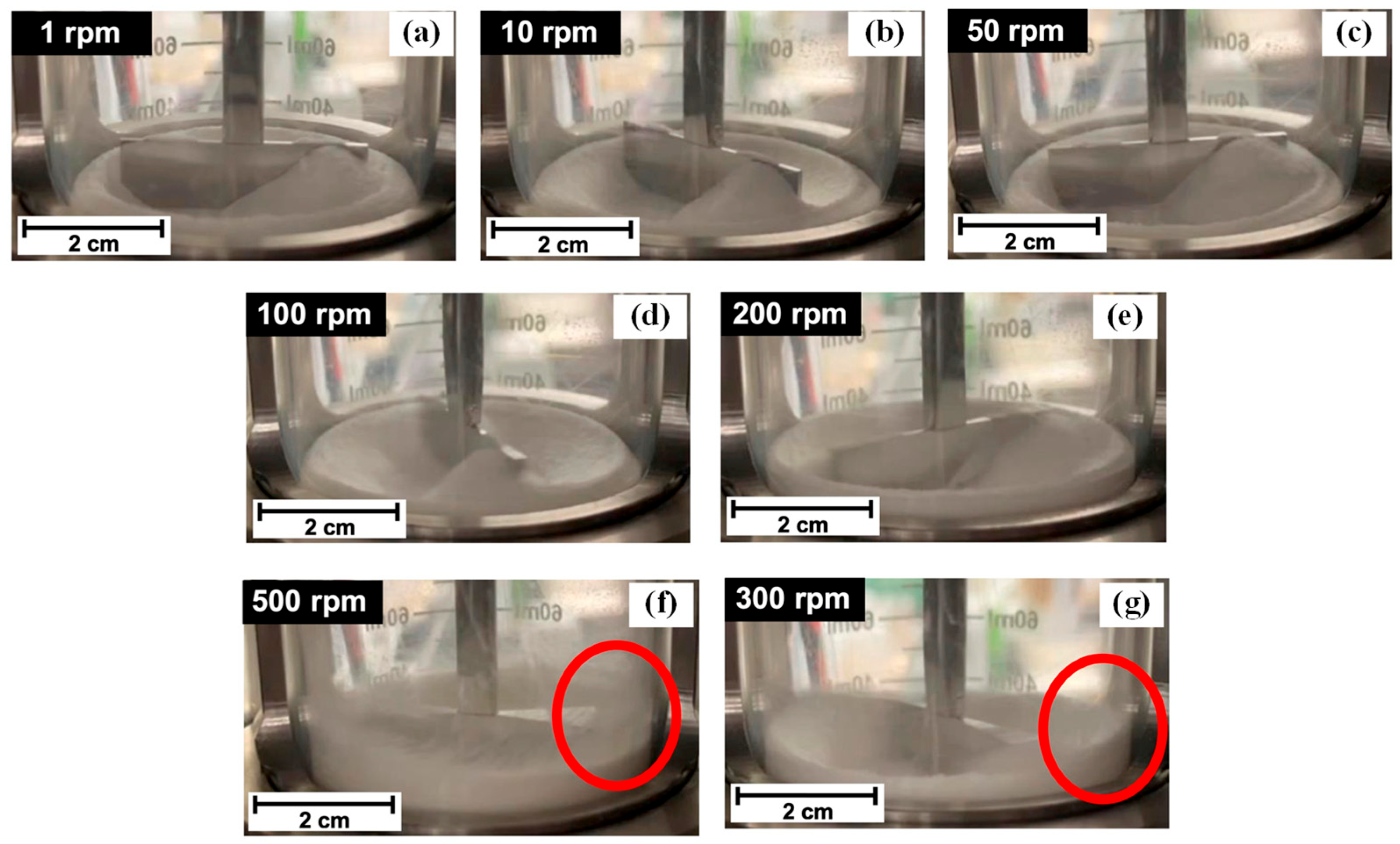

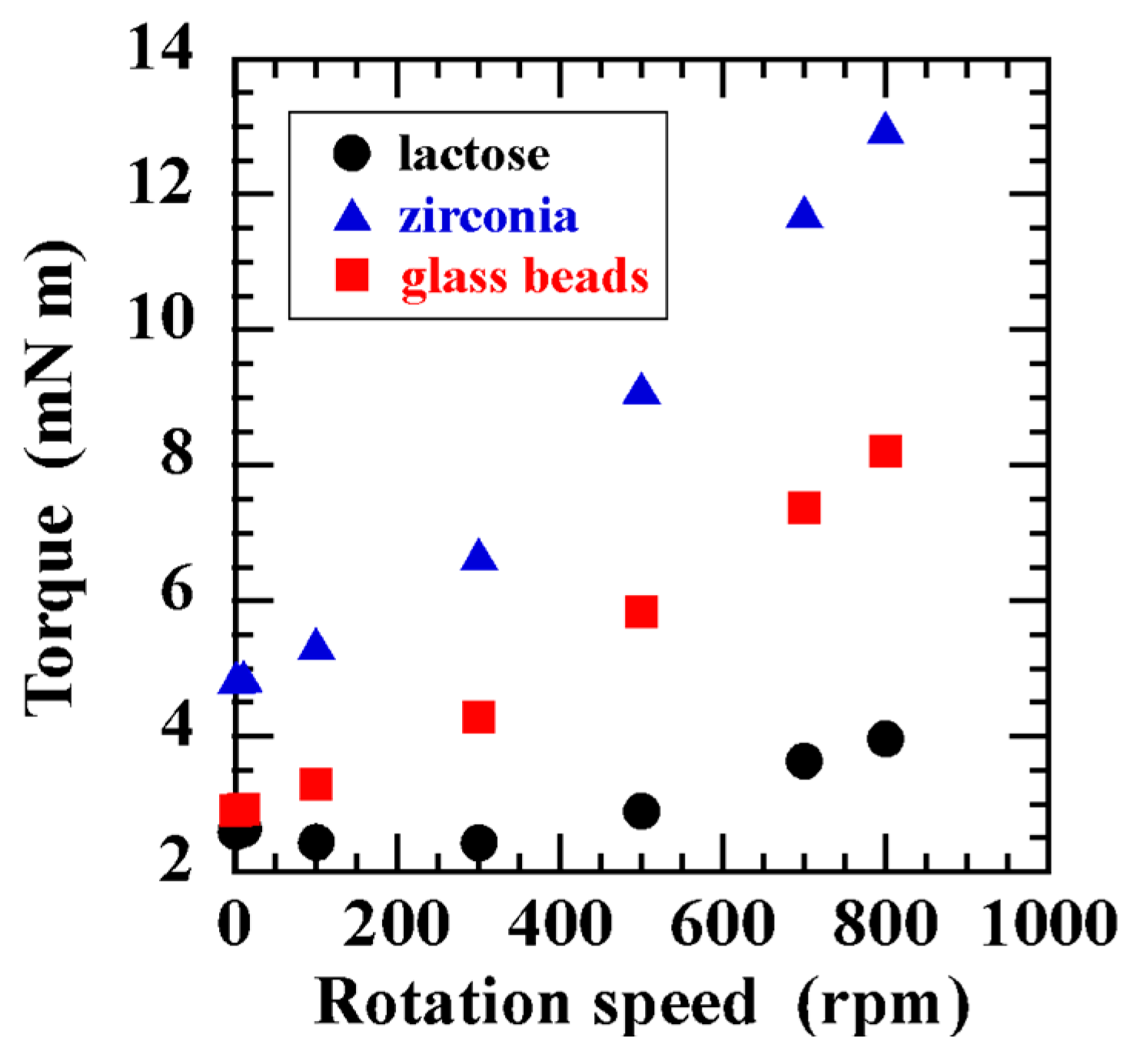

3.3. Effect of Rotation Speed on the Measured Rotation Torque

3.4. Comparison of the Angle of Repose and Bulk Density

4. Conclusions

- (1)

- The effect of rotational speed on rotational torque was minimal for most lactose powders used in this study, except for those stored at a high relative humidity of 99%.

- (2)

- Differences in flowability of lactose powders stored at varying relative humidities were easily distinguished for a powder bed volume of 30 mL, which was the smallest value used in this study.

- (3)

- A powder flow cell, used with a rheometer, enables precise measurement of the rotational torque and evaluation of powder flowability under consistent conditions. In contrast, neither the angle of repose nor the bulk density could be measured reliably under the same standardized conditions.

- (4)

- It was suggested that there should be a critical rotation speed from which the measured rotation torque increased with the rotation speed, and the critical rotation speed should be changed by the powder properties including the particle size distribution and the particle density.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blanco, D.; Antikainen, O.; Räikkönen, H.; Mah, P.T.; Healy, A.M.; Juppo, A.M.; Yliruusi, J. Image-based characterization of powder flow to predict the success of pharmaceutical minitablet manufacturing. Int. J. Pharm. 2020, 581, 119280. [Google Scholar] [CrossRef] [PubMed]

- Düsenberg, B.; Schmidt, J.; Sensoy, I.; Bück, A. Flowability of plant based food powders: Almond, chestnut, chickpea, coconut, hazelnut and rice. J. Food Eng. 2023, 357, 111606. [Google Scholar] [CrossRef]

- Webber, K.G.; Clemens, O.; Buscaglia, V.; Malič, B.; Bordia, R.K.; Fey, T.; Eckstein, U. Review of the opportunities and limitations for powder-based high-throughput solid-state processing of advanced functional ceramics. J. Eur. Ceram. Soc. 2024, 44, 116780. [Google Scholar] [CrossRef]

- Enferad, S.; Pillitteri, S.; Lumay, G.; Gaiani, C.; De Richter, S.K.; Marck, M.; Umbetov, S.; Vandewalle, N.; Jenny, M. Powder flow behavior governed by the surface properties of glass beads. Powder Technol. 2021, 388, 425–433. [Google Scholar] [CrossRef]

- Goh, H.P.; Heng, P.W.S.; Liew, C.V. Comparative evaluation of powder flow parameters with reference to particle size and shape. Int. J. Pharm. 2018, 547, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Schneider, L.C.R.; Sinka, I.C.; Cocks, A.C.F. Characterisation of the flow behaviour of pharmaceutical powders using a model die–shoe filling system. Powder Technol. 2007, 173, 59–71. [Google Scholar] [CrossRef]

- Matsuoka, S. Measurements of Powder Flowability. J. Imaging Soc. Jpn. 2007, 46, 472–477. [Google Scholar]

- Nagashima, H.; Ishikura, T. Identification of flow properties of fine powders based on dynamic flow characteristics obtained by stirring and aerating. J. Soc. Powder Technol. Jpn. 2015, 52, 576–584. [Google Scholar] [CrossRef]

- Schulze, D. Properties exhibited by some bulk solids. In Powders and Bulk Solids: Behavior, Characterization, Storage and Flow; Springer: Cham, Switzerland, 2021; pp. 235–267. [Google Scholar]

- Hu, J.; Mo, P.-Q.; Li, X.-P.; Gao, L.; Zhu, B.; Li, R.-L. The angle of repose and base stress distribution of granular piles: An experimental investigation. Constr. Build. Mater. 2024, 448, 138209. [Google Scholar] [CrossRef]

- Hausmann, A.; Buck, B.; Shaw, L.; Simons, T.; Jäger, F.K.; Williams, D. The importance of humidity control in powder rheometer studies. Powder Technol. 2023, 421, 118425. [Google Scholar] [CrossRef]

- Lumay, G.; Traina, K.; Boschini, F.; Delaval, V.; Rescaglio, A.; Cloots, R.; Vandewalle, N. Effect of relative air humidity on the flowability of lactose powders. J. Drug Deliv. Sci. Technol. 2016, 35, 207–212. [Google Scholar] [CrossRef]

- Lupo, M.; Schütz, D.; Riedl, E.; Barletta, D.; Poletto, M. Assessment of a powder rheometer equipped with a cylindrical impeller for the measurement of powder flow properties at low consolidation. Powder Technol. 2019, 357, 281–290. [Google Scholar] [CrossRef]

- Mishra, I.; Liu, P.; Shetty, A.; Hrenya, C.M. On the use of a powder rheometer to probe defluidization of cohesive particles. Chem. Eng. Sci. 2020, 214, 115422. [Google Scholar] [CrossRef]

- Opaliński, I.; Chutkowski, M.; Hassanpour, A. Rheology of moist food powders as affected by moisture content. Powder Technol. 2016, 294, 315–322. [Google Scholar] [CrossRef]

- Salehi, H.; Barletta, D.; Poletto, M.; Schütz, D.; Romirer, R. On the use of a powder rheometer to characterize the powder flowability at low consolidation with torque resistances. AIChE J. 2017, 63, 4788–4798. [Google Scholar] [CrossRef]

- Salehi, H.; Sofia, D.; Schütz, D.; Barletta, D.; Poletto, M. Experiments and simulation of torque in Anton Paar powder cell. Part. Sci. Technol. 2018, 36, 501–512. [Google Scholar] [CrossRef]

- Salehi, H.; Karde, V.; Hajmohammadi, H.; Dissanayake, S.; Larsson, S.H.; Heng, J.Y.Y.; Bradley, M. Understanding flow properties of mannitol powder at a range of temperature and humidity. Int. J. Pharm. 2021, 596, 120244. [Google Scholar] [CrossRef] [PubMed]

- Tomasetta, I.; Barletta, D.; Lettieri, P.; Poletto, M. The measurement of powder flow properties with a mechanically stirred aerated bed. Chem. Eng. Sci. 2012, 69, 373–381. [Google Scholar] [CrossRef]

- Wu, Z.; Wu, Y.; Zakhvatayeva, A.; Wang, X.; Liu, Z.; Yang, M.; Zheng, Q.; Wu, C.-Y. Influence of moisture content on die filling of pharmaceutical powders. J. Drug Deliv. Sci. Technol. 2022, 78, 103985. [Google Scholar] [CrossRef]

- Shhag, R.; Kellil, A.; Razem, M. Factors influencing food powder flowability. Powders 2024, 3, 65–76. [Google Scholar] [CrossRef]

- Crouter, A.; Briens, L. The effect of moisture on the flowability of pharmaceutical excipients. AAPS PharmSciTech 2014, 15, 65–74. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, S.; Mino, Y.; Nakaso, K.; Gotoh, K.; Satone, H. Flowability evaluation of wet granules with stirring and penetration operations. J. Soc. Powder Technol. Jpn. 2025, 62, 78–83. [Google Scholar] [CrossRef]

- Endo, Y.; Kousaka, Y. Liquid bridge formation and adhesion force between particles. J. Soc. Powder Technol. Jpn. 1996, 33, 30–36. [Google Scholar] [CrossRef]

- Hunter, R.J. Introduction to Modern Colloid Science; Oxford University Press: Oxford, UK, 1993. [Google Scholar]

- Kousaka, Y.; Endo, Y.; Nishie, Y. Theoretical analysis of liquid bridge formation between two particles. Bridge formation by ideal pure water. Kagaku Kogaku Ronbunshu 1992, 18, 942–949. [Google Scholar] [CrossRef]

| Powder Bed Volume (mL) | Relative Humidity During Powder Storage (%) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 30 | 50 | 70 | 85 | 99 | ||||||||

| Before | After | Before | After | Before | After | Before | After | Before | After | Before | After | ||

| 30 | 18.76 | 18.76 | 18.99 | 18.76 | 19.13 | 18.76 | 19.31 | 18.76 | 19.63 | 18.76 | 20.01 | ||

| 40 | 25.02 | 25.02 | 25.31 | 25.02 | 25.50 | 25.02 | 25.75 | 25.02 | 26.17 | 25.02 | 26.69 | ||

| 50 | 31.27 | 31.27 | 31.62 | 31.27 | 31.89 | 31.27 | 32.20 | 31.27 | 32.50 | 31.27 | 33.10 | ||

| 75 | 46.91 | 46.91 | 47.43 | 46.91 | 47.84 | 46.91 | 48.30 | 46.91 | 48.76 | 46.91 | 49.65 | ||

| Powder volume (mL) | 30 | |||||

| Relative humidity (%) | 10 | 30 | 50 | 70 | 85 | 99 |

| Rotation speed dependency | A | A | A | A | A | B |

| Powder volume (mL) | 40 | |||||

| Relative humidity (%) | 10 | 30 | 50 | 70 | 85 | 99 |

| Rotation speed dependency | A | A | A | A | A | B |

| Powder volume (mL) | 50 | |||||

| Relative humidity (%) | 10 | 30 | 50 | 70 | 85 | 99 |

| Rotation speed dependency | A | A | A | A | A | B |

| Powder volume (mL) | 75 | |||||

| Relative humidity (%) | 10 | 30 | 50 | 70 | 85 | 99 |

| Rotation speed dependency | A | A | A | A | A | A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mori, T.; Sakurada, K.; Kitamura, K. Effect of Rotation Speed and Powder Bed Volume on Powder Flowability Measured by a Powder Rheometer: Evaluation of the Humidity Effect on Lactose Powder Flowability. ChemEngineering 2025, 9, 57. https://doi.org/10.3390/chemengineering9030057

Mori T, Sakurada K, Kitamura K. Effect of Rotation Speed and Powder Bed Volume on Powder Flowability Measured by a Powder Rheometer: Evaluation of the Humidity Effect on Lactose Powder Flowability. ChemEngineering. 2025; 9(3):57. https://doi.org/10.3390/chemengineering9030057

Chicago/Turabian StyleMori, Takamasa, Kanaho Sakurada, and Kenta Kitamura. 2025. "Effect of Rotation Speed and Powder Bed Volume on Powder Flowability Measured by a Powder Rheometer: Evaluation of the Humidity Effect on Lactose Powder Flowability" ChemEngineering 9, no. 3: 57. https://doi.org/10.3390/chemengineering9030057

APA StyleMori, T., Sakurada, K., & Kitamura, K. (2025). Effect of Rotation Speed and Powder Bed Volume on Powder Flowability Measured by a Powder Rheometer: Evaluation of the Humidity Effect on Lactose Powder Flowability. ChemEngineering, 9(3), 57. https://doi.org/10.3390/chemengineering9030057